check engine FIAT DUCATO 2009 3.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2009, Model line: DUCATO, Model: FIAT DUCATO 2009 3.GPages: 282, PDF Size: 4.55 MB

Page 159 of 282

158

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

ENGINE

STARTING

EMERGENCY START-UP

If the instrument panel warning light

Yturns on glowing steadily, contact im-

mediately Fiat Dealership.

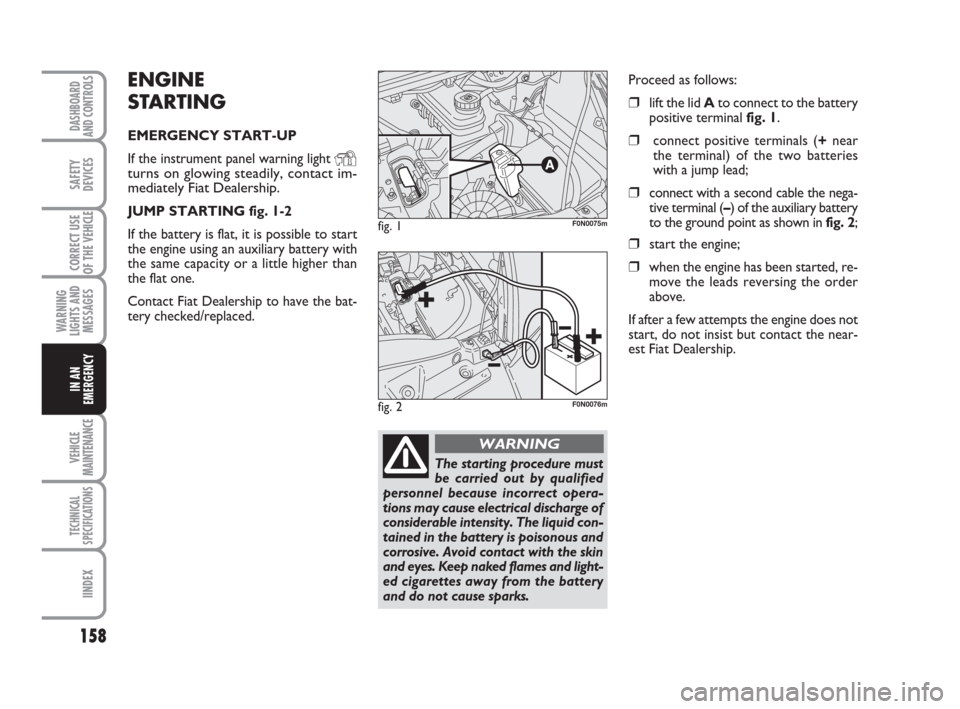

JUMP STARTING fig. 1-2

If the battery is flat, it is possible to start

the engine using an auxiliary battery with

the same capacity or a little higher than

the flat one.

Contact Fiat Dealership to have the bat-

tery checked/replaced.Proceed as follows:

❒lift the lid Ato connect to the battery

positive terminal fig. 1.

❒connect positive terminals (+near

the terminal) of the two batteries

with a jump lead;

❒connect with a second cable the nega-

tive terminal (–) of the auxiliary battery

to the ground point as shown in fig. 2;

❒start the engine;

❒when the engine has been started, re-

move the leads reversing the order

above.

If after a few attempts the engine does not

start, do not insist but contact the near-

est Fiat Dealership.

fig. 1F0N0075m

The starting procedure must

be carried out by qualified

personnel because incorrect opera-

tions may cause electrical discharge of

considerable intensity. The liquid con-

tained in the battery is poisonous and

corrosive. Avoid contact with the skin

and eyes. Keep naked flames and light-

ed cigarettes away from the battery

and do not cause sparks.

