engine FIAT 500E 2016 2.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: 500E, Model: FIAT 500E 2016 2.GPages: 132, PDF Size: 4.59 MB

Page 3 of 132

INTRODUCTION/WELCOMEWELCOME FROM FIAT...............2

IMPORTANT VEHICLE INFORMATION......4

CONTROLS AT A GLANCEDRIVER COCKPIT..................6

INSTRUMENT CLUSTER..............8

GETTING STARTEDELECTRIC VEHICLE FEATURES..........10

ELECTRIC SYSTEM OPERATION.........13

CHARGING THE HIGH VOLTAGE BATTERY...16

STARTING YOUR 500e...............19

KEY FOB......................20

VEHICLE SECURITY ALARM...........21

POWER DOOR LOCKS..............21

OCCUPANT RESTRAINT SYSTEMS........21

HEAD RESTRAINTS.................31

SEATS........................33

REAR SEATS.....................37

TILT STEERING COLUMN.............38

OPERATING YOUR VEHICLEEXTENDING YOUR DRIVING RANGE PER

CHARGE.......................39

LIGHTS.......................40

WIPER/WASHER LEVER..............43

ELECTRONIC SPEED CONTROL........44

POWER WINDOWS................47

AUTOMATIC TEMPERATURE CONTROLS

(ATC).........................48

REAR PARK ASSIST.................49

POWER SUNROOF.................50

ELECTRONICSYOUR VEHICLE'S SOUND SYSTEM........52

CYBERSECURITY..................54

IDENTIFYING YOUR RADIO............55

UCONNECT 5.0..................56

USB/AUX CONTROL................60

UCONNECT 5.0 VOICE RECOGNITION

QUICK TIPS.....................61

UCONNECT PHONE...............68

STEERING WHEEL AUDIO CONTROLS.....77

ELECTRONIC VEHICLE INFORMATION

CENTER (EVIC)...................77

PROGRAMMABLE FEATURES...........78

TRIP BUTTON....................79

POWER OUTLET.................80

UTILITY

