wheel FIAT 500 ABARTH 2012 2.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2012, Model line: 500 ABARTH, Model: FIAT 500 ABARTH 2012 2.GPages: 76, PDF Size: 2.95 MB

Page 43 of 76

• If the light remains lit with the engine running, your vehicle will usually be drivable;however, see an authorized service center immediately. If the light is flashing when

the engine is running, immediate service is required and you may experience

reduced performance, an elevated/rough idle or engine stall and your vehicle may

require towing.

- Electronic Stability Control (ESC) OFF Indicator Light

• This light indicates the Electronic Stability Control system (ESC) has been turned offby the driver.

- Electronic Stability Control (ESC) Activation / Malfunction Indicator

Light

• The “ESC Activation/Malfunction Indicator Light” in the instrument cluster will come on for four seconds when the ignition switch is turned to the ON/RUN position. If the

“ESC Activation/Malfunction Indicator Light” comes on continuously with the engine

running, a malfunction has been detected in the ESC system. If this light remains on,

see your authorized dealer as soon as possible to have the problem diagnosed and

corrected.

NOTE:

• The “ESC Off Indicator Light” and the “ESC Activation/Malfunction Indicator Light” come on momentarily each time the ignition switch is turned to ON/RUN.

• Each time the ignition is turned to ON/RUN, the ESC system will be ON even if it was turned off previously.

TTC (Tire Transfer Control)

• The TTC system uses the brakes to prevent unwanted wheelspin during corning, tomaximize acceleration and minimize understeer during aggressive driving. This

feature is active in all modes. While TTC is active, the “ESC” lamp in the instrument

cluster may flash

- Tire Pressure Monitoring System (TPMS) Light

• Each tire, should be checked monthly, when cold and inflated to the inflationpressure recommended by the vehicle manufacturer on the vehicle placard or tire

inflation pressure label. (If your vehicle has tires of a different size than the size

indicated on the vehicle placard or tire inflation pressure label, you should determine

the proper tire inflation pressure for those tires.)

• As an added safety feature, your vehicle has been equipped with a Tire Pressure Monitoring System (TPMS) that illuminates a low tire pressure telltale when one or

more of your tires is significantly under-inflated. Accordingly, when the low tire

pressure telltale illuminates, you should stop and check your tires as soon as

possible, and inflate them to the proper pressure. Driving on a significantly

under-inflated tire causes the tire to overheat and can lead to tire failure.

Under-inflation also reduces fuel efficiency and tire tread life, and may affect the

vehicle’s handling and stopping ability.

WHAT TO DO IN EMERGENCIES

41

Page 44 of 76

•IF THE LIGHT STARTS FLASHING INDICATING A LOW TIRE PRESSURE,

ADJUST THE AIR PRESSURE IN THE LOW TIRE TO THE AIR PRESSURE

SHOWN ON THE VEHICLE PLACARD OR TIRE INFLATION PRESSURE

LABEL LOCATED ON THE DRIVER'S DOOR. NOTE: AFTER INFLATION,

THE VEHICLE MAY NEED TO BE DRIVEN FOR 20 MINUTES BEFORE THE

FLASHING LIGHT WILL TURN OFF.

• Please note that the TPMS is not a substitute for proper tire maintenance, and it is the driver’s responsibility to maintain correct tire pressure, even if under-inflation has

not reached the level to trigger illumination of the TPMS low tire pressure telltale.

• Your vehicle has also been equipped with a TPMS malfunction indicator to indicate when the system is not operating properly. The TPMS malfunction indicator is

combined with the low tire pressure telltale. When the system detects a malfunction,

the telltale will flash for approximately one minute and then remain continuously

illuminated. This sequence will continue each time the vehicle is restarted as long as

the malfunction exists.

• When the malfunction indicator is illuminated, the system may not be able to detect or signal low tire pressure as intended. TPMS malfunctions may occur for a variety

of reasons, including the installation of replacement or alternate tires or wheels on

the vehicle that prevent the TPMS from functioning properly. Always check the

TPMS malfunction telltale after replacing one or more tires or wheels on your vehicle,

to ensure that the replacement or alternate tires and wheels allow the TPMS to

continue to function properly.

