Specifications FIAT DUCATO 2014 3.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2014, Model line: DUCATO, Model: FIAT DUCATO 2014 3.GPages: 367, PDF Size: 20.39 MB

Page 241 of 367

BATTERYThe battery is “limited maintenance”

type: under normal conditions of use,

the electrolyte does not need topping

up with distilled water.

It does, however, need to be checked

periodically at a Fiat Dealership or

by specialist personnel to make sure it

is working correctly.

The battery is located inside the

passenger compartment, in front of the

pedals. Remove the protective cover

to gain access to it.

184) 185)

REPLACING THE

BATTERY

If required, replace the battery with an

original spare part with the same

specifications.

If a battery with different specifications

is fitted, the service intervals given in

the “Scheduled Servicing Plan” will no

longer be valid.

Follow the battery manufacturer's

instructions for maintenance.

51) 52)186) 187)4)

USEFUL ADVICE FOR

EXTENDING THE LIFE OF

YOUR BATTERY

To avoid draining your battery and

make it last longer, observe the

following instructions:

❒when you park the vehicle, ensure

that the doors, tailgate and bonnet

are closed properly, to prevent any

roof lights from remaining on inside

the passenger's compartment;

❒switch off all roof lights inside the

vehicle: the vehicle is however

equipped with a system which

switches all internal lights off

automatically;

❒do not keep accessories (e.g. sound

system, hazard lights, etc.) switched

on for a long time when the engine

is not running;

❒before carrying out any operation on

the electrical system, disconnect the

negative battery cable through the

suitable terminal;

❒Completely tighten the battery

terminals.

237

Page 244 of 367

WHEELS AND TYRESCheck the pressure of each tyre,

including the space-saver wheel,

approximately every two weeks and

before long journeys: the pressure

should be checked with the tyre rested

and cold.

It is normal for the pressure to increase

when the vehicle is used; for the correct

tyre inflation pressure, see “Wheels” in

the “Technical specifications” section.

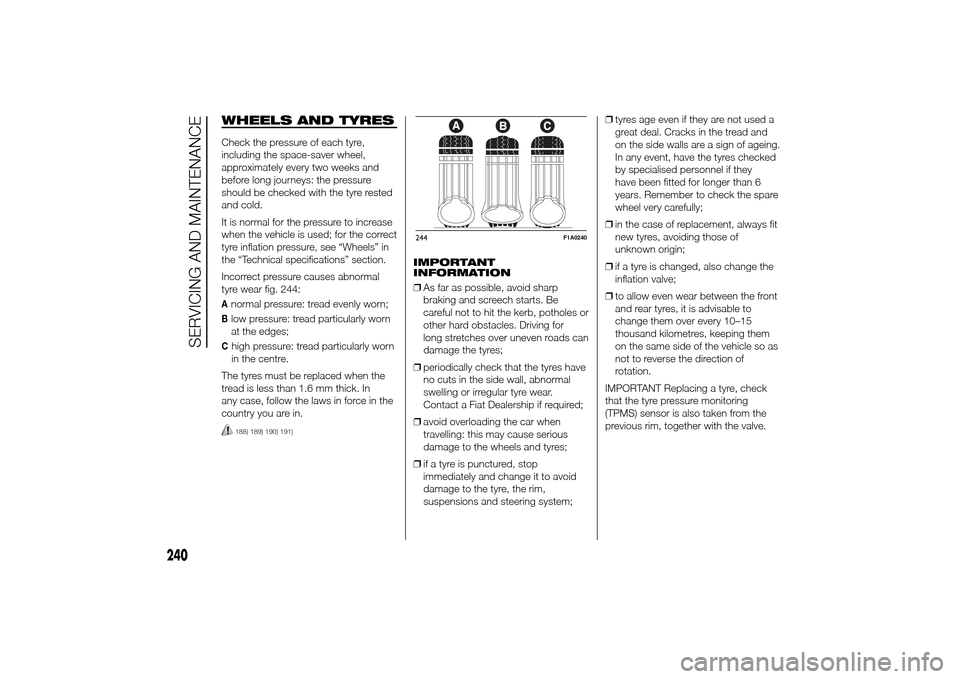

Incorrect pressure causes abnormal

tyre wear fig. 244:Anormal pressure: tread evenly worn;Blow pressure: tread particularly worn

at the edges;Chigh pressure: tread particularly worn

in the centre.

