clock FIAT 500X 2014 2.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2014, Model line: 500X, Model: FIAT 500X 2014 2.GPages: 476, PDF Size: 5.32 MB

Page 295 of 476

5. Install the headlamp bulb and socket; align the tabsand turn it clockwise making sure it is properly

locked.

WARNING!

Carry out the operation of replacing lamps only

with the engine off. Also make sure that the engine

is cold, to avoid the danger of burns. Position Lights/Daytime Running Lights/Fog Lights

To replace the bulbs proceed as follows:

1. Turn the front wheels completely.

2. Use a suitable tool to remove the access door.

3. Remove the electrical connectors.

Headlamp Bulb Connector

Position Light/Daytime Running Light/Fog light Access

1 — Screws

2 — Access Door

8

IN CASE OF EMERGENCY 293

Page 296 of 476

4. Rotate in a counterclockwise direction and removethe bulb and bulb socket.

5. To replace the bulb gently push bulb and rotate counterclockwise. 6. Insert the new bulb by pushing on it and turning it

clockwise. Make sure the bulb is correctly locked in

place.

7. Install the bulb and sockets and rotate them clock- wise, making sure that it is properly locked.

8. Reconnect the electrical connectors.

9. Reinstall the access door.

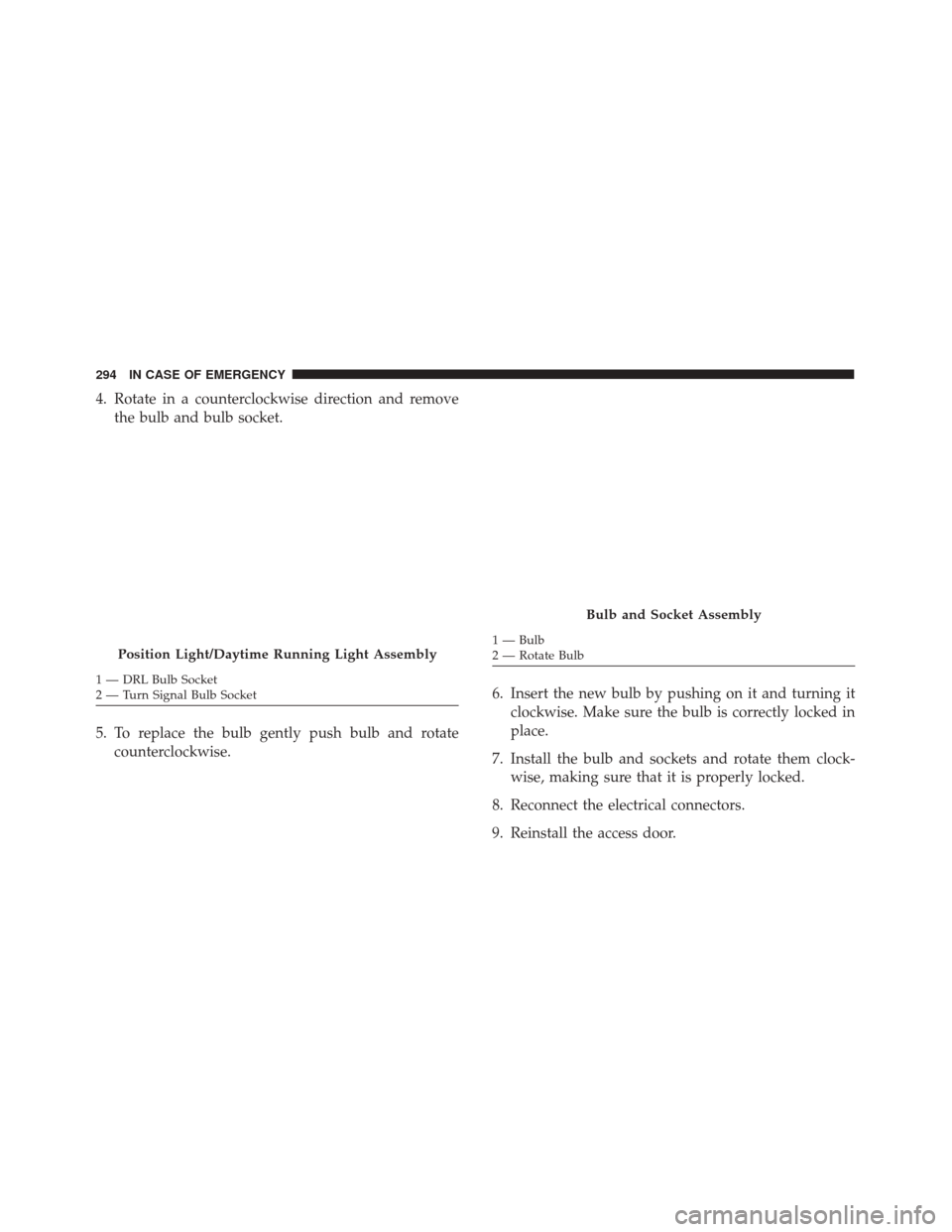

Position Light/Daytime Running Light Assembly

1 — DRL Bulb Socket

2 — Turn Signal Bulb Socket

Bulb and Socket Assembly

1 — Bulb

2 — Rotate Bulb

294 IN CASE OF EMERGENCY

Page 297 of 476

Front Fog Lights

To replace the bulbs proceed as follows:

1. Turn the front wheels completely.

2. Use a suitable tool to remove the access door.

3. By pushing the electrical connector tab remove theelectrical connector. 4. Rotate the bulb counterclockwise, and then replace

the bulb.

