change FIAT DUCATO 2015 3.G Owner's Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: DUCATO, Model: FIAT DUCATO 2015 3.GPages: 387, PDF Size: 20.76 MB

Page 190 of 387

34)

IMPORTANT Apply the handbrake only

when the vehicle is at a standstill or

with the vehicle in motion only in the

event of a failure in the hydraulic

system. If exceptional use is made of

the handbrake with the vehicle in

motion, moderate traction is advisable

in order not to cause locking of the

rear end with consequent swerving of

the vehicle.

WARNING

135) Never leave children

unattended in the vehicle. Always

remove the ignition key when

leaving the vehicle and take it out

with you.

IMPORTANT

34) If the vehicle is equipped with

self-levelling air suspension,

always check that there is

sufficient space above the roof

and around the vehicle when

parking. Indeed, the vehicle could

raise (or lower) automatically

depending on load or temperature

changes.

USING THE

GEARBOX

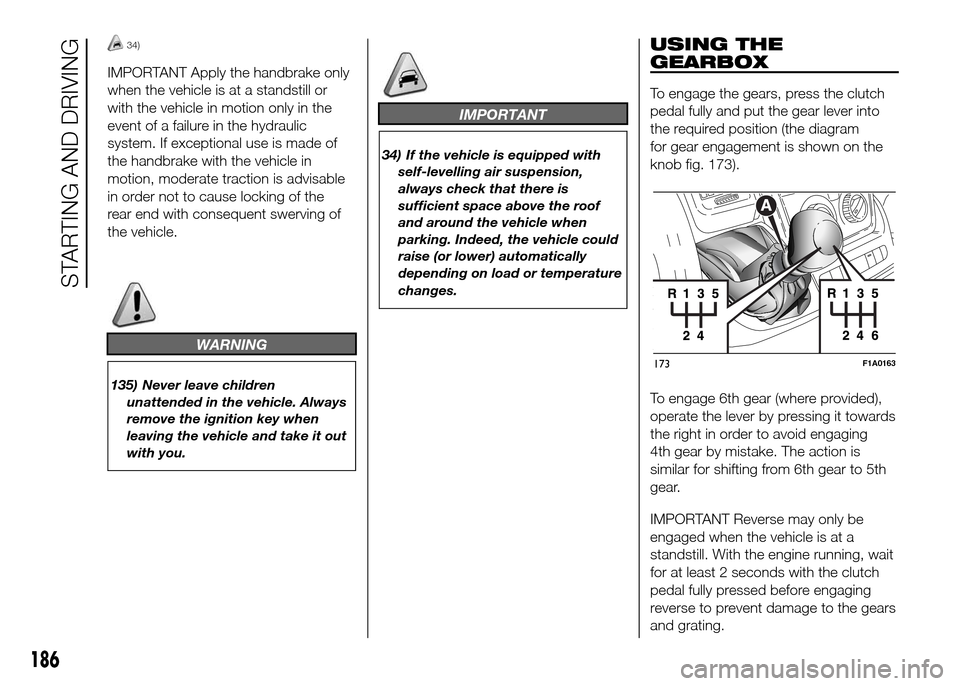

To engage the gears, press the clutch

pedal fully and put the gear lever into

the required position (the diagram

for gear engagement is shown on the

knob fig. 173).

To engage 6th gear (where provided),

operate the lever by pressing it towards

the right in order to avoid engaging

4th gear by mistake. The action is

similar for shifting from 6th gear to 5th

gear.

IMPORTANT Reverse may only be

engaged when the vehicle is at a

standstill. With the engine running, wait

for at least 2 seconds with the clutch

pedal fully pressed before engaging

reverse to prevent damage to the gears

and grating.

173F1A0163

186

STARTING AND DRIVING

Page 191 of 387

To engage reverse R from neutral,

proceed as follows: raise sliding ring A

under the knob and at the same time

move the gear lever to the left and then

forwards.

136)

35)

WARNING

136) Depress the clutch pedal fully

to change gear correctly. It is

therefore essential that there is

nothing under the pedals: make

sure the mats are lying flat and do

not get in the way of the pedals.

