chapter 6 FIAT 500 1971 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1971, Model line: 500, Model: FIAT 500 1971 1.GPages: 128, PDF Size: 9.01 MB

Page 72 of 128

CHAPTER 7

REAR SUSPENSION AND WHEELS

7:1

7:2

7:3

7:4Description

Removal of rear suspension assembly

Servicing swinging arms

Coil springs

7:1 Description

The rear wheels are independently sprung by means of

coil springs and V-shaped swinging arms acting on coil

springs and telescopic double acting hydraulic shock

absorbers. The swinging arms are m o u n t e d at their inner

ends on 'estendblocks', the coil spring is fitted at the outer

end of the swinging arm. At the wheel end of the suspen-

sion arm is attached a steel pressing to which the brake

backplate and wheel bearing housing are bolted so

forming a swinging unit to which is attached the road

wheel.

The inner pivots are so located vertical wheel move-

ments do not influence the drive shaft length which

means that there is no need to fit a splined joint at the

wheel end. Two taper roller bearings which are separated

by a specially designed collapsible spacer are located in

the rear wheel bearing housing and this carries the axle

shaft. The outer end of the axle shaft is flanged and it

is to this flange that the brake drum is bolted. The splined

inner end carries a rubber cushioned coupling to which

the drive shaft flange is attached.

7 : 2 Removal of rear suspension assembly

1 Jack-up the vehicle and place on firmly based stands.

Remove the road wheel on the side from which the

suspension unit is to be removed.

F50079 7:5

7:6

7:7

7:8Installation of rear suspension assembly

Checking and adjusting rear wheel toe-in

Modifications

Fault diagnosis

2 Using a garage hydraulic jack support the swinging

arm to facilitate the removal of the upper shock

absorber mounting nut which is located inside the

vehicle on the floor. To gain access to the nut remove

the rear wheel housing linings.

3 Unhook the parking brake shoe control lever return

spring.

4 Remove the three screws securing the drive shaft

flange to the flexible coupling. Pull back the sleeve and

remove the inner spring.

5 Remove the brake fluid reservoir cap, remove the filter

and plug the delivery hole in the brake f l u i d reservoir

and disconnect the flexible brake pipe from the

bracket on the body floor.

6 Disconnect the parking brake control tie rod by first

removing the cotter pin and removing the cable eye

from the pin on the shoe control lever. Release the

cable adjustment nuts and free the cable from the

fairlead on the swinging arm.

7 Using the hydraulic jack carefully lower the swinging

arm, fully retract the shock absorber by pushing in the

outer cylinder and carefully pull out the coil spring

together with its mounting rubber rings.

8 Remove the self-locking nut securing the swinging

arm to the internal support welded on the floor.

Extract the mounting pin and note the number and

arrangement of shims between the bushings and the

bracket. This will facilitate reassembly.

Page 76 of 128

high bearing preload. To reset remove the wheel shaft

and fit a new resilient spacer. Repeat the rotation

torque test.

Swinging arm adjustment:

To adjust the swinging arm use Fiat fixture A.66064 as

shown in FIG 7 : 3 and proceed as follows:

1 At points A and B as indicated in FIG 7 : 4 between the

'estendblock' and the swinging arm to body front

mounting bracket fit three shims on each side. To

ensure that the shims are correctly centred use Fiat

alignment bar A.66057.

2 Whilst removing the alignment bar, carefully slip in the

mounting pin and screw on the nut. Once the rear

wheel geometry adjustment has been completed this

nut should be tightened to a torque wrench setting

of 43.4 to 50.6 Ib ft.

3 At points C and D (see FIG 7 : 4) , insert the number of

shims required to fill in the gap between the 'estend-

block' and the two fixture shoulders. Having deter-

mined the number of shims required both at locations

C and D, these must later be fitted between the

'estendblock' and the shoulders on the swinging arm

to body mounting bracket.

7 : 4 Coil springs

The coil springs should be thoroughly cleaned and all

traces of rust removed. Inspect the spring coils for hair

line cracks, which if evident, a new pair of springs must

be fitted to ensure correct vehicle height and stability.

Check the free

height and the height under loading of

the coil springs and these must correspond to the figures

quoted in Technical Data.