5. Insert the new bulb in the socket, making sure the bulb is locked into place.

6. Reconnect the electrical connector.

7. Reinstall the access door.

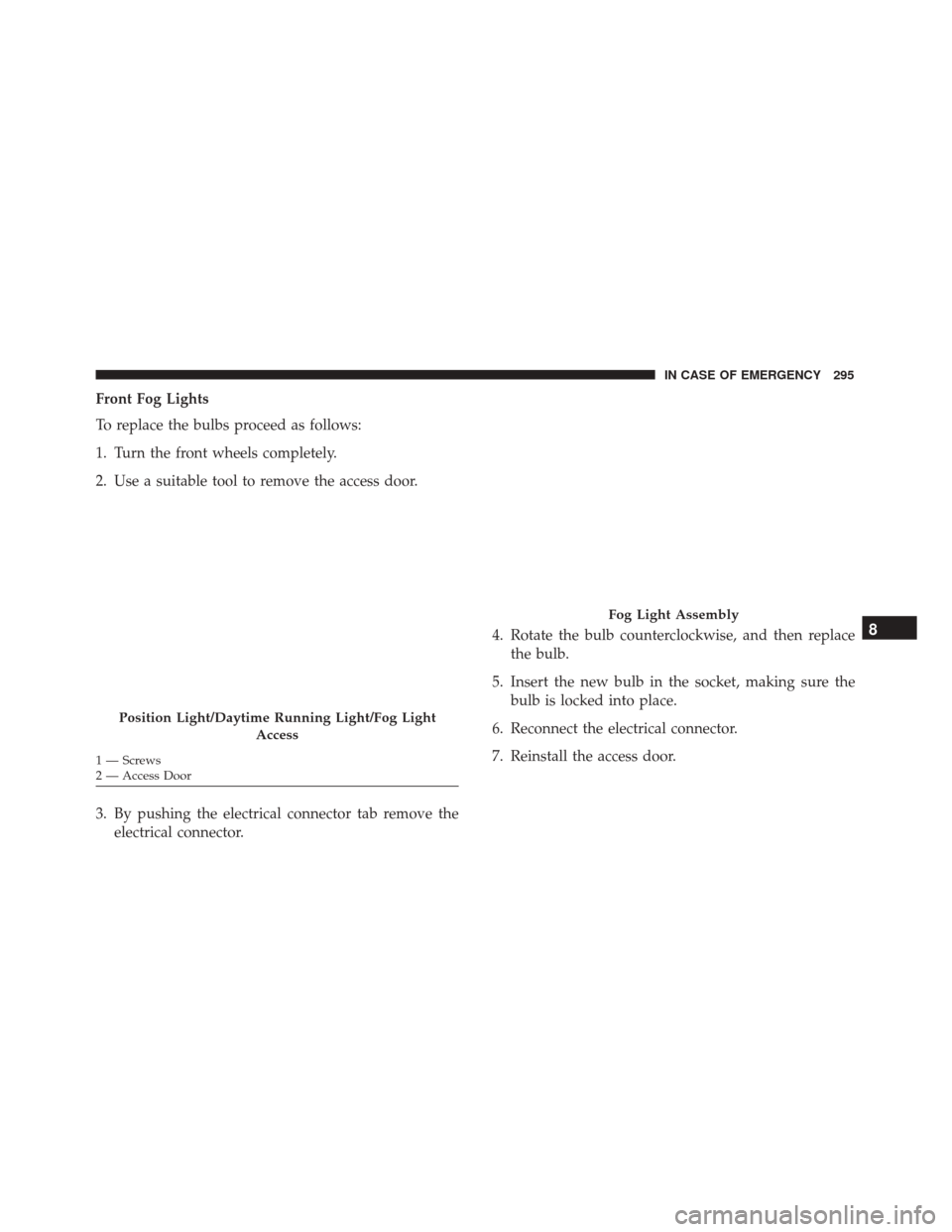

Position Light/Daytime Running Light/Fog Light Access

1 — Screws

2 — Access Door

Fog Light Assembly

8

IN CASE OF EMERGENCY 295

Page 298 of 476

Side Indicators on External Rear View Mirrors – If

Equipped

CAUTION!

The procedure is described as a guideline. For the

replacement of the lamp it is recommended that you

contact your authorized dealer.

To replace the bulb proceed as follows:

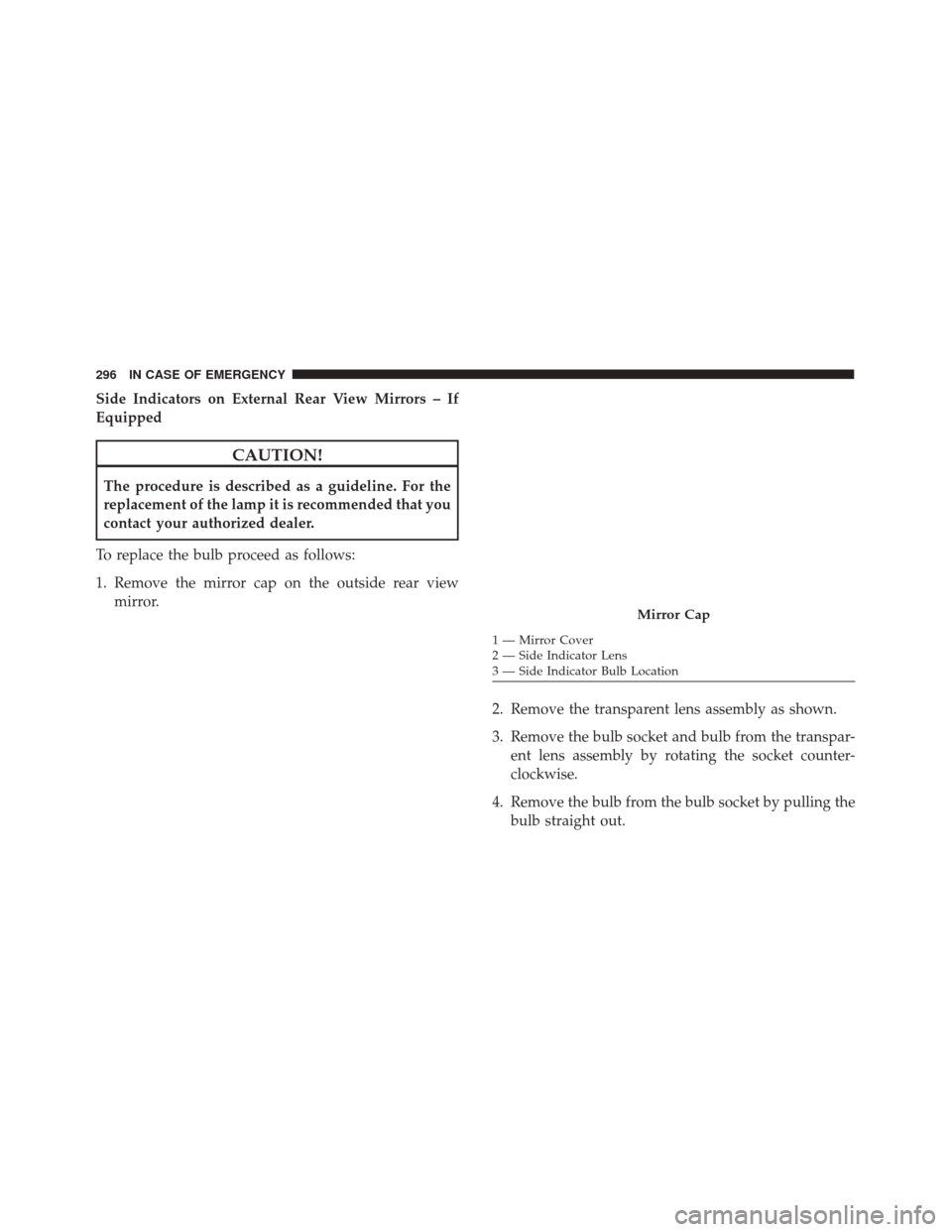

1. Remove the mirror cap on the outside rear view mirror.

2. Remove the transparent lens assembly as shown.

3. Remove the bulb socket and bulb from the transpar-ent lens assembly by rotating the socket counter-

clockwise.

4. Remove the bulb from the bulb socket by pulling the bulb straight out.

Mirror Cap

1 — Mirror Cover

2 — Side Indicator Lens

3 — Side Indicator Bulb Location

296 IN CASE OF EMERGENCY

Page 309 of 476

Access To The Fuses

The fuses are grouped into four controllers located in

the engine compartment, under the instrument panel

and on the inside of the left side cargo trim panel.

Engine Compartment Fuses/Distribution Unit

The engine compartment fuse panel is located on the

left side of the engine compartment.Removing Fuse Cover and Locking Screw

Proceed as follows:

1. Slowly turn the screw counterclockwise.

2. Slowly release the screw.

3. Remove the fuse cover by sliding it upward.

Engine Compartment Fuse Cavities

Fuse Panel And Cover Location

1 — Mounting Screw

2 — Fuse Cover8

IN CASE OF EMERGENCY 307

Page 310 of 476

Mounting Fuse Cover and Locking Screw

Proceed as follows:

1. Properly secure the fuse cover to the box, slidecompletely from top to bottom.

2. Fully depress the screw, using the special screw- driver supplied.

3. Slowly turn the screw clockwise.

4. Release the screw.

Cavity Maxi Fuse Cartage Fuse Mini Fuse Description

F01 70 Amp Tan ––Module Body Com-

puter

F02 60 Amp Blue ––Module Body Com-

puter, Rear Distribu- tion Units

Battery Fuse Cover Location

1 — Fuse Cover Tabs

2 — Fuse Cover

308 IN CASE OF EMERGENCY

Page 321 of 476

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the Jacking

Instructions for this vehicle.

1. Remove the spare tire, jack, and wheel bolt wrench.

2. If equipped with wheels where the center cap covers the wheel bolts, use the wheel bolt wrench to pry the

center cap off carefully before raising the vehicle. 3. Before raising the vehicle, use the wheel bolt wrench

to loosen, but not remove the wheel bolts on the

wheel with the flat tire. Turn the wheel bolts coun-

terclockwise one turn while the wheel is still on the

ground.

4. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack screw clockwise to firmly

engage the jack saddle with the lift area of the sill

flange, centering the jack saddle inside the cutout in

the sill cladding.

Jack Warning Label

Loosen The Wheel Bolt

8

IN CASE OF EMERGENCY 319

Page 324 of 476

NOTE:•Your vehicle may be equipped with a compact

spare tire or a limited — use spare tire. For further

information refer to “Tires — General Information”

in “Maintaining Your Vehicle”.

• For vehicles so equipped, do not attempt to install

a center cap or wheel cover on the compact spare.

8. Install the wheel bolts with the threaded end of the wheel bolt toward the wheel. Lightly tighten the

wheel bolts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not fully tighten the wheel bolts until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

9. Lower the vehicle to the ground by turning the wheel bolt wrench counterclockwise.

10. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened twice. Refer to “Torque Specifications” in “Technical Data”

for the proper lug bolt torque. If in doubt about the

correct tightness, have them checked with a torque

wrench by your authorized dealer or at a service

station.

11. Securely stow the jack, tools, chocks and flat tire.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the

vehicle. Always stow the jack parts and the spare

tire in the places provided. Have the deflated (flat)

tire repaired or replaced immediately.

Road Tire Installation

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threaded end of the wheel bolt toward the wheel. Lightly

tighten the wheel bolts.

322 IN CASE OF EMERGENCY

Page 325 of 476

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle

has been lowered. Failure to follow this warning

may result in serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the wheel bolts in a star pattern

until each wheel bolt has been tightened twice. Refer

to “Torque Specifications” in the “Technical Data”

section for the proper lug bolt torque. If in doubt

about the correct tightness, have them checked with

a torque wrench by your authorized dealer or service

station.

5. Lower the jack until it is free. Remove the wheel chocks. Stow the jack and tools back in the proper

storage location. Release the Electric Park Brake

before driving the vehicle. 6. After 25 miles (40 km) check the wheel bolt torque

with a torque wrench to ensure that all wheel bolts

are properly seated against the wheel.

