suspension FIAT DUCATO 2015 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: DUCATO, Model: FIAT DUCATO 2015Pages: 367, PDF Size: 19.73 MB

Page 2 of 367

We really know your vehicle because we invented,

designed and built it: we really know every single detail. At Fiat Professional Service authorised workshops

you can find technicians directly trained by us, offering quality and professionalism for all service operations.

Fiat Professional workshops are always close to you for the regular servicing operations, season checks and practical recommendations by our experts.

With Fiat Professional Genuine Parts you keep the reliability, comfort and performance features of your new vehicle unchanged in time: that's why you bought it for.

Always ask for Genuine Parts for the components used on our vehicles; we recommend them because they come from our steady commitment in research and development of highly innovative technologies. For all these reasons: rely on Genuine Parts,

because they are the only ones designed by Fiat Professional for your vehicle.

SAFETY: BRAKING SYSTEMENVIRONMENT: PARTICULATE FILTERS,

CLIMATE CONTROL SYSTEM MAINTENANCECOMFORT:

SUSPENSION AND WINDSCREEN WIPERSPERFORMANCE:

SPARK PLUGS, INJECTORS AND BATTERIESLINEACCESSORI:

ROOF RACK BARS, WHEEL RIMS

WHY CHOOSING GENUINE PARTS

COP DUCATO LUM GB 20/01/14 09.58 Pagina 2

Page 13 of 367

KNOW YOUR VEHICLE

In-depth knowledge of your new

vehicle starts here.

The booklet that you are reading

simply and directly explains how it

is made and how it works.

That’s why we advise you to read it

seated comfortably on board, so

that you can see what is described

here for yourself.SYMBOLS ...................................... 10

THE FIAT CODE SYSTEM ............... 10

THE KEYS....................................... 11

ELECTRONIC ALARM..................... 13

IGNITION SWITCH .......................... 15

SEATS ............................................ 16

HEAD RESTRAINTS ........................ 24

STEERING WHEEL ......................... 25

REAR VIEW MIRRORS .................... 25

HEATING AND VENTILATION.......... 28

DIFFUSERS..................................... 29

HEATING AND VENTILATION

CONTROLS .................................... 29

MANUAL CLIMATE CONTROL

SYSTEM ......................................... 32

AUTOMATIC CLIMATE CONTROL

SYSTEM ......................................... 35

ADDITIONAL HEATER ..................... 42

INDEPENDENT ADDITIONAL

HEATER .......................................... 42

EXTERNAL LIGHTS......................... 48

WINDOW CLEANING ...................... 53

CRUISE CONTROL ......................... 55

ROOF LIGHTS ................................ 59

CONTROLS .................................... 60

FUEL CUT-OFF SWITCH ................ 63

INTERIOR FITTINGS ...................... 64

TACHOGRAPH ............................... 69SPEED BLOCK ............................... 70

SELF-LEVELLING AIR

SUSPENSION ................................. 70

DOORS ........................................... 72

ELECTRIC WINDOWS .................... 78

BONNET ......................................... 79

ROOF RACK/SKI RACK .................. 80

HEADLIGHTS.................................. 81

ABS ................................................ 82

ESC (ELECTRONIC STABILITY

CONTROL) SYSTEM ....................... 83

TRACTION PLUS SYSTEM ............. 88

TPMS (TYRE PRESSURE

MONITORING SYSTEM) ................. 89

DRIVING ADVISOR ......................... 92

REAR CAMERA (PARKVIEW®

REAR BACK UP CAMERA) ............. 97

TRAFFIC SIGN RECOGNITION ....... 99

EOBD SYSTEM...............................100

PARKING SENSORS.......................101

START&STOP SYSTEM ..................103

RADIO.............................................107

ACCESSORIES PURCHASED BY

THE OWNER...................................108

REFUELLING THE VEHICLE ...........109

PROTECTING THE

ENVIRONMENT ..............................111

9

Page 74 of 367

The tachograph is installed and

sealed by authorised personnel: do

not try and access the device or

the supply and recording leads

in any way. It is the responsibility of

the owner of the vehicle on which

the tachograph is installed to check

the device regularly.

