chapter FIAT 500 1972 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1972, Model line: 500, Model: FIAT 500 1972 1.GPages: 128, PDF Size: 9.01 MB

Page 2 of 128

CHAPTER 1

THE ENGINE

1 :1

1 :2

1 :3

1 :4

1 :5

1 :6

1 :7

1 :8

1:9

1 :10

1 :11Description

Engine removal (sedan—all versions)

Engine removal (station wagon)

Engine disassembly (sedan—all versions)

Engine disassembly (station wagon)

Cylinder head removal, servicing and

replacement

Timing gear overhaul

Crankcase and cylinders

Piston assembly

Connecting rods

Crankshaft and main bearings

1 :1 Description

The 'New 500' two-cylinder aircooled engine operates

on the four-stroke 'Otto Cycle' and is fitted directly to

the transmission unit which incorporates the rear drive

assembly as shown in FIG 1 :1 and FIG 1 :2.

With the power unit fitted at the rear several advantages

are obtained including better load distribution to the

wheels when the vehicle is loaded, elimination of propeller

shaft reducing the size of centre tunnel and better use of

available space.

The cylinder block comprises t w o cast iron cylinder

barrels w i t h cooling fins. The bottom of the cylinders fit

into machined seats in the aluminium crankcase.

The aluminium crankcase carries eight studs on which

are located the t w o cylinder barrels w i t h the aluminium

cylinder head on the top.

A two bush crankshaft of special cast iron is fitted into

the lower half of the crankcase. The crankshaft is

F5009 provided with a counterweight and is hollow to allow for

lubrication.

The steel connecting rods have thin wall bearing halves

on the big-end, and bronze bushes in the small-end. The

offset piston pin is of steel and retained in the piston by

two circlips.

Light alloy pistons are used and are of the taper-oval-

shaped type with a maximum diameter at the base of the

skirt, along an axis perpendicular to the piston pin. Pistons

are fitted with four rings as follows, one compression at

the top, two standard oil scraper rings and one side slotted

oil scraper ring.

The one-piece aluminium cylinder head is finned to

provide a larger cooling surface and carries the inlet and

exhaust manifolds.

The inlet passages merge into a single centralized

flange onto which is mounted the carburetter. The exhaust

passages run almost parallel to the axis of the engine. 1 :12

1 :13

1 :14

1 :15

1 :16

1 :17

1 :18

1 :19

1 :20

1 :21

1 :22Flywheel and starter ring gear

The oil pump

Lubrication, oil filter, relief valve

Valve timing

Valve stem to rocker clearance

Engine assembly (sedan—all versions)

Engine assembly (station wagon)

