disc FIAT DUCATO 244 2005 3.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2005, Model line: DUCATO 244, Model: FIAT DUCATO 244 2005 3.GPages: 258, PDF Size: 4.05 MB

Page 164 of 258

163VEHICLE MAINTENANCE

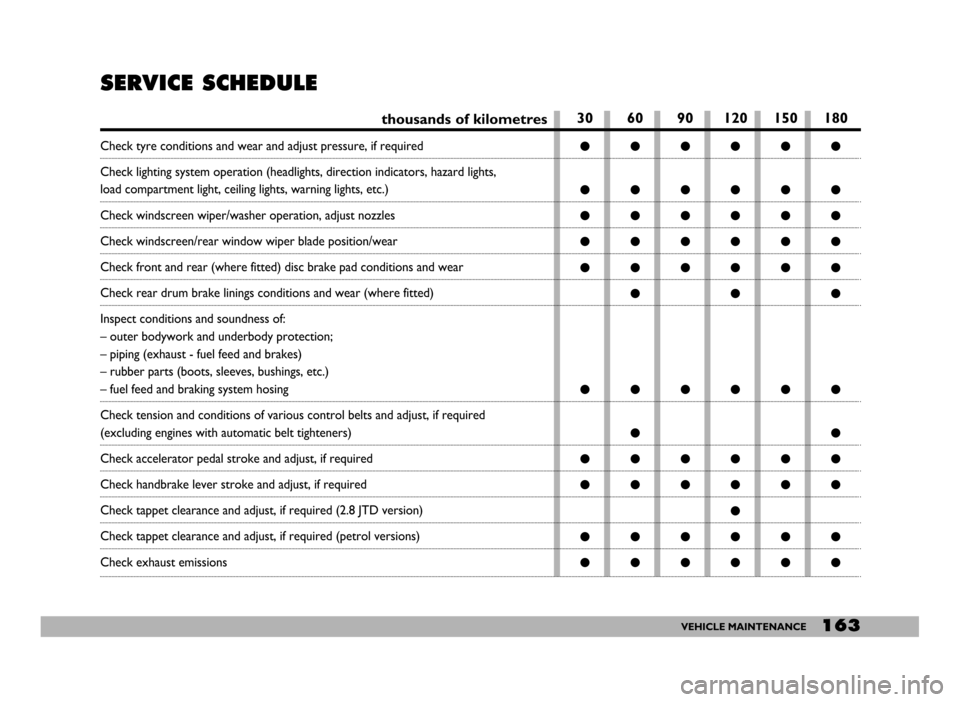

SERVICE SCHEDULE

thousands of kilometres

Check tyre conditions and wear and adjust pressure, if required

Check lighting system operation (headlights, direction indicators, hazard lights,

load compartment light, ceiling lights, warning lights, etc.)

Check windscreen wiper/washer operation, adjust nozzles

Check windscreen/rear window wiper blade position/wear

Check front and rear (where fitted) disc brake pad conditions and wear

Check rear drum brake linings conditions and wear (where fitted)

Inspect conditions and soundness of:

– outer bodywork and underbody protection;

– piping (exhaust - fuel feed and brakes)

– rubber parts (boots, sleeves, bushings, etc.)

– fuel feed and braking system hosing

Check tension and conditions of various control belts and adjust, if required

(excluding engines with automatic belt tighteners)

Check accelerator pedal stroke and adjust, if required

Check handbrake lever stroke and adjust, if required

Check tappet clearance and adjust, if required (2.8 JTD version)

Check tappet clearance and adjust, if required (petrol versions)

Check exhaust emissions

30 60 90 120 150 180

●●●●●●

●●●●●●

●●●●●●

●●●●●●

●●●●●●

●●●

●●●●●●

●●

●●●●●●

●●●●●●

●

●●●●●●

●●●●●●

Page 177 of 258

176VEHICLE MAINTENANCE

Furthermore, remember that high in-

take electric devices (such as baby bot-

tle warmers, vacuum cleaners, cellular

phones, mini-fridges, etc.) powered

when the engine is offcan deploy

the battery.

IMPORTANTWhen installing ad-

ditional systems on the vehicle, bear

in mind that improper branches on

connections of the vehicle wiring are

dangerous, particularly if safety devices

are involved.

