lift FIAT 500 1972 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1972, Model line: 500, Model: FIAT 500 1972 1.GPages: 128, PDF Size: 9.01 MB

Page 90 of 128

CHAPTER 9

THE STEERING SYSTEM

9 : 5 Relay lever and support

9 : 6 Steering rods

9 : 7 Front wheel toe-in

9 : 8 Fault diagnosis 9:1 Description

9 : 2 Steering wheel removal and refitting

9 : 3 Steering box removal and refitting

9 : 4 Steering box dismantling and reassembly

9:1 Description

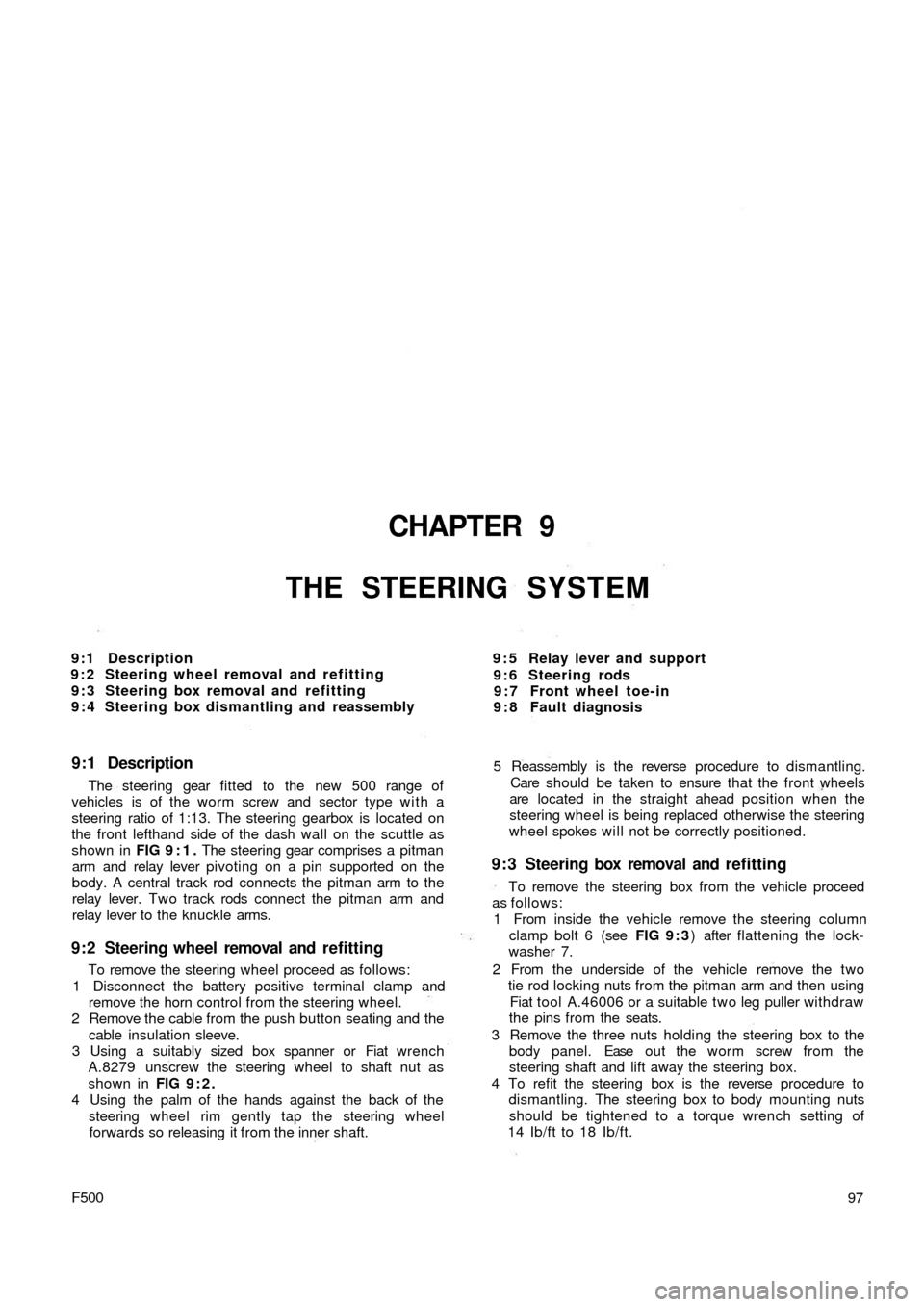

The steering gear fitted to the new 500 range of

vehicles is of the worm screw and sector type with a

steering ratio of 1:13. The steering gearbox is located on

the front lefthand side of the dash wall on the scuttle as

shown in FIG 9:1. The steering gear comprises a pitman

arm and relay lever pivoting on a pin supported on the

body. A central track rod connects the pitman arm to the

relay lever. T w o track rods connect the pitman arm and

relay lever to the knuckle arms.

9:2 Steering wheel removal and refitting

To remove the steering wheel proceed as follows:

1 Disconnect the battery positive terminal clamp and

remove the horn control from the steering wheel.

2 Remove the cable from the push button seating and the

cable insulation sleeve.

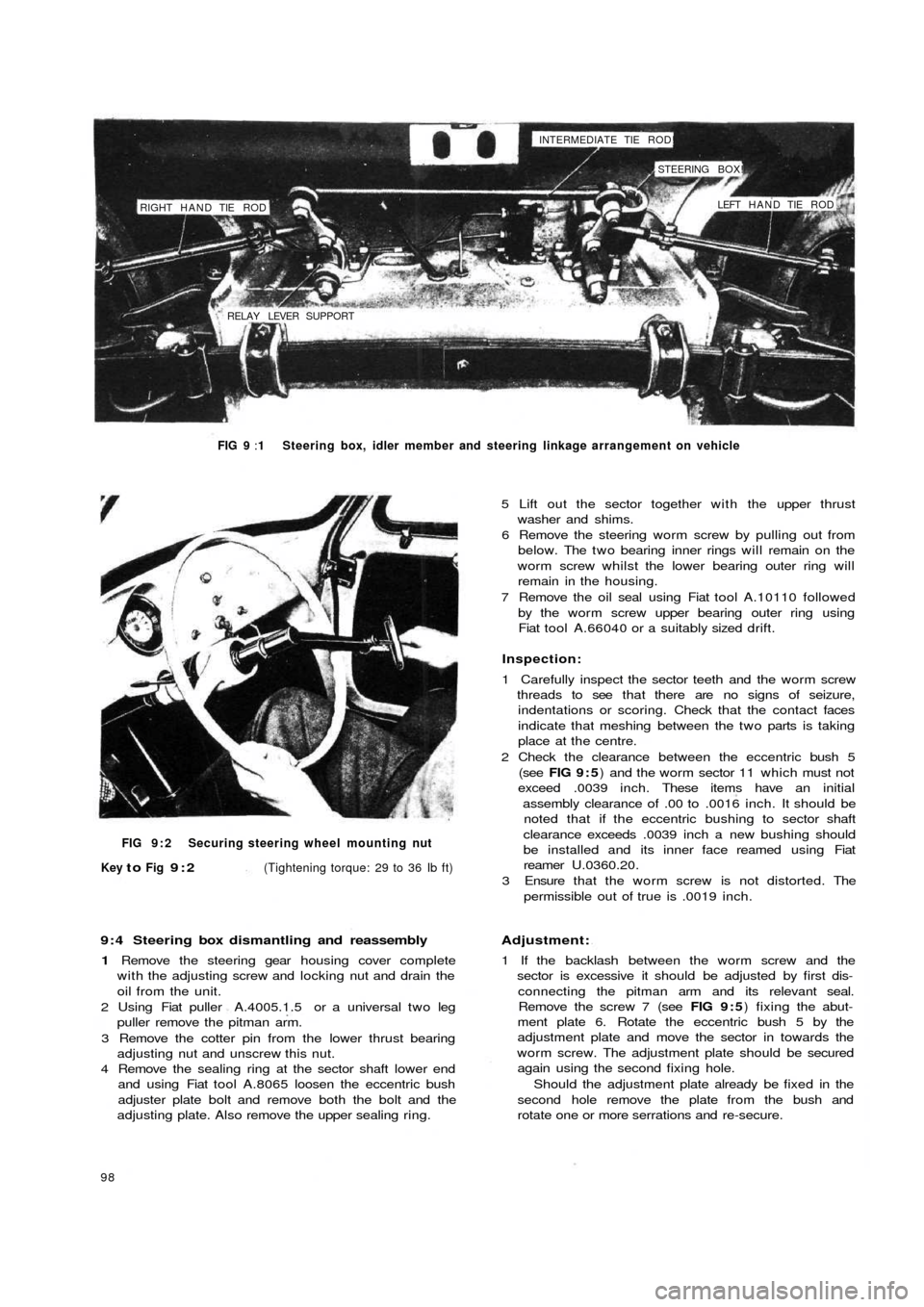

3 Using a suitably sized box spanner or Fiat wrench

A.8279 unscrew the steering wheel to shaft nut as

shown in FIG 9:2.

