rims FIAT DUCATO BASE CAMPER 2016 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2016Pages: 387, PDF Size: 20.76 MB

Page 2 of 387

We really know your vehicle because we invented,

designed and built it: we really know every single detail. At Fiat Professional Service authorised workshops

you can find technicians directly trained by us, offering quality and professionalism for all service operations.

Fiat Professional workshops are always close to you for the regular servicing operations, season checks and practical recommendations by our experts.

With Fiat Professional Genuine Parts you keep the reliability, comfort and performance features of your new vehicle unchanged in time: that's why you bought it for.

Always ask for Genuine Parts for the components used on our vehicles; we recommend them because they come from our steady commitment in research and development of highly innovative technologies. For all these reasons: rely on Genuine Parts,

because they are the only ones designed by Fiat Professional for your vehicle.

SAFETY: BRAKING SYSTEMENVIRONMENT: PARTICULATE FILTERS,

CLIMATE CONTROL SYSTEM MAINTENANCECOMFORT:

SUSPENSION AND WINDSCREEN WIPERSPERFORMANCE:

SPARK PLUGS, INJECTORS AND BATTERIESLINEACCESSORI:

ROOF RACK BARS, WHEEL RIMS

WHY CHOOSING GENUINE PARTS

COP DUCATO LUM GB 10/06/15 09:29 Pagina 2

Page 9 of 387

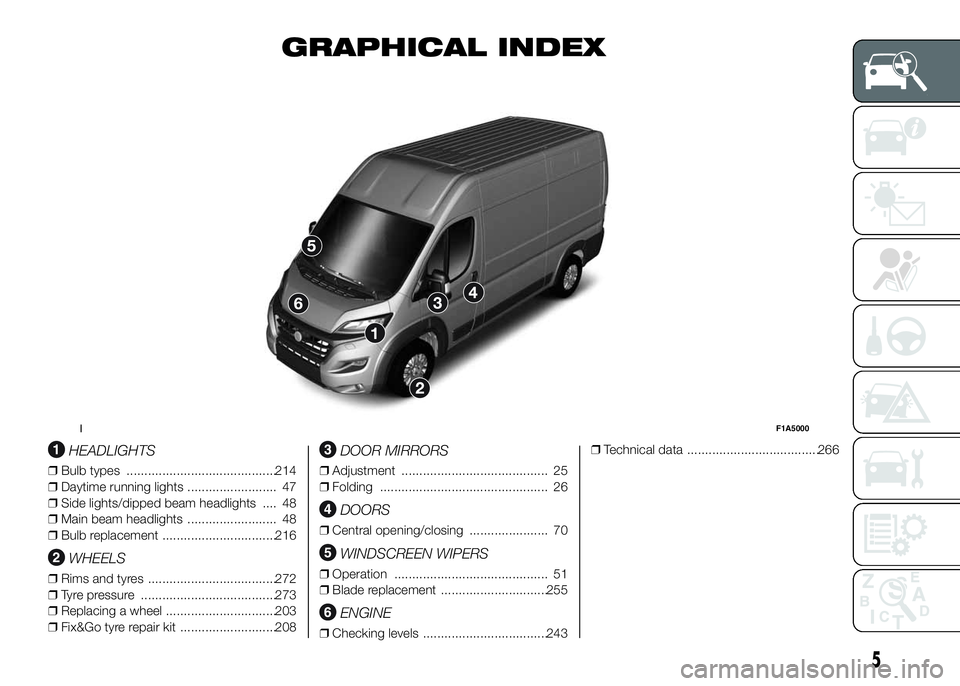

GRAPHICAL INDEX

.