WARNING

fig. 2F0N0076m

Page 161 of 282

160

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

To change a wheel proceed

as follows:

❒stop the vehicle in a position where

it does not present a danger for on-

coming traffic and where you can

change the wheel safely. The ground

must be flat and compact;

❒turn the engine off and apply the hand-

brake;

❒engage first gear or reverse;

❒wear a high visibility safety jacket

(compulsory by law in certain coun-

tries) before getting out of the vehicle;

❒indicate that the vehicle has broken

down using the devices required by

the law of the country (e.g. warning

triangle, hazard lights etc.);

❒take the extension and the wrench

from the tool kit under the passenger

seat (see “Compartment under front

passenger seat” in the “Dashboard and

Controls” section);

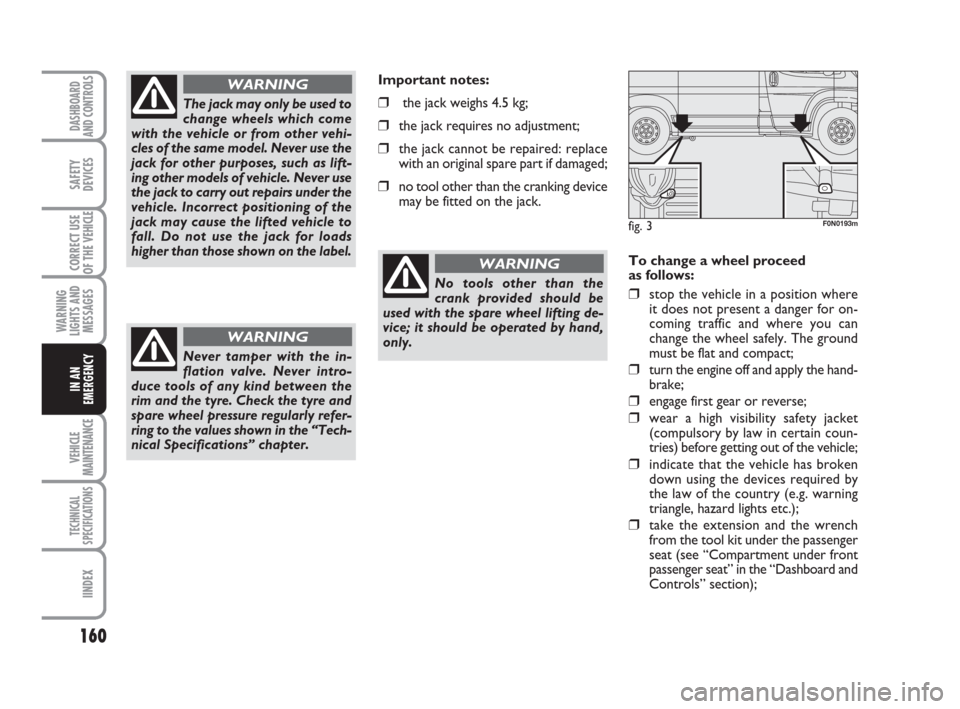

The jack may only be used to

change wheels which come

with the vehicle or from other vehi-

cles of the same model. Never use the

jack for other purposes, such as lift-

ing other models of vehicle. Never use

the jack to carry out repairs under the

vehicle. Incorrect positioning of the

jack may cause the lifted vehicle to

fall. Do not use the jack for loads

higher than those shown on the label.

WARNING

Never tamper with the in-

flation valve. Never intro-

duce tools of any kind between the

rim and the tyre. Check the tyre and

spare wheel pressure regularly refer-

ring to the values shown in the “Tech-

nical Specifications” chapter.

WARNING

Important notes:

❒the jack weighs 4.5 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired: replace

with an original spare part if damaged;

❒no tool other than the cranking device

may be fitted on the jack.

fig. 3F0N0193m

No tools other than the

crank provided should be

used with the spare wheel lifting de-

vice; it should be operated by hand,

only.

WARNING

Page 167 of 282

166

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

IINDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

❒insert the pin E-fig. 14in the near-

est 12V current socket and start the

engine. Turn the selector D-fig. 13

anti-clockwise to the repair position.

Activate the kit by pressing the

on/off switch. Inflate the tyre to the

pressure specified in the “Inflation

pressure” paragraph, in the “Technical

Data” chapter.For a more accurate reading, it is

advisable to check the pressure

reading on the pressure gauge F-

fig. 13with the compressor off and

without moving the centre selector

from the repair position;

❒if a pressure of at least 3 bar is not

reached within 10 minutes, detach

the transparent filler pipe from the

valve and switch off the 12V current

pin, then move the vehicle about 10

metres forward to distribute the

sealant liquid inside the tyre and

repeat the inflation operation;

❒if, in this case too, within 10 minutes

of turning the compressor on, a

pressure of at least 3 bar is not

reached, do not start driving again

because the tyre is too damaged and

the quick repair kit is not sufficient in

this situation and it is necessary to

go to a Fiat Dealership;

❒if the tyre reaches the pressure spec-

ified in “Inflation pressure” pressure

in the “Technical Data” chapter,

start driving immediately;

fig. 13F0N0827m

fig. 14F0N0182m

Apply the adhesive label in a

position clearly visible by the

driver as a reminder that the tyre has

been treated with the quick repair

kit. Drive carefully, particularly on

bends. Do not exceed 80 km/h. Do

not accelerate or brake suddenly.