NOTE: Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C) of air

temperature change. Keep this in mind when checking tire pressure inside a garage,

especially in the Winter. Example: If garage temperature is 68°F (20°C) and the outside

temperature is 32°F (0°C), then the cold tire inflation pressure should be increased by

3 psi (21 kPa), which equals 1 psi (7 kPa) for every 12°F (7°C) for this outside

temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels. TPMS

pressures and warning have been established for the tire size equipped on your

vehicle. Undesirable system operation or sensor damage may result when using

replacement equipment that is not of the same size, type, and/or style.

Aftermarket wheels can cause sensor damage. Do not use tire sealant from a

can, or balance beads if your vehicle is equipped with a TPMS, as damage to the

sensors may result.

BRAKE- Brake Warning Light

• The Brake Warning light illuminates when there is either a system malfunction or the parking brake is applied. If the light is on and the parking brake is not applied, it

indicates a possible brake hydraulic malfunction, brake booster problem or an

Anti-Lock Brake System problem.

• Please have your vehicle serviced immediately.

WHAT TO DO IN EMERGENCIES

42

Page 47 of 76

TIREFIT Kit Components And Operation

1. Sealant Bottle

2. Deflation Button

3. Pressure Gauge

4. Power Button

5. Mode Select Knob

6. Sealant Hose (Clear)

7. Air Pump Hose (Black)

8. Power Plug

Using The Mode Select Knob And Hoses • Your TIREFIT kit is equipped with the following symbols to indicate the air or sealant mode.

Selecting Air Mode

• Turn the Mode Select Knob (5) to this position for air pump operation only. Use the Black Air Pump Hose (7) when selecting this mode.

Selecting Sealant Mode

• Turn the Mode Select Knob (5) to this position to inject the TIREFIT Sealant and to inflate the tire. Use the Sealant Hose (clear hose) (6) when selecting this mode.

Using The Power Button

• Push and release the Power Button (4) once to turn On the TIREFIT kit. Push and release the Power Button (4) again to turn Off the TIREFIT kit.

Using The Deflation Button

• Press the Deflation Button (2) to reduce the air pressure in the tire if it becomes over-inflated.

TIREFIT Usage Precautions

• Replace the TIREFIT Sealant Bottle (1) and Sealant Hose (6) prior to the expirationdate (printed on the bottle label) to assure optimum operation of the system. Refer

to “Sealing a Tire with TIREFIT” section (F) “Sealant Bottle and Hose Replacement”.

• The Sealant Bottle (1) and Sealant Hose (6) are a one tire application use. After each use, always replace these components immediately at an authorized dealer.

• When the TIREFIT sealant is in a liquid form, clean water, and a damp cloth will remove the material from the vehicle or tire and wheel components. Once the

sealant dries, it can easily be peeled off and properly discarded.

• For optimum performance, make sure the valve stem on the wheel is free of debris before connecting the TIREFIT kit.

WHAT TO DO IN EMERGENCIES

45

Page 48 of 76

• You can use the TIREFIT air pump to inflate bicycle tires. The kit also comes withtwo needles, located in the Accessory Storage Compartment (on the bottom of the

air pump) for inflating sport balls, rafts, or similar inflatable items. However, use only

the Air Pump Hose (7) and make sure the Mode Select Knob (5) is in the Air Mode

when inflating such items to avoid injecting sealant into them. The TIREFIT Sealant is

only intended to seal punctures less than

14in (6 mm) diameter in the tread of your

vehicle.

• Do not lift or carry the TIREFIT kit by the hoses.

Sealing A Tire With TIREFIT

(A) Whenever You Stop To Use TIREFIT:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the ground. This will allow the TIREFIT Hoses (6) and (7) to reach the valve

stem and keep the TIREFIT kit flat on the ground. This will provide the best

positioning of the kit when injecting the sealant into the deflated tire and running the

air pump. Move the vehicle as necessary to place the valve stem in this position

before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission) and turn Off the ignition.

4. Set the parking brake.

(B) Setting Up To Use TIREFIT: 1. Turn the Mode Select Knob (5) to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of the hose.

