fuel FIAT 500 1973 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1973, Model line: 500, Model: FIAT 500 1973 1.GPages: 128, PDF Size: 9.01 MB

Page 31 of 128

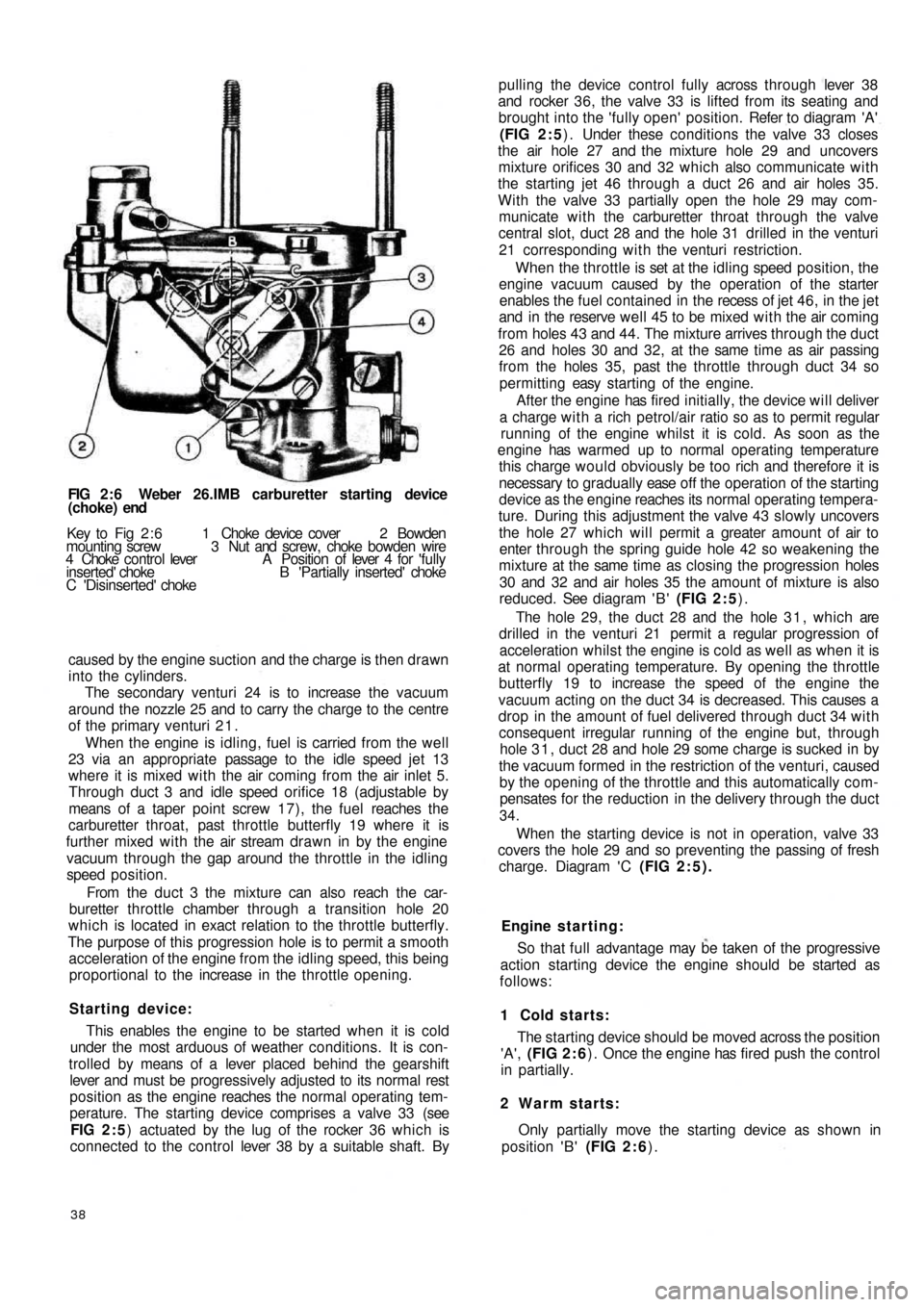

FIG 2 : 6 Weber 26.IMB carburetter starting device

(choke) end

Key to Fig 2 : 6 1 Choke device cover 2 Bowden

mounting screw 3 Nut and screw, choke bowden wire

4 Choke control lever A Position of lever 4 for 'fully

inserted' choke B 'Partially inserted' choke

C 'Disinserted' choke

caused by the engine suction and the charge is then drawn

into the cylinders.

The secondary venturi 24 is to increase the vacuum

around the nozzle 25 and to carry the charge to the centre

of the primary venturi 2 1 .

When the engine is idling, fuel is carried from the well

23 via an appropriate passage to the idle speed jet 13

where it is mixed with the air coming from the air inlet 5.

Through duct 3 and idle speed orifice 18 (adjustable by

means of a taper point screw 17), the fuel reaches the

carburetter throat, past throttle butterfly 19 where it is

further mixed with the air stream drawn in by the engine

vacuum through the gap around the throttle in the idling

speed position.

From the d u c t 3 the mixture can also reach the car-

buretter throttle chamber through a transition hole 20

which is located in exact relation to the throttle butterfly.

The purpose of this progression hole is to permit a smooth

acceleration of the engine from the idling speed, this being

proportional to the increase in the throttle opening.

Starting device:

This enables the engine to be started when it is cold

under the most arduous of weather conditions. It is con-

trolled by means of a lever placed behind the gearshift

lever and must be progressively adjusted to its normal

rest

position as the engine reaches the normal operating tem-

perature. The starting device comprises a valve 33 (see

FIG 2 : 5) actuated by the lug of the rocker 36 which is

connected to the control lever 38 by a suitable shaft. By

38

pulling the device control fully across through lever 38

and rocker 36, the valve 33 is lifted from its seating and

brought into the 'fully open' position. Refer to diagram 'A'

(FIG 2 : 5) . Under these conditions the valve 33 closes

the air hole 27 and the mixture hole 29 and uncovers

mixture orifices 30 and 32 which also communicate with

the starting jet 46 through a duct 26 and air holes 35.

With the valve 33 partially open the hole 29 may com-

municate with the carburetter throat through the valve

central slot, duct 28 and the hole 31 drilled in the venturi

21 corresponding with the venturi restriction.

When the throttle is set at the idling speed position, the

engine vacuum caused by the operation of the starter

enables the fuel contained in the recess of jet 4 6 , in the jet

and in the reserve well 45 to be mixed w i t h the air coming

from holes 43 and 44. The mixture arrives through the duct

26 and holes 30 and 32, at the same time as air passing

from the holes 35, past the throttle through duct 34 so

permitting easy starting of the engine.

After the engine has fired initially, the device will deliver

a charge with a rich petrol/air ratio so as to permit regular

running of the engine whilst it is cold. As soon as the

engine has warmed up to normal operating temperature

this charge would obviously be too rich and therefore it is

necessary to gradually ease o f f the operation of the starting

device as the engine reaches its normal operating tempera-

ture. During this adjustment the valve 43 slowly uncovers

the hole 27 which will permit a greater amount of air to

enter through the spring guide hole 42 so weakening the

mixture at the same time as closing the progression holes

30 and 32 and air holes 35 the amount of mixture is also

reduced. See diagram ' B ' (FIG 2 : 5).

The hole 29, the duct 28 and the hole 3 1 , which are

drilled in the venturi 21 permit a regular progression of

acceleration whilst the engine is cold as well as when it is

at normal operating temperature. By opening the throttle

butterfly 19 to increase the speed of the engine the

vacuum acting on the duct 34 is decreased. This causes a

drop in the amount of fuel delivered through duct 34 with

consequent irregular running of the engine but, through

hole 3 1 , duct 28 and hole 29 some charge is sucked in by

the vacuum formed in the restriction of the venturi, caused

by the opening of the throttle and this automatically com-

pensates for the reduction in the delivery through the duct

34.

When the starting device is not in operation, valve 33

covers the hole 29 and so preventing the passing of fresh

charge. Diagram ' C (FIG 2:5).

Engine s t a rting:

So that full advantage may be taken of the progressive

action starting device the engine should be started as

follows:

1 Cold starts:

The starting device should be moved across the position

'A', (FIG 2 : 6) . Once the engine has fired push the control

in partially.

2 Warm starts:

Only partially move the starting device as shown in

position 'B' (FIG 2 : 6).

Page 32 of 128

3 Engine warm-up:

As the engine begins to warm up to its normal operating

temperature, gradually push home the starting device

lever so as only to supply the engine with the richened

charge enabling the cold engine operation to be smooth

and regular. Position ' B ' (FIG 2:6).