HEADLIGHTS

❒Bulb types ..........................................214

❒Daytime running lights ......................... 47

❒Side lights/dipped beam headlights .... 48

❒Main beam headlights ......................... 48

❒Bulb replacement ................................216

WHEELS

❒Rims and tyres ....................................272

❒Tyre pressure ......................................273

❒Replacing a wheel ...............................203

❒Fix&Go tyre repair kit ...........................208

DOOR MIRRORS

❒Adjustment ......................................... 25

❒Folding ............................................... 26

DOORS

❒Central opening/closing ...................... 70

WINDSCREEN WIPERS

❒Operation ........................................... 51

❒Blade replacement ..............................255

ENGINE

❒Checking levels ...................................243❒Technical data .....................................266

1F1A5000

5

Page 92 of 387

The tyre pressure also increases while

driving the vehicle: this is a normal

condition and does not require any

adjustment of the pressure.

The TPMS continues to advise the

driver of the low tyre pressure condition

until this is corrected; the warning

continues until the pressure

corresponds or exceeds the pressure

prescribed for the cold tyres. When the

tyre low pressure control warning

light

switches on constantly, the

inflation pressure must be adjusted until

it reaches the pressure prescribed for

cold tyres. After the automatic update

of the system, the tyre pressure control

warning light switches off. You may

need to drive the vehicle for about 20

minutes at a speed higher than 20

km/h to allow the TPMS to receive this

information.

NOTE

❒The TPMS does not replace the

normal tyre maintenance service and

does not indicate any fault in a tyre.

❒Therefore, the TPMS should not be

used as pressure switch while

adjusting the tyre inflation pressure.❒Driving with insufficient tyre pressure

causes their overheating and can

result in tyre failure. The low inflation

pressure reduces fuel efficiency

and tyre tread life and may also affect

handling and braking performance

of the vehicle.

❒The TPMS does not replace the

correct tyre maintenance. It is up to

the driver to maintain the correct tyre

pressure level measuring it with a

suitable pressure switch. This is

necessary even if the decrease in the

inflation pressure value does not

cause the tyre pressure control

warning light to switch on.

❒The TPMS warns the driver of any

condition of insufficient tyre pressure

If this drops below the insufficient

pressure limit for any reason including

low temperature and normal

pressure loss of the tyre.

❒The seasonal temperature changes

affect tyre pressure.

The TPMS uses wireless devices with

electronic sensors mounted on the

wheel rims to constantly monitor the

value of tyre pressure. The sensors

mounted on each wheel as part of the

valve stem transmit various information

of the tyres to the receiver module, in

order to calculate the pressure.WARNING Monitoring and maintaining

the correct pressure in all four tyres

are particularly important.

Tyre pressure

monitoring system low

pressure warnings

The system warns the driver if one or

more tyres are flat by switching on

the warning light

on the instrument

panel (together with a warning message

and an acoustic signal).

In this case, stop the vehicle as soon as

possible, check the inflation pressure

of each tyre and inflate to the cold tyre

pressure value prescribed for the

vehicle. The system will automatically

update and after receiving the tyre

pressure update the tyre pressure

control warning light switches off. You

may need to drive the vehicle for about

20 minutes at a speed higher than 20

km/h to allow the system to receive this

information.

