clutch FIAT DOBLO COMBI 2012 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2012, Model line: DOBLO COMBI, Model: FIAT DOBLO COMBI 2012Pages: 283, PDF Size: 6.31 MB

Page 189 of 283

185

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

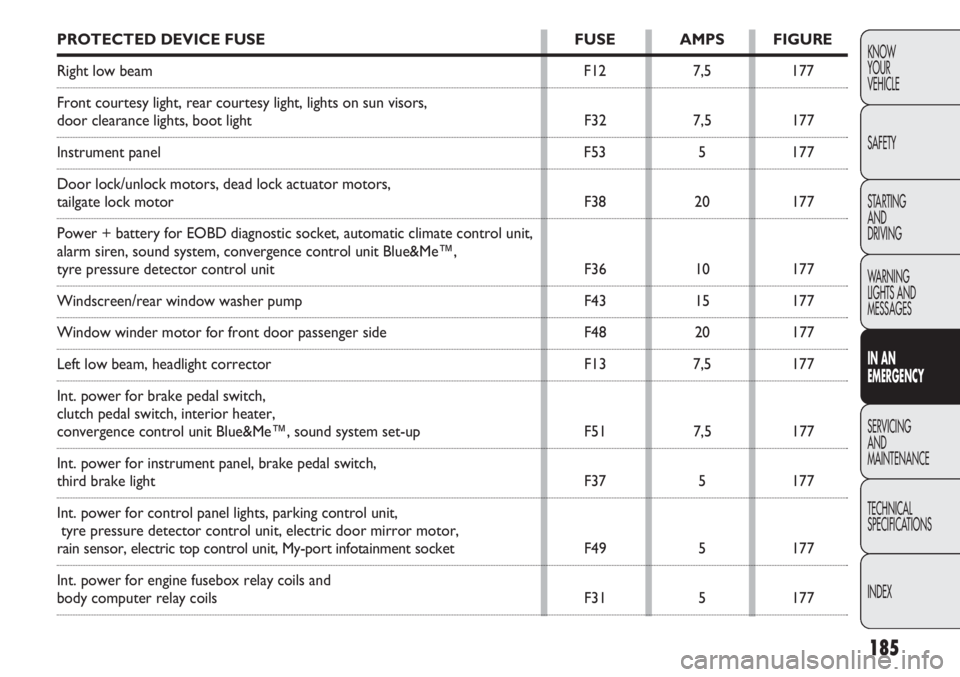

INDEXPROTECTED DEVICE FUSE FUSE AMPS FIGURE

Right low beam F127,5177

Front courtesy light, rear courtesy light, lights on sun visors,

door clearance lights, boot light F327,5177

Instrument panel F535177

Door lock/unlock motors, dead lock actuator motors,

tailgate lock motor F3820177

Power + battery for EOBD diagnostic socket, automatic climate control un\

it,

alarm siren, sound system, convergence control unit Blue&Me™,

tyre pressure detector control unit F3610177

Windscreen/rear window washer pump F4315177

Window winder motor for front door passenger side F4820177

Left low beam, headlight corrector F137,5177

Int. power for brake pedal switch,

clutch pedal switch, interior heater,

convergence control unit Blue&Me™, sound system set-up F517,5177

Int. power for instrument panel, brake pedal switch,

third brake light F375177

Int. power for control panel lights, parking control unit, tyre pressure detector control unit, electric door mirror motor,

