wheels FIAT DUCATO 2016 3.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: DUCATO, Model: FIAT DUCATO 2016 3.GPages: 296, PDF Size: 15.08 MB

Page 118 of 296

16)If the engine fails to start with a gear

engaged, the potentially dangerous

situation due to the fact that the

transmission is automatically placed in

neutral will be signalled by a buzzer.

17)If the warning light

flashes for 60

seconds after starting or during an

extended towing period, this indicates a

problem in the glow plug preheating

system. Use the vehicle normally if the

engine starts, but contact a Fiat Dealership

as soon as possible.

18)Remember that the brake servo and

power steering are not operational until the

engine has been started, so you need to

apply much more force than usual to

the brake pedal and steering wheel.

19)Never bump start the engine by

pushing, towing or coasting downhill. This

could cause fuel to flow into the catalytic

converter and damage it beyond repair.

20)A quick burst on the accelerator before

stopping the engine serves no practical

purpose; it wastes fuel and is especially

damaging to turbocharged engines.

21)In some cases, when the engine

switches off, the fan could activate for max.

120 seconds.

WHEN PARKED

116)

22)

Proceed as follows when parking and

leaving the vehicle:

engage the gear (on a slope, engage

first gear if the vehicle is facing uphill

or reverse if it is facing downhill) and

leave the wheels steered;

stop the engine and engage the

handbrake;

always remove the ignition key.

If the vehicle is parked on a steep

slope, it is advisable to block the

wheels with a wedge or stone.

On versions equipped with automatic

transmission (Comfort matic), wait

for the letterPto appear on the display

before releasing the brake pedal.

IMPORTANTNEVERleave the vehicle

with the gearbox in neutral (or, on

versions equipped with automatic

(Comfort matic) transmission, before

putting the shift lever in thePposition).HANDBRAKE

Handbrake engagement:The

handbrake lever is located to the left of

the driver's seat. Pull the lever upwards

to engage the handbrake and ensure

that the vehicle does not move.

Handbrake disengagement:slightly

raise the lever, hold the button A

pressed and check that the

warning light switches off on the

instrument panel.

Press the brake pedal when carrying

out this operation to prevent the vehicle

from moving accidentally.

WARNING

116)Never leave children unattended in

the vehicle. Always remove the ignition key

when leaving the vehicle and take it out

with you.

WARNING

22)If the vehicle is equipped with

self-levelling air suspension, always check

that there is sufficient space above the roof

and around the vehicle when parking.

Indeed, the vehicle could raise (or lower)

automatically depending on load or

temperature changes.

116

STARTING AND DRIVING

Page 172 of 296

CHANGING A WHEEL

GENERAL

INSTRUCTIONS

Wheel replacement and correct use of

the jack and spare wheel (for

versions/markets, where provided) call

for some precautions, which are listed

below.

145) 146) 147) 148) 149)

Please note that:

the jack weight is 4.5 kg;

the jack requires no adjustment;

the jack cannot be repaired: in the

event of a fault it must be replaced

by another original one;

no tool other than its cranking

device may be fitted on the jack.

150)

To change a wheel, proceed as

follows:

stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel safely.

The ground must be flat and sufficiently

compact;

switch off the engine and pull the

handbrake;

engage first gear or reverse;

put on the reflective safety jacket

(compulsory by law in certain countries)

before getting out of the vehicle;

indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

In the event of a wheel change on a

slope or on unsurfaced roads, put

any object as stop under the wheels;

take the tool bag from under the

passenger seat (see "Compartment

under the front passenger side seat" in

the "Internal equipment" chapter in

"Knowing the vehicle").