TRAILER TOWING.................82

RECREATIONAL TOWING (BEHIND

MOTORHOME, ETC.)...............82

WHAT TO DO IN EMERGENCIES

ROADSIDE ASSISTANCE..............83

WARNING AND INDICATOR LIGHTS......83

TIRE SERVICE KIT..................89

JUMP-STARTING PROCEDURE

(12 VOLT BATTERY ONLY)............96

MANUAL PARK RELEASE.............99

TOWING A DISABLED VEHICLE.........100

ENHANCED ACCIDENT RESPONSE SYSTEM..100

FREEING A STUCK VEHICLE...........101

EVENT DATA RECORDER (EDR)........102

MAINTAINING YOUR VEHICLE

OPENING THE HOOD..............103

ENGINE COMPARTMENT — ELECTRIC....104

FLUID CAPACITIES................106

FLUIDS, LUBES, AND GENUINE PARTS.....106

MAINTENANCE PROCEDURES.........107

MAINTENANCE SCHEDULE..........107

FUSES.......................110

TIRES — GENERAL INFORMATION......113

TIRE ROTATION RECOMMENDATIONS....116

REPLACEMENT BULBS..............117

CUSTOMER ASSISTANCE

FIAT CUSTOMER CENTER............118

ASSISTANCE FOR THE HEARING

IMPAIRED.....................118

PUBLICATIONS ORDERING...........118

REPORTING SAFETY DEFECTS IN THE

UNITED STATES..................118

MOPAR® ACCESSORIES

AUTHENTIC ACCESSORIES BY MOPAR....119

FAQ ’s

FREQUENTLY ASKED QUESTIONS.......120

INDEX......................121

TABLE OF CONTENTS

1

Page 6 of 132

IMPORTANT VEHICLE INFORMATION

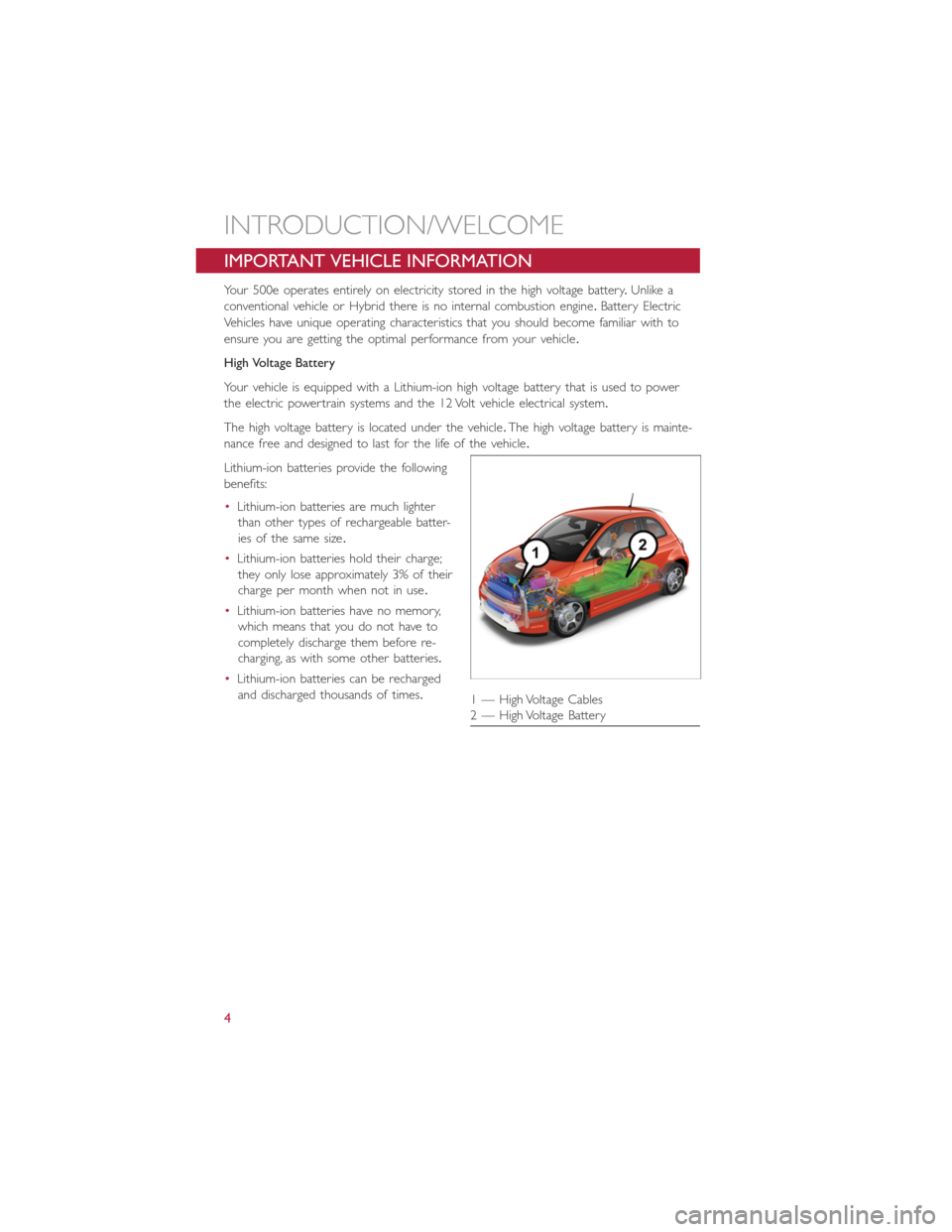

Your 500e operates entirely on electricity stored in the high voltage battery.Unlike a

conventional vehicle or Hybrid there is no internal combustion engine.Battery Electric

Vehicles have unique operating characteristics that you should become familiar with to

ensure you are getting the optimal performance from your vehicle.