4 Using the palm of the hands against the back of the

steering wheel rim gently tap the steering wheel

forwards so releasing it from the inner shaft.

F50097 5 Reassembly is the reverse procedure to dismantling.

Care should be taken to ensure that the front wheels

are located in the straight ahead position when the

steering wheel is being replaced otherwise the steering

wheel spokes will not be correctly positioned.

9 : 3 Steering box removal and refitting

To remove the steering box from the vehicle proceed

as follows:

1 From inside the vehicle remove the steering column

clamp bolt 6 (see FIG 9 : 3) after flattening the lock-

washer 7.

2 From the underside of the vehicle remove the t w o

tie rod locking nuts from the pitman arm and then using

Fiat tool A.46006 or a suitable t w o leg puller withdraw

the pins from the seats.

3 Remove the three nuts holding the steering box to the

body panel. Ease out the worm screw from the

steering shaft and lift away the steering box.

4 To refit the steering box is the reverse procedure to

dismantling. The steering box to body mounting nuts

should be tightened to a torque wrench setting of

14 Ib/ft to 18 Ib/ft.

Page 91 of 128

RIGHT HAND TIE ROD

RELAY LEVER SUPPORTINTERMEDIATE TIE ROD!

STEERING BOX!

LEFT HAND TIE ROD

FIG 9 :1 Steering box, idler member and steering linkage arrangement on vehicle

FIG 9 : 2 Securing steering wheel mounting nut

Key

to Fig 9:2(Tightening torque: 29 to 36 Ib ft)

9 : 4 Steering box dismantling and reassembly

1 Remove the steering gear housing cover complete

with the adjusting screw and locking nut and drain the

oil from the unit.

2 Using Fiat puller A.4005.1.5 or a universal t w o leg

puller remove the pitman arm.

3 Remove the cotter pin from the lower thrust bearing

adjusting nut and unscrew this nut.

4 Remove the sealing ring at the sector shaft lower end

and using Fiat tool A.8065 loosen the eccentric bush

adjuster plate bolt and remove both the bolt and the

adjusting plate. Also remove the upper sealing ring.

98

5 Lift out the sector together with the upper thrust

washer and shims.

6 Remove the steering worm screw by pulling out from

below. The two bearing inner rings will remain on the

worm screw whilst the lower bearing outer ring will

remain in the housing.

7 Remove the oil seal using Fiat tool A.10110 followed

by the worm screw upper bearing outer ring using

Fiat tool A.66040 or a suitably sized drift.

Inspection:

1 Carefully inspect the sector teeth and the worm screw

threads to see that there are no signs of seizure,

indentations or scoring. Check that the contact faces

indicate that meshing between the two parts is taking

place at the centre.

2 Check the clearance between the eccentric bush 5

(see FIG 9 : 5) and the worm sector 11 which must not

exceed .0039 inch. These items have an initial

assembly clearance of .00 to .0016 inch. It should be

noted that if the eccentric bushing to sector shaft

clearance exceeds .0039 inch a new bushing should

be installed and its inner face reamed using Fiat

reamer U.0360.20.

3 Ensure that the worm screw is not distorted. The

permissible out of true is .0019 inch.

Adjustment:

1 If the backlash between the worm screw and the

sector is excessive it should be adjusted by first dis-

connecting the pitman arm and its relevant seal.

Remove the screw 7 (see FIG 9 : 5) fixing the abut-

ment plate 6. Rotate the eccentric bush 5 by the

adjustment plate and move the sector in towards the

worm screw. The adjustment plate should be secured

again using the second fixing hole.

Should the adjustment plate already be fixed in the

second hole remove the plate from the bush and

rotate one or more serrations and re-secure.

Page 98 of 128

2 Using Fiat puller A.46023 as shown in FIG 8 : 9

remove the wheel grease cap.

3 Using a universal t w o leg puller or Fiat puller A.40005

together w i t h items 1 and 9 remove the wheel hub/

drum assembly having first extracted the splitpin if

fitted and released the hub retaining nut (see FIG

8:10).

Dismantling brake unit:

1 Using a compressed air jet thoroughly clean all com-

ponents of the brake assembly.

2 Make a note of the location of the shoe return springs

and gently ease the shoes away from the brake

backplate (see FIG 10:2).

3 Disconnect the hydraulic line from the rear of t h e

wheel cylinder and remove the t w o cylinder retaining

bolts. Lift away the hydraulic cylinder.

Brake shoe lining:

Check the lining thickness and if found to be exces-

sively reduced service replacement shoes must be fitted.

The minimum allowable brake lining thickness is .059

inch.

Thoroughly check the linings for signs of oil or grease

which, if evident, the shoes must be renewed and the

drums and oil seals thoroughly inspected for the cause

of oil ingress and the cause remedied before reassembly.

Do not fit odd brake shoes and do not mix materials or

unbalanced braking will result.

Do not allow grease, oil or paint to contact the friction

linings.

Brake drums:

Whilst servicing the brakes, thoroughly inspect the

drums for scoring, ovality or distortion as well as inspect-

ing for minute hair line cracks. The drums may be refaced

by using a centre lathe and finally finishing by lapping

the drums to smooth out possible tool marks. The

maximum permissible oversize beyond the nominal drum

diameter of 6.702 to 6.712 inch is .039 inch. This limit

must never be exceeded otherwise the strength of the

drum will be impaired or a reduction in braking efficiency

caused by the increase of shoe expansion travel and the

consequent diminished contact pressure.

No brake adjustment will be required on the new 500

Saloon models after the drum has been reassembled as

the self-adjusting device will accommodate for the shoe

position to the new drum diameter during the first

operation of the brake pedal.

Reassembly of front brakes:

This is the reverse procedure to dismantling. Ensure

that the pull-off springs are correctly fitted to the holes in

the webs of the brake shoes and that the shoes register

correctly in the slotted ends of the pistons and the

side

mounting plate.

Upon assembly of the hub and brake drum assembly

liberally pack the space between the two bearings w i t h

Fiat MR grease, and remount the hub according to the

instructions in Chapter 8.

