FIAT 500 1972 1.G Manual Online

Manufacturer: FIAT, Model Year: 1972, Model line: 500, Model: FIAT 500 1972 1.GPages: 128, PDF Size: 9.01 MB

Page 81 of 128

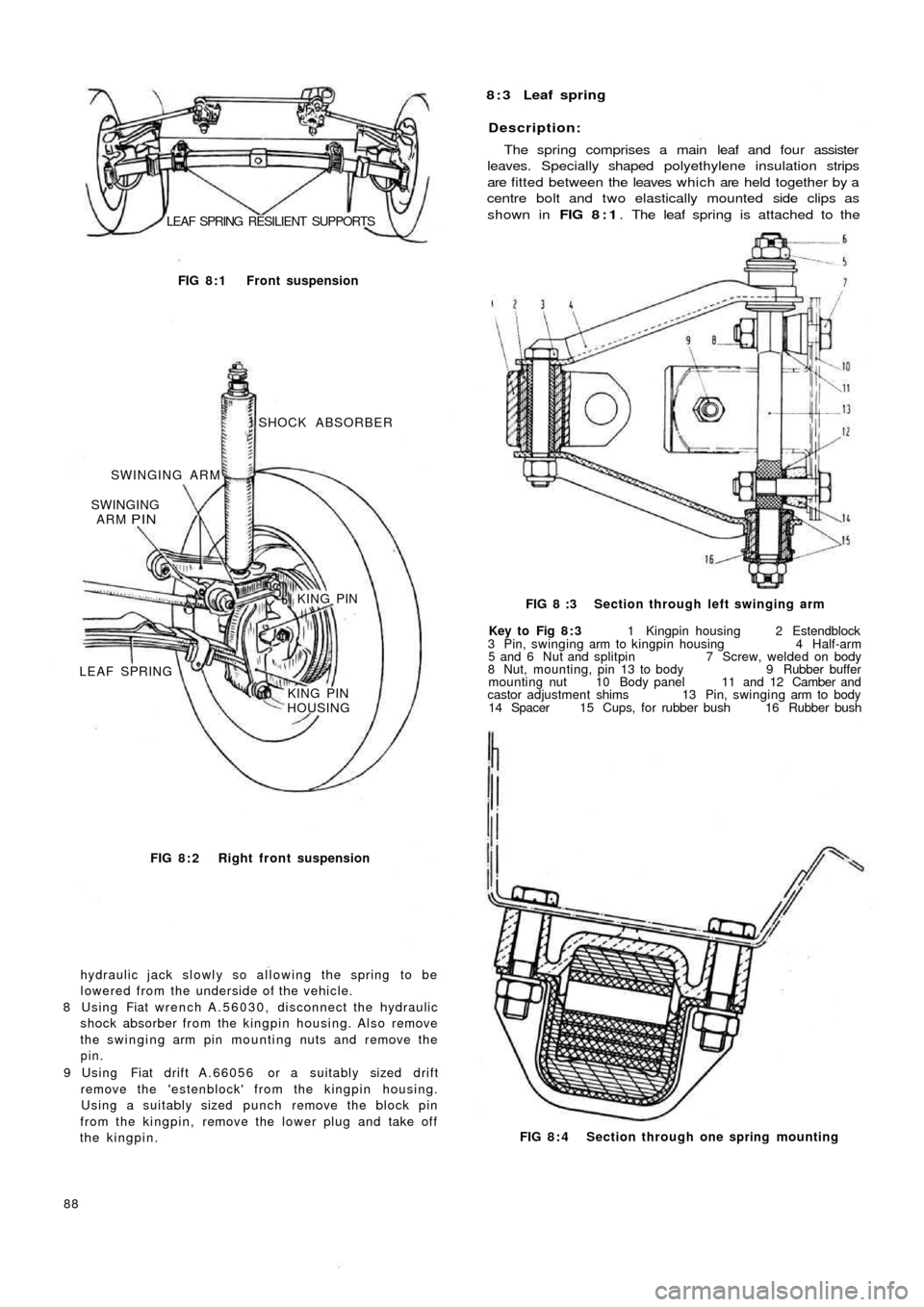

LEAF SPRING RESILIENT SUPPORTS

FIG 8 : 1 Front suspension

SHOCK ABSORBER

SWINGING ARM

SWINGING

ARM

PIN

KING PIN

LEAF SPRING

KING PIN

HOUSING

FIG 8 : 2 Right front suspension

hydraulic jack slowly so allowing the spring to be

lowered from the underside of the vehicle.

8 Using Fiat wrench A.56030, disconnect the hydraulic

shock absorber from the kingpin housing. Also remove

the swinging arm pin mounting nuts and remove the

pin.

9 Using Fiat drift A.66056 or a suitably sized drift

remove the 'estenblock' from the kingpin housing.

Using a suitably sized punch remove the block pin

from the kingpin, remove the lower plug and take off

the kingpin.

88FIG 8 : 4 Section through one spring mounting Key to Fig 8 : 3 1 Kingpin housing 2 Estendblock

3 Pin, swinging arm to kingpin housing 4 Half-arm

5 and 6 Nut and splitpin 7 Screw, welded on body

8 Nut, mounting, pin 13 to body 9 Rubber buffer

mounting nut 10 Body panel 11 and 12 Camber and

castor adjustment shims 13 Pin, swinging arm to body

14 Spacer 15 Cups, for rubber bush 16 Rubber bush FIG 8 :3 Section through left swinging arm

Description:

