tow FIAT 500L 2019 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2019, Model line: 500L, Model: FIAT 500L 2019Pages: 248, PDF Size: 5.74 MB

Page 124 of 248

IN AN EMERGENCY

A punctured tyre or a burnt-out bulb?

At times, a problem may interfere

with our journey.

The pages on emergencies can help

you to deal with critical situations

independently and with calm.

In an emergency we recommend that

you call the freephone number found in

the Warranty Booklet.

It is also possible to call the national or

international universal freephone

number to search for the nearest

Dealership.HAZARD WARNING LIGHTS...........123

REPLACING A WHEEL ...................123

“FIX&GO AUTOMATIC” KIT .............128

CHANGING A BULB .......................130

REPLACING FUSES........................138

JUMP STARTING ............................144

FUEL CUT-OFF SYSTEM ................146

TOWING THE VEHICLE ..................146

122

IN AN EMERGENCY

Page 127 of 248

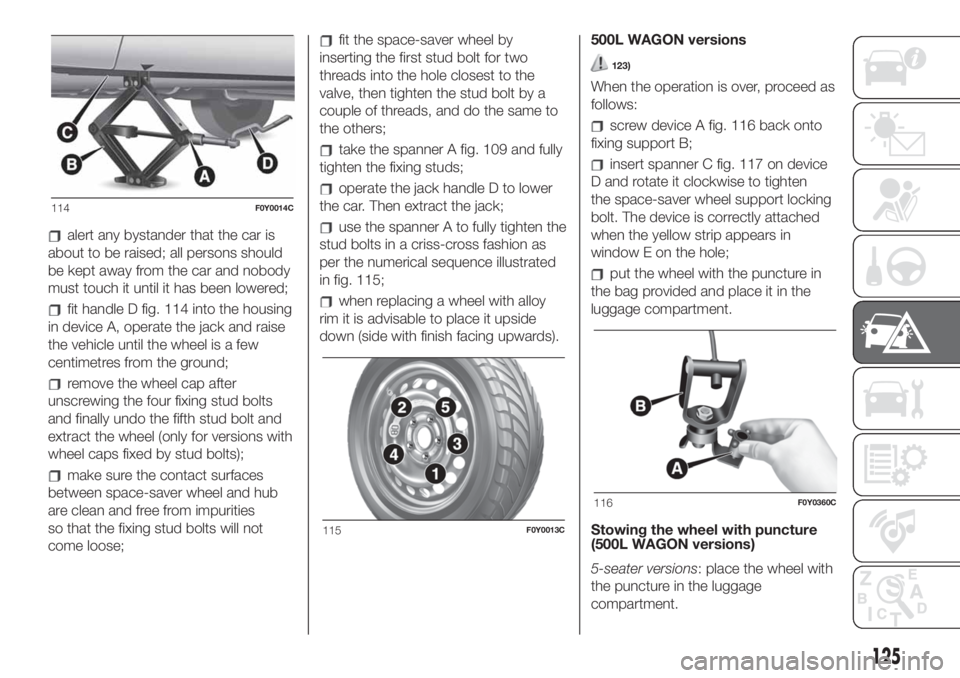

alert any bystander that the car is

about to be raised; all persons should

be kept away from the car and nobody

must touch it until it has been lowered;

fit handle D fig. 114 into the housing

in device A, operate the jack and raise

the vehicle until the wheel is a few

centimetres from the ground;

remove the wheel cap after

unscrewing the four fixing stud bolts

and finally undo the fifth stud bolt and

extract the wheel (only for versions with

wheel caps fixed by stud bolts);

make sure the contact surfaces

between space-saver wheel and hub

are clean and free from impurities

so that the fixing stud bolts will not

come loose;

fit the space-saver wheel by

inserting the first stud bolt for two

threads into the hole closest to the

valve, then tighten the stud bolt by a

couple of threads, and do the same to

the others;

take the spanner A fig. 109 and fully

tighten the fixing studs;

operate the jack handle D to lower

the car. Then extract the jack;

use the spanner A to fully tighten the

stud bolts in a criss-cross fashion as

per the numerical sequence illustrated

in fig. 115;

when replacing a wheel with alloy

rim it is advisable to place it upside

down (side with finish facing upwards).500L WAGON versions

123)

When the operation is over, proceed as

follows:

screw device A fig. 116 back onto

fixing support B;

insert spanner C fig. 117 on device

D and rotate it clockwise to tighten

the space-saver wheel support locking

bolt. The device is correctly attached

when the yellow strip appears in

window E on the hole;

put the wheel with the puncture in

the bag provided and place it in the

luggage compartment.