The tyres must be replaced when the

tread is less than 1.6 mm thick. In

any case, follow the laws in force in the

country you are in.188) 189) 190) 191)

IMPORTANT

INFORMATION

❒As far as possible, avoid sharp

braking and screech starts. Be

careful not to hit the kerb, potholes or

other hard obstacles. Driving for

long stretches over uneven roads can

damage the tyres;

❒periodically check that the tyres have

no cuts in the side wall, abnormal

swelling or irregular tyre wear.

Contact a Fiat Dealership if required;

❒avoid overloading the car when

travelling: this may cause serious

damage to the wheels and tyres;

❒if a tyre is punctured, stop

immediately and change it to avoid

damage to the tyre, the rim,

suspensions and steering system;❒tyres age even if they are not used a

great deal. Cracks in the tread and

on the side walls are a sign of ageing.

In any event, have the tyres checked

by specialised personnel if they

have been fitted for longer than 6

years. Remember to check the spare

wheel very carefully;

❒in the case of replacement, always fit

new tyres, avoiding those of

unknown origin;

❒if a tyre is changed, also change the

inflation valve;

❒to allow even wear between the front

and rear tyres, it is advisable to

change them over every 10–15

thousand kilometres, keeping them

on the same side of the vehicle so as

not to reverse the direction of

rotation.

IMPORTANT Replacing a tyre, check

that the tyre pressure monitoring

(TPMS) sensor is also taken from the

previous rim, together with the valve.244

F1A0240

240

SERVICING AND MAINTENANCE

Page 248 of 367

ADVICE FOR

PRESERVING THE

BODYWORK

Paintwork

Paintwork does not only serve an

aesthetic purpose, but also protects the

underlying sheet metal.

Touch up abrasions and scratches

immediately to prevent rust formation.

Only use genuine spare paint products

for touch-ups (see “Bodywork paint

identification plate” in the “Technical

Specifications” section).

Normal maintenance of paintwork

consists in washing the car: the

frequency depends on the conditions

and environment where the car is used.

For example, it is advisable to wash

the vehicle more often in areas with

high levels of environmental pollution or

on roads spread with salt.To correctly wash the vehicle, proceed

as follows:

❒wash the bodywork using a low

pressure jet of water;

❒wipe a sponge with a slightly soapy

solution over the bodywork,

frequently rinsing the sponge;

❒rinse well with water and dry with a

jet of air or a chamois leather.

If you put the car through a car wash,

follow these recommendations:

❒remove the aerial from the roof so it

does not get damaged;

❒the vehicle should be washed with

water added to a soapy solution;

❒rinse thoroughly to avoid soap marks

remaining on the bodywork or less

visible parts.

54)

Dry the less visible parts, such as the

door frames, bonnet and the headlight

frames with special care, as in these

areas water may stagnate more easily.

It is a good idea to leave the vehicle

outdoors for a while after washing it to

give the water time to evaporate.

Do not wash the vehicle after it has

been left in the sun or with the bonnet

hot: this may alter the shine of the

paintwork.

Exterior plastic parts should be cleaned

in the same way as the rest of the

vehicle. Where possible, do not park

the vehicle under trees; the resinous

substances released by many species

give the paint a dull appearance and

increase the possibility of corrosion.

IMPORTANT Bird droppings must be

washed off immediately and thoroughly

as the acid they contain is particularly

aggressive.

5)

Windows

To clean glasses, use specific cleaning

products. Use clean cloths to avoid

scratching the glass or damaging the

transparency.