Power plant mounting

Adjustment of generator and fan belt drive

Modifications

Fault diagnosis

Page 15 of 128

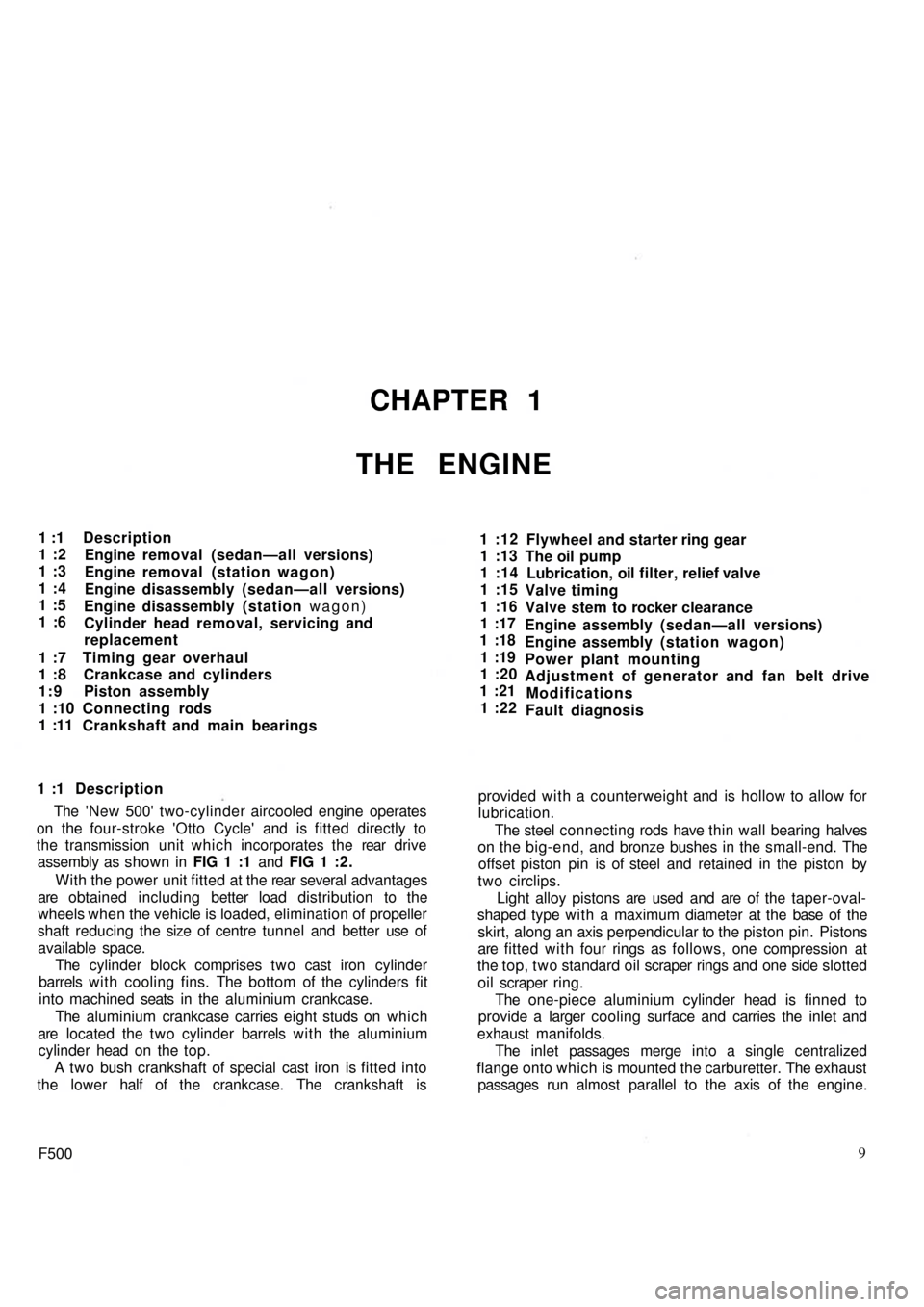

FEELER GAUGE

Checking ring gap (ring in cylinder) FIG 1 :27

FIG 1 :28.A universal piston ring compressor should be

used to keep the rings t i g h t in their grooves. The correct

matching of the piston and connecting rod is described in

a later section of this chapter.

1 :10 Connecting rods

Checking rod bearing inserts and crankpin jour-

nals:

The big-end bearing halves are of the babbit lined thin

wall type and must not be modified in any way. Should

score marks or excessive wear be evident the bearing

inserts must be renewed. It is recommended that if the

bearing inserts are to be renewed due to wear the crank-

pins should be measured to see if regrinding is required.

Before regrinding the crankpins they should be

measured at the maximum point of wear to determine the

class of bearing undersize to be fitted after regrinding the

crankpins. Undersize bearing halves are available in the

f o l l o w i n g sizes .01, .02, .03 and .04 inch. The correct

bearing crankpin clearance is .00043 to .00240 inch and

must be checked as detailed in the following section.

Checking rod bearing insert to crankpin journal

clearance:

Before the crankshaft is installed into the engine after

overhaul the clearance must be checked to ensure that it is

within the manufacturers recommended limits. To check

the clearance proceed as follows:

1

2Lubricate the crankpin and bearing inserts and install

the connecting rod together with its bearing halves on

the crankpin. Tighten the cap nuts to a torque wrench

setting of 23.9 Ibft.

Rotate the connecting rod around the crankshaft jour-

nal several times to seat the bearing insert correctly.

Remove the bearing end cap and carefully wipe away

all traces of the lubricant.

