light FIAT DUCATO BASE CAMPER 2015 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2015Pages: 367, PDF Size: 19.73 MB

Page 187 of 367

USING THE

GEARBOX

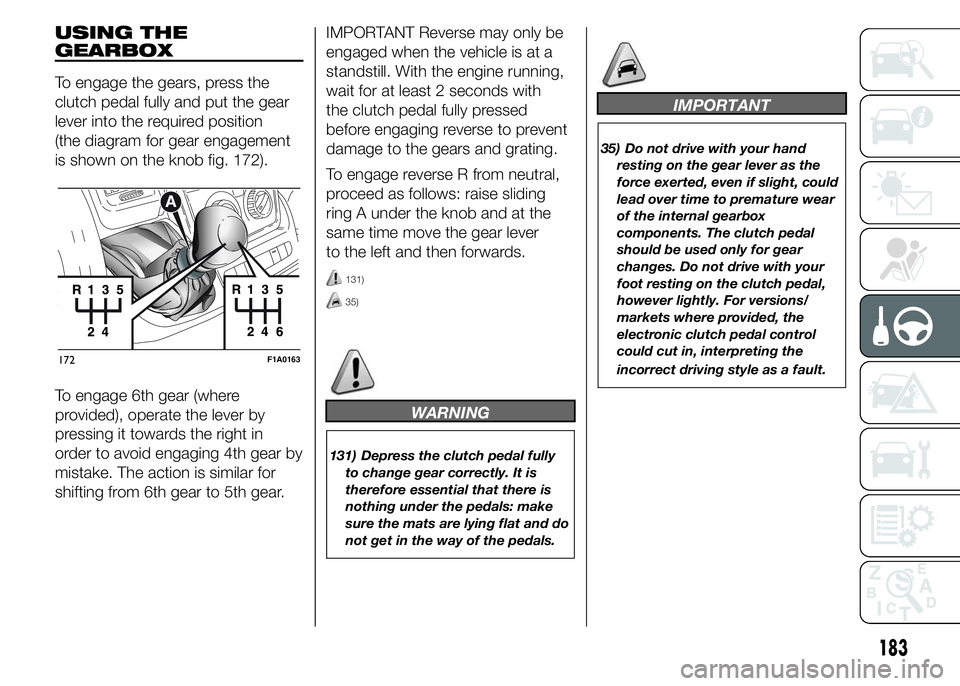

To engage the gears, press the

clutch pedal fully and put the gear

lever into the required position

(the diagram for gear engagement

is shown on the knob fig. 172).

To engage 6th gear (where

provided), operate the lever by

pressing it towards the right in

order to avoid engaging 4th gear by

mistake. The action is similar for

shifting from 6th gear to 5th gear.IMPORTANT Reverse may only be

engaged when the vehicle is at a

standstill. With the engine running,

wait for at least 2 seconds with

the clutch pedal fully pressed

before engaging reverse to prevent

damage to the gears and grating.

To engage reverse R from neutral,

proceed as follows: raise sliding

ring A under the knob and at the

same time move the gear lever

to the left and then forwards.

131)

35)

WARNING

131) Depress the clutch pedal fully

to change gear correctly. It is

therefore essential that there is

nothing under the pedals: make

sure the mats are lying flat and do

not get in the way of the pedals.

IMPORTANT

35) Do not drive with your hand

resting on the gear lever as the

force exerted, even if slight, could

lead over time to premature wear

of the internal gearbox

components. The clutch pedal

should be used only for gear

changes. Do not drive with your

foot resting on the clutch pedal,

however lightly. For versions/

markets where provided, the

electronic clutch pedal control

could cut in, interpreting the

incorrect driving style as a fault.

172F1A0163

183

Page 189 of 367

SAVING FUEL

Some useful tips are given below

for fuel saving and reducing harmful

emissions of CO2 and other

pollutants (nitrogen oxides, unburnt

hydrocarbons, Particulate Matter

(PM), etc.).

GENERAL

CONSIDERATIONS

The general factors that affect fuel

consumption are listed below.

