suspension FIAT DUCATO BASE CAMPER 2017 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2017Pages: 296, PDF Size: 14.44 MB

Page 9 of 296

KNOWING YOUR VEHICLE

In-depth knowledge of your new vehicle

starts here.

The booklet that you are reading simply

and directly explains how it is made

and how it works.

That’s why we advise you to read it

seated comfortably on board, so that

you can see what is described here for

yourself.SYMBOLS ...................................... 8

THE FIAT CODE SYSTEM ............... 8

THE KEYS....................................... 9

IGNITION SWITCH .......................... 10

ELECTRONIC ALARM..................... 11

DOORS ........................................... 12

SEATS ............................................ 16

STEERING WHEEL ......................... 21

REAR VIEW MIRRORS .................... 22

EXTERNAL LIGHTS......................... 24

HEADLIGHTS.................................. 27

ROOF LIGHTS ................................ 28

CONTROLS .................................... 29

WINDOW WASHING ....................... 32

HEATING AND VENTILATION.......... 34

HEATING AND VENTILATION

CONTROLS .................................... 35

MANUAL CLIMATE CONTROL

SYSTEM ......................................... 35

AUTOMATIC CLIMATE CONTROL

SYSTEM ......................................... 36

ADDITIONAL HEATER ..................... 37

INDEPENDENT ADDITIONAL

HEATER .......................................... 38

ELECTRIC WINDOWS .................... 41

BONNET ......................................... 42

HEAD RESTRAINTS ........................ 43

INTERIOR FITTINGS ...................... 44TACHOGRAPH ............................... 45

SELF-LEVELLING AIR

SUSPENSION ................................. 45

7

Page 47 of 296

TACHOGRAPH

For tachograph operation and use,

consult the owner handbook supplied

by the device manufacturer. The

tachograph must be installed on the

vehicle when the vehicle weight (with or

without trailer) exceeds 3.5 tons.

IMPORTANT Anyone making changes

to the monitoring device or signal

transmission system that affects

recording by the monitoring instrument,

particularly if this is done for purposes

of fraud, may be in breach of criminal or

administrative state regulations.

IMPORTANT If a tachograph is fitted, if

the vehicle is parked for more than 5

days, it is advisable to disconnect

the negative battery terminal to

maintain its charge.

IMPORTANT INFORMATION

Do not use abrasive detergents or

solvents to clean the device. To clean

the outside of the device, use a damp

cloth or special products for the care of

synthetic materials.The tachograph is installed and sealed

by authorised personnel: do not try

and access the device or the supply

and recording leads in any way. It is the

responsibility of the owner of the vehicle

on which the tachograph is installed to

check the device regularly.

The check must be carried out at least

every two years and a test must be

carried out to ensure that it is working

properly. Ensure that the data label

is renewed after every check and that

the label contains the specified data.

SELF-LEVELLING AIR

SUSPENSION

GENERAL INFORMATION

The system only acts on the rear

wheels.

The system maintains the rear ride

setting for the vehicle constant in any

loading condition, while ensuring a

greater driving comfort.

HEIGHT ADJUSTMENT

There are 7 pre-defined levels for the

free height from the ground: from “ride

-3” to “ride 0” till “ride +3”.

Automatic adjustment

When moving, the system automatically

shows that the vehicle is in 'ride setting

0' and keeps it constant.

While adjusting, the LED located on the

button (A or B fig. 74) corresponding

to the direction of travel, flashes.

Manual adjustment

5)

With the vehicle stationary and the

engine on or off, the desired height level

can be set.