WARNING

❒after driving for about 10 minutes,

stop and check the tyre pressure

again; remember to engage the

handbrake;

❒if, on the other hand, a pressure of at

least 3 bar is reached, restore the cor-

rect pressure recommended in the

“Tyre inflation” paragraph in the

“Technical Data” chapter (with engine

running and handbrake on) and

resume driving;

Stop if the pressure has

dropped to less than 3 bar:

The automatic Fix & Go fast repair

kit cannot work properly if the tyre

is excessively damaged. Go to a Fiat

Dealership.

WARNING

Page 168 of 282

167

WARNING

LIGHTS AND

MESSAGES

VEHICLE

MAINTENANCE

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE

VEHICLE

IN AN

EMERGENCY

❒drive with the utmost care to the

nearest Fiat Dealership.

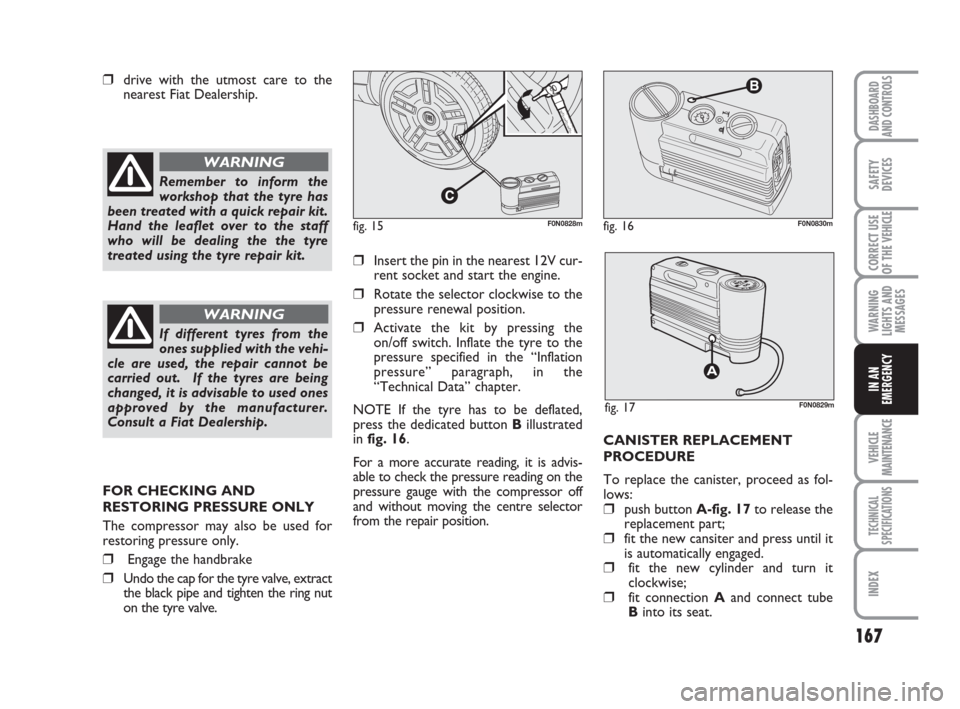

FOR CHECKING AND

RESTORING PRESSURE ONLY

The compressor may also be used for

restoring pressure only.

❒Engage the handbrake

❒Undo the cap for the tyre valve, extract

the black pipe and tighten the ring nut

on the tyre valve.

❒Insert the pin in the nearest 12V cur-

rent socket and start the engine.

❒Rotate the selector clockwise to the

pressure renewal position.

❒Activate the kit by pressing the

on/off switch. Inflate the tyre to the

pressure specified in the “Inflation

pressure” paragraph, in the

“Technical Data” chapter.

NOTE If the tyre has to be deflated,

press the dedicated button Billustrated

in fig. 16.

