ECU FIAT DOBLO PANORAMA 2017 2.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: DOBLO PANORAMA, Model: FIAT DOBLO PANORAMA 2017 2.GPages: 298, PDF Size: 26.04 MB

Page 129 of 298

19)

WARMING UP THE

ENGINE JUST AFTER IT

HAS STARTED

Proceed as follows:

drive off slowly, letting the engine

turn at medium revs. Do not accelerate

abruptly;

do not demand full performance at

first. Wait until the engine coolant

temperature gauge starts moving.

EMERGENCY STARTING

If the instrument panel warning light

stays on steadily, you can perform

an emergency starting by using the

code on the CODE card (see the “In an

emergency” section).

20)

STOPPING THE ENGINE

Turn the ignition key to STOP while the

engine is idling.

IMPORTANT After a taxing drive, you

should allow the engine to “catch

its breath” before turning it off by letting

it idle to allow the temperature in the

engine compartment to fall.

WARNING

17)It is advisable not to demand maximum

performance from your vehicle (e.g.

excessive acceleration, long distances at

high speeds, excessively intense braking,

etc.) during the initial period of use.

18)When the engine is off, do not leave

the key turned to MAR to prevent

unnecessary electrical consumption from

draining the battery.

19)If the indicator flashes for 60

seconds after starting or during an

extended towing period, this indicates

a problem in the glow plug preheating

system. Use the vehicle normally if the

engine starts, but contact a Fiat Dealership

as soon as possible.

20)Never start the engine by pushing,

towing or driving downhill. This could

cause fuel to flow into the catalytic

converter and damage it beyond repair.

WARNING

95)It is dangerous to run the engine in

enclosed areas. The engine takes in

oxygen and releases carbon dioxide,

carbon monoxide and other toxic gases.

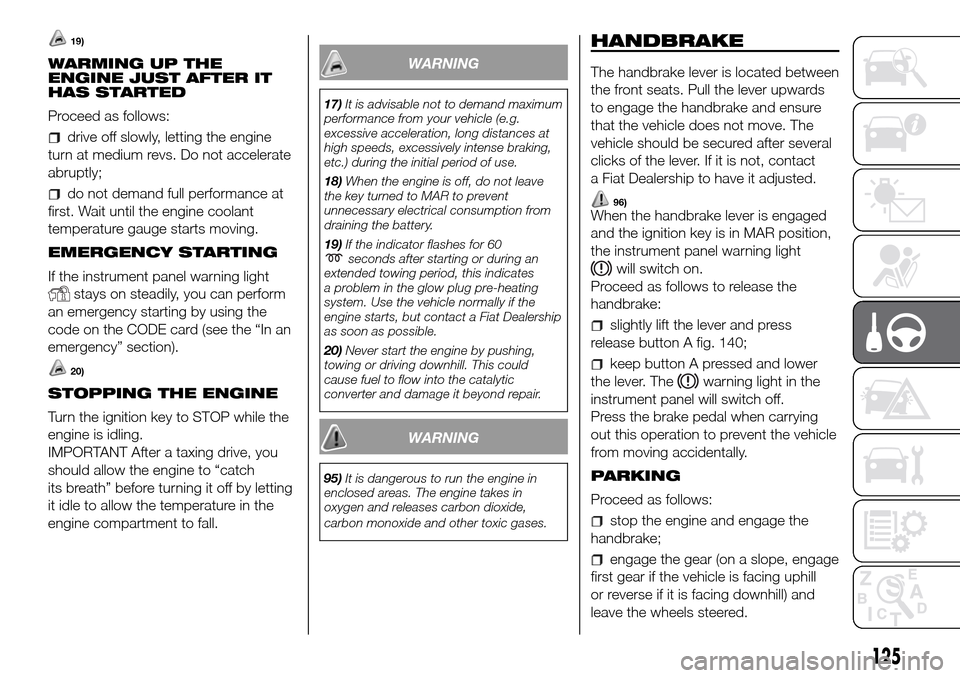

HANDBRAKE

The handbrake lever is located between

the front seats. Pull the lever upwards

to engage the handbrake and ensure

that the vehicle does not move. The

vehicle should be secured after several

clicks of the lever. If it is not, contact

a Fiat Dealership to have it adjusted.

96)When the handbrake lever is engaged

and the ignition key is in MAR position,

the instrument panel warning light

will switch on.

Proceed as follows to release the

handbrake:

slightly lift the lever and press

release button A fig. 140;

keep button A pressed and lower

the lever. The

warning light in the

instrument panel will switch off.

Press the brake pedal when carrying

out this operation to prevent the vehicle

from moving accidentally.

PARKING

Proceed as follows:

stop the engine and engage the

handbrake;

engage the gear (on a slope, engage

first gear if the vehicle is facing uphill

or reverse if it is facing downhill) and

leave the wheels steered.

