mount FIAT 500 1971 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1971, Model line: 500, Model: FIAT 500 1971 1.GPages: 128, PDF Size: 9.01 MB

Page 34 of 128

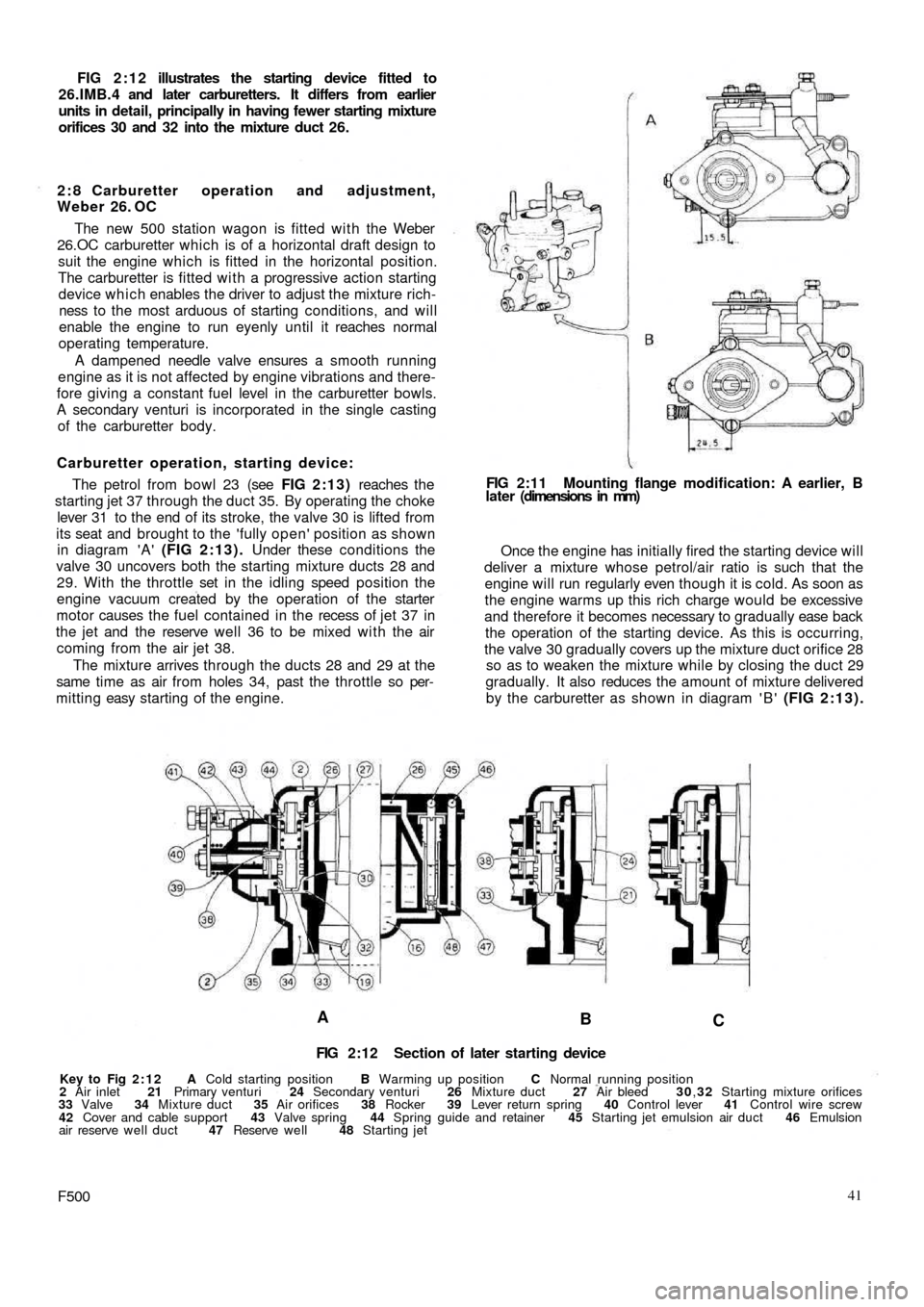

FIG 2:12 illustrates the starting device fitted to

26.IMB.4 and later carburetters. It differs from earlier

units in detail, principally in having fewer starting mixture

orifices 30 and 32 into the mixture duct 26.

2 : 8 Carburetter operation and adjustment,

Weber 26. OC

The new 500 station wagon is fitted with the Weber

26.OC carburetter which is of a horizontal draft design to

suit the engine which is fitted in the horizontal position.

The carburetter is fitted with a progressive action starting

device which enables the driver to adjust the mixture rich-

ness to the most arduous of starting conditions, and will

enable the engine to run eyenly until it reaches normal

operating temperature.

A dampened needle valve ensures a smooth running

engine as it is not affected by engine vibrations and there-

fore giving a constant fuel level in the carburetter bowls.

A secondary venturi is incorporated in the single casting

of the carburetter body.

Carburetter operation, starting device:

The petrol from bowl 23 (see FIG 2:13) reaches the

starting jet 37 through the duct 35. By operating the choke

lever 31 to the end of its stroke, the valve 30 is lifted from

its seat and brought to the 'fully open' position as shown

in diagram 'A' (FIG 2:13). Under these conditions the

valve 30 uncovers both the starting mixture ducts 28 and

29. With the throttle set in the idling speed position the

engine vacuum created by the operation of the starter

motor causes the fuel contained in the recess of j e t 37 in

the jet and the reserve

well 36 to be mixed with the air

coming from the air jet 38.

The mixture arrives through the ducts 28 and 29 at the

same time as air from holes 34, past the throttle so per-

mitting easy starting of the engine.

A

B

C

FIG 2:12 Section of later starting device

Key to Fig 2:12 A Cold starting position B Warming up position C Normal running position

2 Air inlet 21 Primary venturi 24 Secondary venturi 26 Mixture duct 27 Air bleed 30,32 Starting mixture orifices

33 Valve 34 Mixture duct 35 Air orifices 38 Rocker 39 Lever return spring 40 Control lever 41 Control wire screw

42 Cover and cable support 43 Valve spring 44 Spring guide and retainer 45 Starting jet emulsion air duct 46 Emulsion

air reserve well duct 47 Reserve well 48 Starting jet

F50041 Once the engine has initially fired the starting device will

deliver a mixture whose petrol/air ratio is such that the

engine will run regularly even though it is cold. As soon as

the engine warms up this rich charge would be excessive

and therefore it becomes necessary to gradually ease back

the operation of the starting device. As this is occurring,

the valve 30 gradually covers up the mixture duct orifice 28

so as to weaken the mixture while by closing the duct 29

gradually. It also reduces the amount of mixture delivered

by the carburetter as shown in diagram ' B ' (FIG 2:13). FIG 2:11 Mounting flange modification: A earlier, B

later (dimensions in mm)