For a more accurate reading, it is advis-

able to check the pressure reading on the

pressure gauge with the compressor off

and without moving the centre selector

from the repair position.CANISTER REPLACEMENT

PROCEDURE

To replace the canister, proceed as fol-

lows:

❒push button A-fig. 17to release the

replacement part;

❒fit the new cansiter and press until it

is automatically engaged.

❒fit the new cylinder and turn it

clockwise;

❒fit connection Aand connect tube

Binto its seat.

Remember to inform the

workshop that the tyre has

been treated with a quick repair kit.

Hand the leaflet over to the staff

who will be dealing the the tyre

treated using the tyre repair kit.

WARNING

If different tyres from the

ones supplied with the vehi-

cle are used, the repair cannot be

carried out. If the tyres are being

changed, it is advisable to used ones

approved by the manufacturer.

Consult a Fiat Dealership.

WARNING

fig. 16

B

F0N0830m

fig. 17F0N0829m

fig. 15F0N0828m

Page 192 of 282

191

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

45 90 135 180 225

●●●●●

●●●●●

●●●●●

●●●●●

●●●●●

●●●●●

●●

●●●●●

●●●●●

●●●●●

●●●●●

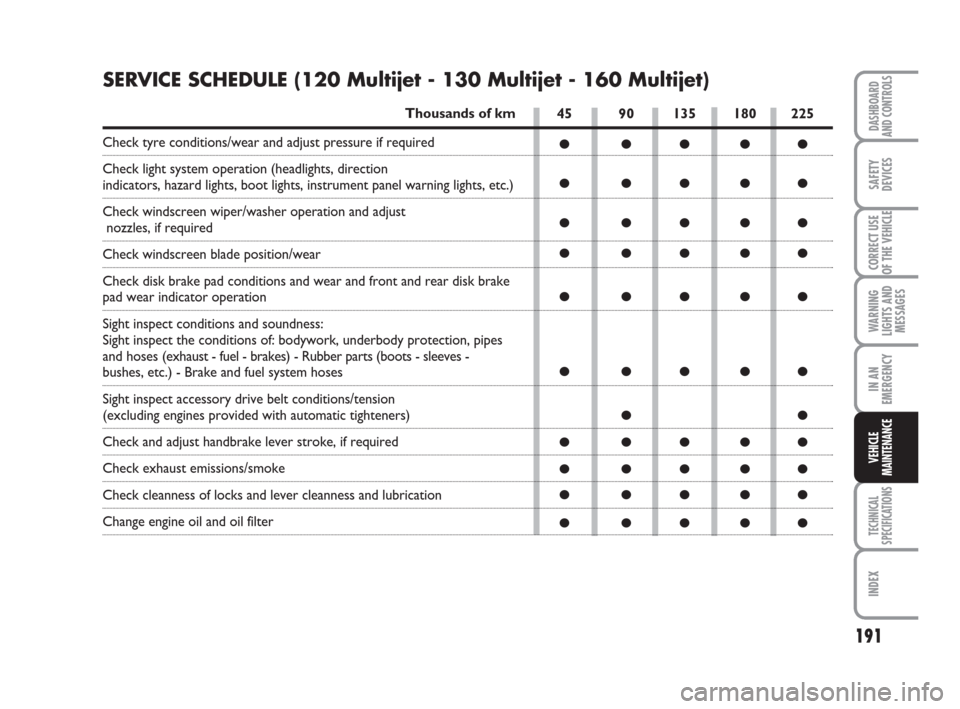

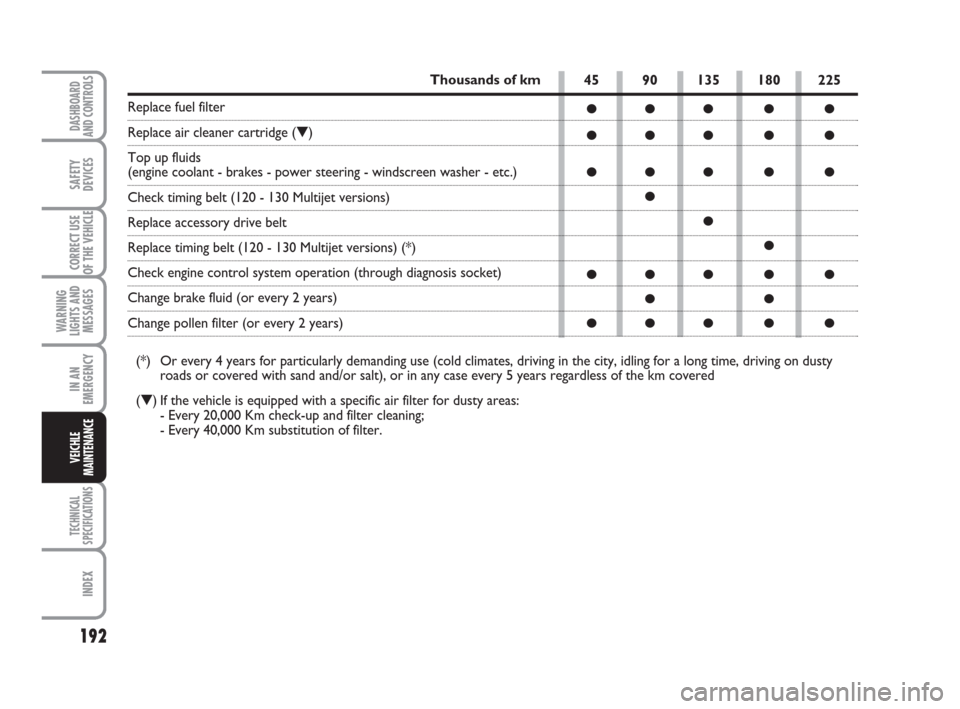

SERVICE SCHEDULE (120 Multijet - 130 Multijet - 160 Multijet)

Thousands of km

Check tyre conditions/wear and adjust pressure if required

Check light system operation (headlights, direction

indicators, hazard lights, boot lights, instrument panel warning lights, etc.)

Check windscreen wiper/washer operation and adjust

nozzles, if required

Check windscreen blade position/wear