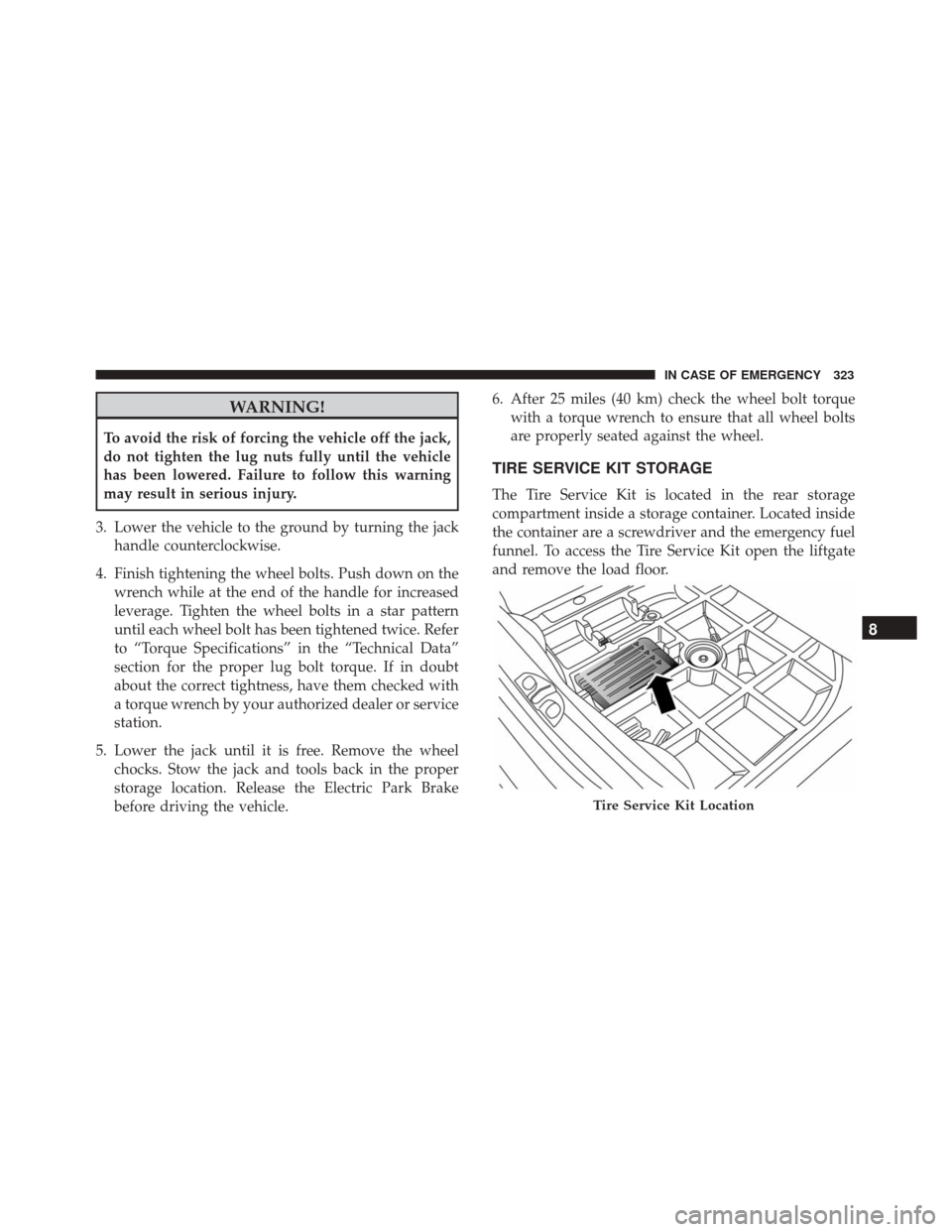

TIRE SERVICE KIT STORAGE

The Tire Service Kit is located in the rear storage

compartment inside a storage container. Located inside

the container are a screwdriver and the emergency fuel

funnel. To access the Tire Service Kit open the liftgate

and remove the load floor.

Tire Service Kit Location

8

IN CASE OF EMERGENCY 323

Page 417 of 476

Buttons On The Faceplate

Buttons on the faceplate are located below, and beside

the Uconnect system in the center of the instrument

panel. In addition, there is a Scroll/Enter control knob

located on the right side. Turn the control knob to scroll

through menus and change settings (i.e., 30, 60, 90),

push the center of the control knob one or more times to

select or change a setting (i.e., ON, OFF).

Your Uconnect system may also have Display Off and

back arrow buttons on the faceplate.

Push the Display Off button on the faceplate to turn off

the Uconnect screen. Push the Display Off button on the

faceplate a second time to turn the screen on.

Push the Back Arrow button on the faceplate to exit out

of a Menu or certain option on the Uconnect system.

Buttons On The Touchscreen

Buttons on the touchscreen are accessible on the

Uconnect touchscreen.

Customer Programmable Features — Uconnect

5.0 Settings

Push the Settingsbutton on the faceplate, to dis-

play the settings menu screen. In this mode the Uconnect system allows you to access programmable

features that may be equipped such as Display,

Units, Voice, Clock & Date, Safety/Assistance,

Lights, Doors & Locks, Engine Off Options, Audio,

Phone/Bluetooth, Radio Setup, Restore Settings and

Clear Personal Data.

NOTE:

Only one touchscreen area may be selected at a

time.

When making a selection, press the button on the

touchscreen to enter the desired mode. Once in the

desired mode, press and release the preferred setting

and make your selection. Once the setting is complete,

either press the Back Arrow button on the touchscreen

or the Back button on the faceplate to return to the

previous menu or press the “X” button on the touch-

screen to close out of the settings screen. Pressing the

Up or Down Arrow buttons on the right side of the

screen will allow you to toggle up or down through the

available settings.

NOTE: All settings should be changed with the ignition

in the “RUN” position.

11

MULTIMEDIA 415