IMPORTANT

35) Do not drive with your hand

resting on the gear lever as the

force exerted, even if slight, could

lead over time to premature wear

of the internal gearbox

components. The clutch pedal

should be used only for gear

changes. Do not drive with your

foot resting on the clutch pedal,

however lightly. For versions/

markets where provided, the

electronic clutch pedal control

could cut in, interpreting the

incorrect driving style as a fault.

LOADING ADVICE

The Fiat Ducato version used by you

has been designed and type approved

on the basis of certain maximum

weights (see "Weights" table in the

"Technical Data" chapter): kerb weight,

payload, total weight, maximum weight

on front axle, maximum weight on

rear axle, towable weight.

IMPORTANT The maximum permitted

load on the floor fastenings is 500

kg; the maximum permitted load on the

side panel is 150 kg.

IMPORTANT For versions with right and

left side flaps, it is advisable to

reposition the release lever in the closed

position before lowering the sides.

36)

137) 138) 139)

In addition to these general

precautions, some simple precautions

can improve driving safety, travelling

comfort and vehicle durability:

❒distribute the load evenly over the

platform: if it is necessary to

concentrate it in a single area,

choose an area mid-way between

both axles;

187

Page 202 of 387

SNOW TYRES

A Fiat Dealership will be happy to

provide advice concerning the most

suitable type of tyre for the customer's

requirements.

The performance of these tyres is

considerably reduced when the tread

depth is less than 4 mm. Replace them

in this case.

Due to the specific characteristics of

snow tyres, in normal weather

conditions or on long motorway

journeys, the performance of these

tyres is lower than that of standard

tyres. Their usage should therefore be

restricted in accordance with their

type approval.

IMPORTANT When using snow tyres

with a maximum speed index below the

one that can be reached by the vehicle

(increased by 5%), place a notice in

the passenger compartment, plainly in

view, which states the maximum speed

allowed by the snow tyres (as per EC

Directive).

All four tyres should be the same (brand

and track) to ensure greater safety

when driving and braking as well as a

good manoeuvrability.

Remember that you should not change

the rotation direction of the tyres.

144)

WARNING

144) The maximum speed for snow

tyres marked "Q" is 160 km/h,

while it is 190 km/h for "T" tyres

and 210 km/h for "H" tyres. You

should, however, always comply

with the speed limits of the

highway code.

SNOW CHAINS

The use of snow chains should be in

compliance with local regulations of

each country.

Snow chains can be fitted to the tyres

of the front wheels (drive wheels) only.

Use of Lineaccessori Fiat snow chains

is recommended. Check the tension

of the snow chains after the first few

metres have been driven.

43)

IMPORTANT With snow chains, use the

accelerator with extreme care to

prevent, or to limit as much as possible,

slipping of the drive wheels that could

cause chain breakage, resulting in

damage to the car body or mechanical

components.

IMPORTANT For versions fitted with

225/75 R16 tyre, use snow chains with

max. thickness 16 mm.

When travelling on snowy roads with

snow chains, it may be helpful to turn

the ASR off: in fact, in these conditions,

the driving wheels skidding when

moving off gives you better traction.

198

STARTING AND DRIVING

Page 207 of 387

WARNING

145) This procedure must be

performed by qualified personnel

as incorrect actions may cause

high-intensity electrical discharge.

Furthermore, battery fluid is

poisonous and corrosive: avoid

contact with skin and eyes. Keep

naked flames and lighted

cigarettes away from the battery

and do not cause sparks.

