fuel cap FIAT 500X 2015 2.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: 500X, Model: FIAT 500X 2015 2.GPages: 240, PDF Size: 10.72 MB

Page 76 of 240

58)The system is an aid for the driver, who

must always pay full attention while driving.

The responsibility always rests with the

driver, who must take into account the

traffic conditions in order to drive in

complete safety. The driver must always

maintain a safe distance from the vehicle in

front.

59)If the driver depresses the brake pedal

fully or carries out a fast steering during

system operation, the automatic braking

function may stop (e.g. to allow a possible

manoeuvre to avoid the obstacle).

60)The system intervenes on vehicles

travelling in the same lane. People, animals

and things (e.g. pushchairs) are not taken

into consideration.

61)If the vehicle must be placed on a roller

bench for maintenance interventions or if

it is washed in an automatic roller washing

tunnel with an obstacle in the front part

(e.g. another vehicle, a wall or another

obstacle), the system may detect its

presence and activate. In this case the

system must be deactivated through the

settings of theUconnect™system.

62)If the system signals a pressure

decrease on a specific tyre, it is

recommended to check the pressure on all

four tyres.

63)iTPMS does not relieve the driver from

the obligation to check the tyre pressure

every month; it is not to be considered

a system to replace maintenance or a

safety system.64)Tyre pressure must be checked with

tyres cold. Should it become necessary for

whatever reason to check pressure with

warm tyres, do not reduce pressure even if

it is higher than the prescribed value,

rather repeat the check when tyres are

cold.

65)The iTPMS cannot indicate sudden tyre

pressure drops (e.g. if a tyre bursts). In

this case, stop the vehicle, braking with

caution and avoiding abrupt steering.

66)The system only warns that the tyre

pressure is low: it is not able to inflate

them.

67)Insufficient tyre inflation increases fuel

consumption, reduces the tread duration

and may affect the capacity to drive safely.

WARNING

22)The system may have limited or absent

operation due to weather conditions such

as: heavy rain, hail, thick fog, heavy snow.

23)The section of the bumper before

the sensor must not be covered with

adhesives, auxiliary headlights or any other

object.

24)System intervention might be

unexpected or delayed when other vehicles

transport loads projecting from the side,

above or from the rear, with respect to the

normal size of the vehicle.

25)Operation can be adversely affected by

any structural change made to the vehicle,

such as a modification to the front

geometry, tyre change, or a heavier load

than the standard load of the vehicle.26)Incorrect repairs made on the front part

of the vehicle (e.g. bumper, chassis) may

alter the position of the radar sensor,

and adversely affect its operation. Go to a

Fiat Dealership for any operation of this

type.

27)Do not tamper with nor carry out any

intervention on the radar sensor or on

the camera on the windscreen. In the event

of a sensor failure, contact a Fiat

Dealership.

28)When towing a trailer (with modules

installed after purchasing the vehicle),

a vehicle or during loading manoeuvres on

a vehicle transporter (or in vehicle for

transport), the system must be deactivated

via theUconnect™system.

29)Do not wash with high-pressure jets in

the bumper lower area: in particular do

not operate on the system's electrical

connector.

30)Be careful in the case of repairs and

new paintings in the area around the

sensor (panel covering the sensor on the

left side of the bumper). In the event of

a frontal impact the sensor may

automatically deactivate and display a

warning to indicate that the sensor needs

to be repaired. Even without a malfunction

warning, deactivate the system operation

if you think that the position of the radar

sensor has changed (e.g. due to

low-speed frontal impact as during parking

manoeuvres). In these cases, go to a Fiat

Dealership to have the radar sensor

realigned or replaced.

74

SAFETY

15-12-2014 8:23 Pagina 74

Page 121 of 240

REFUELLING THE

VEHICLE

122) 123) 124)

PETROL ENGINESOnly use unleaded petrol with a number

of octanes (R.O.N.) not lower than 95

(EN 228 specification).DIESEL ENGINES

50)

Only use Diesel for motor vehicles (EN

590 specification).

When using or parking the vehicle for a

long time in the mountains or cold

areas, it is advisable to refuel using

locally available diesel. In this case, it is

also advisable to keep the tank over

50% full.REFUELLING

PROCEDURE"Capless Fuel" is a device at the

opening for the fuel tank which opens

and recloses automatically when the

fuel supply gun is introduced/removed.