Stowing the wheel with puncture

(500L WAGON versions)

5-seater versions: place the wheel with

the puncture in the luggage

compartment.

114F0Y0014C

115F0Y0013C

116F0Y0360C

125

Page 128 of 248

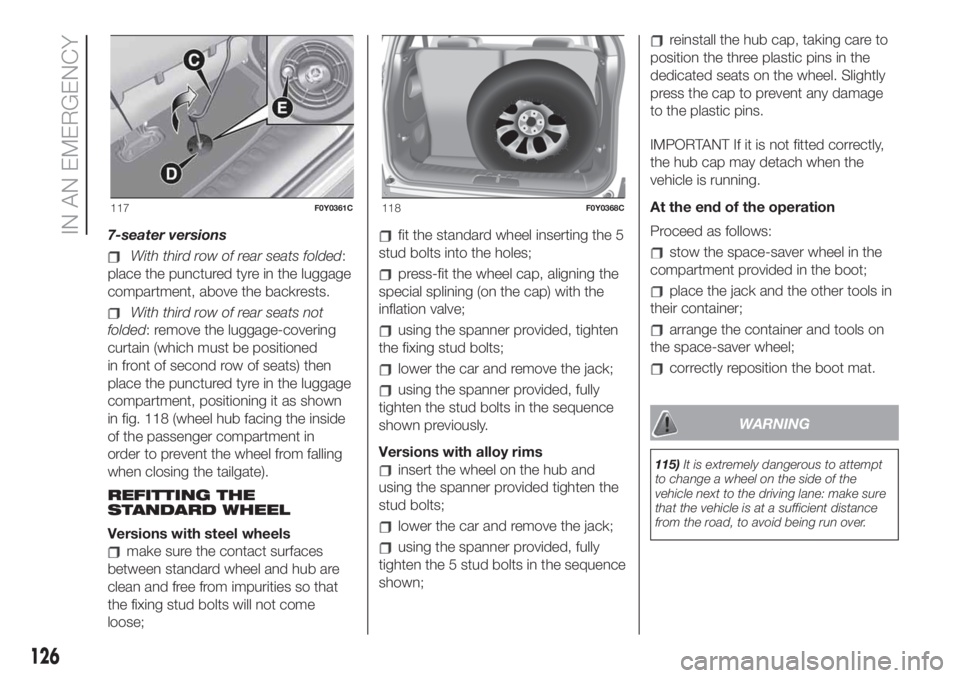

7-seater versions

With third row of rear seats folded:

place the punctured tyre in the luggage

compartment, above the backrests.

With third row of rear seats not

folded: remove the luggage-covering

curtain (which must be positioned

in front of second row of seats) then

place the punctured tyre in the luggage

compartment, positioning it as shown

in fig. 118 (wheel hub facing the inside

of the passenger compartment in

order to prevent the wheel from falling

when closing the tailgate).

REFITTING THE

STANDARD WHEEL

Versions with steel wheels

make sure the contact surfaces

between standard wheel and hub are

clean and free from impurities so that

the fixing stud bolts will not come

loose;

fit the standard wheel inserting the 5

stud bolts into the holes;

press-fit the wheel cap, aligning the

special splining (on the cap) with the

inflation valve;

using the spanner provided, tighten

the fixing stud bolts;

lower the car and remove the jack;

using the spanner provided, fully

tighten the stud bolts in the sequence

shown previously.

Versions with alloy rims

insert the wheel on the hub and

using the spanner provided tighten the

stud bolts;

lower the car and remove the jack;

using the spanner provided, fully

tighten the 5 stud bolts in the sequence

shown;

reinstall the hub cap, taking care to

position the three plastic pins in the

dedicated seats on the wheel. Slightly

press the cap to prevent any damage

to the plastic pins.

IMPORTANT If it is not fitted correctly,

the hub cap may detach when the

vehicle is running.

At the end of the operation

Proceed as follows:

stow the space-saver wheel in the

compartment provided in the boot;

place the jack and the other tools in

their container;

arrange the container and tools on

the space-saver wheel;

correctly reposition the boot mat.

WARNING

115)It is extremely dangerous to attempt

to change a wheel on the side of the

vehicle next to the driving lane: make sure

that the vehicle is at a sufficient distance

from the road, to avoid being run over.