F500

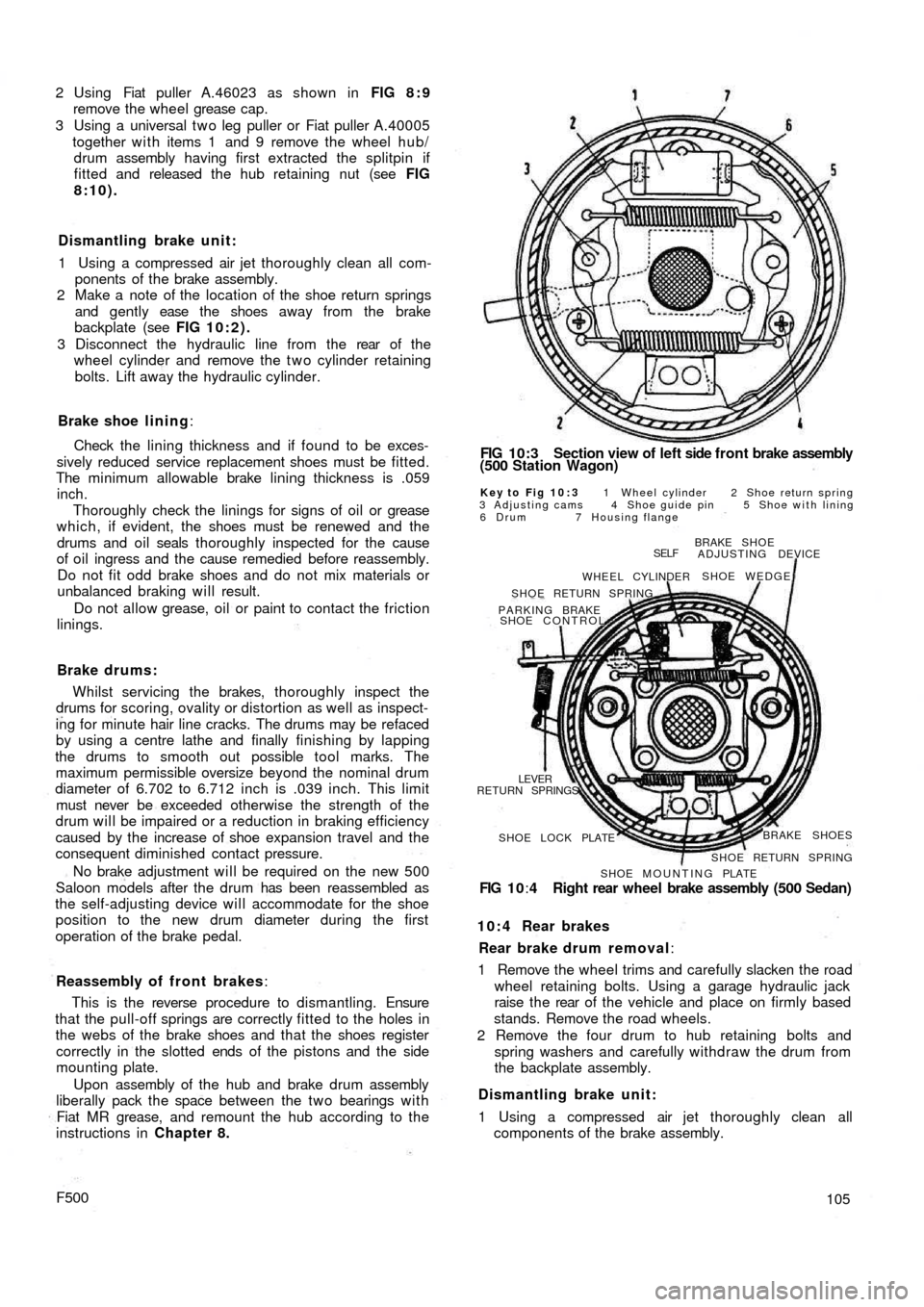

FIG 10:3 Section view of left side f r o n t brake assembly

(500 Station Wagon)

Key to Fig 10:3 1 Wheel cylinder 2 Shoe return spring

3 Adjusting cams 4 Shoe guide pin 5 Shoe with lining

6 Drum 7 Housing flange

BRAKE SHOE

ADJUSTING DEVICE

SHOE WEDGE

SELF

WHEEL CYLINDER

SHOE RETURN SPRING

PARKING BRAKE

SHOE CONTROL

RETURN SPRINGS

LEVER

SHOE LOCK PLATEBRAKE SHOES

SHOE RETURN SPRING

SHOE MOUNTING PLATE

FIG 1 0:4 Right rear wheel brake assembly (500 Sedan)

10:4 Rear brakes

Rear brake drum removal:

1 Remove the wheel trims and carefully slacken the road

wheel retaining bolts. Using a garage hydraulic jack

raise the rear of t h e vehicle and place on firmly based

stands. Remove the road wheels.

2 Remove the four drum to hub retaining bolts and

spring washers and carefully withdraw the drum from

the backplate assembly.

Dismantling brake unit:

1 Using a compressed air jet thoroughly clean all

components of the brake assembly.

105

Page 99 of 128

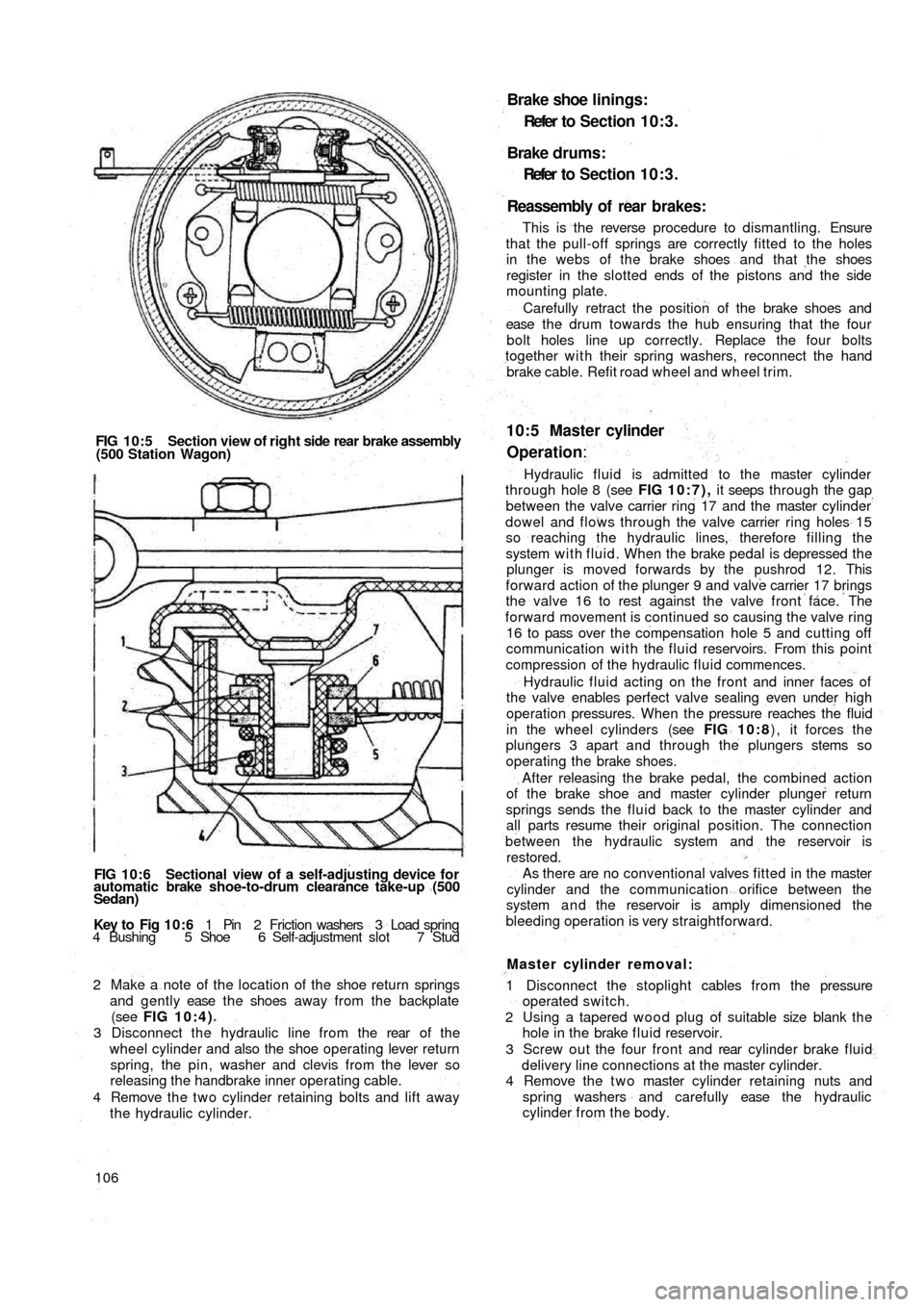

FIG 10:5 Section view of right side rear brake assembly

(500 Station Wagon)

FIG 10:6 Sectional view of a self-adjusting device for

automatic brake shoe-to-drum clearance take-up (500

Sedan)

Key to Fig 1 0 : 6 1 Pin 2 Friction washers 3 Load spring

4 Bushing 5 Shoe 6 Self-adjustment slot 7 Stud

2 Make a note of the location of the shoe return springs

and gently ease t h e shoes away from the backplate

(see FIG 10:4)

3 Disconnect the hydraulic line from the rear of t h e

wheel cylinder and also the shoe operating lever return

spring, the pin, washer and clevis from the lever so

releasing the handbrake inner operating cable.

4 Remove the t w o cylinder retaining bolts and lift away

the hydraulic cylinder.

106

Brake shoe linings:

Refer t o Section 10:3.

Brake drums:

Refer to Section 10:3.

Reassembly of rear brakes:

This is the reverse procedure to dismantling. Ensure

that the pull-off springs are correctly fitted to the holes

in the webs of the brake shoes and that the shoes

register in the slotted ends of the pistons and the side

mounting plate.

Carefully retract the position of the brake shoes and

ease t h e d r u m towards the hub ensuring that the four

bolt holes line up correctly. Replace the four bolts

together with their spring washers, reconnect the hand

brake cable. Refit road wheel and wheel trim.

10:5 Master cylinder

Operation:

Hydraulic fluid is admitted to the master cylinder

through hole 8 (see FIG 10:7), it seeps through the gap

between the valve carrier ring 17 and the master cylinder

dowel and flows through the valve carrier ring holes 15

so reaching the hydraulic lines, therefore filling the

system w i t h fluid. When the brake pedal is depressed the

plunger is moved forwards by the pushrod 12. This

forward action of the plunger 9 and valve carrier 17 brings

the valve 16 to rest against the valve front face. The

forward movement is continued so causing the valve ring

16 to pass over the compensation hole 5 and cutting off

communication with the fluid reservoirs. From this point

compression of the hydraulic fluid commences.

Hydraulic fluid acting on the front and inner faces of

the valve enables perfect valve sealing even under high

operation pressures. When the pressure reaches the fluid

in the wheel cylinders (see FIG 10:8) , it forces the

plungers 3 apart and through the plungers stems so

operating the brake shoes.