88

KNOW YOUR VEHICLE

Page 208 of 387

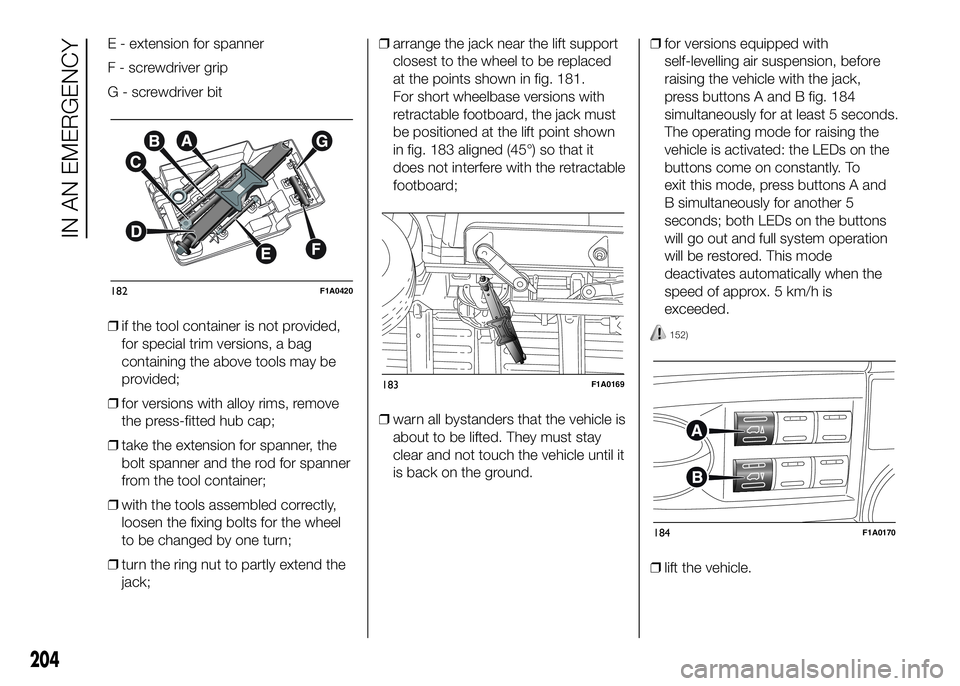

E - extension for spanner

F - screwdriver grip

G - screwdriver bit

❒if the tool container is not provided,

for special trim versions, a bag

containing the above tools may be

provided;

❒for versions with alloy rims, remove

the press-fitted hub cap;

❒take the extension for spanner, the

bolt spanner and the rod for spanner

from the tool container;

❒with the tools assembled correctly,

loosen the fixing bolts for the wheel

to be changed by one turn;

❒turn the ring nut to partly extend the

jack;❒arrange the jack near the lift support

closest to the wheel to be replaced

at the points shown in fig. 181.

For short wheelbase versions with

retractable footboard, the jack must

be positioned at the lift point shown

in fig. 183 aligned (45°) so that it

does not interfere with the retractable

footboard;

❒warn all bystanders that the vehicle is

about to be lifted. They must stay

clear and not touch the vehicle until it

is back on the ground.❒for versions equipped with

self-levelling air suspension, before

raising the vehicle with the jack,

press buttons A and B fig. 184

simultaneously for at least 5 seconds.

The operating mode for raising the

vehicle is activated: the LEDs on the

buttons come on constantly. To

exit this mode, press buttons A and

B simultaneously for another 5

seconds; both LEDs on the buttons

will go out and full system operation

will be restored. This mode

deactivates automatically when the

speed of approx. 5 km/h is

exceeded.

152)

❒lift the vehicle.