117F0Y0361C118F0Y0368C

126

IN AN EMERGENCY

Page 130 of 248

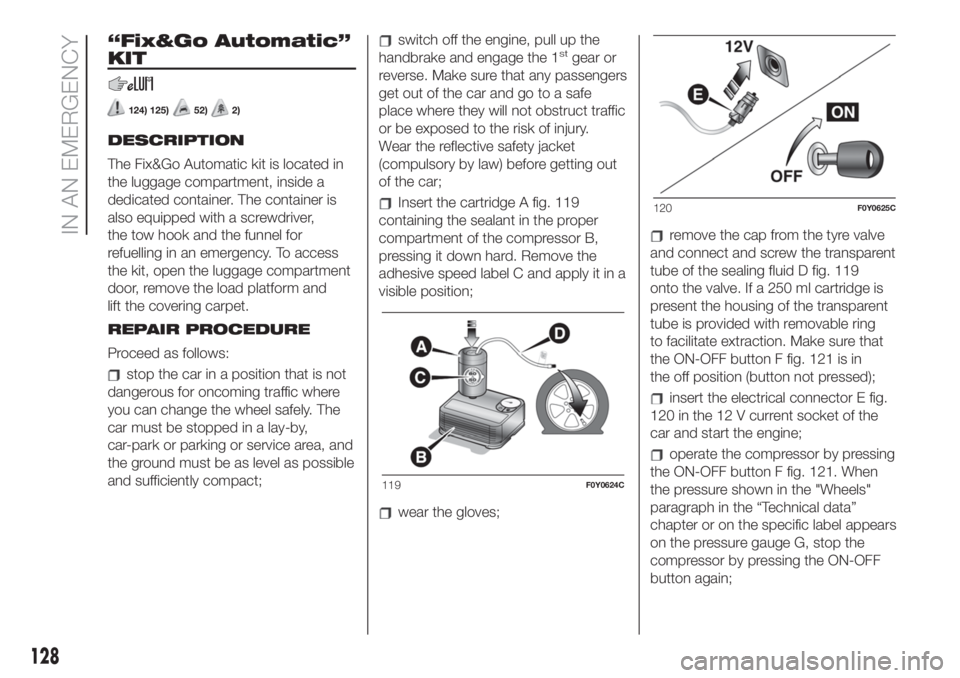

“Fix&Go Automatic”

KIT

124) 125)52)2)

DESCRIPTION

The Fix&Go Automatic kit is located in

the luggage compartment, inside a

dedicated container. The container is

also equipped with a screwdriver,

the tow hook and the funnel for

refuelling in an emergency. To access

the kit, open the luggage compartment

door, remove the load platform and

lift the covering carpet.

REPAIR PROCEDURE

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can change the wheel safely. The

car must be stopped in a lay-by,

car-park or parking or service area, and

the ground must be as level as possible

and sufficiently compact;

switch off the engine, pull up the

handbrake and engage the 1stgear or

reverse. Make sure that any passengers

get out of the car and go to a safe

place where they will not obstruct traffic

or be exposed to the risk of injury.

Wear the reflective safety jacket

(compulsory by law) before getting out

of the car;

Insert the cartridge A fig. 119

containing the sealant in the proper

compartment of the compressor B,

pressing it down hard. Remove the

adhesive speed label C and apply it in a

visible position;

wear the gloves;

remove the cap from the tyre valve

and connect and screw the transparent

tube of the sealing fluid D fig. 119

onto the valve. If a 250 ml cartridge is

present the housing of the transparent

tube is provided with removable ring

to facilitate extraction. Make sure that

the ON-OFF button F fig. 121 is in

the off position (button not pressed);

insert the electrical connector E fig.

120 in the 12 V current socket of the

car and start the engine;

operate the compressor by pressing

the ON-OFF button F fig. 121. When

the pressure shown in the "Wheels"

paragraph in the “Technical data”

chapter or on the specific label appears

on the pressure gauge G, stop the

compressor by pressing the ON-OFF

button again;

119F0Y0624C

120F0Y0625C

128

IN AN EMERGENCY

Page 133 of 248

IMPORTANT When the weather is cold

or damp or after heavy rain or washing,

the surface of headlights or rear lights

may steam up and/or form drops of

condensation on the inside. This is

a natural phenomenon due to the

difference in temperature and humidity

between the inside and the outside

of the glass which does not indicate a

fault and does not compromise the

normal operation of lighting devices.