45

Page 49 of 296

KNOWING THE INSTRUMENT PANEL

This section of the booklet gives you all

the information you need to

understand, interpret and use the

instrument panel correctly.EOBD SYSTEM............................... 49

CONTROL PANEL AND

ON-BOARD INSTRUMENTS ........... 50

DISPLAY ........................................ 52

TRIP COMPUTER ........................... 54

WARNING LIGHTS AND

MESSAGES .................................... 56

- LOW BRAKE FLUID/HANDBRAKE

APPLIED ............................................ 56

- EBD FAILURE .................................. 57

- AIR BAG FAILURE ............................ 57

- SEAT BELTS REMINDER .................. 57

- ENGINE COOLANT TEMPERATURE

TOO HIGH .......................................... 58

- LOW BATTERY CHARGE ................. 59

- LOW ENGINE OIL PRESSURE ......... 60

-ENGINE OIL DETERIORATED ........... 60

-INCOMPLETE DOOR/LOAD

COMPARTMENT CLOSURE ............... 61

-POWER STEERING FAILURE ............ 61

- SELF-LEVELLING SUSPENSION

FAILURE ............................................. 61

- EOBD/INJECTION SYSTEM

FAILURE ............................................. 63

-UREA INJECTION SYSTEM FAILURE

............................................................ 64

-ABS FAILURE .................................... 64

- FUEL RESERVE ............................... 64

-GLOW PLUG PREHEATING / GLOW

PLUG PREHEATING FAILURE ............ 65

-LOW DIESEL EMISSIONS ADDITIVE

(UREA) LEVEL WARNING ................... 65

-VEHICLE PROTECTION SYSTEM

FAILURE - FIAT CODE ........................ 66

-REAR FOG LIGHTS ........................... 66

- GENERAL FAILURE WARNING ........ 67-DPF (PARTICULATE FILTER)

