technical specifications FIAT DUCATO BASE CAMPER 2015 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2015Pages: 367, PDF Size: 19.73 MB

Page 5 of 367

Dear Customer,

We would like to congratulate and thank you for choosing a Fiat Ducato. We have written this handbook to help you get to know all the

features of your vehicle and use it in the best possible way. You should read it right through before taking to the road for the first time.

You will find information, tips and important warnings regarding the use of your vehicle to help you get the most from the technological features

of your Fiat Ducato. It also provides a description of special features and essential information for the care and maintenance of your vehicle

over time as well as for safe driving.

We urge you to read the warnings and indications found throughout the text with care, marked with the following symbols:

personal safety;

vehicle integrity;

environmental protection.

NOTE These symbols, when necessary, are reported at the end of each paragraph and are followed by a number. That number recalls the

corresponding warning at the end of the relevant section.

In the attached Warranty Booklet you will also find a description of the Services that Fiat offers to its customers, the Warranty Certificate and

the detail of the terms and conditions for maintaining its validity.

We are sure that these will help you to get in touch with and appreciate your new vehicle and the service provided by the people at Fiat.

Enjoy reading. Happy motoring!

This Owner Handbook describes all Fiat Ducato versions. As a consequence, you should only consider the information

which is related to the trim level, engine and version that you have purchased. All data contained in this publication is

purely indicative. Fiat Group Automobiles can modify the specifications of the vehicle model described in this publication

at any time, for technical or marketing purposes. For further information, contact a Fiat Dealership.

Page 84 of 367

WARNING

45) For safety reasons, the bonnet

must always be perfectly closed

while travelling. Make sure that

the bonnet is perfectly closed and

that the lock is engaged. If you

notice when driving that the

bonnet has not been properly

locked, stop immediately

and close the bonnet correctly.

46) Incorrect positioning of the stay

rod may cause the bonnet to drop

suddenly.

47) Perform these operations only

when the vehicle is stationary.

ROOF RACK/SKI

RACK

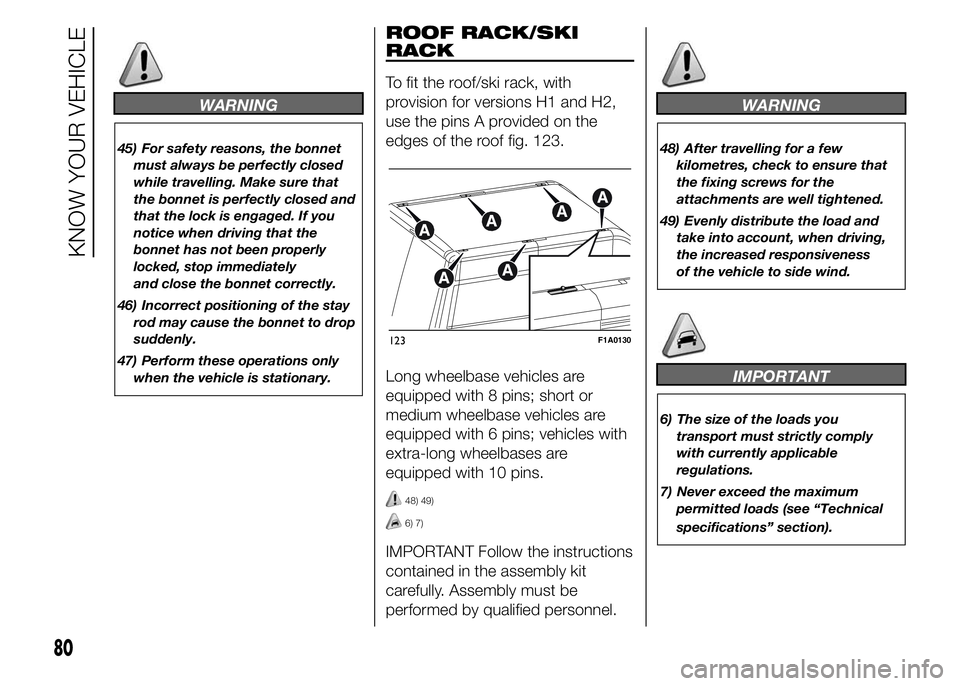

To fit the roof/ski rack, with

provision for versions H1 and H2,

use the pins A provided on the

edges of the roof fig. 123.

