lock FIAT 500 2017 2.G Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: 500, Model: FIAT 500 2017 2.GPages: 350, PDF Size: 3.01 MB

Page 249 of 350

HAZARD WARNING FLASHERS

The Hazard Warning flasher switch is located on the

instrument panel below the radio.Push the switch to turn on the Hazard Warning

flashers. When the switch is activated, all direc-

tional turn signals will flash on and off to warn oncom-

ing traffic of an emergency. Push the switch a second

time to turn off the Hazard Warning flashers.

Do not use this emergency warning system when the

vehicle is in motion. Use it when your vehicle is

disabled and it is creating a safety hazard for other

motorists.

If it is necessary to leave the vehicle to go for service, the

Hazard Warning flashers will continue to operate with

the ignition key removed and the vehicle locked.

NOTE: With extended use, the Hazard Warning flash-

ers may wear down your battery.

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can reduce the

potential for overheating by taking the appropriate action.

• On the highways — slow down. •

In city traffic — while stopped, place the transmis-

sion in NEUTRAL, but do not increase engine idle

speed.

NOTE: There are steps that you can take to slow down

an impending overheat condition:

• If your air conditioner (A/C) is on, turn it off. The

A/C system adds heat to the engine cooling system

and turning the A/C off can help remove this heat.

• You can also turn the temperature control to maxi-

mum heat, the mode control to floor and the blower

control to high. This allows the heater core to act as a

supplement to the radiator and aids in removing heat

from the engine cooling system.

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator. If

you see or hear steam coming from under the hood,

do not open the hood until the radiator has had time

to cool. Never try to open a cooling system pressure

cap when the radiator or coolant bottle is hot.

6

WHAT TO DO IN EMERGENCIES 247

Page 258 of 350

5. Position the new Sealant Bottle (1) in the housing sothat the Sealant Hose (6) aligns with the hose slot in

the front of the housing. Push the bottle into the

housing. An audible click will be heard indicating

the bottle is locked into place.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (6) and return the hose to its

storage area (located on the bottom of the air pump).