182F1A0420

183F1A0169

184F1A0170

204

IN AN EMERGENCY

Page 210 of 387

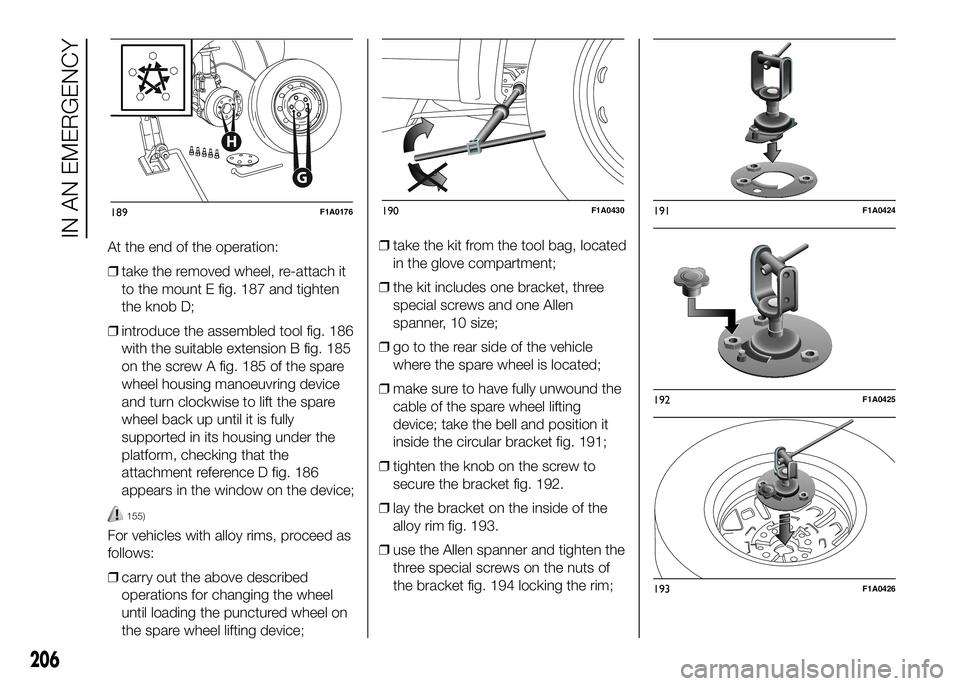

At the end of the operation:

❒take the removed wheel, re-attach it

to the mount E fig. 187 and tighten

the knob D;

❒introduce the assembled tool fig. 186

with the suitable extension B fig. 185

on the screw A fig. 185 of the spare

wheel housing manoeuvring device

and turn clockwise to lift the spare

wheel back up until it is fully

supported in its housing under the

platform, checking that the

attachment reference D fig. 186

appears in the window on the device;

155)

For vehicles with alloy rims, proceed as

follows:

❒carry out the above described

operations for changing the wheel

until loading the punctured wheel on

the spare wheel lifting device;❒take the kit from the tool bag, located

in the glove compartment;

❒the kit includes one bracket, three

special screws and one Allen

spanner, 10 size;

❒go to the rear side of the vehicle

where the spare wheel is located;

❒make sure to have fully unwound the

cable of the spare wheel lifting

device; take the bell and position it

inside the circular bracket fig. 191;

❒tighten the knob on the screw to

secure the bracket fig. 192.

❒lay the bracket on the inside of the

alloy rim fig. 193.

❒use the Allen spanner and tighten the

three special screws on the nuts of

the bracket fig. 194 locking the rim;

G

H

189F1A0176190F1A0430191F1A0424

192F1A0425

193F1A0426

206

IN AN EMERGENCY

Page 259 of 387

WARNING

198) Remember that the road

holding qualities of your vehicle

also depend on the correct

inflation pressure of the tyres.

199) If the pressure is too low, the

tyre will overheat and could be

seriously damaged.

200) Avoid switching the tyres from

the right side of the vehicle to the

left side and vice versa.

201) Never submit alloy rims to

repainting treatments requiring

the use of temperatures

exceeding 150°C. The mechanical

properties of the wheels could

be impaired.

RUBBER HOSES

As far as the brake system and fuel

supply system rubber hoses are

concerned, follow the "Scheduled

Servicing Plan" in this chapter carefully.

Ozone, high temperatures and

prolonged lack of fluid in the system

may cause hardening and cracking of

the hoses, with possible leaks. Careful

checking is therefore necessary.

WINDSCREEN

WIPER

BLADES

Periodically clean the rubber part using

special products; TUTELA

PROFESSIONAL SC 35 is

recommended.

Replace the blades if the rubber edge is

deformed or worn. In any case, it is

advisable to replace them

approximately once a year.

A few simple precautions can reduce

the possibility of damage to the blades:

❒if the temperature falls below zero,

make sure that ice has not frozen

the rubber against the glass. Use a

de-icing product to release it if

required;

❒remove any snow from the glass: in

addition to protecting the blades,

this prevents effort on the motor and

overheating;

❒do not operate the windscreen and

rear window wipers on dry glass.

