cooling FIAT 500 1973 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1973, Model line: 500, Model: FIAT 500 1973 1.GPages: 128, PDF Size: 9.01 MB

Page 44 of 128

indicates the condition inside the combustion chamber

and may be used as a guide to engine tuning.

Before the spark plugs are removed b l o w away any

loose dirt from the plug recesses using a compressed air

jet or tyre pump. Store the plugs in the order of removal

ready for inspection.

Examine the gaskets and if they are about half their

thickness they may be used again otherwise they must be

replaced.

Inspect the electrode end of the plugs and note the

type and colour of the deposit. Normally it should be

powdery and range from b r o w n to a greyish tan in colour.

There will also be slight wear of the electrodes and the

general effect described is one which comes from mixed

periods of high-speed and low-speed driving. Cleaning

and resetting the gap is all that will be necessary.

If the deposits are white or yellowish they indicate long

periods of constant-speed driving or much low-speed

city driving. Again, the treatment is straightforward.

Dry, black, fluffy deposits are usually the result of

running with too rich a mixture. Incomplete combustion

of the petrol air charge may also be a cause and this might

be traced to a defect in the ignition system or excessive

idling.

Overheated sparking plugs have a white blistered look

about the centre electrode and the side electrode may be

badly eroded. This may be caused by poor cooling, wrong

ignition timing or sustained high speeds under heavy load.

To clean the sparking plugs effectively they should be

cleaned using an abrasive blasting machine and tested

under pressure once the electrodes have been reset. File

these until they are clean, bright and the faces parallel and

set the gap to .019 to .023 inch. Do not try to bend the

centre electrode.

Before replacing the plugs use a wire brush to clean the

threads taking care that the electrodes are not touched.

Thoroughly clean the spark plug in petrol, and dry using a

compressed air jet or a tyre pump. If difficulty is found in

screwing the plugs into the cylinder head by hand run a

tap d o w n the threads to clear away any carbon. If a tap is

not available use an old sparking plug with crosscuts d o w nthe threads. Finally tighten the plugs to a torque wrench

setting of 18 to 21 Ib ft.

Sparking plug leads:

The spark plug leads and the lead from the coil to the

distributor cap must be regularly checked for cracking of

the insulation and also correct seating in the distributor

cap and coil top. It is recommended that silicone grease is

smeared around the sockets before the leads are replaced

to ensure no moisture may enter causing difficult starting.

3 : 9 The distributor driving spindle (sedan and

sports engine)

If for any reason, the driving spindle has been removed

from its housing in the crankcase, it must be correctly

meshed w i t h the camshaft gear otherwise it

will be impos-

sible to set the ignition timing.

3:10 Fault diagnosis

(a) Engine w i l l not fire

1 Battery discharged

2 Distributor contact points dirty, pitted or maladjusted

3 Distributor cap dirty, cracked or tracking

4 Carbon brush inside distributor cap not touching rotor

5 Faulty cable or loose connection in low-tension circuit

6 Distributor rotor arm cracked

7 Faulty coil

8 Broken contact breaker spring

9 Contact points stuck open

(b) Engine misfires

1 Check 2, 3, 4, and 7 in (a)

2 Weak contact breaker spring

3 High-tension plug and coil leads cracked or perished

4 Sparking plug(s) loose

5 Sparking plug insulation cracked

6 Sparking plug gap incorrectly set

7 Ignition timing too far advanced

Page 46 of 128

CHAPTER 4

THE COOLING SYSTEM

4:1

4:2

4:3Description

Air outlet thermostat and shutter

Tension adjustment4:4

4:5

4:6Heating system safety device

Maintenance

Fault diagnosis

4:1Description

Sedan:

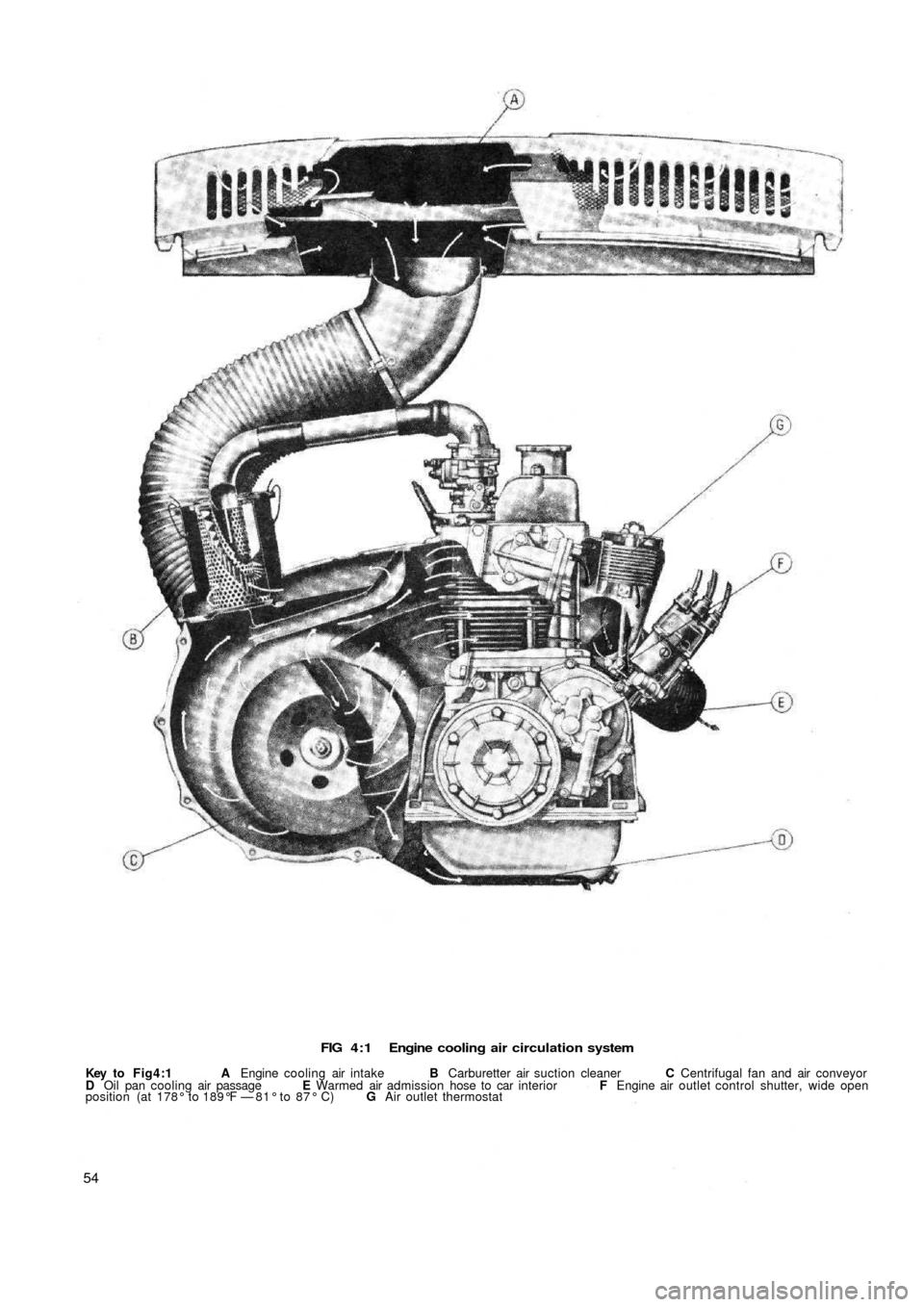

A l l the Fiat new 500 models covered by this manual are

aircooled by the forced air circulation system from a

centrifugal blower which is mounted on the generator

output shaft. The blower fan has fourteen vanes which are

arranged at various angles to reduce operating noise

during high-speed operation. A specially designed

cowling as shown in FIGS 4 : 1 and 4:2 conveys the air

from the blower and distributes it to the various parts of

the exterior of the engine.

The main components of the air cooling system are as

follows:

1 Air intake compartment at the rear end of t h e body.

2 An elbow pipe for the admittance of incoming air.

3 A flexible air pipe connecting the elbow pipe to the

conveyor.

4 A spiral air conveyor which contains the centrifugal fan.

5 Distribution ducting for directing the air flow to various

parts of the engine.

6 A bellows type thermostat is fitted to the cowling which

operates a butterfly shutter controlling the air outlet

from the engine which ensures control of the engine

operating temperature.

F50053 When the shutter is in the open position, engine heated

air is allowed to disperse to the outside of the engine

cowling. With the shutter in its closed position, the air is

recirculated in the engine cowling so ensuring a quick

engine warm-up period.

It should be noted that by operating the heater lever

which is located on the centre tunnel at the rear seat,

warmed air flowing out from the engine cowling is passed

to the inside of the car for heating and demisting purposes.