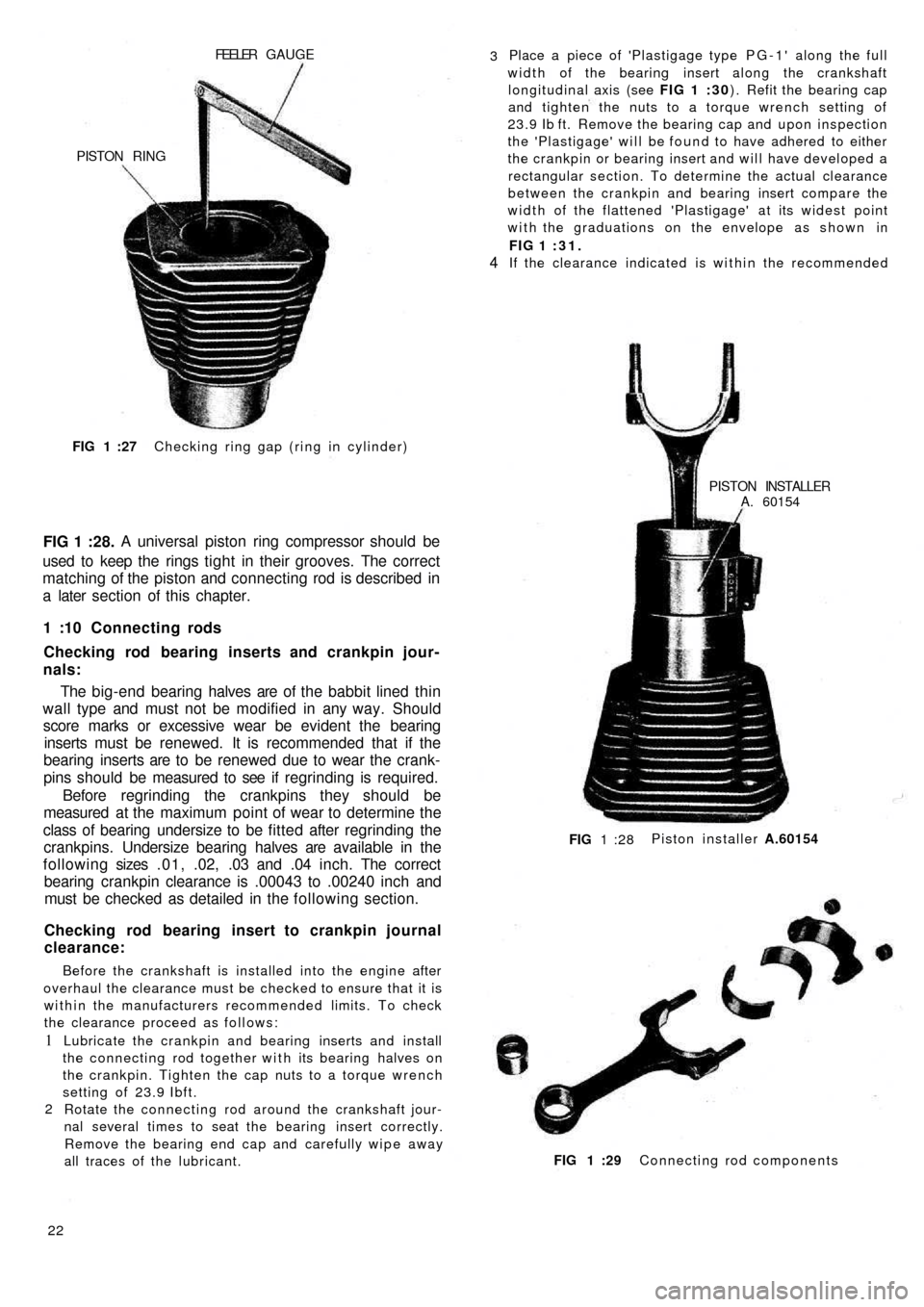

22FIG 1 :29 Connecting rod components Piston installer A.60154

FIG 1 :28PISTON INSTALLER

A. 60154 If the clearance indicated is within the recommended FIG 1 :31.

4

Place a piece of 'Plastigage type PG-1' along the full

width of the bearing insert along the crankshaft

longitudinal axis (see FIG 1 :30) . Refit the bearing cap

and tighten the nuts to a torque wrench setting of

23.9 Ib ft. Remove the bearing cap and upon inspection

the 'Plastigage' will be found to have adhered to either

the crankpin or bearing insert and will have developed a

rectangular section. To determine the actual clearance

between the crankpin and bearing insert compare the

width of the flattened 'Plastigage' at its widest point

with the graduations on the envelope as shown in 3

PISTON RING

Page 26 of 128

4 Mixture too weak

5 Water in fuel system

6 Petrol tank vent blocked

7 Incorrect valve clearance

(c) Engine idles badly

1 Check 1 and 6 in (b)

2 Air leak at manifold joints

3 Slow-running jet blocked or out of adjustment

4 Air leak in carburetter

5 Over-rich mixture

6 Worn piston rings

7 Worn valve stems or guides

8 Weak exhaust valve springs

(d) Engine misfires

1 Check 1, 2, 3, 4, 5, 8, 10, 13, 14, 1 5, 16, 17 in (a);

2, 3, 4 and 7 in (b)