Long wheelbase vehicles are

equipped with 8 pins; short or

medium wheelbase vehicles are

equipped with 6 pins; vehicles with

extra-long wheelbases are

equipped with 10 pins.

48) 49)

6) 7)

IMPORTANT Follow the instructions

contained in the assembly kit

carefully. Assembly must be

performed by qualified personnel.

WARNING

48) After travelling for a few

kilometres, check to ensure that

the fixing screws for the

attachments are well tightened.

49) Evenly distribute the load and

take into account, when driving,

the increased responsiveness

of the vehicle to side wind.

IMPORTANT

6) The size of the loads you

transport must strictly comply

with currently applicable

regulations.

7) Never exceed the maximum

permitted loads (see “Technical

specifications” section).

123F1A0130

80

KNOW YOUR VEHICLE

Page 207 of 367

WARNING

141) Use your hazard lights, warning

triangle, etc. to show that your

vehicle is stationary according to

the regulations in force.

Passengers should get out of the

vehicle, particularly if it is heavily

loaded, and wait for the wheel

to be changed away from the

traffic. Apply the handbrake. in

the event of a wheel change on a

slope or on unsurfaced roads,

put any object as stop under the

wheels.

142) The spare wheel supplied (for

versions/markets, where

provided) is specific for your

vehicle. Therefore, it must not be

used on other models. Do not

use spare wheels of other models

on your vehicle. The wheel bolts

are specific for your vehicle: do

not use them on different models

and do not use bolts from other

models on your car.143) Have the wheel repaired and

refitted as soon as possible. Do

not apply grease to the bolt

threads before fitting: they could

come unscrewed.

144) Use the jack only to replace

wheels on the vehicle with which

it is supplied or on other vehicles

of the same model. Never use

the jack for other purposes, such

as lifting other car models. Never

use the jack to carry out repairs

under the vehicle. Incorrect

positioning of the jack may cause

the lifted vehicle to fall. Do not

use the jack for loads higher than

those shown on the label.

145) Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and spare wheel pressure

regularly, referring to the values

shown in the "Technical

specifications" section.

146) No tools other than the crank

provided should be used with

the spare wheel lifting device; it

should be operated by hand only.147) On versions equipped with

self-levelling air suspension, never

introduce the head or hands in

the wheel arch: the vehicle could

raise or lower automatically

depending on possible load or

temperature changes.

148) The device should only be

operated by hand, without using

any type of tool other than the

crank provided, like pneumatic or

electrical screwers.

149) The moving components of the

jack (screw and joints) can also

cause injuries: do not touch them.

If you come into contact with

lubricating grease, clean yourself

thoroughly.

150) At the end of the operation of

raising/locking the spare wheel,

after having checked the correct

positioning of the wheel under the

platform (yellow notch inside the

window on the device), the

spanner must be extracted, taking

care not to turn it in the wrong

direction (as in fig. 189) to

facilitate the extraction of the

spanner itself, to prevent the

attachment device from being

released and the wheel assembly

not being securely retained.

203

Page 212 of 367

IMPORTANT

2) Replace the bottle containing the

sealant after the expiry date.

Dispose of the bottle and

the sealant properly. Have the

sealing fluid and the bottle

disposed of in compliance with

national and local regulations.

CHANGING A BULB

GENERAL

INSTRUCTIONS

45)

163) 164)

❒When a light is not working, check

that the corresponding fuse is intact

before changing a bulb. For the

location of fuses, refer to the

paragraph "Replacing fuses" in this

chapter.

❒before changing a bulb check the

contacts for oxidation;

❒burnt bulbs must be replaced by

others of the same type and power;

❒always check the headlight beam

direction after changing a bulb;

IMPORTANT A slight misting may

appear on the internal surface

of the headlight: this does

not indicate a fault and is caused

by low temperature and the degree

of humidity in the air. Misting will

rapidly disappear when the

headlights are switched on. The

presence of drops inside the

headlights indicates infiltration of

water. Contact a Fiat Dealership.

IMPORTANT

45) Halogen bulbs must be handled

by holding the metallic part only.

Touching the transparent part

of the bulb with your fingers may

reduce the intensity of the

emitted light and even reduce the

lifespan of the bulb. In the event

of accidental contact, wipe the

bulb with a cloth moistened with

alcohol and let the bulb dry.

