key FIAT DUCATO BASE CAMPER 2017 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2017Pages: 296, PDF Size: 14.44 MB

Page 142 of 296

Please note that the tow bar can be

installed only when in these conditions.

If the locking mechanism of the tow

bar is disengaged before the

installation, or at any other time, and is

in the locked position, it must be

pre-loaded. The locked position can be

identified by the green mark of the

flywheel coinciding with the green mark

of the tow bar and by the flywheel in

the stop position on the tow bar,

namely without slot (see figure).

The locking mechanism is pre-loaded

as follows: with the key inserted and

the lock open, extract the flywheel

following the direction of the arrow and,

to pre-load, rotate according to the

direction of the arrow b until the stop.

The release lever is engaged and the

locking mechanism remains in the

pre-loading position even when the

flywheel is released. The tow bar must

be inserted in the housing pipe with the

coupling pin for the installation. Insert

from the bottom and push upwards.

The mechanism then locks

automatically. Keep your hands far from

the flywheel, as it rotates during the

locking procedure.2. The tow bar must be inserted in the

housing pipe with the coupling pin

for the installation. Insert from the

bottom and push upwards. The

mechanism then locks automatically.

Keep your hands far from the flywheel,

as it rotates during the locking

procedure.

3. Close the lock and always remove

the key. The key cannot be removed

when the lock is released. Apply the

protection cap on the lock.

Removing the tow bar

1. Remove the protection cap from the

lock and press it on the key grip. Open

the lock with the key.

2. Hold the tow bar firmly, remove the

flywheel following the direction of the

arrow and rotate according to the

direction of the arrow b until stopping,

so as to remove till the extracted

position. Then remove the tow bar from

the housing pipe. The flywheel can

then be released; it autonomously

stops in the released position.

3. Arrange the tow bar in the luggage

compartment so that it cannot be

dirtied or damaged by other

transported objects.

4. Insert the suitable plug in the

mounting pipe.

WARNING

40)The removable ball head bar must be

repaired and taken apart by the

manufacturer only.

41)The accompanying plate must be in a

highly visible point of the vehicle, near

the mounting pipe or inside the luggage

compartment.

42)To ensure correct operation of the

system, periodically remove all dirt deposits

from the ball head bar and from the

mounting pipe. The mechanical

components must be serviced at the

specified intervals. The lock must only be

treated with graphite.

43)Periodically lubricate the joints, the

sliding surfaces and the balls with grease

without resin or oil. Lubrication is also a

further corrosion protection.

44)If the vehicle is washed with high-

pressure jets, the ball head bar must be

removed and the dedicated cap fitted. The

ball head bar must never be treated with

steam jets.

45)Two keys are supplied together with

the removable ball tow bar. Note down the

key number on the pawl for any following

order and keep it.

140

STARTING AND DRIVING

Page 143 of 296

PROLONGED

VEHICLE INACTIVITY

If the vehicle needs to be off the road

for longer than one month, the following

precautions must be taken:

park the vehicle indoors in a dry

and, if possible, well-ventilated place;

engage a gear;

check that the handbrake is not

engaged;

disconnect the negative battery

terminal; if the vehicle is equipped with

a battery disconnection function

(disconnector), see the description of

the procedure in the "Controls"

paragraph in the "Dashboard and

controls" section;

clean and protect the painted parts

using protective wax;

clean and protect the shiny metal

parts using special compounds

available commercially;

sprinkle talcum powder on the

windscreen and rear window wiper

rubber blades and lift them off the

glass;

slightly open the windows;

cover the vehicle with a piece of

fabric or perforated plastic sheet. Do

not use compact plastic tarpaulins,

which prevent humidity from

evaporating from the surface of the

vehicle;

inflate tyres to +0.5 bar above the

standard specified pressure and check

it at intervals;

do not drain the engine cooling

system.

IMPORTANT If the vehicle is equipped

with an alarm system, switch off the

vehicle alarm with the remote control.

IMPORTANT After turning the ignition

key to STOP and having closed the

driver side door, wait at least one

minute before disconnecting the

electrical supply from the battery. When

reconnecting the electrical supply to

the battery, make sure that the ignition

key is in the STOP position and the

driver side door is closed.

