technical data FIAT DUCATO BASE CAMPER 2016 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2016Pages: 387, PDF Size: 20.76 MB

Page 5 of 387

Dear Customer,

We would like to congratulate and thank you for choosing a Fiat Ducato. We have written this handbook to help you get to know all the

features of your vehicle and use it in the best possible way. You should read it right through before taking to the road for the first time.

You will find information, tips and important warnings regarding the use of your vehicle to help you get the most from the technological features

of your Fiat Ducato. It also provides a description of special features and essential information for the care and maintenance of your vehicle

over time as well as for safe driving.

We urge you to read the warnings and indications found throughout the text with care, marked with the following symbols:

personal safety;

vehicle integrity;

environmental protection.

NOTE These symbols, when necessary, are reported at the end of each paragraph and are followed by a number. That number recalls the

corresponding warning at the end of the relevant section.

In the attached Warranty Booklet you will also find a description of the Services that Fiat offers to its customers, the Warranty Certificate and

the detail of the terms and conditions for maintaining its validity.

We are sure that these will help you to get in touch with and appreciate your new vehicle and the service provided by the people at Fiat.

Enjoy reading. Happy motoring!

This Owner Handbook describes all Fiat Ducato versions. As a consequence, you should only consider the information

which is related to the trim level, engine and version that you have purchased. All data contained in this publication are

purely indicative. FCA Italy S.p.A. can modify the specifications of the vehicle model described in this publication at any

time, for technical or marketing purposes. For further information, contact a Fiat Dealership.

Page 9 of 387

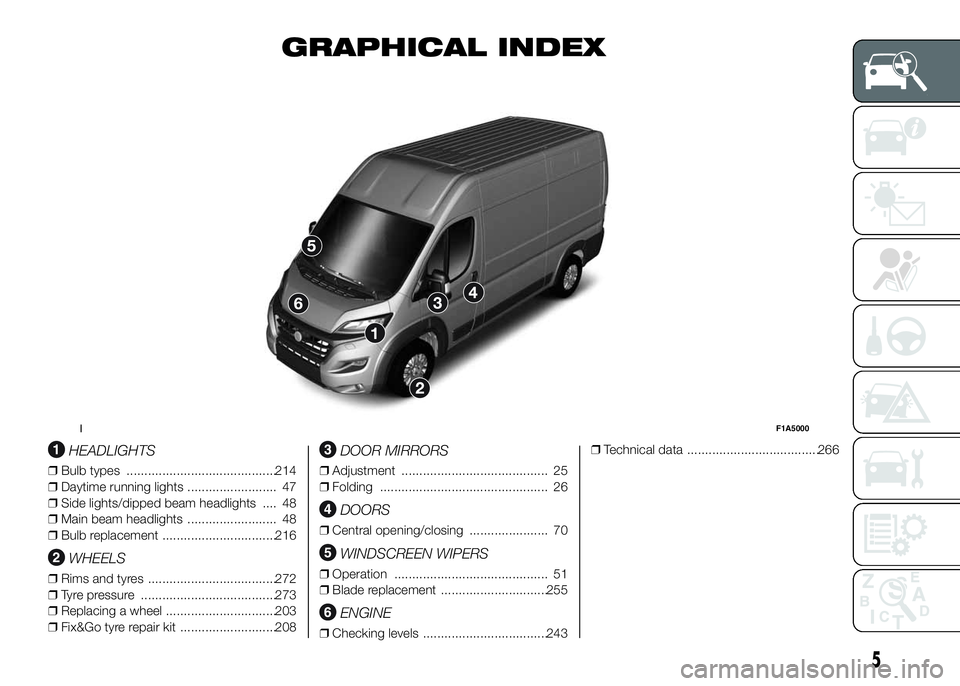

GRAPHICAL INDEX

.

