clock FIAT FREEMONT 2013 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2013, Model line: FREEMONT, Model: FIAT FREEMONT 2013Pages: 352, PDF Size: 5.22 MB

Page 256 of 352

NOTE:Assemble components 2 and 3 by seating the

small ball at the end of component 2 in the small hole at

the end of component 3. This will lock these compo-

nents together. Assemble components 1 and 2 so that

the wheel nut socket at the end of component 1 faces

upward when seated on component 2. This will make it

easier to rotate the assembly when operating the

winch mechanism.

2. Fit the assembled jack-handle over the winch drive nut located in the jack storage area. Rotate the

jack-handle assembly counterclockwise until the

spare tire is on the ground with enough cable slack

to allow you to pull the spare tire out from under-

neath the vehicle.

The winch mechanism is designed for use

with the jack-handle only. Use of an air

wrench or other power tools is not rec-

ommended and it can damage the winch.

3. Pull the spare tire out from underneath the vehicle and raise it upright so the tire's tread is on the

ground.

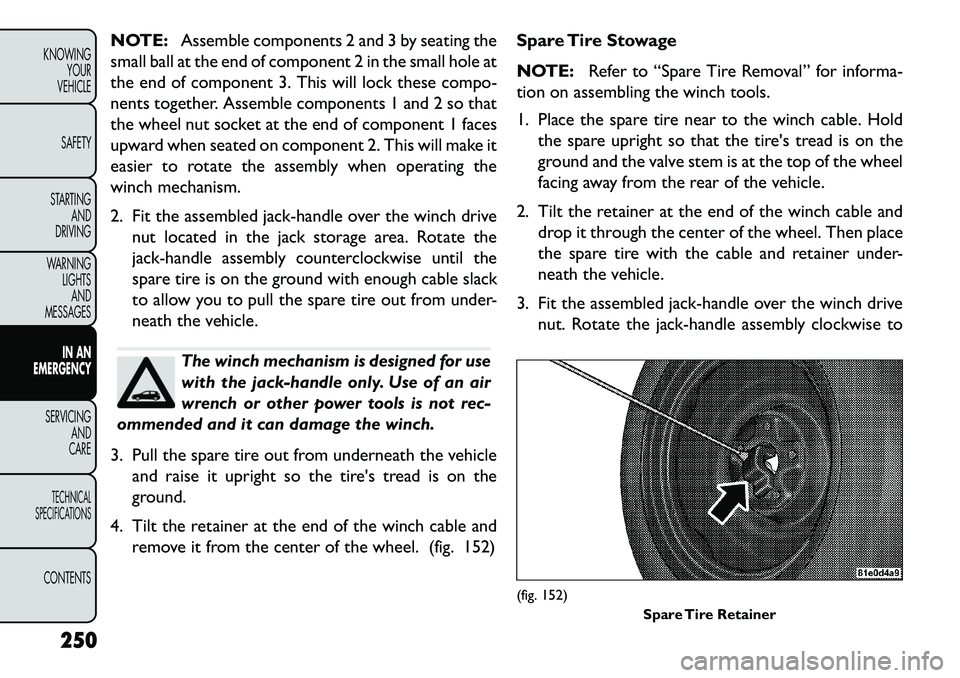

4. Tilt the retainer at the end of the winch cable and remove it from the center of the wheel. (fig. 152) Spare Tire Stowage

NOTE:

Refer to “Spare Tire Removal” for informa-

tion on assembling the winch tools.

1. Place the spare tire near to the winch cable. Hold the spare upright so that the tire's tread is on the

ground and the valve stem is at the top of the wheel

facing away from the rear of the vehicle.

2. Tilt the retainer at the end of the winch cable and drop it through the center of the wheel. Then place

the spare tire with the cable and retainer under-

neath the vehicle.

3. Fit the assembled jack-handle over the winch drive nut. Rotate the jack-handle assembly clockwise to

(fig. 152) Spare Tire Retainer

250

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENC

Y

SERVICING AND

C

ARETECHNICAL

SPECIFICATIONSCONTENTS

Page 258 of 352

Do not attempt to raise the vehicle by

jacking on locations other than those

indicated in the Jacking Instructions for

this vehicle.