7:5 Installation of rear suspension assembly

To replace the rear suspension assembly proceed as

follows:

1 Insert the swinging arm inner end in the mounting

bracket which is welded onto the body floor. Place

between the 'estendblock' and bracket the number of

adjustment shims as previously determined using Fiat

fixture A.66064 as shown in FIG 7 : 4. Insert the Fiat

alignment bar A.66057 through 'estendblock' and

shims, aligning them with the holes in the mounting

bracket. Firmly hold the entire assembly using a garage

hydraulic jack if necessary, and carefully remove the

alignment bar and at the same time ease in t h e

mounting pin. Secure the nut which once the rear

wheels geometry has been checked must be tightened

to a torque wrench setting of 43.4 to 50.6 Ib/ft.

2 Screw in finger tight the three swinging arm external

bracket to body floor mounting screws together w i t h

the plain and spring washers. The screws will have to

be tightened to a torque wrench setting of 28.9 to

36.2 Ib/ft once the rear wheel geometry has been

adjusted.

3 Carefully insert the coil spring, lower insulator ring

onto the swinging arm, insert the spring on the shock

absorber which should be previously secured to the

arm and position the spring onto its seat on the arm.

Place the upper insulator ring onto the spring, raise the

suspension assembly using a garage hydraulic jack and

insert the spring onto its seating under the body floor.

F50083 4 Ensure that the shock absorber to floor rubber ring has

been correctly fitted and extend the shock absorber

until its upper mounting pin protrudes into the vehicle

through the hump in the floor panel. Secure the shock

absorber by its mounting nut and lockwasher having

first inserted the rubber ring and plain washer.

5 Refit the rear wheel housing in place, reconnect the

brake line to the connection on body floor and remove

the plug from the output hole in the brake fluid

reservoir. Bleed the hydraulic brake system as

described in Chapter 10.

Key to Fig 7:8 k Distance of centre rear bracket, for

jacking up the vehicle, from floor level (8.90 inch)