HEADLIGHTS

❒Bulb types ..........................................214

❒Daytime running lights ......................... 47

❒Side lights/dipped beam headlights .... 48

❒Main beam headlights ......................... 48

❒Bulb replacement ................................216

WHEELS

❒Rims and tyres ....................................272

❒Tyre pressure ......................................273

❒Replacing a wheel ...............................203

❒Fix&Go tyre repair kit ...........................208

DOOR MIRRORS

❒Adjustment ......................................... 25

❒Folding ............................................... 26

DOORS

❒Central opening/closing ...................... 70

WINDSCREEN WIPERS

❒Operation ........................................... 51

❒Blade replacement ..............................255

ENGINE

❒Checking levels ...................................243❒Technical data .....................................266

1F1A5000

5

Page 115 of 387

❒if during the topping up, the level of

AdBlue in the bottle does not drop,

it means that you have reached

the full tank, therefore proceed pulling

the bottle towards you in order to

re-lock the safety valve of the bottle

and unscrew the bottle from the

filler (fig. 142, ref. 3);

❒after removing the bottle remount

cap C fig. 141 on the filler neck

UREA, turning it clockwise until it

stops;

❒turn the key in the pawl starter in the

ON position (no need to start the

engine);

❒wait for the signal on the instrument

panel to power off before moving the

vehicle, the warning light may stay

on for a few seconds to half a

minute. In case of motor start-up and

movement of the vehicle, the

warning sign will remain on for a

longer period of time, but there are

no problems on the engine

functionality;

❒If topping up is done with the UREA

tank empty, you have to wait two

minutes before starting the vehicle;NoteThe driving conditions (altitude,

vehicle speed, load, etc.) determine the

quantity of UREA used by the vehicle.

In order to use the additive for Diesel

Emissions (UREA) correctly, see "Fluids

and lubricants" in the "Technical data".

IMPORTANT

❒Exceeding the maximum filling

level of the tank UREA, it can

cause damage to the tank and

spilling UREA. Please avoid

topping up after filling the tank.

❒DO NOT EXCEED THE MAXIMUM

LEVEL. The UREA freezes at

under -11 ° C. Although the

system is designed to operate

below the freezing point of the

UREA, it is advisable not to fill the

tank beyond the maximum level

because if the UREA freezes

the system can be damaged.

❒If the UREA is spilled on painted

surfaces or aluminium,

immediately clean the area with

water and use absorbent material

to collect the fluid that has been

spilled on the ground.

❒Do not try to start the engine if

UREA was accidentally added

to the diesel fuel tank, this can

result in serious engine damage,

contact Dealership.❒Use AdBlue only according to DIN

70 070 and ISO 22241-1. Other

fluids may cause damage to the

system: also exhaust emissions

would no longer comply with

the law. The distribution

companies are responsible for

the compliance of their product.

Observe the precautions of

storage and maintenance, in

order to preserve the initial

qualities. The manufacturer of the

vehicle does not recognize any

guarantee in case of

malfunctions and damage caused

to the vehicle due to the use of

urea (AdBlue) not in accordance

with regulations.

❒Any introduction of diesel fuel

inside the tank AdBlue, causes

irreversible damage to the

pumping unit circuit AdBlue.

❒Do not add additives to AdBlue.

Do not dilute AdBlue with tap

water as this may damage the

system of purification of exhaust

gases.

111

Page 191 of 387

To engage reverse R from neutral,

proceed as follows: raise sliding ring A

under the knob and at the same time

move the gear lever to the left and then

forwards.

136)

35)

WARNING

136) Depress the clutch pedal fully

to change gear correctly. It is

therefore essential that there is

nothing under the pedals: make

sure the mats are lying flat and do

not get in the way of the pedals.

IMPORTANT

35) Do not drive with your hand

resting on the gear lever as the

force exerted, even if slight, could

lead over time to premature wear

of the internal gearbox

components. The clutch pedal

should be used only for gear

changes. Do not drive with your

foot resting on the clutch pedal,

however lightly. For versions/

markets where provided, the

electronic clutch pedal control

could cut in, interpreting the

incorrect driving style as a fault.

LOADING ADVICE

The Fiat Ducato version used by you

has been designed and type approved

on the basis of certain maximum

weights (see "Weights" table in the

"Technical Data" chapter): kerb weight,

payload, total weight, maximum weight

on front axle, maximum weight on

rear axle, towable weight.

IMPORTANT The maximum permitted

load on the floor fastenings is 500

kg; the maximum permitted load on the

side panel is 150 kg.

IMPORTANT For versions with right and

left side flaps, it is advisable to

reposition the release lever in the closed

position before lowering the sides.