High Voltage Battery

Your vehicle is equipped with a Lithium-ion high voltage battery that is used to power

the electric powertrain systems and the 12 Volt vehicle electrical system.

The high voltage battery is located under the vehicle.The high voltage battery is mainte-

nance free and designed to last for the life of the vehicle.

Lithium-ion batteries provide the following

benefits:

•Lithium-ion batteries are much lighter

than other types of rechargeable batter-

ies of the same size.

•Lithium-ion batteries hold their charge;

they only lose approximately 3% of their

charge per month when not in use.

•Lithium-ion batteries have no memory,

which means that you do not have to

completely discharge them before re-

charging, as with some other batteries.

•Lithium-ion batteries can be recharged

and discharged thousands of times.

1 — High Voltage Cables

2 — High Voltage Battery

INTRODUCTION/WELCOME

4

Page 28 of 132

Air Bag Warning Light

The air bags must be ready to inflate for your protection in a collision.The Occupant

Restraint Controller (ORC) monitors the internal circuits and interconnecting wiring asso-

ciated with air bag system electrical components.

The ORC monitors the readiness of the electronic parts of the air bag system whenever

the ignition switch is in the AVV or MAR position.If the ignition switch is in the STOP

position the air bag system is not on and the air bags will not inflate.

The ORC turns on the Air Bag Warning Light in the instrument panel for approximately

four to eight seconds for a self-check when the ignition switch is first turned to the MAR

position.After the self-check, the Air Bag Warning Light will turn off.If the ORC detects

a malfunction in any part of the system, it turns on the Air Bag Warning Light, either mo-

mentarily or continuously.A single chime will sound to alert you if the light comes on

again after initial startup.

If the Air Bag Warning Light in the instrument panel is not on during the four to eight

seconds when the ignition switch is first turned to the MAR position, stays on, or turns

on while driving, have the vehicle serviced by an authorized service center immediately.

NOTE:

If the speedometer, tachometer (if equipped), or any engine related gauges are not work-

ing, the Occupant Restraint Controller (ORC) may also be disabled.In this condition the

air bags may not be ready to inflate for your protection.Have an authorized dealer ser-

vice the air bag system immediately.

Event Data Recorder (EDR)

This vehicle is equipped with an event data recorder (EDR).The main purpose of an

EDR is to record, in certain crash or near crash-like situations, such as an air bag deploy-

ment or hitting a road obstacle, data that will assist in understanding how a vehicle’s sys-

tems performed.The EDR is designed to record data related to vehicle dynamics and

safety systems for a short period of time, typically 30 seconds or less.The EDR in this

vehicle is designed to record such data as:

•How various systems in your vehicle were operating;

•Whether or not the driver and passenger safety belts were buckled/fastened;

•How far (if at all) the driver was depressing the accelerator and/or brake pedal; and,

•How fast the vehicle was traveling.

GETTING STARTED

26

Page 81 of 132

Uconnect Customer Programmable Features

The Uconnect system allows you to access Customer Programmable feature settings.

To change a setting:

1.Push the SETTINGS

button located on the right side of the display.

2.Select a programmable feature you would like to adjust.

3.Make your selection highlighting the button.

Depending on the vehicles options, the following feature settings are available:

•Display•Audio

•Clock & Date•Phone/Bluetooth

•Safety/Assistance•SiriusXM Setup

•Lights•Voice

•Doors & Locks•Restore Settings

•Engine Off Options•Units

•Clear Personal Data•Charging Schedule

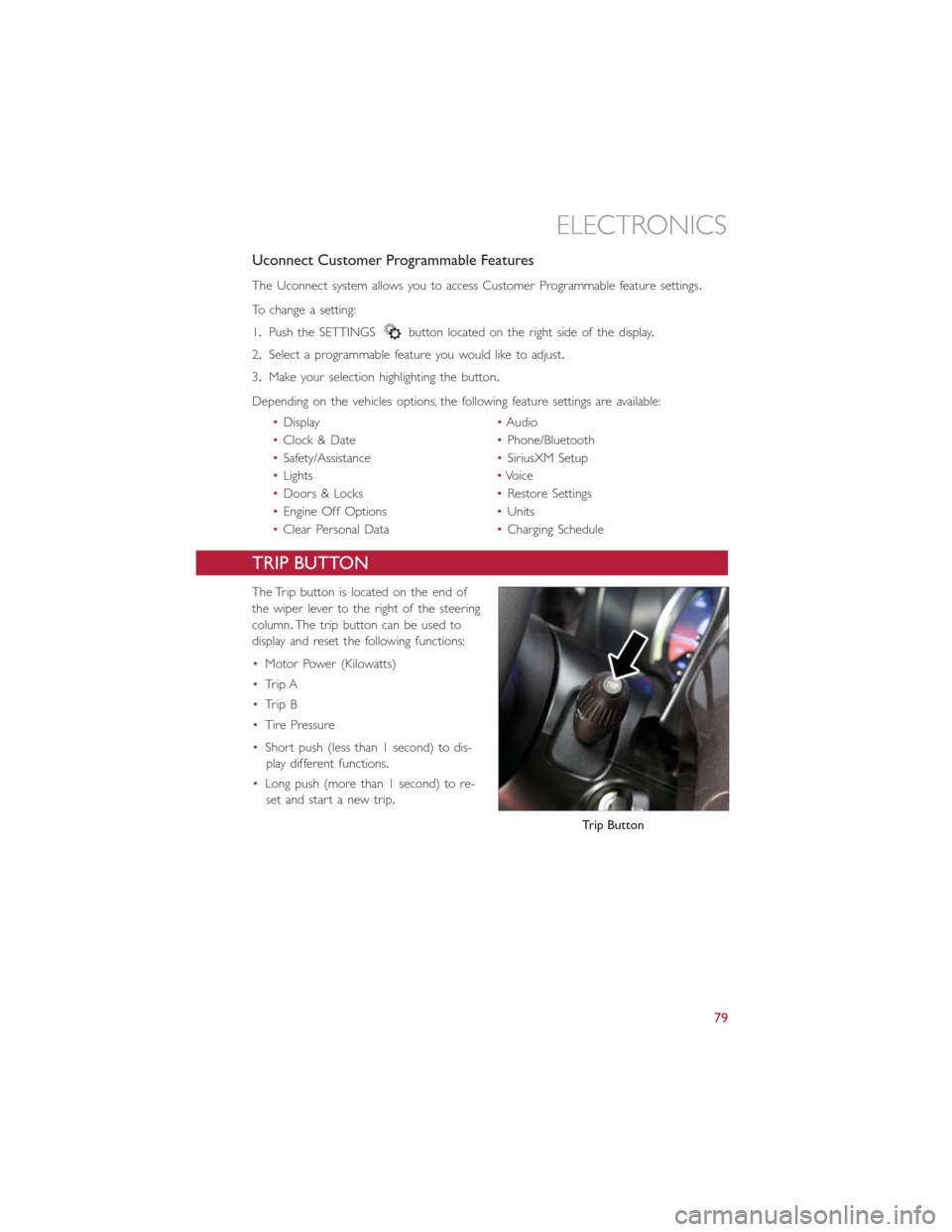

TRIP BUTTON

The Trip button is located on the end of

the wiper lever to the right of the steering

column.The trip button can be used to

display and reset the following functions:

•Motor Power (Kilowatts)

•Trip A

•Trip B

•Tire Pressure

•Short push (less than 1 second) to dis-

play different functions.

•Long push (more than 1 second) to re-

set and start a new trip.

Trip Button

ELECTRONICS

79

Page 89 of 132

NOTE:

Tire pressures change by approximately 1 psi (7 kPa) per 12° F (7° C) of air tempera-

ture change.Keep this in mind when checking tire pressure inside a garage, especially in

the Winter.Example: If garage temperature is 68°F (20°C) and the outside temperature

is 32°F (0°C), then the cold tire inflation pressure should be increased by 3 psi (21 kPa),

which equals 1 psi (7 kPa) for every 12°F (7°C) for this outside temperature condition.