The "Capless Fuel" device is provided

with an inhibitor which prevents

refuelling with incorrect fuel.

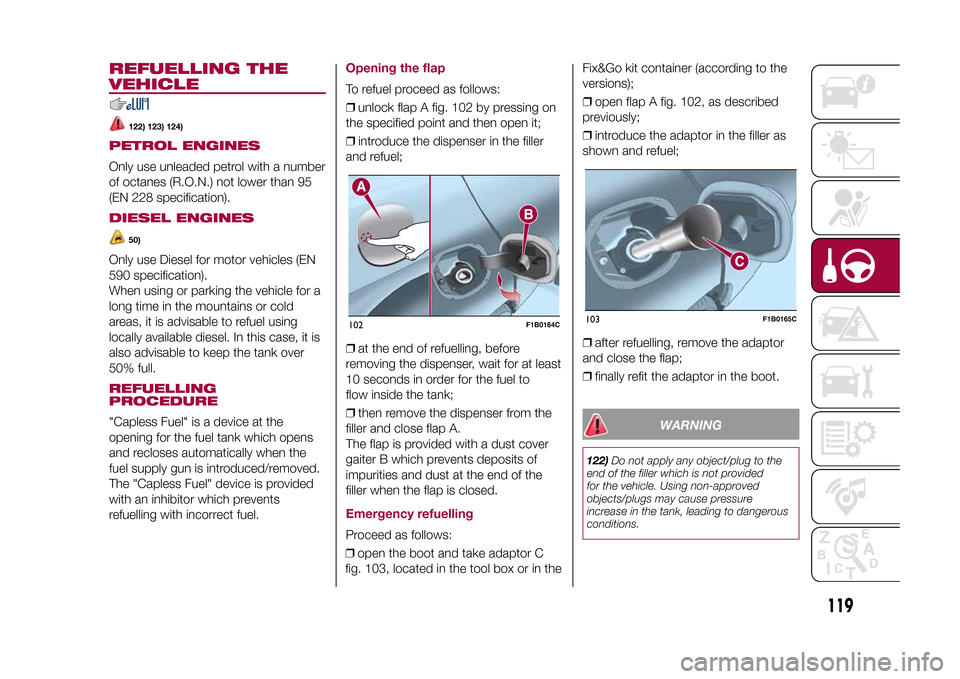

Opening the flapTo refuel proceed as follows:

❒unlock flap A fig. 102 by pressing on

the specified point and then open it;

❒introduce the dispenser in the filler

and refuel;

❒at the end of refuelling, before

removing the dispenser, wait for at least

10 seconds in order for the fuel to

flow inside the tank;

❒then remove the dispenser from the

filler and close flap A.

The flap is provided with a dust cover

gaiter B which prevents deposits of

impurities and dust at the end of the

filler when the flap is closed.Emergency refuellingProceed as follows:

❒open the boot and take adaptor C

fig. 103, located in the tool box or in theFix&Go kit container (according to the

versions);

❒open flap A fig. 102, as described

previously;

❒introduce the adaptor in the filler as

shown and refuel;

❒after refuelling, remove the adaptor

and close the flap;

❒finally refit the adaptor in the boot.

WARNING

122)Do not apply any object/plug to the

end of the filler which is not provided

for the vehicle. Using non-approved

objects/plugs may cause pressure

increase in the tank, leading to dangerous

conditions.

102

F1B0164C

103

F1B0165C

119

15-12-2014 8:23 Pagina 119

Page 138 of 240

137)The jack is a tool developed and

designed only for changing a wheel, if a

tyre gets punctured or damaged, on the

vehicle with which it is supplied or on other

vehicles of the same model. It must not

be used, for example, to jack other vehicle

models or objects. Never use the jack to

carry out maintenance or repairs under the

vehicle. Never position yourself under a

jacked vehicle. Should it be necessary to

work under the vehicle, contact a Fiat

Dealership. Incorrectly positioning the jack

may cause the vehicle to fall: use it only

in the positions indicated. Do not use the

jack for loads higher than the one shown

on its label.