7. Return the Tire Service Kit to its storage location in the vehicle.

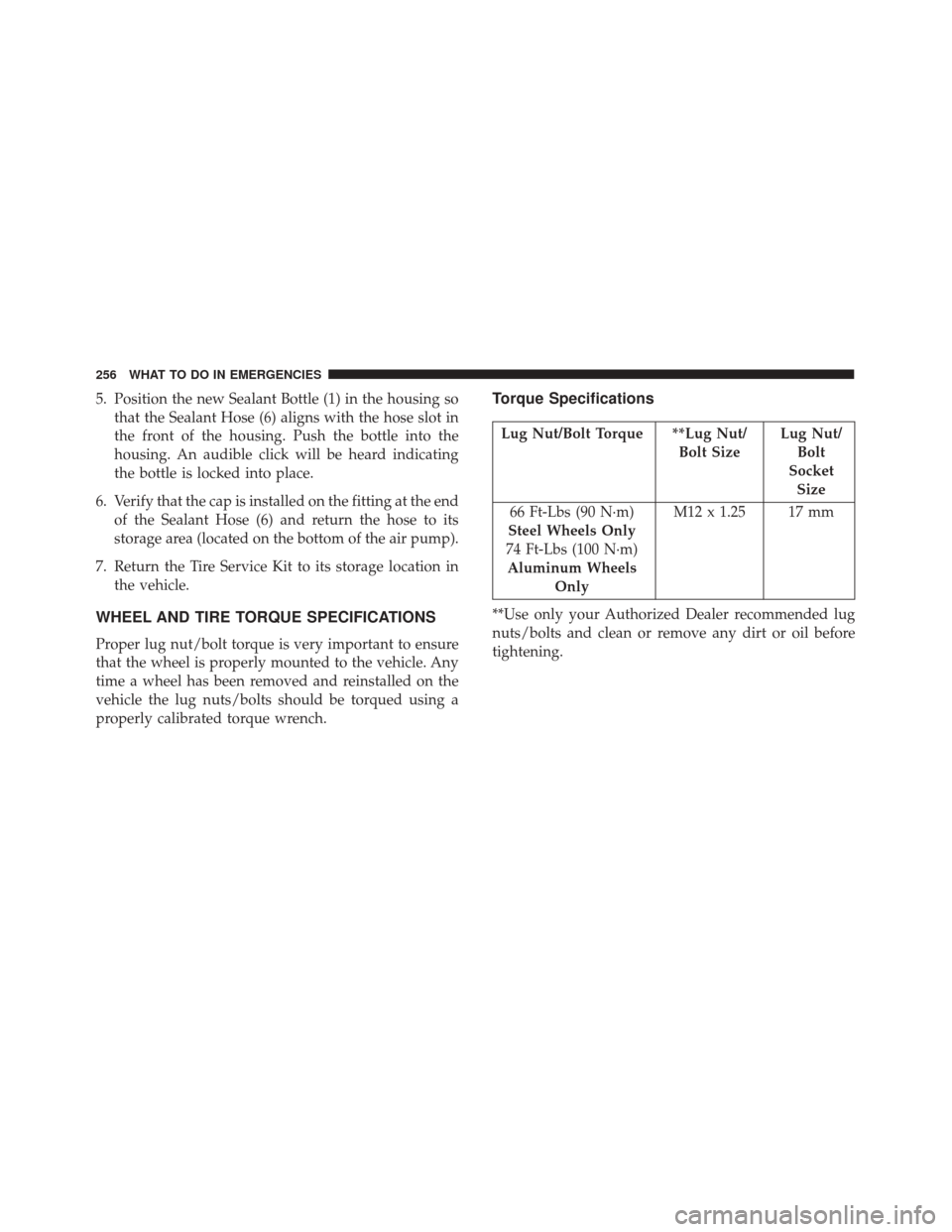

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure

that the wheel is properly mounted to the vehicle. Any

time a wheel has been removed and reinstalled on the

vehicle the lug nuts/bolts should be torqued using a

properly calibrated torque wrench.

Torque Specifications

Lug Nut/Bolt Torque **Lug Nut/ Bolt SizeLug Nut/

Bolt

Socket Size

66 Ft-Lbs (90 N·m)

Steel Wheels Only

74 Ft-Lbs (100 N·m) Aluminum Wheels Only M12 x 1.25 17 mm

**Use only your Authorized Dealer recommended lug

nuts/bolts and clean or remove any dirt or oil before

tightening.

256 WHAT TO DO IN EMERGENCIES

Page 261 of 350

Spare Tire Removal

The spare tire is stowed to the underbody below the

cargo area.

1. Remove the plug located in the rear cargo area.

2. Fit the wrench tool over the drive nut. Use thewrench to rotate the nut counterclockwise until the

spare is on the ground with enough slack in the cable

to allow you to pull the tire out from under the

vehicle.

CAUTION!

The winch mechanism is designed for use with the

jack wrench tool only. Use of an air wrench or other

power tools is not recommended and they can

damage the winch.

Winch Access Plug

Lowering/Raising Spare Tire

6

WHAT TO DO IN EMERGENCIES 259

Page 263 of 350

Preparations For Jacking

1. Park the vehicle on a firm level surface, avoiding iceor slippery areas.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic, pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

2. Turn on the Hazard Warning flashers.

3. Set the parking brake.

4. Place the gear selector in PARK (automatic transmis- sion) or REVERSE (manual transmission).

5. Turn Off the ignition.

6. Block both the front and rear of the wheel diagonally opposite of the jacking position. For example, if

changing the right front tire, block the left rear wheel.

NOTE:Passengers should not remain in

the vehicle while the vehicle is being

jacked.

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

• Always park on a firm, level surface as far from

the edge of the roadway as possible before raising

the vehicle.

• Turn on the Hazard Warning flashers.

• Block the wheel diagonally opposite the wheel to

be raised.

• Set the parking brake firmly and set an automatic

transmission in PARK; a manual transmission in

REVERSE.

• Never start or run the engine with the vehicle on

a jack.

• Do not let anyone sit in the vehicle when it is on

a jack.

• Do not get under the vehicle when it is on a jack.

If you need to get under a raised vehicle, take it to

a service center where it can be raised on a lift.

(Continued)

6

WHAT TO DO IN EMERGENCIES 261

Page 269 of 350

3. Lower the vehicle to the ground by turning the jackhandle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Refer to “Torque Specifications” in this

section for correct wheel bolt torque.

5. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that all wheel bolts

are properly seated against the wheel.

6. Align the valve notch in the wheel cover with the valve stem on the wheel. Install the cover by hand.

Do not use a hammer or excessive force to install the

cover.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the coneshaped end of the nut toward the wheel. Lightly

tighten the wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not fully tighten the lug nuts until the vehicle

has been lowered. Failure to follow this warning

may result in serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Refer to “Torque Specifications” in this

section for correct wheel bolt torque.

5. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that all wheel bolts

are properly seated against the wheel.

6

WHAT TO DO IN EMERGENCIES 267

Page 270 of 350

Spare Tire Stowage

Reverse instructions of the spare removal section.

Rotate the jack wrench tool on the winch drive nut

clockwise until effort becomes heavy and an audible

click is heard indicating the spare is properly stowed.