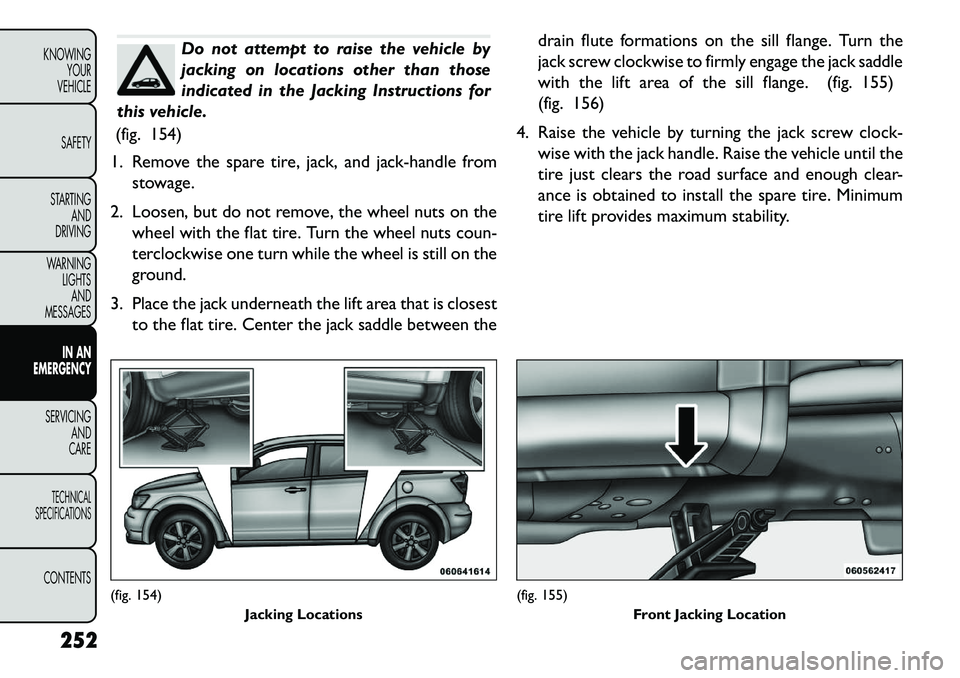

(fig. 154)

1. Remove the spare tire, jack, and jack-handle from stowage.

2. Loosen, but do not remove, the wheel nuts on the wheel with the flat tire. Turn the wheel nuts coun-

terclockwise one turn while the wheel is still on the

ground.

3. Place the jack underneath the lift area that is closest to the flat tire. Center the jack saddle between the drain flute formations on the sill flange. Turn the

jack screw clockwise to firmly engage the jack saddle

with the lift area of the sill flange. (fig. 155)

(fig. 156)

4. Raise the vehicle by turning the jack screw clock- wise with the jack handle. Raise the vehicle until the

tire just clears the road surface and enough clear-

ance is obtained to install the spare tire. Minimum

tire lift provides maximum stability.

(fig. 154) Jacking Locations

(fig. 155)Front Jacking Location

252

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENC

Y

SERVICING AND

C

ARETECHNICAL

SPECIFICATIONSCONTENTS

Page 260 of 352

NOTE:

For vehicles so equipped, do not attempt to install acenter cap or wheel cover on the compact spare.

Refer to “Compact Spare Tire” and to “Limited-Use Spare” under “Tires — General Information” in

“Technical Specifications” for additional warnings,

cautions, and information about the spare tire, its

use, and operation.