202)

255

Page 274 of 387

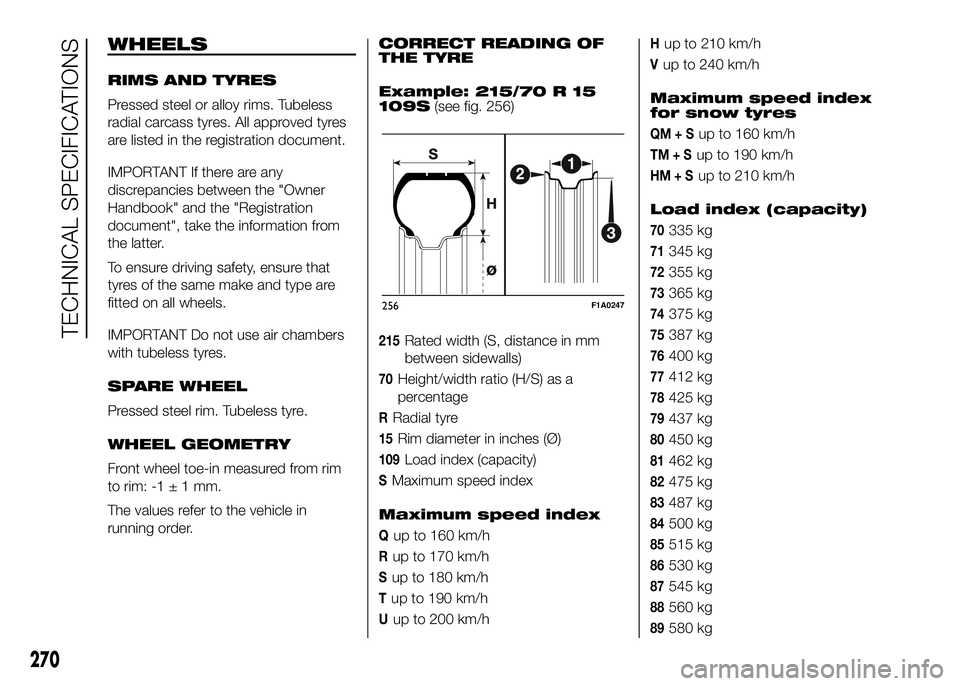

WHEELS

RIMS AND TYRES

Pressed steel or alloy rims. Tubeless

radial carcass tyres. All approved tyres

are listed in the registration document.

IMPORTANT If there are any

discrepancies between the "Owner

Handbook" and the "Registration

document", take the information from

the latter.

To ensure driving safety, ensure that

tyres of the same make and type are

fitted on all wheels.

IMPORTANT Do not use air chambers

with tubeless tyres.

SPARE WHEEL

Pressed steel rim. Tubeless tyre.

WHEEL GEOMETRY

Front wheel toe-in measured from rim

to rim: -1±1mm.

The values refer to the vehicle in

running order.CORRECT READING OF

THE TYRE

Example: 215/70 R 15

109S(see fig. 256)

215Rated width (S, distance in mm

between sidewalls)

70Height/width ratio (H/S) as a

percentage

RRadial tyre

15Rim diameter in inches (Ø)

109Load index (capacity)

SMaximum speed index

Maximum speed index

Qup to 160 km/h

Rup to 170 km/h

Sup to 180 km/h

Tup to 190 km/h

Uup to 200 km/h

Hup to 210 km/h

Vup to 240 km/h

Maximum speed index

for snow tyres

QM+Sup to 160 km/h

TM+Sup to 190 km/h

HM+Sup to 210 km/h

Load index (capacity)