4 Normal car driving:

Once the engine has reached its normal operating

temperature the starting device should be completely

brought out of operation by bringing the control lever to

the position 'C (FIG 2:6).

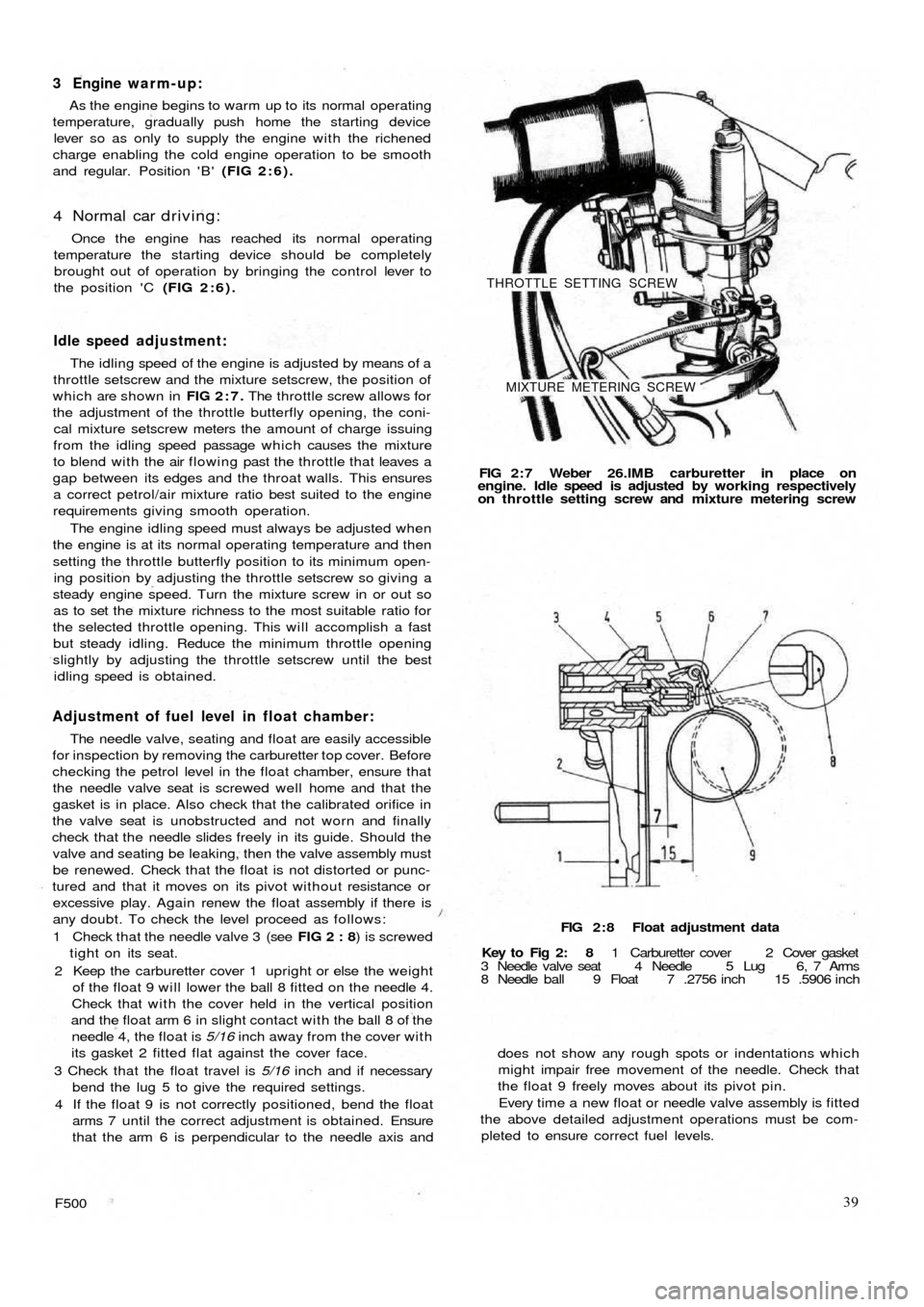

Idle speed adjustment:

The idling speed of the engine is adjusted by means of a

throttle setscrew and the mixture setscrew, the position of

which are shown in FIG 2:7. The throttle screw allows for

the adjustment of the throttle butterfly opening, the coni-

cal mixture setscrew meters the amount of charge issuing

from the idling speed passage which causes the mixture

to blend with the air flowing past the throttle that leaves a

gap between its edges and the throat walls. This ensures

a correct petrol/air mixture ratio best suited to the engine

requirements giving smooth operation.

The engine idling speed must always be adjusted when

the engine is at its normal operating temperature and then

setting the throttle butterfly position to its minimum open-

ing position by adjusting the throttle setscrew so giving a

steady engine speed. Turn the mixture screw in or out so

as to set the mixture richness to the most suitable ratio for

the selected throttle opening. This will accomplish a fast

but steady idling. Reduce the minimum throttle opening

slightly by adjusting the throttle setscrew until the best

idling speed is obtained.

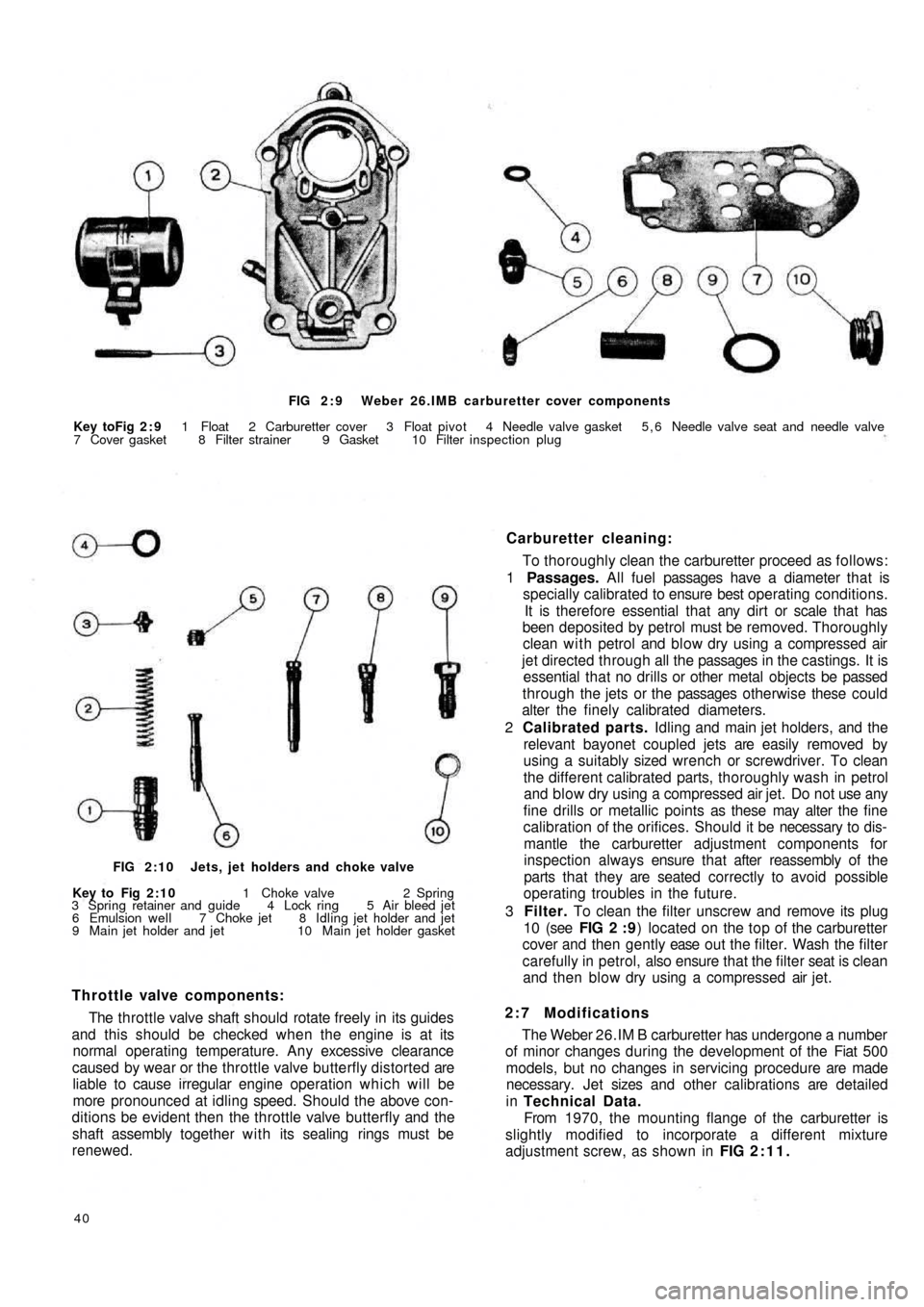

Adjustment of fuel level in float chamber:

The needle valve, seating and float are easily accessible

for inspection by removing the carburetter top cover. Before

checking the petrol level in the float chamber, ensure that

the needle valve seat is screwed well home and that the

gasket is in place. Also check that the calibrated orifice in

the valve seat is unobstructed and not worn and finally

check that the needle slides freely in its guide. Should the

valve and seating be leaking, then the valve assembly must

be renewed. Check that the float is not distorted or punc-

tured and that it moves on its pivot without resistance or

excessive play. Again renew the float assembly if there is

any doubt. To check the level proceed as follows:

1 Check that the needle valve 3 (see FIG 2 : 8) is screwed

tight on its seat.