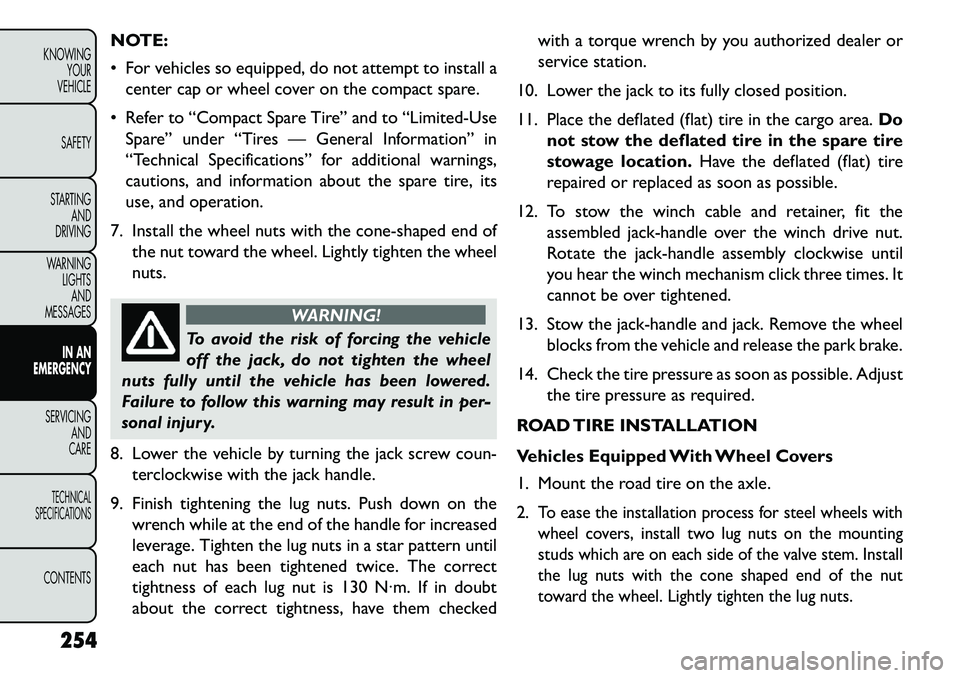

7. Install the wheel nuts with the cone-shaped end of the nut toward the wheel. Lightly tighten the wheel

nuts.

WARNING!

To avoid the risk of forcing the vehicle

of

f the jack, do not tighten the wheel

nuts fully until the vehicle has been lowered.

Failure to follow this warning may result in per-

sonal injury.

8. Lower the vehicle by turning the jack screw coun- terclockwise with the jack handle.

9. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. The correct

tightness of each lug nut is 130 N·m. If in doubt

about the correct tightness, have them checked with a torque wrench by you authorized dealer or

service station.

10. Lower the jack to its fully closed position.

11. Place the deflated (flat) tire in the cargo area. Do

not stow the deflated tire in the spare tire

stowage location. Have the deflated (flat) tire

repaired or replaced as soon as possible.

12. To stow the winch cable and retainer, fit the assembled jack-handle over the winch drive nut.

Rotate the jack-handle assembly clockwise until

you hear the winch mechanism click three times. It

cannot be over tightened.

13. Stow the jack-handle and jack. Remove the wheel blocks from the vehicle and release the park brake.

14. Check the tire pressure as soon as possible. Adjust the tire pressure as required.

ROAD TIRE INSTALLATION

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2.

To ease the installation process for steel wheels with

wheel covers, install two lug nuts on the mounting

studs which are on each side of the valve stem. Install

the lug nuts with the cone shaped end of the nut

toward the wheel. Lightly tighten the lug nuts.

254

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENC

Y

SERVICING AND

C

ARETECHNICAL

SPECIFICATIONSCONTENTS

Page 261 of 352

WARNING!

To avoid the risk of forcing the vehicle

of

f the jack, do not tighten the wheel

nuts fully until the vehicle has been lowered.

Failure to follow this warning may result in per-

sonal injury.