The mist disappears quickly when the

lights are turned on, starting from

the centre of the diffuser, extending

progressively towards the edges.

131

Page 142 of 248

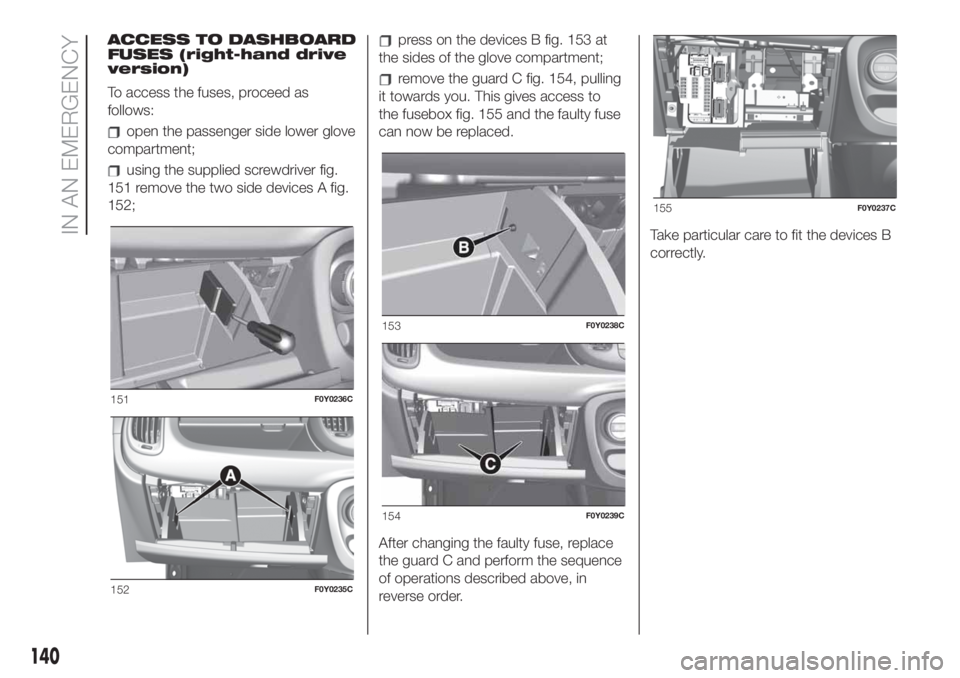

ACCESS TO DASHBOARD

FUSES (right-hand drive

version)

To access the fuses, proceed as

follows:

open the passenger side lower glove

compartment;

using the supplied screwdriver fig.

151 remove the two side devices A fig.

152;

press on the devices B fig. 153 at

the sides of the glove compartment;

remove the guard C fig. 154, pulling

it towards you. This gives access to

the fusebox fig. 155 and the faulty fuse

can now be replaced.

After changing the faulty fuse, replace

the guard C and perform the sequence

of operations described above, in

reverse order.Take particular care to fit the devices B

correctly.

151F0Y0236C

152F0Y0235C

153F0Y0238C

154F0Y0239C

155F0Y0237C

140

IN AN EMERGENCY

Page 147 of 248

disconnect the other end of the

cable used for negative (–) from the

negative terminal (–) of the auxiliary

battery;

disconnect the end of the cable

used for positive (+) from the positive

terminal (+) of the auxiliary battery;

disconnect one end of the cable

used for positive (+) from the positive

terminal (+) of the car with flat battery.

If it is often necessary to perform a

jump starting, have the car battery and

the recharging system checked by a

Fiat Dealership.

BUMP STARTING

Never, under any circumstances, jump

start the engine by pushing, towing

or coasting downhill.

IMPORTANT Remember that the brake

servo and electric power steering are

not active until the engine is started. A

much greater effort will therefore be

required to use the brake pedal or turn

the steering wheel.IMPORTANT Any accessories (e.g.

mobile phones, etc.) connected to the

vehicle power sockets draw current

even if they are not used. These

devices, if left connected too much time

with engine off, may cause the battery

to drain with following reduction of

its life and/or failure to start the engine.

WARNING

136)Do not get too close to the radiator

cooling fan: the electric fan may start;

danger of injury. Scarves, ties and other

loose clothing might be pulled by moving

parts.

137)Remove any metal objects (e.g. rings,

watches, bracelets), that might cause an

accidental electrical contact and cause

serious injury.

138)The batteries contain acid that can

burn skin or eyes. Batteries produce

hydrogen, which is easily flammable and

explosive. Thus keep away flames or

devices which may cause sparks.