Vehicle maintenance

Have checks and adjustments

carried out in accordance with the

“Scheduled Servicing Plan”.

Tyres

Check the tyre pressures at least

once every four weeks: if the

pressure is too low, consumption

levels increase as resistance to

rolling is higher.Unnecessary loads

Do not travel with an overloaded

luggage compartment. The weight

of the vehicle (especially when

driving in town) and its geometry

greatly affect fuel consumption and

stability.

Roof rack/ski rack

Remove the roof rack or the ski

rack from the roof after use. These

accessories decrease aerodynamic

penetration of the vehicle and

have a negative effect on fuel

consumption. When transporting

particularly large objects, use a

trailer if possible.

Electric devices

Use electrical devices only for the

amount of time needed. The heated

rear window, additional headlights,

windscreen/rear window wipers

and heater fan need a considerable

amount of energy, therefore

increasing fuel consumption (by up

to 25% in the urban cycle).Climate control

system

Air conditioning leads to higher fuel

consumption (on average up to

+20%). If the temperature outside

permits, try and use the ventilation

only.

Devices for

aerodynamic control

The use of non-certified spoilers

may adversely affect air drag and

fuel consumption.

DRIVING STYLE

The main driving styles that affect

fuel consumption are listed below.

Cranking

Do not warm up the engine at low

or high revs when the vehicle is

stationary; this causes the engine

to warm up more slowly, thereby

increasing fuel consumption and

emissions. It is therefore advisable

to move off immediately, slowly,

avoiding high speeds: in this way

the engine will warm up more

quickly.

185

Page 190 of 367

Unnecessary actions

Avoid accelerating when stopped at

traffic lights or before switching off

the engine. This action and also

double declutching is absolutely

pointless on modern cars and also

increases consumption and

pollution.

Gear selection

As soon as the conditions of the

traffic and road permit, use a higher

gear. Using a low gear for faster

acceleration will increase

consumption.

In the same way improper use of a

high gear increases consumption,

emissions and engine wear.

Max. speed

Fuel consumption increases

considerably with speed. Maintain a

constant speed, avoiding

unnecessary braking and

acceleration, which cost in terms of

both fuel consumption and

emissions.Acceleration

Accelerating violently will greatly

affect consumption and emissions:

acceleration should be gradual.

USAGE CONDITIONS

The main usage conditions that

negatively affect fuel consumption

are listed below.

Cold starting

Short journeys and frequent cold

starts do not allow the engine

to reach optimum operating

temperature.

This results in a significant increase

in consumption levels (from +15

to +30% on the urban cycle) and

emissions.Traffic and road

conditions

Rather high consumption levels are

linked to situations with heavy

traffic, for instance when travelling

in queues with frequent use of

the lower gears or in cities with

many traffic lights. Winding

mountain roads and rough road

surfaces also adversely affect

consumption.

Stops in traffic

During prolonged hold-ups (e.g.

level crossings) the engine should

be switched off.

186

STARTING AND DRIVING

Page 191 of 367

TOWING TRAILERS

IMPORTANT

INFORMATION

The vehicle must be provided with

a type-approved tow hook and

adequate electrical system to tow

caravans or trailers. Installation

should be carried out by

specialised personnel who will issue

the required papers for travelling

on roads.

Install any specific and/or additional

door mirrors as specified by the

Highway Code.

Remember that when towing a

trailer, steep hills are harder to

climb, the braking spaces increase

and overtaking takes longer

depending on the overall weight.

Engage a low gear when driving

downhill, rather than constantly

using the brake.The weight of the trailer on the

vehicle tow hook will reduce the

loading capacity of the vehicle by

the same amount. Consider the

weight of the trailer fully laden,

including accessories and luggage,

to make sure you do not exceed

the maximum towable weight

(shown on the vehicle registration

document).

Do not exceed the speed limits

specific to each country you are

driving in, in the case of vehicles

towing trailers. In any case, the top

speed must not exceed 100 km/h.

You are advised to fit a suitable

stabiliser to the trailer drawbar.

In the vehicles equipped with

parking sensors, after fitting the tow

hook malfunctioning warnings

may be displayed, as some parts

(tow bar, ball tow hook) may be

within the sensor detection range.

