technical specifications FIAT DUCATO BASE CAMPER 2017 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: DUCATO BASE CAMPER, Model: FIAT DUCATO BASE CAMPER 2017Pages: 296, PDF Size: 14.44 MB

Page 3 of 296

Dear Customer,

We would like to congratulate and thank you for choosing a Fiat Ducato.

We have written this handbook to help you get to know all the features of your vehicle and use it in the best possible way.

Here you will find information, advice and important warnings regarding vehicle use and how to achieve the best performance from the

technical features of your Fiat Ducato.

You are advised to read it right through before taking to the road for the first time, to become familiar with the controls and above all

with those concerning brakes, steering and transmission; at the same time, you can understand the vehicle behaviour on different road

surfaces.

This document also provides a description of special features and tips, as well as essential information for the safe driving, care and

servicing of your Fiat Ducato over time.

After reading it, you are advised to keep the handbook inside the vehicle, for an easy reference and for making sure it remains on

board the vehicle should it be sold.

In the attached Warranty Booklet you will also find a description of the Services that Fiat offers to its customers, the Warranty

Certificate and the detail of the terms and conditions for maintaining its validity.

We are sure that these will help you to get in touch with and appreciate your new vehicle and the service provided by the people at

Fiat.

Enjoy reading. Happy motoring!

IMPORTANT

This Owner Handbook describes all Fiat Ducato versions. As a consequence, you should only consider the information

related to the trim level, engine and version that you have purchased. All data contained in this publication are purely

indicative. FCA Italy S.p.A. can modify the specifications of the vehicle model described in this publication at any time, for

technical or marketing purposes. For further information, contact a Fiat Dealership.

Page 145 of 296

REPLACING A BULB

GENERAL

INSTRUCTIONS

139) 140)

46)

When a light is not working, check

that the corresponding fuse is intact

before changing a bulb. For the location

of fuses, refer to the paragraph

"Replacing fuses" in this chapter.

before changing a bulb check the

contacts for oxidation;

burnt bulbs must be replaced by

others of the same type and power;

always check the headlight beam

direction after changing a bulb;

IMPORTANT A slight misting may

appear on the internal surface of the

headlight: this does not indicate a fault

and is caused by low temperature

and the degree of humidity in the air.

Misting will rapidly disappear when the

headlights are switched on. The

presence of drops inside the headlights

indicates infiltration of water. Contact

a Fiat Dealership.

WARNING

139)Modifications or repairs to the

electric system that are not carried out

properly or do not take the system

technical specifications into account can

cause malfunctions leading to the risk

of fire.

140)Halogen bulbs contain pressurised

gas, in the case of breakage they may

burst causing glass fragments to be

projected outwards.

WARNING

46)Halogen bulbs must be handled

holding the metallic part only. Touching the

transparent part of the bulb with your

fingers may reduce the intensity of the

emitted light and even reduce the lifespan

of the bulb. In the event of accidental

contact, wipe the bulb with a cloth

moistened with alcohol and let the bulb

dry.

143

Page 176 of 296

146)The spare wheel supplied (for

versions/markets, where provided) is

specific for your vehicle. Therefore, it must

not be used on other models. Do not

use spare wheels of other models on your

vehicle. The wheel bolts are specific for

your vehicle: do not use them on different

models and do not use bolts from other

models on your car.

147)Repair and refit the standard wheel as

soon as possible. Do not apply grease to

the bolt threads before fitting: they could

come unscrewed.

148)Use the jack only to replace wheels

on the vehicle with which it is supplied

or on other vehicles of the same model.

Never use the jack for other purposes,

such as lifting other vehicle models. Never

use the jack to carry out repairs under

the vehicle. Incorrect positioning of the jack

may cause the lifted vehicle to fall. Do not

use the jack for loads higher than the

one shown on its label.

149)Never tamper with the inflation valve.

Never introduce tools of any kind between

rim and tyre. Check tyre and spare wheel

pressure regularly, referring to the values

shown in the "Technical specifications"

section.