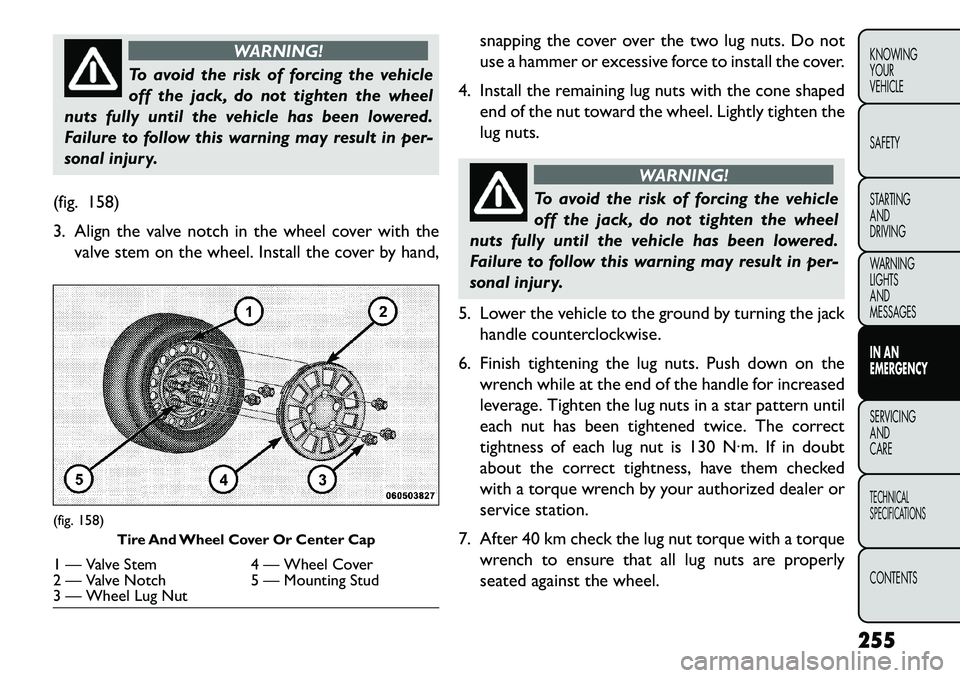

(fig. 158)

3. Align the valve notch in the wheel cover with the valve stem on the wheel. Install the cover by hand, snapping the cover over the two lug nuts. Do not

use a hammer or excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the

lug nuts.

WARNING!

To avoid the risk of forcing the vehicle

of

f the jack, do not tighten the wheel

nuts fully until the vehicle has been lowered.

Failure to follow this warning may result in per-

sonal injury.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. The correct

tightness of each lug nut is 130 N·m. If in doubt

about the correct tightness, have them checked

with a torque wrench by your authorized dealer or

service station.

7. After 40 km check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

(fig. 158) Tire And Wheel Cover Or Center Cap1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Mounting Stud

3 — Wheel Lug Nut

255

KNOWING

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS

AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

C ARETECHNICAL

SPECIFICATIONSCONTENTS

Page 262 of 352

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shapedend of the nut toward the wheel. Lightly tighten the

lug nuts.

WARNING!

To avoid the risk of forcing the vehicle

of

f the jack, do not tighten the wheel

nuts fully until the vehicle has been lowered.

Failure to follow this warning may result in per-

sonal injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. The correct

tightness of each lug nut is 130 N·m. If in doubt

about the correct tightness, have them checked

with a torque wrench by your authorized dealer or

service station.

5. After 40 km check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel. TIREFIT KIT (for versions/markets,

where provided)

Small punctures up to 6 mm in the tire tread can be

sealed with TIREFIT. Foreign objects (e.g., screws or

nails) should not be removed from the tire. TIREFIT

can be used in outside temperatures down to approxi-

mately 20°C.

This kit will provide a temporary tire seal, allowing you

to drive your vehicle up to 160 km with a maximum

speed of 88 km/h.

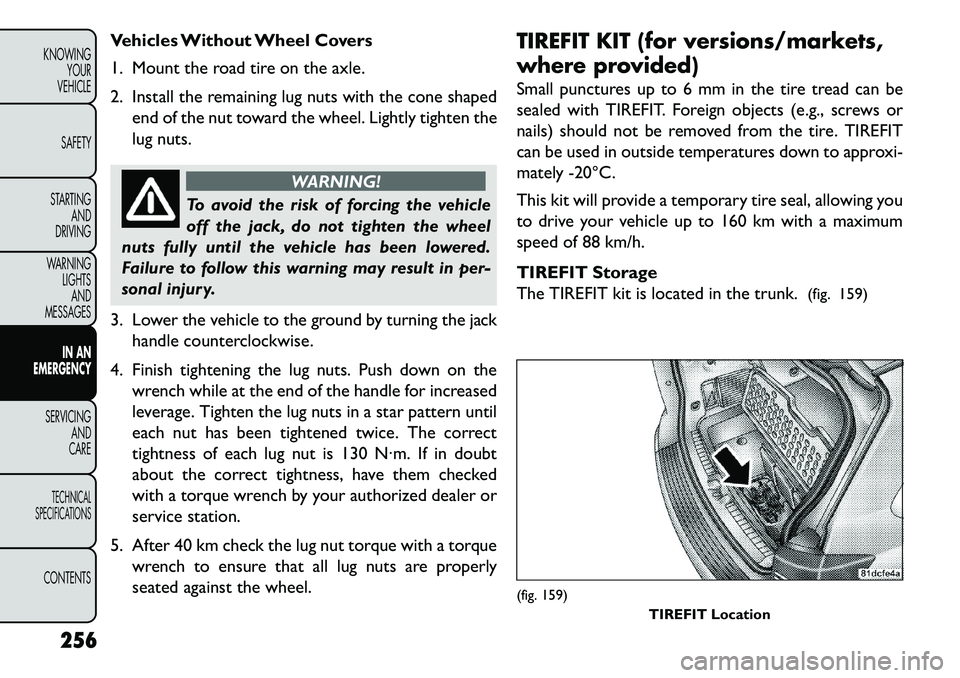

TIREFIT Storage

The TIREFIT kit is located in the trunk.