In this case the detection range

must be adjusted or the parking

assistance function must be

deactivated.

135) 136)

INSTALLING THE TOW

HOOK

The towing device should be

fastened to the body by specialised

personnel according to any

additional and/or integrative

information supplied by the

Manufacturer of the device.

The towing device must meet

current regulations with reference to

Directive 94/20/EC and subsequent

amendments.

For any version the towing device

used must match the towable

weight of the vehicle on which it is

to be installed.

For the electric connection a

standard connector should be used

which is generally placed on a

special bracket normally fastened

to the towing device, and a special

ECU for external trailer light control

must be installed on the vehicle.

For the electrical connection, 7 or

13 pin 12 V DC connections are to

be used (CUNA/UNI and ISO/DIN

Standards). Follow the instructions

provided by the vehicle

manufacturer and/or the tow hitch

manufacturer.

187

Page 192 of 367

An electric brake (or electric winch)

should be supplied directly by the

battery through a cable with a cross

section of no less than 2.5 mm

2.

IMPORTANT Electric brakes or

other devices must be used with

engine running.

In addition to the electrical

branches, the vehicle's electric

system can only be connected to

the supply cable for an electric

brake and to the cable for an

internal light, though not above 15

W. For connections use the preset

control unit with battery cable no

less than 2.5 mm

2.

IMPORTANT The trailer tow hook

contributes to the length of the

vehicle. When installing on long

wheelbase versions, it is only

possible to install removable tow

hooks because the total vehicle

length limit of 6 metres is

exceeded.

If no trailer is fitted, the hook must

be removed from the attachment

base and it must not exceed the

vehicle's original length.IMPORTANT If you wish to leave

the tow hook fitted without towing a

trailer, it is advisable to contact a

Fiat Dealership for the relevant

system update operations because

the tow hook could be detected

as an obstacle by the central

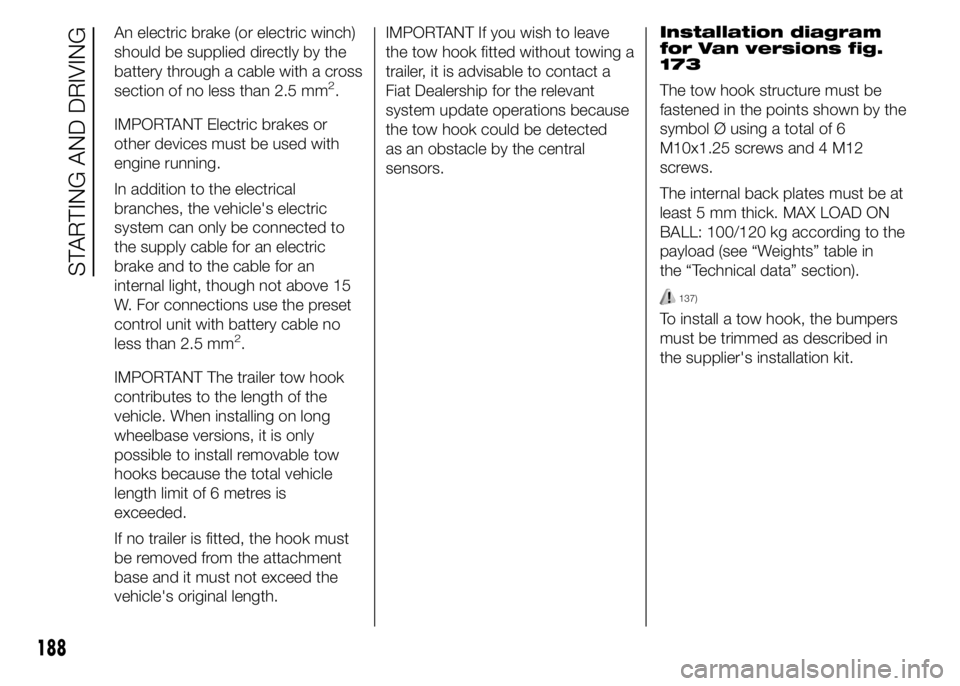

sensors.Installation diagram

for Van versions fig.