The spring comprises a main leaf and four assister

leaves. Specially shaped polyethylene insulation strips

are fitted between the leaves which are held together by a

centre bolt and two elastically mounted side clips as

shown in FIG 8 : 1. The leaf spring is attached to the 8 : 3 Leaf spring

Page 82 of 128

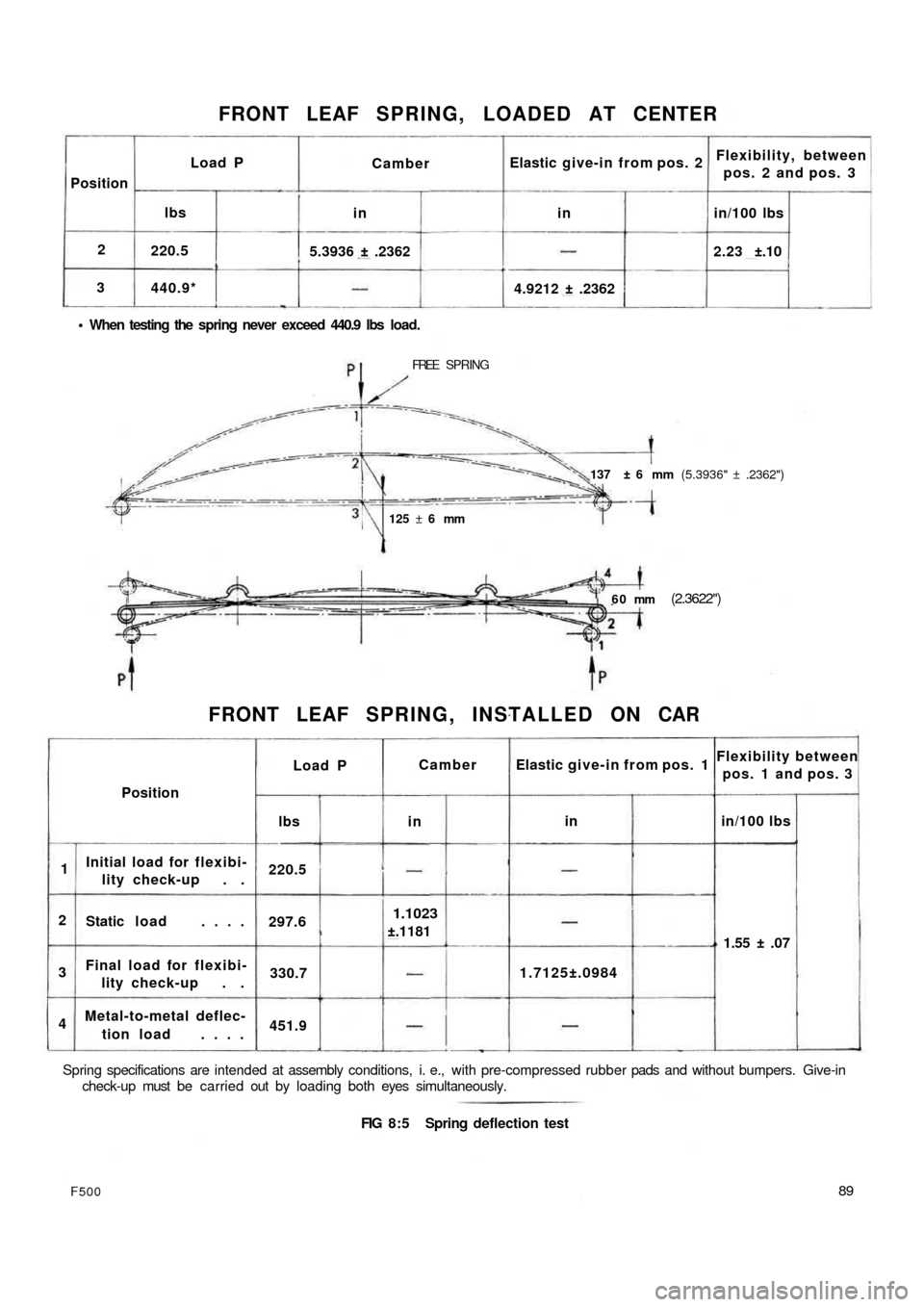

3

440.9* 2

220.5

5.3936 ± .2362

When testing the spring never exceed 440.9 lbs load.4.9212 ± .23622.23 ±.10in/100 lbs inFlexibility, between

pos. 2 and pos. 3 Elastic give-in from pos. 2

Camber

in lbs PositionLoad P

FRONT LEAF SPRING, LOADED AT CENTER

125 ± 6 mm FREE SPRING

60 mm

(2.3622")

137 ± 6 mm (5.3936" ± .2362")

FRONT LEAF SPRING, INSTALLED ON CAR

Flexibility between

pos. 1 and pos. 3 Elastic give-in from pos. 1 Camber

Load P

Position

lbs in

1Initial load for flexibi-

lity check-up . .220.5in in/100 lbs

2

Static l o a d ....

297.6

1.1023

±.1181

1.55 ± .07

1.7125±.0984

330.7 Final load for flexibi-

lity check-up . . 3

4Metal-to-metal deflec-

tion load ....451.9

Spring specifications are intended at assembly conditions, i. e., with pre-compressed rubber pads and without bumpers. Give-in

check-up must be c arried out by loading both eyes simultaneously.

FIG 8 : 5 Spring deflection test

F50089

Page 83 of 128

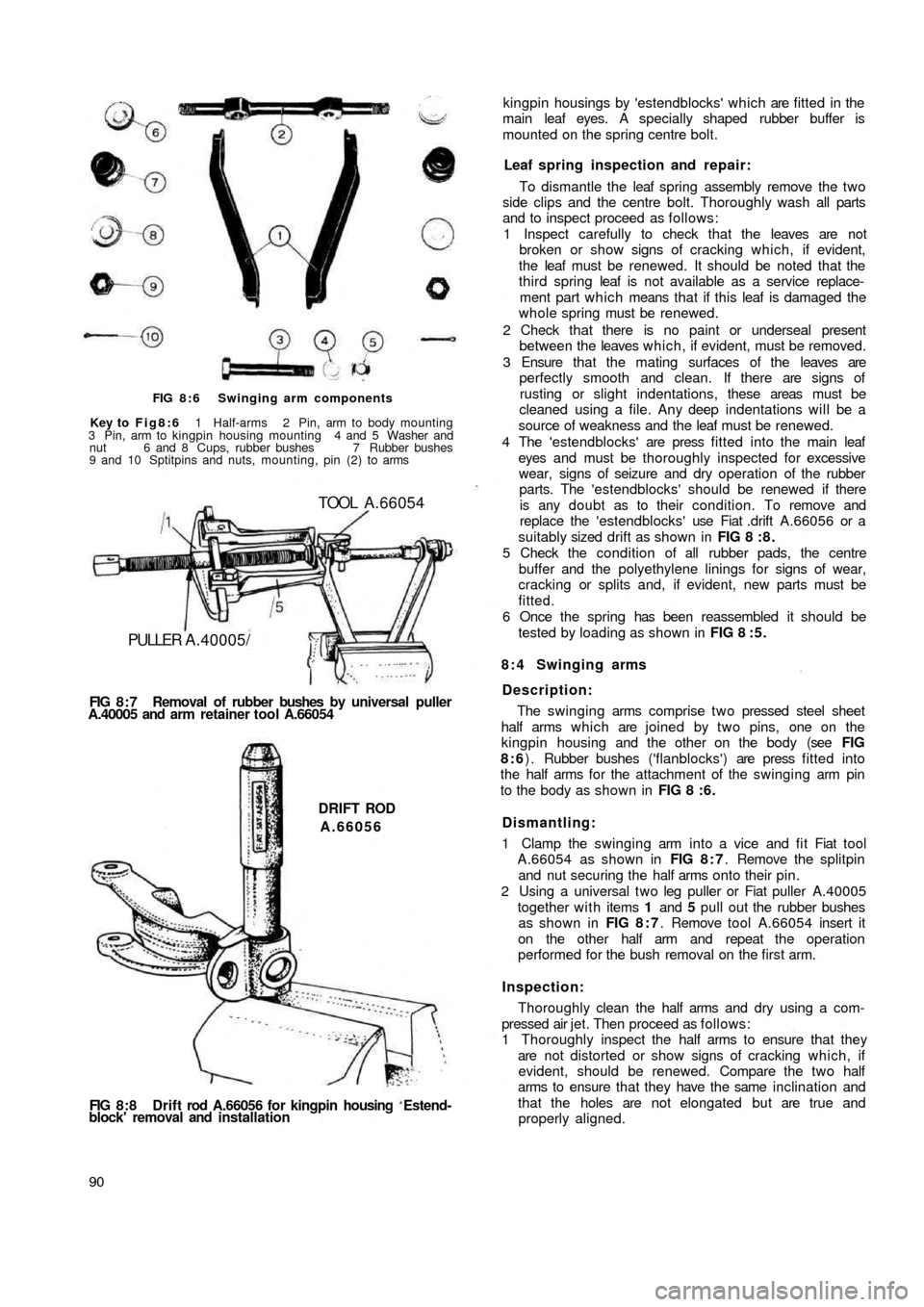

FIG 8:6 Swinging arm components

Key to Fig8:6 1 Half-arms 2 Pin, arm to body mounting

3 Pin, arm to kingpin housing mounting 4 and 5 Washer and

nut 6 and 8 Cups, rubber bushes 7 Rubber bushes

9 and 10 Sptitpins and nuts, mounting, pin (2) to arms

TOOL A.66054

PULLER A.40005/

FIG 8 : 7 Removal of rubber bushes by universal puller

A.40005 and arm retainer tool A.66054

DRIFT ROD

A.66056

FIG 8:8 Drift rod A.66056 for kingpin housing Estend-

block' removal and installation

90Inspection:

Thoroughly clean the half arms and dry using a com-

pressed air jet. Then proceed as follows:

1 Thoroughly inspect the half arms to ensure that they

are not distorted or show signs of cracking which, if

evident, should be renewed. Compare the t w o half

arms to ensure that they have the same inclination and

that the holes are not elongated but are true and

properly aligned. kingpin housings by 'estendblocks' which are fitted in the

main leaf eyes. A specially shaped rubber buffer is

mounted on the spring centre bolt.

Leaf spring inspection and repair:

To dismantle the leaf spring assembly remove the t w o

side clips and the centre bolt. Thoroughly wash all parts

and to inspect proceed as follows:

1 Inspect carefully to check that the leaves are not

broken or show signs of cracking which, if evident,

the leaf must be renewed. It should be noted that the

third spring leaf is not available as a service replace-

ment part which means that if this leaf is damaged the

whole spring must be renewed.

2 Check that there is no paint or underseal present

between the leaves which, if evident, must be removed.

3 Ensure that the mating surfaces of the leaves are

perfectly smooth and clean. If there are signs of

rusting or slight indentations, these areas must be

cleaned using a file. Any deep indentations will be a

source of weakness and the leaf must be renewed.

4 The 'estendblocks' are press fitted into the main leaf

eyes and must be thoroughly inspected for excessive

wear, signs of seizure and dry operation of the rubber

parts. The 'estendblocks' should be renewed if there

is any doubt as to their condition. To remove and

replace the 'estendblocks' use Fiat .drift A.66056 or a

suitably sized drift as shown in FIG 8 : 8 .

5 Check the condition of all rubber pads, the centre

buffer and the polyethylene linings for signs of wear,

cracking or splits and, if evident, new parts must be

fitted.

6 Once the spring has been reassembled it should be

tested by loading as shown in FIG 8 : 5 .

8:4 Swinging arms

Description:

The swinging arms comprise t w o pressed steel sheet

half arms which are joined by two pins, one on the

kingpin housing and the other on the body (see FIG

8:6) . Rubber bushes ('flanblocks') are press fitted into

the half arms for the attachment of the swinging arm pin

to the body as shown in FIG 8 : 6 .

Dismantling:

1 Clamp the swinging arm into a vice and fit Fiat tool

A.66054 as shown in FIG 8 : 7. Remove the splitpin

and nut securing the half arms onto their pin.

2 Using a universal t w o leg puller or Fiat puller A.40005

together with items 1 and 5 pull out the rubber bushes

as shown in FIG 8 : 7. Remove tool A.66054 insert it

on the other half arm and repeat the operation

performed for the bush removal on the first arm.

Page 84 of 128

2 Check that the surface of the pin that is in contact with

the camber and castor adjuster shims does not show

any signs of indentation or roughness which could

affect the accuracy of adjustment on reassembly. If

there are any signs of rust or small markings these

should be smoothed out using a file.

3 Inspect the condition of the half arm bushes, the inner

surface of which must not show signs of seizure and

the clearance of the bush to pin must not be greater

than .01 57 inch. Upon initial assembly the fit clearance

is .00059 to .0059 inch. Ensure t h a t the rubber parts

of the bush are not torn, cracked or show signs of

weakness which, if evident, must be renewed.

4 Use Fiat tool A.66058 or a suitably sized drift for

refitting the rubber bushes into the swinging arms.

Upon reassembly it should be observed that the

tightening of the two swinging arms m o u n t i n g nuts 5

(see FIG 8 : 3) , must be carried out whilst keeping

the axis of the swinging arm and the pin hole for the

screws 7 on the same plane otherwise distortion can

occur.

8 : 5 Kingpin housing

1 To remove and replace the 'estendblocks' use Fiat

tool A.66056 as shown in FIG 8 : 8. Ensure t h a t the

'estendblocks' is not worn and that there are no signs

of seizure on its inner surface, or that the rubber has

hardened. Renew if necessary.

2 Check that the kingpin to bush clearance is not

greater than .0079 inch. The clearance when fitted

new is .00063 to .00213 inch. If the clearance is

excessive the t w o bushes must be renewed and also

the kingpin if excessive wear is evident. To remove and

refit the kingpin bushes use Fiat tool A.66016 and

after reassembly the bushes must be accurately

refaced using a reamer set to a diameter of .5912 to

.5922 inch. If considered necessary use Fiat Fixture

C.1004 to check that the kingpin housing has not been

distorted which, if evident, the housing must be

renewed.

3 Whilst the kingpin assembly is being inspected ensure

that the lubrication hole is free to allow the passage of

oil.

4 To prevent incorrect loading of the 'estendblocks' that

is press fitted into the kingpin housing, the housing

to swinging arm pin nut must be tightened with the

parts so arranged that the angle between the swinging

arm plane and the housing axis is approximately

95 deg. as shown in FIG 8:14.