150)No tools other than the crank

provided should be used with the spare

wheel lifting device; it should be operated

by hand only.

151)On versions equipped with self-

levelling air suspension, never introduce the

head or hands in the wheel arch: the

vehicle could raise or lower automatically

depending on possible load or temperature

changes.152)The device should only be operated

by hand, without using any type of tool

other than the crank provided like

pneumatic or electrical screwers.

153)The moving components of the jack

(screws and joints) can also cause injuries:

avoid touching them. If you come into

contact with lubricating grease, clean

yourself thoroughly.

154)At the end of the operation of

raising/locking the spare wheel, after

checking that the wheel is positioned

correctly under the platform (yellow notch

inside the window on the device), extract

the operating wrench. Take care not to turn

the wrench in the wrong direction (as in

fig. 166) to facilitate extracting it, to prevent

the attachment device from being

released and to ensure that the wheel

assembly remains safely fastened.

155)Each time the spare wheel is moved,

check that it is correctly positioned in its

housing under the platform. If it is not

correctly positioned, this could adversely

affect safety.

156)The spare wheel lifting device is

equipped with a clutch safety system for its

own protection; this could activated if an

excessive load is applied on the

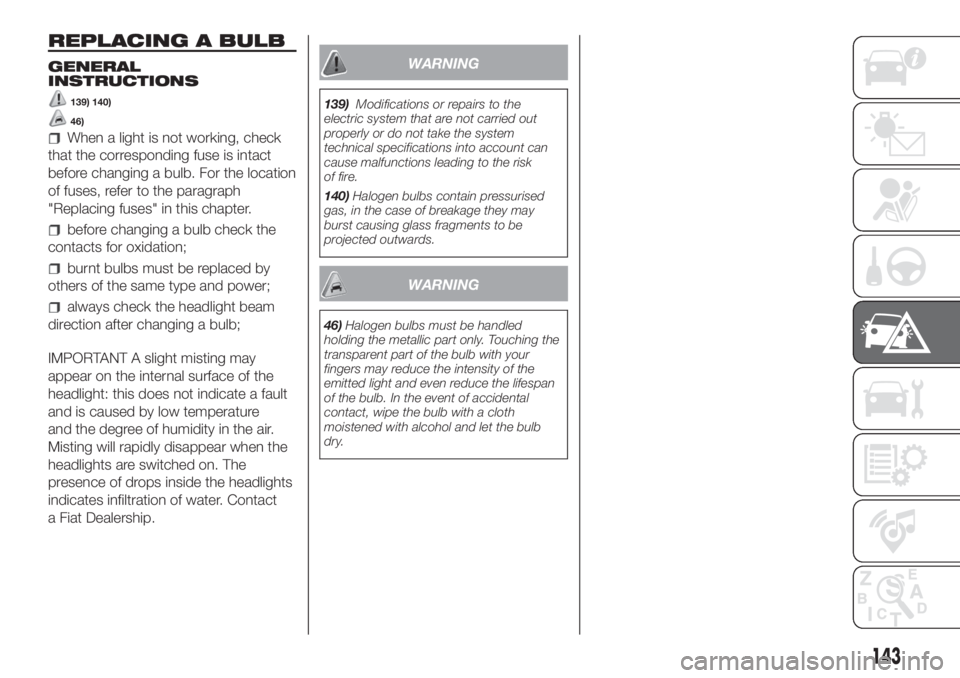

maneuvering screw.FIX & GO

AUTOMATIC QUICK

TYRE REPAIR KIT

(for versions/markets, where provided)

The Fix & Go automatic quick tyre

repair kit is located at the front of the

vehicle passenger compartment and

includes fig. 171:

bottle A containing sealer and fitted

with:

– a transparent filler pipe B;

– a black pressure restoring pipe E;

– sticker C bearing the notice “max. 80

km/h”, to be placed in a position visible

to the driver (on the instrument panel)

after fixing the tyre;

171F1A0180

174

IN AN EMERGENCY

Page 199 of 296

check that the fluid level is at the

MAX mark on the dipstick attached to

the reservoir cap F fig. 185 - fig. 186

- fig. 187 - fig. 188 (use the level shown

on the 20°C side of the dipstick to

check when cold).