WARNING

163) Modifications or repairs to the

electric system that are not

carried out properly or do not take

the system technical

specifications into account can

cause malfunctions leading to the

risk of fire.

164) Halogen bulbs contain

pressurised gas; in the case of

breakage they may burst.

208

IN AN EMERGENCY

Page 243 of 367

POWER STEERING

FLUID

188)

3)

51)

Check that the liquid contained in

the tank is at the maximum level.

This operation must be carried out

with the vehicle level and with

the engine off and cold.

Proceed as follows:

❒remove the plastic cover A fig. 242,

rotating the locking screws B fig.

242 counter-clockwise, to access the

filler of the reservoir;

❒check that the fluid level is up to the

MAX mark on the dipstick attached

to the fuel cap F fig. 239 - fig. 240

- fig. 241 (use the level shown on the

20°C side of the dipstick to check

when cold).

If the level of the fluid in the tank is

lower than the specified level,

top up using only one of the

products indicated in the "Fluid and

lubricants" table in the "Technical

specifications" section, proceeding

as follows:

❒Start the engine and wait for the fluid

level in the tank to stabilise.❒With the engine running, turn the

steering wheel from right to left

fully several times.

❒Top up the fuel to the MAX level and

then retighten the cap.

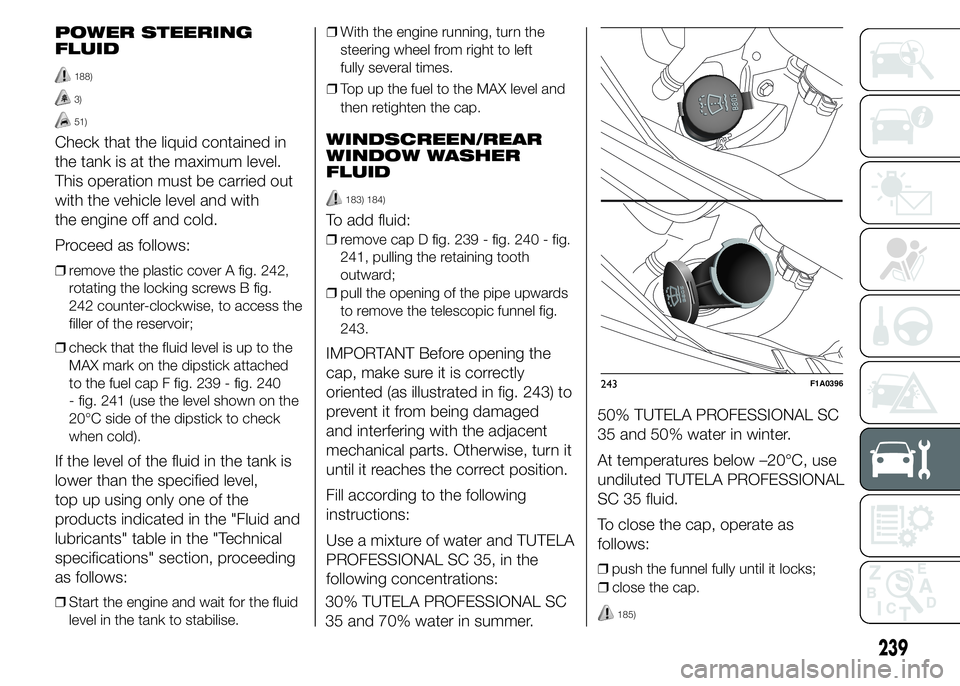

WINDSCREEN/REAR

WINDOW WASHER

FLUID

183) 184)

To add fluid:

❒remove cap D fig. 239 - fig. 240 - fig.

241, pulling the retaining tooth

outward;

❒pull the opening of the pipe upwards

to remove the telescopic funnel fig.

243.

IMPORTANT Before opening the

cap, make sure it is correctly

oriented (as illustrated in fig. 243) to

prevent it from being damaged

and interfering with the adjacent

mechanical parts. Otherwise, turn it

until it reaches the correct position.

Fill according to the following

instructions:

Use a mixture of water and TUTELA

PROFESSIONAL SC 35, in the

following concentrations:

30% TUTELA PROFESSIONAL SC

35 and 70% water in summer.50% TUTELA PROFESSIONAL SC

35 and 50% water in winter.