The check must be carried out at

least every two years and a test

must be carried out to ensure that it

is working properly. Ensure that

the data label is renewed after

every check and that the

label contains the specified data.SPEED BLOCK

(for versions/markets, where

provided)

The vehicle is equipped with a

speed limitation function that can

be set at the user's request to one

of 4 predefined values: 90, 100,

110, 130 km/h.

To activate/deactivate this function,

contact a Fiat Dealership.

Following the operation, a sticker

will be applied to the windscreen

showing the maximum speed

setting.

IMPORTANT The speedometer

could indicate a higher maximum

speed than the effective one, set by

the Dealership, in accordance with

the regulations in force.

SELF-LEVELLING AIR

SUSPENSION

GENERAL

INFORMATION

The system only acts on the rear

wheels.

The system maintains the rear ride

setting for the vehicle constant in

any loading condition, while

ensuring a greater driving comfort.

In addition, the system allows

the height of the vehicle to

be adjusted with the vehicle

stationary, by selecting from 7

different positions to facilitate

access to the rear compartment.

HEIGHT ADJUSTMENT

There are 7 pre-defined levels for

the free height from the ground:

from “ride -3” to “ride 0” till “ride

+3”.

The multifunction display, located in

the middle of the instrument panel,

can show the ride position.

70

KNOW YOUR VEHICLE

Page 104 of 367

WARNING

82) If the camera loses its position

due to a load variation, the system

may not work temporarily to allow

the camera to perform an

autocalibration.

83) The system only detects the

preset traffic signs. If the

minimum visibility conditions and

distance from the sign are met

it can detect all traffic signs.

84) The system is a driving

assistance system but it does not

relieve the driver of the

responsibility of driving with due

attention and diligence in

compliance with the laws in force.

85) When the system is active, the

driver is responsible for

controlling the vehicle and

monitoring the system, and must

intervene as appropriate if

necessary.

IMPORTANT

10) If the sensor is blocked, the

system may not work.

11) In the case of low temperatures

or harsh weather conditions, the

system may not work.

12) Rain, snow, splashes and strong

light contrast may influence the

sensor.

13) Do not repair the area of the

windscreen directly surrounding

the sensor.

14) If the vehicle is equipped with a

non-genuine suspension kit, the

system may not work correctly.

15) Always use genuine spare parts

when replacing the bulbs of the

headlights. Other bulbs may

reduce the system performance.

16) Clean the windscreen from

foreign matters such as bird

droppings, insects, snow or ice.

EOBD SYSTEM

The EOBD system (European On

Board Diagnosis) allows continuous

diagnosis of emission-related

components on the vehicle to be

made.

It also alerts the driver, by turning

on the

warning light in the

instrument panel (together with

relevant message in the

multifunction display, for versions/

markets where provided) when

these components are no longer in

peak condition (see “Warning

lights and messages” paragraph).

The aim of the system is to:

❒monitor system efficiency;

❒indicate an increase in emissions due

to vehicle malfunction;

❒indicate the need to replace

components which have

deteriorated.

100

KNOW YOUR VEHICLE

Page 106 of 367

FAULT INDICATIONS

Any parking sensor faults will be

indicated when reverse is engaged

by the warning light

in the

instrument panel or by the icon

on the display and by the

message in the multifunction

display (for versions/markets, where

provided)

OPERATION WITH

TRAILER

Parking sensor operation is

automatically deactivated when the

electric cable plug of the trailer is

inserted into the vehicle tow hook

socket.

The sensors are automatically

reactivated when the trailer's cable

plug is removed.

17)

86)

IMPORTANT If you wish to leave

the tow hook fitted without towing a

trailer, it is advisable to contact a

Fiat Dealership for the relevant

system update operations because

the tow hook could be detected

as an obstacle by the central

sensors.When using special washing

equipment such as high pressure

jets or steam cleaning, clean the

sensors very quickly keeping the jet

more than 10 cm away.