rain sensor, electric top control unit, My-port infotainment socket F495177

Int. power for engine fusebox relay coils and

body computer relay coils F315177

Page 197 of 283

193

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVIC

ING

AND

MAINTENANCE

TECHNICAL

SPECIFICA TIONS

INDEX

●●

●●●●●●

●

●

●●●●●●

●●●●●●

●●●●●●

●●●●●●

●●●●●● ●●●

●●●●●●

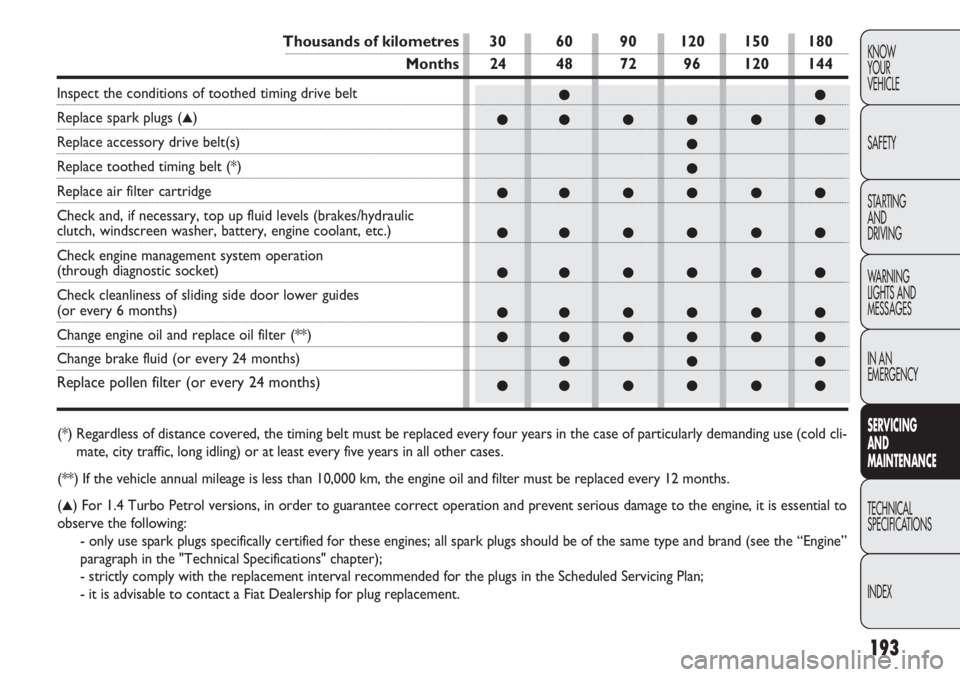

Thousands of kilometres 30 60 90 120 150 180

Months 24 48 72 96 120 144

Inspect the conditions of toothed timing drive belt

Replace spark plugs (▲)

Replace accessory drive belt(s)

Replace toothed timing belt (*)

Replace air filter cartridge

Check and, if necessary, top up fluid levels (brakes/hydraulic

clutch, windscreen washer, battery, engine coolant, etc.)

Check engine management system operation

(through diagnostic socket)

Check cleanliness of sliding side door lower guides

(or every 6 months)

Change engine oil and replace oil filter (**)

Change brake fluid (or every 24 months)

Replace pollen filter (or every 24 months)

(*) Regardless of distance covered, the timing belt must be replaced every f\

our years in the case of particularly demanding use (cold cli-

mate, city traffic, long idling) or at least every five years in all ot\

her cases.

(**) If the vehicle annual mileage is less than 10,000 km, the engine oil and\

filter must be replaced every 12 months.

(

▲) For 1.4 Turbo Petrol versions, in order to guarantee correct operatio\

n and prevent serious damage to the engine, it is essential to

observe the following: - only use spark plugs specifically certified for these engines; all spa\

rk plugs should be of the same type and brand (see the “Engine”

paragraph in the "Technical Specifications" chapter);

- strictly comply with the replacement interval recommended for the plug\

s in the Scheduled Servicing Plan;

- it is advisable to contact a Fiat Dealership for plug replacement.