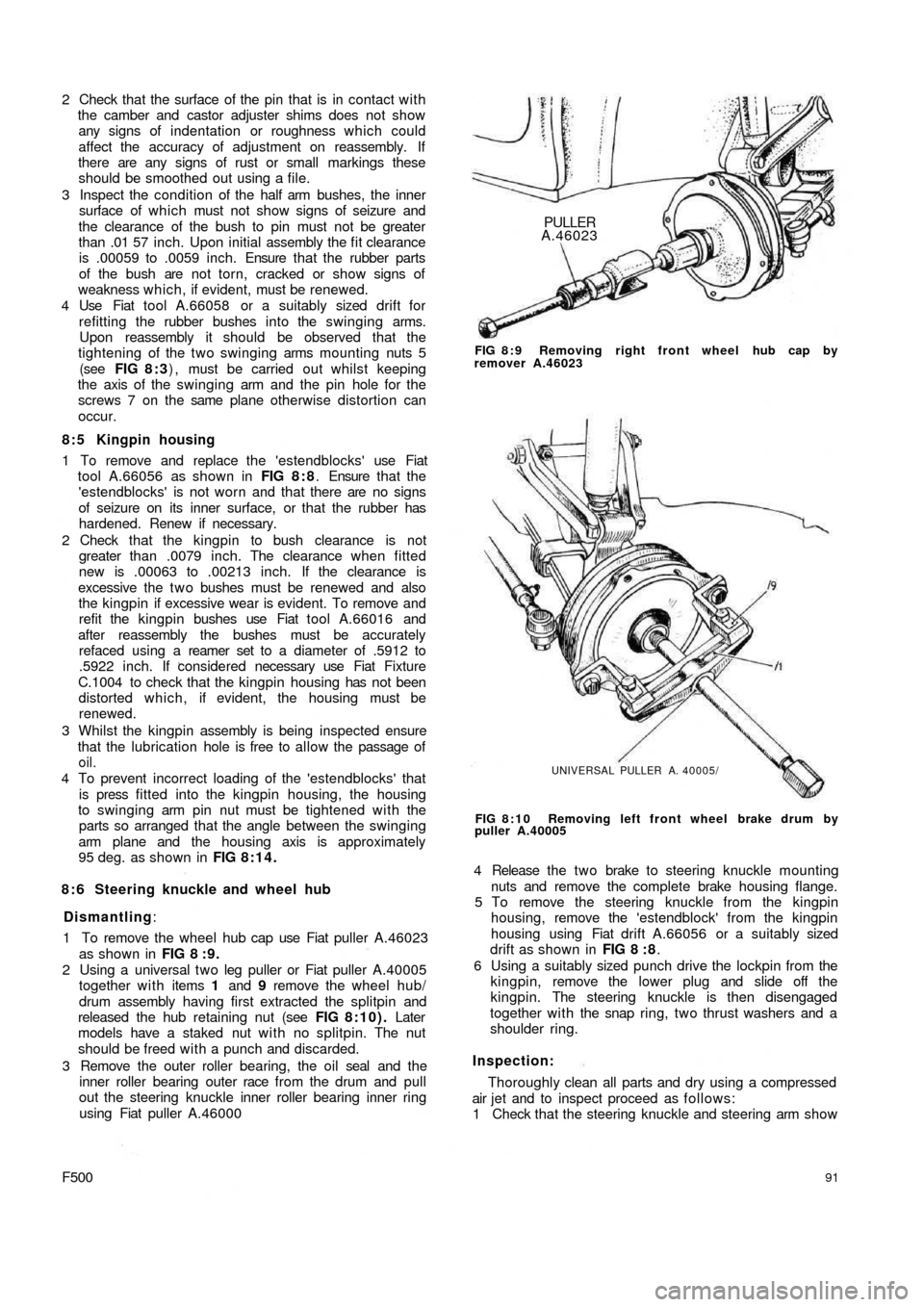

8:6 Steering knuckle and wheel hub

Dismantling:

1 To remove the wheel hub cap use Fiat puller A.46023

as shown in FIG 8 : 9 .

2 Using a universal t w o leg puller or Fiat puller A.40005

together with items 1 and 9 remove the wheel hub/

drum assembly having first extracted the splitpin and

released the hub retaining nut (see FIG 8:10). Later

models have a staked nut w i t h no splitpin. The nut

should be freed with a punch and discarded.

3 Remove the outer roller bearing, the oil seal and the

inner roller bearing outer race from the drum and pull

out the steering knuckle inner roller bearing inner ring

using Fiat puller A.46000

F500PULLER

A.46023

FIG 8 : 9 Removing right front wheel hub cap by

remover A.46023

UNIVERSAL PULLER A. 40005/

FIG 8:10 Removing left front wheel brake drum by

puller A.40005

4 Release the t w o brake to steering knuckle mounting

nuts and remove the complete brake housing flange.

5 To remove the steering knuckle from the kingpin

housing, remove the 'estendblock' from the kingpin

housing using Fiat drift A.66056 or a suitably sized

drift as shown in FIG 8 : 8.

6 Using a suitably sized punch drive the lockpin from the

kingpin, remove the lower plug and slide off the

kingpin. The steering knuckle is then disengaged

together with the snap ring, two thrust washers and a

shoulder ring.

Inspection:

Thoroughly clean all parts and dry using a compressed

air jet and to inspect proceed as follows:

1 Check that the steering knuckle and steering arm show

91

Page 85 of 128

1

2

6

3

8

11

13

17

19

22

25

27

29

31

33

36

35 323430 28

26

24232120 ,1816 15 14 12 10 .9 .15 4

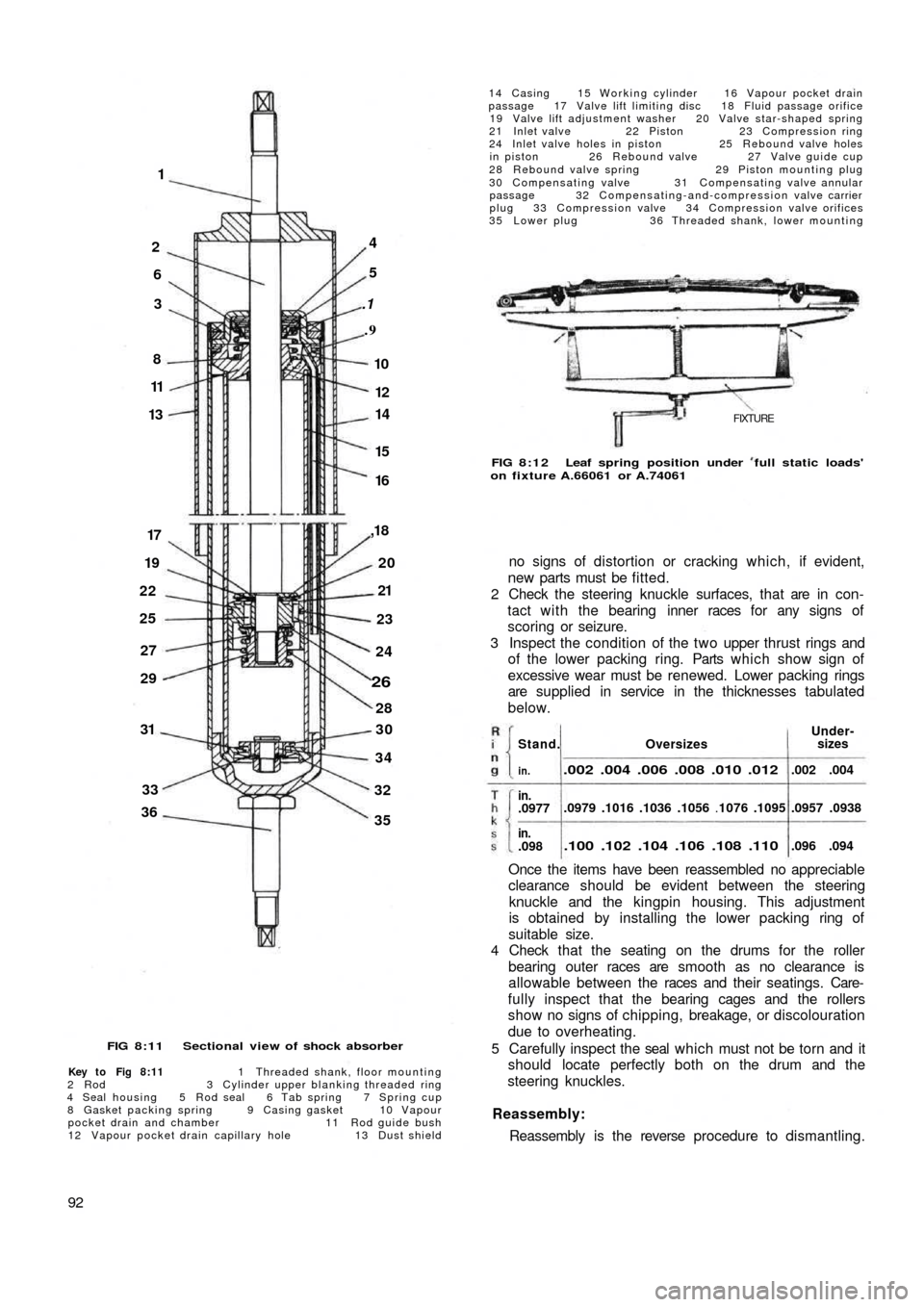

FIG 8:11 Sectional view of shock absorber

Key to Fig 8:11 1 Threaded shank, floor mounting

2 R o d 3 Cylinder upper blanking threaded ring

4 Seal housing 5 Rod seal 6 Tab spring 7 Spring cup

8 Gasket packing spring 9 Casing gasket 10 Vapour

pocket drain and chamber 11 Rod guide bush

12 Vapour pocket drain capillary hole 13 Dust shield

92

14 Casing 15 Working cylinder 16 Vapour pocket drain

passage 17 Valve lift limiting disc 18 Fluid passage orifice

19 Valve lift adjustment washer 20 Valve star-shaped spring

21 Inlet valve 22 Piston 23 Compression ring

24 Inlet valve holes in piston 25 Rebound valve holes

in piston 26 Rebound valve 27 Valve guide cup

28 Rebound valve spring 29 Piston mounting plug

30 Compensating valve 31 Compensating valve annular

passage 32 Compensating-and-compression valve carrier

plug 33 Compression valve 34 Compression valve orifices

35 Lower plug 36 Threaded shank, lower mounting

FIXTURE

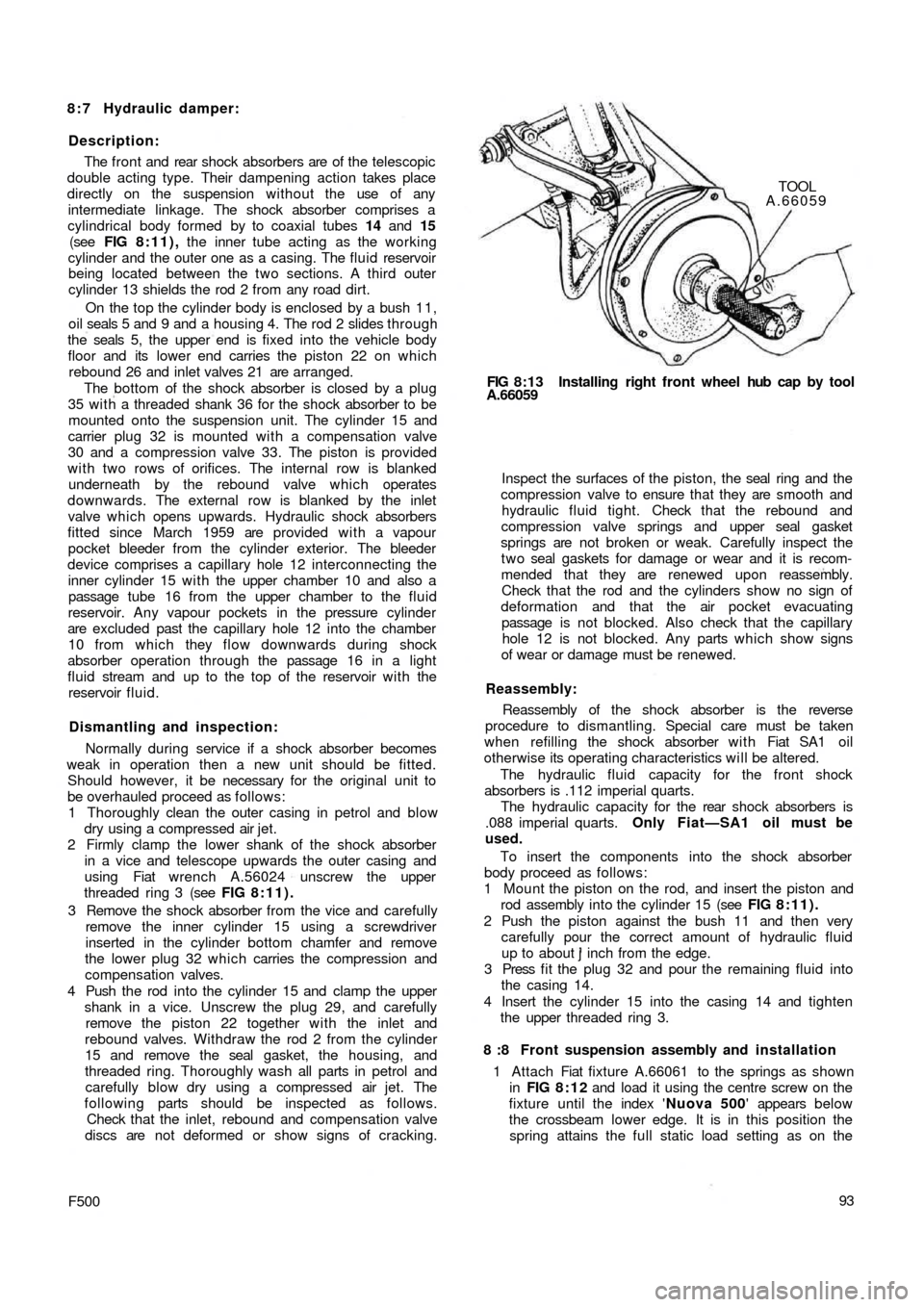

FIG 8:12 Leaf spring position under full static loads'

on fixture A.66061 or A.74061

no signs of distortion or cracking which, if evident,

new parts must be fitted.

2 Check the steering knuckle surfaces, that are in con-

tact with the bearing inner races for any signs of

scoring or seizure.

3 Inspect the condition of the two upper thrust rings and

of the lower packing ring. Parts which show sign of

excessive wear must be renewed. Lower packing rings

are supplied in service in the thicknesses tabulated

below.

Once the items have been reassembled no appreciable

clearance should be evident between the steering

knuckle and the kingpin housing. This adjustment

is obtained by installing the lower packing ring of

suitable size.

4 Check that the seating on the drums for the roller

bearing outer races are smooth as no clearance is

allowable between the races and their seatings. Care-

fully inspect that the bearing cages and the rollers

show no signs of chipping, breakage, or discolouration

due to overheating.

5 Carefully inspect the seal which must not be torn and it

should locate perfectly both on the drum and the

steering knuckles.

Reassembly:

Reassembly is the reverse procedure to dismantling.

OversizesUnder-

sizes

.002 .004 .006 .008 .010 .012

.0979 .1016 .1036 .1056 .1076 .1095

.100 .102 .104 .106 .108 .110

.002 .004

.0957 .0938

.096 .094

Stand.

in.

in..0977

in..098

Page 86 of 128

8 : 7 Hydraulic damper:

Description:

The front and rear shock absorbers are of the telescopic

double acting type. Their dampening action takes place

directly on the suspension without the use of any

intermediate linkage. The shock absorber comprises a

cylindrical body formed by to coaxial tubes 14 and 15

(see FIG 8:11), the inner tube acting as the working

cylinder and the outer one as a casing. The fluid reservoir

being located between the two sections. A third outer

cylinder 13 shields the rod 2 from any road dirt.