125

Page 130 of 298

If the vehicle is parked on a steep

slope, it is advisable to block the

wheels with a wedge or stone.

To prevent draining the battery, do not

leave the ignition key turned to MAR.

Always remove the key when you leave

the vehicle.

Never leave children unattended in the

vehicle. Always remove the ignition

key when leaving the vehicle, and take

it with you.

WARNING

96)The vehicle should be secured after

several clicks of the lever. If it is not,

contact a Fiat Dealership to have it

adjusted.

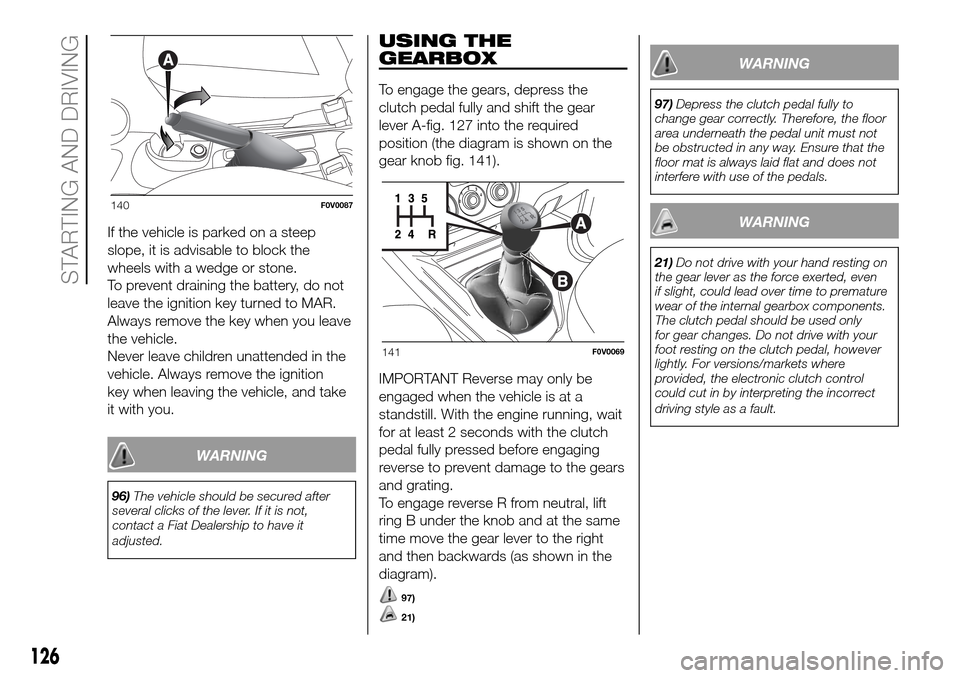

USING THE

GEARBOX

To engage the gears, depress the

clutch pedal fully and shift the gear

lever A-fig. 127 into the required

position (the diagram is shown on the

gear knob fig. 141).

IMPORTANT Reverse may only be

engaged when the vehicle is at a

standstill. With the engine running, wait

for at least 2 seconds with the clutch

pedal fully pressed before engaging

reverse to prevent damage to the gears

and grating.

To engage reverse R from neutral, lift

ring B under the knob and at the same

time move the gear lever to the right

and then backwards (as shown in the

diagram).

97)

21)

WARNING

97)Depress the clutch pedal fully to

change gear correctly. Therefore, the floor

area underneath the pedal unit must not

be obstructed in any way. Ensure that the

floor mat is always laid flat and does not

interfere with use of the pedals.

WARNING

21)Do not drive with your hand resting on

the gear lever as the force exerted, even

if slight, could lead over time to premature

wear of the internal gearbox components.

The clutch pedal should be used only

for gear changes. Do not drive with your

foot resting on the clutch pedal, however

lightly. For versions/markets where

provided, the electronic clutch control

could cut in by interpreting the incorrect

driving style as a fault.