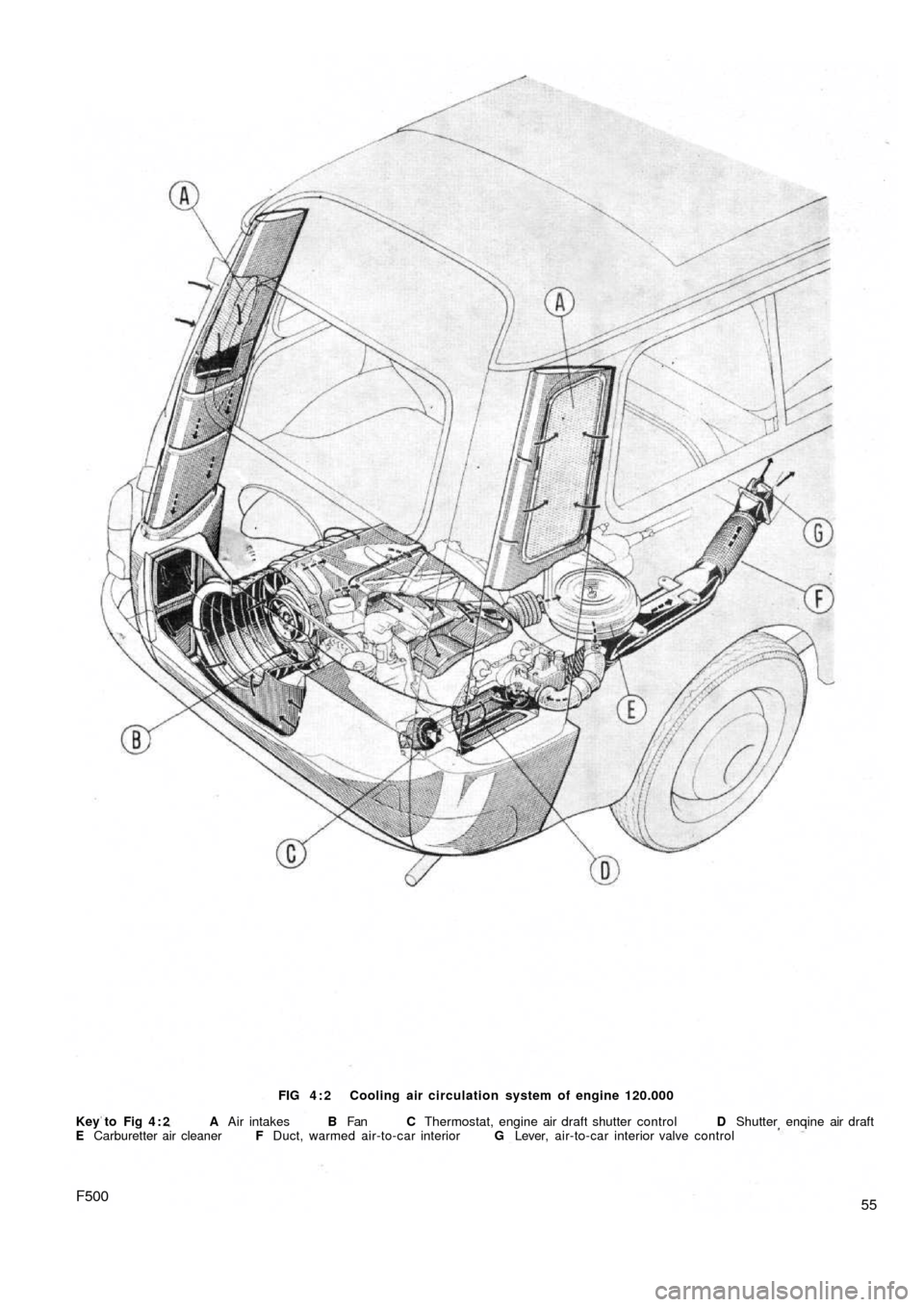

Station wagon:

Refer to FIG 4 : 2 where it will be seen that as the engine

is located on its side underneath the luggage compartment

floor the ducting has been modified and the air intakes are

located at the rear of the side windows. A linear blower is

housed in the engine baffles and cowling and is attached

to the drive end of the generator.

The thermostat 'C' (see FIG 4 : 2) is located on the

righthand side of the engine cowling and should start

opening the engine heated air outlet shutter ' D ' when the

temperature of the air rises to 1 7 8 - 1 8 5 ° F and the shutter

should be wide open when the air is at a temperature of

196-207°F.

Page 47 of 128

FIG 4 : 1 Engine cooling air circulation system

Key to Fig4:1 A Engine cooling air intake B Carburetter air suction cleaner C Centrifugal fan and air conveyor

D Oil pan cooling air passage E Warmed air admission hose to car interior F Engine air outlet control shutter, wide open

position (at 178° to 189°F — 81° to 87° C) G Air outlet thermostat

54

Page 48 of 128

55F500

FIG 4 : 2 Cooling air circulation system of engine 120.000

Key to Fig 4 : 2 A Air intakes B Fan C Thermostat, engine air draft shutter control D Shutter enqine air draft

E Carburetter air cleaner F Duct, warmed air-to-car interior G Lever, air-to-car interior valve control