On the top the cylinder body is enclosed by a bush 1 1 ,

oil seals 5 and 9 and a housing 4. The rod 2 slides through

the seals 5, the upper end is fixed into the vehicle body

floor and its lower end carries the piston 22 on which

rebound 26 and inlet valves 21 are arranged.

The bottom of the shock absorber is closed by a plug

35 with a threaded shank 36 for the shock absorber to be

mounted onto the suspension unit. The cylinder 15 and

carrier plug 32 is mounted with a compensation valve

30 and a compression valve 33. The piston is provided

with two rows of orifices. The internal row is blanked

underneath by the rebound valve which operates

downwards. The external row is blanked by the inlet

valve which opens upwards. Hydraulic shock absorbers

fitted since March 1959 are provided w i t h a vapour

pocket bleeder from the cylinder exterior. The bleeder

device comprises a capillary

hole 12 interconnecting the

inner cylinder 15 with the upper chamber 10 and also a

passage tube 16 from the upper chamber to the fluid

reservoir. Any vapour pockets in the pressure cylinder

are excluded past the capillary hole 12 into the chamber

10 from which they flow downwards during shock

absorber operation through the passage 16 in a light

fluid stream and up to the top of the reservoir with the

reservoir fluid.

Dismantling and inspection:

Normally during service if a shock absorber becomes

weak in operation then a new unit should be fitted.

Should however, it be necessary for the original unit to

be overhauled proceed as follows:

1 Thoroughly clean the outer casing in petrol and blow

dry using a compressed air jet.

2 Firmly clamp the lower shank of the shock absorber

in a vice and telescope upwards the outer casing and

using Fiat wrench A.56024 unscrew the upper

threaded ring 3 (see FIG 8:11).

3 Remove the shock absorber from the vice and carefully

remove the inner cylinder 15 using a screwdriver

inserted in the cylinder bottom chamfer and remove

the lower plug 32 which carries the compression and

compensation valves.

4 Push the rod i n t o the cylinder 15 and clamp the upper

shank in a vice. Unscrew the plug 29, and carefully

remove the piston 22 together with the inlet and

rebound valves. Withdraw the rod 2 from the cylinder

15 and remove the seal gasket, the housing, and

threaded ring. Thoroughly wash all parts in petrol and

carefully blow dry using a c

ompressed air jet. The

following parts should be inspected as follows.

Check that the inlet, rebound and compensation valve

discs are not deformed or show signs of cracking.

F50093 Inspect the surfaces of the piston, the seal ring and the

compression valve to ensure that they are smooth and

hydraulic fluid tight. Check that the rebound and

compression valve springs and upper seal gasket

springs are not broken or weak. Carefully inspect the

t w o seal gaskets for damage or wear and it is recom-

mended that they are renewed upon reassembly.

Check that the rod and the cylinders show no sign of

deformation and that the air pocket evacuating

passage is not blocked. Also check that the capillary

hole 12 is not blocked. Any parts which show signs

of wear or damage must be renewed.

Reassembly:

Reassembly of the shock absorber is the reverse

procedure to dismantling. Special care must be taken

when refilling the shock absorber w i t h Fiat SA1 oil

otherwise its operating characteristics will be altered.

The hydraulic fluid capacity for the front shock

absorbers is .112 imperial quarts.

The hydraulic capacity for the rear shock absorbers is

.088 imperial quarts. Only Fiat—SA1 oil must be

used.

To insert the components into the shock absorber

body proceed as follows:

1 Mount the piston on the rod, and insert the piston and

rod assembly into the cylinder 15 (see FIG 8:11).

2 Push the piston against the bush 11 and then very

carefully pour the correct amount of hydraulic fluid

up to about j inch from the edge.

3 Press f i t t h e plug 32 and pour the remaining fluid into

the casing 14.

4 Insert the cylinder 15 into the casing 14 and tighten

the upper threaded ring 3.