2 Weak or broken valve springs

(e) Engine overheats

1 Generator and fan drive belt too loose

2 Shutter or thermostat seized in closed position

(f) Compression low

1 Check 14 and 15 in (a), 6 and 7 in (c) and 2 in (d)

2 Worn piston ring grooves

3 Scored or worn cylinder bores

(g) Engine lacks power

1 Check 3, 10, 1 1 , 13, 14, 15, 16 and 17 in (a), 2, 3, 4

and 7 in (b) 6 and 7 in (c) and 2 in (d). Also check (e)

and (f)

2 Leaking joint washers

3 Fouled sparking plugs

4 Automatic centrifugal advance not operating

(h) Burnt valves or seats

1 Check 14 and 15 in (a), 7 in (b) and 2 in (d). Alsocheck (e)

2 Excessive carbon around valve seat and head

(j) Sticking valves

1 Check 2 in (d)

2 Bent valve stem

3 Scored valve stem or guide

4 Incorrect valve clearance

(k) Excessive cylinder wear

1 Check 11 in (a) and see Chapter 4

2 Lack of oil

3 Dirty oil

4 Piston rings gummed up or broken

5 Badly fitting piston rings

6 Connecting rods bent

(l) Excessive oil consumption

1 Check 6 and 7 in (c) and check (k)

2 Ring gaps too wide

3 Oil return holes in piston choked with carbon

4 Scored cylinders

5 Oil level too high

6 External oil leaks

7 Ineffective valve stem oil seals

(m) Crankshaft and connecting rod bearing failure

1 Check 2 in (k)

2 Restricted oilways

3 Worn journals or crank pins

4 Loose bearing caps

5 Extremely low oil pressure

6 Bent connecting rod

(n) High fuel consumption (see Chapter 2)

(o) Engine vibration

1 Loose generator bolts

2 Blower blade assembly out-of-balance

3 Incorrect clearance for rear engine mounting rubber

F50033

Page 28 of 128

CHAPTER 2

THE FUEL SYSTEM

2:1 Description

2 : 2 Fuel pump operating principles

2 : 3 Routine maintenance

2 : 4 Pump removal, dismantling and examination

2 : 5 Reassembly, installation and adjustment

2 : 6 Carburetter operation and adjustment,

Weber 26.1MB2 : 7 Modifications

2 : 8 Carburetter operation and adjustment,

Weber 26.OC

2 :9 Air cleaner

2 : 1 0 B l o w - b y gases recirculation device

2:11 Fuel tank

2:12 Fault diagnosis

2:1 Description

All the new 500 models use a mechanical diaphragm

fuel feed pump as shown in FIG 2 : 1. Four types of

carburetter are fitted depending on the model to which

the engine is installed. Each carburetter operation and

adjustment is fully described, together with details of the

recirculation device for blow-by gases and o i l vapours.

2 : 2 Fuel pump operating principles

Refer to FIG 2 : 2. An eccentric on the rotating camshaft

actuates the operating rocker 21 via a pushrod 25 which

depresses the diaphragm 14 and so creates a depression

in the pumping chamber located in upper body 5. Under

atmospheric pressure, petrol passes through the pipeline

connection and inlet valve into the pumping chamber.

The return spring 15 then raises the diaphragm, expelling

the petrol through the outlet valve and pipeline to the

carburetter float chamber.

When the float chamber is full, the pressure in the pipe-

line and pumping chamber holds the diaphragm depressed

against the tension of the return spring.2 : 3 Routine maintenance

A poor delivery of fuel to the carburetter may be due to

a fault in the fuel pump or related lines. Periodically the

pump body screws 19 (see FIG 2 : 2) and upper cover

screw 1 should be checked for tightness. The fuel pump

lines should be disconnected and checked for freedom of

restriction, chafing and loose connections. The fuel pump

filter should be removed and cleaned periodically.

2:4 Pump removal, dismantling and examination

The pump is located on the carburetter side of the

engine crankcase (sedan) or under the generator at the

front of the crankcase (station wagon).

Removal:

1 Disconnect the fuel pipe from the tank to stop petrol

syphoning out of the tank and then release the fuel

inlet and outlet pipes from the pump body.

2 Remove the t w o nuts and washers holding pump to

crankcase.

3 Carefully lift away the pump, gaskets and insulating pad

from the crankcase (see FIG 2 : 3).

F50035

Page 40 of 128

3:1

3:2

3:3

3:4

3:5Description

Operation

Routine maintenance

Ignition faults

Removing and dismantling distributor (sedan

and sports)

CHAPTER 3

THE IGNITION SYSTEM

3:6

3:7

3:8

3:9

3:10

Removing and dismantling

(station wagon)

Timing the ignition

Sparking plugs

The distributor drive spindle

Fault diagnosisdistributor

3 :1 Description

The ignition system fitted to all the models covered by

this manual consists of an ignition coil, ignition distributor

fitted with contact breaker points, a centrifugal automatic

advance system, condenser, low- and high-tension

wiring, spark plugs and a power supply provided by a

generator and battery. The wiring diagram is shown in

FIG 3 : 1

1 The low-tension circuit which is sometimes called the

primary circuit includes the power supply, contact

breaker points, condenser and ignition coil primary

winding.