IMPORTANT

INFORMATION

❒Do not apply stickers to the sensors.

❒When parking, take the utmost

care over obstacles that may be

above or under the sensor.

❒Objects close to the vehicle, in

certain circumstances are not

detected and could therefore cause

damage to the vehicle or be

damaged.

The following conditions may

influence the performance of the

parking assistance system:

❒Reduced sensor sensitivity and a

reduction in the parking assistance

system performance could be due to

the presence on the surface of the

sensor of: ice, snow, mud, thick

paint.❒The sensor may detect a non-

existent obstacle (echo noise) due to

mechanical noises, for example

when washing the vehicle, in case of

rain, strong wind, hail.

❒The signals sent by the sensors can

also be altered by the presence of

ultrasonic systems (e.g. pneumatic

brake systems or pneumatic drills)

near the vehicle.

❒The performance of the parking

assistance system may also be

affected by the position of the

sensors. For example by a change in

the ride setting (caused by the wear

of the shock absorbers, suspension),

changing the tyres, overloading the

vehicle and carrying out specific

tuning operations that require the

vehicle to be lowered.

❒Detection of obstacles in the upper

part of the vehicle (particularly in the

case of vans or chassis cabs) may

not be guaranteed because the

system detects obstacles that could

strike the lower part of the vehicle.

102

KNOW YOUR VEHICLE

Page 117 of 367

KNOWING THE INSTRUMENT PANEL

This section of the booklet gives

you all the information you need to

understand, interpret and use

the instrument panel correctly.CONTROL PANEL AND

INSTRUMENTS ...............................114

DISPLAY ........................................120

TRIP COMPUTER ...........................129

WARNING LIGHTS AND

MESSAGES ....................................132

- LOW BRAKE FLUID/HANDBRAKE

ENGAGED .......................................... 132

- EBD FAILURE .................................. 133

- AIRBAG FAILURE ............................. 133

- SEAT BELTS NOT FASTENED .......... 134

- ENGINE COOLANT TEMPERATURE

TOO HIGH .......................................... 135

- LOW BATTERY CHARGE ................. 135

- LOW ENGINE OIL PRESSURE ......... 136

-ENGINE OIL DETERIORATED ........... 136

-INCOMPLETE DOOR/LOAD

COMPARTMENT CLOSURE ............... 137

- POWER STEERING FAILURE ........... 137

-SELF-LEVELLING SUSPENSION

FAILURE ............................................. 137

- INJECTION/EOBD SYSTEM

FAILURE ............................................. 139

- ABS FAILURE ................................... 140

-FUEL RESERVE ................................ 140

- GLOW PLUG HEATING/GLOW

PLUG HEATING FAILURE ................... 141

- WATER IN DIESEL FILTER ................ 141

-VEHICLE PROTECTION SYSTEM

FAILURE - FIAT CODE ........................ 142

- REAR FOG LIGHTS .......................... 142

-GENERIC FAILURE INDICATION ....... 142

-DPF (PARTICULATE FILTER)