173

The tow hook structure must be

fastened in the points shown by the

symbol Ø using a total of 6

M10x1.25 screws and 4 M12

screws.

The internal back plates must be at

least 5 mm thick. MAX LOAD ON

BALL: 100/120 kg according to the

payload (see “Weights” table in

the “Technical data” section).

137)

To install a tow hook, the bumpers

must be trimmed as described in

the supplier's installation kit.

188

STARTING AND DRIVING

Page 196 of 367

INSTRUCTIONS FOR

USING THE

REMOVABLE BALL

HEAD TOW BAR

37) 38) 39) 40) 41) 42)

Before setting off, check the correct

locking of the removable ball head

tow bar, as follows:

❒The green mark of the flywheel must

coincide with the green mark on the

tow bar.

❒The flywheel is in the stop position on

the tow bar (without slot).

❒Locked lock and key removed. The

flywheel cannot be removed.

❒Ball head bar firmly secured to the

housing pipe. Check by shaking

with a hand.

The fitting procedure must be

repeated if any of the 4 checked

requirements is not met.

If even only one of the requirements

is not met the tow hook must not

be used, as in this case there is risk

of accidents. Contact the joint

manufacturer.

The ball head tow bar can be fitted

and removed manually, without

needing any tool.Never use working tools or means,

as the mechanism could be

damaged.

Never unlock in the case of trailer

attached to the vehicle or fitted

rack.

When driving without trailer or rack

the ball head tow bar must be

removed and the closing plug must

always be inserted in the housing

pipe. This applies particularly if

the visibility of the number plate

characters or of the lighting system

is reduced.

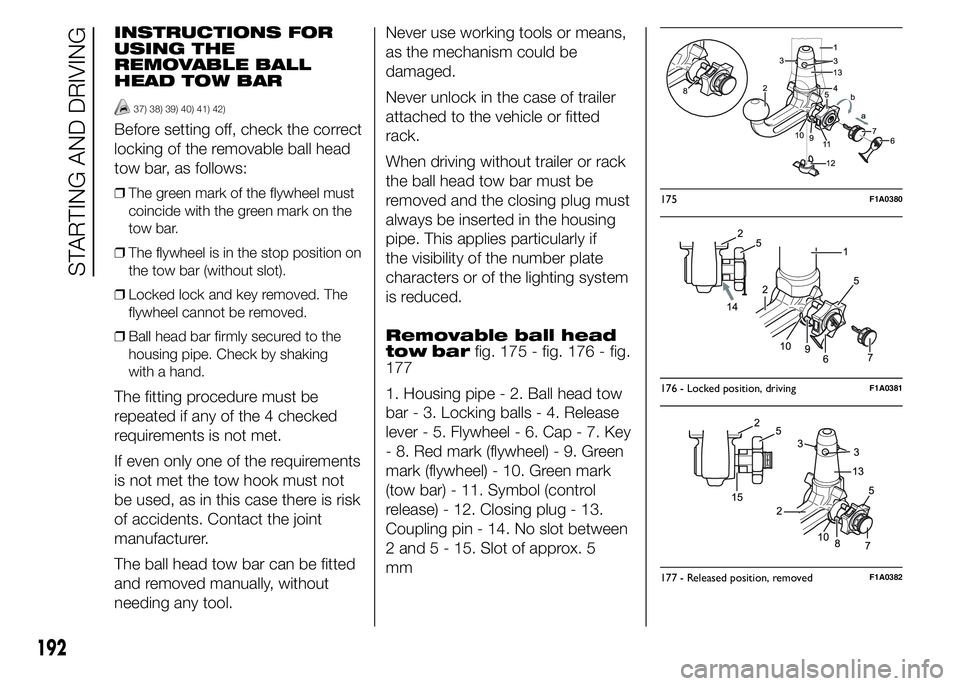

Removable ball head

tow barfig. 175 - fig. 176 - fig.