(fig. 159)

(fig. 159)

TIREFIT Location

256

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENC

Y

SERVICING AND

C

ARETECHNICAL

SPECIFICATIONSCONTENTS

Page 271 of 352

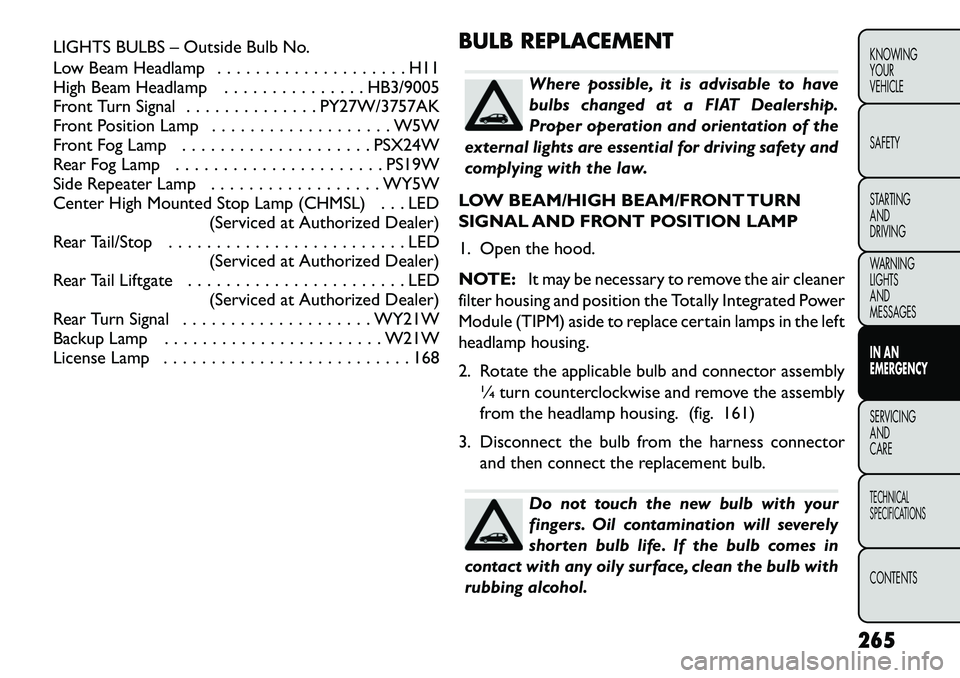

LIGHTS BULBS – Outside Bulb No.

Low Beam Headlamp . . . . . . . . . . . . . . . . . . . . H11

High Beam Headlamp . . . . . . . . . . . . . . . HB3/9005

Front Turn Signal . . . . . . . . . . . . . . PY27W/3757AK

Front Position Lamp . . . . . . . . . . . . . . . . . . . W5W

Front Fog Lamp . . . . . . . . . . . . . . . . . . . . PSX24W

Rear Fog Lamp . . . . . . . . . . . . . . . . . . . . . . PS19W

Side Repeater Lamp . . . . . . . . . . . . . . . . . . WY5W

Center High Mounted Stop Lamp (CHMSL) . . . LED(Serviced at Authorized Dealer)

Rear Tail/Stop . . . . . . . . . . . . . . . . . . . . . . . . . LED (Serviced at Authorized Dealer)

Rear Tail Liftgate . . . . . . . . . . . . . . . . . . . . . . . LED

(Serviced at Authorized Dealer)

Rear Turn Signal . . . . . . . . . . . . . . . . . . . . WY21W

Backup Lamp . . . . . . . . . . . . . . . . . . . . . . . W21W

License Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . 168 BULB REPLACEMENT

Where possible, it is advisable to have

bulbs changed at a FIAT Dealership.