36)

137) 138) 139)

In addition to these general

precautions, some simple precautions

can improve driving safety, travelling

comfort and vehicle durability:

❒distribute the load evenly over the

platform: if it is necessary to

concentrate it in a single area,

choose an area mid-way between

both axles;

187

Page 195 of 387

For the electric connection a standard

connector should be used which is

generally placed on a special bracket

normally fastened to the towing device,

and a special ECU for external trailer

light control must be installed on the

vehicle. For the electrical connection, 7

or 13 pin 12 V DC connections are to

be used (CUNA/UNI and ISO/DIN

Standards). Follow the instructions

provided by the vehicle manufacturer

and/or the tow hitch manufacturer.

An electric brake (or electric winch)

should be supplied directly by the

battery through a cable with a cross

section of no less than 2.5 mm

2.

IMPORTANT Electric brakes or other

devices must be used with engine

running.

In addition to the electrical branches,

the vehicle's electric system can only

be connected to the supply cable for an

electric brake and to the cable for an

internal light, though not above 15

W. For connections use the preset

control unit with battery cable no less

than 2.5 mm

2.IMPORTANT The trailer tow hook

contributes to the length of the vehicle.

When installing on long wheelbase

versions, it is only possible to install

removable tow hooks because the total

vehicle length limit of 6 metres is

exceeded.

If no trailer is fitted, the hook must be

removed from the attachment base and

it must not exceed the vehicle's

original length.

IMPORTANT If you wish to leave the

tow hook fitted without towing a trailer,

it is advisable to contact a Fiat

Dealership for the relevant system

update operations because the tow

hook could be detected as an obstacle

by the central sensors.Installation diagram for

Van versions fig. 174

The tow hook structure must be

fastened in the points shown by the

symbol Ø using a total of 6 M10x1.25

screws and 4 M12 screws.

The internal back plates must be at

least 5 mm thick. MAX LOAD ON

BALL: 100/120 kg according to the

payload (see “Weights” table in the

“Technical data” section).

142)

To install a tow hook, the bumpers

must be trimmed as described in the

supplier's installation kit.

191

Page 196 of 387

Installation diagram for

Truck and Chassis Cab

versions fig. 175

Another tow hook specific to Truck and

Chassis Cab versions in shown in fig.

175.

The structure Ø must be fixed in the

points indicated using a total of 6

M10x1.25 screws and 4 M12 screws.

MAX LOAD ON BALL: 100/120 kg

according to the payload (see

“Weights” table in the “Technical data”

section).

143)

WARNING

140) The ABS device with which the

vehicle may be equipped will not

control the braking system of

the trailer. Particular caution is

required on slippery roads.

141) Never modify the braking

system of the vehicle to control

the trailer brake. The trailer

braking system must be fully

independent from the hydraulic

system of the vehicle.142) After fitting, fixing screw holes

must be sealed to prevent an

exhaust gas inlet.

143) After fitting, fixing screw holes

must be sealed to prevent an

exhaust gas inlet.