CLEANING UNDERWAY ..................... 144

-WORN BRAKE PADS ........................ 145

-DRIVING ADVISOR ........................... 146

- TPMS ............................................... 147

- DIPPED HEADLIGHTS ..................... 148- FOLLOW ME HOME ........................ 148

- LEFT-HAND DIRECTION INDICATOR

............................................................ 148

- RIGHT-HAND DIRECTION

INDICATOR ........................................ 149

-FOG LIGHTS ..................................... 149

- CRUISE CONTROL .......................... 149

-SPEED LIMITER ................................ 149

- AUTOMATIC MAIN BEAM

HEADLIGHTS ..................................... 150

- MAIN BEAM HEADLIGHTS .............. 150

-EXTERIOR LIGHTS FAULT ................ 151

-BRAKE LIGHT FAILURE .................... 151

-MAIN BEAM AUTOMATISM FAULT ... 152

-POSSIBLE ICE ON ROAD ................. 152

-SPEED LIMIT EXCEEDED ................. 152

-SCHEDULED SERVICING ................. 152

-DRIVING ADVISOR SYSTEM

FAILURE ............................................. 153

-TRAFFIC SIGN RECOGNITION

FAILURE ............................................. 153

-LIMITED RANGE ............................... 153

-START&STOP SYSTEM

ACTIVATION/DEACTIVATION .............. 154

-START&STOP FAILURE .................... 154

113

Page 141 of 367

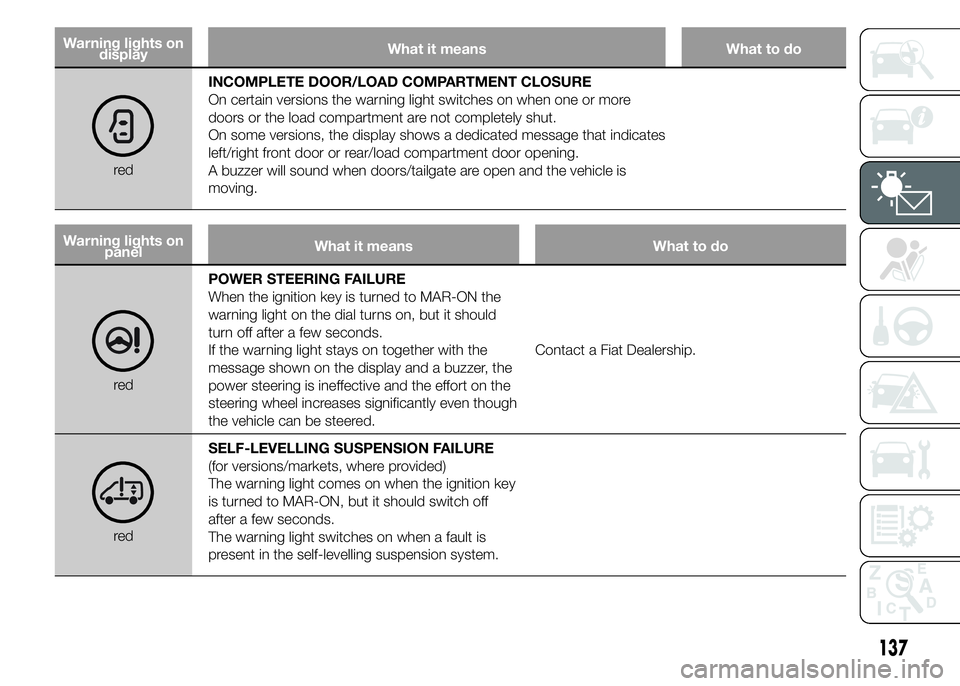

Warning lights on

displayWhat it means What to do

redINCOMPLETE DOOR/LOAD COMPARTMENT CLOSURE

On certain versions the warning light switches on when one or more

doors or the load compartment are not completely shut.

On some versions, the display shows a dedicated message that indicates

left/right front door or rear/load compartment door opening.

A buzzer will sound when doors/tailgate are open and the vehicle is

moving.

Warning lights on

panelWhat it means What to do

redPOWER STEERING FAILURE

When the ignition key is turned to MAR-ON the

warning light on the dial turns on, but it should

turn off after a few seconds.

If the warning light stays on together with the

message shown on the display and a buzzer, the

power steering is ineffective and the effort on the

steering wheel increases significantly even though

the vehicle can be steered.Contact a Fiat Dealership.

redSELF-LEVELLING SUSPENSION FAILURE

(for versions/markets, where provided)

The warning light comes on when the ignition key

is turned to MAR-ON, but it should switch off

after a few seconds.

The warning light switches on when a fault is

present in the self-levelling suspension system.