Battery

60 Ah

88 Ah

100 Ah

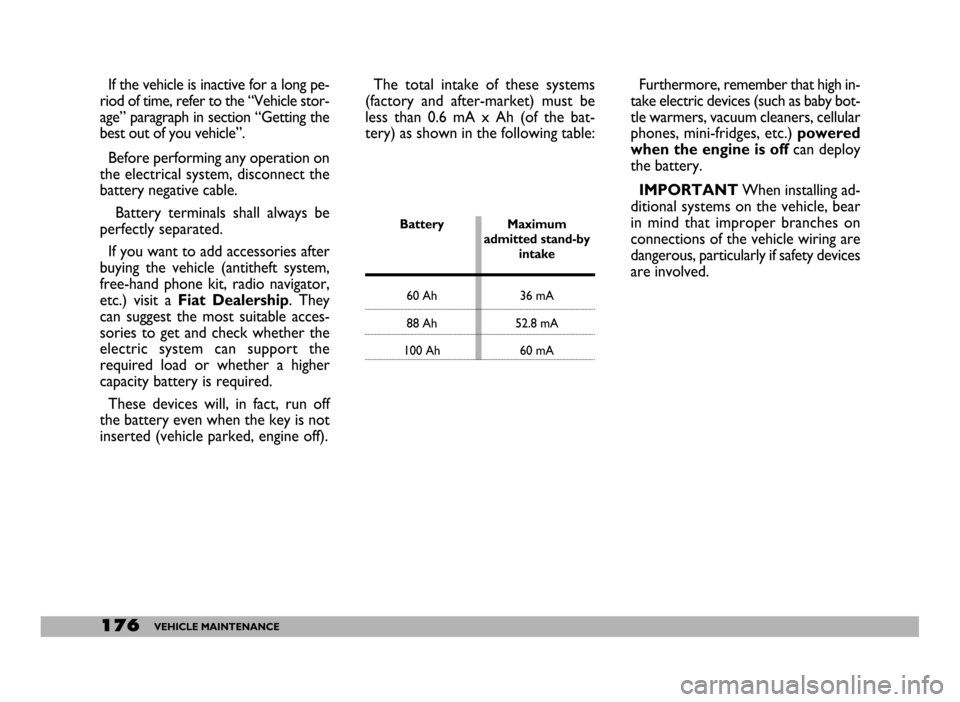

The total intake of these systems

(factory and after-market) must be

less than 0.6 mA x Ah (of the bat-

tery) as shown in the following table:

Maximum

admitted stand-by

intake

36 mA

52.8 mA

60 mA

If the vehicle is inactive for a long pe-

riod of time, refer to the “Vehicle stor-

age” paragraph in section “Getting the

best out of you vehicle”.

Before performing any operation on

the electrical system, disconnect the

battery negative cable.

Battery terminals shall always be

perfectly separated.

If you want to add accessories after

buying the vehicle (antitheft system,

free-hand phone kit, radio navigator,

etc.) visit a Fiat Dealership. They

can suggest the most suitable acces-

sories to get and check whether the

electric system can support the

required load or whether a higher

capacity battery is required.

These devices will, in fact, run off

the battery even when the key is not

inserted (vehicle parked, engine off).

Page 178 of 258

177VEHICLE MAINTENANCE

ELECTRONIC

CONTROL UNIT

When the vehicle is being used nor-

mally, special measures are not nec-

essary.

The following instructions must be

followed very carefully however, if

you work on the electrical system or

in cases where emergency starting is

necessary:

– never disconnect the battery from

the electric system while the engine is

running;

– disconnect the battery from the

electric system if you are recharging it;

– never perform emergency starting

with a battery charger. Always use an

auxiliary battery;

– be particularly careful when con-

necting the battery to the electric sys-

tem. Make sure that the polarity is

correct and that the connection is ef-

ficient;

– do not connect or disconnect the

terminals of the electronic units while

the ignition key is at MAR;

– do not check polarity through

sparking;– disconnect the electronic control

units if you are electrically welding the

vehicle body. Remove the units if tem-

peratures exceed 80 °C (special op-

erations on the bodywork, etc.).

IMPORTANTIf the sound system

or vehicle alarm systems are not in-

stalled correctly, they can interfere

with the working of the electronic

control units.

Modifications or repairs to

the electrical system car-

ried out incorrectly and without

bearing the features of the system

in mind can cause malfunctions

with the risk of fire.