192

STARTING AND DRIVING

Page 213 of 387

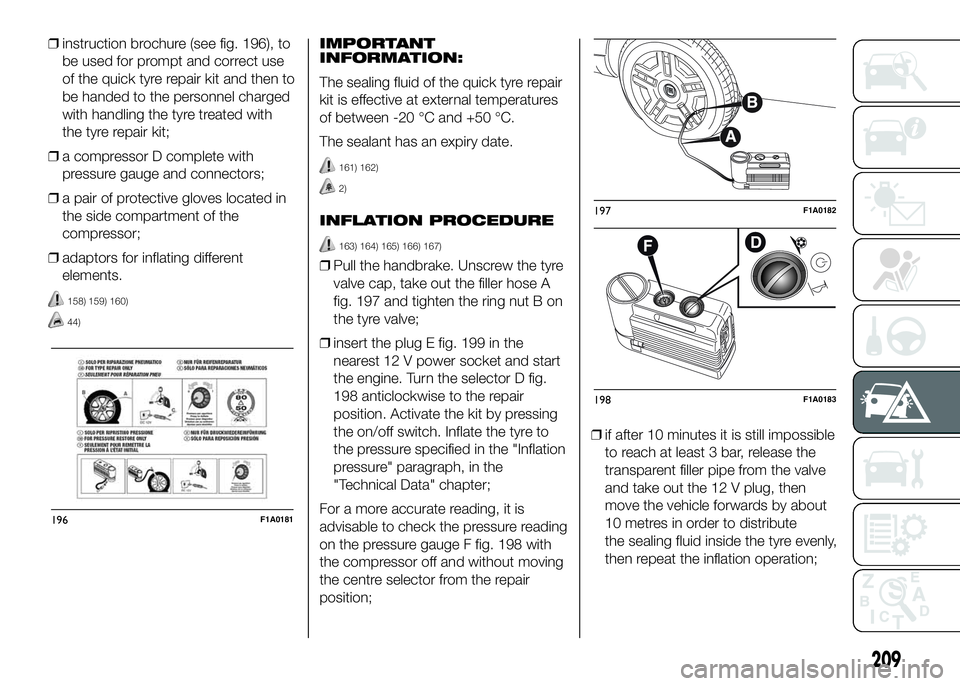

❒instruction brochure (see fig. 196), to

be used for prompt and correct use

of the quick tyre repair kit and then to

be handed to the personnel charged

with handling the tyre treated with

the tyre repair kit;

❒a compressor D complete with

pressure gauge and connectors;

❒a pair of protective gloves located in

the side compartment of the

compressor;

❒adaptors for inflating different

elements.

158) 159) 160)

44)

IMPORTANT

INFORMATION:

The sealing fluid of the quick tyre repair

kit is effective at external temperatures

of between -20 °C and +50 °C.

The sealant has an expiry date.

161) 162)

2)

INFLATION PROCEDURE

163) 164) 165) 166) 167)

❒Pull the handbrake. Unscrew the tyre

valve cap, take out the filler hose A

fig. 197 and tighten the ring nut B on

the tyre valve;

❒insert the plug E fig. 199 in the

nearest 12 V power socket and start

the engine. Turn the selector D fig.

198 anticlockwise to the repair

position. Activate the kit by pressing

the on/off switch. Inflate the tyre to

the pressure specified in the "Inflation

pressure" paragraph, in the

"Technical Data" chapter;

For a more accurate reading, it is

advisable to check the pressure reading

on the pressure gauge F fig. 198 with

the compressor off and without moving

the centre selector from the repair

position;❒if after 10 minutes it is still impossible

to reach at least 3 bar, release the

transparent filler pipe from the valve

and take out the 12 V plug, then

move the vehicle forwards by about

10 metres in order to distribute

the sealing fluid inside the tyre evenly,

then repeat the inflation operation;

196F1A0181

197F1A0182

198F1A0183

209

Page 214 of 387

❒if after this operation you still cannot

reach at least 3 bar after 10 minutes,

do not resume driving because the

tyre is too damaged and the quick

tyre repair kit cannot guarantee

suitable sealing. Contact a Fiat

Dealership;

❒if the tyre reaches the pressure

specified in “Inflation pressure”

paragraph in the "Technical Data"

section, start driving immediately;

❒after having driven for about

10 minutes, stop and recheck the

tyre pressure; remember to apply the

handbrake;❒if a pressure value of at least 3 bar is

detected, restore the correct

pressure prescribed in the paragraph

“Inflation pressure” in “Technical

specification” (with the engine

running and the handbrake

engaged), resume driving and drive

with care to nearest Fiat Dealership.