141

Page 157 of 296

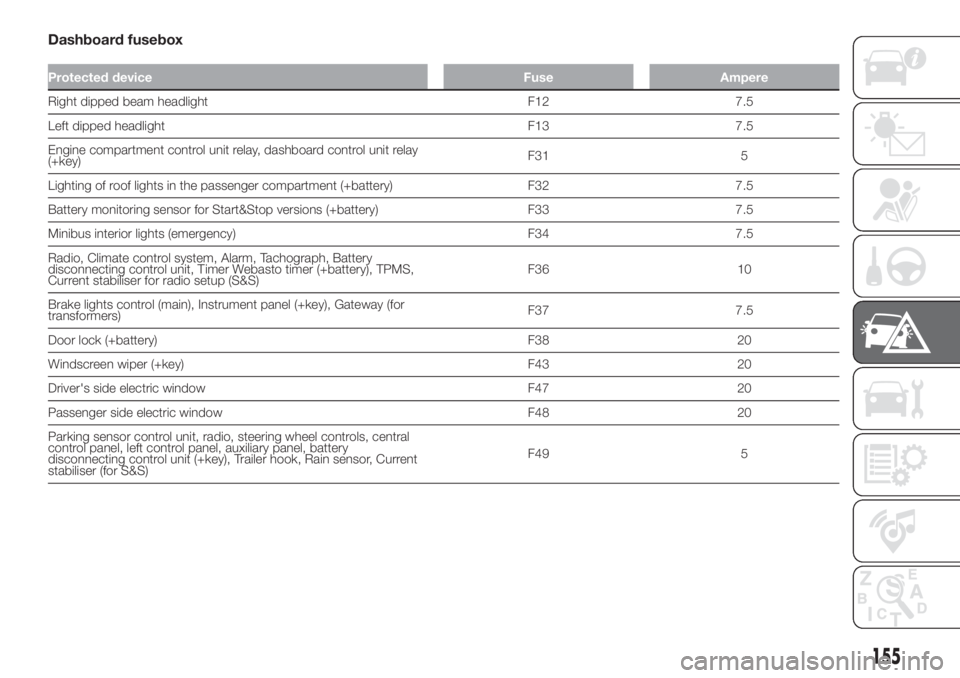

Dashboard fusebox

Protected device Fuse Ampere

Right dipped beam headlight F12 7.5

Left dipped headlight F13 7.5

Engine compartment control unit relay, dashboard control unit relay

(+key)F31 5

Lighting of roof lights in the passenger compartment (+battery) F32 7.5

Battery monitoring sensor for Start&Stop versions (+battery) F33 7.5

Minibus interior lights (emergency) F34 7.5

Radio, Climate control system, Alarm, Tachograph, Battery

disconnecting control unit, Timer Webasto timer (+battery), TPMS,

Current stabiliser for radio setup (S&S)F36 10

Brake lights control (main), Instrument panel (+key), Gateway (for

transformers)F37 7.5

Door lock (+battery) F38 20

Windscreen wiper (+key) F43 20

Driver's side electric window F47 20

Passenger side electric window F48 20

Parking sensor control unit, radio, steering wheel controls, central

control panel, left control panel, auxiliary panel, battery

disconnecting control unit (+key), Trailer hook, Rain sensor, Current

stabiliser (for S&S)F49 5

155

Page 158 of 296

Protected device Fuse Ampere

Climate control system, power steering control unit, reversing lights,

Tachograph (+key), TOM TOM setup, Lane Departure Warning, Rear

camera, Headlight alignment correctorF51 5

Instrument panel (+battery) F53 7.5

Not available F89 -

Left main beam headlight F90 7.5

Right main beam headlight F91 7.5

Left fog light F92 7.5

Right fog light F93 7.5

156

IN AN EMERGENCY

Page 159 of 296

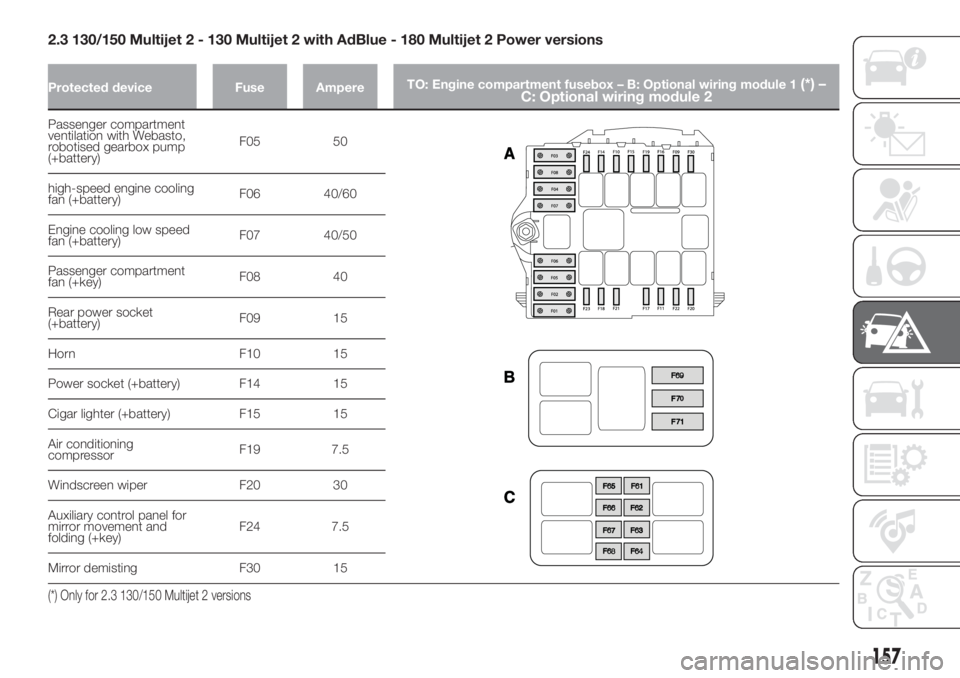

2.3 130/150 Multijet 2 - 130 Multijet 2 with AdBlue - 180 Multijet 2 Power versions

Protected device Fuse AmpereTO: Engine compartment fusebox – B: Optional wiring module 1(*) –