At temperatures below –20°C, use

undiluted TUTELA PROFESSIONAL

SC 35 fluid.

To close the cap, operate as

follows:

❒push the funnel fully until it locks;

243F1A0396

239

❒close the cap.

185)

Page 244 of 367

BRAKE FLUID

186) 187)

50)

Undo the cap E fig. 239 - fig. 240 -

fig. 241 and check that the liquid

contained in the reservoir is at

the maximum level.

The fluid level in the reservoir must

not exceed the MAX mark.

Use the brake fluid shown in the

"Fluids and lubricants" table (see

"Technical Specifications").

NOTE Carefully clean the cap of the

reservoir and the surrounding

surface.

Take great care to ensure that

impurities do not enter the reservoir

when the plug is opened.

For topping-up, always use a funnel

with integrated filter with mesh

equal to or lower than 0.12 mm.IMPORTANT Brake fluid absorbs

moisture. For this reason, if the

vehicle is mainly used in areas with

a high degree of atmospheric

humidity, the fluid should be

replaced at more frequent intervals

than specified in the “Scheduled

Servicing Plan”.

IMPORTANT

47) When topping up, take care not

to mix up the various types of

fluids: they are not compatible

with each other and could

seriously damage the car.

48) The used engine oil and the filter

that has been replaced contain

substances that are harmful to

the environment. To change the

oil and filters, we advise you to

contact a Fiat Dealership.49) PARAFLU

UPantifreeze is used in

the engine cooling system. Use

fluid of the same type as that

contained in the cooling system

for any top-ups. PARAFLU

UP

cannot be mixed with any other

type of fluid. If this happens, do

not start the engine and contact a

Fiat Dealership.

50) Avoid allowing brake fluid, which

is extremely corrosive, to come

into contact with painted areas.

Should it happen, wash

immediately with water.

51) Do not press the power steering

end of travel lock for longer than 8

consecutive seconds with the

engine running because it will

cause noise and risk damaging

the system.

WARNING

180) Never smoke when performing

operations in the engine

compartment. Flammable gases

and fumes may be present and

risk igniting.

240

SERVICING AND MAINTENANCE

Page 249 of 367

WHEELS AND TYRES

Check the pressure of each tyre,

including the space-saver wheel,

approximately every two weeks and

before long journeys: the pressure

should be checked with the tyre

rested and cold.

It is normal for the pressure to

increase when the vehicle is used;

for the correct tyre inflation

pressure, see “Wheels” in the

“Technical specifications” section.

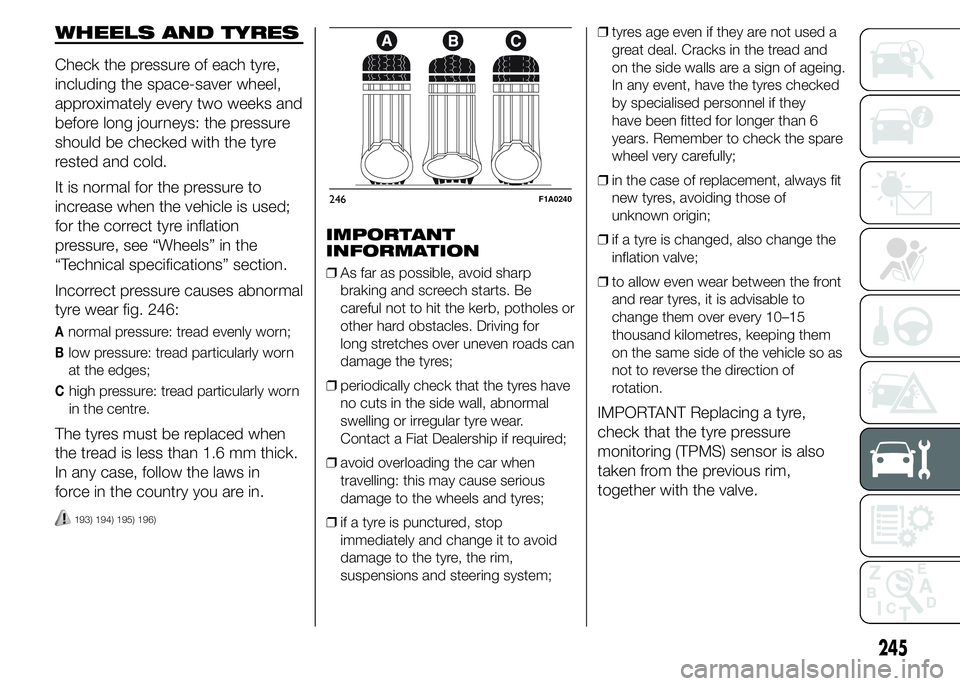

Incorrect pressure causes abnormal

tyre wear fig. 246:

Anormal pressure: tread evenly worn;

Blow pressure: tread particularly worn

at the edges;

Chigh pressure: tread particularly worn

in the centre.