CLEANING UNDERWAY ..................... 68

- BRAKE PAD WEAR .......................... 68

-DRIVING ADVISOR ........................... 69

- TPMS ............................................... 70

-DIPPED BEAM HEADLIGHTS ........... 71

-FOLLOW ME HOME ......................... 71

- LEFT DIRECTION INDICATOR .......... 71

- RIGHT DIRECTION INDICATOR ....... 71

- FOG LIGHTS .................................... 72

- CRUISE CONTROL .......................... 72

- SPEED LIMITER ............................... 72

- AUTOMATIC MAIN BEAM

HEADLIGHTS ..................................... 72

- MAIN BEAM HEADLIGHTS .............. 72

-"UP" FUNCTION ............................... 73

-EXTERIOR LIGHTS FAILURE ............. 74

-LOW ENGINE OIL PRESSURE

WARNING LIGHT FAILURE ................. 74

-BRAKE LIGHTS FAILURE .................. 74

-MAIN BEAM AUTOMATISM FAULT ... 74

-POSSIBLE ICE ON ROAD ................. 75

-SPEED LIMIT EXCEEDED ................. 75

-SCHEDULED SERVICING ................. 75

-FUEL CUT-OFF DEVICE INERTIA

SWITCH TRIPPED .............................. 76

-COMFORT-MATIC SYSTEM FAILURE

INDICATION ........................................ 76

-PARKING SENSOR FAILURE ............ 76

-DRIVING ADVISOR SYSTEM

FAILURE ............................................. 76

-TRAFFIC SIGN RECOGNITION

FAILURE ............................................. 76

-LIMITED RANGE ............................... 76

-START&STOP SYSTEM

ACTIVATION/DEACTIVATION .............. 77

-START&STOP FAILURE .................... 77

47

Page 63 of 296

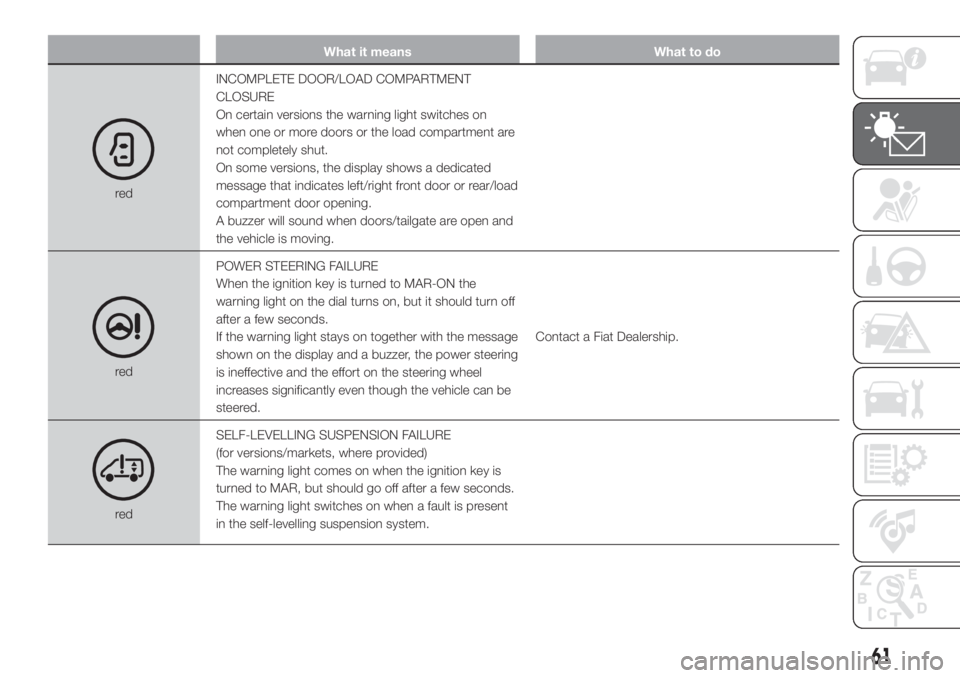

What it means What to do

redINCOMPLETE DOOR/LOAD COMPARTMENT

CLOSURE

On certain versions the warning light switches on

when one or more doors or the load compartment are

not completely shut.

On some versions, the display shows a dedicated

message that indicates left/right front door or rear/load

compartment door opening.

A buzzer will sound when doors/tailgate are open and

the vehicle is moving.

redPOWER STEERING FAILURE

When the ignition key is turned to MAR-ON the

warning light on the dial turns on, but it should turn off

after a few seconds.

If the warning light stays on together with the message

shown on the display and a buzzer, the power steering

is ineffective and the effort on the steering wheel

increases significantly even though the vehicle can be

steered.Contact a Fiat Dealership.

redSELF-LEVELLING SUSPENSION FAILURE

(for versions/markets, where provided)

The warning light comes on when the ignition key is

turned to MAR, but should go off after a few seconds.

The warning light switches on when a fault is present

in the self-levelling suspension system.

61

Page 118 of 296

16)If the engine fails to start with a gear

engaged, the potentially dangerous

situation due to the fact that the

transmission is automatically placed in

neutral will be signalled by a buzzer.

17)If the warning light

flashes for 60

seconds after starting or during an

extended towing period, this indicates a

problem in the glow plug preheating

system. Use the vehicle normally if the

engine starts, but contact a Fiat Dealership

as soon as possible.

18)Remember that the brake servo and

power steering are not operational until the

engine has been started, so you need to

apply much more force than usual to

the brake pedal and steering wheel.

19)Never bump start the engine by

pushing, towing or coasting downhill. This

could cause fuel to flow into the catalytic

converter and damage it beyond repair.

20)A quick burst on the accelerator before

stopping the engine serves no practical

purpose; it wastes fuel and is especially

damaging to turbocharged engines.

21)In some cases, when the engine

switches off, the fan could activate for max.

120 seconds.

WHEN PARKED

116)

22)

Proceed as follows when parking and

leaving the vehicle:

engage the gear (on a slope, engage

first gear if the vehicle is facing uphill

or reverse if it is facing downhill) and

leave the wheels steered;

stop the engine and engage the

handbrake;

always remove the ignition key.

If the vehicle is parked on a steep

slope, it is advisable to block the

wheels with a wedge or stone.