Page 198 of 283

194

KNOWYOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING

LIGHTS AND MESSAGES

IN AN

EMERGENCY

SERV IC

ING

AND

MAINTENANCE

TECHNICAL

SPECIFICA TIONS

INDEX

●●●●●●

●●●●●●

●●●●●●

●●●●●●

●●●●●● ●●●

●●●●●●

●●●●●●

●●●●●●

●●

●●●●●● ●●

●●●●●●

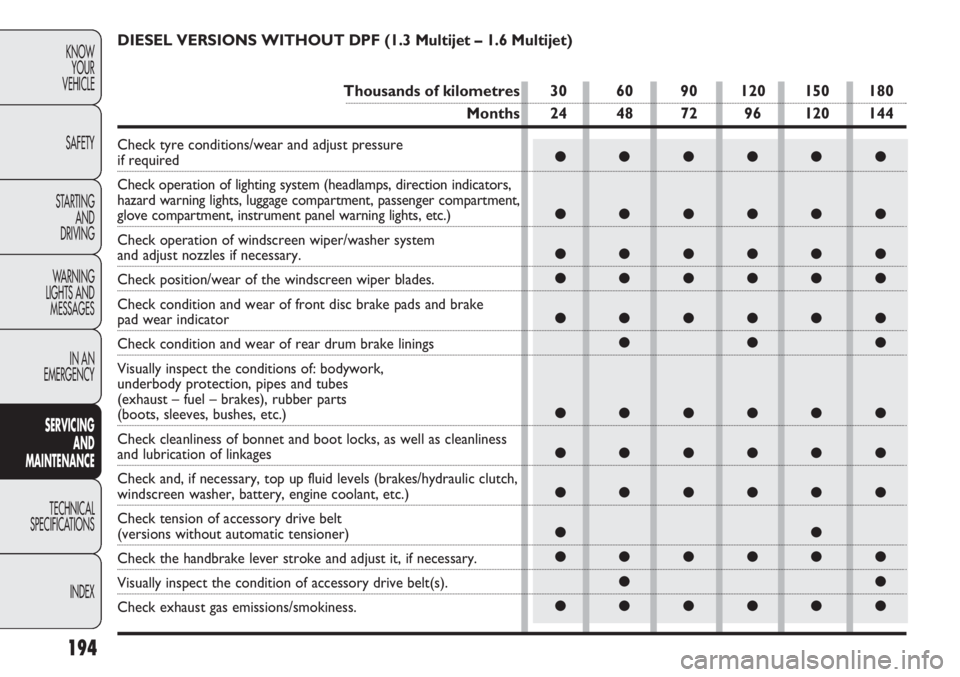

DIESEL VERSIONS WITHOUT DPF (1.3 Multijet – 1.6 Multijet)

Thousands of kilometres 30 60 90 120 150 180

Months 24 48 72 96 120 144

Check tyre conditions/wear and adjust pressure if required

Check operation of lighting system (headlamps, direction indicators,

hazard warning lights, luggage compartment, passenger compartment,

glove compartment, instrument panel warning lights, etc.)

Check operation of windscreen wiper/washer system

and adjust nozzles if necessary.

Check position/wear of the windscreen wiper blades.

Check condition and wear of front disc brake pads and brake

pad wear indicator

Check condition and wear of rear drum brake linings

Visually inspect the conditions of: bodywork,

underbody protection, pipes and tubes

(exhaust – fuel – brakes), rubber parts

(boots, sleeves, bushes, etc.)

Check cleanliness of bonnet and boot locks, as well as cleanliness

and lubrication of linkages

Check and, if necessary, top up fluid levels (brakes/hydraulic clutch, \

windscreen washer, battery, engine coolant, etc.)

Check tension of accessory drive belt

(versions without automatic tensioner)

Check the handbrake lever stroke and adjust it, if necessary.

Visually inspect the condition of accessory drive belt(s).

Check exhaust gas emissions/smokiness.

Page 200 of 283

196

KNOWYOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING

LIGHTS AND MESSAGES

IN AN

EMERGENCY

SERV IC

ING

AND

MAINTENANCE

TECHNICAL

SPECIFICA TIONS

INDEX

● ●●●●

● ●●●●

● ●●●●

● ●●●●

● ●●●● ●●

● ●●●●

● ●●●●

● ●●●●

●●

● ●●●● ●●

● ●●●●

DIESEL VERSIONS WITH DPF (1.3 Multijet – 1.6 Multijet – 2.0 Multijet)

Thousands of kilometres 35 70 105 140 175

Months 24 48 72 96 120

Check tyre conditions/wear and adjust pressure if required

Check lighting system operation

(headlights, direction indicators, hazard lights, boot, passenger compa\

rtment,

glove box, instrument panel warning lights, etc.)

Check operation of windscreen wiper/washer system

and adjust nozzles if necessary

Check position/wear of the windscreen wiper blades.

Check condition and wear of front disc brake pads and brake pad wear ind\

icator

Check condition and wear of rear drum brake linings

Visually inspect the conditions of: bodywork,

underbody protection, pipes and tubes

(exhaust – fuel – brakes), rubber parts

(boots, sleeves, bushes, etc.)