REPLACING A

WHEEL

GENERAL

INSTRUCTIONS

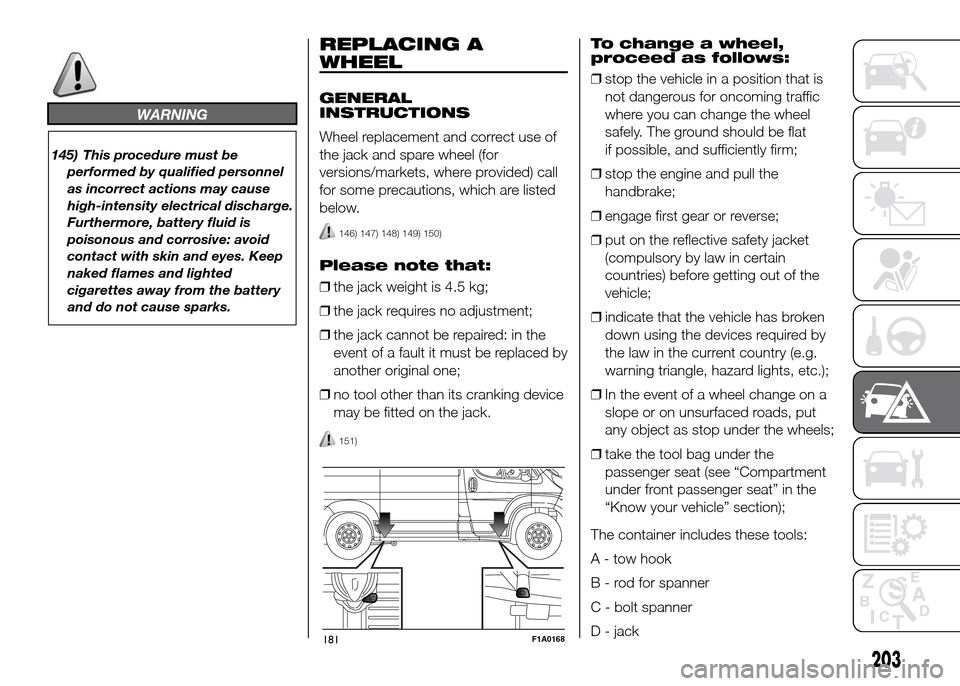

Wheel replacement and correct use of

the jack and spare wheel (for

versions/markets, where provided) call

for some precautions, which are listed

below.

146) 147) 148) 149) 150)

Please note that:

❒the jack weight is 4.5 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired: in the

event of a fault it must be replaced by

another original one;

❒no tool other than its cranking device

may be fitted on the jack.

151)

To change a wheel,

proceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel

safely. The ground should be flat

if possible, and sufficiently firm;

❒stop the engine and pull the

handbrake;

❒engage first gear or reverse;

❒put on the reflective safety jacket

(compulsory by law in certain

countries) before getting out of the

vehicle;

❒indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

❒In the event of a wheel change on a

slope or on unsurfaced roads, put

any object as stop under the wheels;

❒take the tool bag under the

passenger seat (see “Compartment

under front passenger seat” in the

“Know your vehicle” section);

The container includes these tools:

A - tow hook

B - rod for spanner

C - bolt spanner

D - jack

181F1A0168

203

Page 208 of 387

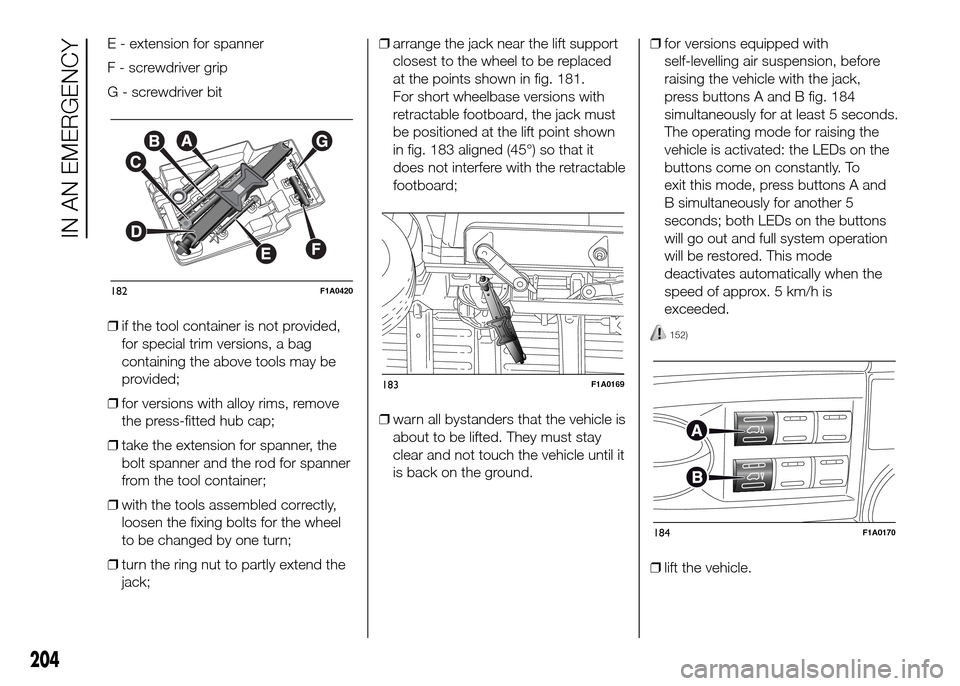

E - extension for spanner

F - screwdriver grip

G - screwdriver bit

❒if the tool container is not provided,

for special trim versions, a bag

containing the above tools may be

provided;

❒for versions with alloy rims, remove

the press-fitted hub cap;

❒take the extension for spanner, the

bolt spanner and the rod for spanner

from the tool container;

❒with the tools assembled correctly,

loosen the fixing bolts for the wheel

to be changed by one turn;

❒turn the ring nut to partly extend the

jack;❒arrange the jack near the lift support

closest to the wheel to be replaced

at the points shown in fig. 181.

For short wheelbase versions with

retractable footboard, the jack must

be positioned at the lift point shown

in fig. 183 aligned (45°) so that it

does not interfere with the retractable

footboard;

❒warn all bystanders that the vehicle is

about to be lifted. They must stay

clear and not touch the vehicle until it

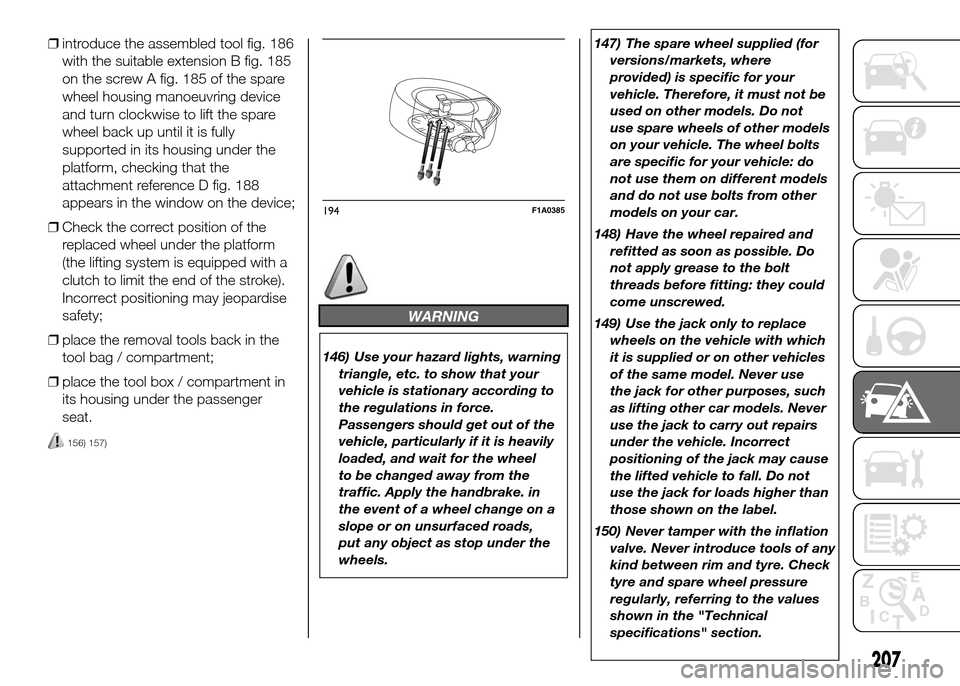

is back on the ground.❒for versions equipped with

self-levelling air suspension, before

raising the vehicle with the jack,

press buttons A and B fig. 184

simultaneously for at least 5 seconds.

The operating mode for raising the

vehicle is activated: the LEDs on the

buttons come on constantly. To

exit this mode, press buttons A and

B simultaneously for another 5

seconds; both LEDs on the buttons

will go out and full system operation

will be restored. This mode

deactivates automatically when the

speed of approx. 5 km/h is

exceeded.