Page 36 of 128

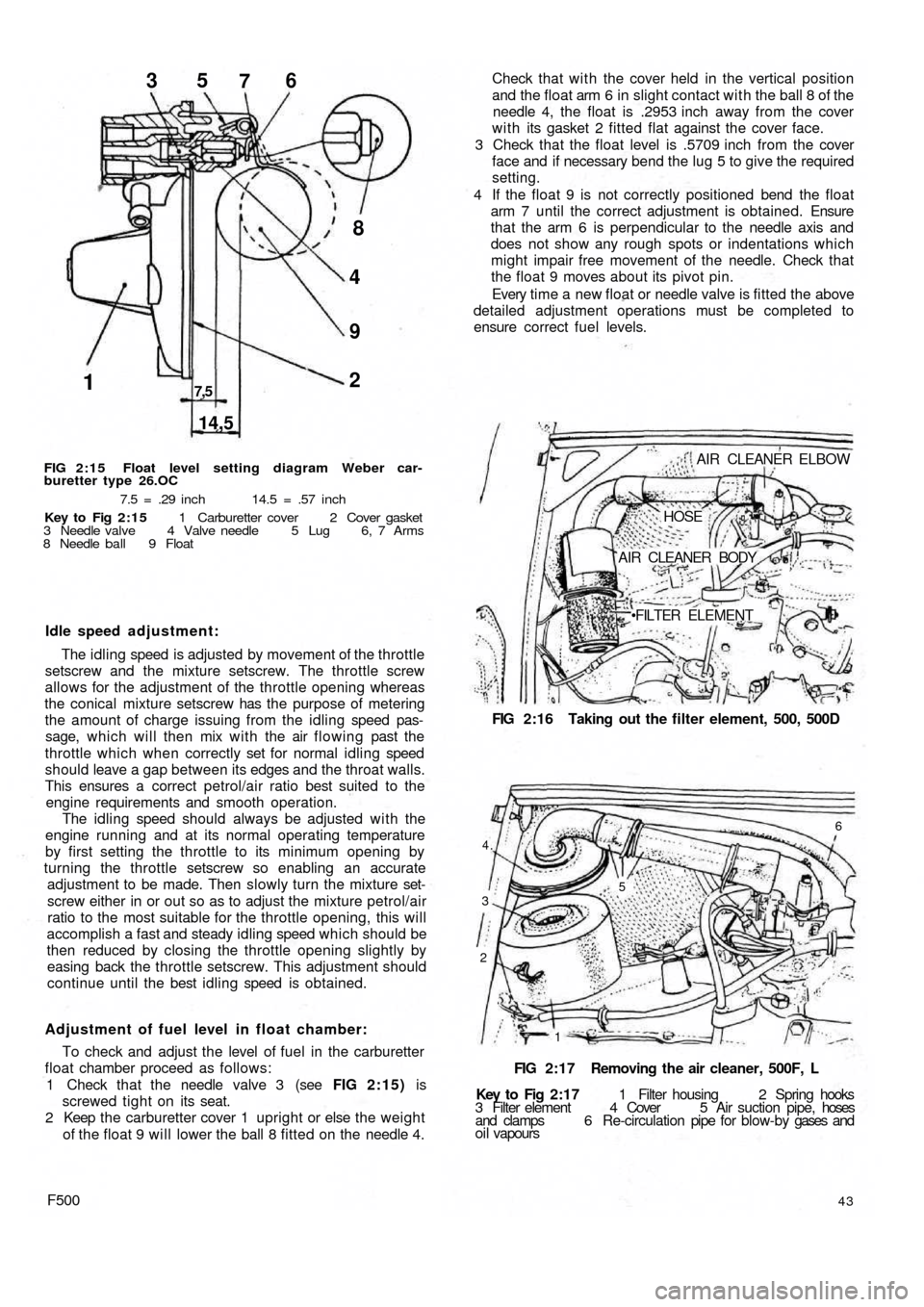

1

14,5

7,52 9 48 35

76

FIG 2:15 Float level setting diagram Weber car-

buretter type 26.OC

7.5 = .29 inch 14.5 = .57 inch

Key to Fig 2:15 1 Carburetter cover 2 Cover gasket

3 Needle valve 4 Valve needle 5 Lug 6, 7 Arms

8 Needle ball 9 Float

Idle speed adjustment:

The idling speed is adjusted by movement of the throttle

setscrew and the mixture setscrew. The throttle screw

allows for the adjustment of the throttle opening whereas

the conical mixture setscrew has the purpose of metering

the amount of charge issuing from the idling speed pas-

sage, which will then mix with the air flowing past the

throttle which when correctly set for normal idling speed

should leave a gap between its edges and the throat walls.

This ensures a correct petrol/air ratio best suited to the

engine requirements and smooth operation.

The idling speed should always be adjusted with the

engine running and at its normal operating temperature

by first setting the throttle to its minimum opening by

turning the throttle setscrew so enabling an accurate

adjustment to be made. Then slowly turn the mixture set-

screw either in or out so as to adjust the mixture petrol/air

ratio to the most suitable for the throttle opening, this will

accomplish a fast and steady idling speed which should be

then reduced by closing the throttle opening slightly by

easing back the throttle setscrew. This adjustment should

continue until the best idling speed is obtained.

Adjustment of fuel level in float chamber:

To check and adjust the level of fuel in the carburetter

float chamber proceed as follows:

1 Check that the needle valve 3 (see FIG 2:15) is

screwed tight on its seat.

2 Keep the carburetter cover 1 upright or else the weight

of the float 9 will lower the ball 8 fitted on the needle 4.

F50043

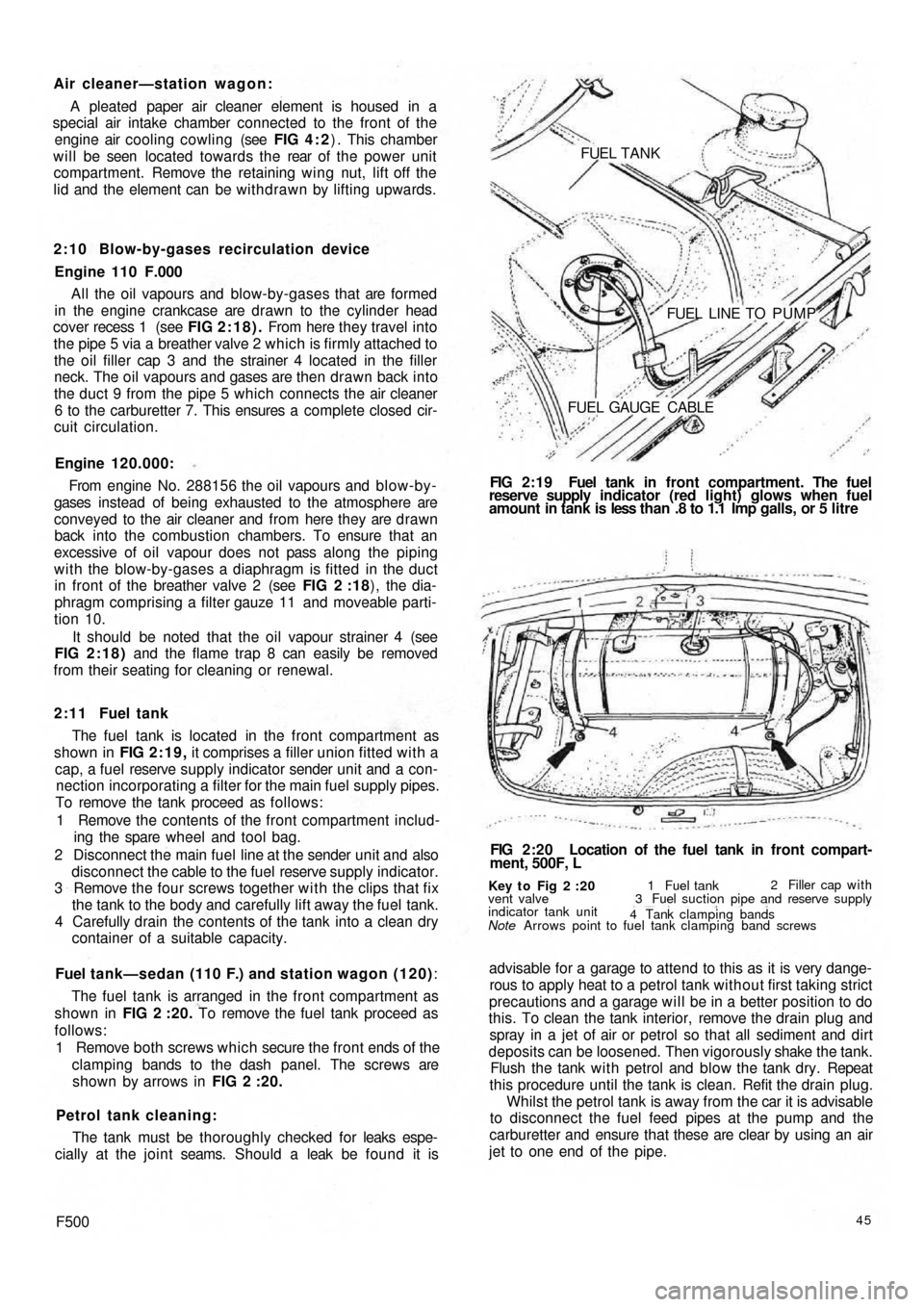

Key to Fig 2:17 1 Filter housing 2 Spring hooks

3 Filter element 4 Cover 5 Air suction pipe, hoses

and clamps 6 Re-circulation pipe for blow-by gases and

oil vapoursFIG 2:17 Removing the air cleaner, 500F, L

2

1 3

4.