Check cleanliness of bonnet and boot locks, as well as cleanliness and

lubrication of linkages

Check and, if necessary, top up fluid levels (brakes/hydraulic clutch, \

windscreen washer, battery, engine coolant, etc.)

Check tension of accessory drive belt

(versions without automatic tensioner)

Check the handbrake lever stroke and adjust it, if necessary.

Visually inspect the condition of accessory drive belt(s).

Check exhaust gas emissions/smokiness.

Page 228 of 283

224

KNOWYOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING

LIGHTS AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICAT IO

NS

INDEX

Modifications or repairs to the fuel supply system that are not carried \

out properly or do not take

the system’s technical specifications into account can cause malfunct\

ions leading to the risk of

fire.

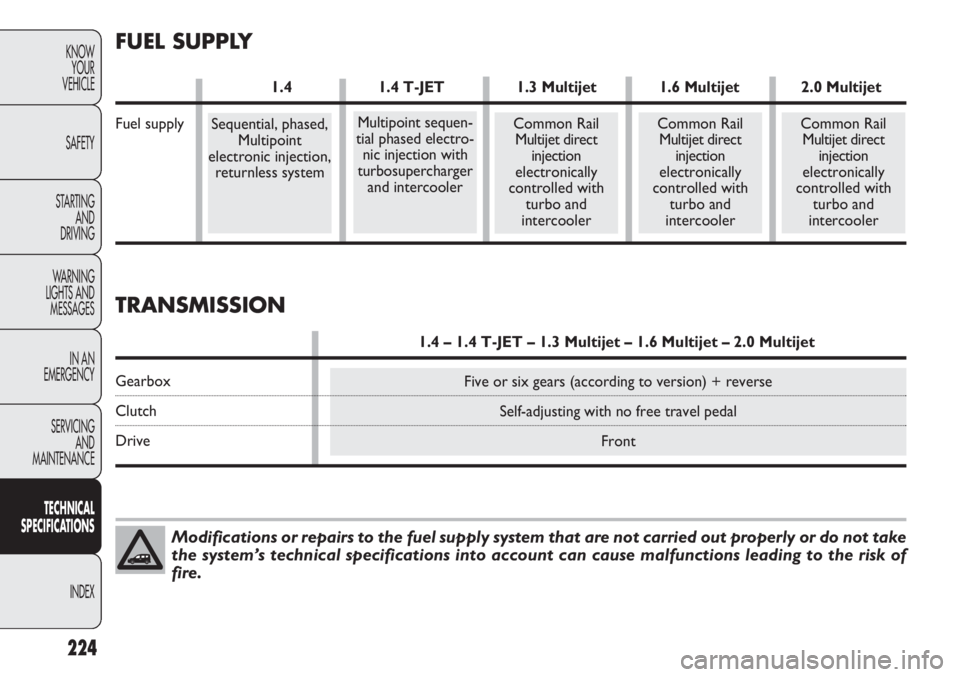

Sequential, phased, Multipoint

electronic injection, returnless systemCommon Rail Multijet direct injection

electronically

controlled with turbo and

intercoolerCommon Rail Multijet direct injection

electronically

controlled with turbo and

intercoolerCommon Rail Multijet direct injection

electronically

controlled with turbo and

intercooler

Five or six gears (according to version) + reverse

Self-adjusting with no free travel pedal Front

TRANSMISSION

1.4 – 1.4 T-JET – 1.3 Multijet – 1.6 Multijet – 2.0 Multijet

Gearbox

Clutch

Drive

Multipoint sequen-

tial phased electro- nic injection with

turbosupercharger and intercooler

FUEL SUPPLY

1.4 1.4 T-JET 1.3 Multijet 1.6 Multijet 2.0 Multijet

Fuel supply

Page 252 of 283

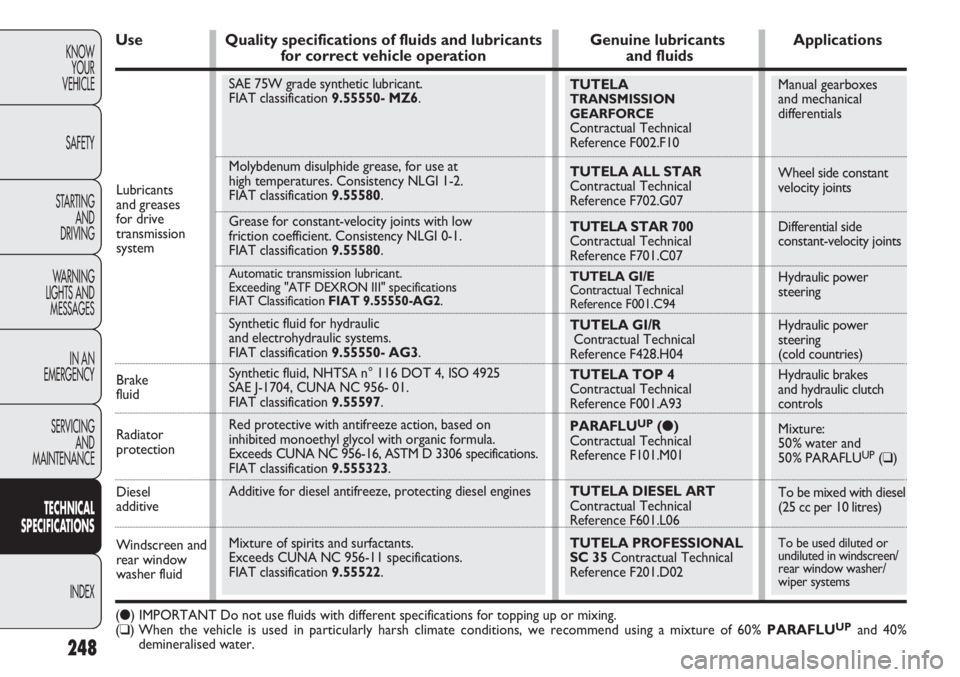

Manual gearboxes

and mechanical

differentials

Wheel side constant

velocity joints

Differential side

constant-velocity joints

Hydraulic power

steering

Hydraulic power

steering

(cold countries)

Hydraulic brakes

and hydraulic clutch

controls

Mixture:

50% water and

50% PARAFLU

UP(❑ )

To be mixed with diesel

(25 cc per 10 litres)

To be used diluted or

undiluted in windscreen/

