wheel bolts FIAT 500 ABARTH 2016 2.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: 500 ABARTH, Model: FIAT 500 ABARTH 2016 2.GPages: 432, PDF Size: 3.32 MB

Page 56 of 432

WARNING!(Continued)

wiring, including adding any kind of badges or

stickers to the steering wheel hub trim cover or the

upper right side of the instrument panel. Do not

modify the front bumper, vehicle body structure, or

add aftermarket side steps or running boards.

• It is dangerous to try to repair any part of the air

bag system yourself. Be sure to tell anyone who

works on your vehicle that it has an air bag system.

• Do not attempt to modify any part of your air bag

system. The air bag may inflate accidentally or may

not function properly if modifications are made.

Take your vehicle to an authorized dealer for any

air bag system service. If your seat, including your

trim cover and cushion, needs to be serviced in any

way (including removal or loosening/tightening of

seat attachment bolts), take the vehicle to your

(Continued)

WARNING! (Continued)

authorized dealer. Only manufacturer approved

seat accessories may be used. If it is necessary to

modify the air bag system for persons with dis-

abilities, contact your authorized dealer.

Event Data Recorder (EDR)

This vehicle is equipped with an event data recorder

(EDR). The main purpose of an EDR is to record, in

certain crash or near crash-like situations, such as an air

bag deployment or hitting a road obstacle, data that will

assist in understanding how a vehicle’s systems per-

formed. The EDR is designed to record data related to

vehicle dynamics and safety systems for a short period of

time, typically 30 seconds or less. The EDR in this vehicle

is designed to record such data as:

•How various systems in your vehicle were operating;

54 THINGS TO KNOW BEFORE STARTING YOUR VEHICLE

Page 81 of 432

Periodic Safety Checks You Should Make Outside

The Vehicle

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts, cracks and bulges.

Check the wheel bolts for tightness. Check the tires for

proper cold inflation pressure.

Lights

Have someone observe the operation of brake lights and

exterior lights while you work the controls. Check turn

signal and high beam indicator lights on the instrument

panel.

Door Latches

Check for proper closing, latching, and locking.

Fluid Leaks

Check area under vehicle after overnight parking for fuel,

engine coolant, oil, or other fluid leaks. Also, if gasoline

fumes are detected or if fuel, power steering fluid (if

equipped), or brake fluid leaks are suspected. The cause

should be located and corrected immediately.

2

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE 79

Page 323 of 432

6. Verify that the cap is installed on the fitting at the endof the Sealant Hose (6) and return the hose to its

storage area (located on the bottom of the air pump).