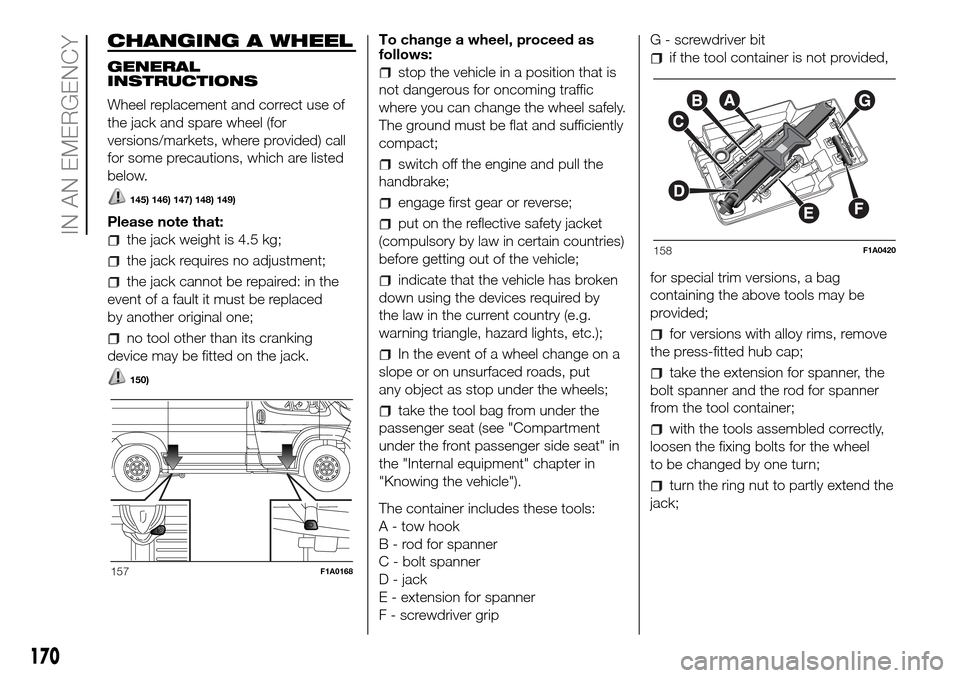

The container includes these tools:

A - tow hook

B - rod for spanner

C - bolt spanner

D - jack

E - extension for spanner

F - screwdriver gripG - screwdriver bit

if the tool container is not provided,

for special trim versions, a bag

containing the above tools may be

provided;

for versions with alloy rims, remove

the press-fitted hub cap;

take the extension for spanner, the

bolt spanner and the rod for spanner

from the tool container;

with the tools assembled correctly,

loosen the fixing bolts for the wheel

to be changed by one turn;

turn the ring nut to partly extend the

jack;

157F1A0168

158F1A0420

170

IN AN EMERGENCY

Page 175 of 296

go to the rear side of the vehicle

where the spare wheel is located;