3. Place the TIREFIT kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose (6) onto the valve stem.

5. Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE: Do not remove foreign objects (e.g., screws or nails) from the tire.

(C) Injecting TIREFIT Sealant Into The Deflated Tire: • Always start the engine before turning ON the TIREFIT kit.

NOTE: Manual transmission vehicles must have the parking brake engaged and the

shift lever in NEUTRAL.

• After pressing the Power Button (4), the sealant (white fluid) will flow from the SealantBottle (1) through the Sealant Hose (6) and into the tire.

NOTE: Sealant may leak out through the puncture in the tire.

WHAT TO DO IN EMERGENCIES

46

Page 51 of 76

CAUTION!

• The metal end fitting from Power Plug (8) may get hot after use, so it should behandled carefully.

• Failure to reinstall the cap on the fitting at the end of the Sealant Hose (6) can result in sealant contacting your skin, clothing, and the vehicle’s interior. It can

also result in sealant contacting internal TIREFIT kit components which may

cause permanent damage to the kit.

WARNING!

• Do not attempt to seal a tire on the side of the vehicle closest to traffic. Pull farenough off the road to avoid the danger of being hit when using the TIREFIT

kit.

• Do not use TIREFIT or drive the vehicle under the following circumstances:

− If the puncture in the tire tread is approximately 1/4 in. (6 mm) or larger.

− If the tire has any sidewall damage.

− If the tire has any damage from driving with extremely low tire pressure.

− If the tire has any damage from driving on a flat tire.

− If the wheel has any damage.

− If you are unsure of the condition of the tire or the wheel.

• Keep TIREFIT away from open flames or heat source.

• A loose TIREFIT kit thrown forward in a collision or hard stop could endanger the occupants of the vehicle. Always stow the TIREFIT kit in the place

provided. Failure to follow these warnings can result in injuries that are serious

or fatal to you, your passengers, and others around you.

• Take care not to allow the contents of TIREFIT to come in contact with hair, eyes, or clothing. TIREFIT is harmful if inhaled, swallowed, or absorbed

through the skin. It causes skin, eye, and respiratory irritation. Flush

immediately with plenty of water if there is any contact with eyes or skin.

Change clothing as soon as possible, if there is any contact with clothing.

• TIREFIT Sealant solution contains latex. In case of an allergic reaction or rash, consult a physician immediately. Keep TIREFIT out of reach of children. If

swallowed, rinse mouth immediately with plenty of water and drink plenty of

water. Do not induce vomiting! Consult a physician immediately.

• TIREFIT is not a permanent flat tire repair. Have the tire inspected and repaired or replaced after using TIREFIT. Do not exceed 55 mph (88 km/h) until the tire

is repaired or replaced. Failure to follow this warning can result in injuries that

are serious or fatal to you, your passengers, and others around you.

WHAT TO DO IN EMERGENCIES

49

Page 53 of 76

9. Disconnect the positive(+)end of the jumper cable from the positive (+)post of the

discharged vehicle.

• If frequent jump-starting is required to start your vehicle, you should have the battery and charging system inspected at your authorized dealer.

CAUTION!

• Accessories that can be plugged into the vehicle power outlets draw powerfrom the vehicle’s battery, even when not in use (i.e., cellular phones, etc.).

Eventually, if plugged in long enough, the vehicle’s battery will discharge

sufficiently to degrade battery life and/or prevent the engine from starting.

• Do not use a portable battery booster pack or any other booster source with a system voltage greater than 12 Volts or damage to the battery, starter motor,

alternator or electrical system may occur.

• Failure to follow these procedures could result in damage to the charging system of the booster vehicle or the discharged vehicle.

WARNING!

• Do not attempt jump-starting if the battery is frozen. It could rupture or explodeand cause personal injury.

• Take care to avoid the radiator cooling fan whenever the hood is raised. It can start anytime the ignition switch is ON. You can be injured by moving fan

blades.

• Remove any metal jewelry such as watch bands or bracelets that might make an inadvertent electrical contact. You could be seriously injured.

• Batteries contain sulfuric acid that can burn your skin or eyes and generate hydrogen gas which is flammable and explosive. Keep open flames or sparks

away from the battery.