On versions equipped with automatic

transmission (Comfort matic), wait

for the letterPto appear on the display

before releasing the brake pedal.

IMPORTANTNEVERleave the vehicle

with the gearbox in neutral (or, on

versions equipped with automatic

(Comfort matic) transmission, before

putting the shift lever in thePposition).HANDBRAKE

Handbrake engagement:The

handbrake lever is located to the left of

the driver's seat. Pull the lever upwards

to engage the handbrake and ensure

that the vehicle does not move.

Handbrake disengagement:slightly

raise the lever, hold the button A

pressed and check that the

warning light switches off on the

instrument panel.

Press the brake pedal when carrying

out this operation to prevent the vehicle

from moving accidentally.

WARNING

116)Never leave children unattended in

the vehicle. Always remove the ignition key

when leaving the vehicle and take it out

with you.

WARNING

22)If the vehicle is equipped with

self-levelling air suspension, always check

that there is sufficient space above the roof

and around the vehicle when parking.

Indeed, the vehicle could raise (or lower)

automatically depending on load or

temperature changes.

116

STARTING AND DRIVING

Page 125 of 296

Reduced sensor sensitivity and a

reduction in the parking assistance

system performance could be due to

the presence on the surface of the

sensor of: ice, snow, mud, thick paint.

The sensor may detect a non-

existent obstacle (echo noise) due to

mechanical noises, for example when

washing the vehicle, in case of rain,

strong wind, hail.

The warnings sent by the sensor

can also be altered by the presence of

ultrasonic systems (e.g. pneumatic

brakes of trucks or pneumatic drills)

near the car.

The performance of the parking

assistance system may also be affected

by the position of the sensors. For

example by a change in the ride setting

(caused by the wear of the shock

absorbers, suspension), changing the

tyres, overloading the vehicle and

carrying out specific tuning operations

that require the vehicle to be lowered.

Detection of obstacles in the upper

part of the vehicle (particularly in the

case of vans or chassis cabs) may not

be guaranteed because the system

detects obstacles that could strike the

lower part of the vehicle.

WARNING

122)The driver is always responsible for

parking and other dangerous manoeuvres.

While carrying out these manoeuvres,

always make sure that no people

(especially children) or animals are in the

area concerned. The parking sensors

are used to assist the driver, who must

never allow his attention to lapse during

potentially dangerous manoeuvres, even

those executed at low speeds.

WARNING

25)For correct operation of the system,

sensors must always be clean from mud,

dirt, snow or ice. Be careful not to scratch

or damage the sensors while cleaning

them. Avoid using dry, rough or hard

cloths. The sensors must be washed using

clean water, with the addition of vehicle

shampoo if necessary.