If the level of the fluid in the tank is

lower than the specified level, top up

using only one of the products

indicated in the "Fluid and lubricants"

table in the "Technical specifications"

section, proceeding as follows:

Start the engine and wait for the fluid

level in the tank to stabilise.

With the engine running, turn the

steering wheel from right to left fully

several times.

Top up the fuel to the MAX level and

then retighten the cap.

WINDSCREEN/REAR

WINDOW WASHING FLUID

185) 186)

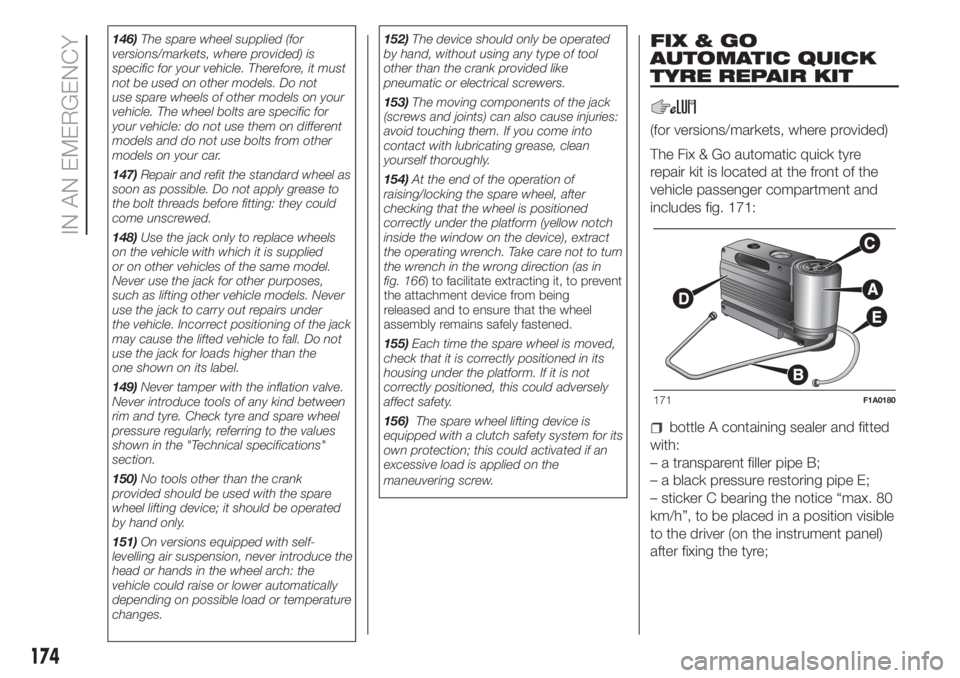

To add fluid:

remove the cap D fig. 185 - fig. 186

- fig. 187 - fig. 188 by pulling the

retaining tooth outwards;

pull the opening of the pipe upwards

to extract the telescopic funnel fig.

190.IMPORTANT To prevent the cap from

being damaged and interfering with the

adjacent mechanical parts, make sure

that it is correctly oriented as shown

in fig. 190 before opening it. Otherwise,

turn it until it reaches the correct

position.

Fill according to the following

instructions:

Use a mixture of water and PETRONAS

DURANCE SC 35, in the following

concentrations:30% PETRONAS DURANCE SC 35

and 70% water in summer.

50% PETRONAS DURANCE SC 35

and 50% water in winter.

At temperatures below -20°C, use

undiluted PETRONAS DURANCE SC

35 fluid.

To close the cap, operate as follows:

push the funnel fully until it locks;

close the cap.