70335 kg

71345 kg

72355 kg

73365 kg

74375 kg

75387 kg

76400 kg

77412 kg

78425 kg

79437 kg

80450 kg

81462 kg

82475 kg

83487 kg

84500 kg

85515 kg

86530 kg

87545 kg

88560 kg

89580 kg

256F1A0247

270

TECHNICAL SPECIFICATIONS

Page 276 of 387

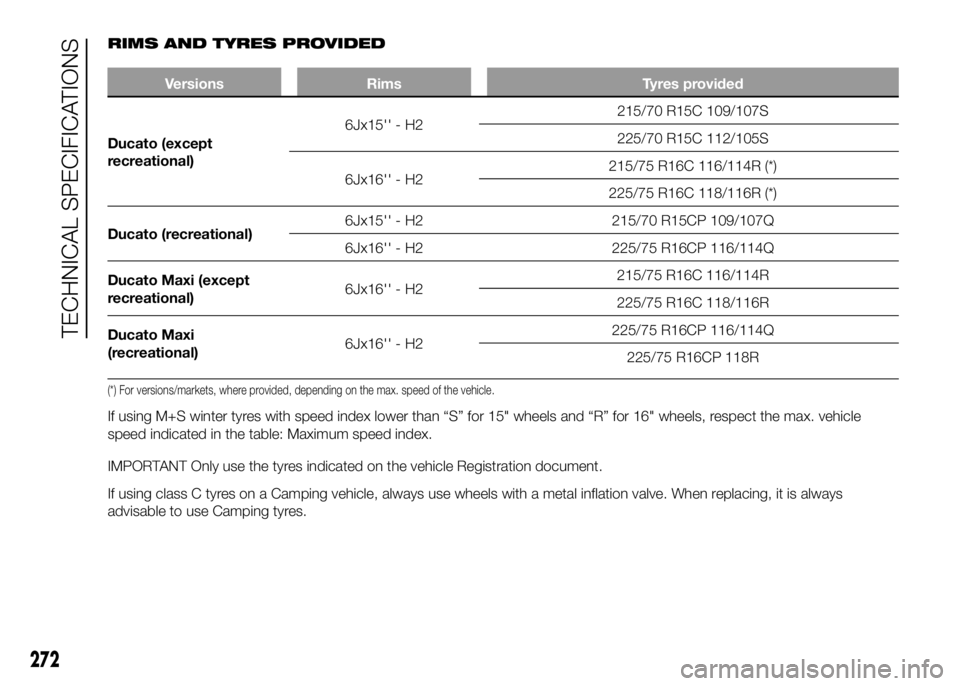

RIMS AND TYRES PROVIDED

Versions Rims Tyres provided

Ducato (except

r

ecreational)6Jx15'' - H2215/70 R15C 109/107S

225/70 R15C 112/105S

6Jx16'' - H2215/75 R16C 116/114R (*)

225/75 R16C 118/116R (*)

Ducato (recreational)6Jx15'' - H2 215/70 R15CP 109/107Q

6Jx16'' - H2 225/75 R16CP 116/114Q

Ducato Maxi (except

recreational)6Jx16'' - H2215/75 R16C 116/114R

225/75 R16C 118/116R

Ducato Maxi

(recreational)6Jx16'' - H2225/75 R16CP 116/114Q

225/75 R16CP 118R

(*) For versions/markets, where provided, depending on the max. speed of the vehicle..

If using M+S winter tyres with speed index lower than “S” for 15" wheels and “R” for 16" wheels, respect the max. vehicle

speed indicated in the table: Maximum speed index.

IMPORTANT Only use the tyres indicated on the vehicle Registration document.

If using class C tyres on a Camping vehicle, always use wheels with a metal inflation valve. When replacing, it is always

advisable to use Camping tyres.