2 The high-tension circuit which is sometimes called the

secondary circuit includes the ignition coil secondary

winding, distributor rotor, distributor cap with terminals

and the central brush, high-tension cables and the spark

plugs.

3 : 2 Operation

The contact breaker unit in the distributor interrupts

the primary circuit by the points opening. The sudden stop

in the flow of current in the primary winding, does not cause

arcing at the contact breaker points because it discharges

into the condenser connected in parallel w i t h the contact

F50047

breaker points. With the sudden collapse of the primary

circuit, the intensity of the magnetic field drops causing

an induced high-tension current in the ignition coil

secondary winding. The high EMF is distributed to the

sparking plugs by the ignition distributor rotor.

The automatic advance mechanism comprises a plate

carrying t w o weights which are symmetrically pivoted on

the plate at one end. Also attached to the weights at

opposite ends to the pivots is the cam carrier shaft with

special tension return springs. Under the action of centri-

fugal force as the rotational speed increases, the weights

move outwards causing the cam carrier shaft to move

angularly compared to the distributor drive shaft thus

causing advancement of the ignition timing.

The contact breaker assembly comprises the cam on the

drive shaft and t w o contact points, one of which is

stationary while the other is under the influence of the

cam, the action of which is transmitted by a rubbing block.

The cam has t w o lobes to control the opening and closing

of contact points. The stationary contact point is mounted

on an adjustable support to enable the contact breaker

point gap to be adjusted.

The HT current reaches the distributor cap central

terminal, from the ignition coil and is distributed to each

of the spark plugs at the correct time by the rotor arm.

Page 46 of 128

CHAPTER 4

THE COOLING SYSTEM

4:1

4:2

4:3Description

Air outlet thermostat and shutter

Tension adjustment4:4

4:5

4:6Heating system safety device

Maintenance

Fault diagnosis

4:1Description

Sedan:

A l l the Fiat new 500 models covered by this manual are

aircooled by the forced air circulation system from a

centrifugal blower which is mounted on the generator

output shaft. The blower fan has fourteen vanes which are

arranged at various angles to reduce operating noise

during high-speed operation. A specially designed

cowling as shown in FIGS 4 : 1 and 4:2 conveys the air

from the blower and distributes it to the various parts of

the exterior of the engine.

The main components of the air cooling system are as

follows:

1 Air intake compartment at the rear end of t h e body.

2 An elbow pipe for the admittance of incoming air.

3 A flexible air pipe connecting the elbow pipe to the

conveyor.

4 A spiral air conveyor which contains the centrifugal fan.

5 Distribution ducting for directing the air flow to various

parts of the engine.

6 A bellows type thermostat is fitted to the cowling which

operates a butterfly shutter controlling the air outlet

from the engine which ensures control of the engine

operating temperature.

F50053 When the shutter is in the open position, engine heated

air is allowed to disperse to the outside of the engine

cowling. With the shutter in its closed position, the air is

recirculated in the engine cowling so ensuring a quick

engine warm-up period.

It should be noted that by operating the heater lever

which is located on the centre tunnel at the rear seat,

warmed air flowing out from the engine cowling is passed

to the inside of the car for heating and demisting purposes.

Station wagon:

Refer to FIG 4 : 2 where it will be seen that as the engine

is located on its side underneath the luggage compartment

floor the ducting has been modified and the air intakes are

located at the rear of the side windows. A linear blower is

housed in the engine baffles and cowling and is attached

to the drive end of the generator.

The thermostat 'C' (see FIG 4 : 2) is located on the

righthand side of the engine cowling and should start

opening the engine heated air outlet shutter ' D ' when the

temperature of the air rises to 1 7 8 - 1 8 5 ° F and the shutter

should be wide open when the air is at a temperature of

196-207°F.

Page 50 of 128

4 : 4 Heating system safety device

110F series sedan engines and later station wagon

engines incorporate a modification to the cylinder head

designed so that in the event of cylinder head gasket

failure exhaust gases are expelled outside the engine and

not leaked into the heating system.

The safety device comprises a square section circular

seat 1 (see FIG 4 :6) which is formed in the upper face of

the cylinder, a special duct in the cylinder head and a

pierced screw 3 for each cylinder.