6

5

FIG 2:16 Taking out the filter element, 500, 500D AIR CLEANER ELBOW

HOSE

AIR CLEANER BODY

FILTER ELEMENT Check that with the cover held in the vertical position

and the float arm 6 in slight contact with the ball 8 of the

needle 4, the float is .2953 inch away from the cover

w i t h its gasket 2 fitted flat against the cover face.

3 Check that the float level is .5709 inch from the cover

face and if necessary bend the lug 5 to give the required

setting.

4 If the float 9 is not correctly positioned bend the float

arm 7 until the correct adjustment is obtained. Ensure

that the arm 6 is perpendicular to the needle axis and

does not show any rough spots or indentations which

might impair free movement of the needle. Check that

the float 9 moves about its pivot pin.

Every time a new float or needle valve is fitted the above

detailed adjustment operations must be completed to

ensure correct fuel levels.

Page 38 of 128

Air cleaner—station wagon:

A pleated paper air cleaner element is housed in a

special air intake chamber connected to the front of the

engine air cooling cowling (see FIG 4 : 2) . This chamber

will be seen located towards the rear of t h e power unit

compartment. Remove the retaining wing nut, lift off the

lid and the element can be withdrawn by lifting upwards.

2:10 Blow-by-gases recirculation device

Engine 110 F.000

All the oil vapours and blow-by-gases that are formed

in the engine crankcase are drawn to the cylinder head

cover recess 1 (see FIG 2:18). From here they travel into

the pipe 5 via a breather valve 2 which is firmly attached to

the oil filler cap 3 and the strainer 4 located in the filler

neck. The oil vapours and gases are then d r a w n back into

the duct 9 from the pipe 5 which connects the air cleaner

6 to the carburetter 7. This ensures a complete closed cir-

cuit circulation.

Engine 120.000:

From engine No. 288156 the oil vapours and blow-by-

gases instead of being exhausted to the atmosphere are

conveyed to the air cleaner and from here they are drawn

back into the combustion chambers. To ensure that an

excessive of oil vapour does not pass along the piping

with the blow-by-gases a diaphragm is fitted in the duct

in front of the breather valve 2 (see FIG 2 :18), the dia-

phragm comprising a filter gauze 11 and moveable parti-

tion 10.

It should be noted that the oil vapour strainer 4 (see

FIG 2:18) and the flame trap 8 can easily be removed

from their seating for cleaning or renewal.

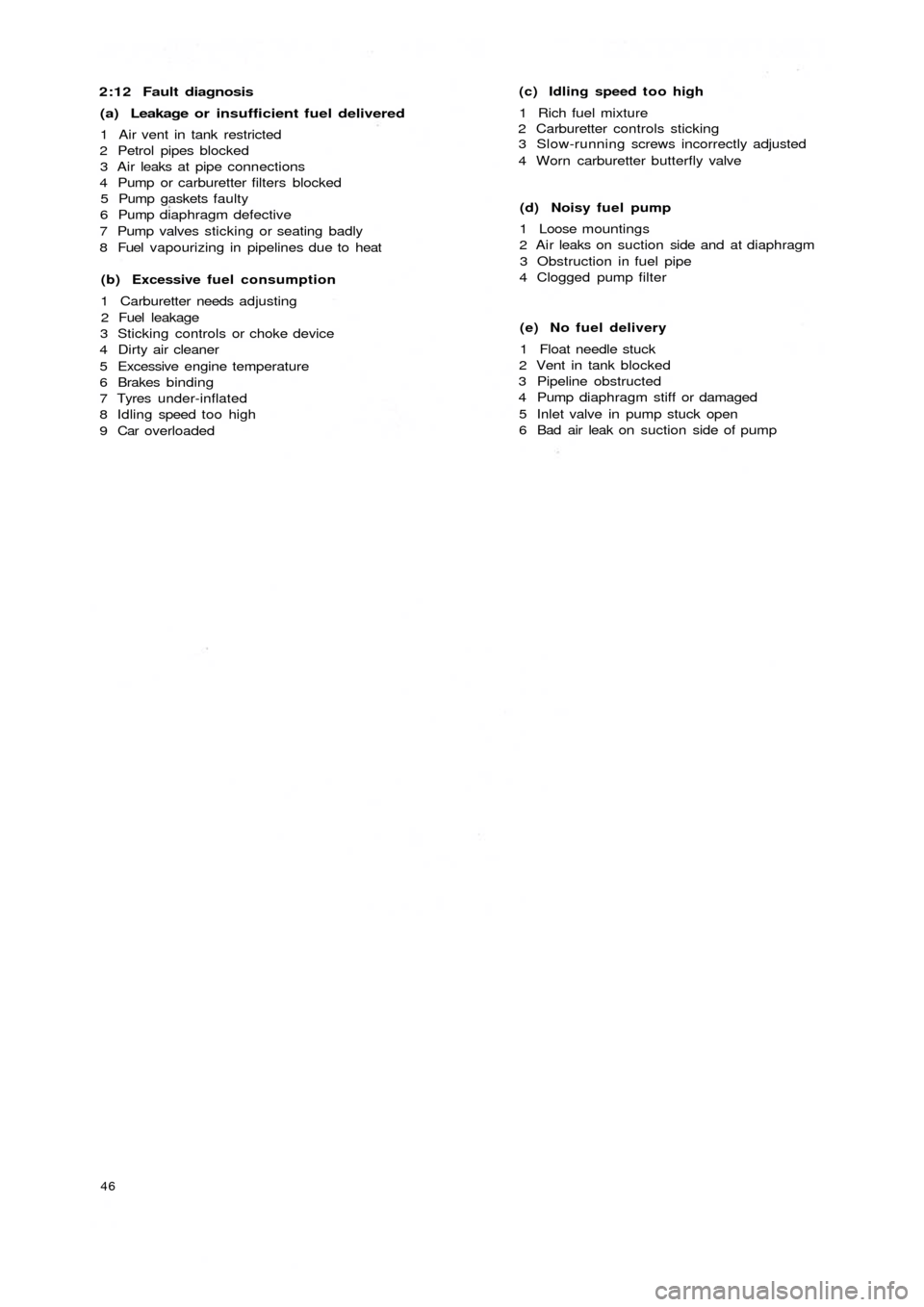

2 : 1 1 Fuel tank

The fuel tank is located in the front compartment as

shown in FIG 2:19, it comprises a filler union fitted with a

cap, a fuel reserve supply indicator sender unit and a con-

nection incorporating a filter for the main fuel supply pipes.

To remove the tank proceed as follows:

1 Remove the contents of the front compartment includ-

ing the spare wheel and tool bag.

2 Disconnect the main fuel line at the sender unit and also

disconnect the cable to the fuel reserve supply indicator.

3 Remove the four screws together w i t h the clips that fix

the tank to the body and carefully lift away the fuel tank.

4 Carefully drain the contents of the tank into a clean dry

container of a suitable capacity.

Fuel tank—sedan (110 F.) and station wagon (120):

The fuel tank is arranged in the front compartment as

shown in FIG 2 :20. To remove the fuel tank proceed as

follows:

1 Remove both screws which secure the front ends of the

clamping bands to the dash panel. The screws are

shown by arrows in FIG 2 :20.