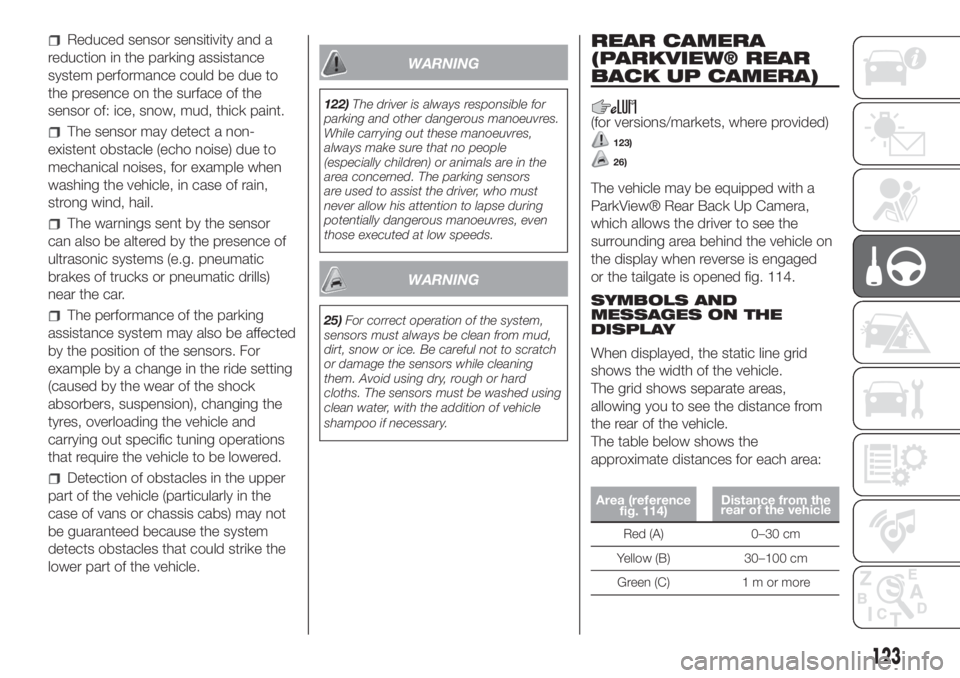

REAR CAMERA

(PARKVIEW® REAR

BACK UP CAMERA)

(for versions/markets, where provided)

123)

26)

The vehicle may be equipped with a

ParkView® Rear Back Up Camera,

which allows the driver to see the

surrounding area behind the vehicle on

the display when reverse is engaged

or the tailgate is opened fig. 114.

SYMBOLS AND

MESSAGES ON THE

DISPLAY

When displayed, the static line grid

shows the width of the vehicle.

The grid shows separate areas,

allowing you to see the distance from

the rear of the vehicle.

The table below shows the

approximate distances for each area:

Area (reference

fig. 114)Distance from the

rear of the vehicle

Red (A) 0–30 cm

Yellow (B) 30–100 cm

Green (C) 1 m or more

123

Page 127 of 296

WARNING

124)If the camera loses its position due to

a load variation, the system may not work

temporarily to allow the camera to perform

an auto-calibration.

125)The system only detects the preset

traffic signs. If the minimum visibility

conditions and distance from the sign are

met it can detect all traffic signs.

126)The system is a driving assistance

system but it does not relieve the driver of

the responsibility of driving with due

attention and diligence in compliance with

the laws in force.

127)When the system is active, the driver

is responsible for controlling the vehicle

and monitoring the system, and must

intervene as appropriate if necessary.

WARNING

27)In the event of errors the system may

not work.

28)At low temperatures and in particularly

adverse weather conditions, the system

may not work.

29)Rain, snow, splashes and strong light

contrast may influence the sensor.

30)Do not repair the area of the

windscreen directly surrounding the sensor.

31)If the vehicle is equipped with a

non-genuine suspension kit, the system

may not work correctly.

32)Always use genuine spare parts when

replacing the bulbs of the headlights. Other

bulbs may reduce the system

performance.

33)Clean the windscreen from foreign

matters such as bird droppings, insects,

snow or ice.

REFUELLING THE

VEHICLE

IN BRIEF

Stop the engine before refuelling.

PETROL ENGINES

Only use petrol with an octane number

(RON) no lower than 95 (EN228

specification).

DIESEL ENGINES

Refuel the vehicle exclusively with diesel

for motor vehicles in compliance with

European specification EN590.

OPERATION AT LOW

TEMPERATURES

When using or parking the vehicle for a

long time in the mountains or cold

areas, it is advisable to refuel using

locally available diesel fuel. In this case,

it is also advisable to keep the tank

over 50% full.