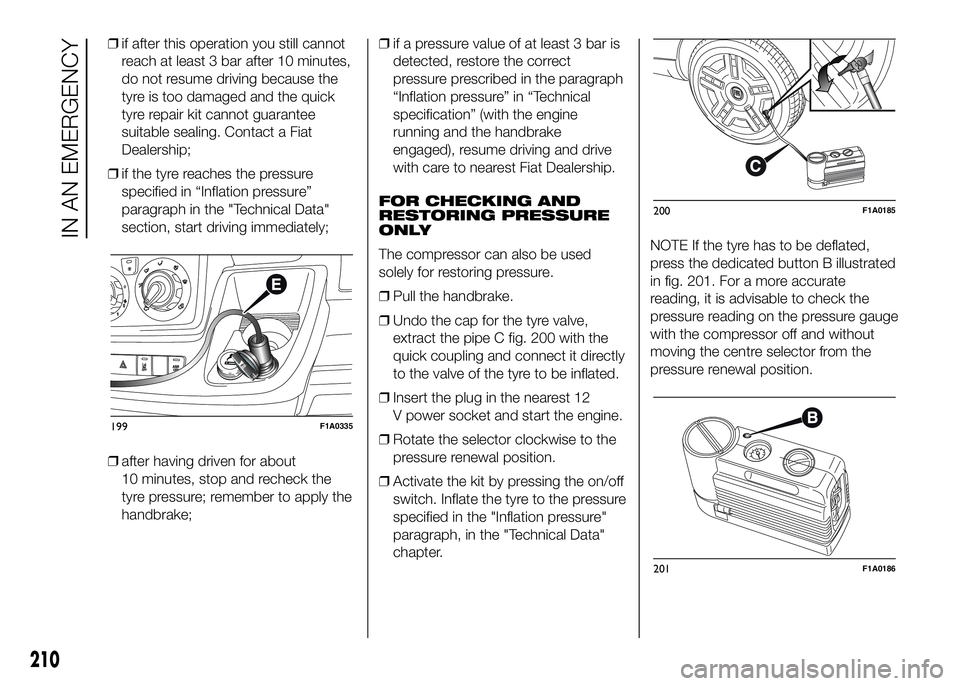

FOR CHECKING AND

RESTORING PRESSURE

ONLY

The compressor can also be used

solely for restoring pressure.

❒Pull the handbrake.

❒Undo the cap for the tyre valve,

extract the pipe C fig. 200 with the

quick coupling and connect it directly

to the valve of the tyre to be inflated.

❒Insert the plug in the nearest 12

V power socket and start the engine.

❒Rotate the selector clockwise to the

pressure renewal position.

❒Activate the kit by pressing the on/off

switch. Inflate the tyre to the pressure

specified in the "Inflation pressure"

paragraph, in the "Technical Data"

chapter.NOTE If the tyre has to be deflated,

press the dedicated button B illustrated

in fig. 201. For a more accurate

reading, it is advisable to check the

pressure reading on the pressure gauge

with the compressor off and without

moving the centre selector from the

pressure renewal position.

199F1A0335

200F1A0185

201F1A0186

210

IN AN EMERGENCY

Page 265 of 387

TECHNICAL SPECIFICATIONS

Everything you may find useful for

understanding how your vehicle

is made and works is contained in this

chapter and illustrated with data, tables

and graphics. For the enthusiasts and

the technician, but also just for those

who want to know every detail of their

vehicle.IDENTIFICATION DATA....................262

ENGINE CODES - BODYWORK

VERSION ........................................264

ENGINE ..........................................266

POWER SUPPLY ............................267

TRANSMISSION .............................268

SUSPENSION .................................268

BRAKES .........................................269

STEERING ......................................269

WHEELS .........................................270

DIMENSIONS ..................................274

PERFORMANCE .............................284

WEIGHTS........................................286

SUPPLIES .......................................327

FLUIDS AND LUBRICANTS ............329

FUEL CONSUMPTION ....................333

CO2 EMISSIONS ............................345

OFFICIAL TYPE APPROVALS .........356

PRESCRIPTIONS FOR HANDLING

THE VEHICLE AT THE END OF ITS

LIFE ................................................360

261

Page 266 of 387

IDENTIFICATION

DATA

It is advisable to take note of the

identification codes. Identification codes

are printed and shown on the plates

as indicated below, together with the

positions:

❒VIN plate.

❒Chassis marking.

❒Bodywork paint identification plate.

❒Engine marking.