2 Keep the carburetter cover 1 upright or else the weight

of the float 9 will lower the ball 8 fitted on the needle 4.

Check that with the cover held in the vertical position

and the float arm 6 in slight contact with the ball 8 of the

needle 4, the float is 5/16 inch away from the cover with

its gasket 2

fitted flat against the cover face.

3 Check that the float travel is 5/16 inch and if necessary

bend the lug 5 to give the required settings.

4 If the float 9 is not correctly positioned, bend the float

arms 7 until the correct adjustment is obtained. Ensure

that the arm 6 is perpendicular to the needle axis and

F50039

does not show any rough spots or indentations which

might impair free movement of the needle. Check that

the float 9 freely moves about its pivot pin.

Every time a new float or needle valve assembly is fitted

the above detailed adjustment operations must be com-

pleted to ensure correct fuel levels. FIG 2 : 8 Float adjustment data

Key to Fig 2: 8 1 Carburetter cover 2 Cover gasket

3 Needle valve seat 4 Needle 5 Lug 6, 7 Arms

8 Needle ball 9 Float 7 .2756 inch 15 .5906 inch FIG 2 : 7 Weber 26.IMB carburetter in place on

engine. Idle speed is adjusted by working respectively

on throttle setting screw and mixture metering screw

THROTTLE SETTING SCREW

MIXTURE METERING SCREW

Page 33 of 128

FIG 2 : 9 Weber 26.IMB carburetter cover components

Key toFig 2 : 9 1 Float 2 Carburetter cover 3 Float pivot 4 Needle valve gasket 5 , 6 Needle valve seat and needle valve

7 Cover gasket 8 Filter strainer 9 Gasket 10 Filter inspection plug

Carburetter cleaning:

To thoroughly clean the carburetter proceed as follows:

1 Passages. All fuel passages have a diameter that is

specially calibrated to ensure best operating conditions.

It is therefore essential that any dirt or scale that has

been deposited by petrol must be removed. Thoroughly

clean with petrol and blow dry using a compressed air

jet directed through all the passages in the castings. It is

essential that no drills or other metal objects be passed

through the jets or the passages otherwise these could

alter the finely calibrated diameters.

2 Calibrated parts. Idling and main jet holders, and the

relevant bayonet coupled jets are easily removed by

using a suitably sized wrench or screwdriver. To clean

the different calibrated parts, thoroughly wash in petrol

and blow dry using a compressed air jet. Do not use any

fine drills or metallic points as these may alter the fine

calibration of the orifices. Should it be necessary to dis-

mantle the carburetter adjustment components for

inspection always ensure that after reassembly of the

parts that they are seated correctly to avoid possible

operating troubles in the future.

3 Filter. To clean the filter unscrew and remove its plug

10 (see FIG 2 : 9) located on the top of the carburetter

cover and then gently ease o u t t h e filter. Wash the filter

carefully in petrol, also ensure that the filter seat is clean

and then blow dry using a compressed air jet.

2:7 Modifications

The Weber 26.IM B carburetter has undergone a number

of minor changes during the development of the Fiat 500

models, but no changes in servicing procedure are made

necessary. Jet sizes and other calibrations are detailed

in Technical Data.

From 1970, the mounting flange of the carburetter is

slightly modified to incorporate a different mixture

adjustment screw, as shown in FIG 2:11.

40

Throttle valve components:

The throttle valve shaft should rotate freely in its guides

and this should be checked when the engine is at its

normal operating temperature. Any excessive clearance

caused by wear or the throttle valve butterfly distorted are

liable to cause irregular engine operation which will be

more pronounced at idling speed. Should the above con-

ditions be evident then the throttle valve butterfly and the

shaft assembly together with its sealing rings must be

renewed.

FIG 2:10 Jets, jet holders and choke valve

Key to Fig 2:10 1 Choke valve 2 Spring

3 Spring retainer and guide 4 Lock ring 5 Air bleed jet

6 Emulsion well 7 Choke jet 8 Idling jet holder and jet

9 Main jet holder and jet 10 Main jet holder gasket

Page 34 of 128

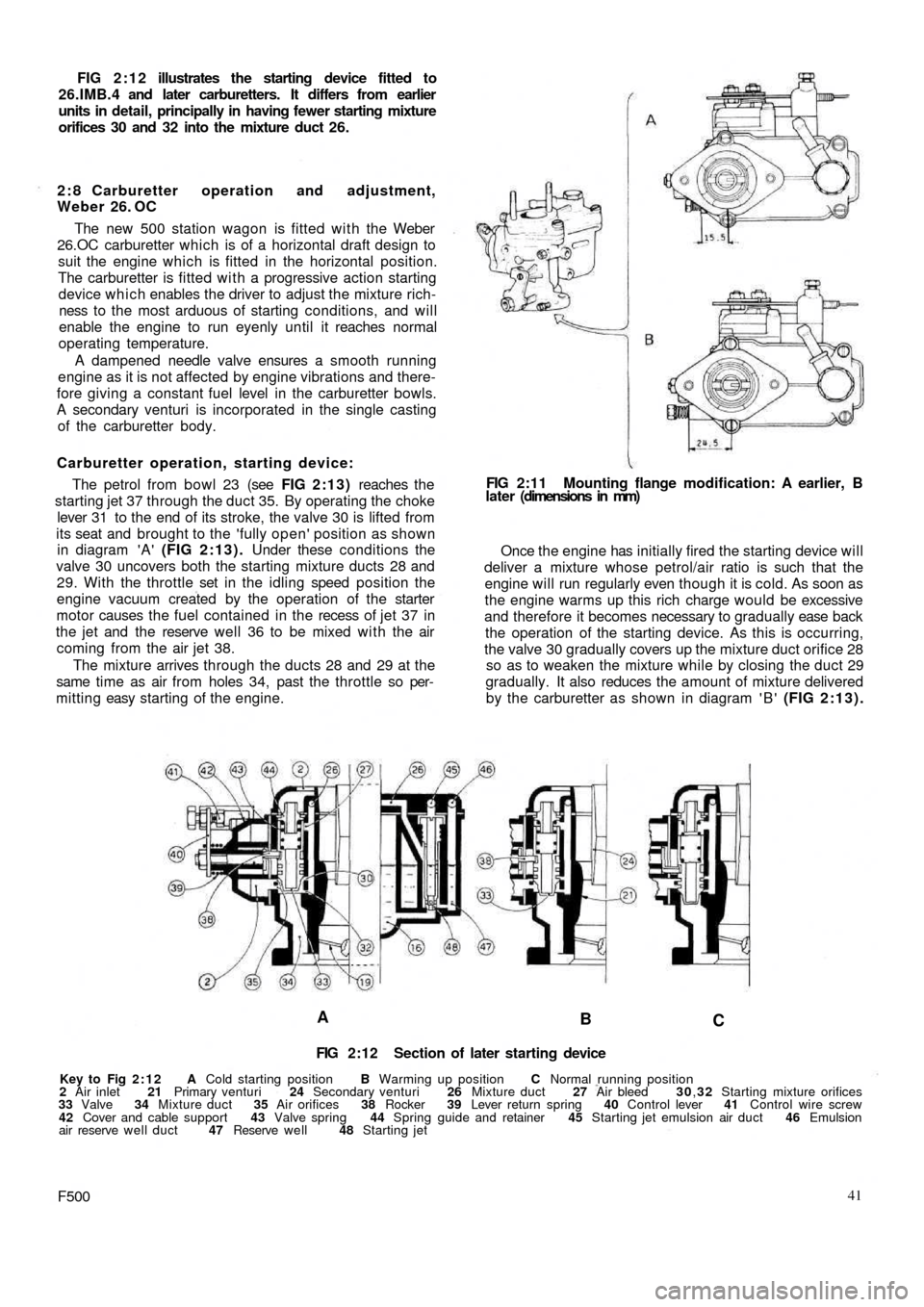

FIG 2:12 illustrates the starting device fitted to

26.IMB.4 and later carburetters. It differs from earlier

units in detail, principally in having fewer starting mixture

orifices 30 and 32 into the mixture duct 26.