7. Return the Tire Service Kit to its storage location in the vehicle.

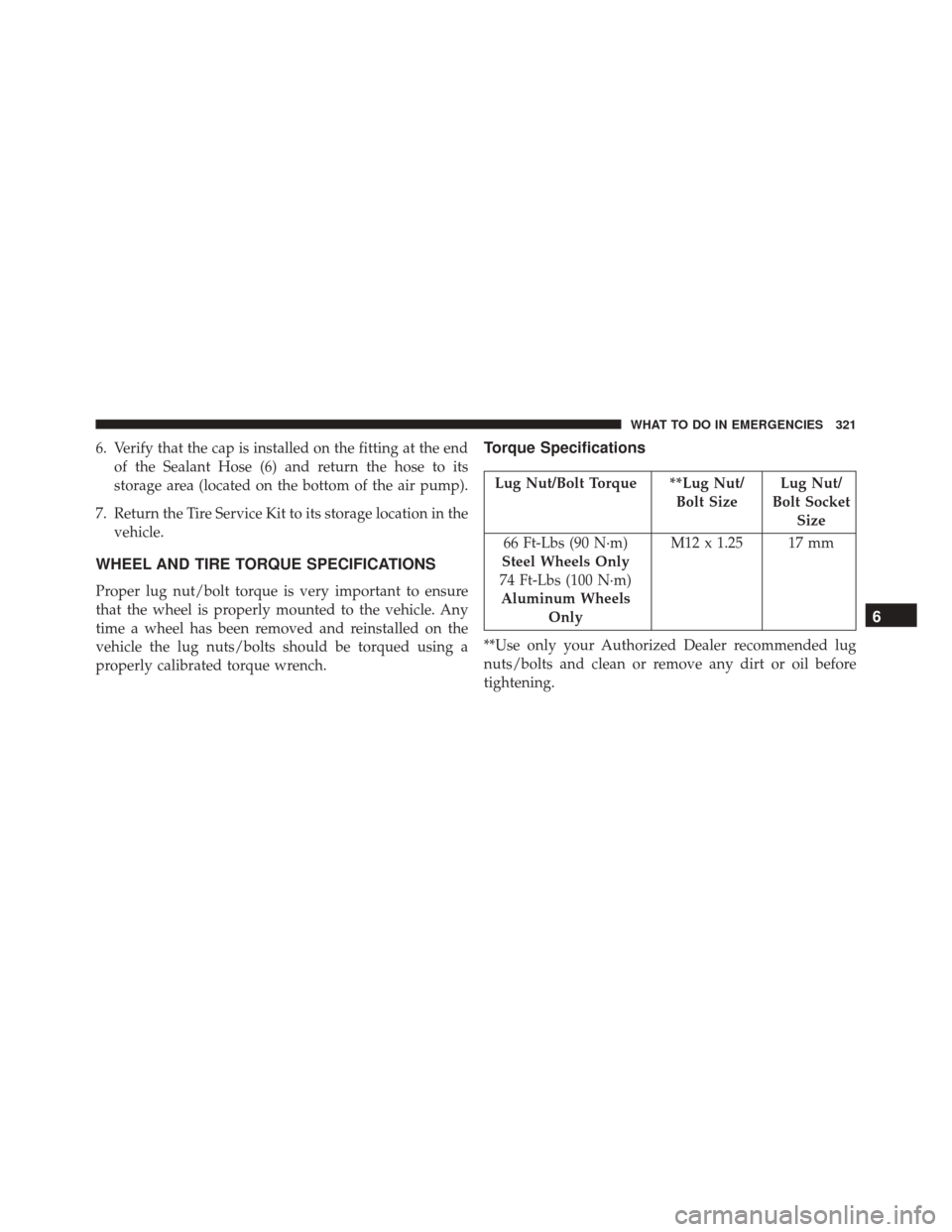

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure

that the wheel is properly mounted to the vehicle. Any

time a wheel has been removed and reinstalled on the

vehicle the lug nuts/bolts should be torqued using a

properly calibrated torque wrench.

Torque Specifications

Lug Nut/Bolt Torque **Lug Nut/ Bolt SizeLug Nut/

Bolt Socket Size

66 Ft-Lbs (90 N·m)

Steel Wheels Only

74 Ft-Lbs (100 N·m) Aluminum Wheels Only M12 x 1.25 17 mm

**Use only your Authorized Dealer recommended lug

nuts/bolts and clean or remove any dirt or oil before

tightening.