137

Page 186 of 367

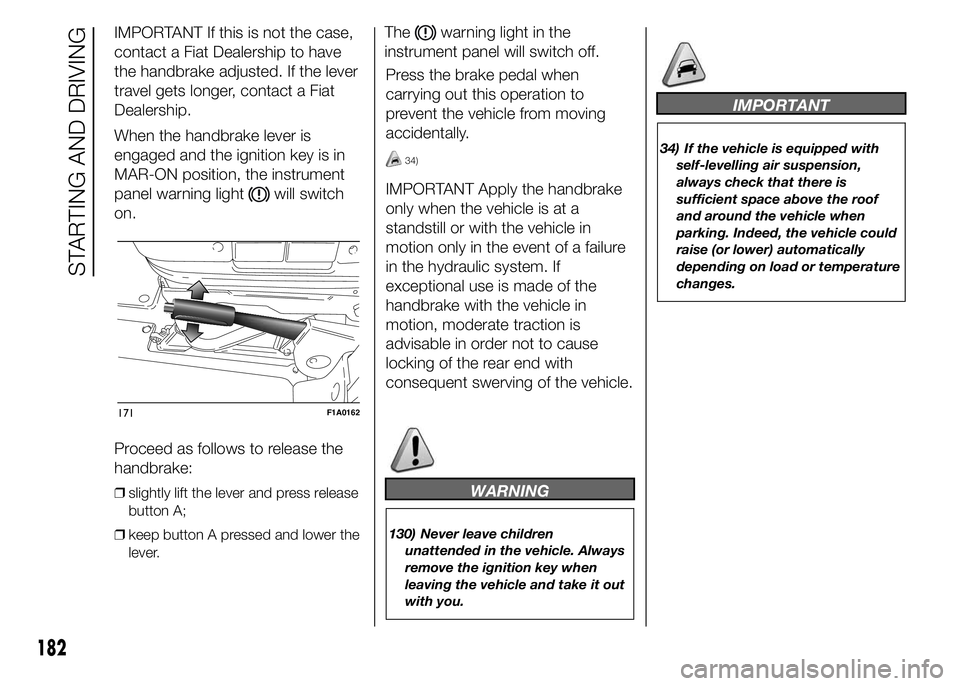

IMPORTANT If this is not the case,

contact a Fiat Dealership to have

the handbrake adjusted. If the lever

travel gets longer, contact a Fiat

Dealership.

When the handbrake lever is

engaged and the ignition key is in

MAR-ON position, the instrument

panel warning light

will switch

on.

Proceed as follows to release the

handbrake:

❒slightly lift the lever and press release

button A;

❒keep button A pressed and lower the

lever.

Thewarning light in the

instrument panel will switch off.

Press the brake pedal when

carrying out this operation to

prevent the vehicle from moving

accidentally.

34)

IMPORTANT Apply the handbrake

only when the vehicle is at a

standstill or with the vehicle in

motion only in the event of a failure

in the hydraulic system. If

exceptional use is made of the

handbrake with the vehicle in

motion, moderate traction is

advisable in order not to cause

locking of the rear end with

consequent swerving of the vehicle.

WARNING

130) Never leave children

unattended in the vehicle. Always

remove the ignition key when

leaving the vehicle and take it out

with you.

IMPORTANT

34) If the vehicle is equipped with

self-levelling air suspension,

always check that there is

sufficient space above the roof

and around the vehicle when

parking. Indeed, the vehicle could

raise (or lower) automatically

depending on load or temperature

changes.