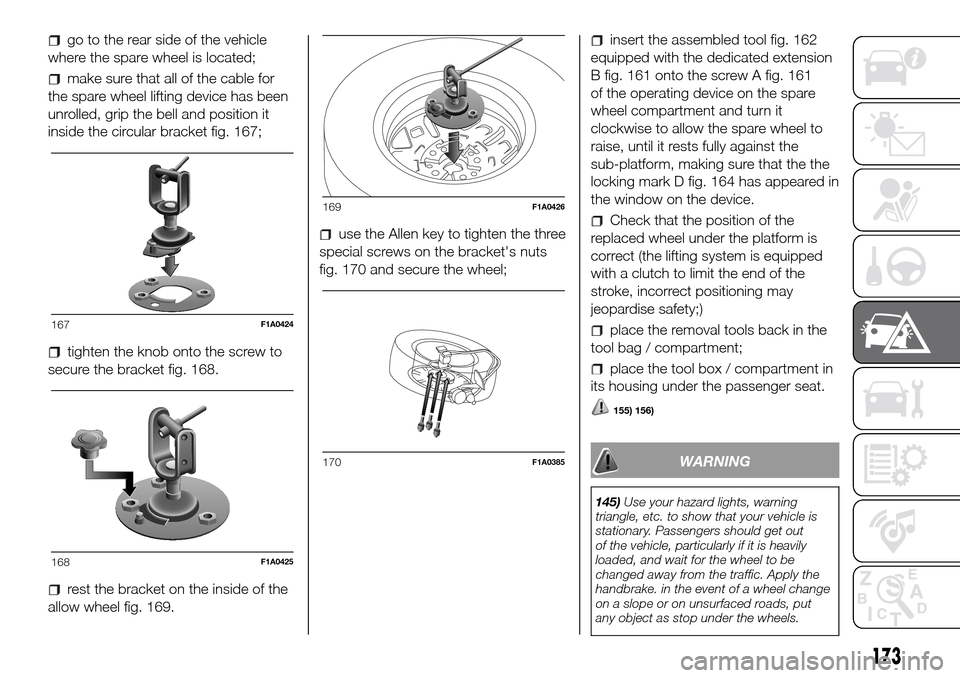

make sure that all of the cable for

the spare wheel lifting device has been

unrolled, grip the bell and position it

inside the circular bracket fig. 167;

tighten the knob onto the screw to

secure the bracket fig. 168.

rest the bracket on the inside of the

allow wheel fig. 169.

use the Allen key to tighten the three

special screws on the bracket's nuts

fig. 170 and secure the wheel;

insert the assembled tool fig. 162

equipped with the dedicated extension

B fig. 161 onto the screw A fig. 161

of the operating device on the spare

wheel compartment and turn it

clockwise to allow the spare wheel to

raise, until it rests fully against the

sub-platform, making sure that the the

locking mark D fig. 164 has appeared in

the window on the device.

Check that the position of the

replaced wheel under the platform is

correct (the lifting system is equipped

with a clutch to limit the end of the

stroke, incorrect positioning may

jeopardise safety;)

place the removal tools back in the

tool bag / compartment;

place the tool box / compartment in

its housing under the passenger seat.

155) 156)

WARNING

145)Use your hazard lights, warning

triangle, etc. to show that your vehicle is

stationary. Passengers should get out

of the vehicle, particularly if it is heavily

loaded, and wait for the wheel to be

changed away from the traffic. Apply the

handbrake. in the event of a wheel change

on a slope or on unsurfaced roads, put

any object as stop under the wheels.

167F1A0424

168F1A0425

169F1A0426

170F1A0385

173

Page 176 of 296

146)The spare wheel supplied (for

versions/markets, where provided) is

specific for your vehicle. Therefore, it must

not be used on other models. Do not

use spare wheels of other models on your

vehicle. The wheel bolts are specific for

your vehicle: do not use them on different

models and do not use bolts from other

models on your car.

147)Repair and refit the standard wheel as

soon as possible. Do not apply grease to

the bolt threads before fitting: they could

come unscrewed.

148)Use the jack only to replace wheels

on the vehicle with which it is supplied

or on other vehicles of the same model.

Never use the jack for other purposes,

such as lifting other vehicle models. Never

use the jack to carry out repairs under

the vehicle. Incorrect positioning of the jack

may cause the lifted vehicle to fall. Do not

use the jack for loads higher than the

one shown on its label.

149)Never tamper with the inflation valve.

Never introduce tools of any kind between

rim and tyre. Check tyre and spare wheel

pressure regularly, referring to the values

shown in the "Technical specifications"

section.

150)No tools other than the crank

provided should be used with the spare

wheel lifting device; it should be operated

by hand only.

151)On versions equipped with self-

levelling air suspension, never introduce the

head or hands in the wheel arch: the

vehicle could raise or lower automatically

depending on possible load or temperature

changes.152)The device should only be operated

by hand, without using any type of tool

other than the crank provided like

pneumatic or electrical screwers.

153)The moving components of the jack

(screws and joints) can also cause injuries:

avoid touching them. If you come into

contact with lubricating grease, clean

yourself thoroughly.