244

SERVICING AND MAINTENANCE

Page 253 of 367

TECHNICAL SPECIFICATIONS

Everything you may find useful for

understanding how your vehicle

is made and works is contained in this

chapter and illustrated with data, tables

and graphics. For the enthusiasts and

the technician, but also just for those

who want to know every detail of their

vehicle.IDENTIFICATION DATA....................250

ENGINE CODES - BODYWORK

VERSION ........................................252

ENGINE ..........................................254

POWER SUPPLY ............................255

TRANSMISSION .............................256

SUSPENSION .................................257

BRAKES .........................................258

STEERING ......................................259

WHEELS .........................................260

DIMENSIONS ..................................264

PERFORMANCE .............................274

WEIGHTS........................................276

SUPPLIES .......................................316

FLUIDS AND LUBRICANTS ............318

FUEL CONSUMPTION ....................321

CO2 EMISSIONS ............................332

OFFICIAL TYPE APPROVALS .........342

PRESCRIPTIONS FOR HANDLING

THE VEHICLE AT THE END OF ITS

LIFE ................................................346

249

Page 254 of 367

IDENTIFICATION

DATAIt is advisable to take note of the

identification codes. Identification codes

are printed and shown on the plates

as indicated below, together with the

positions:

❒VIN plate.

❒Chassis marking.

❒Bodywork paint identification plate.

❒Engine marking.

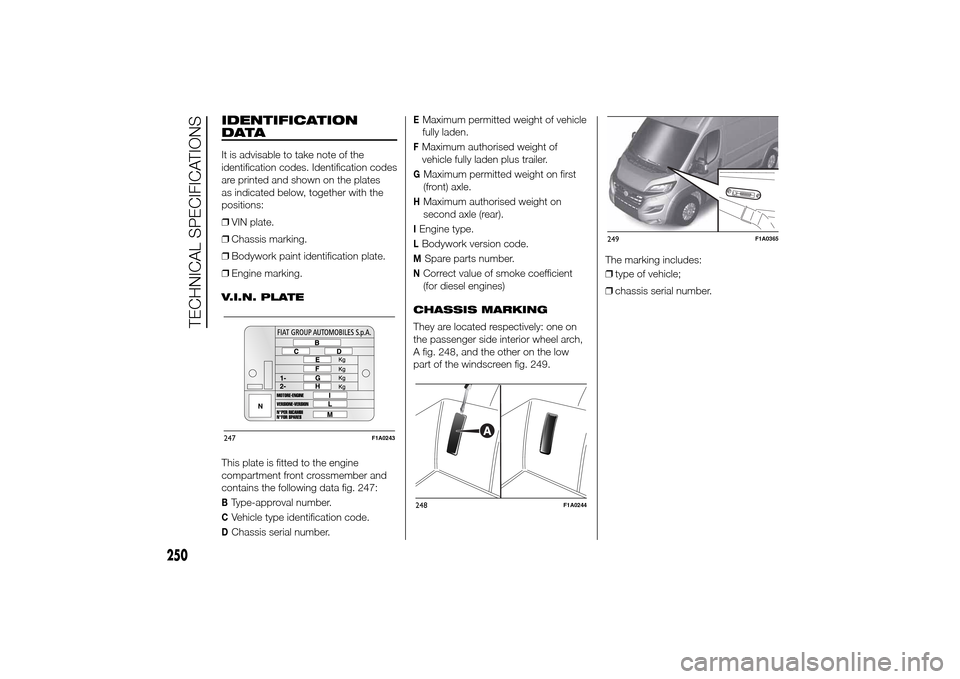

V.I.N. PLATE

This plate is fitted to the engine

compartment front crossmember and

contains the following data fig. 247:BType-approval number.CVehicle type identification code.DChassis serial number.

EMaximum permitted weight of vehicle

fully laden.FMaximum authorised weight of

vehicle fully laden plus trailer.GMaximum permitted weight on first

(front) axle.HMaximum authorised weight on

second axle (rear).IEngine type.LBodywork version code.M

Spare parts number.