2 : 8 Carburetter operation and adjustment,

Weber 26. OC

The new 500 station wagon is fitted with the Weber

26.OC carburetter which is of a horizontal draft design to

suit the engine which is fitted in the horizontal position.

The carburetter is fitted with a progressive action starting

device which enables the driver to adjust the mixture rich-

ness to the most arduous of starting conditions, and will

enable the engine to run eyenly until it reaches normal

operating temperature.

A dampened needle valve ensures a smooth running

engine as it is not affected by engine vibrations and there-

fore giving a constant fuel level in the carburetter bowls.

A secondary venturi is incorporated in the single casting

of the carburetter body.

Carburetter operation, starting device:

The petrol from bowl 23 (see FIG 2:13) reaches the

starting jet 37 through the duct 35. By operating the choke

lever 31 to the end of its stroke, the valve 30 is lifted from

its seat and brought to the 'fully open' position as shown

in diagram 'A' (FIG 2:13). Under these conditions the

valve 30 uncovers both the starting mixture ducts 28 and

29. With the throttle set in the idling speed position the

engine vacuum created by the operation of the starter

motor causes the fuel contained in the recess of j e t 37 in

the jet and the reserve

well 36 to be mixed with the air

coming from the air jet 38.

The mixture arrives through the ducts 28 and 29 at the

same time as air from holes 34, past the throttle so per-

mitting easy starting of the engine.

A

B

C

FIG 2:12 Section of later starting device

Key to Fig 2:12 A Cold starting position B Warming up position C Normal running position

2 Air inlet 21 Primary venturi 24 Secondary venturi 26 Mixture duct 27 Air bleed 30,32 Starting mixture orifices

33 Valve 34 Mixture duct 35 Air orifices 38 Rocker 39 Lever return spring 40 Control lever 41 Control wire screw

42 Cover and cable support 43 Valve spring 44 Spring guide and retainer 45 Starting jet emulsion air duct 46 Emulsion

air reserve well duct 47 Reserve well 48 Starting jet

F50041 Once the engine has initially fired the starting device will

deliver a mixture whose petrol/air ratio is such that the

engine will run regularly even though it is cold. As soon as

the engine warms up this rich charge would be excessive

and therefore it becomes necessary to gradually ease back

the operation of the starting device. As this is occurring,

the valve 30 gradually covers up the mixture duct orifice 28

so as to weaken the mixture while by closing the duct 29

gradually. It also reduces the amount of mixture delivered

by the carburetter as shown in diagram ' B ' (FIG 2:13). FIG 2:11 Mounting flange modification: A earlier, B

later (dimensions in mm)

Page 35 of 128

3938

28 29 30A3132 33

28 29 30 3.1B28

29 30 31C

34 34

34

37 36 35 23

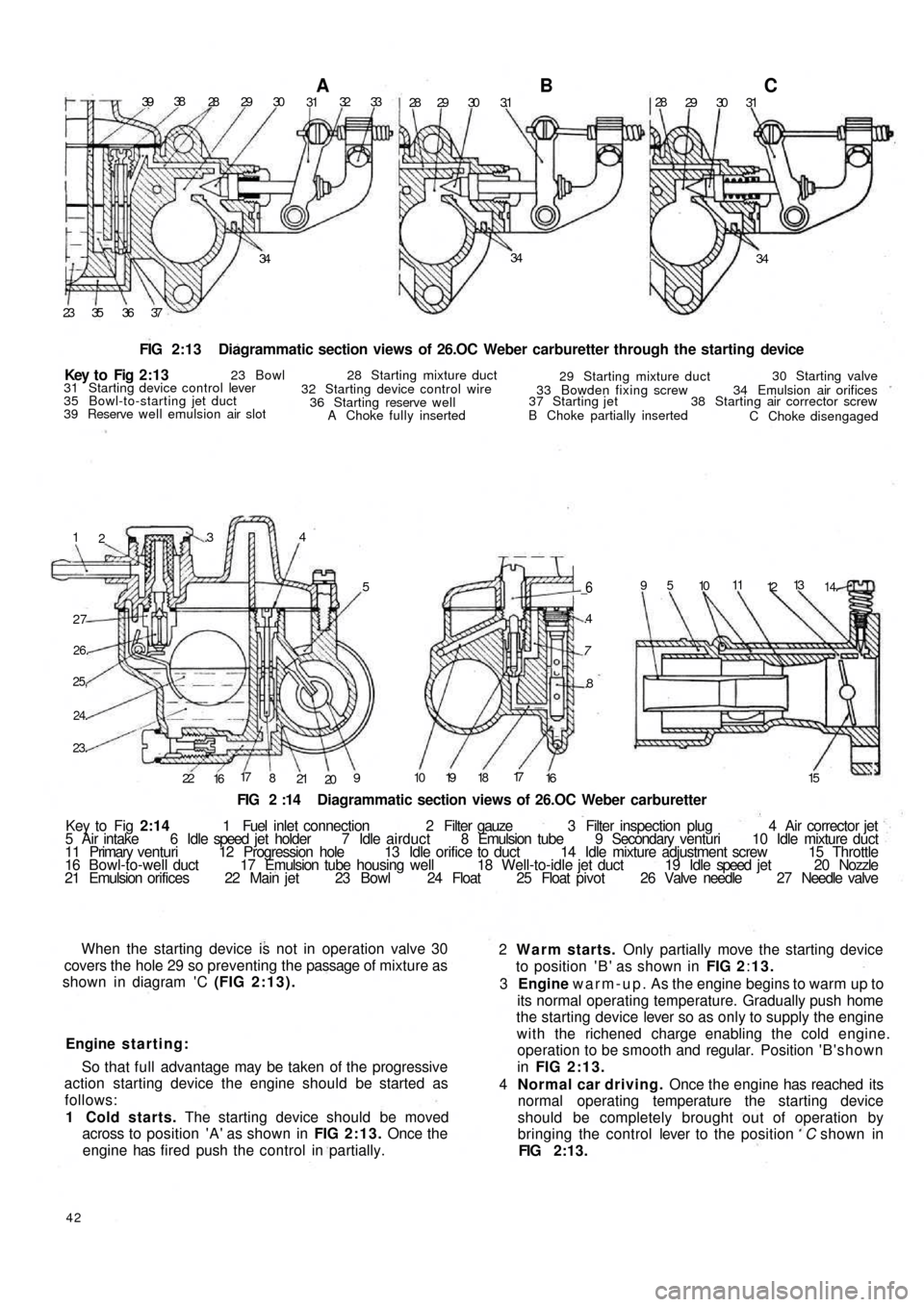

FIG 2:13 Diagrammatic section views of 26.OC Weber carburetter through the starting device

1

2.34

5

27

26.

25,

24.

23.

22

1617

8

21

209

_6

.4

7

.8

10 19 1817

16 1595

1011

1213

14.

FIG 2 :14 Diagrammatic section views of 26.OC Weber carburetter

Key to Fig 2:14 1 Fuel inlet connection 2 Filter gauze 3 Filter inspection plug 4 Air corrector jet

5 Air intake 6 Idle speed jet holder 7 Idle airduct 8 Emulsion tube 9 Secondary venturi 10 Idle mixture duct

11 Primary venturi 12 Progression hole 13 Idle orifice to duct 14 Idle mixture adjustment screw 15 Throttle

16 B o w l - t o - w e l l duct 17 Emulsion tube housing well 18 Well-to-idle jet duct 19 Idle speed jet 20 Nozzle

21 Emulsion orifices 22 Main jet 23 Bowl 24 Float 25 Float pivot 26 Valve needle 27 Needle valve

When the starting device is not in operation valve 30

covers the hole 29 so preventing the passage of mixture as

shown in diagram 'C (FIG 2:13).

Engine starting:

So that full advantage may be taken of the progressive

action starting device the engine should be started as

follows:

1 Cold starts. The starting device should be moved

across to position 'A' as shown in FIG 2:13. Once the

engine has fired push the control in partially.

42

2 Warm starts. Only partially move the starting device

to position ' B ' as shown in FIG 2:13.

3 Engine warm-up. As the engine begins to warm up to

its normal operating temperature. Gradually push home

the starting device lever so as only to supply the engine

with the richened charge enabling the cold engine.

operation to be smooth and regular. Position ' B ' s h o w n

in FIG 2:13.