34)

100

115F1A0373

125

Page 171 of 296

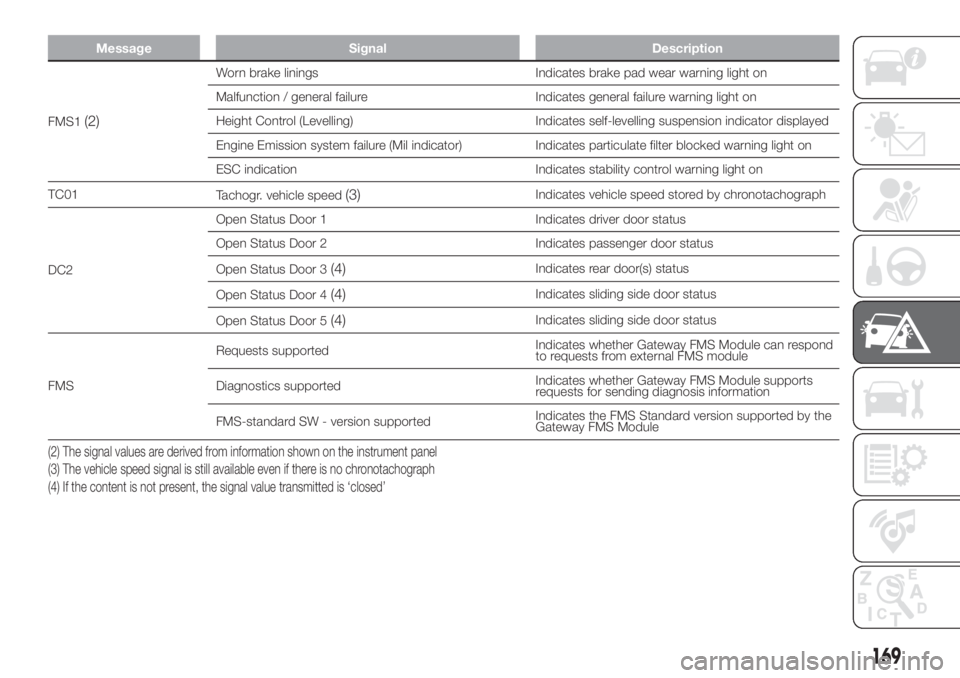

Message Signal Description

FMS1(2)

Worn brake linings Indicates brake pad wear warning light on

Malfunction / general failure Indicates general failure warning light on

Height Control (Levelling) Indicates self-levelling suspension indicator displayed

Engine Emission system failure (Mil indicator) Indicates particulate filter blocked warning light on

ESC indication Indicates stability control warning light on

TC01

Tachogr. vehicle speed

(3)Indicates vehicle speed stored by chronotachograph

DC2Open Status Door 1 Indicates driver door status

Open Status Door 2 Indicates passenger door status

Open Status Door 3

(4)Indicates rear door(s) status

Open Status Door 4

(4)Indicates sliding side door status

Open Status Door 5

(4)Indicates sliding side door status

FMSRequests supportedIndicates whether Gateway FMS Module can respond

to requests from external FMS module

Diagnostics supportedIndicates whether Gateway FMS Module supports

requests for sending diagnosis information

FMS-standard SW - version supportedIndicates the FMS Standard version supported by the

Gateway FMS Module

(2) The signal values are derived from information shown on the instrument panel

(3) The vehicle speed signal is still available even if there is no chronotachograph

(4) If the content is not present, the signal value transmitted is ‘closed’