rear window washer/

wiper systems

TUTELA TRANSMISSION

GEARFORCE

Contractual Technical

Reference F002.F10

TUTELA ALL STAR

Contractual Technical

Reference F702.G07

TUTELA STAR 700

Contractual Technical

Reference F701.C07

TUTELA GI/E

Contractual Technical

Reference F001.C94

TUTELA GI/R Contractual Technical

Reference F428.H04

TUTELA TOP 4

Contractual Technical

Reference F001.A93

PARAFLU

UP(●)

Contractual Technical

Reference F101.M01

TUTELA DIESEL ART

Contractual Technical

Reference F601.L06

TUTELA PROFESSIONAL

SC 35 Contractual Technical

Reference F201.D02

SAE 75W grade synthetic lubricant.

FIAT classification 9.55550- MZ6.

Molybdenum disulphide grease, for use at

high temperatures. Consistency NLGI 1-2.

FIAT classification 9.55580.

Grease for constant-velocity joints with low

friction coefficient. Consistency NLGI 0-1.

FIAT classification 9.55580.

Automatic transmission lubricant.

Exceeding "ATF DEXRON III" specifications

FIAT Classification FIAT 9.55550-AG2.

Synthetic fluid for hydraulic

and electrohydraulic systems.

FIAT classification 9.55550- AG3.

Synthetic fluid, NHTSA n° 116 DOT 4, ISO 4925

SAE J-1704, CUNA NC 956- 01.

FIAT classification 9.55597.

Red protective with antifreeze action, based on

inhibited monoethyl glycol with organic formula.

Exceeds CUNA NC 956-16, ASTM D 3306 specifications.

FIAT classification 9.555323.

Additive for diesel antifreeze, protecting diesel engines

Mixture of spirits and surfactants.

Exceeds CUNA NC 956-11 specifications.

FIAT classification 9.55522.

248

KNOW

YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING

LIGHTS AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICAT IO

NS

INDEX

Lubricants

and greases

for drive

transmission

system

Brake

fluid

Radiator

protection

Diesel

additive

Windscreen and

rear window

washer fluid

Use Quality specifications of fluids and lubricants Genuine lubricants Applications for correct vehicle operation and fluids

(●) IMPORTANT Do not use fluids with different specifications for topping\

up or mixing.

