spark plugs replace FIAT 500 1970 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1970, Model line: 500, Model: FIAT 500 1970 1.GPages: 128, PDF Size: 9.01 MB

Page 12 of 128

Cylinder head installation:

To refit the cylinder head proceed as follows:

Place a new cylinder head joint on the cleaned faces of

the cylinder barrels. Insert the rocker pushrod and

lubrication pipe sleeves together with the relevant

gaskets and rings.

Fit the washers and nuts to the studs and tighten to

fingertight.

Tighten the nuts in the order shown in FIG 1 :44 and

FIG 1 :46 to a torque wrench setting of 18.1 Ibft. Reset

the torque wrench to a new setting of 23.9 Ibft and

tighten the nuts once more in the recommended order.

Replace the pushrods in the correct order.

Refit the rocker shaft ensuring correct location of the

lubrication tube to the rocker shaft and replace the

plain and lockwashers. Tighten the nuts to a torque

wrench setting of 15.2 Ibft. Reset the tappet to rocker

clearance adjustment.

Connect the t w o exhaust side manifolds to the cylinder

head. Using new gasket refit the spark plugs and HT

cables. Replace the rocker cover fitted with a new cork

gasket and blower conveyor to the cylinder head

securing screws. Refit the carburetter and reconnect its

fuel line and controls. Refit the air cleaner and elbow

and connect the rocker cover breather pipe (if fitted).

1

2

3

4

5

1 :7 Timing gear overhaul

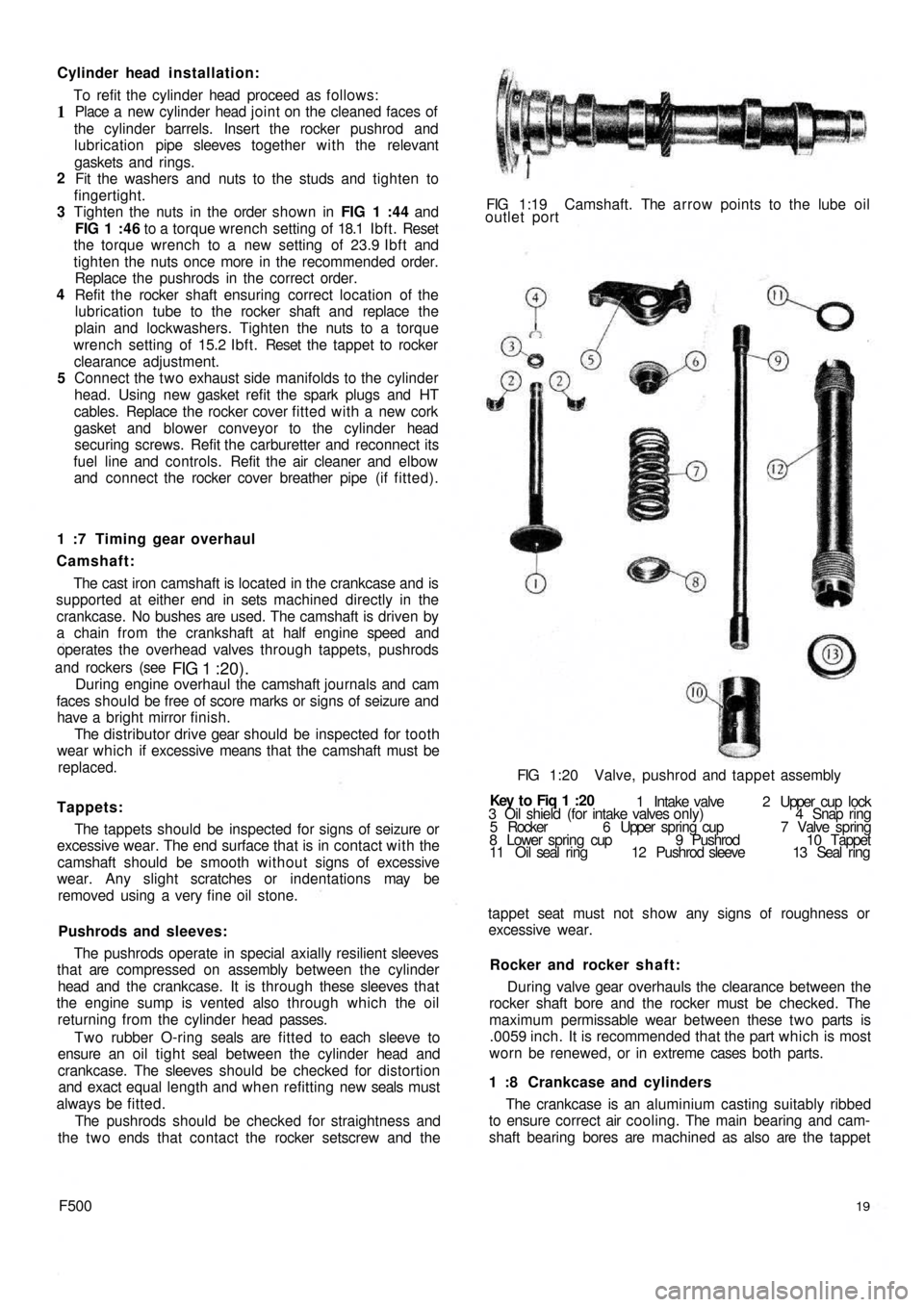

Camshaft:

The cast iron camshaft is located in the crankcase and is

supported at either end in sets machined directly in the

crankcase. No bushes are used. The camshaft is driven by

a chain from the crankshaft at half engine speed and

operates the overhead valves through tappets, pushrods

and rockers (see

FIG 1 :20).During engine overhaul the camshaft journals and cam

faces should be free of score marks or signs of seizure and

have a bright mirror finish.

The distributor drive gear should be inspected for tooth

wear which if excessive means that the camshaft must be

replaced.

Tappets:

The tappets should be inspected for signs of seizure or

excessive wear. The end surface that is in contact with the

camshaft should be smooth without signs of excessive

wear. Any slight scratches or indentations may be

removed using a very fine oil stone.

Pushrods and sleeves:

The pushrods operate in special axially resilient sleeves

that are compressed on assembly between the cylinder

head and the crankcase. It is through these sleeves that

the engine sump is vented also through which the oil

returning from the cylinder head passes.

Two rubber O-ring seals are fitted to each sleeve to

ensure an oil t i g h t seal between the cylinder head and

crankcase. The sleeves should be checked for distortion

and exact equal length and when refitting new seals must

always be fitted.

The pushrods should be checked for straightness and

the t w o ends that contact the rocker setscrew and the

F50019

The crankcase is an aluminium casting suitably ribbed

to ensure correct air cooling. The main bearing and cam-

shaft bearing bores are machined as also are the tappet 1 :8 Crankcase and cylinders During valve gear overhauls the clearance between the

rocker shaft bore and the rocker must be checked. The

maximum permissable wear between these t w o parts is

.0059 inch. It is recommended that the part which is most

worn be renewed, or in extreme cases both parts. Rocker and rocker shaft: tappet seat must not show any signs of roughness or