140F0V0087

141F0V0069

126

STARTING AND DRIVING

Page 154 of 298

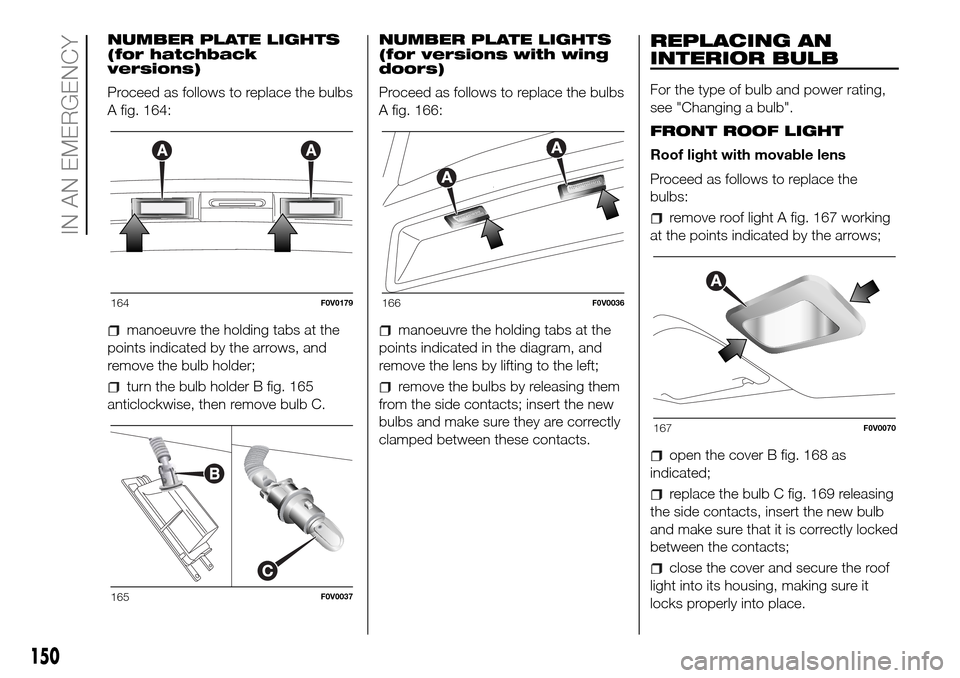

NUMBER PLATE LIGHTS

(for hatchback

versions)

Proceed as follows to replace the bulbs

A fig. 164:

manoeuvre the holding tabs at the

points indicated by the arrows, and

remove the bulb holder;

turn the bulb holder B fig. 165

anticlockwise, then remove bulb C.NUMBER PLATE LIGHTS

(for versions with wing

doors)

Proceed as follows to replace the bulbs

A fig. 166:

manoeuvre the holding tabs at the

points indicated in the diagram, and

remove the lens by lifting to the left;

remove the bulbs by releasing them

from the side contacts; insert the new

bulbs and make sure they are correctly

clamped between these contacts.

REPLACING AN

INTERIOR BULB

For the type of bulb and power rating,

see "Changing a bulb".

FRONT ROOF LIGHT

Roof light with movable lens

Proceed as follows to replace the

bulbs:

remove roof light A fig. 167 working

at the points indicated by the arrows;

open the cover B fig. 168 as

indicated;

replace the bulb C fig. 169 releasing

the side contacts, insert the new bulb

and make sure that it is correctly locked

between the contacts;

close the cover and secure the roof

light into its housing, making sure it

locks properly into place.

164F0V0179

165F0V0037

166F0V0036

167F0V0070

150

IN AN EMERGENCY

Page 155 of 298

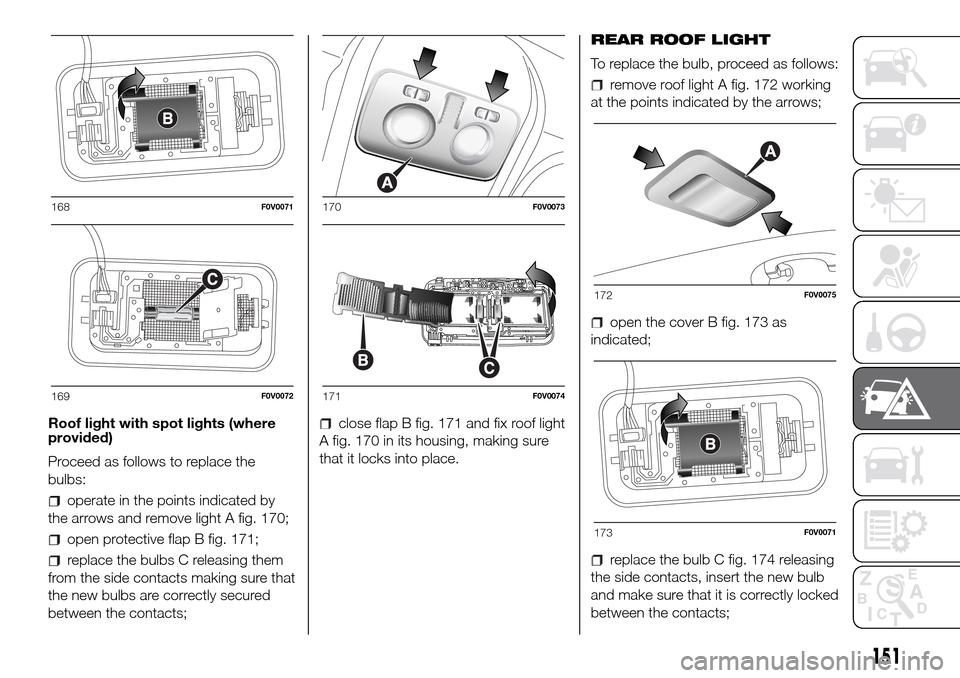

Roof light with spot lights (where

provided)