C: Optional wiring module 2

Passenger compartment

ventilation with Webasto,

robotised gearbox pump

(+battery)F05 50

high-speed engine cooling

fan (+battery)F06 40/60

Engine cooling low speed

fan (+battery)F07 40/50

Passenger compartment

fan (+key)F08 40

Rear power socket

(+battery)F09 15

Horn F10 15

Power socket (+battery) F14 15

Cigar lighter (+battery) F15 15

Air conditioning

compressorF19 7.5

Windscreen wiper F20 30

Auxiliary control panel for

mirror movement and

folding (+key)F24 7.5

Mirror demisting F30 15

(*) Only for 2.3 130/150 Multijet 2 versions

157

Page 161 of 296

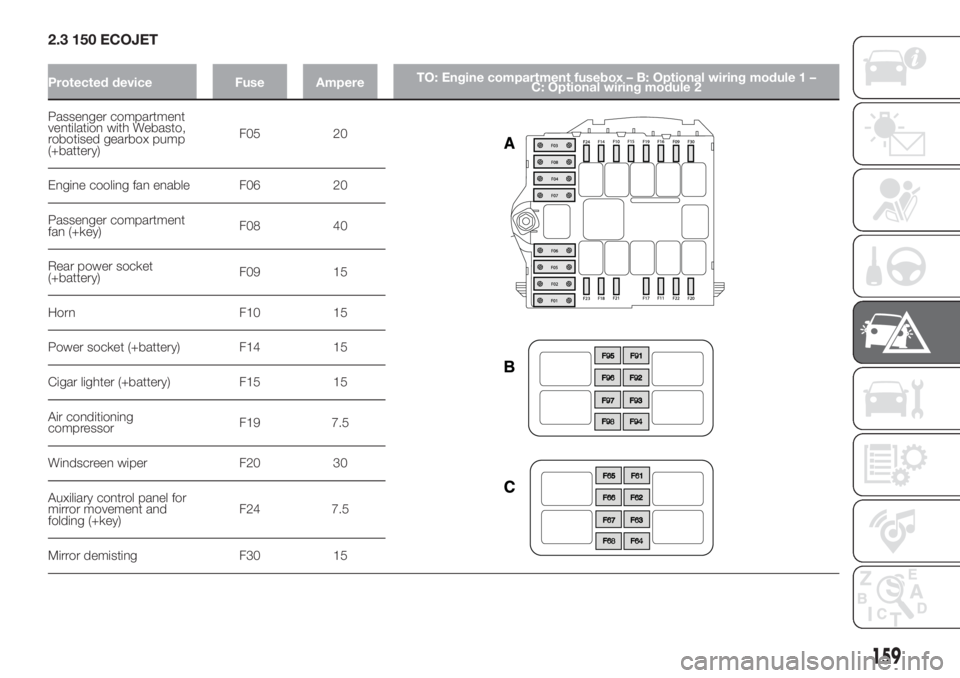

2.3 150 ECOJET

Protected device Fuse AmpereTO: Engine compartment fusebox – B: Optional wiring module 1 –

C: Optional wiring module 2

Passenger compartment

ventilation with Webasto,

robotised gearbox pump

(+battery)F05 20

Engine cooling fan enable F06 20

Passenger compartment

fan (+key)F08 40

Rear power socket

(+battery)F09 15

Horn F10 15

Power socket (+battery) F14 15

Cigar lighter (+battery) F15 15

Air conditioning