(❑) When the vehicle is used in particularly harsh climate conditions, we re\

commend using a mixture of 60% PARAFLUUPand 40%

demineralised water.

Page 254 of 283

250

KNOWYOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING

LIGHTS AND MESSAGES

IN AN

EMERGENCY

SERVICING AND

MAINTENANCE

TECHNICAL

SPECIFICAT IO

NS

INDEX

9. Air conditioning leads to higher fuel consumption (on average up to +30%). If the temperature outside is not

too extreme, try and use the air vents.

Driving style

1. After starting the engine you should drive away im-

mediately and slowly, avoiding high revs. Do not warm

up the engine at low or high revs when the vehicle is

stationary; this causes the engine to warm up more

slowly, thereby increasing fuel consumption, emissions

and mechanical component wear.

2. Avoid pointless actions such as revving up when at

traffic lights or before stopping the engine. The latter

action, like double-declutching, is unnecessary and caus-

es increased fuel consumption and pollution.

3. Gear selection: select a high gear as soon as possible

(taking into account normal engine operation and traf-

fic conditions) without pushing the engine to high revs

during the intermediate gears. Using low gears at high

revs to get excellent acceleration increases fuel con-

sumption, harmful emissions and engine wear.

PRACTICAL ADVICE FOR REDUCING FUEL

CONSUMPTION AND HARMFUL EMISSIONS

Vehicle condition

1. Have checks and

servicingcarried out in accordance

with the “Scheduled servicing plan”.

2. Check tyre pressure regularly, at least once every four

weeks. Excessively low pressures will increase con-

sumption because rolling resistance will be higher. In

these conditions, the tyre will wear and performance

will decay faster.

3. Use snow tyres only when the weather conditions

make them absolutely necessary. They increase con-

sumption and noise.

4. Do not travel with a heavy load: the weight of the

vehicle (especially when driving in town) and its trim

greatly affect fuel consumption and stability.

5. Remove roof racks or ski racks after use. These ac-

cessories reduce the vehicle’s aerodynamic penetra-

tion and have a negative effect on fuel consumption.

6. It is better to use a trailer to transport particularly bulky objects.

7. Use the vehicle’s air vents if possible: travelling with the windows open impairs aerodynamics.

8. Use electrical devices only for the amount of time needed. The heated rear window, auxiliary headlights,

windscreen wipers and fan heater use up a consider-

able amount of current, causing increased fuel con-

sumption (up to +25% in the urban cycle).

Page 273 of 283

269

KNOW

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEXDashboard .................................. 3

Dead lock device ....................... 8

Defrosting-demisting – rear windscreen ..... 46-49-58

– windscreen and front side windows .......... 45-48-57

Demisting/defrosting – door mirro rs ..........46-49-58

– rear windscreen ..... 46-49-58

– windscreen and front side windows ................ 45-49

Diesel filter ............................. 206

– water in the filter warning light ..................... 151

Diesel particulate filter (DPF) ..................................... 114

Digital di splay ........................... 14

– control buttons .................. 14

– Set-up menu ....................... 15

– standard screen ................. 14Dipped beam headlights

– bulb replace ment.............. 173

– switching on......................... 59

Direction indicators – front bulb replacement ... 173

– rear bulb replacement ..............175-176

– side bulb replacement ..... 173

– switching on ....................... 60

Document holder clip ............. 76

Door lock ing ............................ 77

Doors – central locking .................... 77

– child safety device ............. 80

– load compartment unlocking device ................ 77

– opening/closing from the inside ........................ 79-80

– remote opening/closing ....... 6

Cleaning your vehicle

– engine compartment ...... 216

– exterior ............................. 214

– interio rs ............................ 216

Climate control system ... 47-51 – Air vents .............................. 43

Climate control vents ............ 43

Clock – adjusting .............................. 22

Clutch – technical specifications .... 224

CO

2emissions at exhaust .. 257

CODE Card ............................... 5

Constant speed regulator (Cruise Control) ................... 63

Control buttons ...................... 70

Cruise Control (constant speed regulator) .................... 63

Cut-off system ......................... 70