Half-track = 22.264 inch ±.059 inch

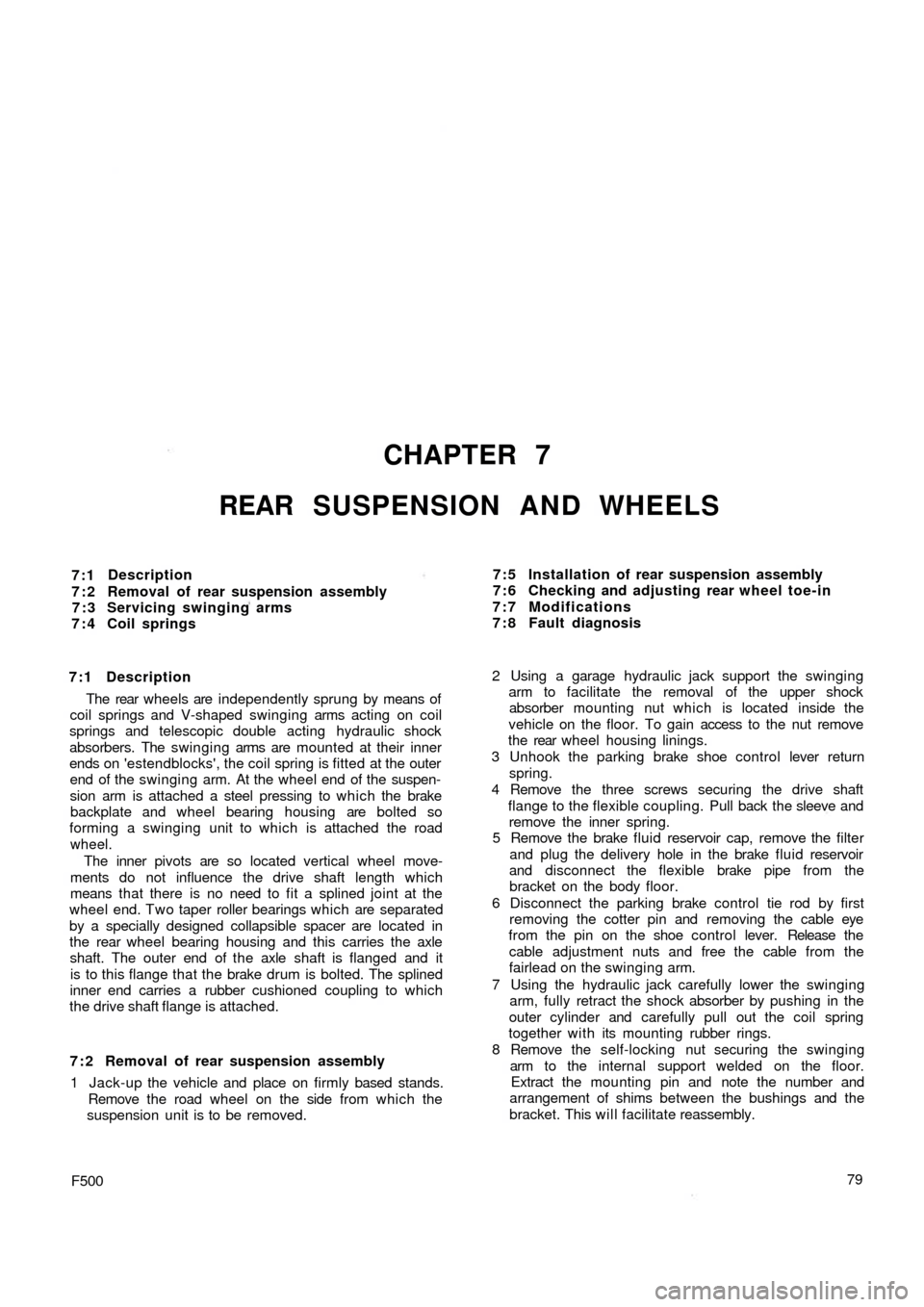

FIG 7 : 8 Position of rear suspension f o r rear wheel

toe-in inspection and adjustment ('500 Station Wagon') FIG 7 : 7 Adjusting rear wheel toe-in angle

Key to Fig 7 : 7 Rear wheel plane must be perpendicular to

ground and parallel to car longitudinal centerline with a

tolerance of 0° 10'

To adjust rear wheel geometry, move suitably the swinging arm

outer support. Slight movements are permitted by the play

existing between the support holes A and the mounting screws.

Screws B must be tightened to 28.9 to 36.2 Ibft (4000 to 5000

kg mm). Nuts C must be tightened to 43.4 to 50.6 Ib ft (6000

to 7000 kgmm), after adjustment has been carried out. (These

directions and specifications are also applicable to 500 Station

Wagon).

Page 80 of 128

CHAPTER 8

FRONT SUSPENSION AND HUBS

8:1

8:2

8:3

8:4

8:5

8:6Description

Front suspension removal and dismantling

Leaf spring

Swinging arms

Kingpin housing

Steering knuckle and wheel hub

8:1 Description

The independent front suspension assembly fitted to

the 'new 500' range comprises a transverse leaf spring

which is anchored to the body through two rubber

mountings and kingpins through 'estendblocks' as

shown in FIG 8:1. The leaf spring also acts as an anti-

roll bar which gives normal spring reaction even when the

front road wheels encounter a rough road surface.

Special polyethylene insulating strips are fitted

between the five springs leaves which are all clamped

together by t w o rubber cushioned clamps.

Upper movement of the kingpins in the swinging arm

is obtained by 'estendblocks'. The half arms are anchored

to the body as shown in FIG 8 : 3 and pivot on their pins

through rubber bushes. Double acting hydraulic shock

absorbers are fitted to the kingpin housings at the lower

end and anchored at the top to the vehicle body. Two

rubber buffers are secured to brackets mounted onto the

body to limit the spring oscillations. The spring centre

bolt is also fitted with a rubber pad.

8 : 2 Front suspension removal and

dismantling

To remove the front suspension assembly proceed as

follows:

F50087

1 Remove the hub caps and carefully slacken the road

wheel retaining bolts. Using a garage hydraulic jack

raise the front of the vehicle and place on firmly

based stands. Remove the road wheels.

2 Disconnect the steering linkages from the pitman arm,

the drag link and the steering knuckle arms.

3 Remove the shock absorber upper mounting nut from

the body, lift away the half rubber bush and push d o w n

the outer cylinder.

4 Blank off the brake fluid reservoir outlet by inserting

a suitable wooden peg through the reservoir filler

opening and disconnect the brake hydraulic lines at

the wheel cylinders.

5 Fit Fiat crossbeam Arr.2072 under the leaf spring

and support this, using a garage hydraulic jack.

6 Remove the self-locking nut securing the leaf spring

to the kingpin housing and ease o u t the spring

mounting bolt taking care not to damage the thread.