138)The space-saver wheel cannot be

fitted with snow chains. If a front (drive) tyre

is punctured and chains are needed, use

a standard wheel from the rear axle and

install the space-saver wheel on the rear

axle. In this way, with two normal drive

wheels at the front axle, it is possible to use

snow chains (this instruction is also valid

for 4x4 versions).

139)Never tamper with the inflation valve.

Never introduce tools of any kind between

the rim and the tyre. Check tyre and

space-saver wheel pressures regularly,

complying with the values given in the

"Technical specifications" chapter.

FIX&GO AUTOMATIC

KIT(where provided)DESCRIPTION

140) 141) 142) 143) 144) 145) 146) 147)54)3)

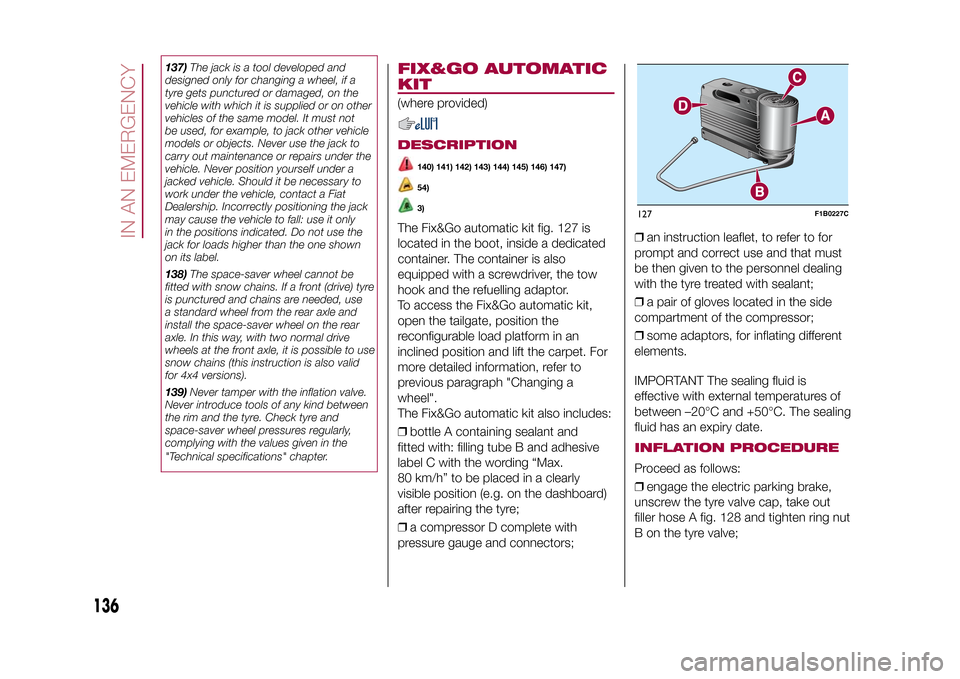

The Fix&Go automatic kit fig. 127 is

located in the boot, inside a dedicated

container. The container is also

equipped with a screwdriver, the tow

hook and the refuelling adaptor.

To access the Fix&Go automatic kit,

open the tailgate, position the

reconfigurable load platform in an

inclined position and lift the carpet. For

more detailed information, refer to

previous paragraph "Changing a

wheel".

The Fix&Go automatic kit also includes:

❒bottle A containing sealant and

fitted with: filling tube B and adhesive

label C with the wording “Max.

80 km/h” to be placed in a clearly

visible position (e.g. on the dashboard)

after repairing the tyre;

❒a compressor D complete with

pressure gauge and connectors;❒an instruction leaflet, to refer to for

prompt and correct use and that must

be then given to the personnel dealing

with the tyre treated with sealant;

❒a pair of gloves located in the side

compartment of the compressor;

❒some adaptors, for inflating different

elements.

IMPORTANT The sealing fluid is

effective with external temperatures of

between –20°C and +50°C. The sealing

fluid has an expiry date.

INFLATION PROCEDUREProceed as follows:

❒engage the electric parking brake,

unscrew the tyre valve cap, take out

filler hose A fig. 128 and tighten ring nut

B on the tyre valve;127

F1B0227C

136

IN AN EMERGENCY

15-12-2014 8:23 Pagina 136