154)At the end of the operation of

raising/locking the spare wheel, after

checking that the wheel is positioned

correctly under the platform (yellow notch

inside the window on the device), extract

the operating wrench. Take care not to turn

the wrench in the wrong direction (as in

fig. 166) to facilitate extracting it, to prevent

the attachment device from being

released and to ensure that the wheel

assembly remains safely fastened.

155)Each time the spare wheel is moved,

check that it is correctly positioned in its

housing under the platform. If it is not

correctly positioned, this could adversely

affect safety.

156)The spare wheel lifting device is

equipped with a clutch safety system for its

own protection; this could activated if an

excessive load is applied on the

maneuvering screw.FIX & GO

AUTOMATIC QUICK

TYRE REPAIR KIT

(for versions/markets, where provided)

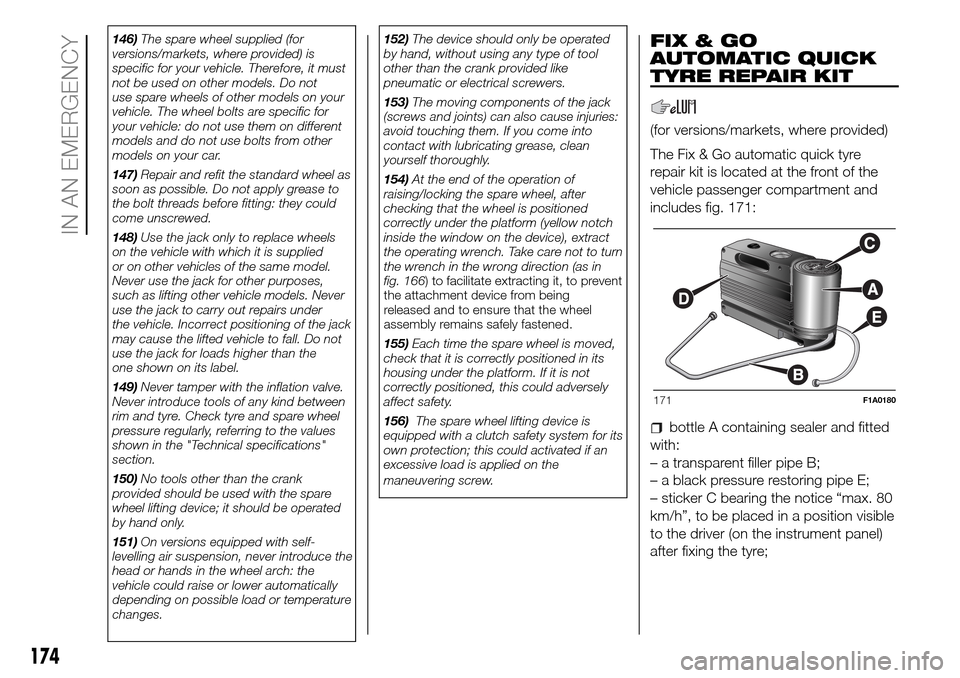

The Fix & Go automatic quick tyre

repair kit is located at the front of the

vehicle passenger compartment and

includes fig. 171:

bottle A containing sealer and fitted

with:

– a transparent filler pipe B;

– a black pressure restoring pipe E;

– sticker C bearing the notice “max. 80

km/h”, to be placed in a position visible

to the driver (on the instrument panel)

after fixing the tyre;

171F1A0180

174

IN AN EMERGENCY

Page 184 of 296

SERVICING AND CARE

Correct maintenance permits the

performance of the car to be

maintained over time, as well as limited

running costs and safeguarding the

efficiency of the safety systems.