Also remove the nuts securing the swinging arm pin

to studs on the body and remove the swinging arm

assembly. Carefully lift out the adjusting shims and

spacers from the studs making a careful note of the

number of the shims and their locations.

7 Remove the nuts securing the leaf spring elastic

mounting to the body (see FIG 8 : 4) , and lower the 8:7

8:8

8:9

8:10

8:11Hydraulic damper

Front suspension assembly and

installation

Steering geometry

Modifications

Fault diagnosis

Page 90 of 128

CHAPTER 9

THE STEERING SYSTEM

9 : 5 Relay lever and support

9 : 6 Steering rods

9 : 7 Front wheel toe-in

9 : 8 Fault diagnosis 9:1 Description

9 : 2 Steering wheel removal and refitting

9 : 3 Steering box removal and refitting

9 : 4 Steering box dismantling and reassembly

9:1 Description

The steering gear fitted to the new 500 range of

vehicles is of the worm screw and sector type with a

steering ratio of 1:13. The steering gearbox is located on

the front lefthand side of the dash wall on the scuttle as

shown in FIG 9:1. The steering gear comprises a pitman

arm and relay lever pivoting on a pin supported on the

body. A central track rod connects the pitman arm to the

relay lever. T w o track rods connect the pitman arm and

relay lever to the knuckle arms.

9:2 Steering wheel removal and refitting

To remove the steering wheel proceed as follows:

1 Disconnect the battery positive terminal clamp and

remove the horn control from the steering wheel.

2 Remove the cable from the push button seating and the

cable insulation sleeve.

3 Using a suitably sized box spanner or Fiat wrench

A.8279 unscrew the steering wheel to shaft nut as

shown in FIG 9:2.

4 Using the palm of the hands against the back of the

steering wheel rim gently tap the steering wheel

forwards so releasing it from the inner shaft.

F50097 5 Reassembly is the reverse procedure to dismantling.

Care should be taken to ensure that the front wheels

are located in the straight ahead position when the

steering wheel is being replaced otherwise the steering

wheel spokes will not be correctly positioned.

9 : 3 Steering box removal and refitting

To remove the steering box from the vehicle proceed

as follows:

1 From inside the vehicle remove the steering column

clamp bolt 6 (see FIG 9 : 3) after flattening the lock-

washer 7.

2 From the underside of the vehicle remove the t w o

tie rod locking nuts from the pitman arm and then using

Fiat tool A.46006 or a suitable t w o leg puller withdraw

the pins from the seats.

3 Remove the three nuts holding the steering box to the

body panel. Ease out the worm screw from the

steering shaft and lift away the steering box.