Page 49 of 128

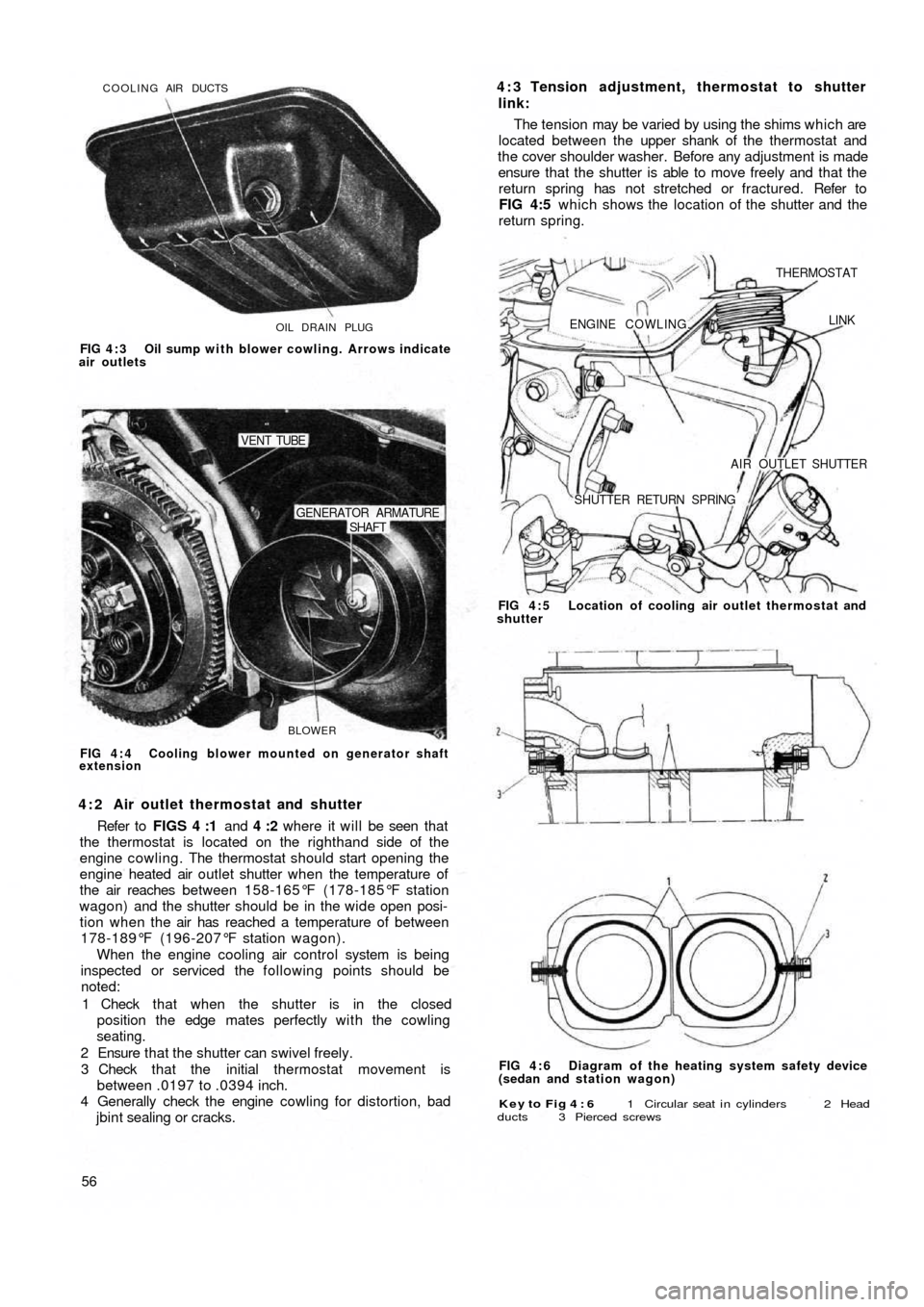

OIL DRAIN PLUG COOLING AIR DUCTS

FIG 4 : 3 Oil sump with blower cowling. Arrows indicate

air outlets

BLOWER

SHAFT GENERATOR ARMATURE

VENT TUBE

FIG 4 : 4 Cooling blower mounted on generator shaft

extension

4 : 2 Air outlet thermostat and shutter

Refer to FIGS 4 :1 and 4 :2 where it will be seen that

the thermostat is located on the righthand side of the

engine cowling. The thermostat should start opening the

engine heated air outlet shutter when the temperature of

the air reaches between 158-165°F (178-185°F station

wagon) and the shutter should be in the wide open posi-

tion when the air has reached a temperature of between

178-189°F (196-207°F station wagon).

When the engine cooling air control system is being

inspected or serviced the following points should be

noted:

1 Check that when the shutter is in the closed

position the edge mates perfectly with the cowling

seating.

2 Ensure that the shutter can swivel freely.

3 Check that the initial thermostat movement is

between .0197 to .0394 inch.

4 Generally check the engine cowling for distortion, bad

jbint sealing or cracks.

56

Key to Fig 4 : 6 1 Circular seat i n cylinders 2 Head

ducts 3 Pierced screws

FIG 4 : 6 Diagram of the heating system safety device

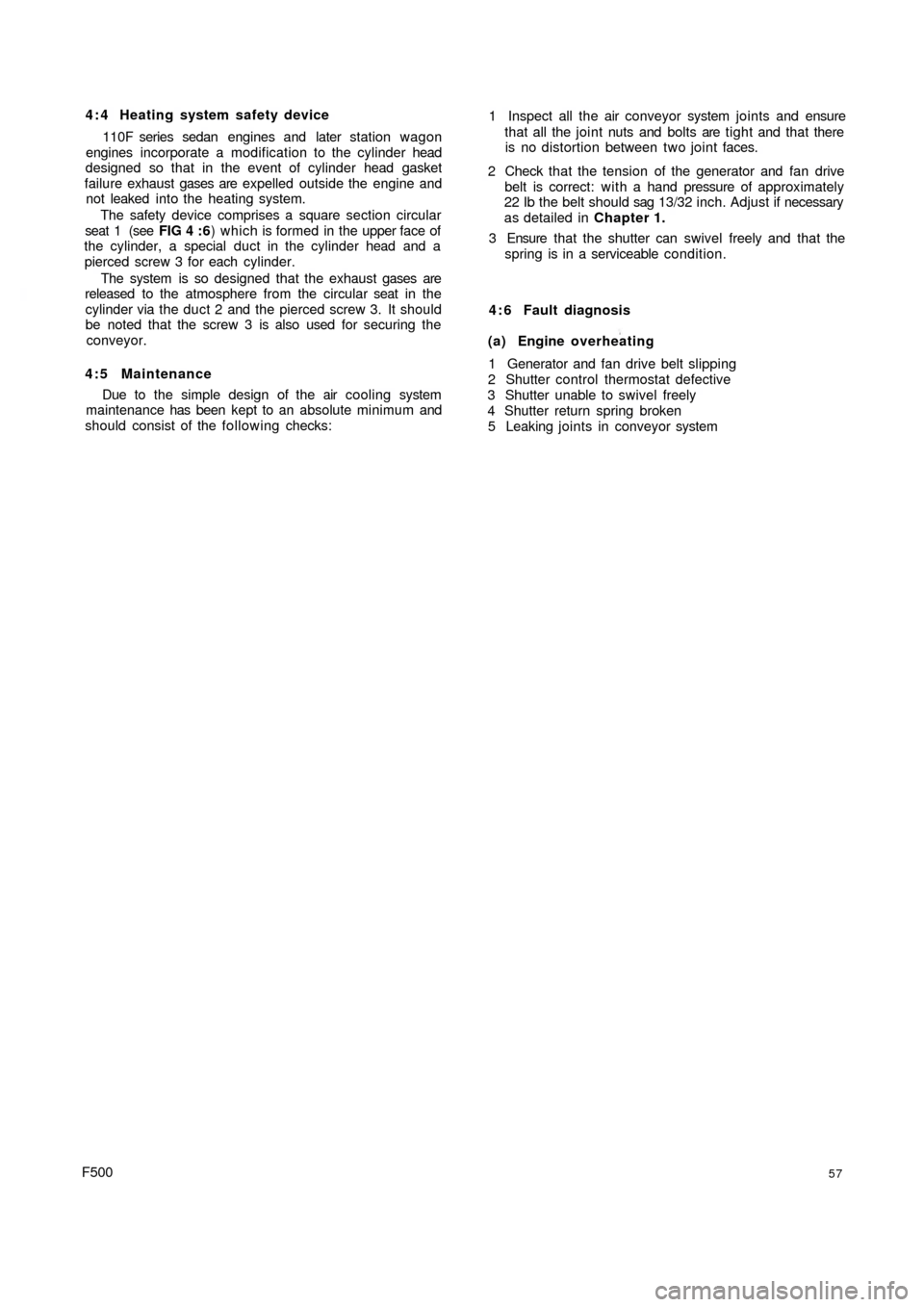

(sedan and station wagon) FIG 4 : 5 Location of cooling air outlet thermostat and

shutter

ENGINE COWLING.