CAUTION!

The winch mechanism is designed for use with the

jack wrench extension tool only. Use of air wrench

or power tool may damage the winch.

JUMP-STARTING PROCEDURE

If your vehicle has a discharged battery, it can be

jump-started using a set of jumper cables and a battery

in another vehicle or by using a portable battery booster

pack. Jump-starting can be dangerous if done improp-

erly so please follow the procedures in this section

carefully.NOTE:

When using a portable battery booster pack,

follow the manufacturer ’s operating instructions and

precautions.

WARNING!

Do not attempt jump-starting if the battery is fro-

zen. It could rupture or explode and cause personal

injury.

CAUTION!

Do not use a portable battery booster pack or any

other booster source with a system voltage greater

than 12 Volts or damage to the battery, starter motor,

alternator or electrical system may occur.

268 WHAT TO DO IN EMERGENCIES

Page 271 of 350

Preparations For Jump-Start

The battery in your vehicle is located between the left

front headlight assembly and the left front wheel splash

shield.

WARNING!

•Take care to avoid the radiator cooling fan when-

ever the hood is raised. It can start anytime the

ignition switch is ON. You can be injured by

moving fan blades.

• Remove any metal jewelry such as rings, watch

bands and bracelets that could make an inadver-

tent electrical contact. You could be seriously

injured.

• Batteries contain sulfuric acid that can burn your

skin or eyes and generate hydrogen gas which is

flammable and explosive. Keep open flames or

sparks away from the battery.

1. Set the parking brake, shift the automatic transmis- sion into PARK and turn the ignition to LOCK.

2. Turn off the heater, radio, and all unnecessary elec- trical accessories.

3. Remove the protective cover over the positive (+)

battery post. To remove the cover, push the locking

tab and pull upward on the cover.

Battery Posts

1 — Positive (+) Post (Covered With Protective Cap)

2 — Negative (-) Post

6

WHAT TO DO IN EMERGENCIES 269

Page 293 of 350

5. Install the A/C air filter with the air filter positionindicators pointing in the same direction as removal.

CAUTION!

The cabin air filter is identified with an arrow to

indicate airflow direction through the filter. Failure

to properly install the filter will result in the need

to replace it more often.

6. Install the passenger side console closeout.

Refer to the “Maintenance Schedule” for the proper

maintenance intervals.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should

be lubricated periodically with a lithium based grease,

such as MOPAR Spray White Lube to assure quiet, easy

operation and to protect against rust and wear. Prior to

the application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit; after

lubricating excess oil and grease should be removed.

Particular attention should also be given to hood latch-

ing components to ensure proper function. When per-

forming other underhood services, the hood latch,

release mechanism and safety catch should be cleaned

and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as MOPAR

Lock Cylinder Lubricant directly into the lock cylinder.

Wiper Blades

Clean the rubber edges of the wiper blades and the

windshield and rear window periodically with a

sponge or soft cloth and a mild nonabrasive cleaner.

A/C Air Filter7

MAINTAINING YOUR VEHICLE 291

Page 313 of 350

WARNING!(Continued)

•If the replaced fuse blows again, contact an au-

thorized dealer.

• If a general protection fuse for safety systems (air

bag system, braking system), power unit systems

(engine system, gearbox system) or steering sys-

tem blows, contact an authorized dealer.

Interior Fuses

The interior fuse panel is part of the Body Control

Module (BCM) and is located on the driver’s side under

the instrument panel.

Cavity Vehicle Fuse

Number Mini Fuse

Description

1 F127.5 Amp Brown Right Low Beam

2 F325 Amp Tan Front and Rear Ceiling Lights Trunk and

Door Courtesy Lights

3 F535 Amp Tan Instrument Panel Node

4 F3820 Amp Yellow Central Door Locking

5 F3610 Amp Red Diagnostic Socket, Vehicle Radio, Climate

Control System

Fuse Panel7

MAINTAINING YOUR VEHICLE 311

Page 315 of 350

Underhood Fuses

The Front Distribution Unit is located on the right side of

the engine compartment, next to the battery. To access the

fuses, press the release tabs and remove the cover.

The ID number of the electrical component correspond-

ing to each fuse can be found on the back of the cover.

CavityMaxi Fuse Mini Fuse Description

F01 60 Amp Blue –Body Controller

F02 20 Amp Yellow –Audio Amplifier

F03 20 Amp Yellow –Ignition Switch

F04 40 Amp Orange –Anti-Lock Brake Pump

F05 70 Amp Tan –Electric Power Steering

Front Distribution Unit

7

MAINTAINING YOUR VEHICLE 313