CAUTION!

The TPMS has been optimized for the original equipment tires and wheels.TPMS pres-

sures and warning have been established for the tire size equipped on your vehicle.

Undesirable system operation or sensor damage may result when using replacement

equipment that is not of the same size, type, and/or style.Aftermarket wheels can cause

sensor damage.Do not use tire sealant from a can, or balance beads if your vehicle is

equipped with a TPMS, as damage to the sensors may result.

– Electronic Stability Control (ESC) Activation / Malfunction Indicator Light

The “ESC Activation/Malfunction Indicator Light” in the instrument cluster will come on

for four seconds when the ignition switch is turned to the ON/RUN position.If the “ESC

Activation/Malfunction Indicator Light” comes on continuously with the engine running, a

malfunction has been detected in the ESC system.If this light remains on, see your au-

thorized dealer as soon as possible to have the problem diagnosed and corrected.

NOTE:

•The “ESC Off Indicator Light” and the “ESC Activation/Malfunction Indicator Light”

come on momentarily each time the ignition switch is turned to ON/RUN.

•Each time the ignition is turned to ON/RUN, the ESC system will be ON even if it

was turned off previously.

•ESC Activation/Malfunction Light can blink during a ESC or TC intervention.

WHAT TO DO IN EMERGENCIES

87

Page 94 of 132

Sealing A Tire With Tire Service Kit

(A) Whenever You Stop To Use Tire Service Kit:

1.Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2.Verify that the valve stem (on the wheel with the deflated tire) is in a position that is

near to the ground.This will allow the Tire Service Kit Hoses (6) and (7) to reach the

valve stem and keep the Tire Service Kit flat on the ground.This will provide the best

positioning of the kit when injecting the sealant into the deflated tire and running the

air pump.Move the vehicle as necessary to place the valve stem in this position be-

fore proceeding.

3.Place the transmission in PARK (auto transmission) or in Gear (manual transmission)

and place the ignition in the OFF position.

4.Set the parking brake.

(B) Setting Up To Use Tire Service Kit:

1.Push in the Mode Select Knob (5) and turn to the Sealant Mode position.

2.Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of

the hose.

3.Place the Tire Service Kit flat on the ground next to the deflated tire.

4.Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose (6) onto the valve stem.

5.Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

NOTE:

Do not remove foreign objects (e.g., screws or nails) from the tire.

(C) Injecting Tire Service Kit Sealant Into The Deflated Tire:

•Always start the engine before turning ON the Tire Service Kit.

NOTE:

Manual transmission vehicles must have the parking brake engaged and the gear selector

in NEUTRAL.

•After pushing the Power Button (4), the sealant (white fluid) will flow from the Sealant

Bottle (1) through the Sealant Hose (6) and into the tire.

NOTE:

Sealant may leak out through the puncture in the tire.

WHAT TO DO IN EMERGENCIES

92

Page 95 of 132

If the sealant (white fluid) does not flow within0–10seconds through the Sealant

Hose (6):

1.Push the Power Button (4) to turn Off the Tire Service Kit.Disconnect the Sealant

Hose (6) from the valve stem.Make sure the valve stem is free of debris.Reconnect

the Sealant Hose (6) to the valve stem.Check that the Mode Select Knob (5) is in

the Sealant Mode position and not Air Mode.Push the Power Button (4) to turn On

the Tire Service Kit.

2.Connect the Power Plug (8) to a different 12 Volt power outlet in your vehicle or

another vehicle, if available.Make sure the engine is running before turning ON the

Tire Service Kit.

3.The Sealant Bottle (1) may be empty due to previous use.Call for assistance.

NOTE:

If the Mode Select Knob (5) is on Air Mode and the pump is operating, air will dispense

from the Air Pump Hose (7) only, not the Sealant Hose (6).