187)

BRAKE FLUID

188) 189)

53)

Undo the cap E fig. 185 - fig. 186 - fig.

187 - fig. 188 and check that the fluid

in the reservoir is at the maximum level.

The fluid level in the reservoir must

not exceed the MAX mark.

Use the brake fluid shown in the "Fluids

and lubricants" table (see "Technical

Specifications").

NOTE Carefully clean the plug of the

reservoir and the surrounding surface.

Take great care to ensure that

impurities do not enter the reservoir

when the cap is opened.

For topping-up, always use a funnel

with integrated filter with mesh equal to

or lower than 0.12 mm.

190F1A0396

197

Page 205 of 296

WHEELS AND TYRES

Check the pressure of each tyre,

including the space-saver wheel,

approximately every two weeks and

before long journeys: the pressure

should be checked with the tyre rested

and cold.

It is normal for the pressure to increase

when the vehicle is used; for the correct

tyre inflation pressure, see “Wheels” in

the “Technical specifications” section.

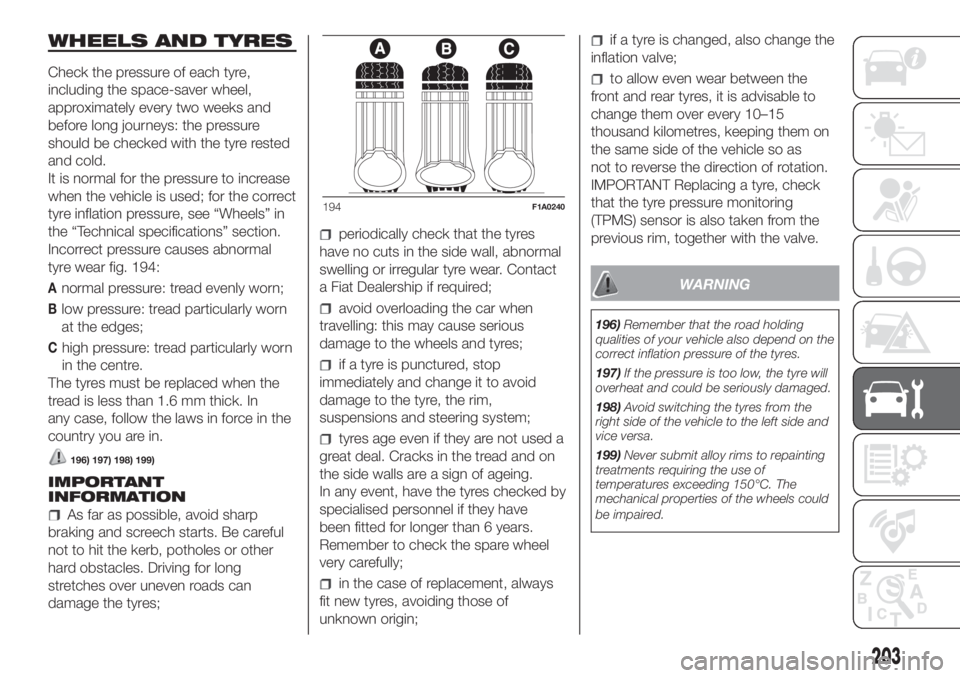

Incorrect pressure causes abnormal

tyre wear fig. 194:

Anormal pressure: tread evenly worn;

Blow pressure: tread particularly worn

at the edges;

Chigh pressure: tread particularly worn

in the centre.

The tyres must be replaced when the

tread is less than 1.6 mm thick. In

any case, follow the laws in force in the

country you are in.

196) 197) 198) 199)

IMPORTANT

INFORMATION

As far as possible, avoid sharp

braking and screech starts. Be careful

not to hit the kerb, potholes or other

hard obstacles. Driving for long

stretches over uneven roads can

damage the tyres;

periodically check that the tyres

have no cuts in the side wall, abnormal

swelling or irregular tyre wear. Contact

a Fiat Dealership if required;

avoid overloading the car when

travelling: this may cause serious

damage to the wheels and tyres;

if a tyre is punctured, stop

immediately and change it to avoid

damage to the tyre, the rim,

suspensions and steering system;

tyres age even if they are not used a

great deal. Cracks in the tread and on

the side walls are a sign of ageing.