The system is so designed that the exhaust gases are

released to the atmosphere from the circular seat in the

cylinder via the duct 2 and the pierced screw 3. It should

be noted that the screw 3 is also used for securing the

conveyor.

4 : 5 Maintenance

Due to the simple design of the air cooling system

maintenance has been kept to an absolute minimum and

should consist of the following checks:1 Inspect all the air conveyor system joints and ensure

that all the joint nuts and bolts are tight and that there

is no distortion between two joint faces.

2 Check that the tension of the generator and fan drive

belt is correct: with a hand pressure of approximately

22 Ib the belt should sag 13/32 inch. Adjust if necessary

as detailed in Chapter 1.

3 Ensure that the shutter can swivel freely and that the

spring is in a serviceable condition.

4 : 6 Fault diagnosis

(a) Engine overheating

1 Generator and fan drive belt slipping

2 Shutter control thermostat defective

3 Shutter unable to swivel freely

4 Shutter return spring broken

5 Leaking joints in conveyor system

F50057

Page 52 of 128

CHAPTER 5

THE CLUTCH

5:1

5:2

5:3

5:4Description

Removal and installation

Dismantling and inspection of clutch cover

Assembly and adjustment

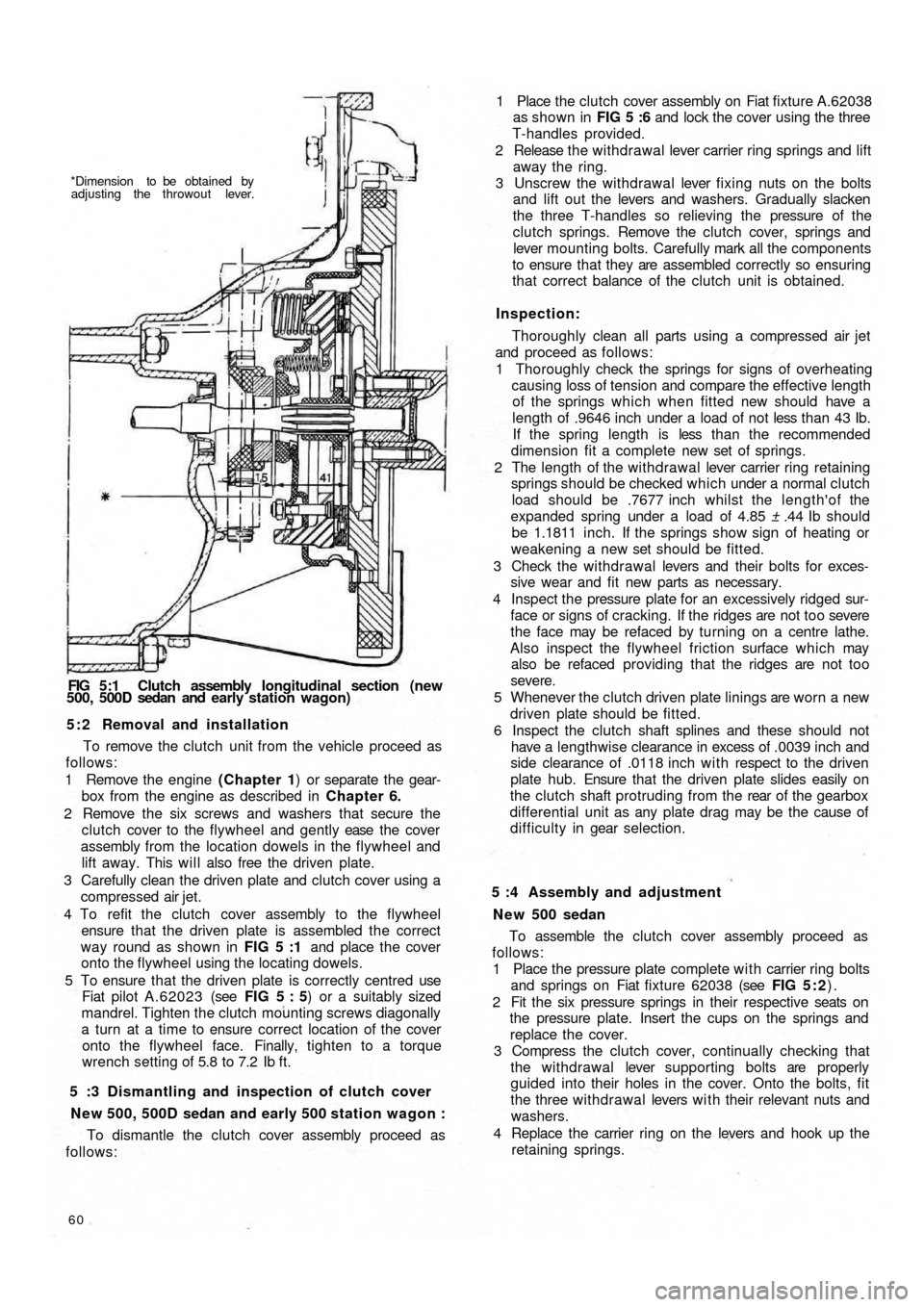

5:1 Description

New 500, 500D sedan and early station wagon:

The clutch is a single plate dry disc type operating on

the inner face of the flywheel. FIG 5 :1 shows a longitudi-

nal cross section of the clutch as it is assembled in the

power unit.

A sheet metal clutch cover is attached to the flywheel

by means of six screws and this encloses a clutch driven

plate, the pressure plate and six springs. Three withdrawal

levers are fitted so that the inner ends are attached to a

carrier ring through which three springs hold the levers in

place and the carrier ring in contact with the pressure plate,

(see FIG 5 : 1) . Release of the driven plate is obtained

through a throw-out ring fitted with a central carbon

thrust ring which acts on the withdrawal levers carrier

ring. This is controlled by the clutch pedal through suitable

linkage to the control fork.

When the clutch pedal is operated, the throw-out ring,

together with the carbon thrust ring is pushed towards the

flywheel and this exerts a pressure on the w i t h d rawal

levers carrier ring and the lever inner tips. The lever outer

tips lift the pressure plate so disengaging the clutch.

F50059

Each of the three withdrawal levers is mounted on a bolt

together with an adjustment nut which is inserted in the

pressure plate. The levers are kept in their location by a

guide which is formed in the pressure plate.

500 F and L sedans and late station wagon:

A single plate dry type clutch is fitted with a diaphragm

pressure spring. This design of clutch differs from the con-

ventional clutch because the pressure coil springs and

throw-out mechanism components are replaced by a

single diaphragm spring.

The new system offers certain advantages which are as

follows:

1 The load on the clutch pedal does not increase as the

clutch disc lining wears but remains constant through-

out the life of the clutch.

2 Due to the special shape and location of the diaphragm

spring, which offers a constant force on the pressure

plate throughout the clutch life, the clutch does not slip

even though the driven plate linings may be worn. 5:5

5:6

5:7

5:8Installation of clutch on flywheel

Pilot bushing

Withdrawal mechanism

Fault diagnosis

Page 53 of 128

*Dimension to be obtained by

adjusting the throwout lever.

FIG 5:1 Clutch assembly longitudinal section (new

500, 500D sedan and early station wagon)

5 : 2 Removal and installation

To remove the clutch unit from the vehicle proceed as

follows:

1 Remove the engine (Chapter 1) or separate the gear-

box from the engine as described in Chapter 6.

2 Remove the six screws and washers that secure the

clutch cover to the flywheel and gently ease the cover

assembly from the location dowels in the flywheel and

lift away. This will also free the driven plate.

3 Carefully clean the driven plate and clutch cover using a

compressed air jet.

4 To refit the clutch cover assembly to the flywheel

ensure that the driven plate is assembled the correct

way round as shown in FIG 5 :1 and place the cover

onto the flywheel using the locating dowels.

5 To ensure that the driven plate is correctly centred use

Fiat pilot A.62023 (see FIG 5 : 5) or a suitably sized

mandrel. Tighten the clutch mounting screws diagonally

a turn at a time to ensure correct location of the cover

onto the flywheel face. Finally, tighten to a torque

wrench setting of 5.8 to 7.2 Ib ft.

5 :3 Dismantling and inspection of clutch cover

New 500, 500D sedan and early 500 station wagon :

To dismantle the clutch cover assembly proceed as

follows:

60

To assemble the clutch cover assembly proceed as

follows:

1 Place the pressure plate complete with carrier ring bolts

and springs on Fiat fixture 62038 (see FIG 5 : 2).

2 Fit the six pressure springs in their respective seats on

the pressure plate. Insert the cups on the springs and

replace the cover.

3 Compress the clutch cover, continually checking that

the withdrawal lever supporting bolts are properly

guided into their holes in the cover. Onto the bolts, fit

the three withdrawal levers w i t h their relevant nuts and

washers.

4 Replace the carrier ring on the levers and hook up the

retaining springs. 5 :4 Assembly and adjustment

N e w 500 sedan1 Place the clutch cover assembly on Fiat fixture A.62038

as shown in FIG 5 :6 and lock the cover using the three

T-handles provided.