6

WHAT TO DO IN EMERGENCIES 321

Page 324 of 432

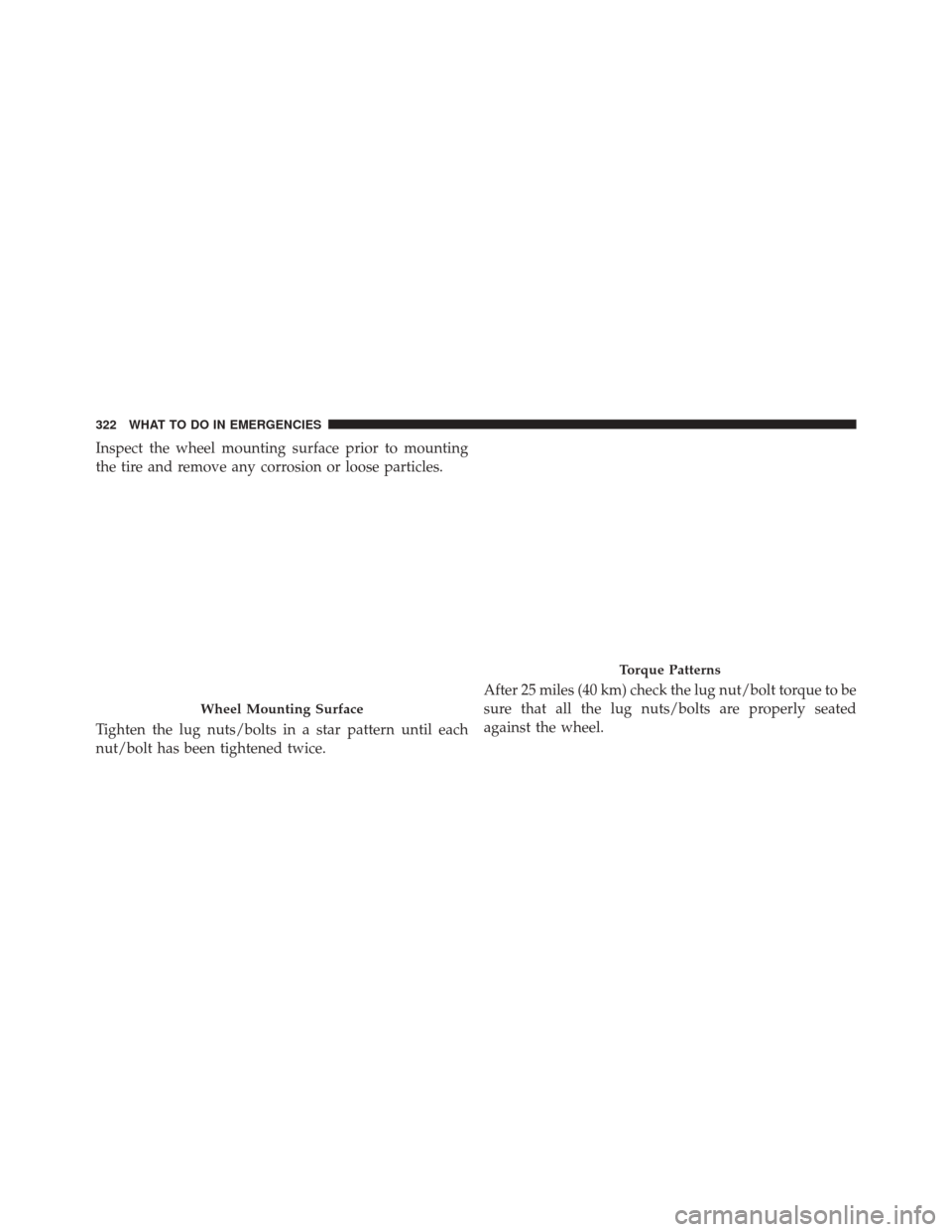

Inspect the wheel mounting surface prior to mounting

the tire and remove any corrosion or loose particles.

Tighten the lug nuts/bolts in a star pattern until each

nut/bolt has been tightened twice.After 25 miles (40 km) check the lug nut/bolt torque to be

sure that all the lug nuts/bolts are properly seated

against the wheel.