The tyres must be replaced when

the tread is less than 1.6 mm thick.

In any case, follow the laws in

force in the country you are in.

193) 194) 195) 196)

IMPORTANT

INFORMATION

❒As far as possible, avoid sharp

braking and screech starts. Be

careful not to hit the kerb, potholes or

other hard obstacles. Driving for

long stretches over uneven roads can

damage the tyres;

❒periodically check that the tyres have

no cuts in the side wall, abnormal

swelling or irregular tyre wear.

Contact a Fiat Dealership if required;

❒avoid overloading the car when

travelling: this may cause serious

damage to the wheels and tyres;

❒if a tyre is punctured, stop

immediately and change it to avoid

damage to the tyre, the rim,

suspensions and steering system;❒tyres age even if they are not used a

great deal. Cracks in the tread and

on the side walls are a sign of ageing.

In any event, have the tyres checked

by specialised personnel if they

have been fitted for longer than 6

years. Remember to check the spare

wheel very carefully;

❒in the case of replacement, always fit

new tyres, avoiding those of

unknown origin;

❒if a tyre is changed, also change the

inflation valve;

❒to allow even wear between the front

and rear tyres, it is advisable to

change them over every 10–15

thousand kilometres, keeping them

on the same side of the vehicle so as

not to reverse the direction of

rotation.

IMPORTANT Replacing a tyre,

check that the tyre pressure

monitoring (TPMS) sensor is also

taken from the previous rim,

together with the valve.

246F1A0240

245

Page 252 of 367

BODYWORK

PROTECTION AGAINST

ATMOSPHERIC

AGENTS

The main causes of corrosion are

the following:

❒atmospheric pollution;

❒salty air and humidity (coastal areas,

or hot humid climates);

❒seasonal environmental conditions.

The abrasive action of wind-borne

atmospheric dust and sand, as well

as mud and gravel raised by other

vehicles is also not to be

underestimated.

On your vehicle, Fiat has

implemented the best

manufacturing technologies to

effectively protect the bodywork

against corrosion.

These include:

❒painting products and systems which

give the vehicle particular resistance

to corrosion and abrasion;

❒Use of galvanised (or pretreated)

steel sheets, with high resistance

to corrosion;❒spraying the underbody, engine

compartment, wheelhouse internal

parts and other parts with highly

protective wax products;

❒spraying of plastic parts, with a

protective function in the more

exposed points: underdoor, inner

wing, edges, etc;

❒use of “open” boxed sections to

prevent condensation and pockets of

moisture from triggering rust inside.

VEHICLE BODY AND

UNDERBODY

WARRANTY

Your vehicle is covered by warranty

against perforation due to corrosion

of any original element of the

structure or body.

For the general terms of this

warranty, refer to the Warranty

Booklet.

ADVICE FOR

PRESERVING THE

BODYWORK

Paintwork

Paintwork does not only serve an

aesthetic purpose, but also

protects the underlying sheet metal.Touch up abrasions and scratches

immediately to prevent rust

formation. Only use genuine spare

paint products for touch-ups (see

“Bodywork paint identification

plate” in the “Technical

Specifications” section).

Normal maintenance of paintwork

consists in washing the car: the

frequency depends on the

conditions and environment where

the car is used.

For example, it is advisable to wash

the vehicle more often in areas

with high levels of environmental

pollution or on roads spread with

salt.

To correctly wash the vehicle,

proceed as follows:

❒wash the bodywork using a low

pressure jet of water;

❒wipe a sponge with a slightly soapy

solution over the bodywork,

frequently rinsing the sponge;

248

SERVICING AND MAINTENANCE

❒rinse well with water and dry with a

jet of air or a chamois leather.