Petrol tank cleaning:

The tank must be thoroughly checked for leaks espe-

cially at the joint seams. Should a leak be found it is

F50045

advisable for a garage to attend to this as it is very dange-

rous to apply heat to a petrol tank without first taking strict

precautions and a garage will be in a better position to do

this. To clean the tank interior, remove the drain plug and

spray in a jet of air or petrol so that all sediment and dirt

deposits can be loosened. Then vigorously shake the tank.

Flush the tank w i t h petrol and blow the tank dry. Repeat

this procedure until the tank is clean. Refit the drain plug.

Whilst the petrol tank is away from the car it is advisable

to disconnect the fuel feed pipes at the pump and the

carburetter and ensure that these are clear by using an air

jet to one end of the pipe.

Key t o Fig 2 :20

Note Arrows point to fuel tank clamping band screws vent valve

indicator tank unit1 Fuel tank2 Filler cap with

3 Fuel suction pipe and reserve supply

4 Tank clamping bands

FIG 2:20 Location of the fuel tank in front compart-

ment, 500F, L FIG 2:19 Fuel tank in front compartment. The fuel

reserve supply indicator (red light) glows when fuel

amount in tank is less than .8 to 1.1 Imp galls, or 5 litre FUEL TANK

FUEL LINE TO PUMP

FUEL GAUGE CABLE

Page 39 of 128

2:12 Fault diagnosis

(a) Leakage or insufficient fuel delivered

1 Air vent in tank restricted

2 Petrol pipes blocked

3 Air leaks at pipe connections

4 Pump or carburetter filters blocked

5 Pump gaskets faulty

6 Pump diaphragm defective

7 Pump valves sticking or seating badly

8 Fuel vapourizing in pipelines due to heat

(b) Excessive fuel consumption

1 Carburetter needs adjusting

2 Fuel leakage

3 Sticking controls or choke device

4 Dirty air cleaner

5 Excessive engine temperature

6 Brakes binding

7 Tyres under-inflated

8 Idling speed too high

9 Car overloaded(c) Idling speed too high

1 Rich fuel mixture

2 Carburetter controls sticking

3 Slow-running screws incorrectly adjusted

4 Worn carburetter butterfly valve

(d) Noisy fuel pump

1 Loose mountings

2 Air leaks on suction side and at diaphragm

3 Obstruction in fuel pipe

4 Clogged pump filter

(e) No fuel delivery

1 Float needle stuck

2 Vent in tank blocked

3 Pipeline obstructed

4 Pump diaphragm stiff or damaged

5 Inlet valve in pump stuck open

6 Bad air leak on suction side of pump

46

Page 40 of 128

3:1

3:2

3:3

3:4

3:5Description

Operation

Routine maintenance

Ignition faults

Removing and dismantling distributor (sedan

and sports)

CHAPTER 3

THE IGNITION SYSTEM

3:6

3:7

3:8

3:9

3:10

Removing and dismantling

(station wagon)

Timing the ignition

Sparking plugs

The distributor drive spindle

Fault diagnosisdistributor

3 :1 Description

The ignition system fitted to all the models covered by

this manual consists of an ignition coil, ignition distributor

fitted with contact breaker points, a centrifugal automatic

advance system, condenser, low- and high-tension

wiring, spark plugs and a power supply provided by a

generator and battery. The wiring diagram is shown in

FIG 3 : 1

1 The low-tension circuit which is sometimes called the

primary circuit includes the power supply, contact

breaker points, condenser and ignition coil primary

winding.

2 The high-tension circuit which is sometimes called the

secondary circuit includes the ignition coil secondary

winding, distributor rotor, distributor cap with terminals

and the central brush, high-tension cables and the spark

plugs.

3 : 2 Operation

The contact breaker unit in the distributor interrupts

the primary circuit by the points opening. The sudden stop

in the flow of current in the primary winding, does not cause

arcing at the contact breaker points because it discharges

into the condenser connected in parallel w i t h the contact

F50047

breaker points. With the sudden collapse of the primary

circuit, the intensity of the magnetic field drops causing

an induced high-tension current in the ignition coil

secondary winding. The high EMF is distributed to the

sparking plugs by the ignition distributor rotor.

The automatic advance mechanism comprises a plate

carrying t w o weights which are symmetrically pivoted on

the plate at one end. Also attached to the weights at

opposite ends to the pivots is the cam carrier shaft with

special tension return springs. Under the action of centri-

fugal force as the rotational speed increases, the weights

move outwards causing the cam carrier shaft to move

angularly compared to the distributor drive shaft thus

causing advancement of the ignition timing.

The contact breaker assembly comprises the cam on the

drive shaft and t w o contact points, one of which is

stationary while the other is under the influence of the

cam, the action of which is transmitted by a rubbing block.

The cam has t w o lobes to control the opening and closing

of contact points. The stationary contact point is mounted

on an adjustable support to enable the contact breaker

point gap to be adjusted.

The HT current reaches the distributor cap central

terminal, from the ignition coil and is distributed to each

of the spark plugs at the correct time by the rotor arm.

Page 42 of 128

a n 0—20 v o ltmeter. If the circuit is in order the meter

should read approximately 12-volts.

3 Battery to fuse box terminal 30. Connect the volt-

meter between the terminal 30 and earth. No reading

indicates a faulty cable or loose connection.

4 Fuse box. Connect the voltmeter between the other

auxiliary terminal 30 and earth. No reading indicates a

broken or loose connection.

5 Fuse box auxiliary terminal 30 to terminal

number 30 on ignition switch. Connect the meter

between terminal number 30 on the ignition switch

and earth. No reading indicates a damaged cable or

loose connection.

6 Ignition switch. Connect the meter between termi-

nal 15/54 and earth. Switch onto the ignition position,

when no reading indicates a fault in the switch.

7 Ignition switch to low-tension cable connection

on the coil (blue cable). Connect the meter

between ignition coil terminal (blue cable) and earth.

No reading indicates a damaged cable or loose con-

nection.

8 Ignition coil. Disconnect the black low-tension cable

connecting the coil to the distributor side terminal at

the coil and connect the meter between this terminal

and earth. No reading indicates a fault in the primary

winding of the coil and a replacement coil must be

fitted. If the reading is correct remake the connections

to the coil.

9 Ignition coil to distributor. Disconnect the thin

black low-tension cable at the side of the distributor

and connect the meter between the end of this cable

and earth. No reading indicates a damaged cable or

loose connections.

10 Contact breaker and capacitor. Connect the

meter across the contact breaker points. No reading

indicates a faulty capacitor.

Capacitor:

The best method of testing a capacitor (condenser) is

by substitution. Disconnect the original capacitor and

connect a new one between the low-tension terminal on

the side of the distributor and earth.

If a new capacitor is needed, fit a new one complete

w i t h bracket, but if necessary unsolder the original bracket

and solder it onto the new capacitor using as little heat as

possible. Capacitor capacity is .15-.20 microfarads.