compressorF19 7.5

Windscreen wiper F20 30

Auxiliary control panel for

mirror movement and

folding (+key)F24 7.5

Mirror demisting F30 15

159

Page 163 of 296

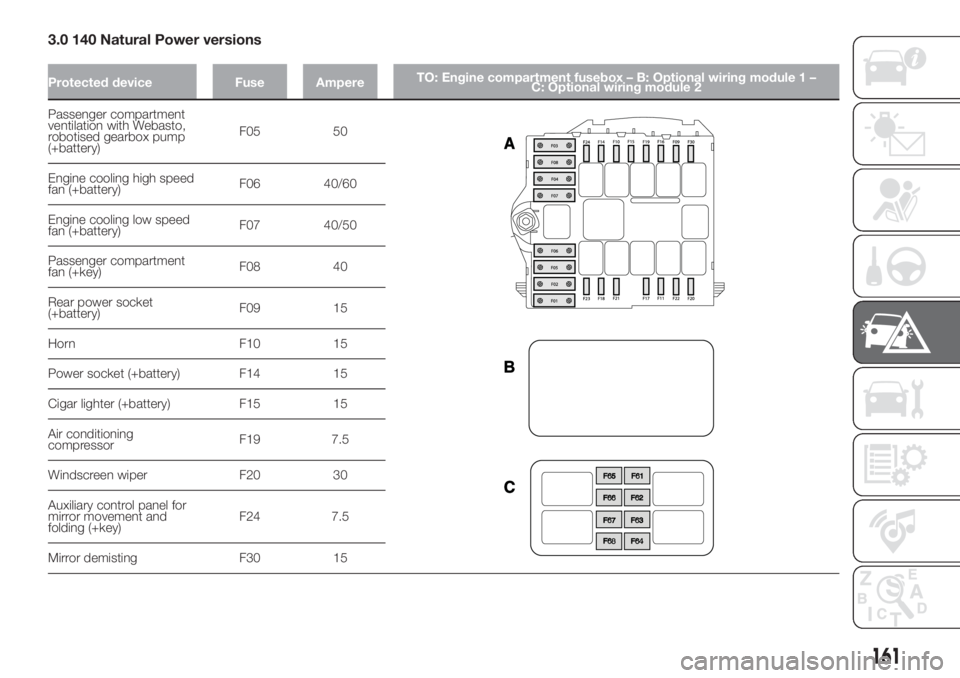

3.0 140 Natural Power versions

Protected device Fuse AmpereTO: Engine compartment fusebox – B: Optional wiring module 1 –

C: Optional wiring module 2

Passenger compartment

ventilation with Webasto,

robotised gearbox pump

(+battery)F05 50

Engine cooling high speed

fan (+battery)F06 40/60

Engine cooling low speed

fan (+battery)F07 40/50

Passenger compartment

fan (+key)F08 40

Rear power socket

(+battery)F09 15

Horn F10 15

Power socket (+battery) F14 15

Cigar lighter (+battery) F15 15

Air conditioning

compressorF19 7.5

Windscreen wiper F20 30

Auxiliary control panel for

mirror movement and

folding (+key)F24 7.5

Mirror demisting F30 15

161

Page 166 of 296

WARNING

141)Never replace a fuse with another with a higher amp rating; RISK OF FIRE. If a general protection fuse (MEGA-FUSE, MIDI-FUSE) is

activated, contact a Fiat Dealership.