177

1. Housing pipe - 2. Ball head tow

bar - 3. Locking balls - 4. Release

lever - 5. Flywheel - 6. Cap - 7. Key

- 8. Red mark (flywheel) - 9. Green

mark (flywheel) - 10. Green mark

(tow bar) - 11. Symbol (control

release) - 12. Closing plug - 13.

Coupling pin - 14. No slot between

2 and 5 - 15. Slot of approx. 5

mm

175F1A0380

176 - Locked position, drivingF1A0381

177 - Released position, removedF1A0382

192

STARTING AND DRIVING

Page 200 of 367

IMPORTANT

43) Keep your speed down when

snow chains are fitted; do not

exceed 50 km/h. Avoid potholes,

steps and pavements and avoid

driving for long distances on

roads not covered with snow to

prevent damaging the vehicle and

the roadbed.

PROLONGED

VEHICLE INACTIVITY

If the vehicle needs to be off the

road for longer than one month, the

following precautions must be

taken:

❒park the vehicle indoors in a dry and,

if possible, well-ventilated place;

❒engage a gear;

❒check that the handbrake is not

engaged;

❒disconnect the negative battery

terminal; if the vehicle is equipped

with a battery disconnection function

(disconnector), see the description

of the procedure in the "Controls"

paragraph in the "Dashboard and

controls" section;

❒clean and protect the painted parts

using protective wax;

❒clean and protect the shiny metal

parts using special compounds

available commercially;

❒sprinkle talcum powder on the

windscreen and rear window wiper

rubber blades and lift them off the

glass;

❒slightly open the windows;❒cover the vehicle with a piece of

fabric or perforated plastic sheet. Do

not use compact plastic tarpaulins,

which prevent humidity from

evaporating from the surface of the

vehicle;

❒inflate tyres to +0.5 bar above the

standard specified pressure and

check it at intervals;

❒do not drain the engine cooling

system.

IMPORTANT If the vehicle is

equipped with an alarm system,

switch off the vehicle alarm with the

remote control.

IMPORTANT After turning the

ignition key to STOP and having

closed the driver side door, wait at

least one minute before

disconnecting the electrical supply

from the battery. When

reconnecting the electrical supply

to the battery, make sure that

the ignition key is in the STOP

position and the driver side door is

closed.

196

STARTING AND DRIVING

Page 202 of 367

STARTING THE

ENGINE

Go to a Fiat Dealership immediately

if warning light

stays on

constantly on the instrument panel.

JUMP STARTING

If the battery is flat, it is possible to

start the engine using an auxiliary

battery with the same capacity or a

little higher than the flat one.

It is advisable to contact a Fiat

Dealership to check/replace the

battery.

140)