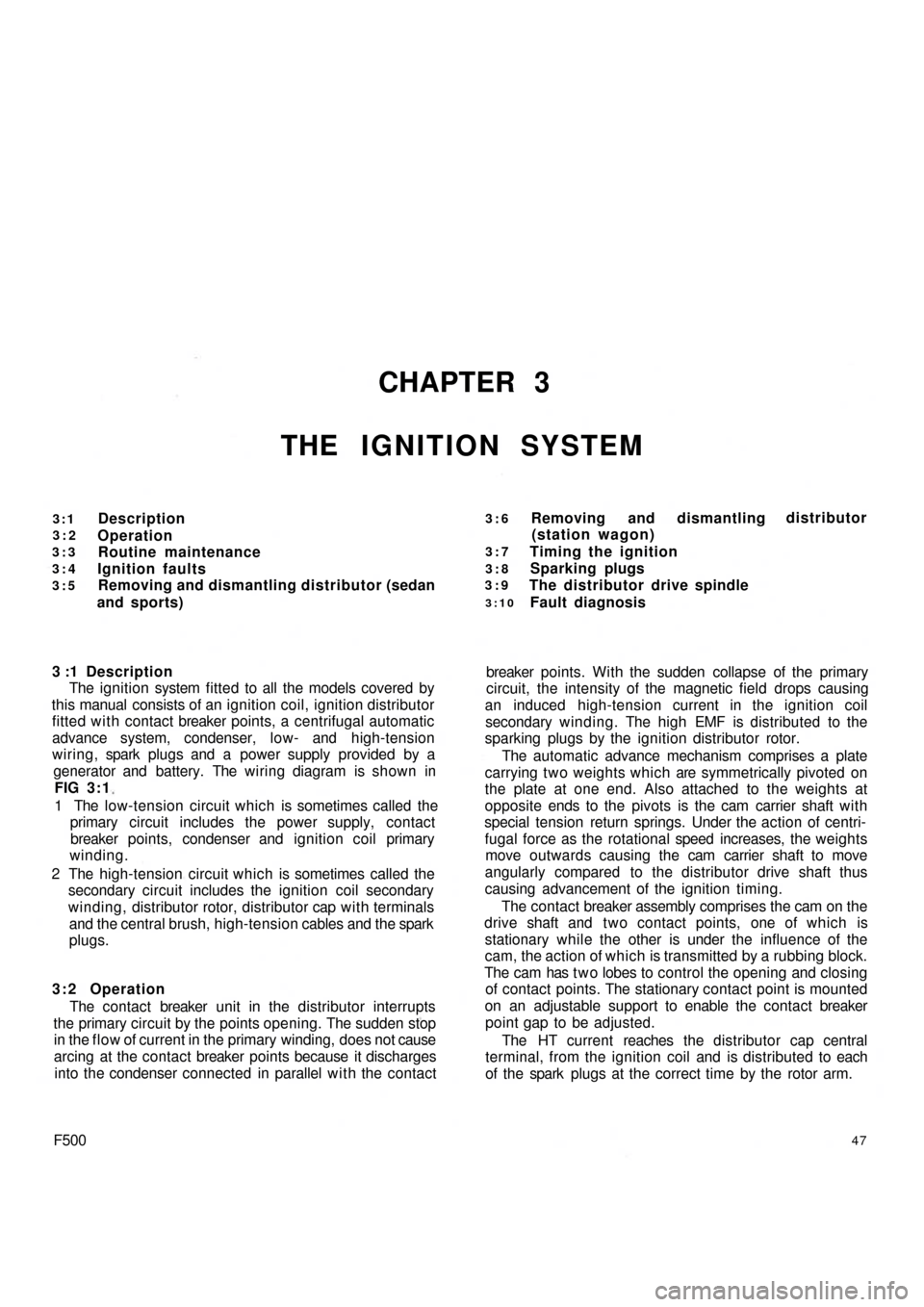

3 : 5 Removing and dismantling distributor (sedan

and sports)

To remove the distributor proceed as follows:

1 Rotate the engine slowly until the distributor rotor arm

is opposite the brass segment in the distributor cap

connected to No. 1 plug lead. This will provide a datum

for replacement.

2 Disconnect the cable from the low-tension terminal on

the side of the distributor body. Mark position of distri-

butor on support. Release the distributor retaining nut

and washer from the underside of the top flange of the

distributor support and carefully lift away the dis-

tributor.

3 Pull off the rotor arm. Remove the insulated terminal

assembly from the side of distributor body. Release the

contact breaker carrier plate retaining screws and con-

denser flange screw from the outside of the distributor

F50049 body. Carefully lift out the contact breaker plate

assembly.

4 Before further dismantling note the relative positions of

the driving dog and the rotor arm driving slot at the top

of the distributor cam spindle. The driving dog is offset

and can only engage its driving spindle in one position.

Then when the cam assembly is fitted to the centrifugal

weights during reassembly the timing is not 180 deg.

out.

5 Take out the cam lubrication felt pad recessed in the

rotor arm housing on the end of the cam spindle.

Remove the retaining screw, carefully disengage the

springs and lift out the cam spindle. It should be noted

that there is a small retaining ball and spring located in a

drilling nearly at the top of the drive shaft spindle.

Carefully lift away the weights.

6 Thoroughly clean all parts and inspect for excessive

wear. The distributor cap must not be cracked or show

signs of tracking. The cap terminals, rotor and contact

breaker points can be cleaned with a very fine file.

Emerypaper must not be used. If the clearance between

the rotor and distributor cap segments exceeds .0118

inch both the rotor and distributor cap must be replaced.

Inspect the contact breaker arm rubbing block for exces-

sive wear and also the points for wear so that if the gap

exceeds the last setting limit of .0209 inch and adjust-

ment through the stationary contact carrier screw is no

longer possible (see FIG 3 : 2) , the contact breaker set

must be renewed.

If the distributor drive shaft side or vertical movement is

excessive the distributor must be renewed.

Weak centri-

fugal weight springs or damaged weights must be

renewed using original Fiat spares otherwise the auto-

matic ignition advance characteristics could be altered.

FIG 3 : 3 Ignition distributor in place on engine SPARK PLUG CABLES

IGNITION COIL CABLE!