THERMOSTAT

LINK

AIR OUTLET SHUTTER

SHUTTER RETURN SPRING

4 : 3 Tension adjustment, thermostat to shutter

link:

The tension may be varied by using the shims which are

located between the upper shank of the thermostat and

the cover shoulder washer. Before any adjustment is made

ensure that the shutter is able to move freely and that the

return spring has not stretched or fractured. Refer to

FIG 4:5 which shows the location of the shutter and the

return spring.

Page 50 of 128

4 : 4 Heating system safety device

110F series sedan engines and later station wagon

engines incorporate a modification to the cylinder head

designed so that in the event of cylinder head gasket

failure exhaust gases are expelled outside the engine and

not leaked into the heating system.

The safety device comprises a square section circular

seat 1 (see FIG 4 :6) which is formed in the upper face of

the cylinder, a special duct in the cylinder head and a

pierced screw 3 for each cylinder.

The system is so designed that the exhaust gases are

released to the atmosphere from the circular seat in the

cylinder via the duct 2 and the pierced screw 3. It should

be noted that the screw 3 is also used for securing the

conveyor.

4 : 5 Maintenance

Due to the simple design of the air cooling system

maintenance has been kept to an absolute minimum and

should consist of the following checks:1 Inspect all the air conveyor system joints and ensure

that all the joint nuts and bolts are tight and that there

is no distortion between two joint faces.

2 Check that the tension of the generator and fan drive

belt is correct: with a hand pressure of approximately

22 Ib the belt should sag 13/32 inch. Adjust if necessary

as detailed in Chapter 1.

3 Ensure that the shutter can swivel freely and that the

spring is in a serviceable condition.

4 : 6 Fault diagnosis

(a) Engine overheating

1 Generator and fan drive belt slipping

2 Shutter control thermostat defective

3 Shutter unable to swivel freely

4 Shutter return spring broken

5 Leaking joints in conveyor system

F50057

Page 106 of 128

indicates a break in the cable from the generator to

regulator. Repeat the test on terminal 67. Finally,

remove the temporary link from the generator. If the

readings are correct, test the regulator as described in

Section 11:5.

Removing generator:

1 Disconnect the leads from the generator.

2 Remove the drive belt as previously described.

3 Release t h e rear mounting bracket at the side of the

power unit.

4 Remove the air cooling ducting from around the fan

and generator area and lift away the unit.

5 Release the blower from the end of the armature shaft

and finally, the mounting bolts from the air ducting.

Dismantling generator:

1 Release the pulley self-locking nut and slide the pulley

off the armature shaft.

2 Remove the t w o Woodruff keys on armature shaft.

3 Unscrew the t w o through bolt nuts and pull out the

bolts.

4 Partially remove the commutator end head to the point

where the brushes are. s t i l l seating on the commutator.

Using a piece of hooked wire relieve the load of the

springs on the brushes by arranging the spring ends

on the brush sides. The brushes will be locked in their

holders and cannot be chipped by striking against the

armature shaft during the commutator end head

removal.

5 Gently ease the commutator and fan end heads apart

and, slide out the armature.

Servicing brushes:

Lift the brushes up in the boxes and hold them in that

position by letting each brush spring bear on the side of

its brush. Fit the commutator end bracket over the

commutator end of the armature shaft and release the

brushes by hooking up the springs using a thin screw

driver. Hold back each spring in turn and move the brush

by pulling gently on the flexible connector. If the brush

moves sluggishly remove it and polish the sides using a

smooth file. Before this operation is actually carried out it

is suggested that the brush is marked before removal so

that it is replaced in its original working position.

inch,The minimum permissible length of a brush is

so renew any t h a t are less than this figure. Test the brush

springs using a spring tension scale. New springs should

have a tension of 1.3 to 1.6 Ib. In service this value could

fall slightly before performance is affected. Always bed in

new brushes by wrapping fine sandpaper round the

commutator, pressing down on the brush and rotating

the commutator under it, or draw the paper t o o and f r o .

If new brushes are fitted always fit genuine Fiat replace-

ments.

Servicing the commutator:

A commutator in good condition should be smooth and

free from pitting or signs of the segments burning. Clean

with a rag moistened in petrol. If necessary, polish using

a fine glasspaper whilst rotating the armature. Never use

emerycloth.