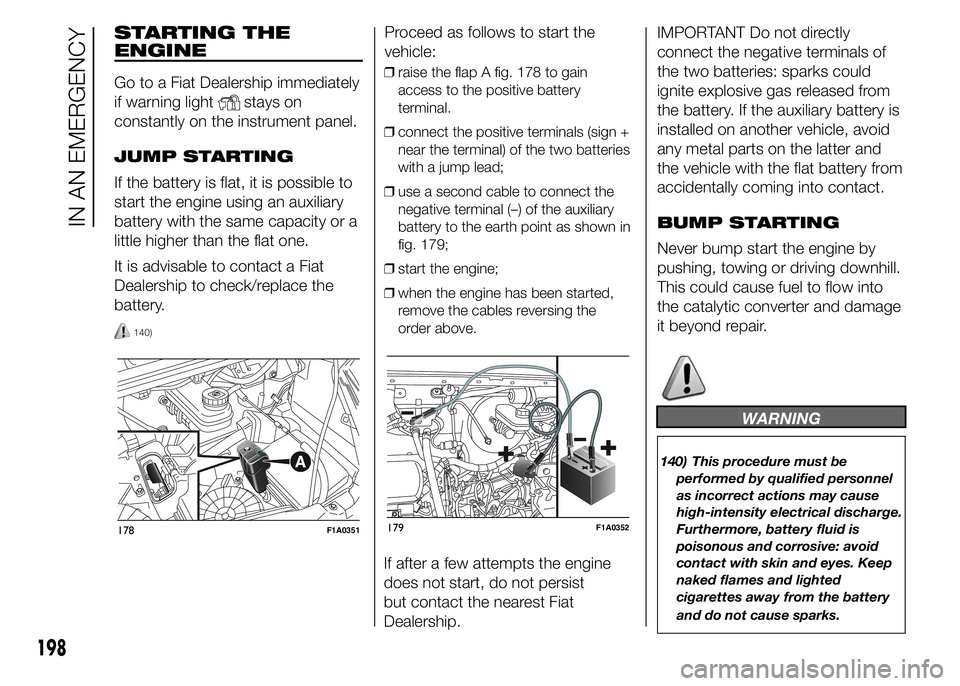

Proceed as follows to start the

vehicle:

❒raise the flap A fig. 178 to gain

access to the positive battery

terminal.

❒connect the positive terminals (sign +

near the terminal) of the two batteries

with a jump lead;

❒use a second cable to connect the

negative terminal (–) of the auxiliary

battery to the earth point as shown in

fig. 179;

❒start the engine;

❒when the engine has been started,

remove the cables reversing the

order above.

If after a few attempts the engine

does not start, do not persist

but contact the nearest Fiat

Dealership.IMPORTANT Do not directly

connect the negative terminals of

the two batteries: sparks could

ignite explosive gas released from

the battery. If the auxiliary battery is

installed on another vehicle, avoid

any metal parts on the latter and

the vehicle with the flat battery from

accidentally coming into contact.

BUMP STARTING

Never bump start the engine by

pushing, towing or driving downhill.

This could cause fuel to flow into

the catalytic converter and damage

it beyond repair.

WARNING

140) This procedure must be

performed by qualified personnel

as incorrect actions may cause

high-intensity electrical discharge.

Furthermore, battery fluid is

poisonous and corrosive: avoid

contact with skin and eyes. Keep

naked flames and lighted

cigarettes away from the battery

and do not cause sparks.

178F1A0351179F1A0352

198

IN AN EMERGENCY

Page 203 of 367

REPLACING A

WHEEL

GENERAL

INSTRUCTIONS

Wheel replacement and correct use

of the jack and spare wheel (for

versions/markets, where provided)

call for some precautions, which

are listed below.

141) 142) 143) 144) 145)

Please note that:

❒the jack weight is 4.5 kg;

❒the jack requires no adjustment;

❒the jack cannot be repaired: in the

event of a fault it must be replaced by

another original one;

❒no tool other than its cranking device

may be fitted on the jack.

146)

To change a wheel,

proceed as follows:

❒stop the vehicle in a position that is

not dangerous for oncoming traffic

where you can change the wheel

safely. The ground should be flat

if possible, and sufficiently firm;❒stop the engine and pull the

handbrake;

❒engage first gear or reverse;

❒put on the reflective safety jacket

(compulsory by law in certain

countries) before getting out of the

vehicle;

❒indicate that the vehicle has broken

down using the devices required by

the law in the current country (e.g.

warning triangle, hazard lights, etc.);

❒In the event of a wheel change on a

slope or on unsurfaced roads, put

any object as stop under the wheels;

❒take the tool bag under the

passenger seat (see “Compartment

under front passenger seat” in the

“Know your vehicle” section);