If the sealant (white fluid) does flow through the Sealant Hose (6):

1.Continue to operate the pump until sealant is no longer flowing through hose (typi-

cally takes 30 - 70 seconds).As the sealant flows through the Sealant Hose (6), the

Pressure Gauge (3) can read as high as 70 psi (4.8 Bar).The Pressure Gauge (3) will

decrease quickly from approximately 70 psi (4.8 Bar) to the actual tire pressure when

the Sealant Bottle (1) is empty.

2.The pump will start to inject air into the tire immediately after the Sealant Bottle (1)

is empty.Continue to operate the pump and inflate the tire to the pressure indicated

on the tire pressure label on the driver-side latch pillar (recommended pressure).

Check the tire pressure by looking at the Pressure Gauge (3).

If the tire does not inflate to at least 26 psi (1.8 Bar) pressure within 15 minutes:

•The tire is too badly damaged.Do not attempt to drive the vehicle further.Call for

assistance.

NOTE:

If the tire becomes over-inflated, push the Deflation Button to reduce the tire pressure

to the recommended inflation pressure before continuing.

If the tire inflates to the recommended pressure or is at least 26 psi (1.8 Bar) pressure

within 15 minutes:

1.Push the Power Button (4) to turn off the Tire Service Kit.

2.Remove the Speed Limit sticker from the top of the Sealant Bottle (1) and place the

sticker on the instrument panel.

3.Immediately disconnect the Sealant Hose (6) from the valve stem, reinstall the cap on

the fitting at the end of the hose, and place the Tire Service Kit in the vehicle storage

location.Quickly proceed to (D) “Drive Vehicle.”

WHAT TO DO IN EMERGENCIES

93

Page 100 of 132

Connecting The Jumper Cables

1.Connect the positive(+)end of the jumper cable to the positive(+)post of the dis-

charged vehicle.

2.Connect the opposite end of the positive(+)jumper cable to the positive(+)post of

the booster battery.

3.Connect the negative end(-)of the jumper cable to the negative(-)post of the

booster battery.

4.Connect the opposite end of the negative(-)jumper cable to a good engine ground

(exposed metal part of the discharged vehicle underhood compartment) away from

the battery.

WARNING!

Do not connect the jumper cable to the negative(-)post of the discharged battery.

The resulting electrical spark could cause the battery to explode and could result in

personal injury.Only use the specific ground point, do not use any other exposed metal

parts.

5.Start the engine in the vehicle that has the booster battery, let the engine idle a few

minutes, and then turn the key to RUN position on the vehicle with the discharged

battery.

6.Once the vehicle is started, remove the jumper cables in the reverse sequence:

Disconnecting The Jumper Cables

1.Disconnect the negative(-)jumper cable from the engine ground(-)of the vehicle

with the discharged battery.

2.Disconnect the negative end(-)of the jumper cable from the negative(-)post of the

booster battery.

3.Disconnect the opposite end of the positive(+)jumper cable from the positive(+)

post of the booster battery.

4.Disconnect the positive(+)end of the jumper cable from the positive(+)post of the

discharged vehicle.

If frequent jump-starting is required to start your vehicle, you should have the battery

and charging system inspected at your authorized dealer.