This chapter explains how.SCHEDULED SERVICING ...............183

PERIODIC CHECKS ........................183

DEMANDING VEHICLE USE ...........184

SCHEDULED SERVICING PLAN .....185

CHECKING LEVELS........................192

AIR CLEANER/POLLEN FILTER ......199

BATTERY ........................................199

WINDSCREEN WIPER ....................201

LIFTING THE VEHICLE....................202

WHEELS AND TYRES.....................203

SNOW TYRES ................................204

SNOW CHAINS...............................204

BODYWORK ...................................205

INTERIOR .......................................206

RUBBER HOSES ............................207

182

SERVICING AND CARE

Page 205 of 296

WHEELS AND TYRES

Check the pressure of each tyre,

including the space-saver wheel,

approximately every two weeks and

before long journeys: the pressure

should be checked with the tyre rested

and cold.

It is normal for the pressure to increase

when the vehicle is used; for the correct

tyre inflation pressure, see “Wheels” in

the “Technical specifications” section.

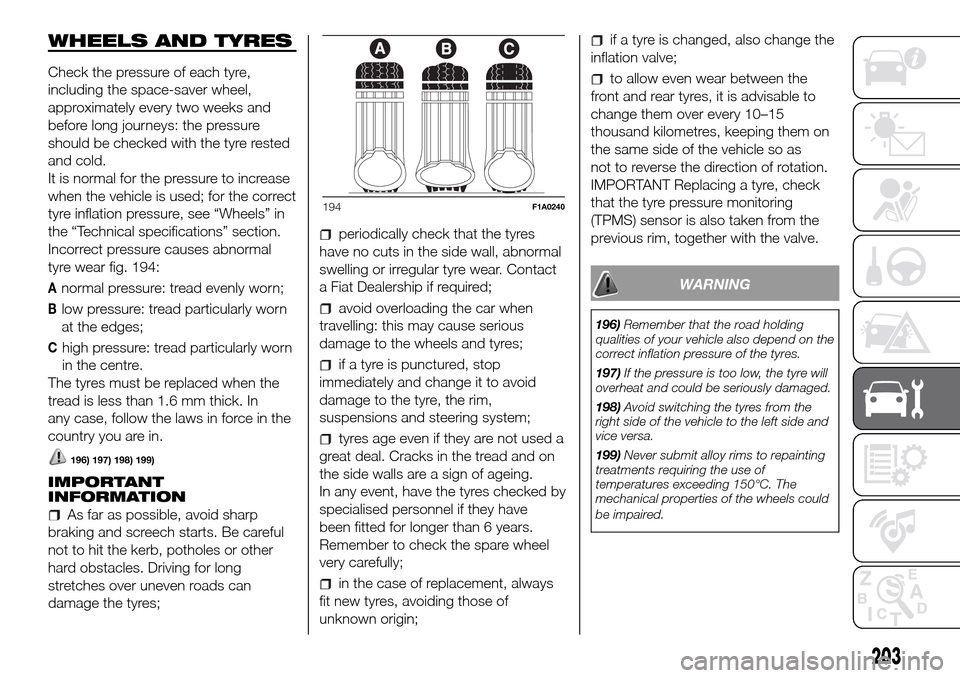

Incorrect pressure causes abnormal

tyre wear fig. 194:

Anormal pressure: tread evenly worn;

Blow pressure: tread particularly worn

at the edges;

Chigh pressure: tread particularly worn

in the centre.

The tyres must be replaced when the

tread is less than 1.6 mm thick. In

any case, follow the laws in force in the

country you are in.

196) 197) 198) 199)

IMPORTANT

INFORMATION

As far as possible, avoid sharp

braking and screech starts. Be careful

not to hit the kerb, potholes or other

hard obstacles. Driving for long

stretches over uneven roads can

damage the tyres;

periodically check that the tyres

have no cuts in the side wall, abnormal

swelling or irregular tyre wear. Contact

a Fiat Dealership if required;

avoid overloading the car when

travelling: this may cause serious

damage to the wheels and tyres;

if a tyre is punctured, stop

immediately and change it to avoid

damage to the tyre, the rim,

suspensions and steering system;

tyres age even if they are not used a

great deal. Cracks in the tread and on

the side walls are a sign of ageing.