142)Before replacing a fuse, make sure that the ignition key has been removed and that all the other services are switched off and/or

disengaged.

143)If the replaced fuse blows again, contact a Fiat Dealership.

144)Contact Fiat Dealership if a safety system (airbags, brakes), engine system (engine, gearbox) or steering system general protection fuse

blows.

WARNING

47)Never replace a faulty fuse with metal wires or anything else.

164

IN AN EMERGENCY

Page 175 of 296

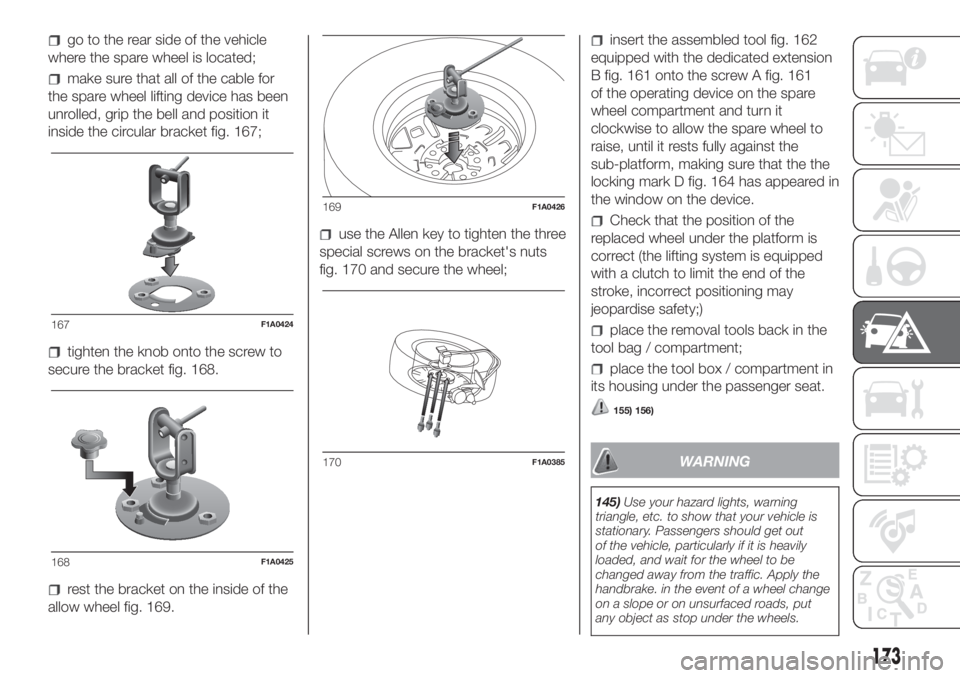

go to the rear side of the vehicle

where the spare wheel is located;

make sure that all of the cable for

the spare wheel lifting device has been

unrolled, grip the bell and position it

inside the circular bracket fig. 167;

tighten the knob onto the screw to

secure the bracket fig. 168.

rest the bracket on the inside of the

allow wheel fig. 169.

use the Allen key to tighten the three

special screws on the bracket's nuts

fig. 170 and secure the wheel;

insert the assembled tool fig. 162

equipped with the dedicated extension

B fig. 161 onto the screw A fig. 161

of the operating device on the spare

wheel compartment and turn it

clockwise to allow the spare wheel to

raise, until it rests fully against the

sub-platform, making sure that the the

locking mark D fig. 164 has appeared in

the window on the device.

Check that the position of the

replaced wheel under the platform is

correct (the lifting system is equipped

with a clutch to limit the end of the

stroke, incorrect positioning may

jeopardise safety;)

place the removal tools back in the

tool bag / compartment;

place the tool box / compartment in

its housing under the passenger seat.

155) 156)

WARNING

145)Use your hazard lights, warning

triangle, etc. to show that your vehicle is

stationary. Passengers should get out

of the vehicle, particularly if it is heavily

loaded, and wait for the wheel to be

changed away from the traffic. Apply the

handbrake. in the event of a wheel change

on a slope or on unsurfaced roads, put

any object as stop under the wheels.