WHAT TO DO IN EMERGENCIES

98

Page 105 of 132

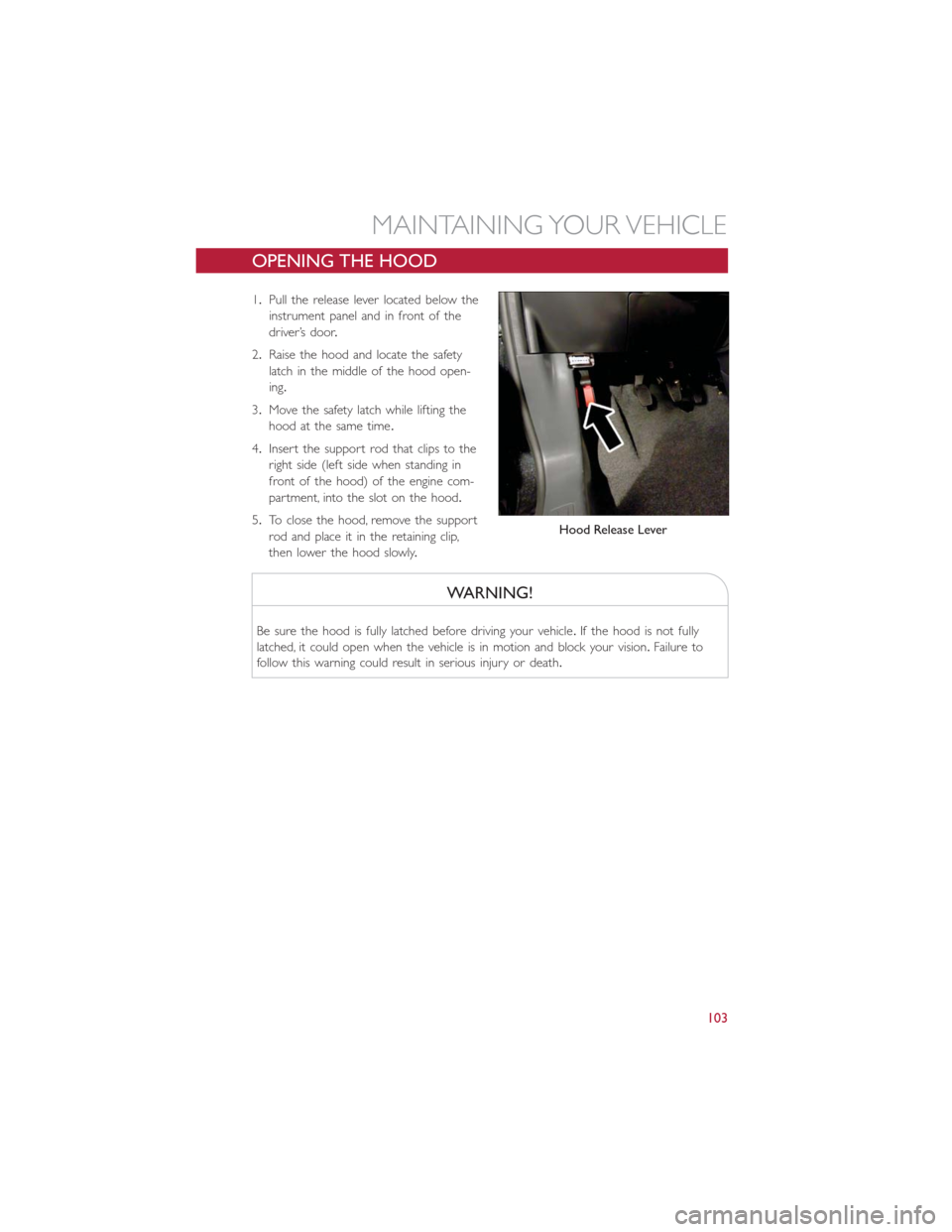

OPENING THE HOOD

1.Pull the release lever located below the

instrument panel and in front of the

driver’s door.

2.Raise the hood and locate the safety

latch in the middle of the hood open-

ing.

3.Move the safety latch while lifting the

hood at the same time.

4.Insert the support rod that clips to the

right side (left side when standing in

front of the hood) of the engine com-

partment, into the slot on the hood.

5.To close the hood, remove the support

rod and place it in the retaining clip,

then lower the hood slowly.

WARNING!

Be sure the hood is fully latched before driving your vehicle.If the hood is not fully

latched, it could open when the vehicle is in motion and block your vision.Failure to

follow this warning could result in serious injury or death.