In any event, have the tyres checked by

specialised personnel if they have

been fitted for longer than 6 years.

Remember to check the spare wheel

very carefully;

in the case of replacement, always

fit new tyres, avoiding those of

unknown origin;

if a tyre is changed, also change the

inflation valve;

to allow even wear between the

front and rear tyres, it is advisable to

change them over every 10–15

thousand kilometres, keeping them on

the same side of the vehicle so as

not to reverse the direction of rotation.

IMPORTANT Replacing a tyre, check

that the tyre pressure monitoring

(TPMS) sensor is also taken from the

previous rim, together with the valve.

WARNING

196)Remember that the road holding

qualities of your vehicle also depend on the

correct inflation pressure of the tyres.

197)If the pressure is too low, the tyre will

overheat and could be seriously damaged.

198)Avoid switching the tyres from the

right side of the vehicle to the left side and

vice versa.

199)Never submit alloy rims to repainting

treatments requiring the use of

temperatures exceeding 150°C. The

mechanical properties of the wheels could

be impaired.

194F1A0240

203

Page 207 of 296

WARNING

57)Keep your speed down when snow

chains are fitted; do not exceed 50 km/h.

Avoid potholes, steps and pavements

and avoid driving for long distances on

roads not covered with snow to prevent

damaging the vehicle and the roadbed.

BODYWORK

PROTECTION AGAINST

ATMOSPHERIC AGENTS

The main causes of corrosion are the

following:

atmospheric pollution;

salty air and humidity (coastal areas,

or hot humid climates);

seasonal environmental conditions.

ADVICE FOR

PRESERVING THE

BODYWORK

Paintwork

Paintwork does not only serve an

aesthetic purpose, but also protects the

underlying sheet metal.

Touch up abrasions and scratches

immediately to prevent rust formation.

Use only original paint products for

touch-ups (see “Bodywork paint

identification plate” in the “Technical

specifications” section).

Normal maintenance of paintwork

consists in washing the car: the

frequency depends on the conditions

and environment where the car is used.

For example, it is advisable to wash

the vehicle more often in areas with

high levels of environmental pollution or

on roads spread with salt.To correctly wash the vehicle, proceed

as follows:

wash the bodywork using a low

pressure jet of water;

wipe a sponge with a slightly soapy

solution over the bodywork, frequently

rinsing the sponge;

rinse well with water and dry with a

jet of air or a chamois leather.

If you put the vehicle through a car

wash, follow these recommendations:

remove the aerial from the roof

so it does not get damaged;

the vehicle should be washed with

water added to a soapy solution;

rinse thoroughly to avoid soap

marks remaining on the bodywork or

less visible parts.

58)

6)

WARNING

58)Some automatic systems equipped

with old generation blades and/or with

a poor maintenance can damage the paint,

promoting the creation of microscoring

which give an opaque/coated appearance

to the paint, especially on dark colours.

In this case, just lightly polish with specific

products.