In any event, have the tyres checked by

specialised personnel if they have

been fitted for longer than 6 years.

Remember to check the spare wheel

very carefully;

in the case of replacement, always

fit new tyres, avoiding those of

unknown origin;

if a tyre is changed, also change the

inflation valve;

to allow even wear between the

front and rear tyres, it is advisable to

change them over every 10–15

thousand kilometres, keeping them on

the same side of the vehicle so as

not to reverse the direction of rotation.

IMPORTANT Replacing a tyre, check

that the tyre pressure monitoring

(TPMS) sensor is also taken from the

previous rim, together with the valve.

WARNING

196)Remember that the road holding

qualities of your vehicle also depend on the

correct inflation pressure of the tyres.

197)If the pressure is too low, the tyre will

overheat and could be seriously damaged.

198)Avoid switching the tyres from the

right side of the vehicle to the left side and

vice versa.

199)Never submit alloy rims to repainting

treatments requiring the use of

temperatures exceeding 150°C. The

mechanical properties of the wheels could

be impaired.

194F1A0240

203

Page 206 of 296

SNOW TYRES

A Fiat Dealership will be happy to

provide advice concerning the most

suitable type of tyre for the customer's

requirements.

The performance of these tyres is

considerably reduced when the tread

depth is less than 4 mm. Replace them

in this case.

Due to the specific characteristics of

snow tyres, in normal weather

conditions or on long motorway

journeys, the performance of these

tyres is lower than that of standard

tyres. Their usage should therefore be

restricted in accordance with their

type approval.

IMPORTANT When using snow tyres

with a maximum speed index below the

one that can be reached by the vehicle

(increased by 5%), place a notice in

the passenger compartment, plainly in

view, which states the maximum speed

allowed by the snow tyres (as per EC

Directive).

All four tyres should be the same (brand

and track) to ensure greater safety

when driving and braking as well as a

good manoeuvrability.Remember that you should not change

the rotation direction of the tyres.200)

WARNING

200)The maximum speed for snow tyres

marked “Q” is 160 km/h, while it is 190

km/h for “T” tyres and 210 km/h for "H"

tyres. You should, however, always stick to

the speed limits of the highway code.

SNOW CHAINS

The use of snow chains should be in

compliance with local regulations of

each country.

Snow chains can be fitted to the tyres

of the front wheels (drive wheels) only.

Use of Lineaccessori Fiat snow chains

is recommended. Check the tension

of the snow chains after the first few

metres have been driven.

57)

IMPORTANT With snow chains, use the

accelerator with extreme care to

prevent, or to limit as much as possible,

slipping of the drive wheels that could

cause chain breakage, resulting in

damage to the car body or mechanical

components.

IMPORTANT For versions fitted with

225/75 R16 tyre, use snow chains with

max. thickness 16 mm.

When travelling on snowy roads with

snow chains, it may be helpful to turn

the ASR off: in fact, in these conditions,

the driving wheels skidding when

moving off gives you better traction.

204

SERVICING AND CARE

Page 210 of 296

TECHNICAL DATA

Everything you may find useful for

understanding how your vehicle

is made and works is contained in this

chapter and illustrated with data, tables

and graphics. For the enthusiasts and

the technician, but also just for those

who want to know every detail of their

vehicle.IDENTIFICATION DATA....................209

ENGINE CODES - BODYWORK

VERSION ........................................211

ENGINE ..........................................213

STEERING SYSTEM .......................216

WHEELS .........................................217

DIMENSIONS ..................................222

PERFORMANCE .............................232

WEIGHTS AND LOADS...................234

REFUELLING ..................................237

FLUIDS AND LUBRICANTS ............242

FUEL CONSUMPTION ....................245

CO2 EMISSIONS ...........................252

208

TECHNICAL DATA

Page 219 of 296

WHEELS

RIMS AND TYRES

Alloy or pressed steel rims. Tubeless

radial carcass tyres.