After releasing the brake pedal, the combined action

of the brake shoe and master cylinder plunger return

springs sends the fluid back to the master cylinder and

all parts resume their original position. The connection

between the hydraulic

system and the reservoir is

restored.

As there are no conventional valves fitted in the master

cylinder and the communication orifice between the

system a n d the reservoir is amply dimensioned the

bleeding operation is very straightforward.

Master cylinder removal:

1 Disconnect the stoplight cables from the pressure

operated switch.

2 Using a tapered w o o d plug of suitable size blank t h e

hole in the brake f l u i d reservoir.

3 Screw out the four front and rear cylinder brake fluid

delivery line connections at the master cylinder.

4 Remove the t w o master cylinder retaining nuts and

spring washers and carefully ease the hydraulic

cylinder from the body.

Page 106 of 128

indicates a break in the cable from the generator to

regulator. Repeat the test on terminal 67. Finally,

remove the temporary link from the generator. If the

readings are correct, test the regulator as described in

Section 11:5.

Removing generator:

1 Disconnect the leads from the generator.

2 Remove the drive belt as previously described.

3 Release t h e rear mounting bracket at the side of the

power unit.

4 Remove the air cooling ducting from around the fan

and generator area and lift away the unit.

5 Release the blower from the end of the armature shaft

and finally, the mounting bolts from the air ducting.

Dismantling generator:

1 Release the pulley self-locking nut and slide the pulley

off the armature shaft.

2 Remove the t w o Woodruff keys on armature shaft.

3 Unscrew the t w o through bolt nuts and pull out the

bolts.

4 Partially remove the commutator end head to the point

where the brushes are. s t i l l seating on the commutator.

Using a piece of hooked wire relieve the load of the

springs on the brushes by arranging the spring ends

on the brush sides. The brushes will be locked in their

holders and cannot be chipped by striking against the

armature shaft during the commutator end head

removal.

5 Gently ease the commutator and fan end heads apart

and, slide out the armature.

Servicing brushes:

Lift the brushes up in the boxes and hold them in that

position by letting each brush spring bear on the side of

its brush. Fit the commutator end bracket over the

commutator end of the armature shaft and release the

brushes by hooking up the springs using a thin screw

driver. Hold back each spring in turn and move the brush

by pulling gently on the flexible connector. If the brush

moves sluggishly remove it and polish the sides using a

smooth file. Before this operation is actually carried out it

is suggested that the brush is marked before removal so

that it is replaced in its original working position.

inch,The minimum permissible length of a brush is

so renew any t h a t are less than this figure. Test the brush

springs using a spring tension scale. New springs should

have a tension of 1.3 to 1.6 Ib. In service this value could

fall slightly before performance is affected. Always bed in

new brushes by wrapping fine sandpaper round the

commutator, pressing down on the brush and rotating

the commutator under it, or draw the paper t o o and f r o .

If new brushes are fitted always fit genuine Fiat replace-

ments.

Servicing the commutator:

A commutator in good condition should be smooth and

free from pitting or signs of the segments burning. Clean

with a rag moistened in petrol. If necessary, polish using

a fine glasspaper whilst rotating the armature. Never use

emerycloth.