2 Release the w i thdrawal lever carrier ring springs and lift

away the ring.

3 Unscrew the withdrawal lever fixing nuts on the bolts

and lift out the levers and washers. Gradually slacken

the three T-handles so relieving the pressure of the

clutch springs. Remove the clutch cover, springs and

lever mounting bolts. Carefully mark all the components

to ensure that they are assembled correctly so ensuring

that correct balance of the clutch unit is obtained.

Inspection:

Thoroughly clean all parts using a compressed air jet

and proceed as follows:

1 Thoroughly check the springs for signs of overheating

causing loss of tension and compare the effective length

of the springs which when fitted new should have a

length of .9646 inch under a load of not less than 43 Ib.

If the spring length is less t h a n t h e recommended

dimension fit a complete new set of springs.

2 The length of the withdrawal lever carrier ring retaining

springs should be checked which under a normal clutch

load should be .7677 inch whilst the length'of the

expanded spring under a load of 4.85 ± .44 Ib should

be 1.1811 inch. If the springs show sign of heating or

weakening a new set should be fitted.

3 Check the withdrawa l levers and their bolts for exces-

sive wear and fit new parts as necessary.

4 Inspect the pressure plate for an excessively ridged sur-

face or signs of cracking. If the ridges are not too severe

the face may be refaced by turning on a centre lathe.

Also inspect the flywheel friction surface which may

also be refaced providing that the ridges are not too

severe.

5 Whenever the clutch driven plate linings are worn a new

driven plate should be fitted.

6 Inspect the clutch shaft splines and these should not

have a lengthwise clearance in excess of .0039 inch and

side clearance of .0118 inch w i t h respect to the driven

plate hub. Ensure that the driven plate slides easily on

the clutch shaft protruding from the rear of the gearbox

differential unit as any plate drag may be the cause of

d i f f i c u l t y in gear selection.

Page 58 of 128

CHAPTER 6

GEARBOX AND DIFFERENTIAL UNIT

6:1

6:2

6:3

6:4

6:5

6:6Description

Removal of gearbox/differential unit

Dismantling — gearbox

Reassembly — gearbox

Dismantling — differential and final drive

Reassembly— differential and final drive6:7

6:8

6:9

6:10

6:11

6:12Final drive gear set adjustment

Replacement of gearbox/differential unit

Swing axle shafts and slip joints

Gear shift control mechanism

Modifications

Fault diagnosis

6 :1 Description

The gearbox and differential unit are housed in an

aluminium alloy casing made up of t w o parts which split

at the differential centre line. The output drive is trans-

mitted by means of t w o half axle drive shafts coupled

through wheel shafts and slip joints to the rear wheels (see

FIG 6 : 1)

The gearbox provides four forward-speeds and a reverse,

the fourth-speed being considered as an overdrive. All

gears except first and reverse gears, which are straight

toothed sliding gears, are in constant mesh and have heli-

cal teeth. No synchromesh is provided, gear engagement

being completed by sliding shifter sleeves of the dog

clutch type. The first-speed gear slides on the outside of

the third and fourth shifter sleeve, whilst the reverse gear

train moves on a fixed shaft. The clutch shaft is integral

with the third, top and combined and first and second gear

pinions, whilst the second gear pinion is splined at the

front end. An internal splined

coupling sleeve joins the

clutch shaft and the input shaft and transmits the power

from the engine to the gearbox. The mainshaft and

differential drive pinion are combined together and besides

carrying the constant mesh gears and the sliding first gear

pinion, it also has attached the sliding sleeves and hubs.

F50065 The speedometer drive pinion is located at the front end.

The gearbox/differential casing is attached to the engine

by six studs which locate in the crankcase. The front of the

unit rests upon the rubber mounted support which is

secured to the body floor.

The complete unit comprises three detachable parts

made up as follows:

1 The support for the connection of the gearbox to the

engine which also acts as part of the differential front

end and clutch/flywheel housing at rear.

2 A central body which is divided into two compartments.

The front compartment contains first, third, fourth and

reverse gears w i t h the primary shaft, layshaft and reverse

shaft as well as the necessary gear selection striker rods

and forks. The rear of this compartment also forms a half

cover for the differential unit.

3 The gearbox casing cover, which contains the second-

speed gears together with the relative fork, gear

selection rod and speedometer drive gears.

The central part of the casing is provided with a top

inspection cover. The primary shaft is coupled to the clutch

shaft through an internally splined sleeve and t w o pins

which are retained by rings. The primary shaft together

with the first, third and fourth driving gears form a cluster.