4 To refit the steering box is the reverse procedure to

dismantling. The steering box to body mounting nuts

should be tightened to a torque wrench setting of

14 Ib/ft to 18 Ib/ft.

Page 96 of 128

CHAPTER 10

THE BRAKING SYSTEM

10:1 Description

10:2 Maintenance

10:3 Front brakes

10:4 Rear brakes

10:5 Master cylinder

10:6 Wheel cylinder10:7 Self-adjusting device

10:8 Removing a flexible hose

10:9 Brake fluid reservoir

10:10 Bleeding the system

10:11 Hand parking brake

10:12 Fault diagnosis

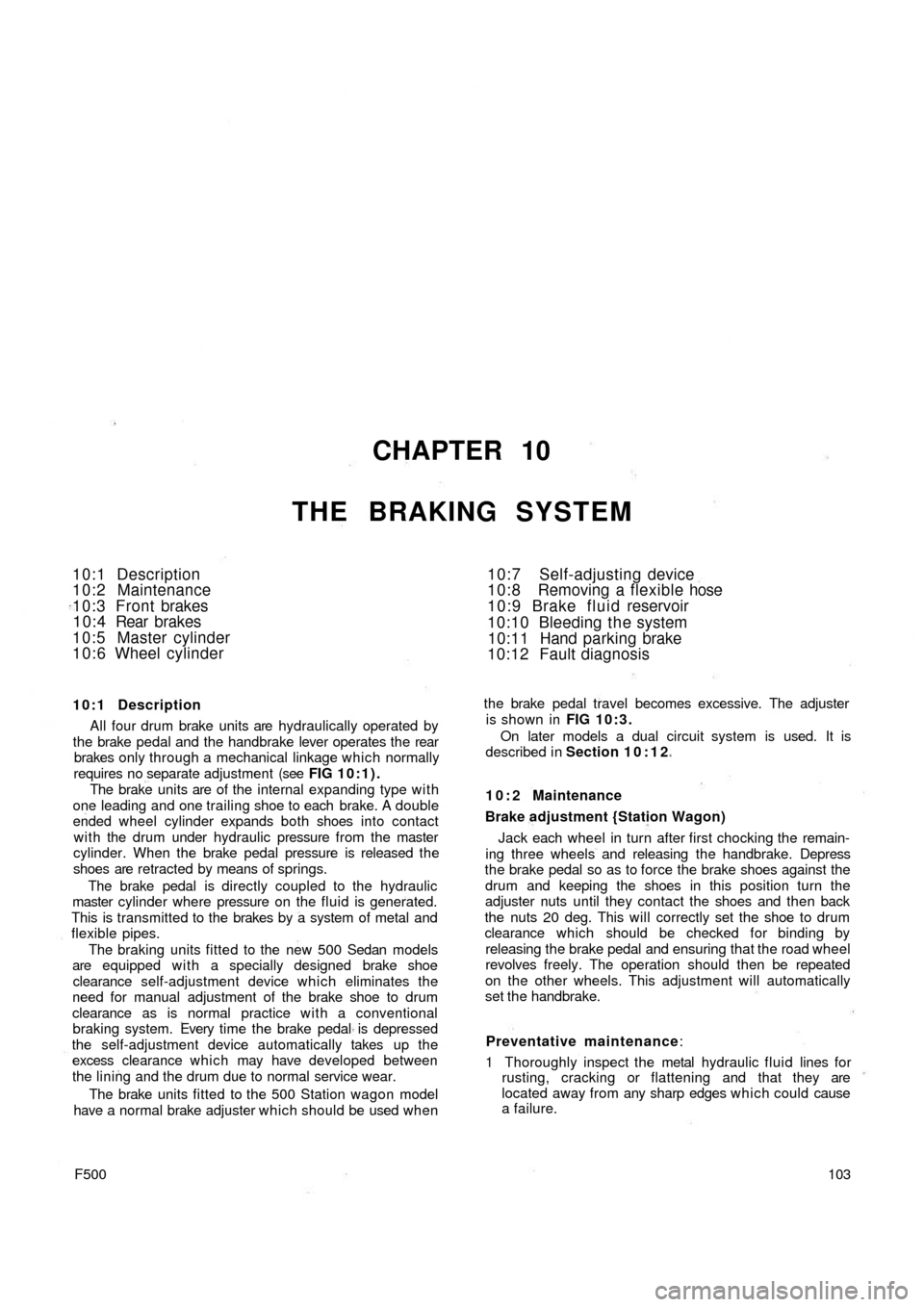

10:1 Description

All four drum brake units are hydraulically operated by

the brake pedal and the handbrake lever operates the rear

brakes only through a mechanical linkage which normally

requires no separate adjustment (see FIG 10:1).

The brake units are of the internal expanding type with

one leading and one trailing shoe to each brake. A double

ended wheel cylinder expands both shoes into contact

with the drum under hydraulic pressure from the master

cylinder. When the brake pedal pressure is released the

shoes are retracted by means of springs.

The brake pedal is directly coupled to the hydraulic

master cylinder where pressure on the fluid is generated.

This is transmitted to the brakes by a system of metal and

flexible pipes.

The braking units fitted to the new 500 Sedan models

are equipped with a specially designed brake shoe

clearance self-adjustment device which eliminates the

need for manual adjustment of the brake shoe to drum

clearance as is normal practice w i t h a conventional

braking system. Every time the brake pedal is depressed

the self-adjustment device automatically takes up the

excess clearance which may have developed between

the lining and the drum due to normal service wear.

The brake units fitted to the 500 Station wagon model

have a normal brake adjuster which should be used when

F500103 the brake pedal travel becomes excessive. The adjuster

is shown in FIG 10:3.

On later models a dual circuit system is used. It is

described in Section 10:12

10:2 Maintenance

Brake adjustment {Station Wagon)

Jack each wheel in turn after first chocking the remain-

ing three wheels and releasing the handbrake. Depress

the brake pedal so as to force the brake shoes against the

drum and keeping the shoes in this position turn the

adjuster nuts until they contact the shoes and then back

the nuts 20 deg. This will correctly set the shoe to drum

clearance which should be checked for binding by

releasing the brake pedal and ensuring that the road wheel

revolves freely. The operation should then be repeated

on the other wheels. This adjustment will automatically

set the handbrake.