All approved tyres are listed in the

Vehicle Registration Document.

IMPORTANT If there are any

discrepancies between the Owner

Handbook and the Registration

Document, take the information from

the latter. To ensure driving safety, make

sure that all the wheels are fitted with

tyres of the same make and type.

IMPORTANT Do not use inner tubes

with Tubeless tyres.

SPARE WHEEL

Pressed steel rim. Tubeless tyre.

WHEEL GEOMETRY

Front wheels toe-in measured between

rims: -1 ±1 mm.

The values refer to the vehicle in

running order.

217

Page 220 of 296

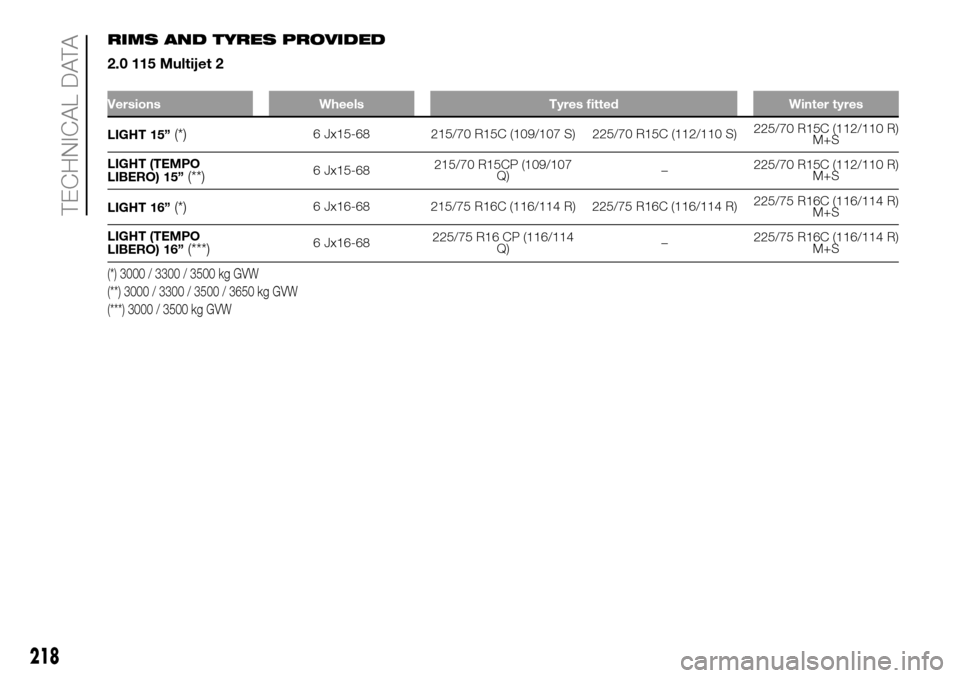

RIMS AND TYRES PROVIDED

2.0 115 Multijet 2

Versions Wheels Tyres fitted Winter tyres

LIGHT 15”(*)6 Jx15-68 215/70 R15C (109/107 S) 225/70 R15C (112/110 S)225/70 R15C (112/110 R)

M+S

LIGHT (TEMPO

LIBERO) 15”

(**)6 Jx15-68215/70 R15CP (109/107

Q)–225/70 R15C (112/110 R)

M+S

LIGHT 16”

(*)6 Jx16-68 215/75 R16C (116/114 R) 225/75 R16C (116/114 R)225/75 R16C (116/114 R)

M+S

LIGHT (TEMPO

LIBERO) 16”

(***)6 Jx16-68225/75 R16 CP (116/114

Q)–225/75 R16C (116/114 R)

M+S

(*) 3000 / 3300 / 3500 kg GVW

(**) 3000 / 3300 / 3500 / 3650 kg GVW

(***) 3000 / 3500 kg GVW

218

TECHNICAL DATA