Proceed as follows to replace the

bulbs:

operate in the points indicated by

the arrows and remove light A fig. 170;

open protective flap B fig. 171;

replace the bulbs C releasing them

from the side contacts making sure that

the new bulbs are correctly secured

between the contacts;

close flap B fig. 171 and fix roof light

A fig. 170 in its housing, making sure

that it locks into place.REAR ROOF LIGHT

To replace the bulb, proceed as follows:

remove roof light A fig. 172 working

at the points indicated by the arrows;

open the cover B fig. 173 as

indicated;

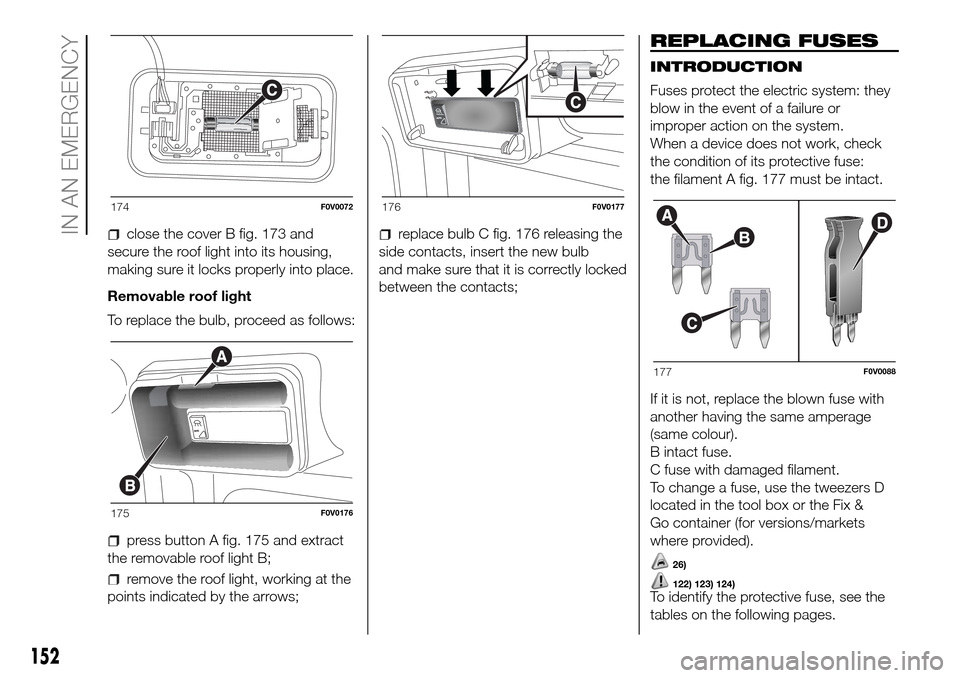

replace the bulb C fig. 174 releasing

the side contacts, insert the new bulb

and make sure that it is correctly locked

between the contacts;

168F0V0071

169F0V0072

170F0V0073

171F0V0074

172F0V0075

173F0V0071

151

Page 156 of 298

close the cover B fig. 173 and

secure the roof light into its housing,

making sure it locks properly into place.

Removable roof light

To replace the bulb, proceed as follows:

press button A fig. 175 and extract

the removable roof light B;

remove the roof light, working at the

points indicated by the arrows;

replace bulb C fig. 176 releasing the

side contacts, insert the new bulb

and make sure that it is correctly locked

between the contacts;

REPLACING FUSES

INTRODUCTION

Fuses protect the electric system: they

blow in the event of a failure or

improper action on the system.

When a device does not work, check

the condition of its protective fuse:

the filament A fig. 177 must be intact.

If it is not, replace the blown fuse with

another having the same amperage

(same colour).

B intact fuse.

C fuse with damaged filament.

To change a fuse, use the tweezers D

located in the tool box or the Fix &

Go container (for versions/markets

where provided).

26)

122) 123) 124)To identify the protective fuse, see the

tables on the following pages.