139)This starting procedure must be

performed by expert personnel because

incorrect actions could cause electrical

discharge of considerable intensity.

Furthermore, battery fluid is poisonous and

corrosive: avoid contact with skin and

eyes. Keep naked flames and lighted

cigarettes away from the battery and do

not cause sparks.

WARNING

56)Do not connect the cable to the

negative terminal (–) of the flat battery. The

following spark could lead to battery

explosion and cause serious harm. Only

use the specific earth point; do not use any

other exposed metallic part.

57)Never use a fast battery-charger to

start the engine as this could damage the

electronic systems of your vehicle,

particularly the ignition and engine fuel

supply control units.

145

Page 148 of 248

FUEL CUT-OFF

SYSTEM

140)

This intervenes in the case of an impact

causing:

the interruption of the fuel supply

with the engine consequently cutting

out;

the automatic unlocking of the

doors;

turning on the lights inside the car;

the switching on of the hazard

warning lights.

The intervention of the system is

indicated by a message shown on the

display.

IMPORTANT Carefully check the car for

fuel leaks, for instance in the engine

compartment, under the car or near the

tank area. After an impact, turn the

ignition key to STOP to prevent the

battery from running down.

Reset procedure

To restore correct operation of the

system, carry out the following Reset

procedure (the procedure must be

completed in less than 1 minute):

turn the ignition key to the MAR

position;

activate the right direction indicator

and then stop it;

activate the left direction indicator

and then stop it;

activate the right direction indicator

and then stop it;

activate the left direction indicator

and then stop it;

turn the ignition key to the STOP

position and then to MAR.

WARNING

140)If, after an impact, you smell fuel or

notice leaks from the fuel system, do

not reactivate the system to avoid the risk

of fire.

TOWING THE

VEHICLE

ATTACHING THE TOW

RING

141) 142) 143) 144)

The tow rings, which are supplied with

the car, are housed in the tool box,

under the carpet in the luggage

compartment.

IMPORTANT The shorter tow ring is for

use on the front of the car and the

longer one on the rear.

500L WAGON versions

NOTE 500L WAGON versions have

only one tow ring, which can be used

on either the front or the rear bumper.

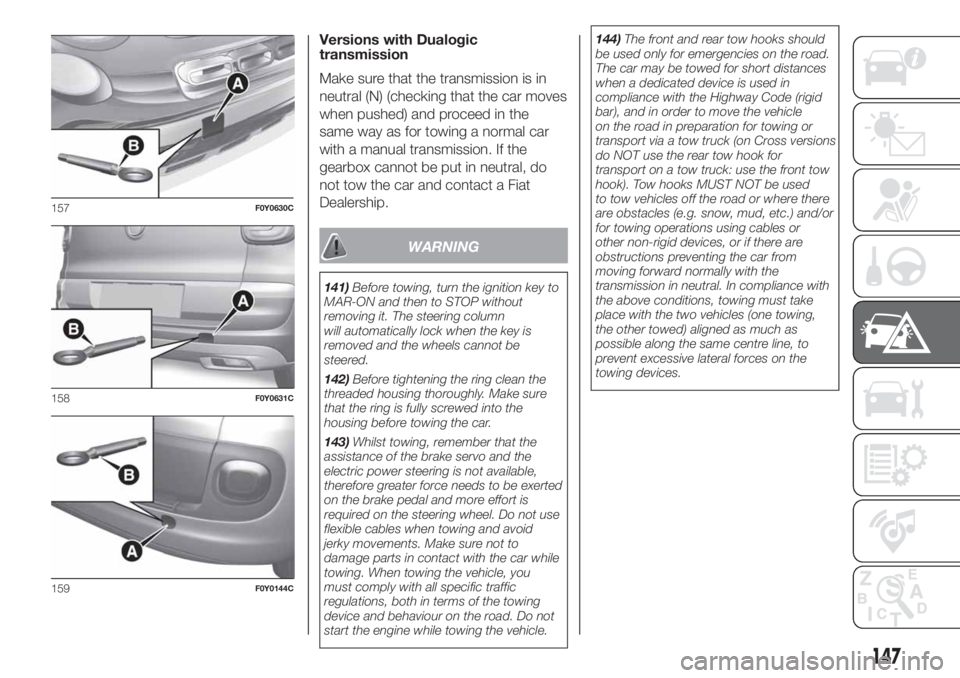

Front

Manually remove cap A fig. 157,

pressing in the lower part. Take tow ring

B from its housing in the tool support

and screw it completely onto the

threaded pin.