Proper operation and orientation of the

external lights are essential for driving safety and

complying with the law.

LOW BEAM/HIGH BEAM/FRONT TURN

SIGNAL AND FRONT POSITION LAMP

1. Open the hood.

NOTE: It may be necessary to remove the air cleaner

filter housing and position the Totally Integrated Power

Module (TIPM) aside to replace certain lamps in the left

headlamp housing.

2. Rotate the applicable bulb and connector assembly ¼ turn counterclockwise and remove the assembly

from the headlamp housing. (fig. 161)

3. Disconnect the bulb from the harness connector and then connect the replacement bulb.Do not touch the new bulb with your

fingers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the bulb with

rubbing alcohol.

265

KNOWING

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS

AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

C ARETECHNICAL

SPECIFICATIONSCONTENTS

Page 272 of 352

4. Install the bulb and connector assembly into theheadlamp housing and rotate it ¼ turn clockwise to

lock it in place.

FRONT FOG LAMP

NOTE: Turn the steering wheel to the right if replac-

ing the left front fog lamp or to the left if replacing the

right front fog lamp to allow for easier access to the

front of the wheel well.

1. Remove the fasteners retaining the front lower wheel well access panel and remove the access

panel.

2. Remove the electrical connector from the fog lamp housing. (fig. 162)

3. Firmly grasp the bulb by the two side latches and squeeze them together to unlock the bulb from the

back of the front fog lamp housing.

4. Pull the bulb straight out from the keyed opening in the housing.

5. Align the index tabs of the replacement front fog lamp bulb with the slots in the collar of the bulb

opening on the back of the front fog lamp housing.(fig. 161)1 — Front Turn Signal Lamp Bulb

2 — Low Beam Headlamp Bulb

3 — Front Position Bulb

4 — High Beam Headlamp Bulb

(fig. 162)

266

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENC

Y

SERVICING AND

C

ARETECHNICAL

SPECIFICATIONSCONTENTS

Page 275 of 352

with the other hand. Use the trim stick and hand

pressure together to disengage the taillamp housing

from the vehicle.

4. Rotate the applicable bulb's electrical connector ¼ turn counterclockwise and remove it from the tail-

lamp housing.

5. Remove the bulb from the connector socket and install the replacement bulb.

6. Install the bulb and connector assembly into the taillamp housing and rotate the connector ¼ turn

clockwise to lock it in place.

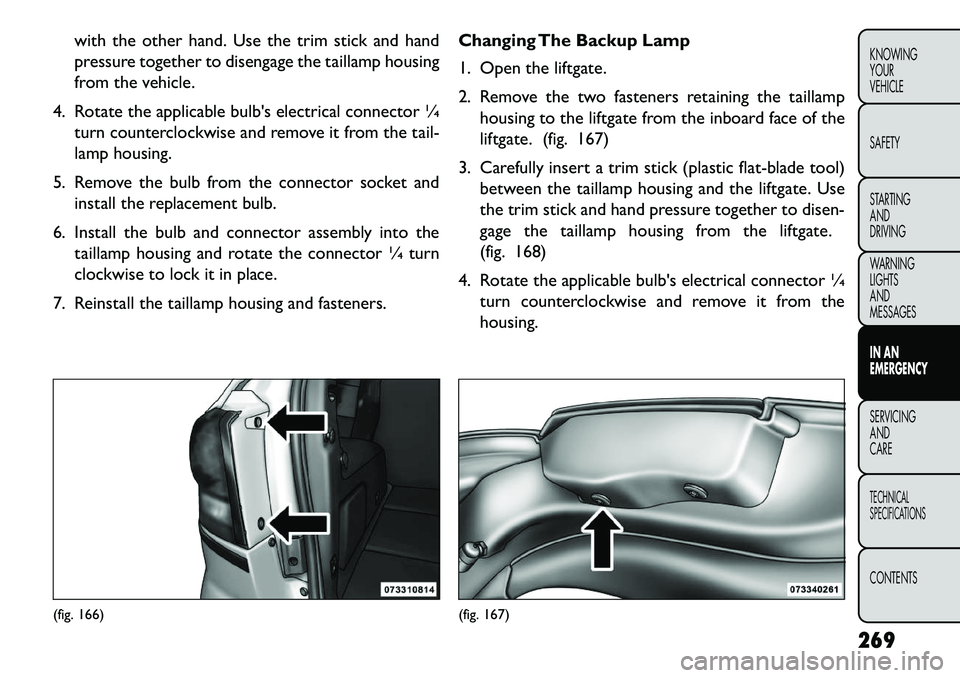

7. Reinstall the taillamp housing and fasteners. Changing The Backup Lamp

1. Open the liftgate.

2. Remove the two fasteners retaining the taillamp

housing to the liftgate from the inboard face of the

liftgate. (fig. 167)