4 Normal car driving. Once the engine has reached its

normal operating temperature the starting device

should be completely brought out of operation by

bringing the control lever to the position C shown in

FIG 2:13. Key t o Fig 2 : 1 3

23 Bowl 28 Starting mixture duct

29 Starting mixture duct30 Starting valve

34 Emulsion air orifices

38 Starting air corrector screw

C Choke disengaged B Choke partially inserted 37 Starting jet33 Bowden fixing screw

A Choke fully inserted 36 Starting reserve well 32 Starting device control wire 31 Starting device control lever

35 Bowl-to-starting jet duct

39 Reserve well emulsion air slot

Page 36 of 128

1

14,5

7,52 9 48 35

76

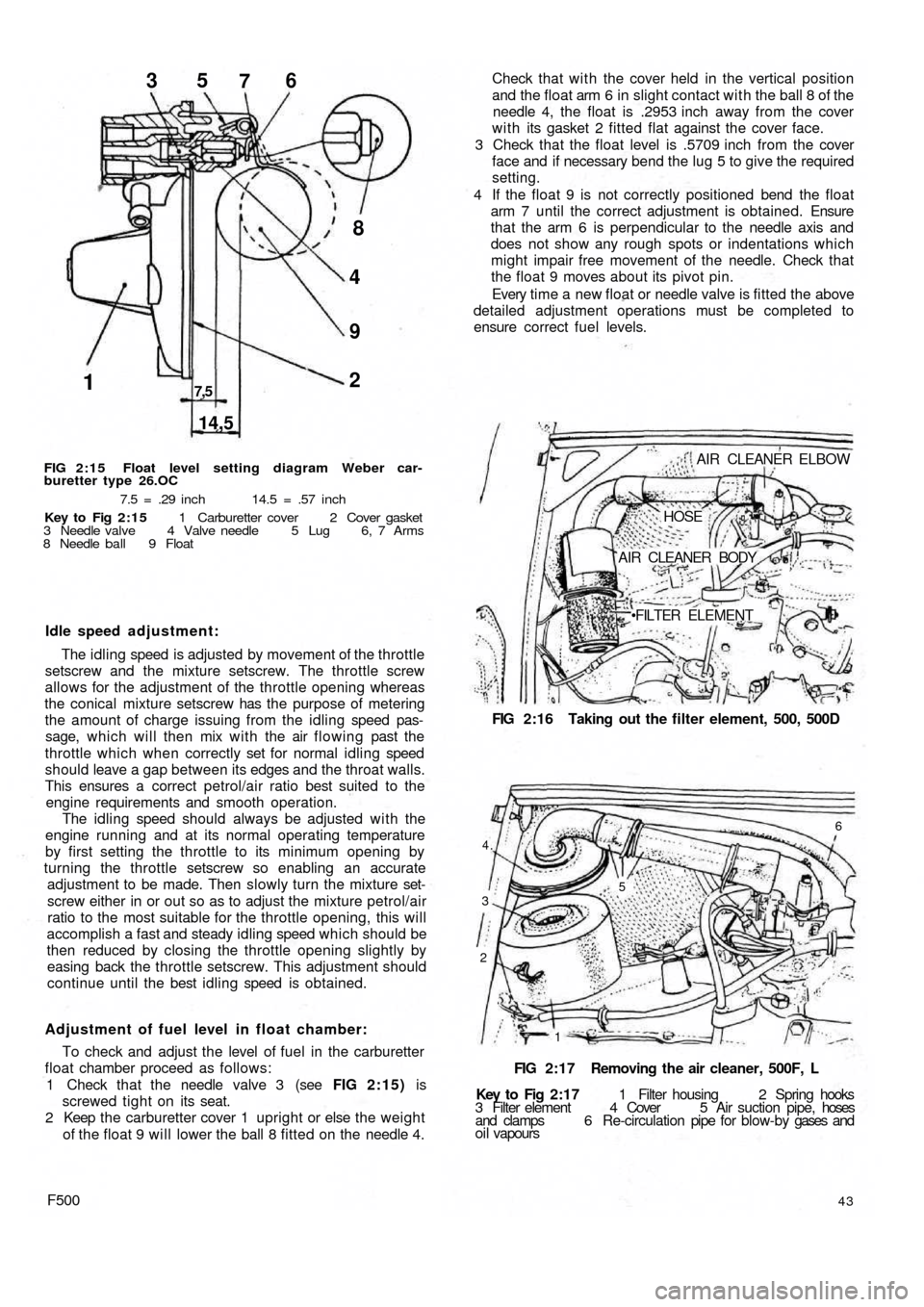

FIG 2:15 Float level setting diagram Weber car-

buretter type 26.OC

7.5 = .29 inch 14.5 = .57 inch

Key to Fig 2:15 1 Carburetter cover 2 Cover gasket

3 Needle valve 4 Valve needle 5 Lug 6, 7 Arms

8 Needle ball 9 Float

Idle speed adjustment:

The idling speed is adjusted by movement of the throttle

setscrew and the mixture setscrew. The throttle screw

allows for the adjustment of the throttle opening whereas

the conical mixture setscrew has the purpose of metering

the amount of charge issuing from the idling speed pas-

sage, which will then mix with the air flowing past the

throttle which when correctly set for normal idling speed

should leave a gap between its edges and the throat walls.

This ensures a correct petrol/air ratio best suited to the

engine requirements and smooth operation.

The idling speed should always be adjusted with the

engine running and at its normal operating temperature

by first setting the throttle to its minimum opening by

turning the throttle setscrew so enabling an accurate

adjustment to be made. Then slowly turn the mixture set-

screw either in or out so as to adjust the mixture petrol/air

ratio to the most suitable for the throttle opening, this will

accomplish a fast and steady idling speed which should be

then reduced by closing the throttle opening slightly by

easing back the throttle setscrew. This adjustment should

continue until the best idling speed is obtained.

Adjustment of fuel level in float chamber:

To check and adjust the level of fuel in the carburetter

float chamber proceed as follows:

1 Check that the needle valve 3 (see FIG 2:15) is

screwed tight on its seat.

2 Keep the carburetter cover 1 upright or else the weight

of the float 9 will lower the ball 8 fitted on the needle 4.

F50043

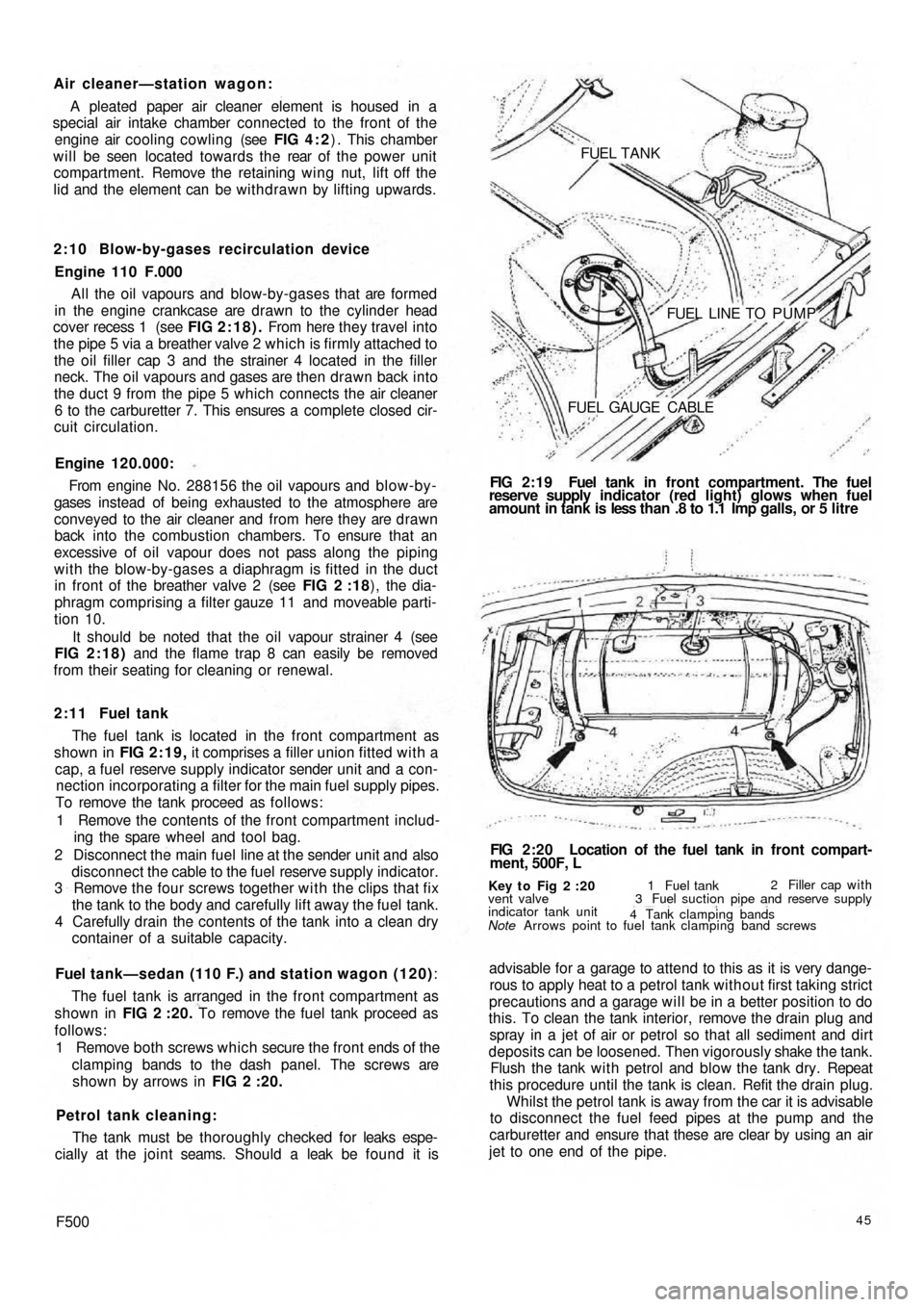

Key to Fig 2:17 1 Filter housing 2 Spring hooks

3 Filter element 4 Cover 5 Air suction pipe, hoses

and clamps 6 Re-circulation pipe for blow-by gases and

oil vapoursFIG 2:17 Removing the air cleaner, 500F, L

2

1 3

4.