8 :8 Front suspension assembly and installation

1 Attach Fiat fixture A.66061 to the springs as shown

in FIG 8:12 and load it using the centre screw on the

fixture until the index 'Nuova 500' appears below

the crossbeam lower edge. It is in this position the

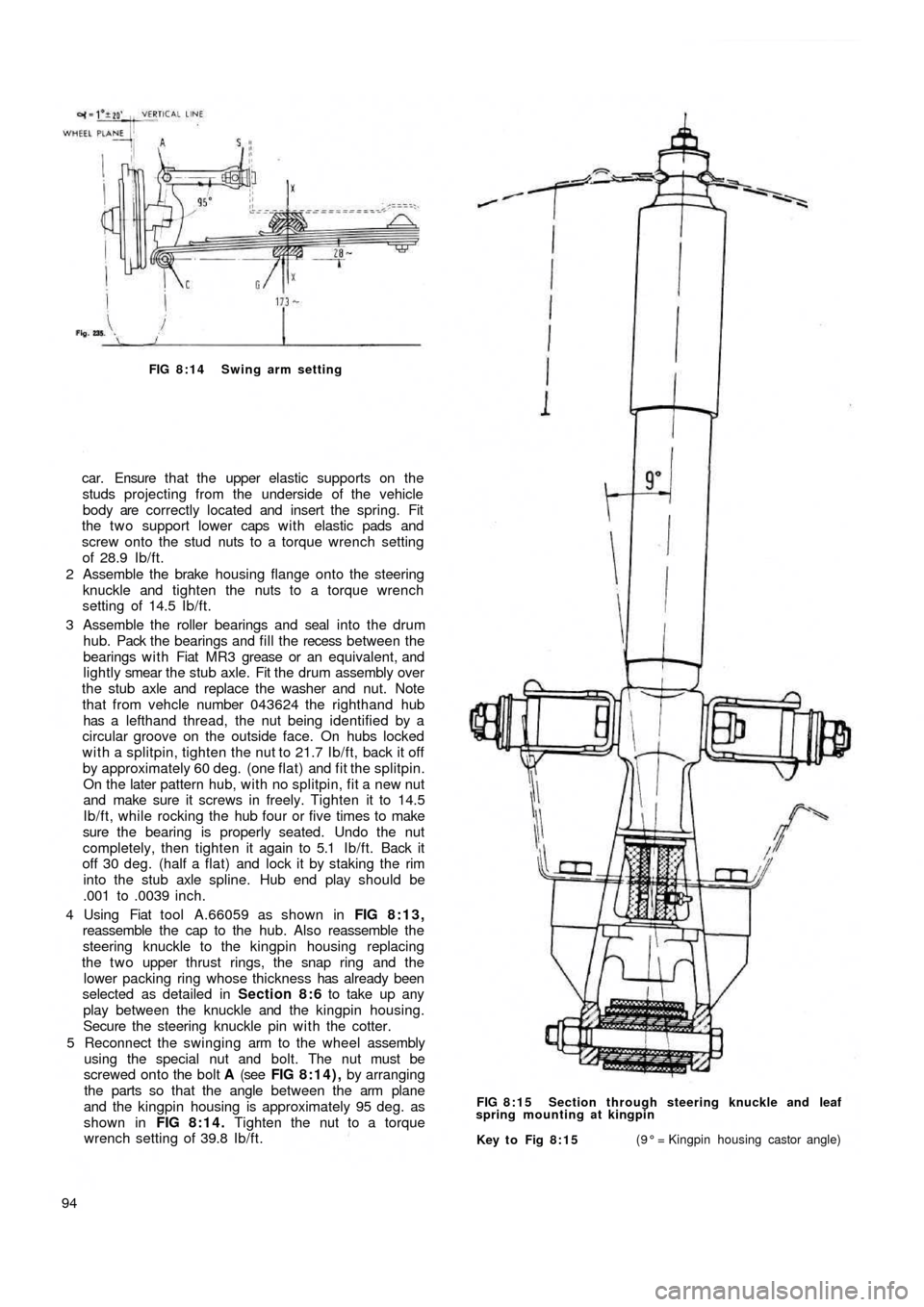

spring attains the full static load setting as on the FIG 8:13 Installing right front wheel hub cap by tool

A.66059TOOL

A.66059

Page 87 of 128

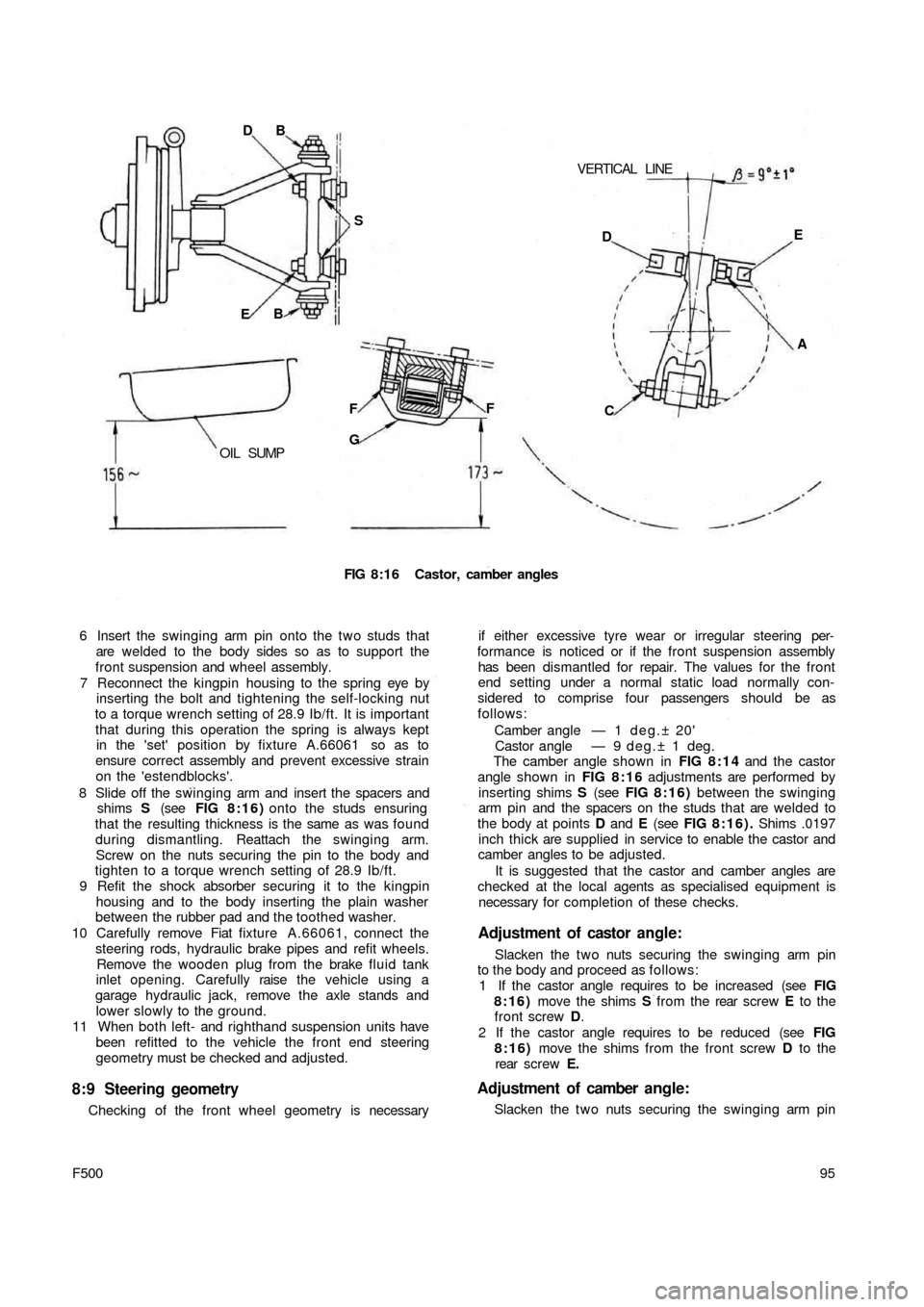

FIG 8:14 Swing arm setting

car. Ensure t h a t the upper elastic supports on the

studs projecting from the underside of the vehicle

body are correctly located and insert the spring. Fit

the two support lower caps w i t h elastic pads and

screw onto the stud nuts to a torque wrench setting

of 28.9 Ib/ft.

2 Assemble the brake housing flange onto the steering

knuckle and tighten the nuts to a torque wrench

setting of 14.5 Ib/ft.

3 Assemble the roller bearings and seal into the drum

hub. Pack the bearings and fill the recess between the

bearings w i t h Fiat MR3 grease or an equivalent, and

lightly smear the stub axle. Fit the drum assembly over

the stub axle and replace the washer and nut. Note

that from vehcle number 043624 the righthand hub

has a lefthand thread, the nut being identified by a

circular groove on the outside face. On hubs locked

with a splitpin, tighten the nut to 21.7 Ib/ft, back it off

by approximately 60 deg. (one flat) and fit the splitpin.

On the later pattern hub, with no splitpin, fit a new nut

and make sure it screws in freely. Tighten it to 14.5

Ib/ft, while rocking the hub four or five times to make

sure the bearing is properly seated. Undo the nut

completely, then tighten it again to 5.1 Ib/ft. Back it

off 30 deg. (half a flat) and lock it by staking the rim

into the stub axle spline. Hub end play should be

.001 to .0039 inch.

4 Using Fiat tool A.66059 as shown in FIG 8:13,

reassemble the cap to the hub. Also reassemble the

steering knuckle to the kingpin housing replacing

the t w o upper

thrust rings, the snap ring and the

lower packing ring whose thickness has already been

selected as detailed in Section 8:6 to take up any

play between the knuckle and the kingpin housing.

Secure the steering knuckle pin with the cotter.

5 Reconnect the swinging arm to the wheel assembly

using the special nut and bolt. The nut must be

screwed onto the bolt A (see FIG 8:14), by arranging

the parts so that the angle between the arm plane

and the kingpin housing is approximately 95 deg. as

shown in FIG 8:14. Tighten the nut to a torque

wrench setting of 39.8 Ib/ft.