If the commutator is badly worn it may be skimmed

using a centre lathe. Use a high rotational speed and take

F500113

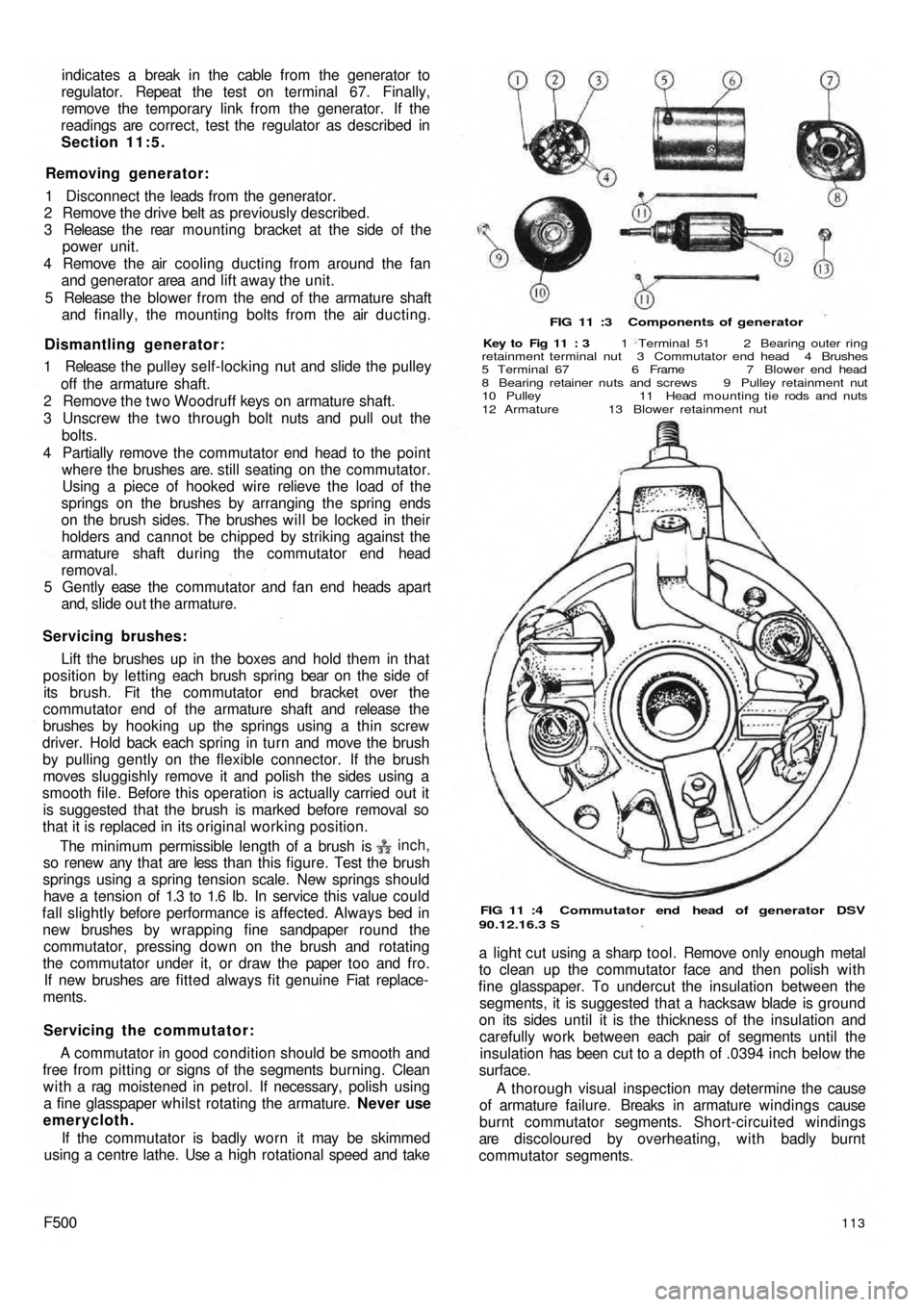

FIG 11 :3 Components of generator

Key to Fig 11 : 3 1 Terminal 51 2 Bearing outer ring

retainment terminal nut 3 Commutator end head 4 Brushes

5 Terminal 67 6 Frame 7 Blower end head

8 Bearing retainer nuts and screws 9 Pulley retainment nut

10 Pulley 11 Head mounting tie rods and nuts

12 Armature 13 Blower retainment nut

FIG 11 :4 Commutator end head of generator DSV

90.12.16.3 S

a light cut using a sharp tool. Remove only enough metal

to clean up the commutator face and then polish with

fine glasspaper. To undercut the insulation between the

segments, it is suggested that a hacksaw blade is ground

on its sides until it is the thickness of the insulation and

carefully work between each pair of segments until the

insulation has been cut to a depth of .0394 inch below the

surface.

A thorough visual inspection may determine the cause

of armature failure. Breaks in armature windings cause

burnt commutator segments. Short-circuited windings

are discoloured by overheating, with badly burnt

commutator segments.