174F0V0072

175F0V0176

176F0V0177

177F0V0088

152

IN AN EMERGENCY

Page 164 of 298

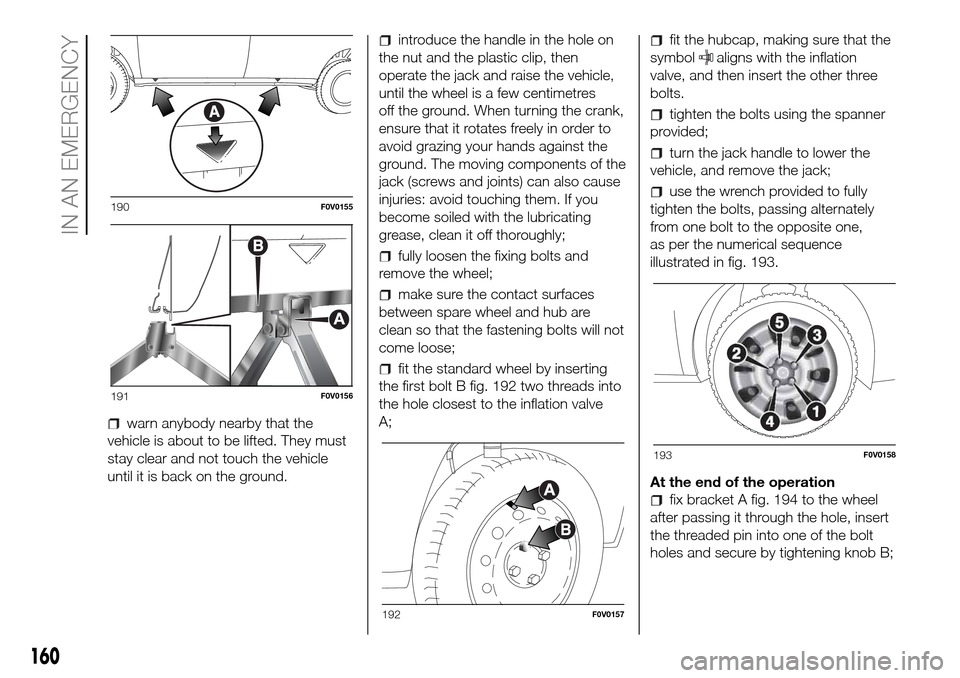

warn anybody nearby that the

vehicle is about to be lifted. They must

stay clear and not touch the vehicle

until it is back on the ground.

introduce the handle in the hole on

the nut and the plastic clip, then

operate the jack and raise the vehicle,

until the wheel is a few centimetres

off the ground. When turning the crank,

ensure that it rotates freely in order to

avoid grazing your hands against the

ground. The moving components of the

jack (screws and joints) can also cause

injuries: avoid touching them. If you

become soiled with the lubricating

grease, clean it off thoroughly;

fully loosen the fixing bolts and

remove the wheel;

make sure the contact surfaces

between spare wheel and hub are

clean so that the fastening bolts will not

come loose;

fit the standard wheel by inserting

the first bolt B fig. 192 two threads into

the hole closest to the inflation valve

A;

fit the hubcap, making sure that the

symbol

aligns with the inflation

valve, and then insert the other three

bolts.

tighten the bolts using the spanner

provided;

turn the jack handle to lower the

vehicle, and remove the jack;

use the wrench provided to fully

tighten the bolts, passing alternately

from one bolt to the opposite one,

as per the numerical sequence

illustrated in fig. 193.

At the end of the operation

fix bracket A fig. 194 to the wheel

after passing it through the hole, insert

the threaded pin into one of the bolt

holes and secure by tightening knob B;

190F0V0155

191F0V0156

192F0V0157

193F0V0158

160

IN AN EMERGENCY

Page 166 of 298

126)Use your hazard lights, warning

triangle, etc. to show that your vehicle is

stationary according to the regulations

in force. Passengers should get out of the

vehicle, particularly if it is heavily loaded,

and wait for the wheel to be changed away

from the traffic. If you are on a slope or

uneven surface, place wedges or other

suitable objects under the wheels to secure

the vehicle. Have the wheel repaired and

refitted as soon as possible. Do not apply

grease to the bolt threads before

assembly: they might spontaneously

unscrew.

127)Use the jack only to replace wheels

on the vehicle with which it is supplied

or on other vehicles of the same model.

Never use the jack for other purposes,

such as lifting other models. Never use the

jack to carry out repairs under the vehicle.

Incorrect positioning of the jack may cause

the lifted vehicle to fall. Do not use the

jack for loads higher than those shown on

the label.