94

Key to Fig 8:15(9° = Kingpin housing castor angle) FIG 8:15 Section through steering knuckle and leaf

spring mounting at kingpin

Page 88 of 128

VERTICAL LINE DB

S

EB

OIL SUMPF

GF

FIG 8:16 Castor, camber angles

6 Insert the swinging arm pin onto the two studs that

are welded to the body sides so as to support the

front suspension and wheel assembly.

7 Reconnect the kingpin housing to the spring eye by

inserting the bolt and tightening the self-locking nut

to a torque wrench setting of 28.9 Ib/ft. It is important

that during this operation the spring is always kept

in the 'set' position by fixture A.66061 so as to

ensure correct assembly and prevent excessive strain

on the 'estendblocks'.

8 Slide off the swinging arm and insert the spacers and

shims S (see FIG 8:16) onto the studs ensuring

that the resulting thickness is the same as was found

during dismantling. Reattach the swinging arm.

Screw on the nuts securing the pin to the body and

tighten to a torque wrench setting of 28.9 Ib/ft.

9 Refit the shock absorber securing it to the kingpin

housing and to the body inserting the plain washer

between the rubber pad and the toothed washer.

10 Carefully remove Fiat fixture A.66061, connect the

steering rods, hydraulic brake pipes and refit wheels.

Remove the wooden plug from the brake fluid tank

inlet opening. Carefully raise the vehicle using a

garage hydraulic jack, remove the axle stands and

lower slowly to the ground.

11 When both left- and righthand suspension units have

been refitted to the vehicle the front end steering

geometry must be checked and adjusted.

8:9 Steering geometry

Checking of the front wheel geometry is necessary

95

F500

if either excessive tyre wear or irregular steering per-

formance is noticed or if the front suspension assembly

has been dismantled for repair. The values for the front

end setting under a normal static load normally con-

sidered to comprise four passengers should be as

follows:

Camber angle — 1 d e g . ± 20'

Castor angle — 9 deg.± 1 deg.

The camber angle shown in FIG 8:14 and the castor

angle shown in FIG 8 : 1 6 adjustments are performed by

inserting shims S (see FIG 8 : 1 6 ) between the swinging

arm pin and the spacers on the studs that are welded to

the body at points D and E (see FIG 8:16). Shims .0197

inch thick are supplied in service to enable the castor and

camber angles to be adjusted.

It is suggested that the castor and camber angles are

checked at the local agents as specialised equipment is

necessary for completion of these checks.

Adjustment of castor angle:

Slacken the t w o nuts securing the swinging arm pin

to the body and proceed as follows:

1 If the castor angle requires to be increased (see FIG

8:16) move the shims S from the rear screw E to the

front screw D.

2 If the castor angle requires to be reduced (see FIG

8:16) move the shims from the front screw D to the

rear screw E.

Adjustment of camber angle:

Slacken the t w o nuts securing the swinging arm pin DE

A

C

Page 89 of 128

to the body and proceed as follows:

1 If the camber angle requires to be increased (see FIG

8:16) add the same number of shims S on both

screws D and E.

2 If the camber angle requires to be reduced (see FIG

8:16) remove the same number of shims from both

screws D and E.

The addition or removal of shims at the t w o points D

and E permits camber adjustment to be made without

any disturbing of the castor angle.

8:10 Modifications

Checking and adjusting castor and camber angles:

When checking the castor and camber angle the

static loading should be such that the distance between

the semi-elliptic spring mountings G (see FIG 8:16)

and the floor level to be approximately 6.81 inches, also a

distance between the lowermost portion of the sump and

the floor level of approximately 6.14 inch for the Model

500D. For the 500 Station Wagon version the distance

between centre rear bracket for jacking-up the vehicle

and the floor level should be approximately 8.90 inches.

All other front wheel alignment specifications are the

same as for the remaining 500 saloon models.

8:11 Fault diagnosis

(a) Wheel bounce

1 Tyre casing faulty

2 Uneven tyre pressures

3 Wheels out of balance

4 Semi-elliptic mounting spring worn5 Weak or seized shock absorber

6 Wheel rim or tyre misaligned

(b) Suspension noise

1 Lack of lubrication

2 Noisy or inoperative shock absorbers

3 Worn or loose wheel bearings

(c) Pull to one side

1 Low or uneven tyre pressures

2 Incorrect front wheel alignment

3 Suspension arms distorted

4 Inoperative shock absorbers

5 Brakes binding

(d) Excessive t y r e wear

1 Incorrect tyre rotation during servicing periods

2 Incorrect camber angle

3 Incorrect toe-in

4 Incorrect tyre inflation

5 Excessive play at wheel bearings

6 Wheel wobble

7 Stiff suspension arms

8 Brakes out of adjustment

(e) Wheel wobble

1 Uneven tyre pressures

2 Loose or worn wheel bearings

3 Inoperative shock absorbers

4 Loose steering knuckle or kingpin housing

5 Incorrect front wheel alignment

6 Control arm rubber bushings, or kingpin housing and

semi-elliptic spring 'estendblock' worn

96

Page 90 of 128

CHAPTER 9

THE STEERING SYSTEM

9 : 5 Relay lever and support

9 : 6 Steering rods

9 : 7 Front wheel toe-in

9 : 8 Fault diagnosis 9:1 Description

9 : 2 Steering wheel removal and refitting

9 : 3 Steering box removal and refitting

9 : 4 Steering box dismantling and reassembly

9:1 Description

The steering gear fitted to the new 500 range of

vehicles is of the worm screw and sector type with a

steering ratio of 1:13. The steering gearbox is located on

the front lefthand side of the dash wall on the scuttle as

shown in FIG 9:1. The steering gear comprises a pitman

arm and relay lever pivoting on a pin supported on the

body. A central track rod connects the pitman arm to the

relay lever. T w o track rods connect the pitman arm and

relay lever to the knuckle arms.

9:2 Steering wheel removal and refitting

To remove the steering wheel proceed as follows:

1 Disconnect the battery positive terminal clamp and

remove the horn control from the steering wheel.

2 Remove the cable from the push button seating and the

cable insulation sleeve.

3 Using a suitably sized box spanner or Fiat wrench

A.8279 unscrew the steering wheel to shaft nut as

shown in FIG 9:2.

4 Using the palm of the hands against the back of the

steering wheel rim gently tap the steering wheel

forwards so releasing it from the inner shaft.

F50097 5 Reassembly is the reverse procedure to dismantling.

Care should be taken to ensure that the front wheels

are located in the straight ahead position when the

steering wheel is being replaced otherwise the steering

wheel spokes will not be correctly positioned.

9 : 3 Steering box removal and refitting

To remove the steering box from the vehicle proceed

as follows:

1 From inside the vehicle remove the steering column

clamp bolt 6 (see FIG 9 : 3) after flattening the lock-

washer 7.

2 From the underside of the vehicle remove the t w o

tie rod locking nuts from the pitman arm and then using

Fiat tool A.46006 or a suitable t w o leg puller withdraw

the pins from the seats.

3 Remove the three nuts holding the steering box to the

body panel. Ease out the worm screw from the

steering shaft and lift away the steering box.

4 To refit the steering box is the reverse procedure to

dismantling. The steering box to body mounting nuts

should be tightened to a torque wrench setting of

14 Ib/ft to 18 Ib/ft.