169

Page 173 of 296

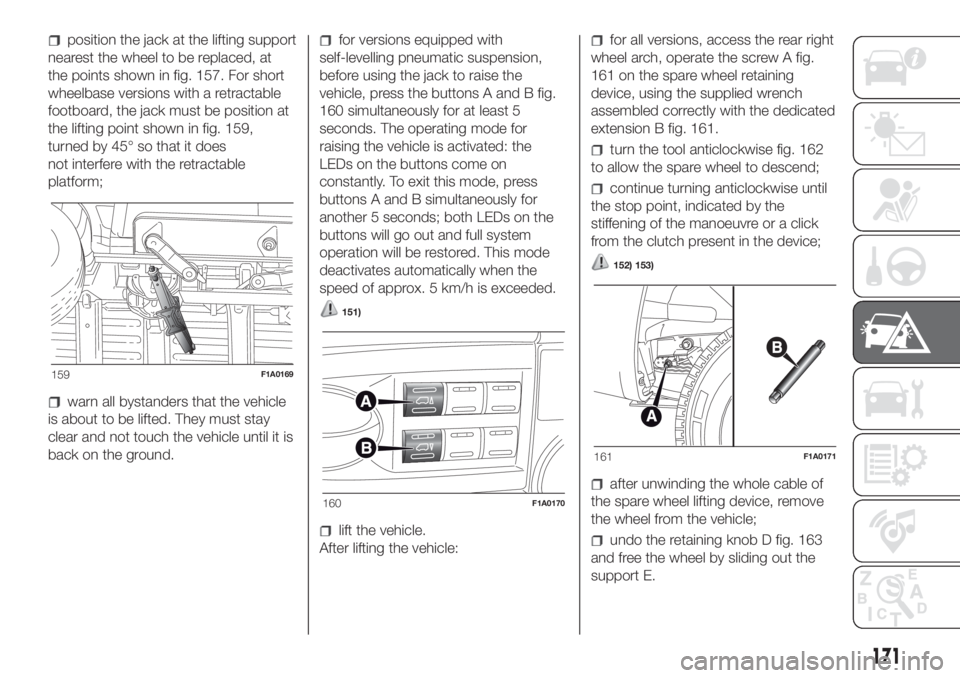

position the jack at the lifting support

nearest the wheel to be replaced, at

the points shown in fig. 157. For short

wheelbase versions with a retractable

footboard, the jack must be position at

the lifting point shown in fig. 159,

turned by 45° so that it does

not interfere with the retractable

platform;

warn all bystanders that the vehicle

is about to be lifted. They must stay

clear and not touch the vehicle until it is

back on the ground.

for versions equipped with

self-levelling pneumatic suspension,

before using the jack to raise the

vehicle, press the buttons A and B fig.

160 simultaneously for at least 5

seconds. The operating mode for

raising the vehicle is activated: the

LEDs on the buttons come on

constantly. To exit this mode, press

buttons A and B simultaneously for

another 5 seconds; both LEDs on the

buttons will go out and full system

operation will be restored. This mode

deactivates automatically when the

speed of approx. 5 km/h is exceeded.

151)

lift the vehicle.

After lifting the vehicle:

for all versions, access the rear right

wheel arch, operate the screw A fig.

161 on the spare wheel retaining

device, using the supplied wrench

assembled correctly with the dedicated

extension B fig. 161.

turn the tool anticlockwise fig. 162

to allow the spare wheel to descend;

continue turning anticlockwise until

the stop point, indicated by the

stiffening of the manoeuvre or a click

from the clutch present in the device;

152) 153)

after unwinding the whole cable of

the spare wheel lifting device, remove

the wheel from the vehicle;

undo the retaining knob D fig. 163

and free the wheel by sliding out the

support E.

159F1A0169

160F1A0170

161F1A0171

171

Page 176 of 296

146)The spare wheel supplied (for

versions/markets, where provided) is

specific for your vehicle. Therefore, it must

not be used on other models. Do not

use spare wheels of other models on your

vehicle. The wheel bolts are specific for

your vehicle: do not use them on different

models and do not use bolts from other

models on your car.

147)Repair and refit the standard wheel as

soon as possible. Do not apply grease to

the bolt threads before fitting: they could

come unscrewed.

148)Use the jack only to replace wheels

on the vehicle with which it is supplied

or on other vehicles of the same model.

Never use the jack for other purposes,

such as lifting other vehicle models. Never

use the jack to carry out repairs under

the vehicle. Incorrect positioning of the jack

may cause the lifted vehicle to fall. Do not

use the jack for loads higher than the

one shown on its label.

149)Never tamper with the inflation valve.

Never introduce tools of any kind between

rim and tyre. Check tyre and spare wheel

pressure regularly, referring to the values

shown in the "Technical specifications"

section.

150)No tools other than the crank

provided should be used with the spare

wheel lifting device; it should be operated

by hand only.