Preventative maintenance:

1 Thoroughly inspect the metal hydraulic fluid lines for

rusting, cracking or flattening and that they are

located away from any sharp edges which could cause

a failure.

Page 98 of 128

2 Using Fiat puller A.46023 as shown in FIG 8 : 9

remove the wheel grease cap.

3 Using a universal t w o leg puller or Fiat puller A.40005

together w i t h items 1 and 9 remove the wheel hub/

drum assembly having first extracted the splitpin if

fitted and released the hub retaining nut (see FIG

8:10).

Dismantling brake unit:

1 Using a compressed air jet thoroughly clean all com-

ponents of the brake assembly.

2 Make a note of the location of the shoe return springs

and gently ease the shoes away from the brake

backplate (see FIG 10:2).

3 Disconnect the hydraulic line from the rear of t h e

wheel cylinder and remove the t w o cylinder retaining

bolts. Lift away the hydraulic cylinder.

Brake shoe lining:

Check the lining thickness and if found to be exces-

sively reduced service replacement shoes must be fitted.

The minimum allowable brake lining thickness is .059

inch.

Thoroughly check the linings for signs of oil or grease

which, if evident, the shoes must be renewed and the

drums and oil seals thoroughly inspected for the cause

of oil ingress and the cause remedied before reassembly.

Do not fit odd brake shoes and do not mix materials or

unbalanced braking will result.

Do not allow grease, oil or paint to contact the friction

linings.

Brake drums:

Whilst servicing the brakes, thoroughly inspect the

drums for scoring, ovality or distortion as well as inspect-

ing for minute hair line cracks. The drums may be refaced

by using a centre lathe and finally finishing by lapping

the drums to smooth out possible tool marks. The

maximum permissible oversize beyond the nominal drum

diameter of 6.702 to 6.712 inch is .039 inch. This limit

must never be exceeded otherwise the strength of the

drum will be impaired or a reduction in braking efficiency

caused by the increase of shoe expansion travel and the

consequent diminished contact pressure.

No brake adjustment will be required on the new 500

Saloon models after the drum has been reassembled as

the self-adjusting device will accommodate for the shoe

position to the new drum diameter during the first

operation of the brake pedal.

Reassembly of front brakes:

This is the reverse procedure to dismantling. Ensure

that the pull-off springs are correctly fitted to the holes in

the webs of the brake shoes and that the shoes register

correctly in the slotted ends of the pistons and the

side

mounting plate.

Upon assembly of the hub and brake drum assembly

liberally pack the space between the two bearings w i t h

Fiat MR grease, and remount the hub according to the

instructions in Chapter 8.

F500

FIG 10:3 Section view of left side f r o n t brake assembly

(500 Station Wagon)