DISTRIBUTOR CAP

DISTRIBUTOR BODY

GROUND CABLE

CONDENSER

DISTRIBUTOR SHAFT

LUBRICATION FITTING

DISTRIBUTORSUPPORT-TO--CRANKCASE NUT

[MOUNTING SCREWDISTRIBUTOR

DISTRIBUTOR SUPPORT

Page 43 of 128

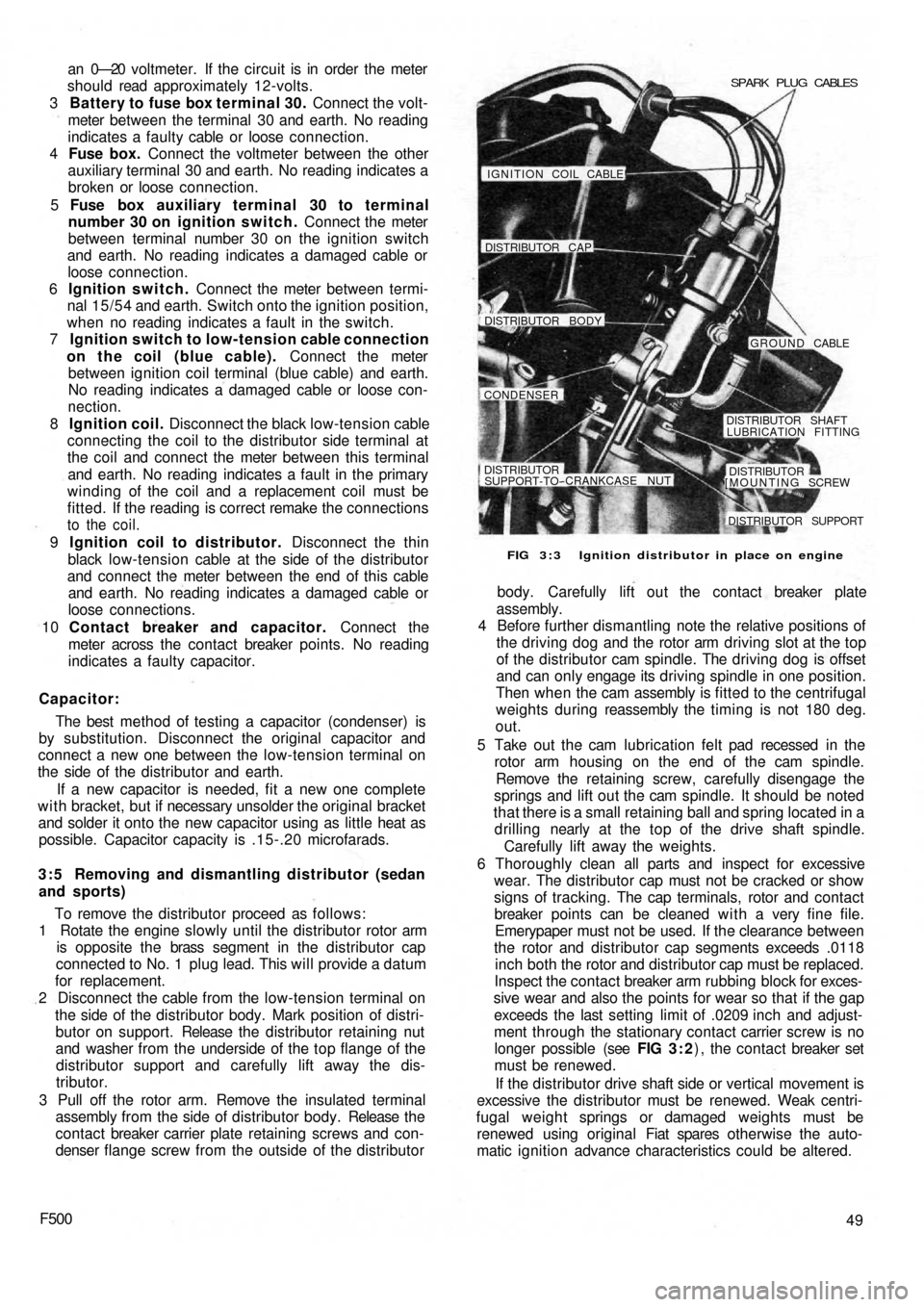

FIG 3 : 4 Use of fixture Ap.5030/1 to check ignition

timing

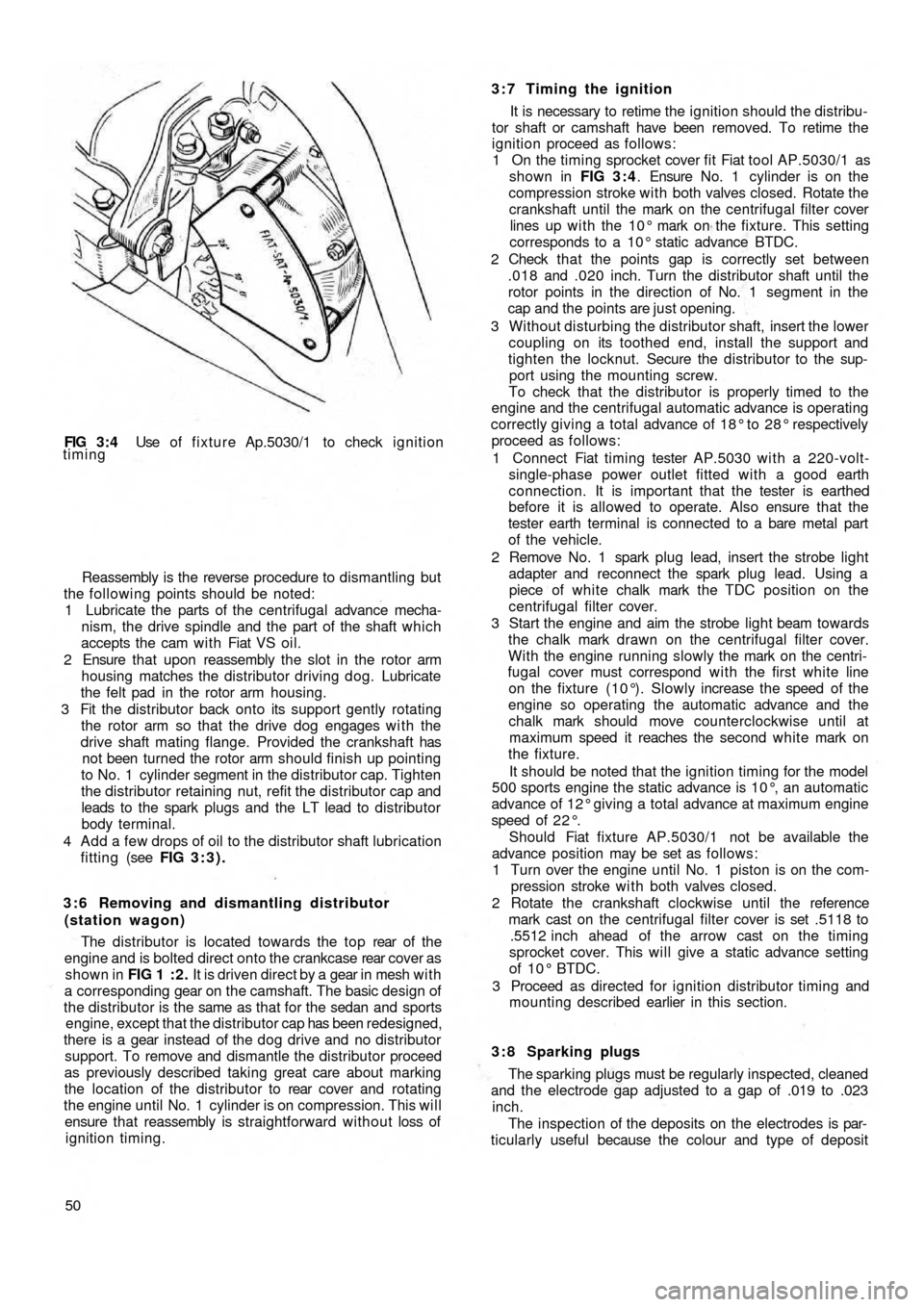

Reassembly is the reverse procedure to dismantling but

the following points should be noted:

1 Lubricate the parts of the centrifugal advance mecha-

nism, the drive spindle and the part of the shaft which

accepts the cam w i t h Fiat VS oil.

2 Ensure that upon reassembly the slot in the rotor arm

housing matches the distributor driving dog. Lubricate

the felt pad in the rotor arm housing.

3 Fit the distributor back onto its support gently rotating

the rotor arm so that the drive dog engages w i t h the

drive shaft mating flange. Provided the crankshaft has

not been turned the rotor arm should finish up pointing

to No. 1 cylinder segment in the distributor cap. Tighten

the distributor retaining nut, refit the distributor cap and

leads to the spark plugs and the LT lead to distributor

body terminal.

4 Add a few drops of oil to the distributor shaft lubrication

fitting (see FIG 3:3).

3 : 6 Removing and dismantling distributor

(station wagon)

The distributor is located towards the top rear of t h e

engine and is bolted direct onto the crankcase rear cover as

shown in FIG 1 : 2 . It is driven direct by a gear in mesh w i t h

a corresponding gear on the camshaft. The basic design of

the distributor is the same as that for the sedan and sports

engine, except that the distributor cap has been redesigned,

there is a gear instead of the dog

drive and no distributor

support. To remove and dismantle the distributor proceed

as previously described taking great care about marking

the location of the distributor to rear cover and rotating

the engine until No. 1 cylinder is on compression. This will

ensure that reassembly is straightforward without loss of

ignition timing.

503:7 Timing the ignition

It is necessary to retime the ignition should the distribu-

tor shaft or camshaft have been removed. To retime the

ignition proceed as follows:

1 On the timing sprocket cover fit Fiat tool AP.5030/1 as

shown in FIG 3 : 4. Ensure No. 1 cylinder is on the

compression stroke with both valves closed. Rotate the

crankshaft until the mark on the centrifugal filter cover

lines up w i t h the 10° mark on the fixture. This setting

corresponds to a 10° static advance BTDC.

2 Check t h a t the points gap is correctly set between

.018 and .020 inch. Turn the distributor shaft until the

rotor points in the direction of No. 1 segment in the

cap and the points are just opening.

3 Without disturbing the distributor shaft, insert the lower

coupling on its toothed end, install the support and

tighten the locknut. Secure the distributor to the sup-

port using the mounting screw.