WARNING

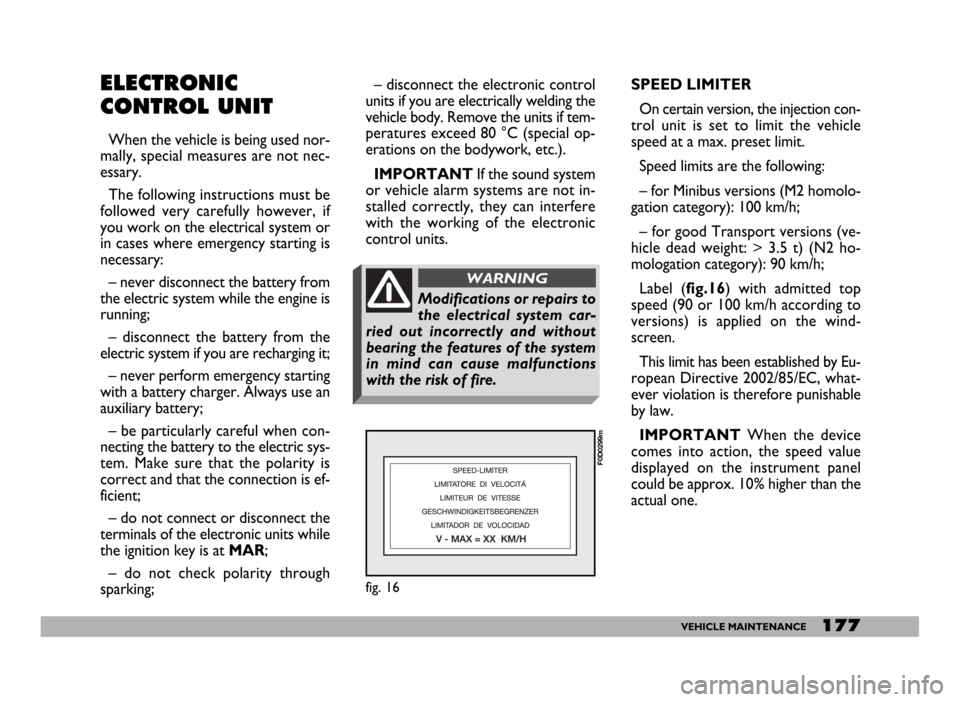

SPEED LIMITER

On certain version, the injection con-

trol unit is set to limit the vehicle

speed at a max. preset limit.

Speed limits are the following:

– for Minibus versions (M2 homolo-

gation category): 100 km/h;

– for good Transport versions (ve-

hicle dead weight: > 3.5 t) (N2 ho-

mologation category): 90 km/h;

Label (fig.16) with admitted top

speed (90 or 100 km/h according to

versions) is applied on the wind-

screen.

This limit has been established by Eu-

ropean Directive 2002/85/EC, what-

ever violation is therefore punishable

by law.

IMPORTANTWhen the device

comes into action, the speed value

displayed on the instrument panel

could be approx. 10% higher than the

actual one.

fig. 16

F0D0299m

Page 217 of 258

216TECHNICAL SPECIFICATIONS

BRAKES

SERVICE AND EMERGENCY

BRAKES

Front: disc, floating caliper with two

operating cylinders for each wheel and

pad wear warning light.

Rear: self-centring shoes and micro-

metric mechanism for clearance take-

up.

Certain versions are fitted with rear

disc brakes with Drum in hat device

(i.e. drum on disc to block the vehicle

when parked with handbrake en-

gaged).

Cross-over hydraulic circuit control.

Four sensors ABS system with EBD.

Automatic recovery of the friction

gasket wear; versions with rear disc

brake excluded (Drum in hat ver-

sions).

Lacking ABS system brakeforce dis-

tributor acting on rear brake hydraulic

circuit according to rear axle load.HANDBRAKE

Controlled by a lever, it works me-

chanically on the rear brake shoes.

For versions with rear disc brakes,

the handbrake works on the Drum in

hat device shoes.

IMPORTANTPull the handbrake

lever only when the vehicle is at a

standstill, or when the vehicle is run-

ning, but however only in case of a

failure of the hydraulic system.

Should the handbrake be exception-

ally used when the vehicle is running,

it is suggested to keep a moderate

traction to avoid causing the rear axle

block, entailing vehicle side skidding.

TRANSMISSION

CLUTCH

Hydraulically controlled without

travel-free pedal.

MECHANICAL GEARBOX

AND DIFFERENTIAL

Five forward gears and reverse with

synchromesh for front gear engage-

ment.

Cyclical gear reduction and differen-

tial assembly incorporated in the gear-

box.

Drive transmission to the front

wheels by means of drive shafts con-

nected to the differential assembly and

the wheels with CV joints.

Water, ice or salt on road

surfaces can deposit on

brake discs, reducing braking effi-

ciency on the first braking.

WARNING