152)

❒lift the vehicle.

182F1A0420

183F1A0169

184F1A0170

204

IN AN EMERGENCY

Page 211 of 387

❒introduce the assembled tool fig. 186

with the suitable extension B fig. 185

on the screw A fig. 185 of the spare

wheel housing manoeuvring device

and turn clockwise to lift the spare

wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 188

appears in the window on the device;

❒Check the correct position of the

replaced wheel under the platform

(the lifting system is equipped with a

clutch to limit the end of the stroke).

Incorrect positioning may jeopardise

safety;

❒place the removal tools back in the

tool bag / compartment;

❒place the tool box / compartment in

its housing under the passenger

seat.

156) 157)

WARNING

146) Use your hazard lights, warning

triangle, etc. to show that your

vehicle is stationary according to

the regulations in force.

Passengers should get out of the

vehicle, particularly if it is heavily

loaded, and wait for the wheel

to be changed away from the

traffic. Apply the handbrake. in

the event of a wheel change on a

slope or on unsurfaced roads,

put any object as stop under the

wheels.147) The spare wheel supplied (for

versions/markets, where

provided) is specific for your

vehicle. Therefore, it must not be

used on other models. Do not

use spare wheels of other models

on your vehicle. The wheel bolts

are specific for your vehicle: do

not use them on different models

and do not use bolts from other

models on your car.

148) Have the wheel repaired and

refitted as soon as possible. Do

not apply grease to the bolt

threads before fitting: they could

come unscrewed.

149) Use the jack only to replace

wheels on the vehicle with which

it is supplied or on other vehicles

of the same model. Never use

the jack for other purposes, such

as lifting other car models. Never

use the jack to carry out repairs

under the vehicle. Incorrect

positioning of the jack may cause

the lifted vehicle to fall. Do not

use the jack for loads higher than

those shown on the label.

150) Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and spare wheel pressure

regularly, referring to the values

shown in the "Technical

specifications" section.

194F1A0385

207

Page 212 of 387

151) No tools other than the crank

provided should be used with

the spare wheel lifting device; it

should be operated by hand only.

152) On versions equipped with

self-levelling air suspension, never

introduce the head or hands in

the wheel arch: the vehicle could

raise or lower automatically

depending on possible load or

temperature changes.

153) The device should only be

operated by hand, without using

any type of tool other than the

crank provided, like pneumatic or

electrical screwers.

154) The moving components of the

jack (screw and joints) can also

cause injuries: do not touch them.

If you come into contact with

lubricating grease, clean yourself

thoroughly.155) At the end of the operation of

raising/locking the spare wheel,

after having checked the correct

positioning of the wheel under the

platform (yellow notch inside the

window on the device), the

spanner must be extracted, taking

care not to turn it in the wrong

direction (as in fig. 190) to

facilitate the extraction of the

spanner itself, to prevent the

attachment device from being

released and the wheel assembly

not being securely retained.

156) Each time the spare wheel is

moved, check that it is correctly

positioned in its housing under

the platform. If it is not correctly

positioned, this could adversely

affect safety.