205

Page 244 of 296

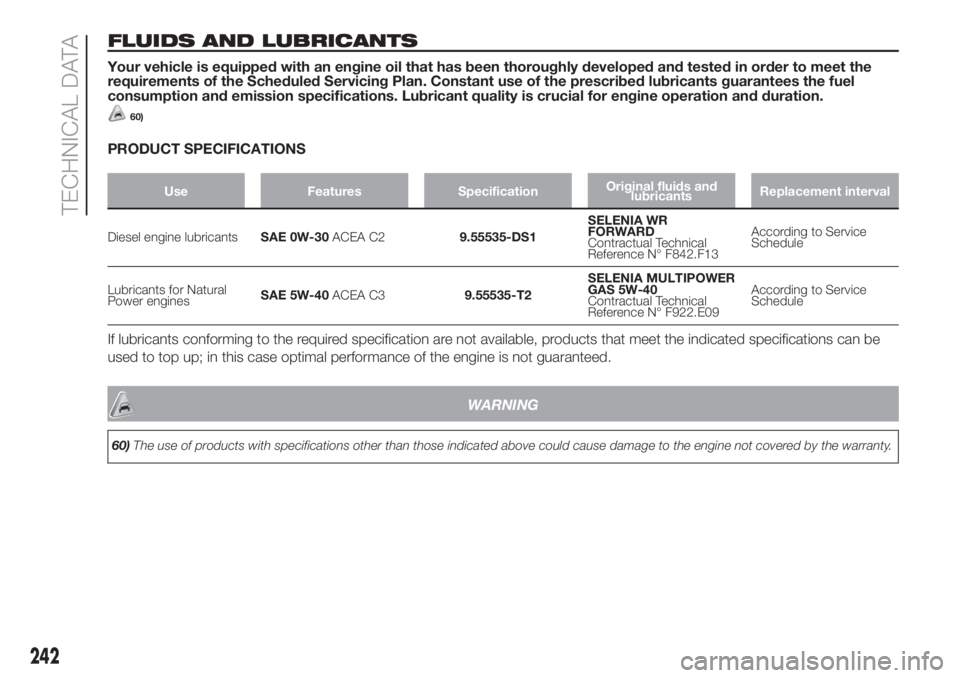

FLUIDS AND LUBRICANTS

Your vehicle is equipped with an engine oil that has been thoroughly developed and tested in order to meet the

requirements of the Scheduled Servicing Plan. Constant use of the prescribed lubricants guarantees the fuel

consumption and emission specifications. Lubricant quality is crucial for engine operation and duration.

60)

PRODUCT SPECIFICATIONS

Use Features SpecificationOriginal fluids and

lubricantsReplacement interval

Diesel engine lubricantsSAE 0W-30ACEA C29.55535-DS1SELENIA WR

FORWARD

Contractual Technical

Reference N° F842.F13According to Service

Schedule

Lubricants for Natural

Power enginesSAE 5W-40ACEA C39.55535-T2SELENIA MULTIPOWER

GAS 5W-40

Contractual Technical

Reference N° F922.E09According to Service

Schedule

If lubricants conforming to the required specification are not available, products that meet the indicated specifications can be

used to top up; in this case optimal performance of the engine is not guaranteed.

WARNING

60)The use of products with specifications other than those indicated above could cause damage to the engine not covered by the warranty.