171F1A0162

182

STARTING AND DRIVING

Page 204 of 367

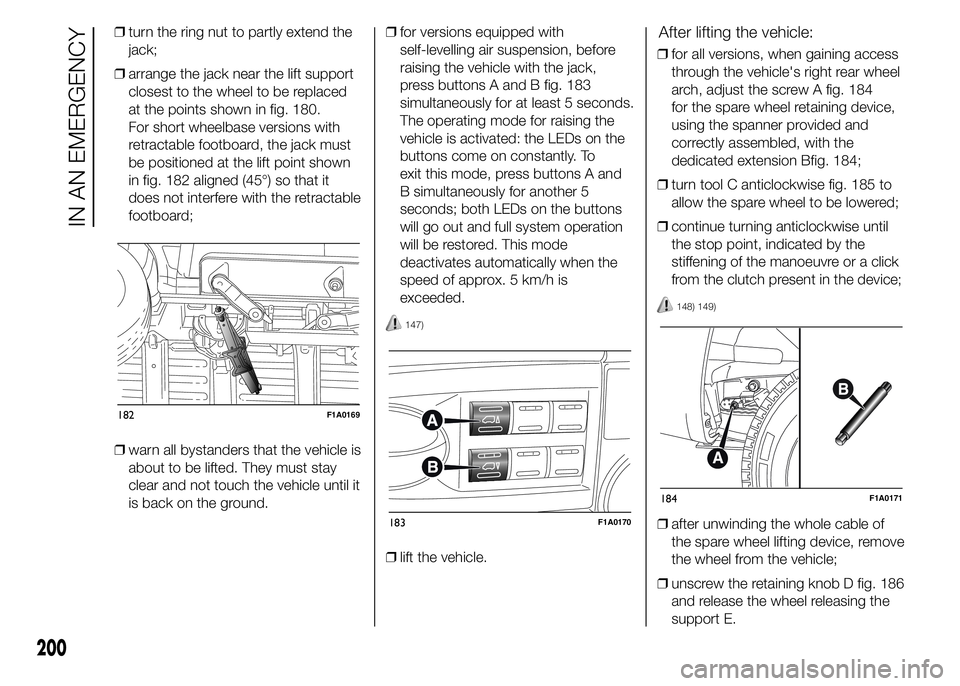

❒turn the ring nut to partly extend the

jack;

❒arrange the jack near the lift support

closest to the wheel to be replaced

at the points shown in fig. 180.

For short wheelbase versions with

retractable footboard, the jack must

be positioned at the lift point shown

in fig. 182 aligned (45°) so that it

does not interfere with the retractable

footboard;