128)Incorrect hub cap assembly may

cause it to come off when the vehicle is

moving. Never tamper with the inflation

valve. Never introduce tools of any kind

between rim and tyre. Check tyre and

spare wheel pressures regularly, referring to

the values shown in the "Technical

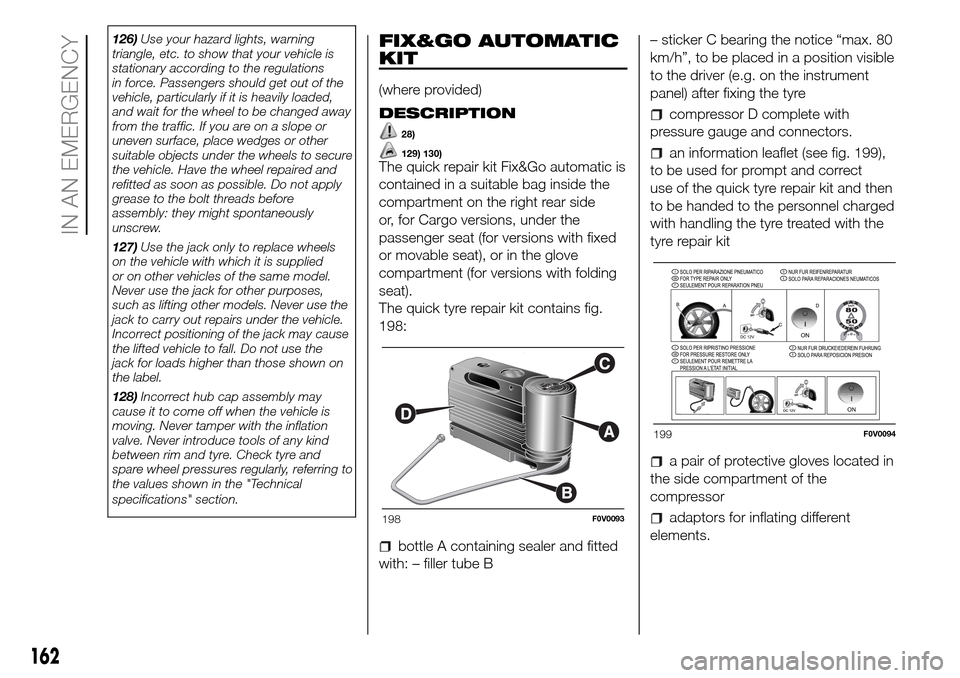

specifications" section.FIX&GO AUTOMATIC

KIT

(where provided)

DESCRIPTION

28)

129) 130)The quick repair kit Fix&Go automatic is

contained in a suitable bag inside the

compartment on the right rear side

or, for Cargo versions, under the

passenger seat (for versions with fixed

or movable seat), or in the glove

compartment (for versions with folding

seat).

The quick tyre repair kit contains fig.

198:

bottle A containing sealer and fitted

with: – filler tube B– sticker C bearing the notice “max. 80

km/h”, to be placed in a position visible

to the driver (e.g. on the instrument

panel) after fixing the tyre

compressor D complete with

pressure gauge and connectors.

an information leaflet (see fig. 199),

to be used for prompt and correct

use of the quick tyre repair kit and then

to be handed to the personnel charged

with handling the tyre treated with the

tyre repair kit

a pair of protective gloves located in

the side compartment of the

compressor

adaptors for inflating different

elements.198F0V0093

199F0V0094

162

IN AN EMERGENCY

Page 167 of 298

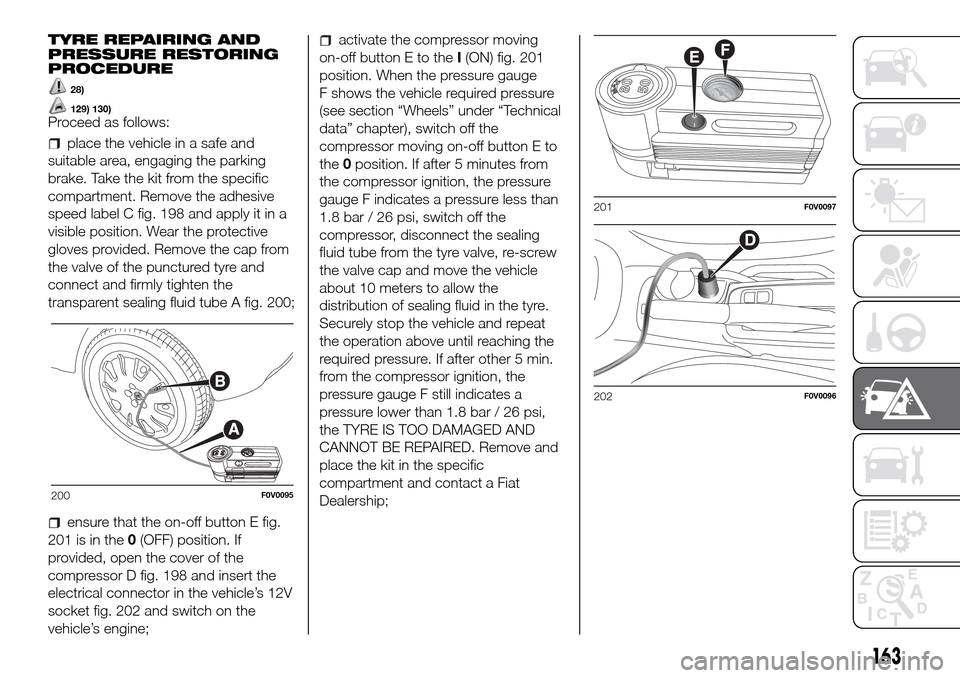

TYRE REPAIRING AND

PRESSURE RESTORING

PROCEDURE

28)