3. Carefully insert a trim stick (plastic flat-blade tool) between the taillamp housing and the liftgate. Use

the trim stick and hand pressure together to disen-

gage the taillamp housing from the liftgate.

(fig. 168)

4. Rotate the applicable bulb's electrical connector ¼ turn counterclockwise and remove it from the

housing.

(fig. 166)

(fig. 167)

269

KNOWING

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS

AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

C ARETECHNICAL

SPECIFICATIONSCONTENTS

Page 276 of 352

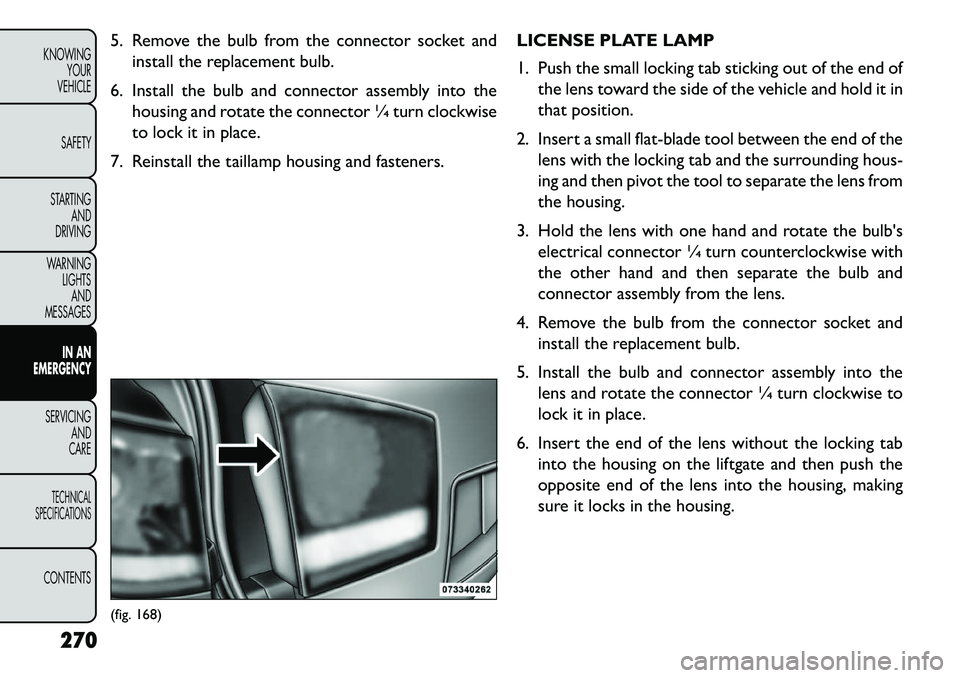

5. Remove the bulb from the connector socket andinstall the replacement bulb.

6. Install the bulb and connector assembly into the housing and rotate the connector ¼ turn clockwise

to lock it in place.

7. Reinstall the taillamp housing and fasteners. LICENSE PLATE LAMP

1. Push the small locking tab sticking out of the end of

the lens toward the side of the vehicle and hold it in

that position.

2. Insert a small flat-blade tool between the end of the lens with the locking tab and the surrounding hous-

ing and then pivot the tool to separate the lens from

the housing.

3. Hold the lens with one hand and rotate the bulb's electrical connector ¼ turn counterclockwise with

the other hand and then separate the bulb and

connector assembly from the lens.

4. Remove the bulb from the connector socket and install the replacement bulb.

5. Install the bulb and connector assembly into the lens and rotate the connector ¼ turn clockwise to

lock it in place.

6. Insert the end of the lens without the locking tab into the housing on the liftgate and then push the

opposite end of the lens into the housing, making

sure it locks in the housing.(fig. 168)

270

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENC

Y

SERVICING AND

C

ARETECHNICAL

SPECIFICATIONSCONTENTS