151)On versions equipped with self-

levelling air suspension, never introduce the

head or hands in the wheel arch: the

vehicle could raise or lower automatically

depending on possible load or temperature

changes.152)The device should only be operated

by hand, without using any type of tool

other than the crank provided like

pneumatic or electrical screwers.

153)The moving components of the jack

(screws and joints) can also cause injuries:

avoid touching them. If you come into

contact with lubricating grease, clean

yourself thoroughly.

154)At the end of the operation of

raising/locking the spare wheel, after

checking that the wheel is positioned

correctly under the platform (yellow notch

inside the window on the device), extract

the operating wrench. Take care not to turn

the wrench in the wrong direction (as in

fig. 166) to facilitate extracting it, to prevent

the attachment device from being

released and to ensure that the wheel

assembly remains safely fastened.

155)Each time the spare wheel is moved,

check that it is correctly positioned in its

housing under the platform. If it is not

correctly positioned, this could adversely

affect safety.

156)The spare wheel lifting device is

equipped with a clutch safety system for its

own protection; this could activated if an

excessive load is applied on the

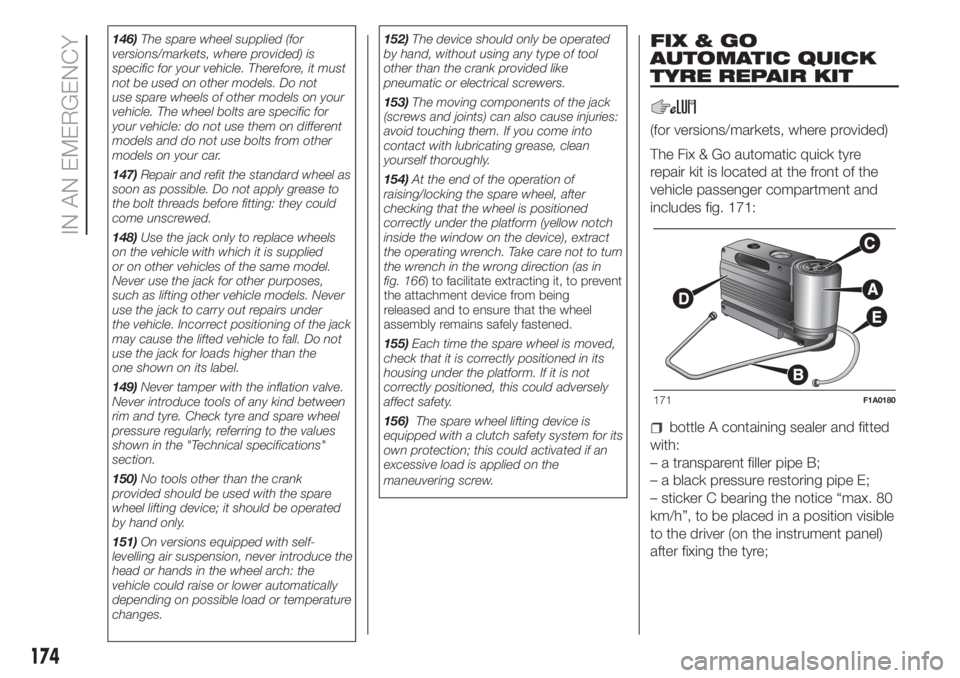

maneuvering screw.FIX & GO

AUTOMATIC QUICK

TYRE REPAIR KIT

(for versions/markets, where provided)

The Fix & Go automatic quick tyre

repair kit is located at the front of the

vehicle passenger compartment and

includes fig. 171:

bottle A containing sealer and fitted

with:

– a transparent filler pipe B;

– a black pressure restoring pipe E;

– sticker C bearing the notice “max. 80

km/h”, to be placed in a position visible

to the driver (on the instrument panel)

after fixing the tyre;

171F1A0180

174

IN AN EMERGENCY