If the commutator is badly worn it may be skimmed

using a centre lathe. Use a high rotational speed and take

F500113

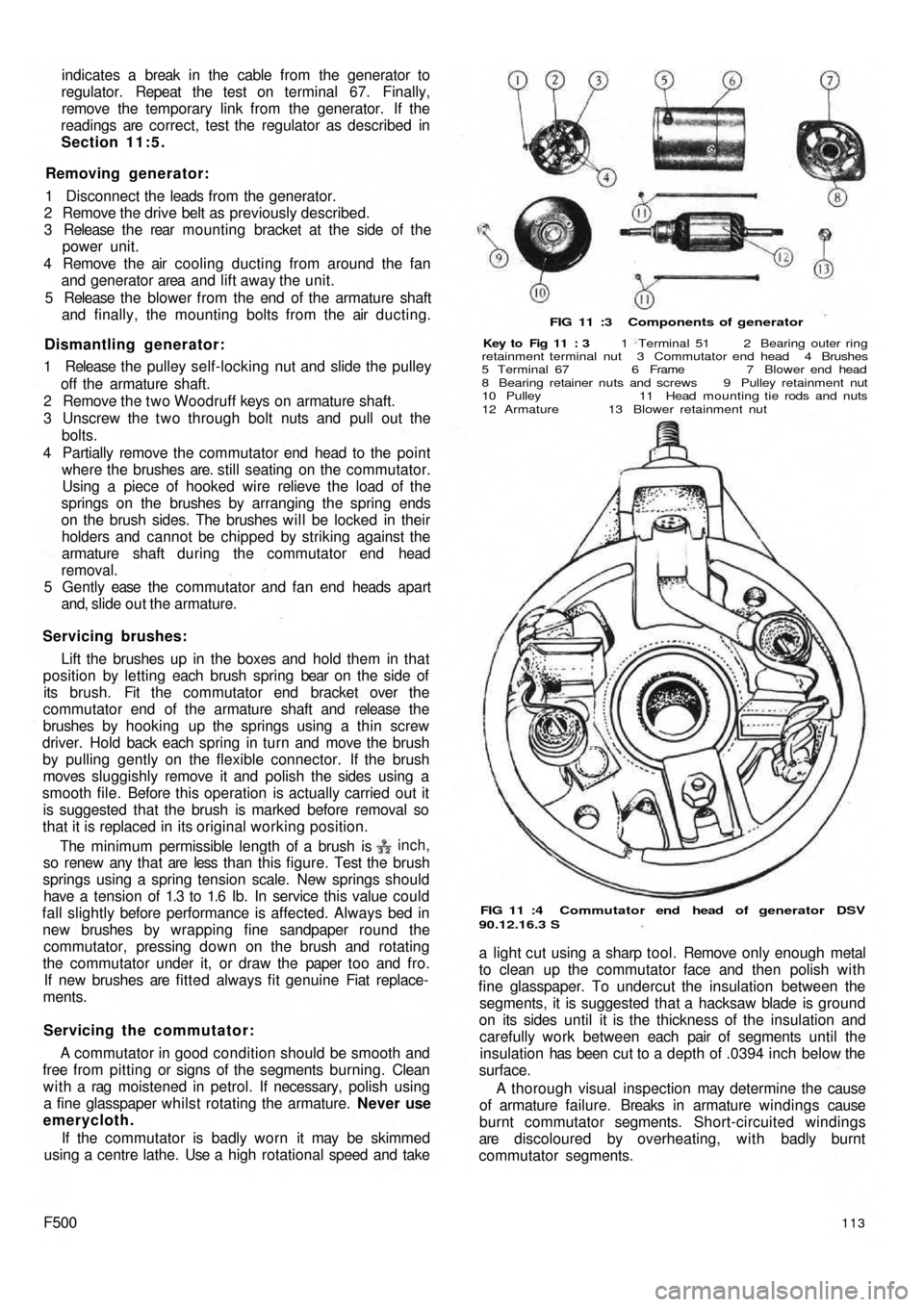

FIG 11 :3 Components of generator

Key to Fig 11 : 3 1 Terminal 51 2 Bearing outer ring

retainment terminal nut 3 Commutator end head 4 Brushes

5 Terminal 67 6 Frame 7 Blower end head

8 Bearing retainer nuts and screws 9 Pulley retainment nut

10 Pulley 11 Head mounting tie rods and nuts

12 Armature 13 Blower retainment nut

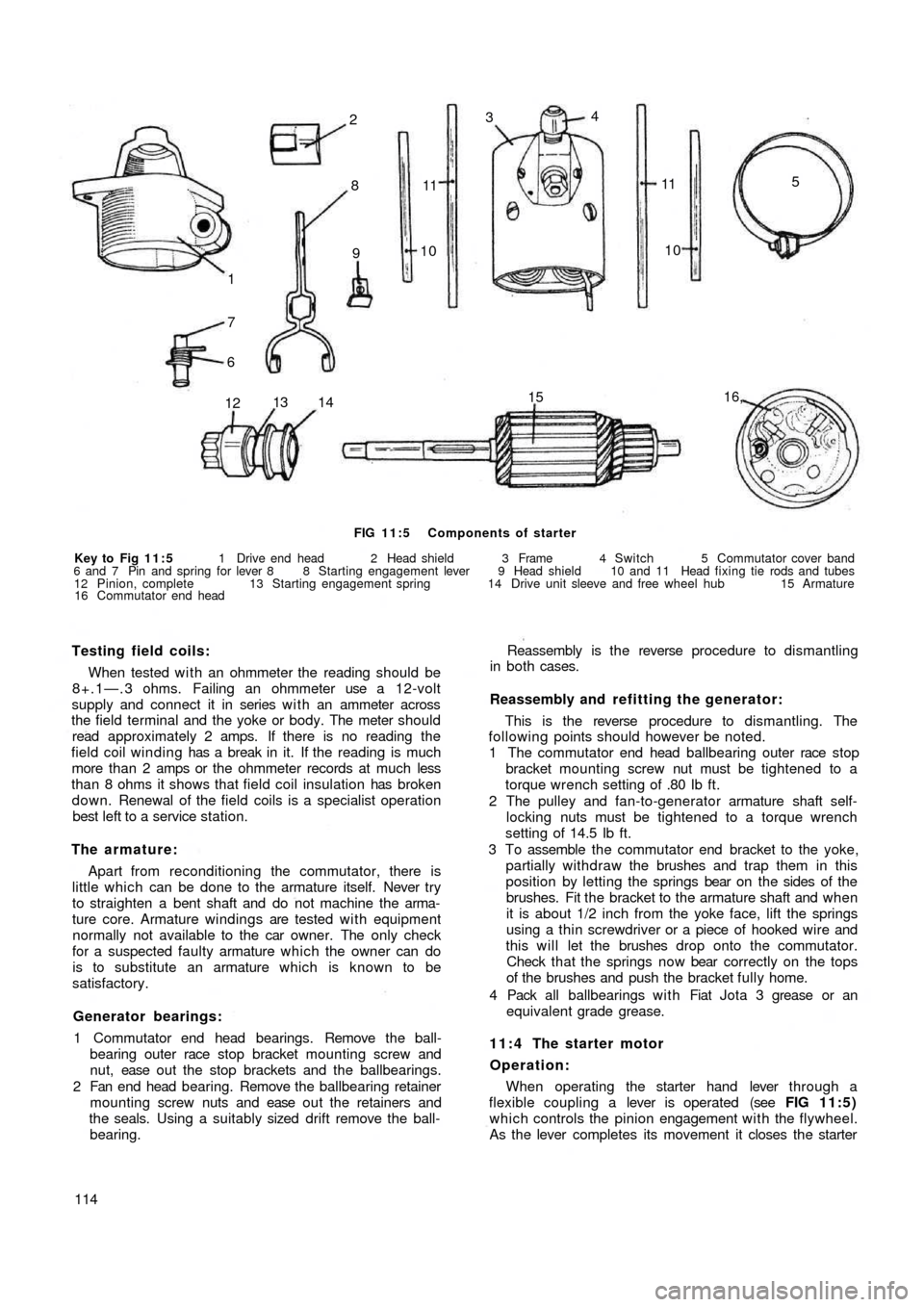

FIG 11 :4 Commutator end head of generator DSV

90.12.16.3 S

a light cut using a sharp tool. Remove only enough metal

to clean up the commutator face and then polish with

fine glasspaper. To undercut the insulation between the

segments, it is suggested that a hacksaw blade is ground

on its sides until it is the thickness of the insulation and

carefully work between each pair of segments until the

insulation has been cut to a depth of .0394 inch below the

surface.

A thorough visual inspection may determine the cause

of armature failure. Breaks in armature windings cause

burnt commutator segments. Short-circuited windings

are discoloured by overheating, with badly burnt

commutator segments.

Page 107 of 128

1

791011 8 234

11

10

16,15

14 13

1265

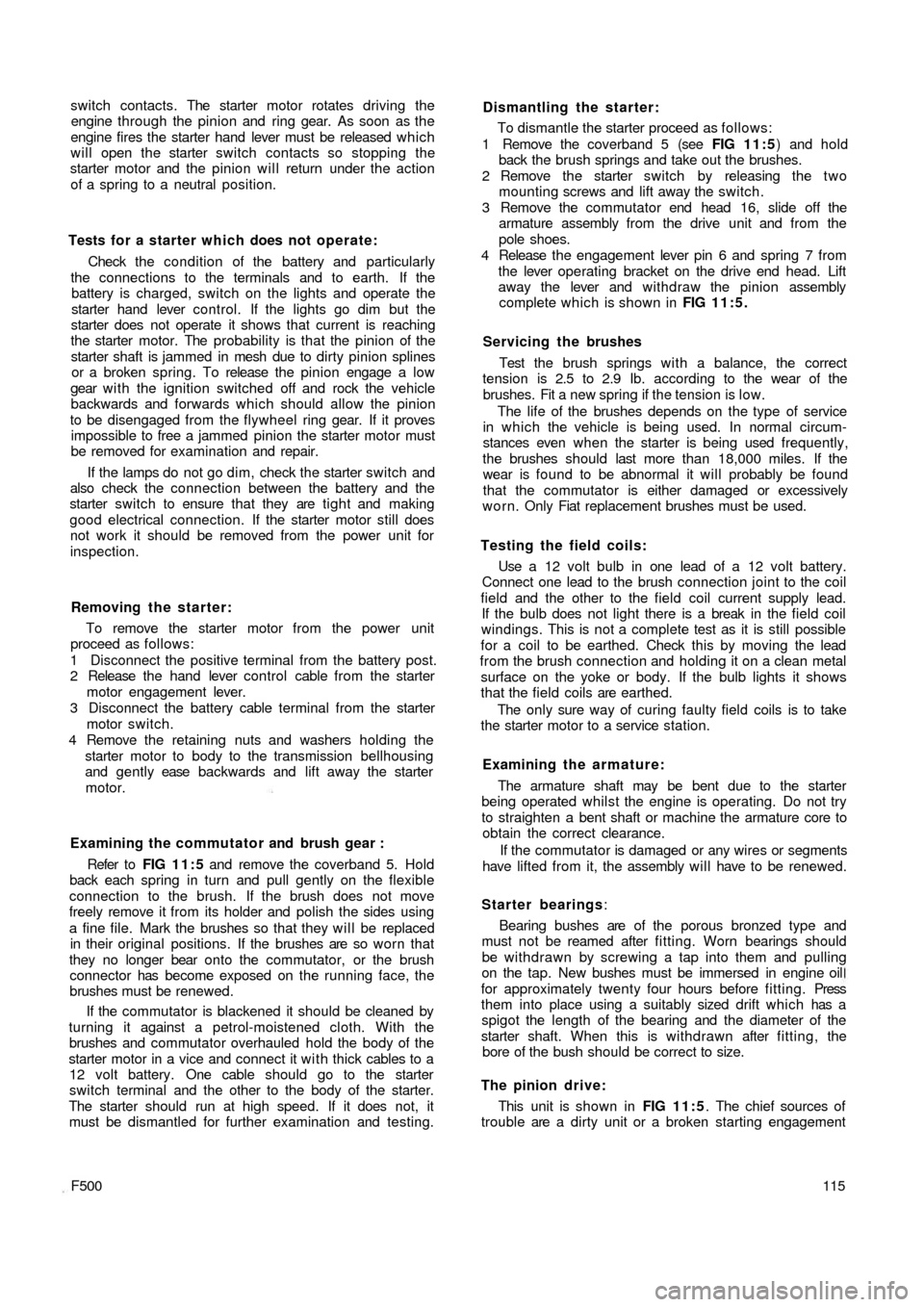

FIG 11:5 Components of starter

Key to Fig 11:5 1 Drive end head 2 Head shield 3 Frame 4 Switch 5 Commutator cover band

6 and 7 Pin and spring for lever 8 8 Starting engagement lever 9 Head shield 10 and 11 Head fixing tie rods and tubes

12 Pinion, complete 13 Starting engagement spring 14 Drive unit sleeve and free wheel hub 15 Armature

16 Commutator end head

Testing field coils:

When tested w i t h an ohmmeter the reading should be

8+.1—.3 ohms. Failing an ohmmeter use a 12-volt

supply and connect it in series w i t h an ammeter across

the field terminal and the yoke or body. The meter should

read approximately 2 amps. If there is no reading the

field coil winding has a break in it. If the reading is much

more than 2 amps or the ohmmeter records at much less

than 8 ohms it shows that field coil insulation has broken

down. Renewal of the field coils is a specialist operation

best left to a service station.

The armature:

Apart from reconditioning the commutator, there is

little which can be done to the armature itself. Never try

to straighten a bent shaft and do not machine the arma-

ture core. Armature windings are tested w i t h equipment

normally not available to the car owner. The only check

for a suspected faulty armature which the owner can do

is to substitute an armature which is known to be

satisfactory.

Generator bearings:

1 Commutator end head bearings. Remove the ball-

bearing outer race stop bracket mounting screw and

nut, ease o u t t h e stop brackets and the ballbearings.

2 Fan end head bearing. Remove the ballbearing retainer

mounting screw nuts and ease o u t t h e retainers and

the seals. Using a suitably sized drift remove the ball-

bearing.