Rear

Manually remove cap A fig. 158 or fig.

159 (500L WAGON versions) by

pressing at the bottom. Take tow ring B

from its housing in the tool support

and screw it completely onto the

threaded pin.

146

IN AN EMERGENCY

Page 149 of 248

Versions with Dualogic

transmission

Make sure that the transmission is in

neutral (N) (checking that the car moves

when pushed) and proceed in the

same way as for towing a normal car

with a manual transmission. If the

gearbox cannot be put in neutral, do

not tow the car and contact a Fiat

Dealership.

WARNING

141)Before towing, turn the ignition key to

MAR-ON and then to STOP without

removing it. The steering column

will automatically lock when the key is

removed and the wheels cannot be

steered.

142)Before tightening the ring clean the

threaded housing thoroughly. Make sure

that the ring is fully screwed into the

housing before towing the car.

143)Whilst towing, remember that the

assistance of the brake servo and the

electric power steering is not available,

therefore greater force needs to be exerted

on the brake pedal and more effort is

required on the steering wheel. Do not use

flexible cables when towing and avoid

jerky movements. Make sure not to

damage parts in contact with the car while

towing. When towing the vehicle, you

must comply with all specific traffic

regulations, both in terms of the towing

device and behaviour on the road. Do not

start the engine while towing the vehicle.144)The front and rear tow hooks should

be used only for emergencies on the road.

The car may be towed for short distances

when a dedicated device is used in

compliance with the Highway Code (rigid

bar), and in order to move the vehicle

on the road in preparation for towing or

transport via a tow truck (on Cross versions

do NOT use the rear tow hook for

transport on a tow truck: use the front tow

hook). Tow hooks MUST NOT be used

to tow vehicles off the road or where there

are obstacles (e.g. snow, mud, etc.) and/or

for towing operations using cables or

other non-rigid devices, or if there are

obstructions preventing the car from

moving forward normally with the

transmission in neutral. In compliance with

the above conditions, towing must take

place with the two vehicles (one towing,

the other towed) aligned as much as

possible along the same centre line, to

prevent excessive lateral forces on the

towing devices.

157F0Y0630C

158F0Y0631C

159F0Y0144C

147

Page 151 of 248

SCHEDULED

SERVICING

Correct servicing is crucial for

guaranteeing a long life for the car

under the best conditions. For

this reason, Fiat has planned a series of

checks and services at fixed distance

and/or time intervals, as described

in the Service Schedule.

To keep the car in tip-top conditions, a

few additional checks which should

be carried out more frequently with

respect to the normal service deadlines

are listed in the Scheduled Service

plan on the previous pages.

IMPORTANT Scheduled Servicing

interventions are set out by the

Manufacturer. Failure to have them

carried out may invalidate the warranty.

We advise you to report any doubts

regarding the proper operation of the

car to your Fiat Dealership, before

waiting for the next service deadline.

REGULAR CHECKS

Every 1,000 kmor before long trips

check and, if necessary, top up:

engine coolant level;

brake fluid level;

AdBlue® (UREA) diesel emission

additive level (where present);

windscreen washer fluid level;

tyre inflation pressure and condition;

operation of lighting system

(headlights, direction indicators, hazard

warning lights, etc.);

operation of windscreen washer/

wiper system and positioning/wear of

rear window wiper blades.

Every3,000km, check and top up if

required: engine oil level.

DEMANDING USE OF THE

CAR

If the vehicle is used in one of the

following conditions:

law enforcement (or security

service), taxi service;

towing a trailer or caravan;

dusty roads;

short, repeated journeys (less than

7-8 Km) at sub-zero outdoor

temperatures;

engine often idling or driving long

distances at low speeds or long periods

of inactivity;

the following checks must be carried

out more often than indicated in the

Service Schedule:

check front disc brake pad condition

and wear;

check cleanliness of bonnet and

luggage compartment locks,

cleanliness and lubrication of linkage;

visually inspect conditions of:

engine, gearbox, transmission, pipes

and hoses (exhaust/fuel system/brakes)

and rubber elements (gaiters/sleeves/

bushes, etc.);

check battery charge and battery

fluid level (electrolyte);

visually inspect conditions of the

accessory drive belts;

check and, if necessary, change

engine oil and replace oil filter;

check and, if necessary, replace

pollen filter;

check and, if necessary, replace air

cleaner.

149