Hood Release Lever

MAINTAINING YOUR VEHICLE

103

Page 106 of 132

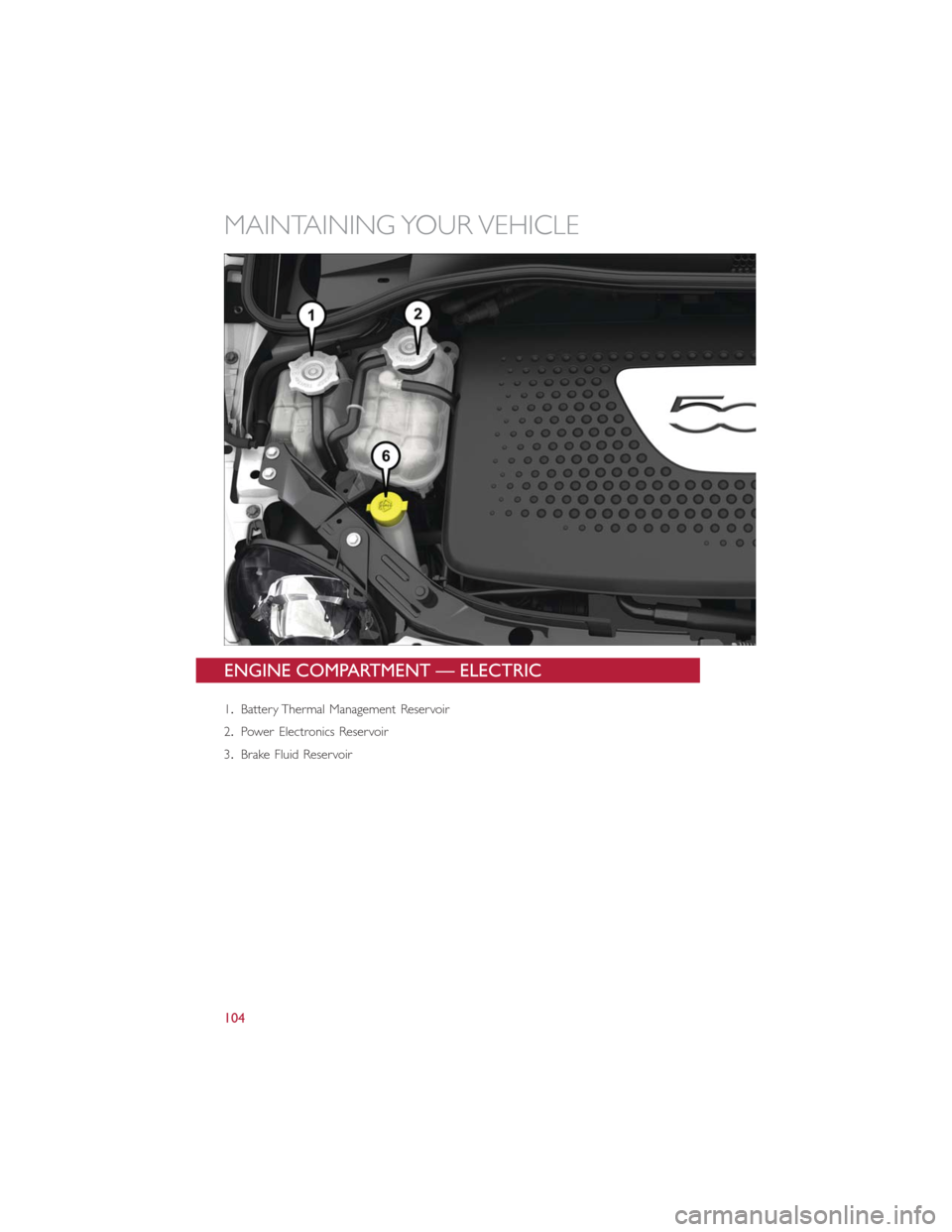

ENGINE COMPARTMENT — ELECTRIC

1.Battery Thermal Management Reservoir

2.Power Electronics Reservoir

3.Brake Fluid Reservoir

MAINTAINING YOUR VEHICLE

104