114Reassembly is the reverse procedure to dismantling

in both cases.

Reassembly and refitting the generator:

This is the reverse procedure to dismantling. The

following points should however be noted.

1 The commutator end head ballbearing outer race stop

bracket mounting screw nut must be tightened to a

torque wrench setting of .80 Ib ft.

2 The pulley and fan-to-generator armature shaft self-

locking nuts must be tightened to a torque wrench

setting of 14.5 Ib ft.

3 To assemble the commutator end bracket to the yoke,

partially withdraw the brushes and trap them in this

position by letting the springs bear on the sides of the

brushes. Fit the bracket to the armature shaft and when

it is about 1/2 inch from the yoke face, lift the springs

using a thin screwdriver or a piece of hooked wire and

this will let the brushes drop onto the commutator.

Check that the springs now bear correctly on the tops

of the brushes and push the bracket fully home.

4 Pack all ballbearings with Fiat Jota 3 grease or an

equivalent grade grease.

11:4 The starter motor

Operation:

When operating the starter hand lever through a

flexible coupling a lever is operated (see FIG 11:5)

which controls the pinion engagement with the flywheel.

As the lever completes its movement it closes the starter

Page 108 of 128

switch contacts. The starter motor rotates driving the

engine through the pinion and ring gear. As soon as the

engine fires the starter hand lever must be released which

will open the starter switch contacts so stopping the

starter motor and the pinion will return under the action

of a spring to a neutral position.

Tests for a starter which does not operate:

Check the condition of the battery and particularly

the connections to the terminals and to earth. If the

battery is charged, switch on the lights and operate the

starter hand lever control. If the lights go dim but the

starter does not operate it shows that current is reaching

the starter motor. The probability is that the pinion of the

starter shaft is jammed in mesh due to dirty pinion splines

or a broken spring. To release the pinion engage a low

gear with the ignition switched off and rock the vehicle

backwards and forwards which should allow the pinion

to be disengaged from the flywheel ring gear. If it proves

impossible to free a jammed pinion the starter motor must

be removed for examination and repair.

If the lamps do not go dim, check the starter switch and

also check the connection between the battery and the

starter switch to ensure that they are tight and making

good electrical connection. If the starter motor still does

not work it should be removed from the power unit for

inspection.

Removing the starter:

To remove the starter motor from the power unit

proceed as follows:

1 Disconnect the positive terminal from the

battery post.

2 Release the hand lever control cable from the starter

motor engagement lever.

3 Disconnect the battery cable terminal from the starter

motor switch.

4 Remove the retaining nuts and washers holding the

starter motor to body to the transmission bellhousing

and gently ease backwards and lift away the starter

motor.

Examining the commutator and brush gear :

Refer to FIG 11:5 and remove the coverband 5. Hold

back each spring in turn and pull gently on the flexible

connection to the brush. If the brush does not move

freely remove it from its holder and polish the sides using

a fine file. Mark the brushes so that they will be replaced

in their original positions. If the brushes are so worn that

they no longer bear onto the commutator, or the brush

connector has become exposed on the running face, the

brushes must be renewed.

If the commutator is blackened it should be cleaned by

turning it against a petrol-moistened cloth. With the

brushes and commutator overhauled hold the body of the

starter motor in a vice and connect it with thick cables to a

12 volt battery. One cable should go to the starter

switch terminal and the other to the body of the starter.

The starter should run at high speed. If it does not, it

must be dismantled for further examination and testing.

F500115 Dismantling the starter:

To dismantle the starter proceed as follows:

1 Remove the coverband 5 (see FIG 11:5) and hold

back the brush springs and take out the brushes.

2 Remove the starter switch by releasing the t w o

mounting screws and lift away the switch.

3 Remove the commutator end head 16, slide off the

armature assembly from the drive unit and from the

pole shoes.

4 Release the engagement lever pin 6 and spring 7 from

the lever operating bracket on the drive end head. Lift

away the lever and withdraw the pinion assembly

complete which is shown in FIG 11:5.

Servicing the brushes

Test the brush springs with a balance, the correct

tension is 2.5 to 2.9 Ib. according to the wear of the

brushes. Fit a new spring if the tension is low.

The life of the brushes depends on the type of service

in which the vehicle is being used. In normal circum-

stances even when the starter is being used frequently,

the brushes should last more than 18,000 miles. If the

wear is found to be abnormal it will probably be found

that the commutator is either damaged or excessively

w o r n . Only Fiat replacement brushes must be used.

Testing the field coils:

Use a 12 volt bulb in one lead of a 12 volt battery.

Connect one lead to the brush connection joint to the coil

field and the other to the field coil current supply lead.

If the bulb does not light there is a break in the f i e l d coil

windings. This is not a complete test as it is still possible

for a coil to be earthed. Check this by moving the lead

from the brush connection and holding it on a clean

metal

surface on the yoke or body. If the bulb lights it shows

that the field coils are earthed.

The only sure way of curing faulty field coils is to take

the starter motor to a service station.

Examining the armature:

The armature shaft may be bent due to the starter

being operated whilst the engine is operating. Do not try

to straighten a bent shaft or machine the armature core to

obtain the correct clearance.

If the commutator is damaged or any wires or segments

have lifted from it, the assembly will have to be renewed.

Starter bearings:

Bearing bushes are of the porous bronzed type and

must not be reamed after fitting. Worn bearings should

be withdrawn by screwing a tap into them and pulling

on the tap. New bushes must be immersed in engine oil

for approximately twenty four hours before fitting. Press

them into place using a suitably sized drift which has a

spigot the length of the bearing and the diameter of the

starter shaft. When this is withdrawn after fitting, the

bore of the bush should be correct to size.

The pinion drive:

This unit is shown in FIG 11:5. The chief sources of

trouble are a dirty unit or a broken starting engagement

Page 114 of 128

parking position the trouble will be found in the sliding

sector which fails to open the switch D (see FIG

11 :16) . Check by removing the four motor cover

mounting screws and uncover the sliding sector. If

possible suitably bend the sector to bring it against

into contact with the rod tip of switch D.

3 If the automatic parking of the blades does not occur

when the switch lever is fully depressed to the parking

position but the motor stops when the switch is

operated the cause of the trouble is that the switch D

is not closing and consequently no current is flowing

between the terminals C and INT. This will probably

be due to dirt lodged between the movable contact

and the fixed contacts of switch D. Thoroughly wash

the components with petrol and if necessary reface

the contacts using a very fine file.

4 Should the motor unit be noisy in operation although

still operating reliably the noise is probably due to the

reduction gear operation, whereby the pinion and

worm are excessively worn or a tooth chipped. The

motor unit must be renewed as motor unit parts are

not available in service.

5 If the switch lever is pushed upwards to the 'on'

position or depressed downwards to the Parking

position and the wiper is still inoperative thoroughly

check all terminal connections for tightness and

cables for damage which if all appear to be correct the

failure of the wiper to operate indicates an internal

fault of the motor unit which

should be repaired or

renewed as necessary.

Removal and refitting the motor:

Remove the wiper arms and the electrical connections

to the motor. Dismantling is a straightforward operation

providing that as all items are removed so they are

inspected and a note made of their locations. However,

reassembly requires more care and the following

procedure should be adopted.

1 Mount the wiper unit onto the body by fully tightening

the nuts fixing the pivots onto which the arms are

fitted. Ensure t h a t the rubber sealing bushes between

the pivots and body are correctly assembled to prevent

water ingress. Slightly lubricate with glycerine.

2 Secure the mounting bracket lower edge to the body

by means of the special square bracket. It is important

not to distort the mounting bracket and ease of

assembly is ensured by elongated holes in the square

bracket. By suitable adjustment the linkages will not

be subjected to distortion or abnormal stresses during

operation.

3 Fit the motor unit to the mounting bracket tightening

the screws and reassemble the main link to the pivot

lever. Ensure t h a t the l o c k i n g of the fastener on the

pivot lever is secure so that it does not become loose

during operation.

4 Remake all the electrical connections and run the

motor for a short time whilst checking all the switch

positions including the automatic parking. It is at this

position that the wiper blades and arms are assembled

to the wiper mechanism.

5 Onto the pivots, install the shims, snap ring, wiper arm,

plain washer and lockwasher. Fully tighten the nuts

with the wiper arms in the parked position.