Check disk brake pad conditions and wear and front and rear disk brake

pad wear indicator operation

Sight inspect conditions and soundness:

Sight inspect the conditions of: bodywork, underbody protection, pipes

and hoses (exhaust - fuel - brakes) - Rubber parts (boots - sleeves -

bushes, etc.) - Brake and fuel system hoses

Sight inspect accessory drive belt conditions/tension

(excluding engines provided with automatic tighteners)

Check and adjust handbrake lever stroke, if required

Check exhaust emissions/smoke

Check cleanness of locks and lever cleanness and lubrication

Change engine oil and oil filter

Page 193 of 282

192

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE VEHICLE

IN AN

EMERGENCY

VEICHLE

MAINTENANCE

45 90 135 180 225

●●●●●

●●●●●

●●●●●

●

●

●

●●●●●

●●

●●●●●

Thousands of km

Replace fuel filter

Replace air cleaner cartridge (▼)

Top up fluids

(engine coolant - brakes - power steering - windscreen washer - etc.)

Check timing belt (120 - 130 Multijet versions)

Replace accessory drive belt

Replace timing belt (120 - 130 Multijet versions) (*)

Check engine control system operation (through diagnosis socket)

Change brake fluid (or every 2 years)

Change pollen filter (or every 2 years)

(*) Or every 4 years for particularly demanding use (cold climates, driving in the city, idling for a long time, driving on dusty

roads or covered with sand and/or salt), or in any case every 5 years regardless of the km covered

(▼) If the vehicle is equipped with a specific air filter for dusty areas:

- Every 20,000 Km check-up and filter cleaning;

- Every 40,000 Km substitution of filter.