6

5

FIG 2:16 Taking out the filter element, 500, 500D AIR CLEANER ELBOW

HOSE

AIR CLEANER BODY

FILTER ELEMENT Check that with the cover held in the vertical position

and the float arm 6 in slight contact with the ball 8 of the

needle 4, the float is .2953 inch away from the cover

w i t h its gasket 2 fitted flat against the cover face.

3 Check that the float level is .5709 inch from the cover

face and if necessary bend the lug 5 to give the required

setting.

4 If the float 9 is not correctly positioned bend the float

arm 7 until the correct adjustment is obtained. Ensure

that the arm 6 is perpendicular to the needle axis and

does not show any rough spots or indentations which

might impair free movement of the needle. Check that

the float 9 moves about its pivot pin.

Every time a new float or needle valve is fitted the above

detailed adjustment operations must be completed to

ensure correct fuel levels.

Page 38 of 128

Air cleaner—station wagon:

A pleated paper air cleaner element is housed in a

special air intake chamber connected to the front of the

engine air cooling cowling (see FIG 4 : 2) . This chamber

will be seen located towards the rear of t h e power unit

compartment. Remove the retaining wing nut, lift off the

lid and the element can be withdrawn by lifting upwards.

2:10 Blow-by-gases recirculation device

Engine 110 F.000

All the oil vapours and blow-by-gases that are formed

in the engine crankcase are drawn to the cylinder head

cover recess 1 (see FIG 2:18). From here they travel into

the pipe 5 via a breather valve 2 which is firmly attached to

the oil filler cap 3 and the strainer 4 located in the filler

neck. The oil vapours and gases are then d r a w n back into

the duct 9 from the pipe 5 which connects the air cleaner

6 to the carburetter 7. This ensures a complete closed cir-

cuit circulation.

Engine 120.000:

From engine No. 288156 the oil vapours and blow-by-

gases instead of being exhausted to the atmosphere are

conveyed to the air cleaner and from here they are drawn

back into the combustion chambers. To ensure that an

excessive of oil vapour does not pass along the piping

with the blow-by-gases a diaphragm is fitted in the duct

in front of the breather valve 2 (see FIG 2 :18), the dia-

phragm comprising a filter gauze 11 and moveable parti-

tion 10.

It should be noted that the oil vapour strainer 4 (see

FIG 2:18) and the flame trap 8 can easily be removed

from their seating for cleaning or renewal.

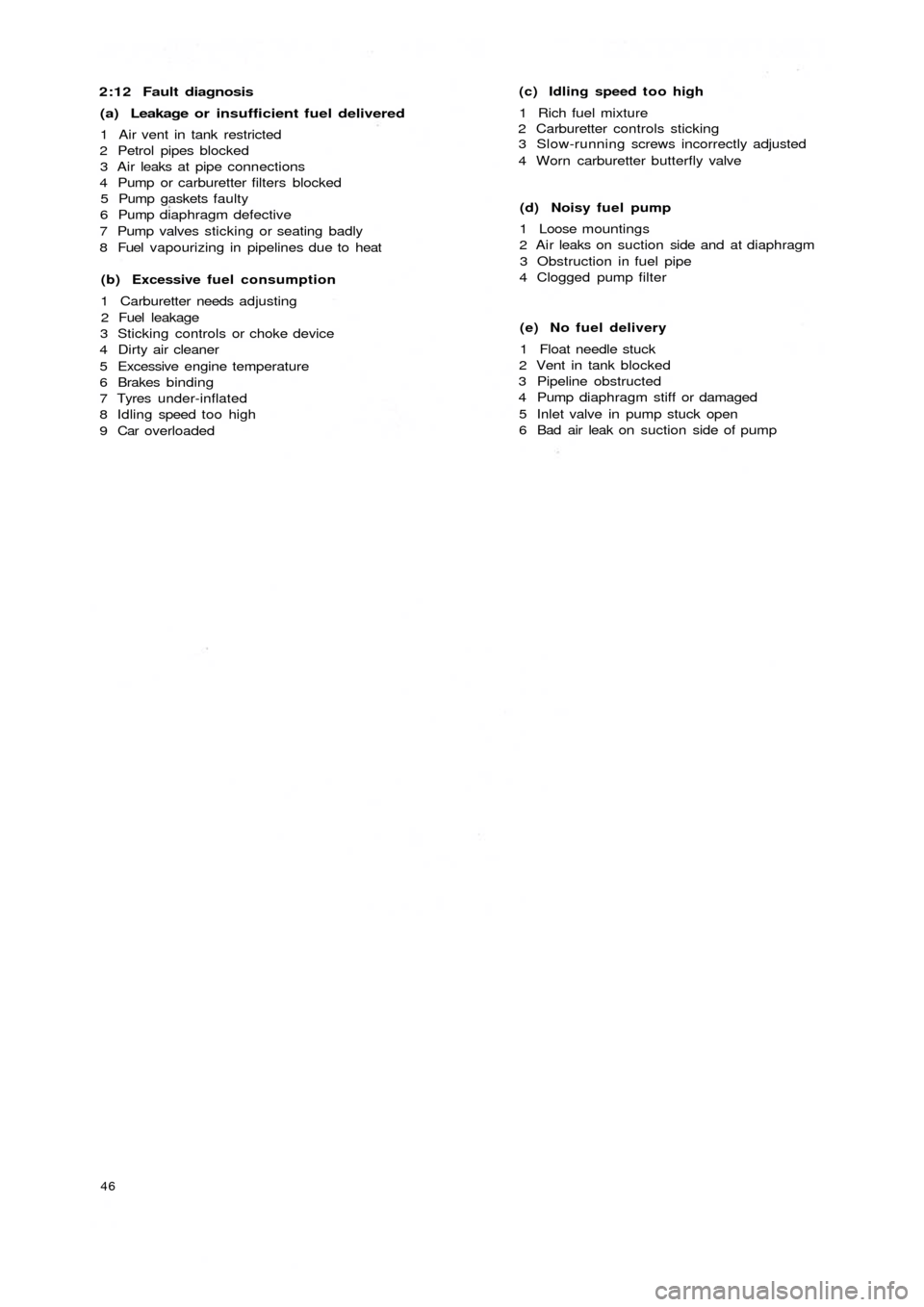

2 : 1 1 Fuel tank

The fuel tank is located in the front compartment as

shown in FIG 2:19, it comprises a filler union fitted with a

cap, a fuel reserve supply indicator sender unit and a con-

nection incorporating a filter for the main fuel supply pipes.

To remove the tank proceed as follows:

1 Remove the contents of the front compartment includ-

ing the spare wheel and tool bag.

2 Disconnect the main fuel line at the sender unit and also

disconnect the cable to the fuel reserve supply indicator.

3 Remove the four screws together w i t h the clips that fix

the tank to the body and carefully lift away the fuel tank.

4 Carefully drain the contents of the tank into a clean dry

container of a suitable capacity.

Fuel tank—sedan (110 F.) and station wagon (120):

The fuel tank is arranged in the front compartment as

shown in FIG 2 :20. To remove the fuel tank proceed as

follows:

1 Remove both screws which secure the front ends of the

clamping bands to the dash panel. The screws are

shown by arrows in FIG 2 :20.