To check that the distributor is properly timed to the

engine and the centrifugal automatic advance is operating

correctly giving a

total advance of 18° to 28° respectively

proceed as follows:

1 Connect Fiat timing tester AP.5030 with a 220-volt-

single-phase power outlet fitted with a good earth

connection. It is important that the tester is earthed

before it is allowed to operate. Also ensure that the

tester earth terminal is connected to a bare metal part

of the vehicle.

2 Remove No. 1 spark plug lead, insert the strobe light

adapter and reconnect the spark plug lead. Using a

piece of white chalk mark the TDC position on the

centrifugal filter cover.

3 Start the engine and aim the strobe light beam towards

the chalk mark drawn on the centrifugal filter cover.

With the engine running slowly the mark on the centri-

fugal cover must correspond wi th the first white line

on the fixture (10°). Slowly increase the speed of the

engine so operating the automatic advance and the

chalk mark should move counterclockwise until at

maximum speed it reaches the second white mark on

the fixture.

It should be noted that the ignition timing for the model

500 sports engine the static advance is 10°, an automatic

advance of 12° giving a total advance at maximum engine

speed of 2 2 ° .

Should Fiat fixture AP.5030/1 not be available the

advance position may be set as follows:

1 Turn over the

engine until No. 1 piston is on the com-

pression stroke w i t h both valves closed.

2 Rotate the crankshaft clockwise until the reference

mark cast on the centrifugal filter cover is set .5118 to

.5512 inch ahead of the arrow cast on the timing

sprocket cover. This will give a static advance setting

of 10° BTDC.

3 Proceed as directed for ignition distributor timing and

mounting described earlier in this section.

3 : 8 Sparking plugs

The sparking plugs must be regularly inspected, cleaned

and the electrode gap adjusted to a gap of .019 to .023

inch.

The inspection of the deposits on the electrodes is par-

ticularly useful because the colour and type of deposit

Page 46 of 128

CHAPTER 4

THE COOLING SYSTEM

4:1

4:2

4:3Description

Air outlet thermostat and shutter

Tension adjustment4:4

4:5

4:6Heating system safety device

Maintenance

Fault diagnosis

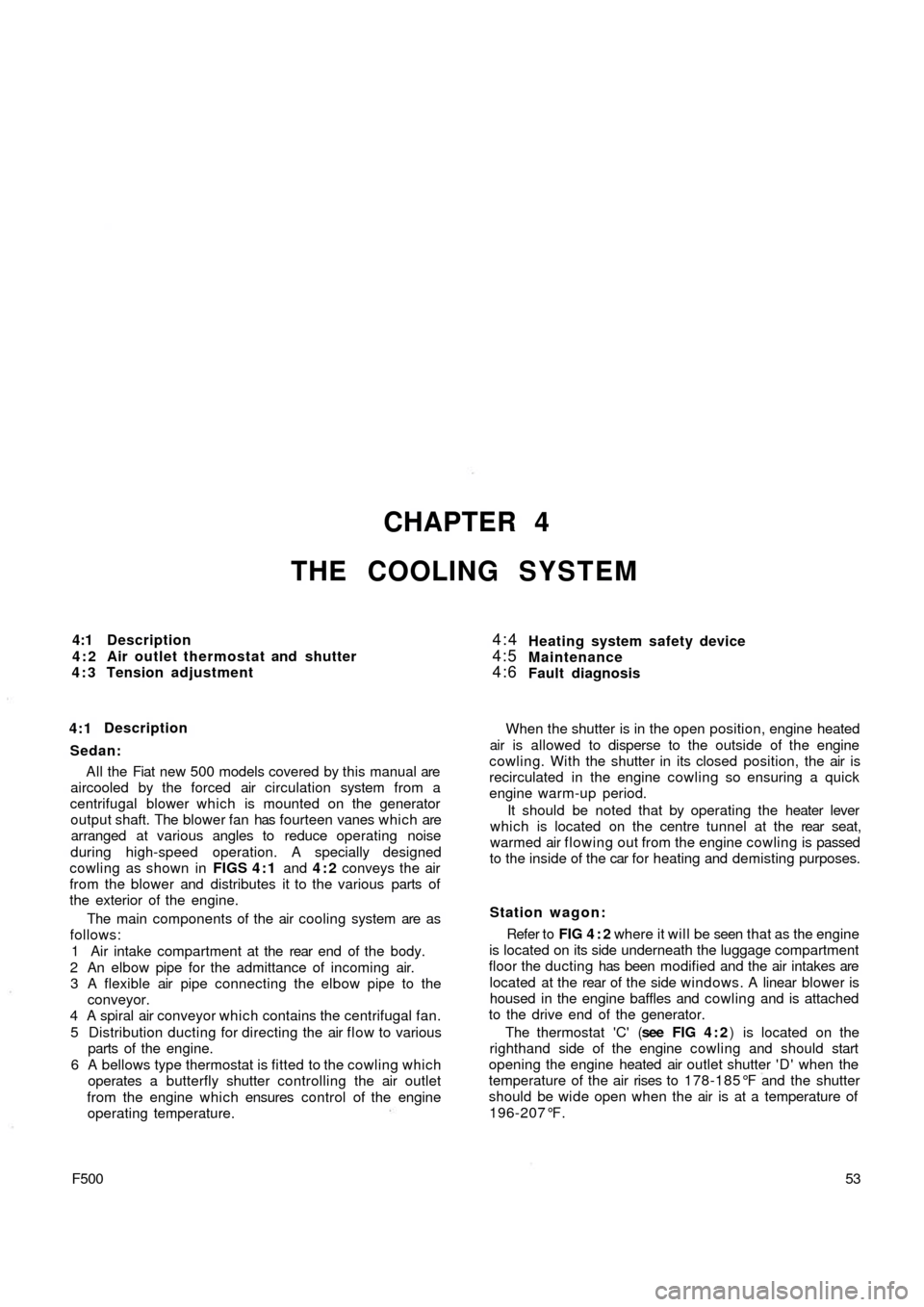

4:1Description

Sedan:

A l l the Fiat new 500 models covered by this manual are

aircooled by the forced air circulation system from a

centrifugal blower which is mounted on the generator

output shaft. The blower fan has fourteen vanes which are

arranged at various angles to reduce operating noise

during high-speed operation. A specially designed

cowling as shown in FIGS 4 : 1 and 4:2 conveys the air

from the blower and distributes it to the various parts of

the exterior of the engine.

The main components of the air cooling system are as

follows:

1 Air intake compartment at the rear end of t h e body.

2 An elbow pipe for the admittance of incoming air.

3 A flexible air pipe connecting the elbow pipe to the

conveyor.

4 A spiral air conveyor which contains the centrifugal fan.

5 Distribution ducting for directing the air flow to various

parts of the engine.

6 A bellows type thermostat is fitted to the cowling which

operates a butterfly shutter controlling the air outlet

from the engine which ensures control of the engine

operating temperature.

F50053 When the shutter is in the open position, engine heated

air is allowed to disperse to the outside of the engine

cowling. With the shutter in its closed position, the air is

recirculated in the engine cowling so ensuring a quick

engine warm-up period.

It should be noted that by operating the heater lever

which is located on the centre tunnel at the rear seat,

warmed air flowing out from the engine cowling is passed

to the inside of the car for heating and demisting purposes.

Station wagon:

Refer to FIG 4 : 2 where it will be seen that as the engine

is located on its side underneath the luggage compartment

floor the ducting has been modified and the air intakes are

located at the rear of the side windows. A linear blower is

housed in the engine baffles and cowling and is attached

to the drive end of the generator.

The thermostat 'C' (see FIG 4 : 2) is located on the

righthand side of the engine cowling and should start

opening the engine heated air outlet shutter ' D ' when the

temperature of the air rises to 1 7 8 - 1 8 5 ° F and the shutter

should be wide open when the air is at a temperature of

196-207°F.