Page 126 of 128

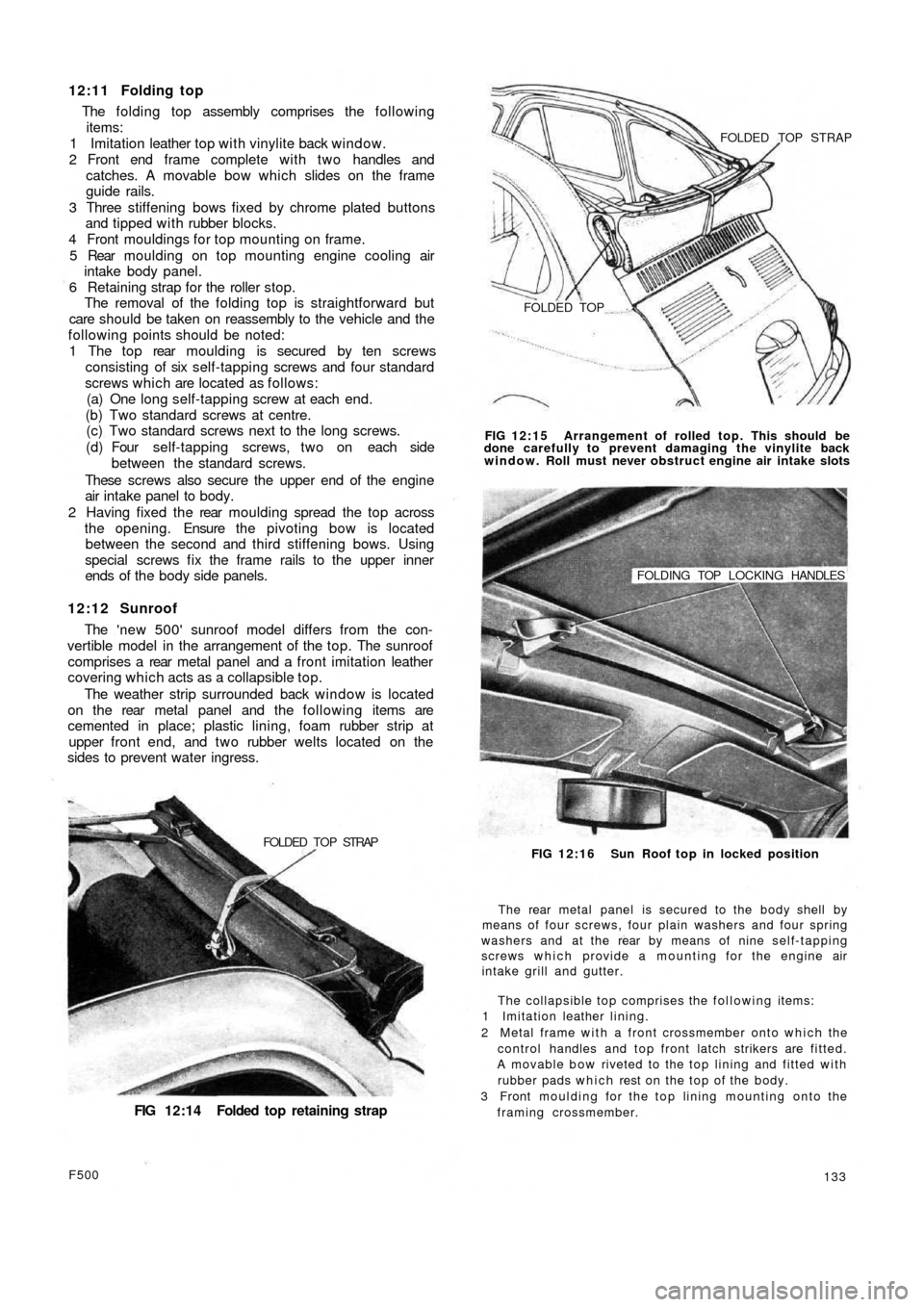

12:11 Folding top

The f ol di n g top assembly comprises the following

items:

1 Imitation leather top w i t h vinylite back window.

2 Front end frame complete with two handles and

catches. A movable bow which slides on the frame

guide rails.

3 Three stiffening bows fixed by chrome plated buttons

and tipped with rubber blocks.

4 Front mouldings for t o p mounting on frame.

5 Rear moulding on top mounting engine cooling air

intake body panel.

6 Retaining strap for the roller stop.

The removal of the folding top is straightforward but

care should be taken on reassembly to the vehicle and the

following points should be noted:

1 The t o p rear moulding is secured by ten screws

consisting of six self-tapping screws and four standard

screws which are located as follows:

(a) One long self-tapping screw at each end.

(b) Two standard screws at centre.

(c) Two standard screws next to the long screws.

(d) Four self-tapping screws, two on each side

between the standard screws.

These screws also secure the upper end of the engine

air intake panel to body.

2 Having fixed the rear moulding spread the top across

t h e o p e n i n g . Ensure t h e pivoting bow is located

between the second and third stiffening bows. Using

special screws fix the frame rails to the upper inner

ends of the body side panels.

12:12 Sunroof

The 'new 500' sunroof model differs from the con-

vertible model in the arrangement of the top. The sunroof

comprises a rear metal panel and a front imitation leather

covering which acts as a collapsible top.

The weather strip surrounded back window is

located

on t h e rear metal panel and the following items are

cemented in place; plastic lining, foam rubber strip at

upper front end, and two rubber welts located on the

sides to prevent water ingress.

FIG 12:14 Folded top retaining strap

F500

133 FOLDED TOP STRAP

FOLDED TOP

FIG 12:15 Arrangement of rolled top. This should be

done carefully to prevent damaging the vinylite back

window. Roll must never obstruct engine air intake slots

FOLDING TOP LOCKING HANDLES

FIG 12:16 Sun Roof top in locked position

The rear metal panel is secured to the body shell by

means of four screws, four plain washers and four spring

washers and at the rear by means of nine self-tapping

screws which provide a mounting for the engine air

intake grill and gutter.

The collapsible top comprises the following items:

1 Imitation leather lining.

2 Metal frame with a front crossmember onto which the

control handles and top front latch strikers are fitted.

A movable bow riveted to the top lining and fitted with

rubber pads which rest on t h e t o p of t h e body.