Petrol tank cleaning:

The tank must be thoroughly checked for leaks espe-

cially at the joint seams. Should a leak be found it is

F50045

advisable for a garage to attend to this as it is very dange-

rous to apply heat to a petrol tank without first taking strict

precautions and a garage will be in a better position to do

this. To clean the tank interior, remove the drain plug and

spray in a jet of air or petrol so that all sediment and dirt

deposits can be loosened. Then vigorously shake the tank.

Flush the tank w i t h petrol and blow the tank dry. Repeat

this procedure until the tank is clean. Refit the drain plug.

Whilst the petrol tank is away from the car it is advisable

to disconnect the fuel feed pipes at the pump and the

carburetter and ensure that these are clear by using an air

jet to one end of the pipe.

Key t o Fig 2 :20

Note Arrows point to fuel tank clamping band screws vent valve

indicator tank unit1 Fuel tank2 Filler cap with

3 Fuel suction pipe and reserve supply

4 Tank clamping bands

FIG 2:20 Location of the fuel tank in front compart-

ment, 500F, L FIG 2:19 Fuel tank in front compartment. The fuel

reserve supply indicator (red light) glows when fuel

amount in tank is less than .8 to 1.1 Imp galls, or 5 litre FUEL TANK

FUEL LINE TO PUMP

FUEL GAUGE CABLE

Page 39 of 128

2:12 Fault diagnosis

(a) Leakage or insufficient fuel delivered

1 Air vent in tank restricted

2 Petrol pipes blocked

3 Air leaks at pipe connections

4 Pump or carburetter filters blocked

5 Pump gaskets faulty

6 Pump diaphragm defective

7 Pump valves sticking or seating badly

8 Fuel vapourizing in pipelines due to heat

(b) Excessive fuel consumption

1 Carburetter needs adjusting

2 Fuel leakage

3 Sticking controls or choke device

4 Dirty air cleaner

5 Excessive engine temperature

6 Brakes binding

7 Tyres under-inflated

8 Idling speed too high

9 Car overloaded(c) Idling speed too high

1 Rich fuel mixture

2 Carburetter controls sticking

3 Slow-running screws incorrectly adjusted

4 Worn carburetter butterfly valve

(d) Noisy fuel pump

1 Loose mountings

2 Air leaks on suction side and at diaphragm

3 Obstruction in fuel pipe

4 Clogged pump filter

(e) No fuel delivery

1 Float needle stuck

2 Vent in tank blocked

3 Pipeline obstructed

4 Pump diaphragm stiff or damaged

5 Inlet valve in pump stuck open

6 Bad air leak on suction side of pump

46

Page 102 of 128

10:9 Brake fluid reservoir

The reservoir is located in the front compartment to the

side of the fuel tank as shown in FIG 10:9. Should it be

necessary to detach the fluid outlet line from the reservoir

the outlet hole must be blanked off using a tapered

wooden peg of suitable length so that the cap may be

replaced to prevent the ingress of foreign matter into

the reservoir and the absorbtion of moisture, oil or petrol

vapours which would alter the properties of the hydraulic

fluid.

A special filter is fitted into the top of the reservoir

through which all fluid used for topping-up the reservoir

must pass to ensure utmost inner cleanliness of the

hydraulic system.

10:10 Bleeding the system

This is not a routine maintenance operation and is only

necessary if air has entered the hydraulic system because

parts have been dismantled or because the f l u i d level in

the reservoir has dropped so low that air has been drawn

into the main feed pipe to the master cylinders.

1 Fill the reservoir w i t h Fiat 'Blue Label' hydraulic fluid.

During the bleeding operation fluid will be used and

constant topping-up of the supply reservoir will be

needed. If this is not done it is possible for air to enter

the master cylinder main feed pipe which will nullify

the operation and necessitate a fresh start.

2 Attach a length of rubber or plastic tubing to the

bleeder screw on the rear wheel cylinder furthermost

from the master cylinder. Immerse the free end of the

tube in a small volume of hydraulic brake fluid in a

clean jar.

3 Open the bleed screw one turn and get a second

operator to press down slowly on the brake pedal. After

a full stroke let the pedal return without assistance,

pause a moment and repeat the d o w n stroke. At first

there will be air bubbles issuing from the bleed tube,

but when fluid alone is ejected, hold the pedal firmly

down on the floor panel and tighten the bleed screw.

Repeat this operation on the other rear brake and then

repeat the operation on the two front brakes.

4 On completion, top-up the fluid in the reservoir to the

correct level. Discard all dirty fluid. If fluid is perfectly

clean, let it stand for twenty four hours to become

clear of air bubbles before using it again.

10:11 Hand parking brake

Normally with the new 500 Sedan model automatic

brake adjusting device, adjustment of the rear brakes

will take up excessive handbrake travel.

If there is excessive travel on the handbrake of the

Sedan model at any time, or in the case of Station Wagon

model even after the rear brakes have been manually

adjusted, suspect worn brake shoe linings or stretched

handbrake cables. Examine the linings and fit replace-

ment shoes if necessary. Check the action of the hand

parking brake again and if there is still too much travel

before the brakes are applied it is permissible to take up as

follows:

1 It is essential to ensure that the rear shoes are correctly

adjusted as described in Section 10:2.

2 Apply the hand parking brake lever until the pawl

engages with the ratchet at the second notch.

F500

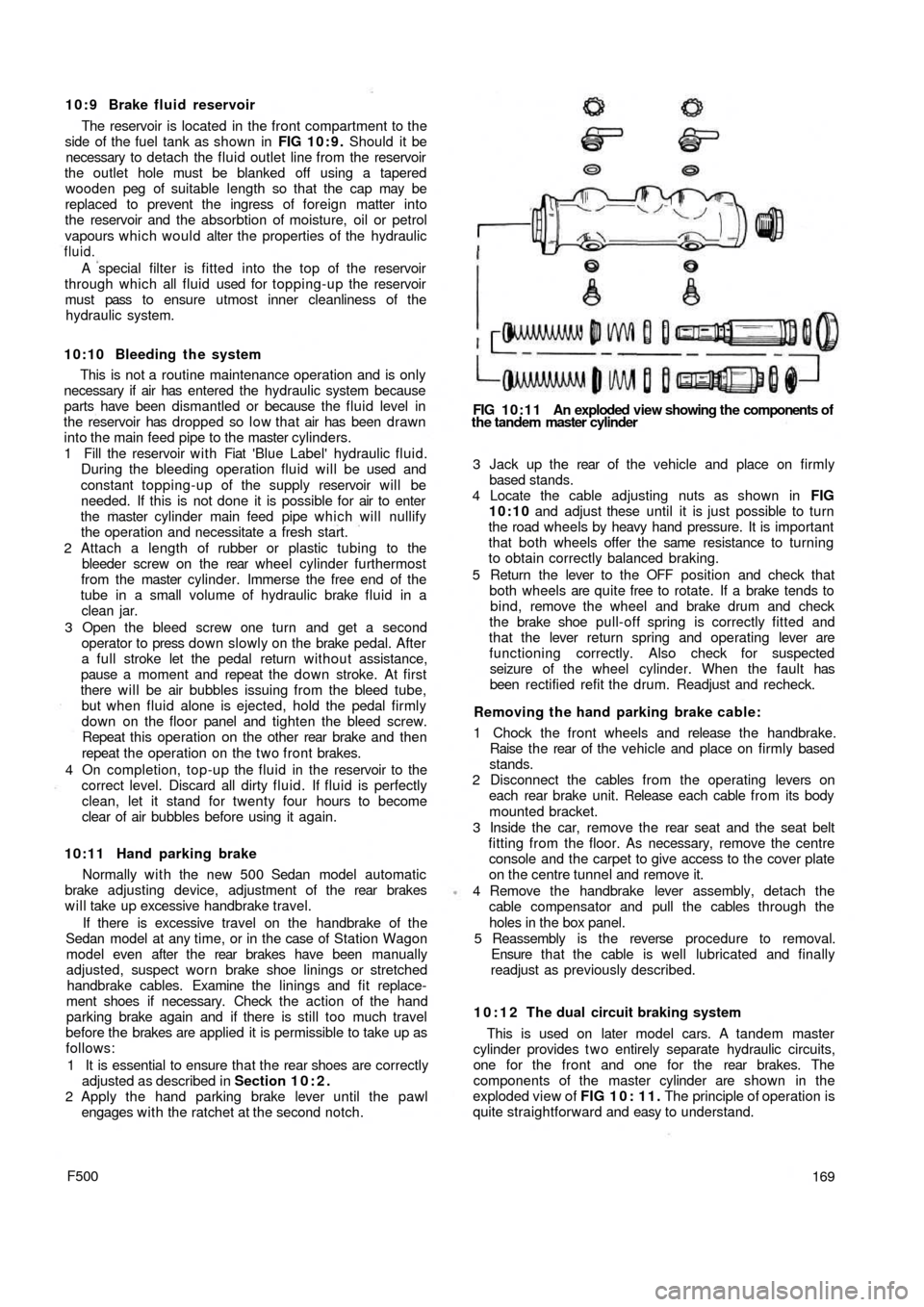

FIG 10:11 An exploded view showing the components of

the tandem master cylinder

3 Jack up the rear of t h e vehicle and place on firmly

based stands.