129) 130)Proceed as follows:

place the vehicle in a safe and

suitable area, engaging the parking

brake. Take the kit from the specific

compartment. Remove the adhesive

speed label C fig. 198 and apply it in a

visible position. Wear the protective

gloves provided. Remove the cap from

the valve of the punctured tyre and

connect and firmly tighten the

transparent sealing fluid tube A fig. 200;

ensure that the on-off button E fig.

201 is in the0(OFF) position. If

provided, open the cover of the

compressor D fig. 198 and insert the

electrical connector in the vehicle’s 12V

socket fig. 202 and switch on the

vehicle’s engine;

activate the compressor moving

on-off button E to theI(ON) fig. 201

position. When the pressure gauge

F shows the vehicle required pressure

(see section “Wheels” under “Technical

data” chapter), switch off the

compressor moving on-off button E to

the0position. If after 5 minutes from

the compressor ignition, the pressure

gauge F indicates a pressure less than

1.8 bar / 26 psi, switch off the

compressor, disconnect the sealing

fluid tube from the tyre valve, re-screw

the valve cap and move the vehicle

about 10 meters to allow the

distribution of sealing fluid in the tyre.

Securely stop the vehicle and repeat

the operation above until reaching the

required pressure. If after other 5 min.

from the compressor ignition, the

pressure gauge F still indicates a

pressure lower than 1.8 bar / 26 psi,

the TYRE IS TOO DAMAGED AND

CANNOT BE REPAIRED. Remove and

place the kit in the specific

compartment and contact a Fiat

Dealership;

200F0V0095

201F0V0097

202F0V0096

163

Page 169 of 298

WARNING

28)The label on the Fix&Go kit’s packaging

gives the information required by the laws

in force. To ensure that the Fix&Go kit is

safe and effective, it is essential to comply

with all the instructions given on the label.

Carefully read the label before use, avoid

improper use. Fix&Go is subject to

expiration and must be replaced

periodically. The kit should be used by

adults and cannot be used by children.

WARNING

129)Show the package and the label to

the personnel charged with handling

the tyre treated with the tyre repair kit.

130)Fix&Go provides a temporary repair,

therefore the tyre must be examined and

repaired by a specialist as soon as

possible. The sealing fluid is effective at

temperatures between -40°C and +50°C. It

is possible to repair tyres which have

been damaged on tread up to a diameter

of 4mm; however, tyres damaged on

their side cannot be repaired. Before using

Fix&Go kit, ensure that the tyre isn't

excessively damaged and that the rim is in

good condition, otherwise do not use it

and contact a Fiat Dealership. Do not

remove foreign bodies from the tyre. Do

not let the compressor turned on for more

than 20 consecutive minutes - overheating

hazard.

EMERGENCY

STARTING

Go to a Fiat Dealership immediately if

warning light

stays on constantly on

the instrument panel.

JUMP STARTING

If the battery is flat, it is possible to start

the engine using an auxiliary battery

with the same capacity or a little higher

than the flat one.