Page 257 of 367

TECHNICAL SPECIFICATIONS

Everything you may find useful for

understanding how your vehicle

is made and works is contained in

this chapter and illustrated with

data, tables and graphics. For the

enthusiasts and the technician, but

also just for those who want to

know every detail of their vehicle.IDENTIFICATION DATA....................254

ENGINE CODES - BODYWORK

VERSION ........................................256

ENGINE ..........................................258

POWER SUPPLY ............................259

TRANSMISSION .............................260

SUSPENSION .................................261

BRAKES .........................................262

STEERING ......................................263

WHEELS .........................................264

DIMENSIONS ..................................268

PERFORMANCE .............................278

WEIGHTS........................................280

SUPPLIES .......................................319

FLUIDS AND LUBRICANTS ............321

FUEL CONSUMPTION ....................324

CO2 EMISSIONS ............................335

OFFICIAL TYPE APPROVALS .........345

PRESCRIPTIONS FOR HANDLING

THE VEHICLE AT THE END OF ITS

LIFE ................................................349

253

Page 258 of 367

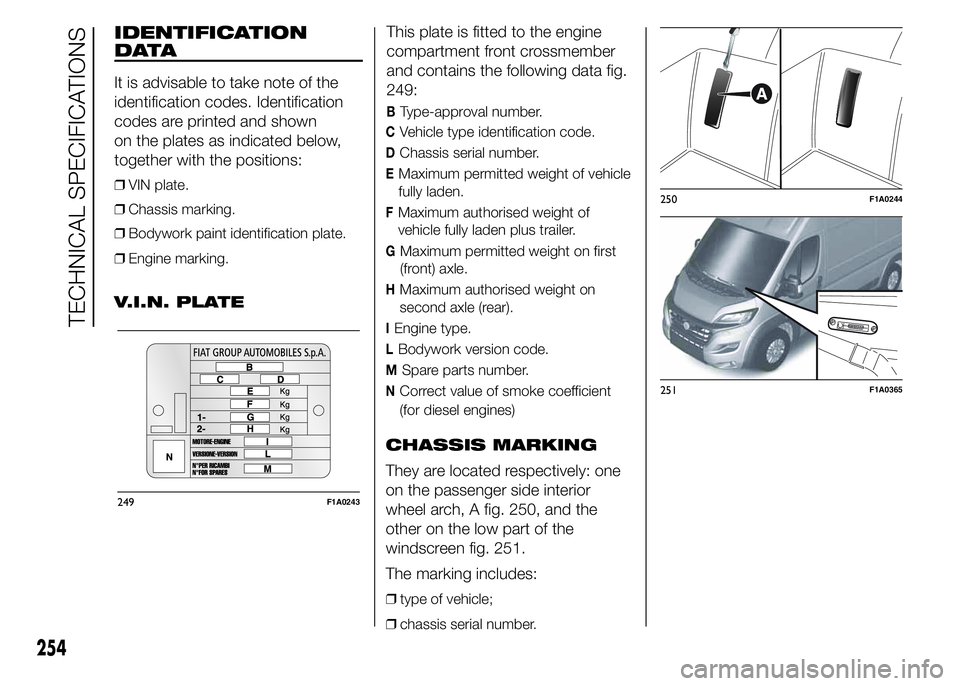

IDENTIFICATION

DATA

It is advisable to take note of the

identification codes. Identification

codes are printed and shown

on the plates as indicated below,

together with the positions:

❒VIN plate.

❒Chassis marking.

❒Bodywork paint identification plate.

❒Engine marking.

V.I.N. PLATEThis plate is fitted to the engine

compartment front crossmember

and contains the following data fig.

249:

BType-approval number.

CVehicle type identification code.

DChassis serial number.

EMaximum permitted weight of vehicle

fully laden.

FMaximum authorised weight of

vehicle fully laden plus trailer.

GMaximum permitted weight on first

(front) axle.

HMaximum authorised weight on

second axle (rear).

IEngine type.

LBodywork version code.

MSpare parts number.

NCorrect value of smoke coefficient

(for diesel engines)

CHASSIS MARKING

They are located respectively: one

on the passenger side interior

wheel arch, A fig. 250, and the

other on the low part of the

windscreen fig. 251.

The marking includes:

❒type of vehicle;

❒chassis serial number.

249F1A0243

250F1A0244

251F1A0365

254

TECHNICAL SPECIFICATIONS