3 Front moulding for the top lining mounting onto the

framing crossmember. FOLDED TOP STRAP

Page 127 of 128

BOW

FIG 12:17 Sun Roof top in unlatched position

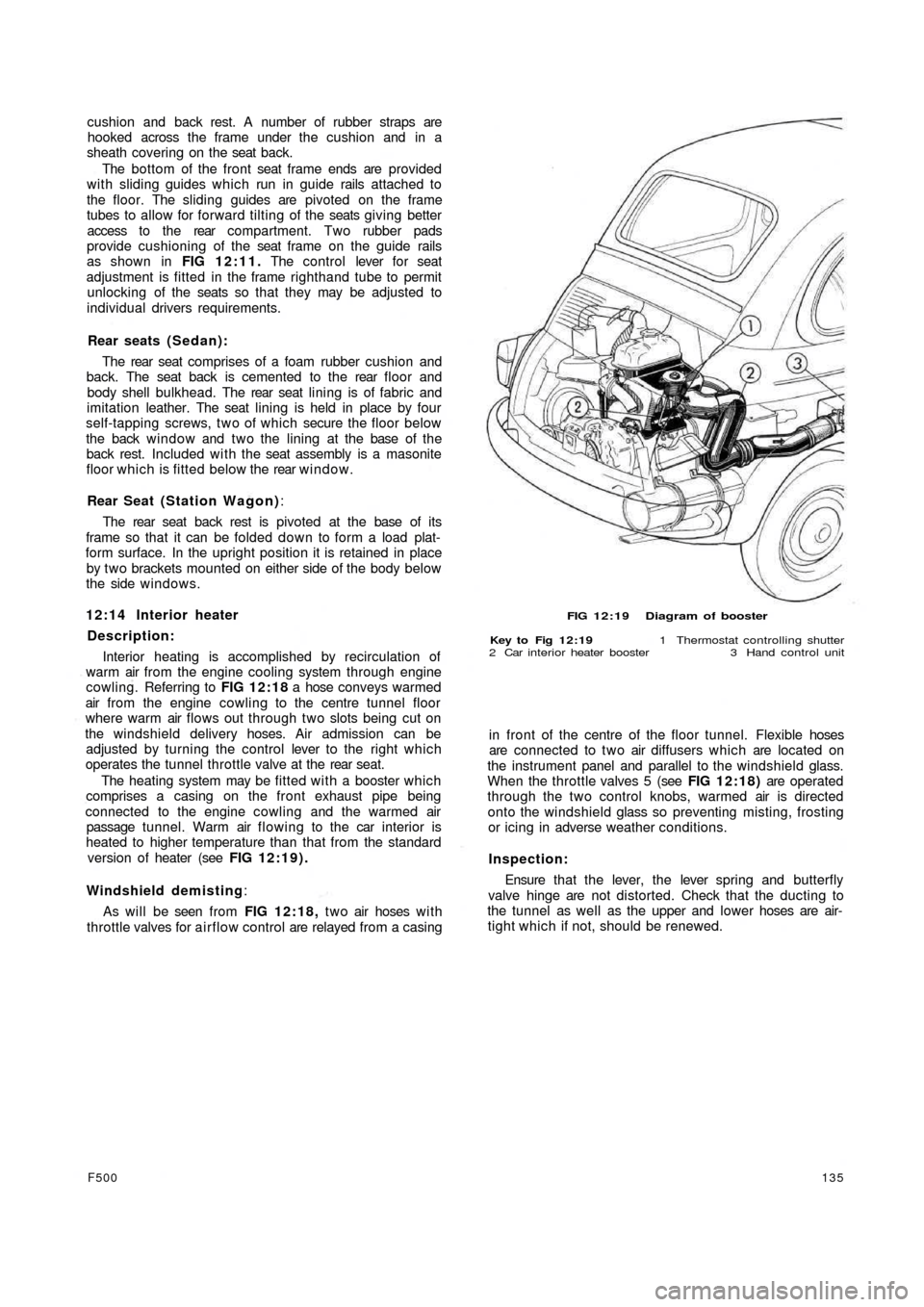

FIG 12:18 Diagrammatic view of car heating system

Key to Fig 12 :18 1 Thermostat controlling shutter 2 Shutter, engine cooling air outlet 3 Lever, heater hand control

4 Warm air outlet slots 5 Demister valve control knobs 6 Windshield demister diffusers

NOTE—The car may be also equipped, optionally, with a heating booster as shown in FIG 12:19

134

4 Rear moulding for the top lining mounting onto the

rear metal panel.

5 Top lining retaining strap which is secured to the front

end of t h e rear metal panel using a bridge bracket.

6 Bracket for strap which hooks up the top lining when

in the folded position.

Dismantling and reassembly is a straightforward

operation providing that careful note is made of the

location of all screws that are removed. To reassemble

it is suggested that the rear metal panel is mounted on

the body shell first. The collapsible top assembly is then

positioned and secured to the rear metal panel using eight

rivets. The top covering should be stretched to the closed

position and secured to both framing side arms to t h e

body shell wells using the special screws. 500F and L

models are similar, but with a single central sun roof latch:

t h e rear metal panel is no longer removable.

12:13 Seats

Front seats:

The front bucket seats comprise a one-piece tubular

frame covered with imitation leather or cloth padded

Page 128 of 128

cushion and back rest. A number of rubber straps are

hooked across the frame under the cushion and in a

sheath covering on the seat back.

The bottom of the front seat frame ends are provided

with sliding guides which run in guide rails attached to

the floor. The sliding guides are pivoted on the frame

tubes to allow for forward tilting of the seats giving better

access to the rear compartment. Two rubber pads

provide cushioning of the seat frame on the guide rails

as shown in FIG 12:11. The control lever for seat

adjustment is fitted in the frame righthand tube to permit

unlocking of the seats so that they may be adjusted to

individual drivers requirements.

Rear seats (Sedan):

The rear seat comprises of a foam rubber cushion and

back. The seat back is cemented to the rear floor and

body shell bulkhead. The rear seat lining is of fabric and

imitation leather. The seat lining is held in place by four

self-tapping screws, t w o of which secure the floor below

the back window and two the lining at the base of t h e

back rest. Included with the seat assembly is a masonite

floor which is fitted below the rear window.

Rear Seat (Station Wagon):

The rear seat back rest is pivoted at the base of its

frame so that it can be folded down to form a load plat-

form surface. In the upright position it is retained in place

by t w o brackets mounted on either side of the body below

the side

windows.

12:14 Interior heater

Description:

Interior heating is accomplished by recirculation of

warm air from the engine cooling system through engine

cowling. Referring to FIG 12:18 a hose conveys warmed

air from the engine cowling to the centre tunnel floor

where warm air flows out through two slots being cut on

the windshield delivery hoses. Air admission can be

adjusted by turning the control lever to the right which

operates the tunnel throttle valve at the rear seat.

The heating system may be fitted with a booster which

comprises a casing on the front exhaust pipe being

connected to the engine cowling and the warmed air

passage tunnel. Warm air flowing to the car interior is

heated to higher temperature than that from the standard

version of heater (see FIG 12:19).

Windshield demisting:

As will be seen from FIG 12:18, t w o air hoses w i t h

throttle valves for airflow control are relayed from a casing

F500135

FIG 12:19 Diagram of booster

Key to Fig 12:19 1 Thermostat controlling shutter

2 Car interior heater booster 3 Hand control unit

in front of the centre of the floor tunnel. Flexible hoses

are connected to two air diffusers which are located on

the instrument panel and parallel to the windshield glass.

When the throttle valves 5 (see FIG 12:18) are operated

through the two control knobs, warmed air is directed

onto the windshield glass so preventing misting, frosting

or icing in adverse weather conditions.

Inspection:

Ensure that t h e lever, the lever spring and butterfly

valve hinge are not distorted. Check that the ducting to

the tunnel as well as the upper and lower hoses are air-

tight which if not, should be renewed.