NCorrect value of smoke coefficient

(for diesel engines)

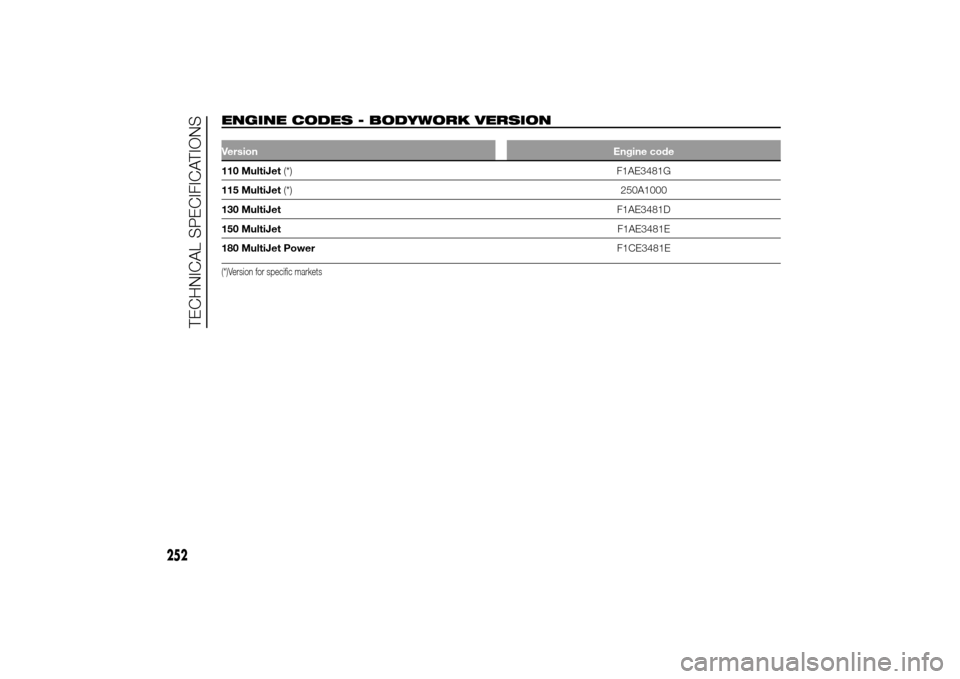

CHASSIS MARKING

They are located respectively: one on

the passenger side interior wheel arch,

A fig. 248, and the other on the low

part of the windscreen fig. 249.The marking includes:

❒type of vehicle;

❒chassis serial number.