• Do not allow vehicles to touch each other as this could establish a ground connection and personal injury could result.

• Failure to follow this procedure could result in personal injury or property damage due to battery explosion.

• Do not connect the cable to the negative post (-) of the discharged

battery. The resulting electrical spark could cause the battery to

explode and could result in personal injury.

TOWING A DISABLED VEHICLE

With Ignition Key

Manual Transmission

• Vehicle can be flat towed (all four wheels on the ground) with the transmission in NEUTRAL.

• Vehicle can be towed with the front wheels elevated.

WHAT TO DO IN EMERGENCIES

51

Page 54 of 76

• Vehicle can be towed on a flatbed truck (all wheels off the ground).

NOTE: If it is necessary to use the accessories while being towed (wipers, defrosters,

etc.), the key must be in the ON/RUN position. Make certain the transmission remains in

NEUTRAL.

Without The Ignition Key

• Special care must be taken when the vehicle is towed with the ignition in the OFF/LOCK position. A dolly should be used under the front wheels if the rear wheels

are raised. Proper towing equipment is necessary to prevent damage to the vehicle.

CAUTION!

• Failure to follow these towing methods can cause severe transmissiondamage. Such damage is not covered by the New Vehicle Limited Warranty.

• If the vehicle being towed requires steering, the ignition switch must be in the ON/RUN position.

• Do not attempt to use sling-type equipment when towing. When securing the vehicle to a flatbed truck, do not attach to front or rear suspension

components. Damage to your vehicle may result from improper towing.

ENHANCED ACCIDENT RESPONSE SYSTEM

• In the event of an impact causing airbag deployment, if the communication networkremains intact, and the power remains intact, depending on the nature of the event

the ORC will determine whether to have the Enhanced Accident Response System

perform the following functions:

• Cut off fuel to the engine.

• Flash hazard lights as long as the battery has power or until the ignition key is turned off.

• Turn on the interior lights, which remain on as long as the battery has power or until the ignition key is removed.

• Unlock the doors automatically.

• After the event occurs, when the system is active, the message "Fuel Cutoff See Handbook" is displayed.

• Carefully check the vehicle for fuel leaks in the engine compartment and on the ground near the engine compartment and fuel tank before resetting the system and

starting the engine.

NOTE: In order to start the engine and move the vehicle to a safe location after an

impact, the System Reset Procedure must be completed.

System Reset Procedure

• After an impact causing airbag deployment, the left and right turn signal lights, located in the instrument panel cluster, will both be blinking, until the ignition is

turned off.

• In order to move your vehicle to the side of the road you must follow the system reset procedure.