Page 49 of 128

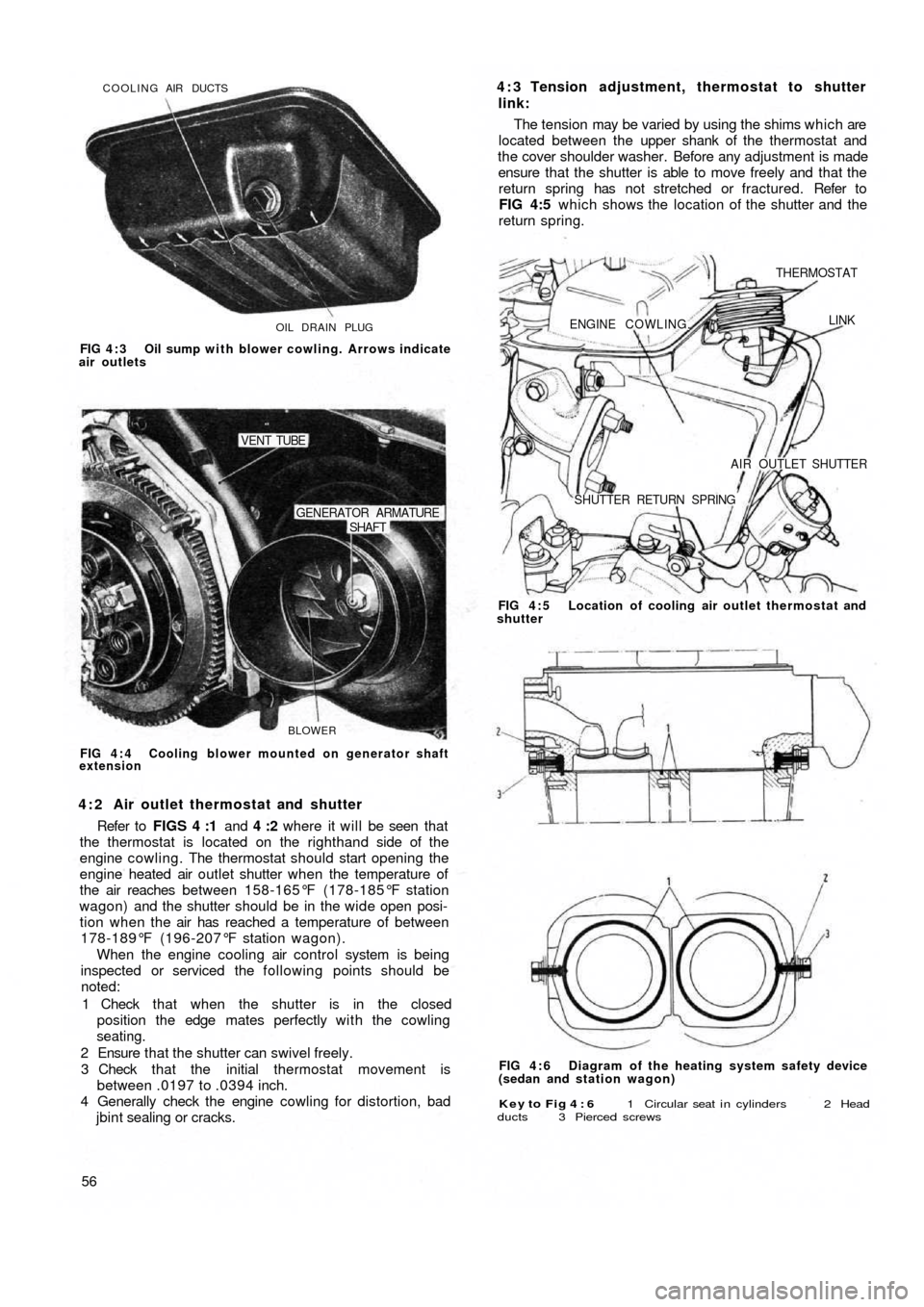

OIL DRAIN PLUG COOLING AIR DUCTS

FIG 4 : 3 Oil sump with blower cowling. Arrows indicate

air outlets

BLOWER

SHAFT GENERATOR ARMATURE

VENT TUBE

FIG 4 : 4 Cooling blower mounted on generator shaft

extension

4 : 2 Air outlet thermostat and shutter

Refer to FIGS 4 :1 and 4 :2 where it will be seen that

the thermostat is located on the righthand side of the

engine cowling. The thermostat should start opening the

engine heated air outlet shutter when the temperature of

the air reaches between 158-165°F (178-185°F station

wagon) and the shutter should be in the wide open posi-

tion when the air has reached a temperature of between

178-189°F (196-207°F station wagon).

When the engine cooling air control system is being

inspected or serviced the following points should be

noted:

1 Check that when the shutter is in the closed

position the edge mates perfectly with the cowling

seating.

2 Ensure that the shutter can swivel freely.

3 Check that the initial thermostat movement is

between .0197 to .0394 inch.

4 Generally check the engine cowling for distortion, bad

jbint sealing or cracks.

56

Key to Fig 4 : 6 1 Circular seat i n cylinders 2 Head

ducts 3 Pierced screws

FIG 4 : 6 Diagram of the heating system safety device

(sedan and station wagon) FIG 4 : 5 Location of cooling air outlet thermostat and

shutter

ENGINE COWLING.

THERMOSTAT

LINK

AIR OUTLET SHUTTER

SHUTTER RETURN SPRING

4 : 3 Tension adjustment, thermostat to shutter

link:

The tension may be varied by using the shims which are

located between the upper shank of the thermostat and

the cover shoulder washer. Before any adjustment is made

ensure that the shutter is able to move freely and that the

return spring has not stretched or fractured. Refer to

FIG 4:5 which shows the location of the shutter and the

return spring.

Page 52 of 128

CHAPTER 5

THE CLUTCH

5:1

5:2

5:3

5:4Description

Removal and installation

Dismantling and inspection of clutch cover

Assembly and adjustment

5:1 Description

New 500, 500D sedan and early station wagon:

The clutch is a single plate dry disc type operating on

the inner face of the flywheel. FIG 5 :1 shows a longitudi-

nal cross section of the clutch as it is assembled in the

power unit.

A sheet metal clutch cover is attached to the flywheel

by means of six screws and this encloses a clutch driven

plate, the pressure plate and six springs. Three withdrawal

levers are fitted so that the inner ends are attached to a

carrier ring through which three springs hold the levers in

place and the carrier ring in contact with the pressure plate,

(see FIG 5 : 1) . Release of the driven plate is obtained

through a throw-out ring fitted with a central carbon

thrust ring which acts on the withdrawal levers carrier

ring. This is controlled by the clutch pedal through suitable

linkage to the control fork.

When the clutch pedal is operated, the throw-out ring,

together with the carbon thrust ring is pushed towards the

flywheel and this exerts a pressure on the w i t h d rawal

levers carrier ring and the lever inner tips. The lever outer

tips lift the pressure plate so disengaging the clutch.

F50059

Each of the three withdrawal levers is mounted on a bolt

together with an adjustment nut which is inserted in the

pressure plate. The levers are kept in their location by a

guide which is formed in the pressure plate.

500 F and L sedans and late station wagon:

A single plate dry type clutch is fitted with a diaphragm

pressure spring. This design of clutch differs from the con-

ventional clutch because the pressure coil springs and

throw-out mechanism components are replaced by a

single diaphragm spring.

The new system offers certain advantages which are as

follows:

1 The load on the clutch pedal does not increase as the

clutch disc lining wears but remains constant through-

out the life of the clutch.

2 Due to the special shape and location of the diaphragm

spring, which offers a constant force on the pressure

plate throughout the clutch life, the clutch does not slip

even though the driven plate linings may be worn. 5:5

5:6

5:7

5:8Installation of clutch on flywheel

Pilot bushing

Withdrawal mechanism

Fault diagnosis