excessive wear. 3 Oil shield (for intake valves only) 4 Snap ring

5 Rocker 6 Upper spring cup 7 Valve spring

8 Lower spring cup 9 Pushrod 10 Tappet

11 Oil seal ring 12 Pushrod sleeve 13 Seal ring 1 Intake valve 2 Upper cup lock Key t o Fiq

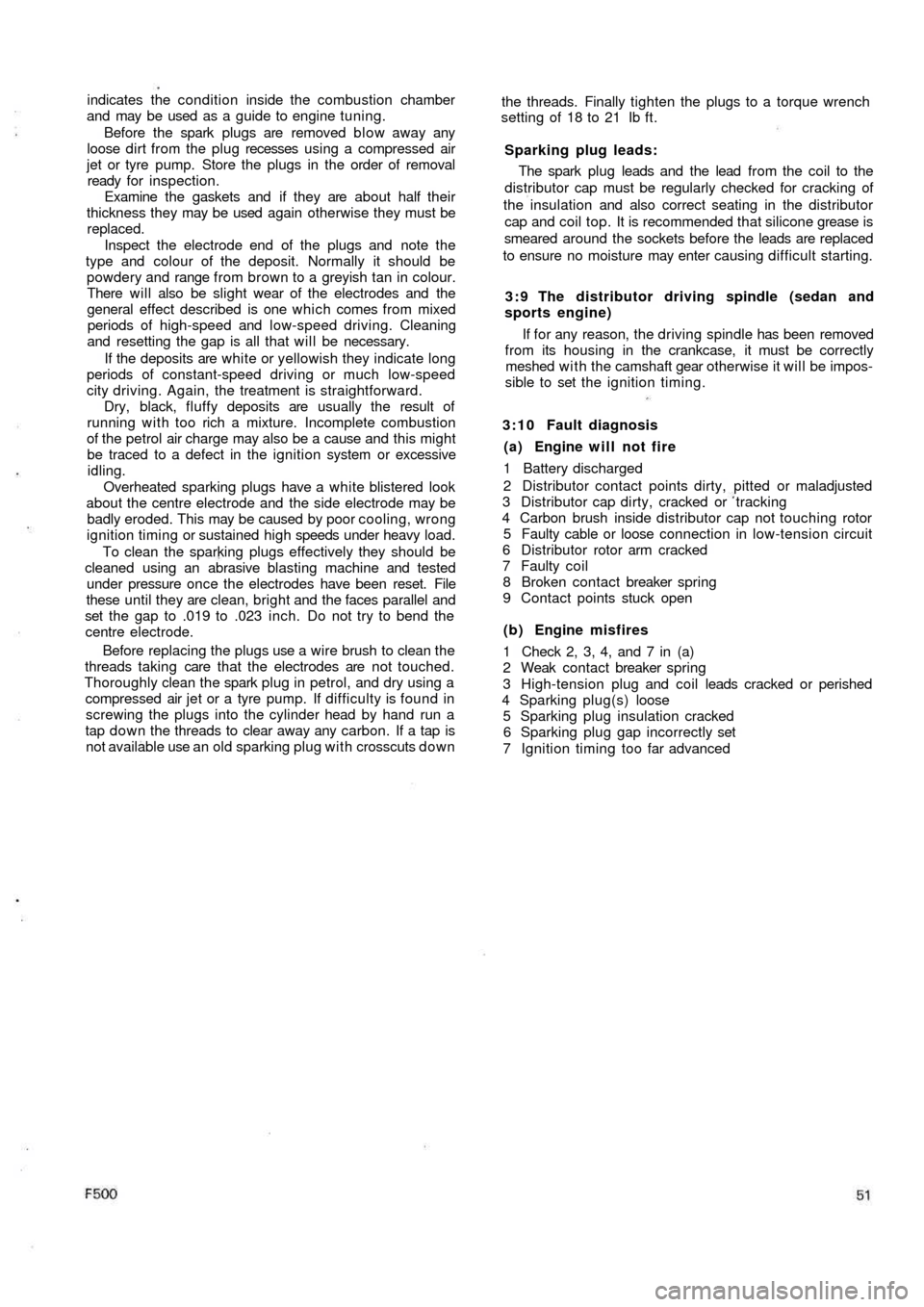

1 :20 FIG 1:20 Valve, pushrod and tappet assembly FIG 1:19 Camshaft. The arrow points to the lube oil

outlet port

Page 44 of 128

indicates the condition inside the combustion chamber

and may be used as a guide to engine tuning.

Before the spark plugs are removed b l o w away any

loose dirt from the plug recesses using a compressed air

jet or tyre pump. Store the plugs in the order of removal

ready for inspection.

Examine the gaskets and if they are about half their

thickness they may be used again otherwise they must be

replaced.

Inspect the electrode end of the plugs and note the

type and colour of the deposit. Normally it should be

powdery and range from b r o w n to a greyish tan in colour.

There will also be slight wear of the electrodes and the

general effect described is one which comes from mixed

periods of high-speed and low-speed driving. Cleaning

and resetting the gap is all that will be necessary.

If the deposits are white or yellowish they indicate long

periods of constant-speed driving or much low-speed

city driving. Again, the treatment is straightforward.

Dry, black, fluffy deposits are usually the result of

running with too rich a mixture. Incomplete combustion

of the petrol air charge may also be a cause and this might

be traced to a defect in the ignition system or excessive

idling.

Overheated sparking plugs have a white blistered look

about the centre electrode and the side electrode may be

badly eroded. This may be caused by poor cooling, wrong

ignition timing or sustained high speeds under heavy load.

To clean the sparking plugs effectively they should be

cleaned using an abrasive blasting machine and tested

under pressure once the electrodes have been reset. File

these until they are clean, bright and the faces parallel and

set the gap to .019 to .023 inch. Do not try to bend the

centre electrode.

Before replacing the plugs use a wire brush to clean the

threads taking care that the electrodes are not touched.

Thoroughly clean the spark plug in petrol, and dry using a

compressed air jet or a tyre pump. If difficulty is found in

screwing the plugs into the cylinder head by hand run a

tap d o w n the threads to clear away any carbon. If a tap is

not available use an old sparking plug with crosscuts d o w nthe threads. Finally tighten the plugs to a torque wrench

setting of 18 to 21 Ib ft.

Sparking plug leads:

The spark plug leads and the lead from the coil to the

distributor cap must be regularly checked for cracking of

the insulation and also correct seating in the distributor

cap and coil top. It is recommended that silicone grease is

smeared around the sockets before the leads are replaced

to ensure no moisture may enter causing difficult starting.

3 : 9 The distributor driving spindle (sedan and

sports engine)

If for any reason, the driving spindle has been removed

from its housing in the crankcase, it must be correctly

meshed w i t h the camshaft gear otherwise it

will be impos-

sible to set the ignition timing.

3:10 Fault diagnosis

(a) Engine w i l l not fire

1 Battery discharged

2 Distributor contact points dirty, pitted or maladjusted

3 Distributor cap dirty, cracked or tracking

4 Carbon brush inside distributor cap not touching rotor

5 Faulty cable or loose connection in low-tension circuit

6 Distributor rotor arm cracked

7 Faulty coil

8 Broken contact breaker spring

9 Contact points stuck open

(b) Engine misfires

1 Check 2, 3, 4, and 7 in (a)

2 Weak contact breaker spring

3 High-tension plug and coil leads cracked or perished

4 Sparking plug(s) loose

5 Sparking plug insulation cracked

6 Sparking plug gap incorrectly set

7 Ignition timing too far advanced