167F1A0424

168F1A0425

169F1A0426

170F1A0385

173

Page 181 of 296

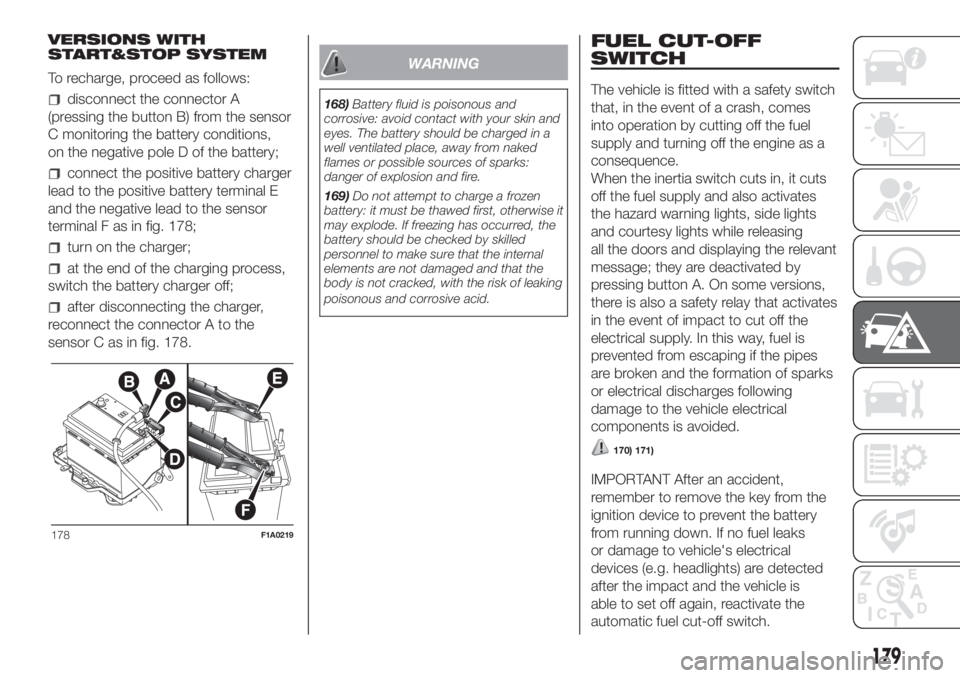

VERSIONS WITH

START&STOP SYSTEM

To recharge, proceed as follows:

disconnect the connector A

(pressing the button B) from the sensor

C monitoring the battery conditions,

on the negative pole D of the battery;

connect the positive battery charger

lead to the positive battery terminal E

and the negative lead to the sensor

terminal F as in fig. 178;

turn on the charger;

at the end of the charging process,

switch the battery charger off;

after disconnecting the charger,

reconnect the connector A to the

sensor C as in fig. 178.

WARNING

168)Battery fluid is poisonous and

corrosive: avoid contact with your skin and

eyes. The battery should be charged in a

well ventilated place, away from naked

flames or possible sources of sparks:

danger of explosion and fire.

169)Do not attempt to charge a frozen

battery: it must be thawed first, otherwise it

may explode. If freezing has occurred, the

battery should be checked by skilled

personnel to make sure that the internal

elements are not damaged and that the

body is not cracked, with the risk of leaking

poisonous and corrosive acid.

FUEL CUT-OFF

SWITCH

The vehicle is fitted with a safety switch

that, in the event of a crash, comes

into operation by cutting off the fuel

supply and turning off the engine as a

consequence.

When the inertia switch cuts in, it cuts

off the fuel supply and also activates

the hazard warning lights, side lights

and courtesy lights while releasing

all the doors and displaying the relevant

message; they are deactivated by

pressing button A. On some versions,

there is also a safety relay that activates

in the event of impact to cut off the

electrical supply. In this way, fuel is

prevented from escaping if the pipes

are broken and the formation of sparks

or electrical discharges following

damage to the vehicle electrical

components is avoided.

170) 171)

IMPORTANT After an accident,

remember to remove the key from the

ignition device to prevent the battery

from running down. If no fuel leaks

or damage to vehicle's electrical

devices (e.g. headlights) are detected

after the impact and the vehicle is

able to set off again, reactivate the

automatic fuel cut-off switch.

178F1A0219

179