Page 194 of 282

193

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

40 80 120 160 200

●●●●●

●●●●●

●●●●●

●●●●●

●●●●●

●●●●●

●●

●●●●●

●●●●●

●●●●●

●●●●●

●●●●●

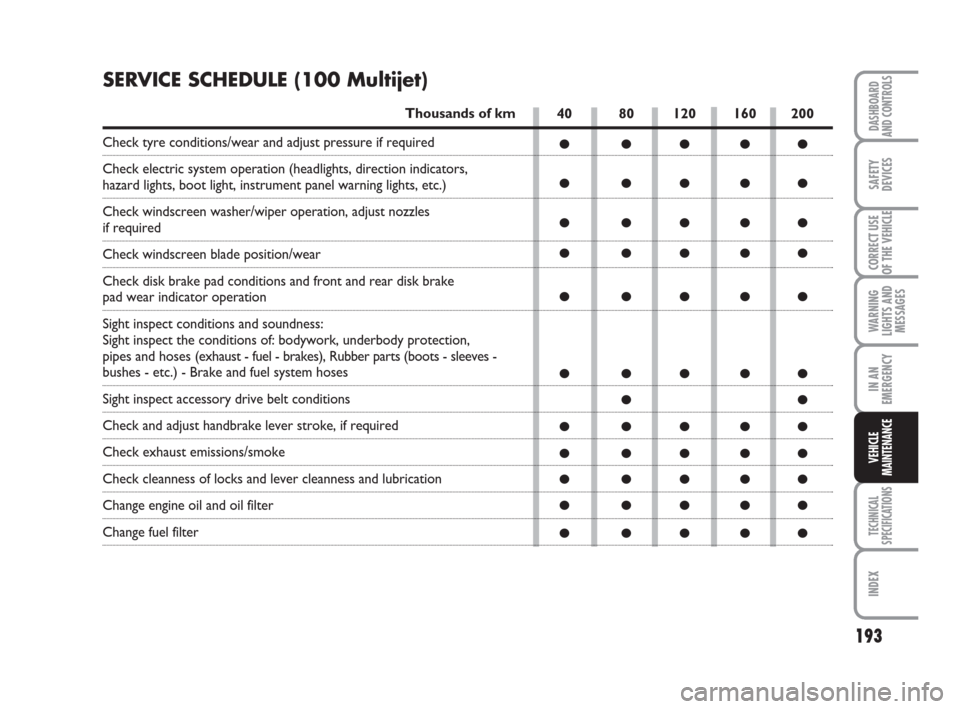

SERVICE SCHEDULE (100 Multijet)

Thousands of km

Check tyre conditions/wear and adjust pressure if required

Check electric system operation (headlights, direction indicators,

hazard lights, boot light, instrument panel warning lights, etc.)

Check windscreen washer/wiper operation, adjust nozzles

if required

Check windscreen blade position/wear

Check disk brake pad conditions and front and rear disk brake

pad wear indicator operation

Sight inspect conditions and soundness:

Sight inspect the conditions of: bodywork, underbody protection,

pipes and hoses (exhaust - fuel - brakes), Rubber parts (boots - sleeves -

bushes - etc.) - Brake and fuel system hoses

Sight inspect accessory drive belt conditions

Check and adjust handbrake lever stroke, if required

Check exhaust emissions/smoke

Check cleanness of locks and lever cleanness and lubrication

Change engine oil and oil filter

Change fuel filter

Page 195 of 282

194

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE VEHICLE

IN AN

EMERGENCY

VEICHLE

MAINTENANCE

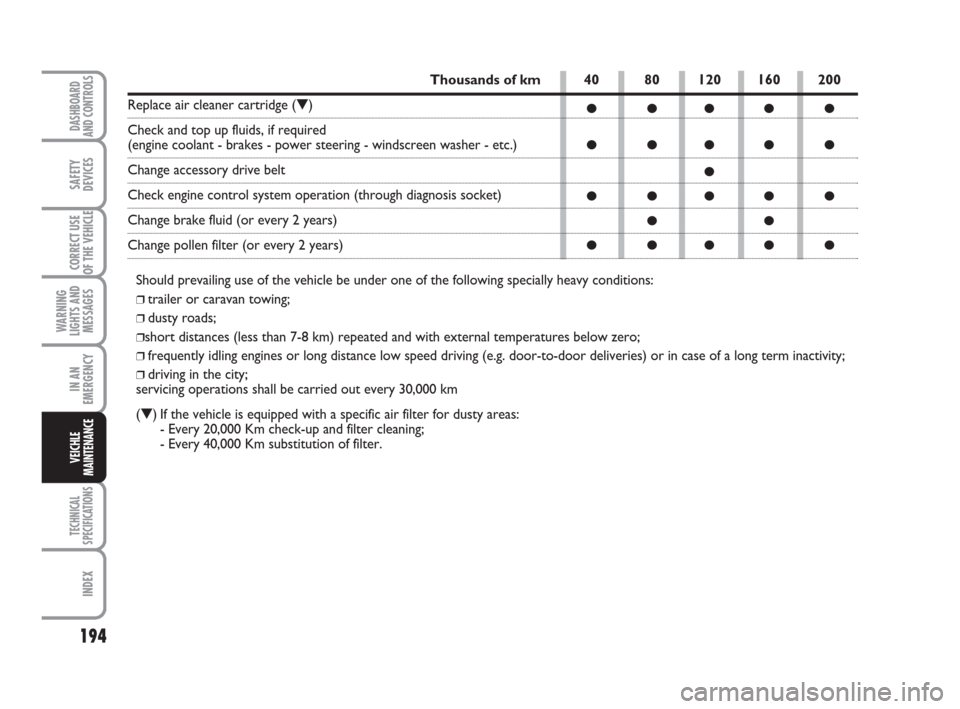

40 80 120 160 200

●●●●●

●●●●●

●

●●●●●

●●

●●●●●

Thousands of km

Replace air cleaner cartridge (▼)

Check and top up fluids, if required

(engine coolant - brakes - power steering - windscreen washer - etc.)

Change accessory drive belt

Check engine control system operation (through diagnosis socket)

Change brake fluid (or every 2 years)

Change pollen filter (or every 2 years)

Should prevailing use of the vehicle be under one of the following specially heavy conditions:

❒trailer or caravan towing;

❒dusty roads;

❒short distances (less than 7-8 km) repeated and with external temperatures below zero;

❒frequently idling engines or long distance low speed driving (e.g. door-to-door deliveries) or in case of a long term inactivity;

❒driving in the city;

servicing operations shall be carried out every 30,000 km

(▼) If the vehicle is equipped with a specific air filter for dusty areas:

- Every 20,000 Km check-up and filter cleaning;

- Every 40,000 Km substitution of filter.

Page 196 of 282

195

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE VEHICLE

IN AN

EMERGENCY

VEHICLE

MAINTENANCE

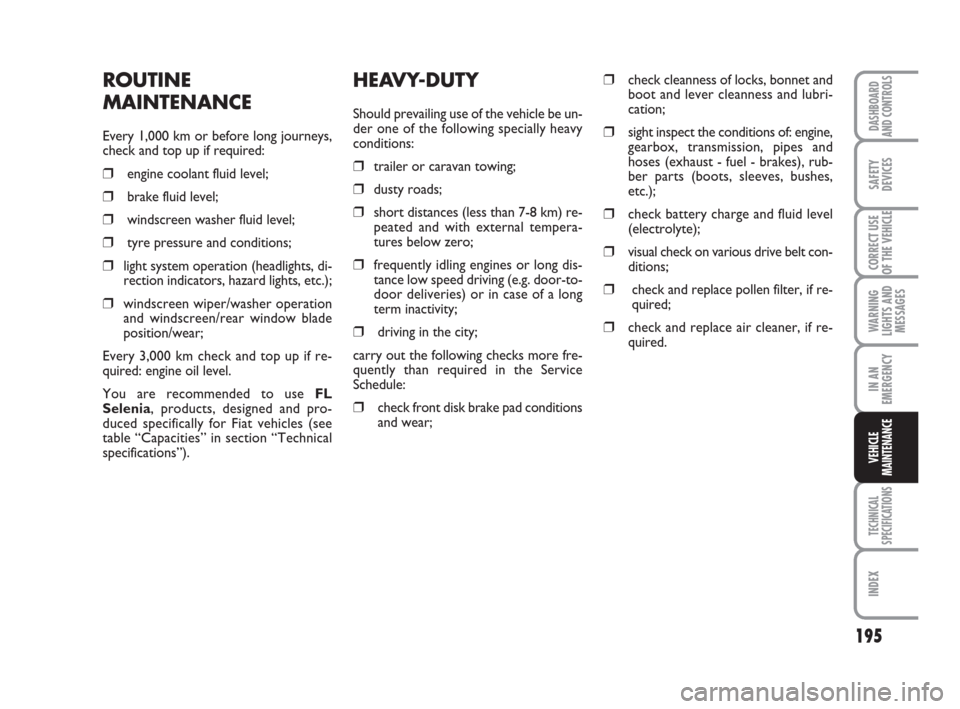

HEAVY-DUTY

Should prevailing use of the vehicle be un-

der one of the following specially heavy

conditions:

❒trailer or caravan towing;

❒dusty roads;

❒short distances (less than 7-8 km) re-

peated and with external tempera-

tures below zero;

❒frequently idling engines or long dis-

tance low speed driving (e.g. door-to-

door deliveries) or in case of a long

term inactivity;

❒driving in the city;

carry out the following checks more fre-

quently than required in the Service

Schedule:

❒check front disk brake pad conditions

and wear;

❒check cleanness of locks, bonnet and

boot and lever cleanness and lubri-

cation;

❒sight inspect the conditions of: engine,

gearbox, transmission, pipes and

hoses (exhaust - fuel - brakes), rub-

ber parts (boots, sleeves, bushes,

etc.);

❒check battery charge and fluid level

(electrolyte);

❒visual check on various drive belt con-

ditions;

❒check and replace pollen filter, if re-

quired;

❒check and replace air cleaner, if re-

quired.