247

F1A0243

248

F1A0244

249

F1A0365

250

TECHNICAL SPECIFICATIONS

Page 256 of 367

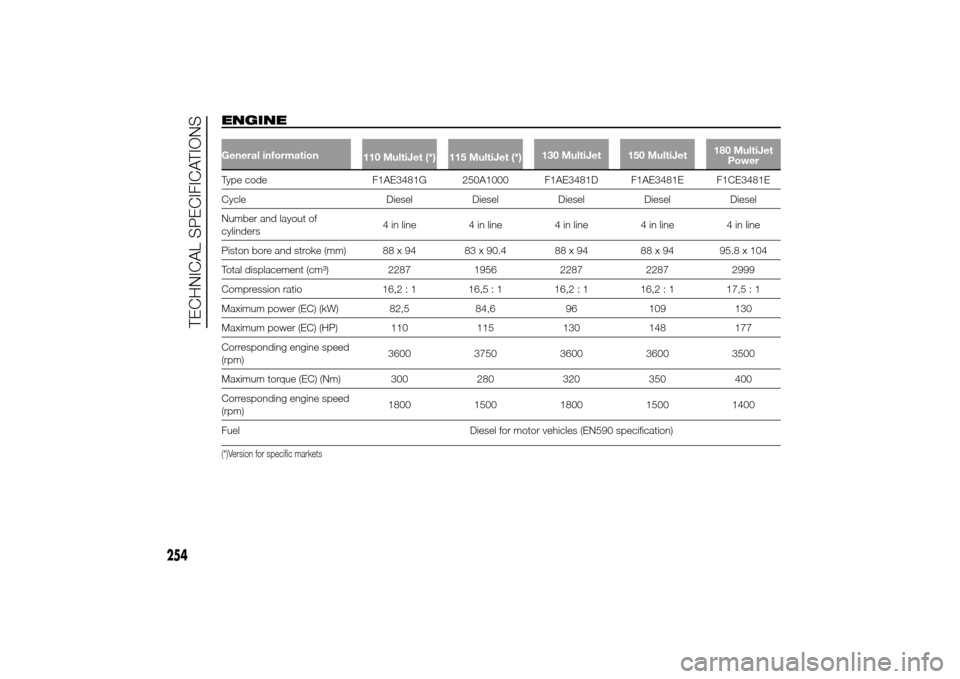

ENGINE CODES - BODYWORK VERSION

.