WHAT TO DO IN EMERGENCIES

52

Page 55 of 76

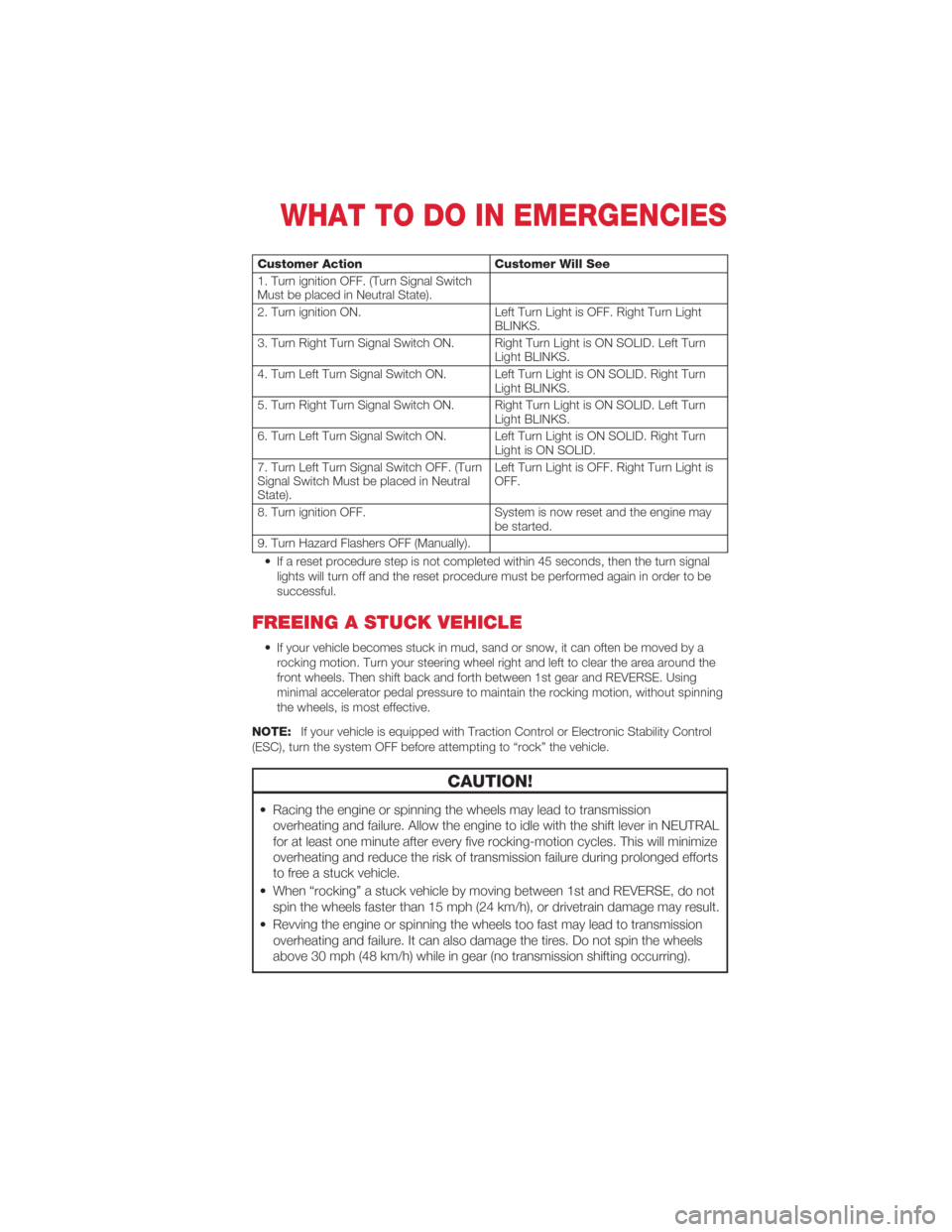

Customer ActionCustomer Will See

1. Turn ignition OFF. (Turn Signal Switch

Must be placed in Neutral State).

2. Turn ignition ON. Left Turn Light is OFF. Right Turn Light

BLINKS.

3. Turn Right Turn Signal Switch ON. Right Turn Light is ON SOLID. Left Turn Light BLINKS.

4. Turn Left Turn Signal Switch ON. Left Turn Light is ON SOLID. Right Turn Light BLINKS.

5. Turn Right Turn Signal Switch ON. Right Turn Light is ON SOLID. Left Turn Light BLINKS.

6. Turn Left Turn Signal Switch ON. Left Turn Light is ON SOLID. Right Turn Light is ON SOLID.

7. Turn Left Turn Signal Switch OFF. (Turn

Signal Switch Must be placed in Neutral

State). Left Turn Light is OFF. Right Turn Light is

OFF.

8. Turn ignition OFF. System is now reset and the engine may

be started.

9. Turn Hazard Flashers OFF (Manually).

• If a reset procedure step is not completed within 45 seconds, then the turn signal lights will turn off and the reset procedure must be performed again in order to be

successful.

FREEING A STUCK VEHICLE

• If your vehicle becomes stuck in mud, sand or snow, it can often be moved by arocking motion. Turn your steering wheel right and left to clear the area around the

front wheels. Then shift back and forth between 1st gear and REVERSE. Using

minimal accelerator pedal pressure to maintain the rocking motion, without spinning

the wheels, is most effective.

NOTE: If your vehicle is equipped with Traction Control or Electronic Stability Control

(ESC), turn the system OFF before attempting to “rock” the vehicle.

CAUTION!

• Racing the engine or spinning the wheels may lead to transmission overheating and failure. Allow the engine to idle with the shift lever in NEUTRAL

for at least one minute after every five rocking-motion cycles. This will minimize

overheating and reduce the risk of transmission failure during prolonged efforts

to free a stuck vehicle.