157) The spare wheel lifting device

is equipped with a clutch safety

system for its own protection; this

could activated if an excessive

load is applied on the

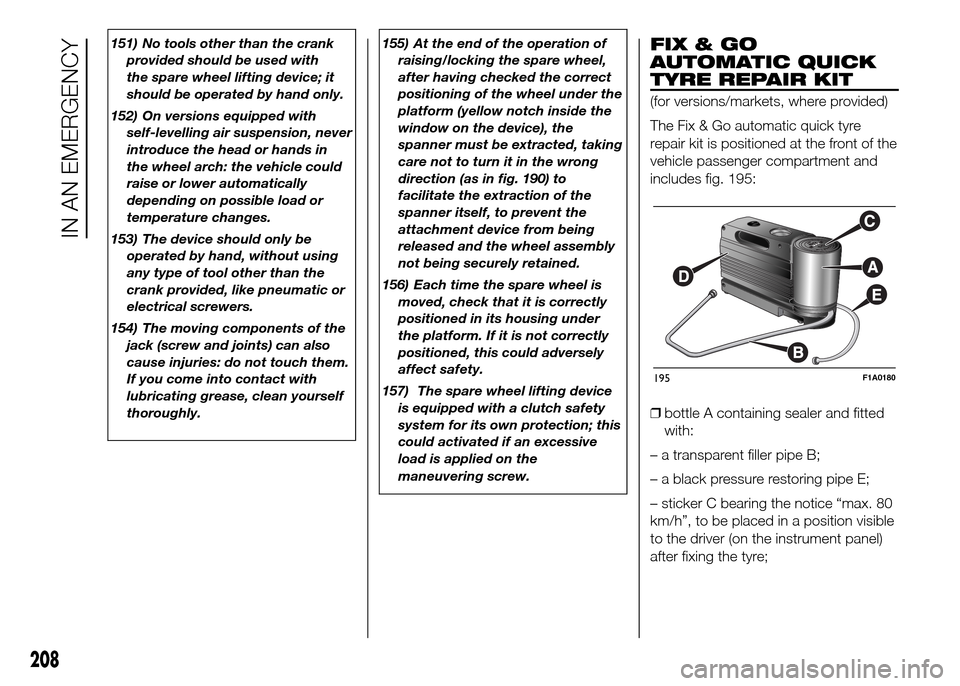

maneuvering screw.FIX&GO

AUTOMATIC QUICK

TYRE REPAIR KIT

(for versions/markets, where provided)

The Fix & Go automatic quick tyre

repair kit is positioned at the front of the

vehicle passenger compartment and

includes fig. 195:

❒bottle A containing sealer and fitted

with:

– a transparent filler pipe B;

– a black pressure restoring pipe E;

– sticker C bearing the notice “max. 80

km/h”, to be placed in a position visible

to the driver (on the instrument panel)

after fixing the tyre;

195F1A0180

208

IN AN EMERGENCY

Page 222 of 387

❒fit the new bulb, ensuring that the

outline of the metal part coincides

with the grooves on the curve of the

headlight, pressing to engage it

with the side clips;

❒reconnect the electrical connector;

❒refit the protective rubber cover B fig.

206.

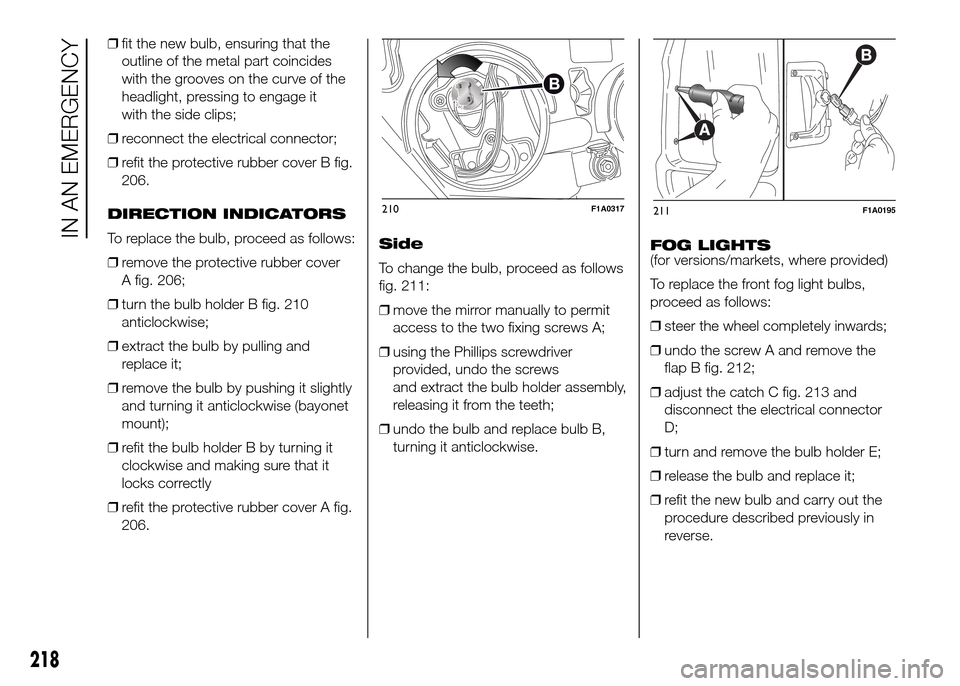

DIRECTION INDICATORS

To replace the bulb, proceed as follows:

❒remove the protective rubber cover

A fig. 206;

❒turn the bulb holder B fig. 210

anticlockwise;

❒extract the bulb by pulling and

replace it;

❒remove the bulb by pushing it slightly

and turning it anticlockwise (bayonet

mount);

❒refit the bulb holder B by turning it

clockwise and making sure that it

locks correctly

❒refit the protective rubber cover A fig.

206.Side

To change the bulb, proceed as follows

fig. 211:

❒move the mirror manually to permit

access to the two fixing screws A;

❒using the Phillips screwdriver

provided, undo the screws

and extract the bulb holder assembly,

releasing it from the teeth;

❒undo the bulb and replace bulb B,

turning it anticlockwise.FOG LIGHTS

(for versions/markets, where provided)

To replace the front fog light bulbs,

proceed as follows:

❒steer the wheel completely inwards;

❒undo the screw A and remove the

flap B fig. 212;

❒adjust the catch C fig. 213 and

disconnect the electrical connector

D;

❒turn and remove the bulb holder E;

❒release the bulb and replace it;

❒refit the new bulb and carry out the

procedure described previously in

reverse.

210F1A0317211F1A0195

218

IN AN EMERGENCY

Page 223 of 387

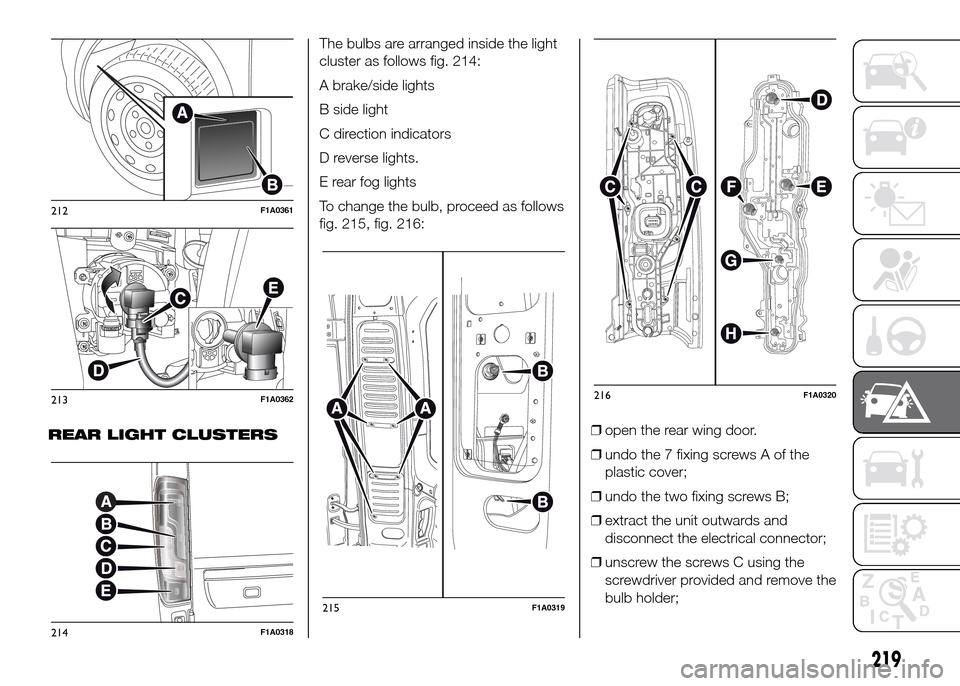

REAR LIGHT CLUSTERSThe bulbs are arranged inside the light

cluster as follows fig. 214:

A brake/side lights

B side light

C direction indicators

D reverse lights.

E rear fog lights

To change the bulb, proceed as follows

fig. 215, fig. 216:

❒open the rear wing door.