242

TECHNICAL DATA

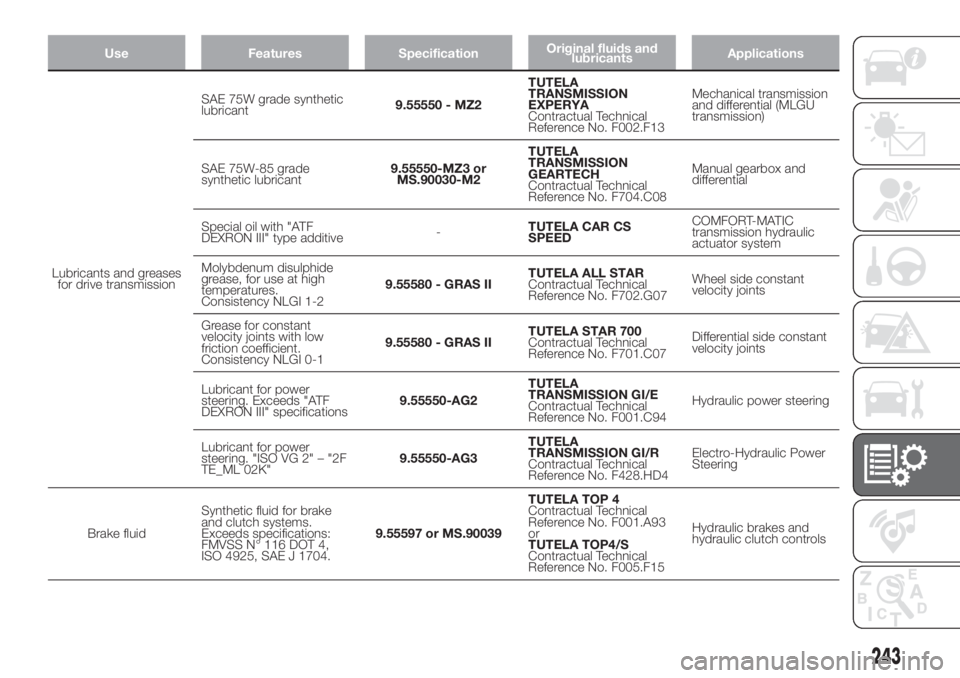

Page 245 of 296

Use Features SpecificationOriginal fluids and

lubricantsApplications

Lubricants and greases

for drive transmissionSAE 75W grade synthetic

lubricant9.55550 - MZ2TUTELA

TRANSMISSION

EXPERYA

Contractual Technical

Reference No. F002.F13Mechanical transmission

and differential (MLGU

transmission)

SAE 75W-85 grade

synthetic lubricant9.55550-MZ3 or

MS.90030-M2TUTELA

TRANSMISSION

GEARTECH

Contractual Technical

Reference No. F704.C08Manual gearbox and

differential

Special oil with "ATF

DEXRON III" type additive-TUTELA CAR CS

SPEEDCOMFORT-MATIC

transmission hydraulic

actuator system

Molybdenum disulphide

grease, for use at high

temperatures.

Consistency NLGI 1-29.55580 - GRAS IITUTELA ALL STAR

Contractual Technical

Reference No. F702.G07Wheel side constant

velocity joints

Grease for constant

velocity joints with low

friction coefficient.

Consistency NLGI 0-19.55580 - GRAS IITUTELA STAR 700

Contractual Technical

Reference No. F701.C07Differential side constant

velocity joints

Lubricant for power

steering. Exceeds "ATF

DEXRON III" specifications9.55550-AG2TUTELA

TRANSMISSION GI/E

Contractual Technical

Reference No. F001.C94Hydraulic power steering

Lubricant for power

steering. "ISO VG 2" – "2F

TE_ML 02K"9.55550-AG3TUTELA

TRANSMISSION GI/R

Contractual Technical

Reference No. F428.HD4Electro-Hydraulic Power

Steering

Brake fluidSynthetic fluid for brake

and clutch systems.

Exceeds specifications:

FMVSS N° 116 DOT 4,

ISO 4925, SAE J 1704.9.55597 or MS.90039TUTELA TOP 4

Contractual Technical

Reference No. F001.A93

or

TUTELA TOP4/S

Contractual Technical

Reference No. F005.F15Hydraulic brakes and

hydraulic clutch controls

243

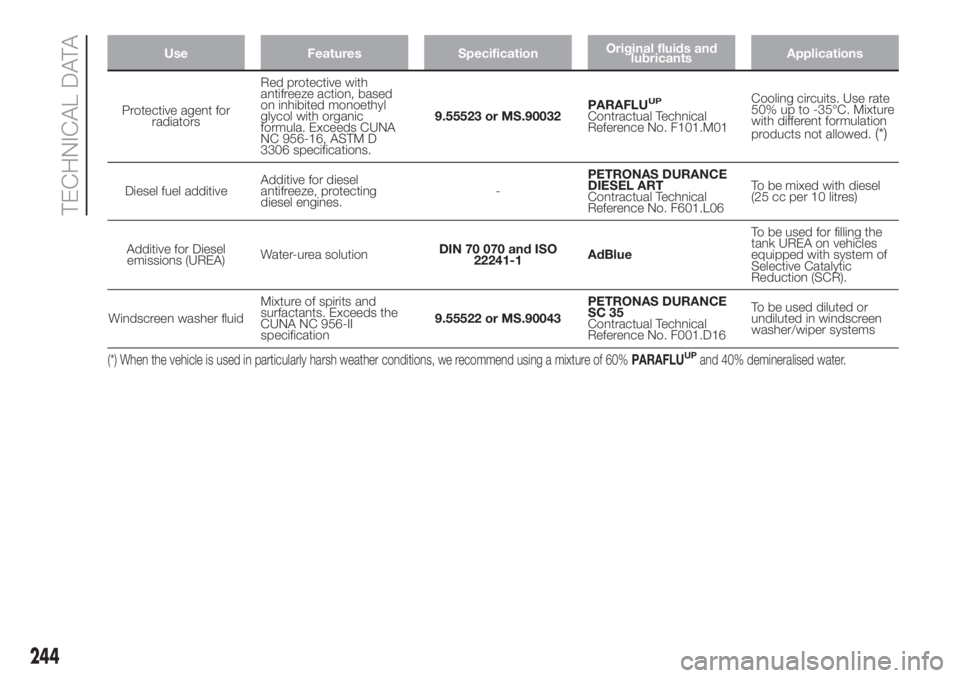

Page 246 of 296

Use Features SpecificationOriginal fluids and

lubricantsApplications

Protective agent for

radiatorsRed protective with

antifreeze action, based

on inhibited monoethyl

glycol with organic

formula. Exceeds CUNA

NC 956-16, ASTM D

3306 specifications.9.55523 or MS.90032PARAFLUUP

Contractual Technical

Reference No. F101.M01Cooling circuits. Use rate

50% up to -35°C. Mixture

with different formulation

products not allowed.

(*)

Diesel fuel additiveAdditive for diesel

antifreeze, protecting

diesel engines.-PETRONAS DURANCE

DIESEL ART

Contractual Technical

Reference No. F601.L06To be mixed with diesel

(25 cc per 10 litres)

Additive for Diesel

emissions (UREA)Water-urea solutionDIN 70 070 and ISO

22241-1AdBlueTo be used for filling the

tank UREA on vehicles

equipped with system of

Selective Catalytic

Reduction (SCR).

Windscreen washer fluidMixture of spirits and

surfactants. Exceeds the

CUNA NC 956-II

specification9.55522 or MS.90043PETRONAS DURANCE

SC 35

Contractual Technical

Reference No. F001.D16To be used diluted or

undiluted in windscreen

washer/wiper systems

(*) When the vehicle is used in particularly harsh weather conditions, we recommend using a mixture of 60%PARAFLUUPand 40% demineralised water.

244

TECHNICAL DATA

Page 285 of 296

WARNING

LUGGAGE CARRIER

Follow the instructions contained in the assembly kit carefully. Assembly must be performed by qualified personnel.

After travelling for a few kilometres, check to ensure that the fixing screws for the attachments are well tightened. Distribute the load

evenly and pay attention to side winds when driving.

Fully comply with the regulations in force concerning maximum clearance. Never exceed the maximum permitted loads (see chapter

"Technical specifications").

ACCESSORIES PURCHASED BY THE OWNER

Take care when fitting additional spoilers, alloy wheels or non-standard wheel hubs: they could reduce the ventilation of the brakes and

affect efficiency under sharp, repeated braking or on long descents. Make sure that nothing obstructs the pedal stroke (mats, etc.).

PROTECTING THE ENVIRONMENT

The Diesel particulate filter (DPF) reaches high temperatures during normal operation. Therefore, do not park the vehicle on flammable

material (grass, dry leaves, pine needles etc.): fire hazard.

RIM PROTECTOR TYRES

DO NOT fit wheel hub caps when using integral hub caps fixed (with springs) to the steel rim and after sale tyres provided with a Rim

Protector. Use of unsuitable tyres and wheel caps may cause sudden decrease of tyre pressure.

283