VersionEngine code110 MultiJet(*) F1AE3481G

115 MultiJet(*)250A1000

130 MultiJetF1AE3481D

150 MultiJetF1AE3481E

180 MultiJet PowerF1CE3481E(*)Version for specific markets

252

TECHNICAL SPECIFICATIONS

Page 258 of 367

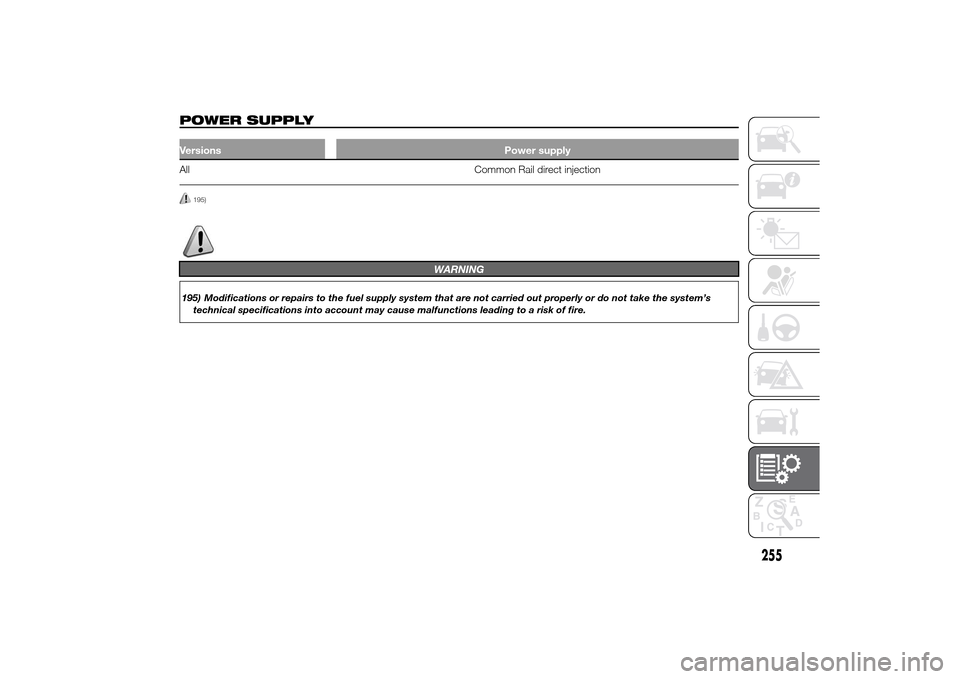

ENGINEGeneral information

110 MultiJet (*) 115 MultiJet (*)130 MultiJet 150 MultiJet180 MultiJet

PowerType code F1AE3481G 250A1000 F1AE3481D F1AE3481E F1CE3481E

Cycle Diesel Diesel Diesel Diesel Diesel

Number and layout of

cylinders4 in line 4 in line 4 in line 4 in line 4 in line

Piston bore and stroke (mm) 88 x 94 83 x 90.4 88 x 94 88 x 94 95.8 x 104

Total displacement (cm³) 2287 1956 2287 2287 2999

Compression ratio 16,2 : 1 16,5 : 1 16,2 : 1 16,2 : 1 17,5 : 1

Maximum power (EC) (kW) 82,5 84,6 96 109 130

Maximum power (EC) (HP) 110 115 130 148 177

Corresponding engine speed

(rpm)3600 3750 3600 3600 3500

Maximum torque (EC) (Nm) 300 280 320 350 400

Corresponding engine speed

(rpm)1800 1500 1800 1500 1400

Fuel Diesel for motor vehicles (EN590 specification)(*)Version for specific markets

254

TECHNICAL SPECIFICATIONS

Page 259 of 367

POWER SUPPLYVersions Power supplyAll Common Rail direct injection

195)

WARNING

195) Modifications or repairs to the fuel supply system that are not carried out properly or do not take the system’s

technical specifications into account may cause malfunctions leading to a risk of fire.

255

Page 260 of 367

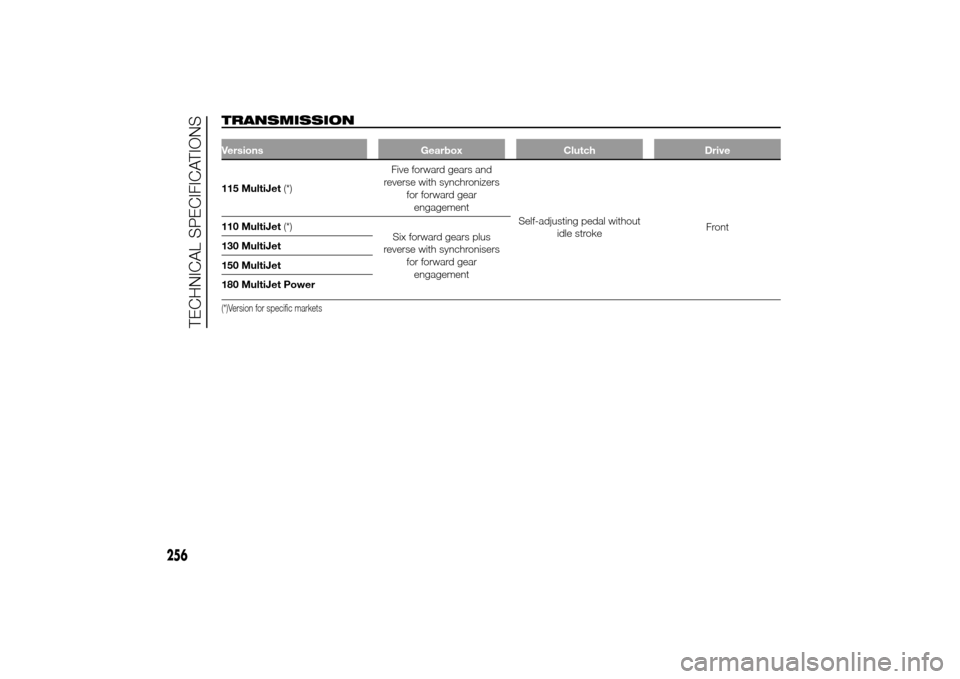

TRANSMISSIONVersions Gearbox Clutch Drive115 MultiJet(*)Five forward gears and

reverse with synchronizers

for forward gear

engagement

Self-adjusting pedal without

idle strokeFront 110 MultiJet(*)

Six forward gears plus

reverse with synchronisers

for forward gear

engagement 130 MultiJet

150 MultiJet

180 MultiJet Power(*)Version for specific markets

256

TECHNICAL SPECIFICATIONS

Page 262 of 367

BRAKES

Front service brakes Rear service brakes Parking brakeself-ventilated discs discscontrolled by hand lever, working on rear

brakes

IMPORTANT Water, ice and salt spread on the roads may deposit on the brake discs reducing braking efficiency the first time

the brakes are applied.

258

TECHNICAL SPECIFICATIONS