Key to Fig 10:3 1 Wheel cylinder 2 Shoe return spring

3 Adjusting cams 4 Shoe guide pin 5 Shoe with lining

6 Drum 7 Housing flange

BRAKE SHOE

ADJUSTING DEVICE

SHOE WEDGE

SELF

WHEEL CYLINDER

SHOE RETURN SPRING

PARKING BRAKE

SHOE CONTROL

RETURN SPRINGS

LEVER

SHOE LOCK PLATEBRAKE SHOES

SHOE RETURN SPRING

SHOE MOUNTING PLATE

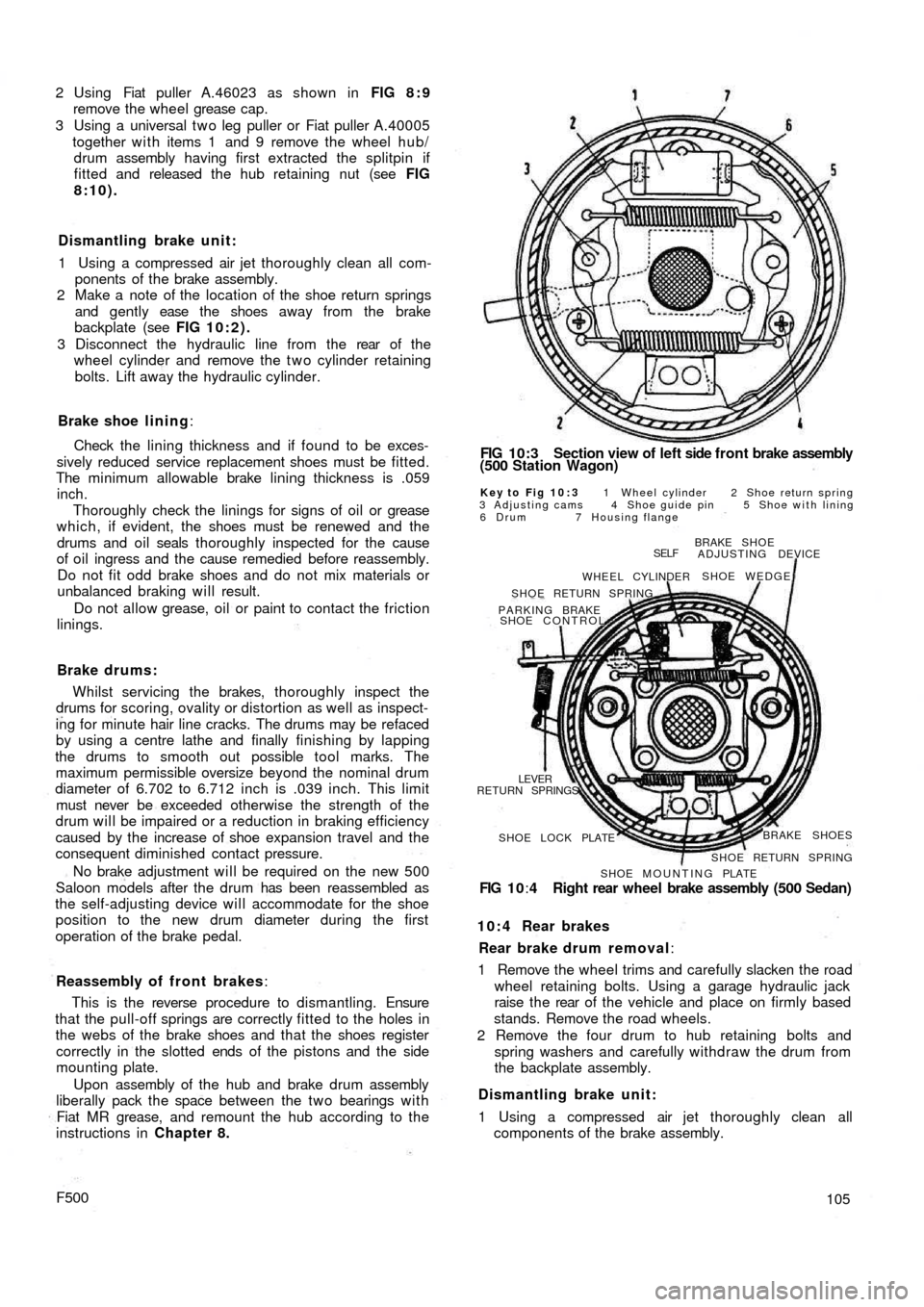

FIG 1 0:4 Right rear wheel brake assembly (500 Sedan)

10:4 Rear brakes

Rear brake drum removal:

1 Remove the wheel trims and carefully slacken the road

wheel retaining bolts. Using a garage hydraulic jack

raise the rear of t h e vehicle and place on firmly based

stands. Remove the road wheels.

2 Remove the four drum to hub retaining bolts and

spring washers and carefully withdraw the drum from

the backplate assembly.

Dismantling brake unit:

1 Using a compressed air jet thoroughly clean all

components of the brake assembly.

105

Page 104 of 128

CHAPTER 11

THE ELECTRICAL EQUIPMENT

11:1 Description

11:2 Battery

11:3 The generator

11:4 The starter

11:5 The control box

1 1 : 6 Fuses

1 1 : 7 Flasher unit

11:1 Description

All models covered by this manual have 12 volts

electrical systems in which the negative battery terminal

is earthed. There are three units in the regulator box to

control the charging circuit; a cut-out, a current regulator

and a voltage regulator. These are adjustable but it must

be stressed that accurate moving coil meters are required

when checking or altering the settings. Cheap and

unreliable instruments will make accurate adjustments

impossible.

There are wiring diagrams in Technical Data at the end

of this manual to enable those with electrical experience

to trace and correct wiring faults.