❒warn all bystanders that the vehicle is

about to be lifted. They must stay

clear and not touch the vehicle until it

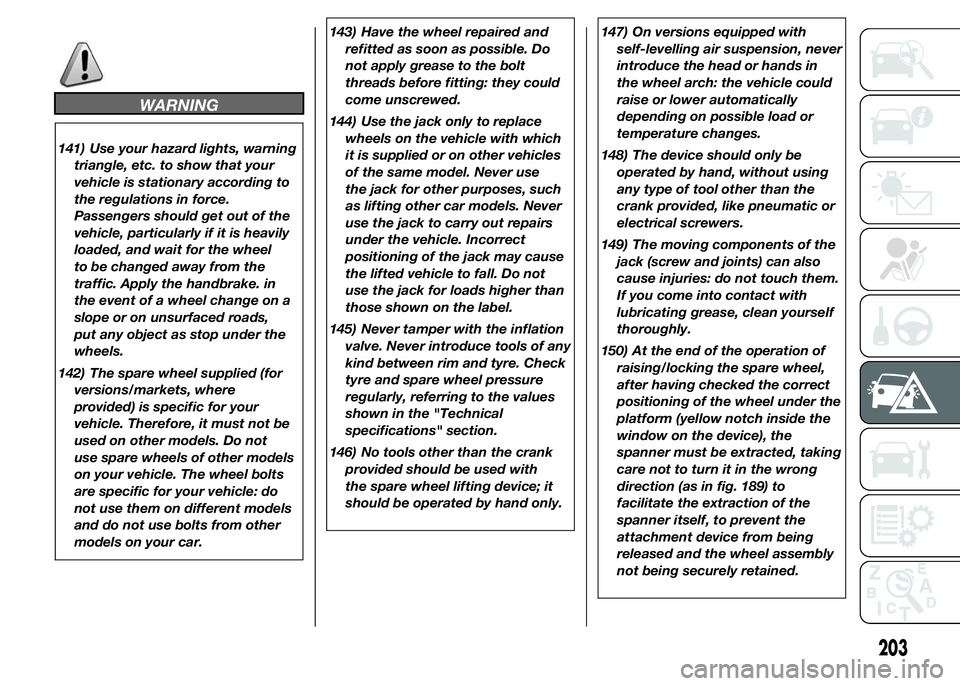

is back on the ground.❒for versions equipped with

self-levelling air suspension, before

raising the vehicle with the jack,

press buttons A and B fig. 183

simultaneously for at least 5 seconds.

The operating mode for raising the

vehicle is activated: the LEDs on the

buttons come on constantly. To

exit this mode, press buttons A and

B simultaneously for another 5

seconds; both LEDs on the buttons

will go out and full system operation

will be restored. This mode

deactivates automatically when the

speed of approx. 5 km/h is

exceeded.

147)

❒lift the vehicle.

After lifting the vehicle:

❒for all versions, when gaining access

through the vehicle's right rear wheel

arch, adjust the screw A fig. 184

for the spare wheel retaining device,

using the spanner provided and

correctly assembled, with the

dedicated extension Bfig. 184;

❒turn tool C anticlockwise fig. 185 to

allow the spare wheel to be lowered;

❒continue turning anticlockwise until

the stop point, indicated by the

stiffening of the manoeuvre or a click

from the clutch present in the device;

148) 149)

❒after unwinding the whole cable of

the spare wheel lifting device, remove

the wheel from the vehicle;

❒unscrew the retaining knob D fig. 186

and release the wheel releasing the

support E.

182F1A0169

183F1A0170

184F1A0171

200

IN AN EMERGENCY

Page 207 of 367

WARNING

141) Use your hazard lights, warning

triangle, etc. to show that your

vehicle is stationary according to

the regulations in force.

Passengers should get out of the

vehicle, particularly if it is heavily

loaded, and wait for the wheel

to be changed away from the

traffic. Apply the handbrake. in

the event of a wheel change on a

slope or on unsurfaced roads,

put any object as stop under the

wheels.

142) The spare wheel supplied (for

versions/markets, where

provided) is specific for your

vehicle. Therefore, it must not be

used on other models. Do not

use spare wheels of other models

on your vehicle. The wheel bolts

are specific for your vehicle: do

not use them on different models

and do not use bolts from other

models on your car.143) Have the wheel repaired and

refitted as soon as possible. Do

not apply grease to the bolt

threads before fitting: they could

come unscrewed.

144) Use the jack only to replace

wheels on the vehicle with which

it is supplied or on other vehicles

of the same model. Never use

the jack for other purposes, such

as lifting other car models. Never

use the jack to carry out repairs

under the vehicle. Incorrect

positioning of the jack may cause

the lifted vehicle to fall. Do not

use the jack for loads higher than

those shown on the label.

145) Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and spare wheel pressure

regularly, referring to the values

shown in the "Technical

specifications" section.

146) No tools other than the crank

provided should be used with

the spare wheel lifting device; it

should be operated by hand only.147) On versions equipped with

self-levelling air suspension, never

introduce the head or hands in

the wheel arch: the vehicle could

raise or lower automatically

depending on possible load or

temperature changes.

148) The device should only be

operated by hand, without using

any type of tool other than the

crank provided, like pneumatic or

electrical screwers.

149) The moving components of the

jack (screw and joints) can also

cause injuries: do not touch them.

If you come into contact with

lubricating grease, clean yourself

thoroughly.

150) At the end of the operation of

raising/locking the spare wheel,

after having checked the correct

positioning of the wheel under the

platform (yellow notch inside the

window on the device), the

spanner must be extracted, taking

care not to turn it in the wrong

direction (as in fig. 189) to

facilitate the extraction of the

spanner itself, to prevent the

attachment device from being

released and the wheel assembly

not being securely retained.

203