272

TECHNICAL SPECIFICATIONS

Page 385 of 387

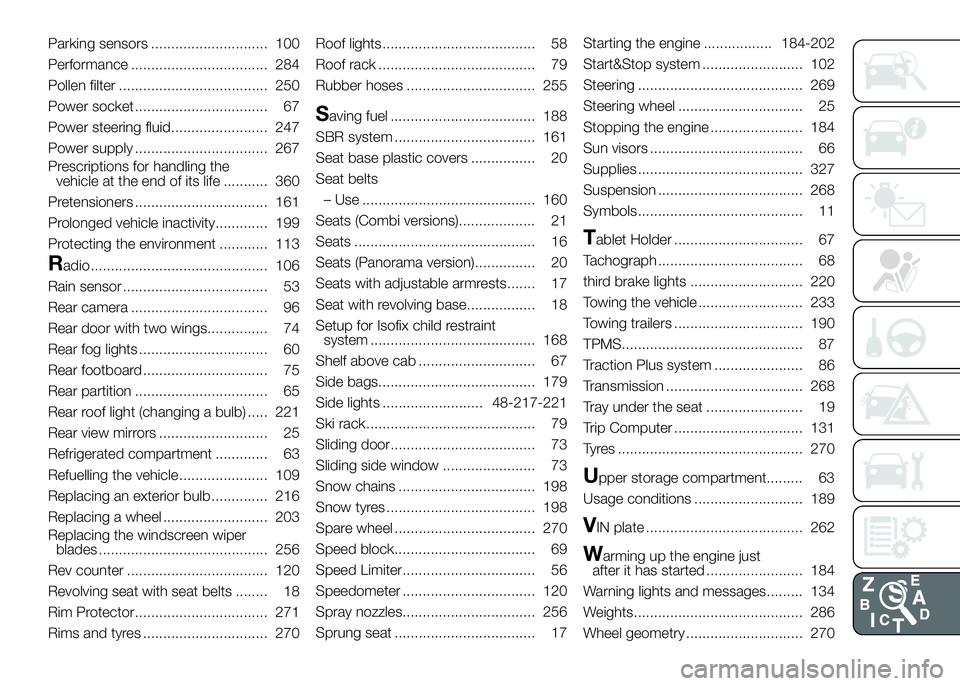

Parking sensors ............................. 100

Performance .................................. 284

Pollen filter ..................................... 250

Power socket ................................. 67

Power steering fluid........................ 247

Power supply ................................. 267

Prescriptions for handling the

vehicle at the end of its life ........... 360

Pretensioners ................................. 161

Prolonged vehicle inactivity............. 199

Protecting the environment ............ 113

Radio ............................................ 106

Rain sensor .................................... 53

Rear camera .................................. 96

Rear door with two wings............... 74

Rear fog lights ................................ 60

Rear footboard ............................... 75

Rear partition ................................. 65

Rear roof light (changing a bulb) ..... 221

Rear view mirrors ........................... 25

Refrigerated compartment ............. 63

Refuelling the vehicle ...................... 109

Replacing an exterior bulb .............. 216

Replacing a wheel .......................... 203

Replacing the windscreen wiper

blades .......................................... 256

Rev counter ................................... 120

Revolving seat with seat belts ........ 18

Rim Protector................................. 271

Rims and tyres ............................... 270Roof lights...................................... 58

Roof rack ....................................... 79

Rubber hoses ................................ 255

Saving fuel .................................... 188

SBR system ................................... 161

Seat base plastic covers ................ 20

Seat belts

– Use ........................................... 160

Seats (Combi versions)................... 21

Seats ............................................. 16

Seats (Panorama version)............... 20

Seats with adjustable armrests....... 17

Seat with revolving base................. 18

Setup for Isofix child restraint

system ......................................... 168

Shelf above cab ............................. 67

Side bags....................................... 179

Side lights ......................... 48-217-221

Ski rack.......................................... 79

Sliding door.................................... 73

Sliding side window ....................... 73

Snow chains .................................. 198

Snow tyres ..................................... 198

Spare wheel ................................... 270

Speed block................................... 69

Speed Limiter................................. 56

Speedometer ................................. 120

Spray nozzles................................. 256

Sprung seat ................................... 17Starting the engine ................. 184-202

Start&Stop system ......................... 102

Steering ......................................... 269

Steering wheel ............................... 25

Stopping the engine ....................... 184

Sun visors ...................................... 66

Supplies ......................................... 327

Suspension .................................... 268

Symbols......................................... 11

Tablet Holder ................................ 67

Tachograph .................................... 68

third brake lights ............................ 220

Towing the vehicle .......................... 233

Towing trailers ................................ 190

TPMS............................................. 87

Traction Plus system ...................... 86

Transmission .................................. 268

Tray under the seat ........................ 19

Trip Computer ................................ 131

Tyres .............................................. 270

Upper storage compartment......... 63

Usage conditions ........................... 189

VIN plate ....................................... 262

Warming up the engine just

after it has started ........................ 184

Warning lights and messages......... 134

Weights.......................................... 286

Wheel geometry ............................. 270