F500

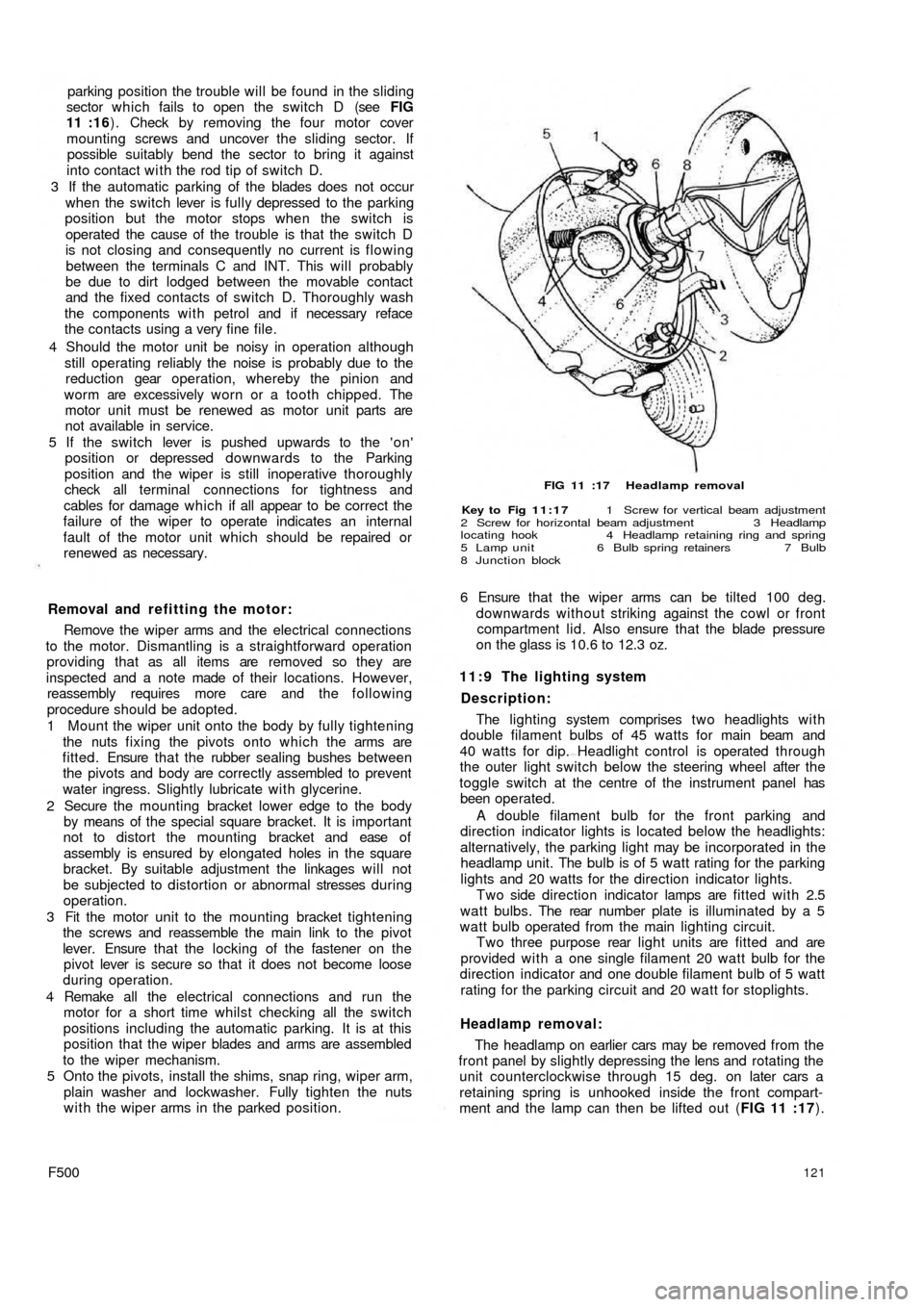

FIG 11 :17 Headlamp removal

Key to Fig 11:17 1 Screw for vertical beam adjustment

2 Screw for horizontal beam adjustment 3 Headlamp

locating hook 4 Headlamp retaining ring and spring

5 Lamp unit 6 Bulb spring retainers 7 Bulb

8 Junction block

6 Ensure that the wiper arms can be tilted 100 deg.

downwards without striking against the cowl or front

compartment lid. Also ensure that the blade pressure

on the glass is 10.6 to 12.3 oz.

1 1 : 9 The lighting system

Description:

The lighting system comprises t w o headlights with

double filament bulbs of 45 watts for main beam and

40 watts for dip. Headlight control is operated through

the outer light switch below the steering wheel after the

toggle switch at the centre of the instrument panel has

been operated.

A double filament bulb for the front parking and

direction indicator lights is located below the headlights:

alternatively, the parking light may be incorporated in the

headlamp unit. The bulb is of 5 watt rating for the parking

lights and 20 watts for the direction indicator lights.

Two side direction indicator lamps are fitted with 2.5

w a t t b u l b s . The rear number plate is illuminated by a 5

watt bulb operated from the main lighting circuit.

Two three purpose rear light units are fitted and are

provided with a one single filament 20 watt bulb for the

direction indicator and one double filament bulb of 5 watt

rating for the parking circuit and 20 watt for stoplights.

Headlamp removal:

The headlamp on earlier cars may be removed from the

front panel by slightly depressing the lens and rotating the

unit counterclockwise through 15 deg. on later cars a

retaining spring is unhooked inside the front compart-

ment and the lamp can then be lifted out (FIG 11 :17).

121

Page 122 of 128

Inner panels:

Imitation leather-lined masonite trim panels are fitted

to all versions of the new 500' models. The panels are

secured in the housing below the door window by means

of four stiff clips located at the top and seven spring clips

located at the bottom equally spaced around the panel

border. The fasteners are located in holes in the door

framework inner flange. The door framework has a plate

which should be bent downwards onto the trim panel

once it has been installed. This will ensure correct seating

of the trim panel in the door housing.

When the door trim panel is being reassembled ensure

that the tarred felt pad is cemented correctly on the door

inner flange so that any water that may seep in through to

the door interior from the window rubber weather strips

may be kept away from the trim panel which would

otherwise cause distortion and rapid deterioration.

12:4 Door handles and locks

The doors are provided with locks which are operated

by handles either from inside or outside the vehicle.

Removal of the lock is a straightforward operation but

upon reassembly the following procedure should be

followed:

1 Mount the handle assembly from the outside and

insert the washer onto the stud. Screw in the nut several

turns to allow correct handle-to-lock mating on final

fitting.

2 Arrange the locking handle dog so that it is horizontally

positioned and tighten the mounting nut.

3 Mount the lock to the door panel and secure w i t h three

screws and washers.

4 Fit the plate w i t h the t w o rubber guide blocks fastening

by the t w o screws.

Striker plates are fitted with shim adjustment to the

door pillars and are secured by three screws.

12:5 Removing window regulator and door glass

Window regulator:

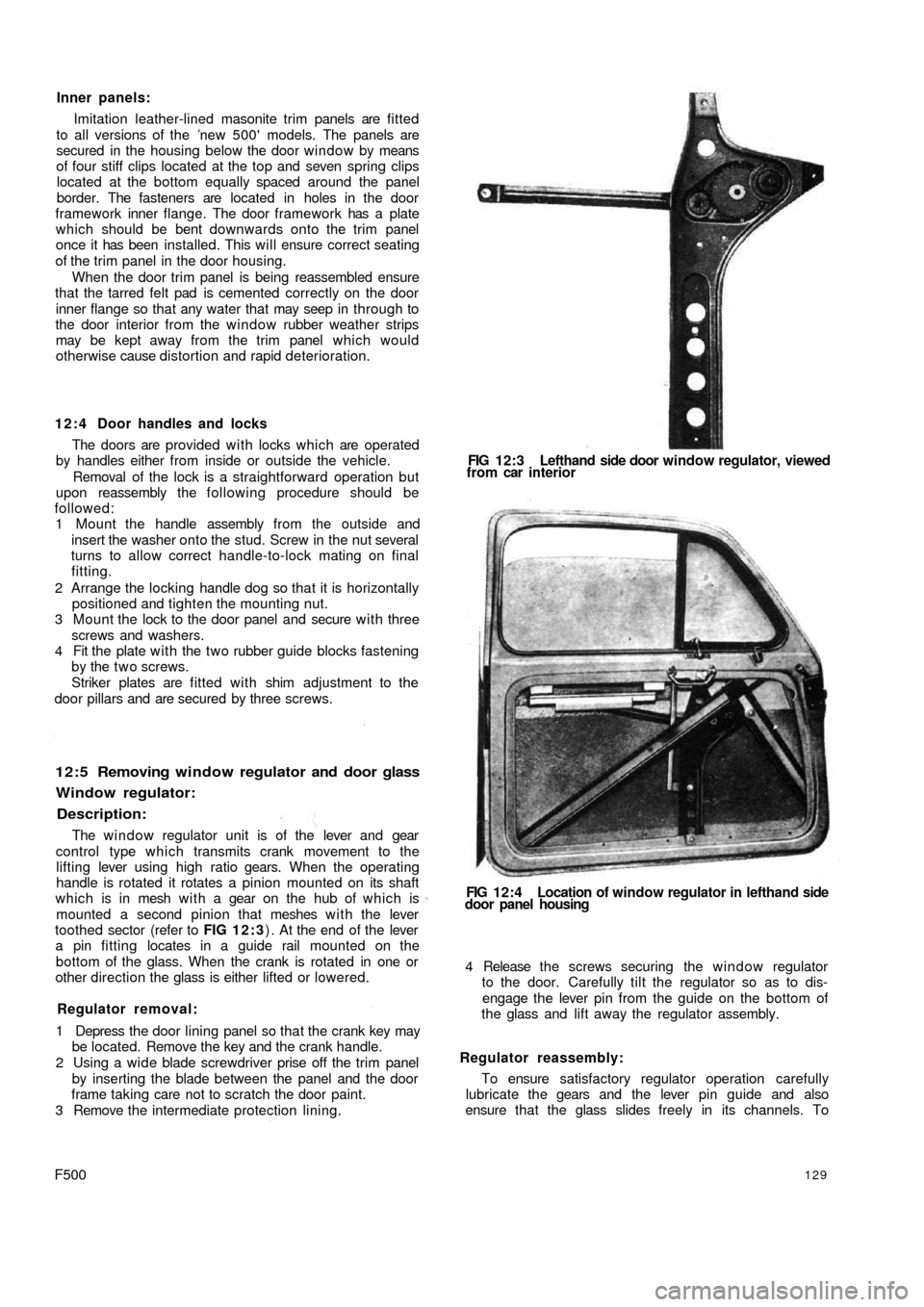

Description:

The window regulator unit is of the lever and gear

control type which transmits crank movement to the

lifting lever using high ratio gears. When the operating

handle is rotated it rotates a pinion mounted on its shaft

which is in mesh w i t h a gear on the hub of which is

mounted a second pinion that meshes with the lever

toothed sector (refer to FIG 1 2 : 3) . At the end of the lever

a pin fitting locates in a guide rail mounted on the

bottom of the glass. When the crank is rotated in one or

other direction the glass is either lifted or lowered.

Regulator removal:

1 Depress the door lining panel so that the crank key may

be located. Remove the key and the crank handle.

2 Using a wide blade screwdriver prise off the trim panel

by inserting the blade between the panel and the door

frame taking care not to scratch the door paint.

3 Remove the intermediate protection lining.

F500129

FIG 12:3 Lefthand side door window regulator, viewed

from car interior

FIG 12:4 Location of window regulator in lefthand side

door panel housing

4 Release the screws securing the window regulator

to the door. Carefully tilt the regulator so as to dis-

engage the lever pin from the guide on the bottom of

the glass and lift away the regulator assembly.

Regulator reassembly:

To ensure satisfactory regulator operation carefully

lubricate the gears and the lever pin guide and also

ensure that the glass slides freely in its channels. To

Page 123 of 128

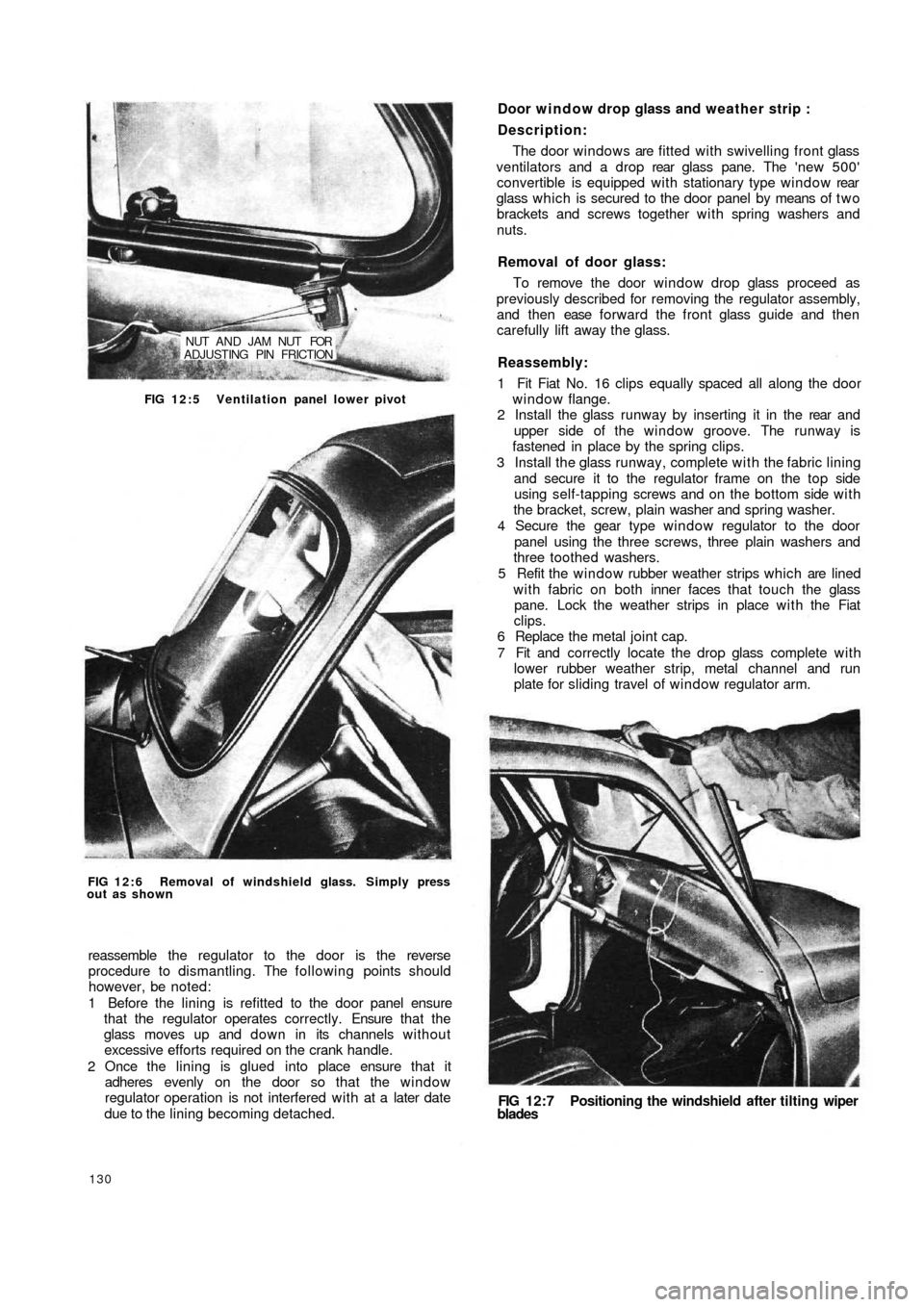

NUT AND JAM NUT FOR

ADJUSTING PIN FRICTION

FIG 12:5 Ventilation panel lower pivot

FIG 12:6 Removal of windshield glass. Simply press

out as shown

reassemble the regulator to the door is the reverse

procedure to dismantling. The following points should

however, be noted:

1 Before the lining is refitted to the door panel ensure

that the regulator operates correctly. Ensure t h a t the

glass moves up and down in its channels without

excessive efforts required on the crank handle.

2 Once the lining is glued into place ensure that it

adheres evenly on the door so that the window

regulator operation is not interfered with at a later date

due to the lining becoming detached.

130

FIG 12:7 Positioning the windshield after tilting wiperblades

Door window drop glass and weather strip :

Description:

The door windows are fitted with swivelling front glass

ventilators and a drop rear glass pane. The 'new 500'

convertible is equipped with stationary type window rear

glass which is secured to the door panel by means of t w o

brackets and screws together with spring washers and

nuts.

Removal of door glass:

To remove the door window drop glass proceed as

previously described for removing the regulator assembly,

and t h e n ease forward the front glass guide and then

carefully lift away the glass.

Reassembly:

1 Fit Fiat No. 16 clips equally spaced all along the door

window flange.

2 Install the glass runway by inserting it in the rear and

upper side of the window groove. The runway is

fastened in place by the spring clips.

3 Install the glass runway, complete with the fabric lining

and secure it to the regulator frame on the top side

using self-tapping screws and on the bottom side w i t h

the bracket, screw, plain washer and spring washer.

4 Secure the gear type window regulator to the door

panel using the three screws, three plain washers and

three toothed washers.

5 Refit the window rubber weather strips which are lined

with fabric on both inner faces that touch the glass

pane. Lock the weather strips in place w i t h the Fiat

clips.

6 Replace the metal joint cap.

7 Fit and correctly locate the drop glass complete with

lower rubber weather strip, metal channel and run

plate for sliding travel of window regulator arm.