Wheel Mounting Surface

Torque Patterns

322 WHAT TO DO IN EMERGENCIES

Page 329 of 432

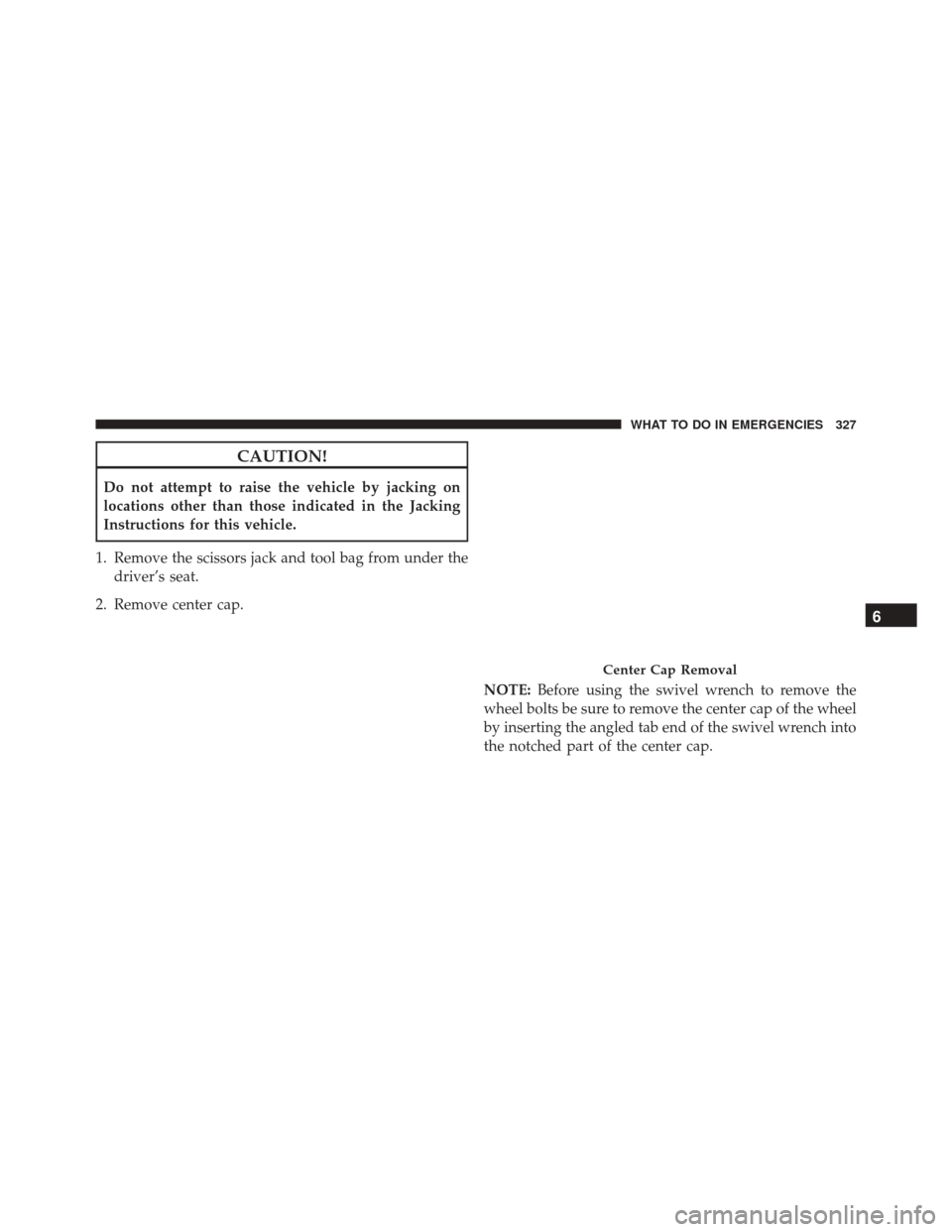

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

1. Remove the scissors jack and tool bag from under the driver’s seat.

2. Remove center cap.

NOTE:Before using the swivel wrench to remove the

wheel bolts be sure to remove the center cap of the wheel

by inserting the angled tab end of the swivel wrench into

the notched part of the center cap.

Center Cap Removal

6

WHAT TO DO IN EMERGENCIES 327

Page 330 of 432

3. Loosen, but do not remove, the wheel bolts by turningthem to the left one turn while the wheel is still on the

ground.

NOTE: •There are front and rear jacking locations on each

side of the body (as indicated by the triangular lift

point symbol on the sill molding)

• Do not raise the vehicle until you are sure the jack is

securely engaged.

Front Jacking Location

328 WHAT TO DO IN EMERGENCIES

Page 332 of 432

5. Using the swivel wrench, raise the vehicle by turningthe jack screw to the right. Raise the vehicle only until

the tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.

6. Remove the wheel bolts and pull the wheel off the hub. For vehicles equipped with aluminum wheels,

the center caps must be removed to remove the wheel

bolts. For vehicles equipped with steel wheels the

wheel covers must be removed to remove the wheel

bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not fully tighten the wheel bolts until the vehicle

has been lowered. Failure to follow this warning may

result in serious injury.

CAUTION!

Be sure to mount the spare tire with the valve stem

facing outward. The vehicle could be damaged if the

spare tire is mounted incorrectly.

WARNING!

To avoid possible personal injury, handle the wheel

covers with care to avoid contact with any sharp

edges.

7. Install the spare wheel and hand start the wheel bolts. Lightly tighten the bolts. To avoid the risk of forcing

the vehicle off the jack, do not tighten the bolts fully

until the vehicle has been lowered.

8. Lower the vehicle by turning the jack screw to the left.

9. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

330 WHAT TO DO IN EMERGENCIES

Page 333 of 432

leverage. Tighten the wheel bolts in a star pattern until

each bolt has been tightened twice. For the correct

wheel bolt torque refer to Torque Specifications in this

section. If in doubt about the correct tightness, have

them checked with a torque wrench by your autho-

rized dealership or service station.

10. Disassemble the jack and tools and place them in the bag. Stow it under the driver’s seat and secure the

bag to the floor with the straps attached to the floor

of the vehicle.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided. 11. Place the deflated (flat) tire in the cargo area. Have

the tire repaired or replaced as soon as possible.

WARNING!

A loose tire thrown forward in a collision or hard

stop could injure the occupants in the vehicle. Have

the deflated (flat) tire repaired or replaced immedi-

ately.

12. Check the spare tire pressure as soon as possible. Correct the tire pressure as required.

JUMP-STARTING PROCEDURE

If your vehicle has a discharged battery, it can be jump-

started using a set of jumper cables and a battery in

another vehicle or by using a portable battery booster

pack. Jump-starting can be dangerous if done improperly

so please follow the procedures in this section carefully.

6

WHAT TO DO IN EMERGENCIES 331