❒undo the 7 fixing screws A of the

plastic cover;

❒undo the two fixing screws B;

❒extract the unit outwards and

disconnect the electrical connector;

❒unscrew the screws C using the

screwdriver provided and remove the

bulb holder;

212F1A0361

213F1A0362

214F1A0318

215F1A0319

216F1A0320

219

Page 225 of 387

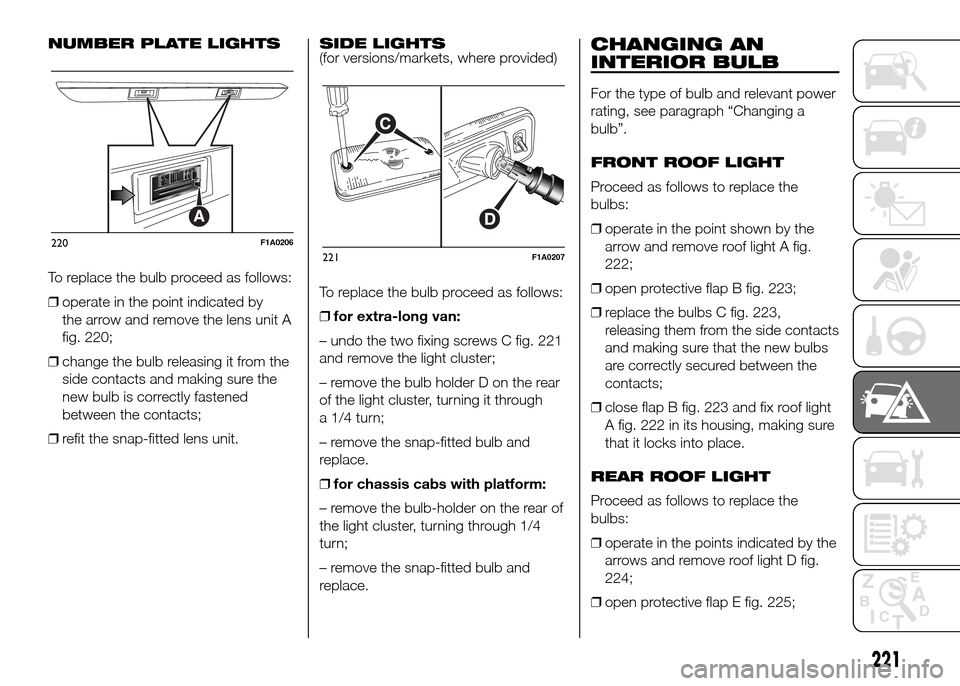

NUMBER PLATE LIGHTS

To replace the bulb proceed as follows:

❒operate in the point indicated by

the arrow and remove the lens unit A

fig. 220;

❒change the bulb releasing it from the

side contacts and making sure the

new bulb is correctly fastened

between the contacts;

❒refit the snap-fitted lens unit.SIDE LIGHTS

(for versions/markets, where provided)

To replace the bulb proceed as follows:

❒for extra-long van:

– undo the two fixing screws C fig. 221

and remove the light cluster;

– remove the bulb holder D on the rear

of the light cluster, turning it through

a 1/4 turn;

– remove the snap-fitted bulb and

replace.

❒for chassis cabs with platform:

– remove the bulb-holder on the rear of

the light cluster, turning through 1/4

turn;

– remove the snap-fitted bulb and

replace.CHANGING AN

INTERIOR BULB

For the type of bulb and relevant power

rating, see paragraph “Changing a

bulb”.

FRONT ROOF LIGHT

Proceed as follows to replace the

bulbs:

❒operate in the point shown by the

arrow and remove roof light A fig.

222;

❒open protective flap B fig. 223;

❒replace the bulbs C fig. 223,

releasing them from the side contacts

and making sure that the new bulbs

are correctly secured between the

contacts;

❒close flap B fig. 223 and fix roof light

A fig. 222 in its housing, making sure

that it locks into place.

REAR ROOF LIGHT

Proceed as follows to replace the

bulbs:

❒operate in the points indicated by the

arrows and remove roof light D fig.

224;

❒open protective flap E fig. 225;

220F1A0206221F1A0207

221