4 Locate the cable adjusting nuts as shown in FIG

10:10 and adjust these until it is just possible to turn

the road wheels by heavy hand pressure. It is important

that both wheels offer the same resistance to turning

to obtain correctly balanced braking.

5 Return the lever to the OFF position and check that

both wheels are quite free to rotate. If a brake tends to

bind, remove the wheel and brake drum and check

the brake shoe pull-off spring is correctly fitted and

that the lever return spring and operating lever are

functioning correctly. Also check for suspected

seizure of the wheel cylinder. When the fault has

been rectified refit the drum. Readjust and recheck.

Removing the hand parking brake cable:

1 Chock the front wheels and release the handbrake.

Raise t h e rear of the vehicle and place on firmly based

stands.

2 Disconnect the cables from the operating levers on

each rear brake unit. Release each cable from its body

mounted bracket.

3 Inside the car, remove the rear seat and the seat belt

fitting from the floor. As necessary, remove the centre

console and the carpet to give access to the cover plate

on the centre tunnel and remove it.

4 Remove the handbrake lever assembly, detach the

cable compensator and pull the cables through the

holes in the box panel.

5 Reassembly is the reverse procedure to removal.

Ensure t h a t the cable is well lubricated and finally

readjust as previously described.

10:12 The dual circuit braking system

This is used on later model cars. A tandem master

cylinder provides t w o entirely separate hydraulic circuits,

one for the front and one for the rear brakes. The

components of the master cylinder are shown in the

exploded view of FIG 1 0 : 1 1 . The principle of operation is

quite straightforward and easy to understand.

169

Page 116 of 128

Lamp brilliance varies w i t h the speed of t h e car:

Check the condition of the battery. Examine the battery

connections. Make sure they are tight and renew faulty

cables.

11:10 Panel and warning lights:

All the gauges are clustered in a single instrument

mounted on the dashboard above the steering column.

Incorporated in this cluster is the parking light pilot light,

generator charge indicator, fuel reserve supply indicator,

low oil pressure indicator, and the speedometer w i t h

mileage recorder.

The parking lamp indicator glows green when the

ignition lock switch key is in either position 1 or 2 once

the toggle switch on the instrument panel has been

operated.

The generator charge indicator shows red only when

the ignition is turned on. It should be extinguished when

the generator output is sufficient for battery charge

(12.6 ± 0.2 volts) with the engine running at a speed

of 1100 rev/min and the headlights switched off.

The fuel reserve supply indicator shows red only when

the ignition is turned on and the amount of fuel in the

petrol tank has dropped to approximately .8 to 1.1

Imp. gallons.

The low oil pressure indicator shows red only when the

ignition is turned on and should be extinguished when

the oil pressure reaches 7.1 to 21.3 Ib/sq in, and opens

the sending unit contacts. Once the engine is at normal

operating temperature but at a speed below 1000 rev/

min the indicator might light up even the pressure is under

control and with normal operation.

All the bulbs fitted to the above described units are of

the tubular 2.5W type and to renew a bulb extract the

bulb holder from the rear of t h e instrument cluster and

release the bulb which is attached by a normal bayonet

coupling.

Fuel reserve supply indicator sender u n i t:

The fuel reserve supply indicator should be checked for

correct indication by allowing the fuel tank to empty and

then inserting .8 to 1.1 Imp. gallons at which stage the

light should extinguish. Any failure to do so should be

checked as follows:

1 Ensure that the indicator bulb operates correctly.

2 Check for complete circuit between the sender unit and

the indicator bulb.

3 If the sender unit float bracket is distorted the bulb

will

indicate a reserve supply of fuel greater or smaller than

specified. The bracket should be adjusted to give

correct indication of fuel level.

4 The sender unit could have been inadvertantly

damaged in which case the unit must be renewed.

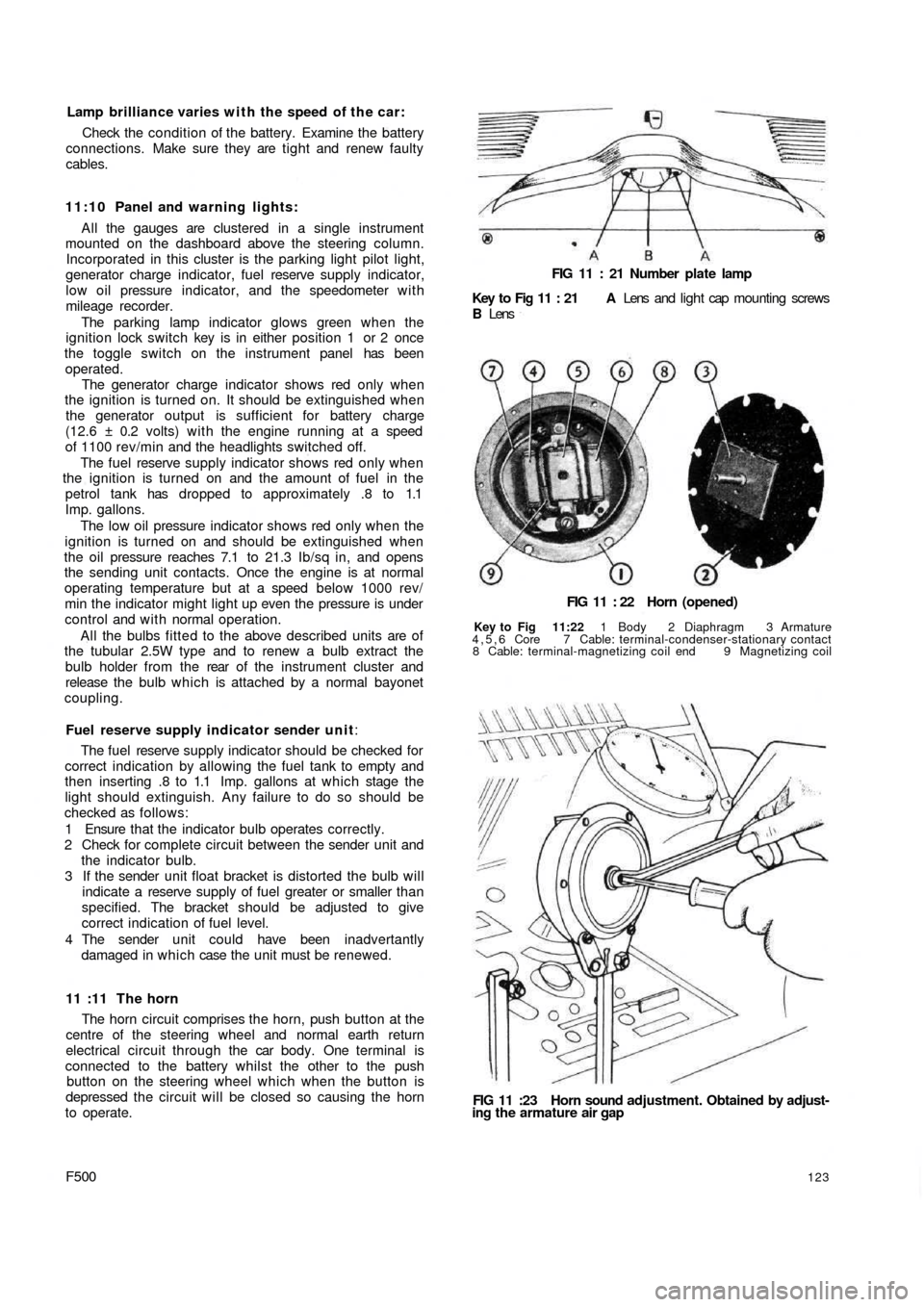

11 :11 The horn

The horn circuit comprises the horn, push button at the

centre of the steering wheel and normal earth return

electrical circuit through the car body. One terminal is

connected to the battery whilst the other to the push

button on the steering wheel which when the button is

depressed the circuit will be closed so causing the horn

to operate.

F500

FIG 11 : 21 Number plate lamp

Key to Fig 11 : 21 A Lens and light cap mounting screws

B Lens

FIG 11 : 22 Horn (opened)

Key to Fig 11:22 1 Body 2 Diaphragm 3 Armature

4,5,6 Core 7 Cable: terminal-condenser-stationary contact

8 Cable: terminal-magnetizing coil end 9 Magnetizing coil

FIG 11 :23 Horn sound adjustment. Obtained by adjust-

ing the armature air gap

123