• When “rocking” a stuck vehicle by moving between 1st and REVERSE, do not spin the wheels faster than 15 mph (24 km/h), or drivetrain damage may result.

• Revving the engine or spinning the wheels too fast may lead to transmission overheating and failure. It can also damage the tires. Do not spin the wheels

above 30 mph (48 km/h) while in gear (no transmission shifting occurring).

WHAT TO DO IN EMERGENCIES

53

Page 56 of 76

WARNING!

Fast spinning tires can be dangerous. Forces generated by excessive wheel

speeds may cause damage, or even failure, of the axle and tires. A tire could

explode and injure someone. Do not spin your vehicle's wheels faster than

30 mph (48 km/h) or for longer than 30 seconds continuously without stopping

when you are stuck and do not let anyone near a spinning wheel, no matter what

the speed.

EVENT DATA RECORDER (EDR)

• This vehicle is equipped with an event data recorder (EDR). The main purpose of anEDR is to record, in certain crash or near crash-like situations, such as an air bag

deployment or hitting a road obstacle, data that will assist in understanding how a

vehicle’s systems performed. The EDR is designed to record data related to vehicle

dynamics and safety systems for a short period of time, typically 30 seconds or less.

The EDR in this vehicle is designed to record such data as:

• How various systems in your vehicle were operating;

• Whether or not the driver and passenger safety belts were buckled/fastened;

• How far (if at all) the driver was depressing the accelerator and/or brake pedal; and,

• How fast the vehicle was traveling.

• These data can help provide a better understanding of the circumstances in which crashes and injuries occur.

NOTE: EDR data are recorded by your vehicle only if a non-trivial crash situation

occurs; no data are recorded by the EDR under normal driving conditions and no

personal data (e.g. name, gender, age, and crash location) are recorded. However, other

parties, such as law enforcement, could combine the EDR data with the type of

personally identifying data routinely acquired during a crash investigation.

• To read data recorded by an EDR, special equipment is required, and access to thevehicle or the EDR is needed. In addition to the vehicle manufacturer, other parties

such as law enforcement, that have the special equipment, can read the information

if they have access to the vehicle or the EDR.

WHAT TO DO IN EMERGENCIES

54

Page 64 of 76

WARNING!

• Overloading of your tires is dangerous. Overloading can cause tire failure,affect vehicle handling, and increase your stopping distance. Use tires of the

recommended load capacity for your vehicle. Never overload them.

• Improperly inflated tires are dangerous and can cause collisions. Under-inflation is the leading cause of tire failure and may result in severe

cracking, component separation, or “blow out”. Over-inflation reduces a tire’s

ability to cushion shock. Objects on the road and chuck holes can cause

damage that results in tire failure. Unequal tire pressures can cause steering

problems. You could lose control of your vehicle. Over-inflated or

under-inflated tires can affect vehicle handling and can fail suddenly, resulting

in loss of vehicle control.

SUMMER/THREE-SEASON TIRES

• This vehicle may be equipped with wheels and tires to enhance traction in both wetand dry conditions.

• Summer tires are not intended to be driven in snow or on ice.

• Use summer tires only in sets of four.

NOTE: Summer tires will not contain the all season designation or mountain/snowflake

symbol on the sidewall of the tire.

WARNING!

Do not use summer tires in snow/ice conditions. You could lose control, resulting

in severe injury or death.

WHEEL AND WHEEL TRIM CARE

• All wheels and wheel trim, especially aluminum and chrome plated wheels, should be cleaned regularly with a mild soap and water to prevent corrosion.

• To remove heavy soil and/or excessive brake dust, use MOPAR

®Wheel Cleaner or

equivalent or select a non-abrasive, non-acidic cleaner.

CAUTION!

Do not use scouring pads, steel wool, a bristle brush, or metal polishes. Do not

use oven cleaner. These products may damage the wheel's protective finish.

Avoid automatic car washes that use acidic solutions or harsh brushes that may

damage the wheel's protective finish. Only MOPAR

®Wheel Cleaner or equivalent

is recommended.

MAINTAINING YOUR VEHICLE

62