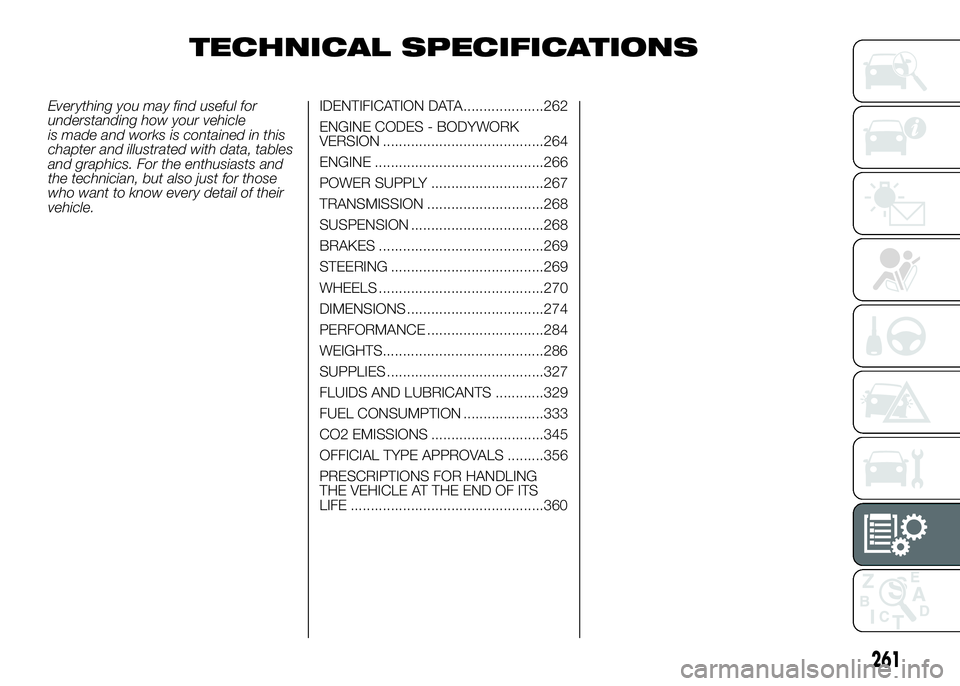

V.I.N. PLATE

This plate is fitted to the engine

compartment front crossmember and

contains the following data fig. 252:

BType-approval number.

CVehicle type identification code.

DChassis serial number.

EMaximum permitted weight of vehicle

fully laden.

FMaximum authorised weight of

vehicle fully laden plus trailer.

GMaximum permitted weight on first

(front) axle.

HMaximum authorised weight on

second axle (rear).

IEngine type.

LBodywork version code.

MSpare parts number.

NCorrect value of smoke coefficient

(for diesel engines)

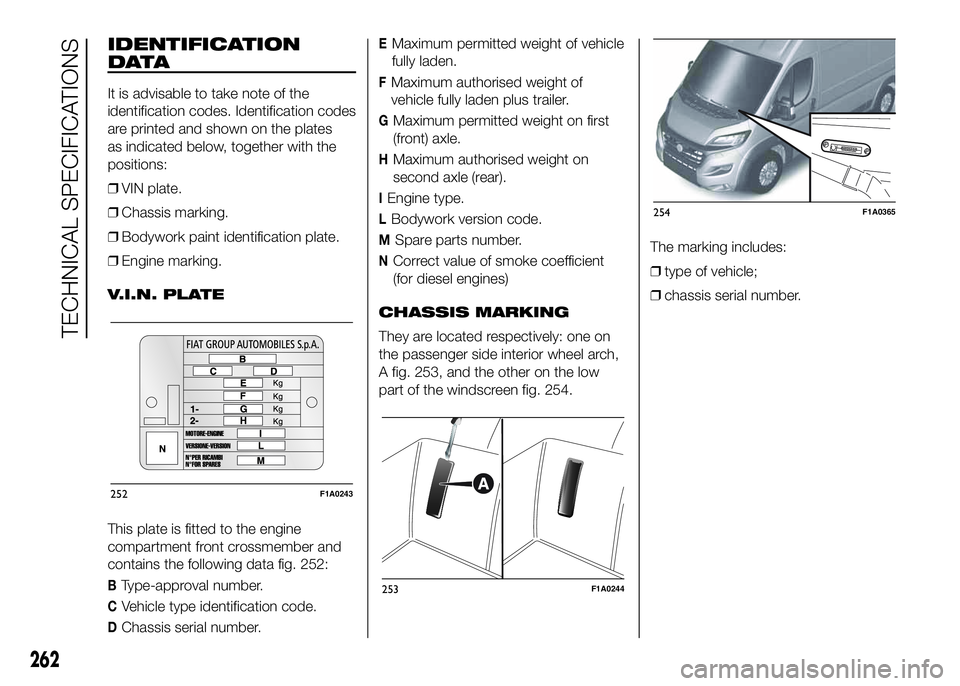

CHASSIS MARKING

They are located respectively: one on

the passenger side interior wheel arch,

A fig. 253, and the other on the low

part of the windscreen fig. 254.The marking includes:

❒type of vehicle;

❒chassis serial number.

252F1A0243

253F1A0244

254F1A0365

262

TECHNICAL SPECIFICATIONS