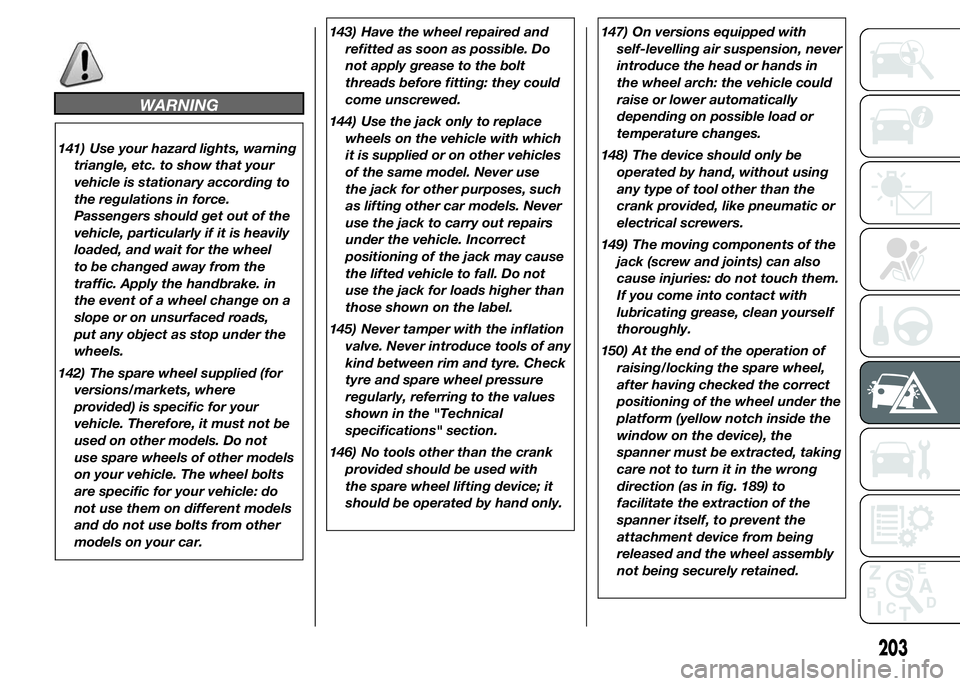

The container includes these tools:

A - tow hook

B - rod for spanner

C - bolt spanner

D - jack

E - extension for spanner

F - screwdriver grip

G - screwdriver bit

❒if the tool container is not provided,

for special trim versions, a bag

containing the above tools may be

provided;

❒for versions with alloy rims, remove

the press-fitted hub cap;

❒take the extension for spanner, the

bolt spanner and the rod for spanner

from the tool container;

❒with the tools assembled correctly,

loosen the fixing bolts for the wheel

to be changed by one turn;

180F1A0168

181F1A0420

199

Page 207 of 367

WARNING

141) Use your hazard lights, warning

triangle, etc. to show that your

vehicle is stationary according to

the regulations in force.

Passengers should get out of the

vehicle, particularly if it is heavily

loaded, and wait for the wheel

to be changed away from the

traffic. Apply the handbrake. in

the event of a wheel change on a

slope or on unsurfaced roads,

put any object as stop under the

wheels.

142) The spare wheel supplied (for

versions/markets, where

provided) is specific for your

vehicle. Therefore, it must not be

used on other models. Do not

use spare wheels of other models

on your vehicle. The wheel bolts

are specific for your vehicle: do

not use them on different models

and do not use bolts from other

models on your car.143) Have the wheel repaired and

refitted as soon as possible. Do

not apply grease to the bolt

threads before fitting: they could

come unscrewed.

144) Use the jack only to replace

wheels on the vehicle with which

it is supplied or on other vehicles

of the same model. Never use

the jack for other purposes, such

as lifting other car models. Never

use the jack to carry out repairs

under the vehicle. Incorrect

positioning of the jack may cause

the lifted vehicle to fall. Do not

use the jack for loads higher than

those shown on the label.

145) Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and spare wheel pressure

regularly, referring to the values

shown in the "Technical

specifications" section.

146) No tools other than the crank

provided should be used with

the spare wheel lifting device; it

should be operated by hand only.147) On versions equipped with

self-levelling air suspension, never

introduce the head or hands in

the wheel arch: the vehicle could

raise or lower automatically

depending on possible load or

temperature changes.

148) The device should only be

operated by hand, without using

any type of tool other than the

crank provided, like pneumatic or

electrical screwers.

149) The moving components of the

jack (screw and joints) can also

cause injuries: do not touch them.

If you come into contact with

lubricating grease, clean yourself

thoroughly.

150) At the end of the operation of

raising/locking the spare wheel,

after having checked the correct

positioning of the wheel under the

platform (yellow notch inside the

window on the device), the

spanner must be extracted, taking

care not to turn it in the wrong

direction (as in fig. 189) to

facilitate the extraction of the

spanner itself, to prevent the

attachment device from being

released and the wheel assembly

not being securely retained.

203