ROUTINE

MAINTENANCE

Every 1,000 km or before long journeys,

check and top up if required:

❒engine coolant fluid level;

❒brake fluid level;

❒windscreen washer fluid level;

❒tyre pressure and conditions;

❒light system operation (headlights, di-

rection indicators, hazard lights, etc.);

❒windscreen wiper/washer operation

and windscreen/rear window blade

position/wear;

Every 3,000 km check and top up if re-

quired: engine oil level.

You are recommended to use FL

Selenia, products, designed and pro-

duced specifically for Fiat vehicles (see

table “Capacities” in section “Technical

specifications”).

Page 197 of 282

196

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

INDEX

DASHBOARD

AND CONTROLS

SAFETY

DEVICES

CORRECT USE

OF THE VEHICLE

IN AN

EMERGENCY

VEICHLE

MAINTENANCE

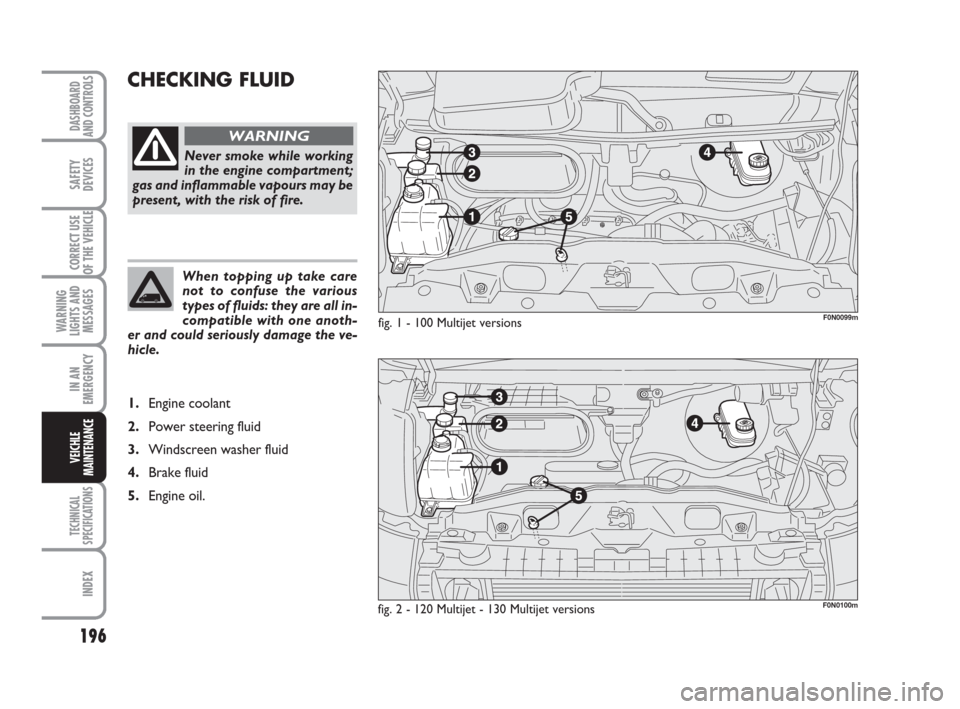

CHECKING FLUID

fig. 1 - 100 Multijet versions

Never smoke while working

in the engine compartment;

gas and inflammable vapours may be

present, with the risk of fire.

WARNING

When topping up take care

not to confuse the various

types of fluids: they are all in-

compatible with one anoth-

er and could seriously damage the ve-

hicle.

1.Engine coolant

2.Power steering fluid

3.Windscreen washer fluid

4.Brake fluid

5.Engine oil.

F0N0099m

fig. 2 - 120 Multijet - 130 Multijet versionsF0N0100m