For t h e U.K. Market the headlamps are of the double

filament dipping renewable bulb type with adjustments

for individual beam settings.

The battery is located in the front compartment

forward of the petrol tank and the fuses to the rear o f the

petrol tank.

Detailed instructions for servicing the electrical equip-

ment will be found in this chapter, but it must be pointed

out that it is not sensible to try to repair that which is

seriously defective, electrically or mechanically. Such

equipment should be replaced by new units which can

be obtained on an exchange basis.

F500111

11 :8 Windscreen wipers

1 1 : 9 The lighting system

11:10 Panel and warning lights

11:11 The horn

11:12 Lighting and flasher switch

1 1 : 1 3 Fault diagnosis

11.2 The battery

This of the 12-volt lead/acid type and has to meet

heavy demands for current particularly in the winter. To

maintain the performance of the battery at its maximum

it is essential to carry out the following operations.

Keep the top of the battery and surrounding parts dry

and clean, as dampness can cause leakage between the

securing clamps and the battery terminals. Clean off any

corrosion from the metal parts of the battery mounting

with diluted ammonia and paint them with an anti-

sulphuric paint. If the terminal posts are corroded,

remove the cables and clean w i t h diluted ammonia.

Smear the posts w i t h petroleum jelly before remaking the

connections and fit the terminals securely. High electrical

resistance due to corrosion at the terminal posts is often

responsible for lack of sufficient current to operate the

starter motor.

Ensure t h a t the filler plugs are in good condition and

show no signs of cracks. This may cause leakage of

electrolyte and consequent corrosion. Test the condition

of the cells after topping-up the electrolyte level with

distilled water to just above the tops of the separators as

shown in FIG 11 :2 . Never add neat acid. If it is

necessary to make a new electrolyte due to loss by

spillage add sulphuric acid to the

distilled water.

It is highly dangerous to add water to acid.

Page 120 of 128

CHAPTER 12

THE BODYWORK

12:1

12:2

12:3

12:4

12:5

12:6

12:7Bodywork finish

Interior and chrome cleaning

Door trim and accessories

Door handles and locks

Removing regulator and door glass

Removing windshield glass

Removing rear side windows12:8

12:9

12:10

12:11

12:12

12:13

12:14Removing rear window glass

Front compartment lid

Engine compartment lid

Folding top

Sun roof

Seats

Interior heater

12:1 Bodywork finish

Large scale repairs to body panels are best left to

expert panel beaters. Even small dents can be tricky, as too

much hammering will stretch the metal and make things

worse instead of better. Filling minor dents and scratches

is probably the best method of restoring the surface. The

touching up of paintwork is well within the powers of

most car owners, particularly as self-spraying cans of

paint in the correct colours are now readily available. It

must be remembered, however, that paint changes colour

w i t h age and it is better to spray a whole wing rather than

try to touch up a small area.

Before spraying it is essential to remove all traces of

wax polish with white spirit. More drastic treatment is

required if silicone polishes have been applied. Use a

primer surfacer or paste stopper according to the amount

of filling required, and when it is dry, rub it down with

400 grade Wet or Dry paper until the surface is smooth

and flush with the surrounding area. Spend time on

getting the best finish as this will control the final effect.

Apply the retouching paint, keeping it wet in the centre

and light and dry round the edges. After a few hours of

drying, use a cutting compound to remove the dry spray

and finish with liquid polish.

F500127

12:2 Interior and chrome cleaning

The cloth upholstery of the seating and the rear

compartment lining must be regularly cleaned to ensure

long life and preserve its attractive appearance. Any dust

or dirt that is blown into the car will settle on the uphol-

stery and will tend to wear the cloth causing an unsightly

appearance. It is recommended that the dust is wiped off

using either a vacuum cleaner or a stiff brush. To remove

ordinary soiling of the upholstery cloth proceed as

follows:

1 Using luke warm water and a neutral soap and a piece

of clean cloth wipe over the upholstery in the direction

of the nap.

2 Repeat the operation using a clean damp cloth and

warm water but no soap.

3 Allow the upholstery cloth to dry, use a stiff brush

against the direction of the upholstery nap to restore

its original fluffy look.

To obtain best results, any stains must be removed as

soon as possible otherwise as time passes they will

become more difficult, if not impossible to remove.

Certain stains require specific solvents and the instruc-

tions must be strictly adhered to.