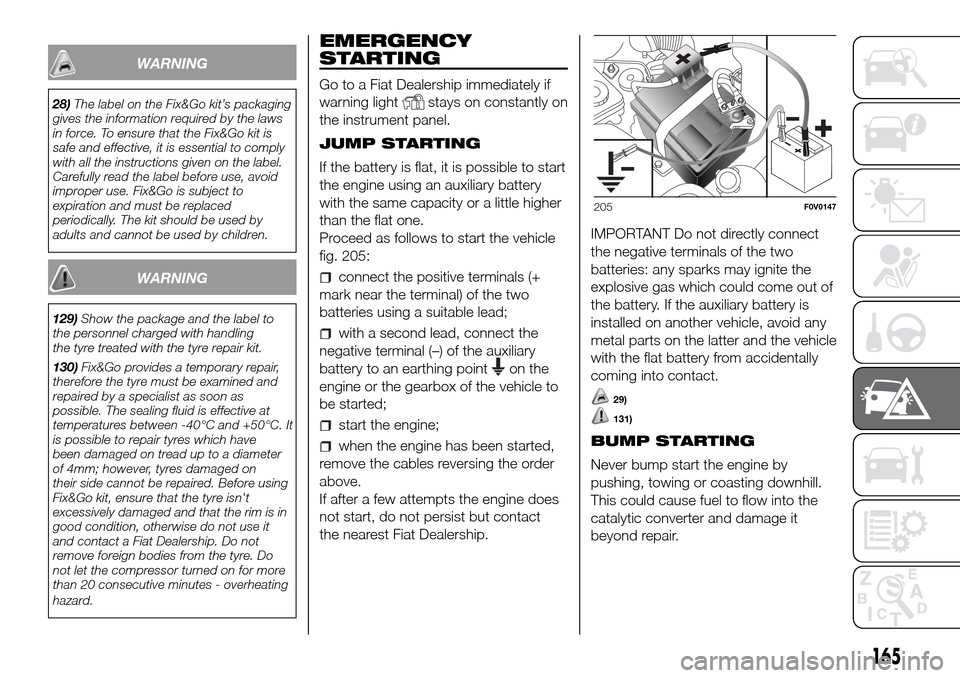

Proceed as follows to start the vehicle

fig. 205:

connect the positive terminals (+

mark near the terminal) of the two

batteries using a suitable lead;

with a second lead, connect the

negative terminal (–) of the auxiliary

battery to an earthing point

on the

engine or the gearbox of the vehicle to

be started;

start the engine;

when the engine has been started,

remove the cables reversing the order

above.

If after a few attempts the engine does

not start, do not persist but contact

the nearest Fiat Dealership.IMPORTANT Do not directly connect

the negative terminals of the two

batteries: any sparks may ignite the

explosive gas which could come out of

the battery. If the auxiliary battery is

installed on another vehicle, avoid any

metal parts on the latter and the vehicle

with the flat battery from accidentally

coming into contact.

29)

131)

BUMP STARTING

Never bump start the engine by

pushing, towing or coasting downhill.

This could cause fuel to flow into the

catalytic converter and damage it

beyond repair.

205F0V0147

165

Page 192 of 298

Take great care to ensure that

impurities do not enter the reservoir

when the cap is opened.

For topping-up, always use a funnel

with integrated filter with mesh equal to

or lower than 0.12 mm.

IMPORTANT Brake fluid absorbs

moisture. For this reason, if the vehicle

is mainly used in areas with a high

degree of atmospheric humidity, the

fluid should be replaced at more

frequent intervals than specified in the

“Scheduled Servicing Plan”.

34)

140) 141)

POWER STEERING FLUID

Check that the oil level with the vehicle

on flat ground and the engine cold is

between the MIN and MAX marks

on the reservoir body G fig. 208 - fig.

209 - fig. 210 - fig. 211 - fig. 213 - fig.

214 - fig. 215.

The level may exceed the MAX mark

when the oil is hot.

If topping up is required, make sure the

oil you use has the same specifications

as that already in the system.

142)

3)

35)

WARNING

136)Never smoke while working in the

engine compartment: gas and inflammable

vapours may be present, with the risk of

fire.

137)When the engine is hot, take care

when working inside the engine

compartment to avoid burns. Remember

that when the engine is hot, the fan may

operate: danger of injury. Scarves, ties and

other loose clothing might be pulled by

moving parts.

138)The cooling system is pressurised. If

necessary, only replace the plug with

another original or the operation of the

system may be adversely affected. Do not

remove the reservoir plug when the engine

is hot: you risk scalding yourself.

139)Do not travel with the windscreen

washer fluid reservoir empty: the

windscreen washer is essential for

improving visibility. Some commercial

windscreen washer additives are

flammable. The engine compartment

contains hot components which may set it

on fire.

140)Brake fluid is poisonous and highly

corrosive. In the event of accidental

contact, immediately wash the affected

parts with water and mild soap. Then rinse

thoroughly. Call a doctor immediately if

swallowed.141)The symbol

, on the brake fluid

container indicates if a brake fluid is

synthetic or mineralbased. Using

a mineral-type fluid will damage the special

rubber seals of the braking system beyond

repair.

142)Prevent power steering fluid from

coming into contact with hot engine parts:

it is flammable.

WARNING

31)When topping up, take care not to mix

up the various types of fluids: they are

not compatible with each other and could

seriously damage the vehicle.

32)Do not add oil with specifications other

than those of the oil already existing in

the engine.

33)PARAFLU

UPanti-freeze is used in the

engine cooling system. Use the same

fluid as in the cooling system when topping

up. PARAFLU

UPcannot be mixed with

any other type of fluid. If this occurs, do not

start the engine and contact your Fiat

Dealership immediately.

34)Prevent brake fluid, which is highly

corrosive, from coming into contact with

painted parts. Should it happen,

immediately wash with water.

35)Do not press on the power steering

end of travel with engine on for more than

8 consecutive seconds, since noise is

produced and there is a risk of system

damages.

188

SERVICING AND CARE