clock FIAT FREEMONT 2015 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: FREEMONT, Model: FIAT FREEMONT 2015 1.GPages: 412, PDF Size: 3.37 MB

Page 93 of 412

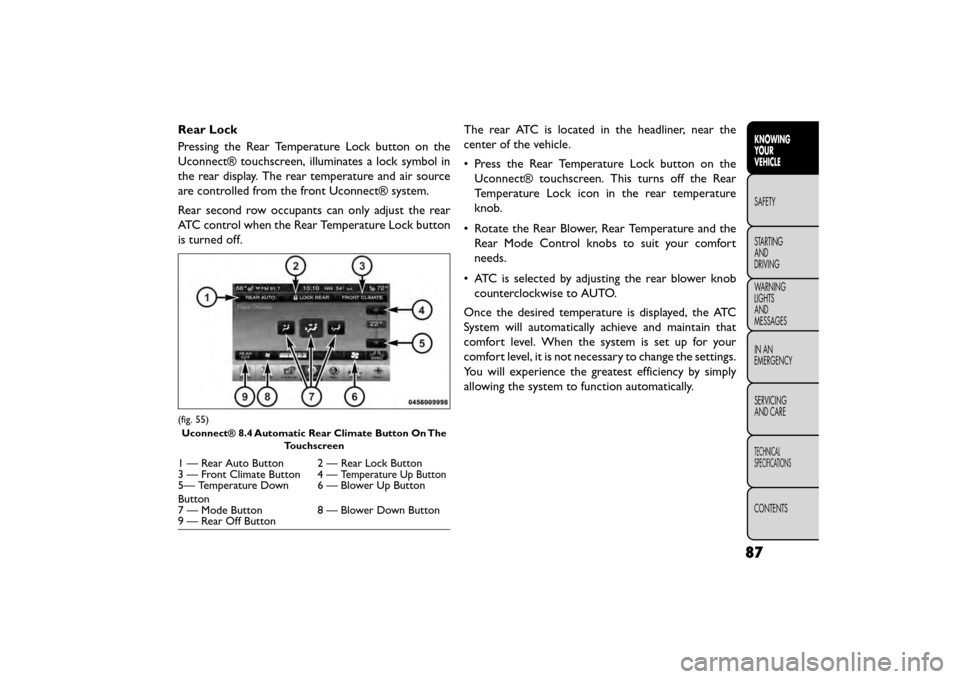

Rear Lock

Pressing the Rear Temperature Lock button on the

Uconnect® touchscreen, illuminates a lock symbol in

the rear display. The rear temperature and air source

are controlled from the front Uconnect® system.

Rear second row occupants can only adjust the rear

ATC control when the Rear Temperature Lock button

is turned off.The rear ATC is located in the headliner, near the

center of the vehicle.

• Press the Rear Temperature Lock button on the

Uconnect® touchscreen. This turns off the Rear

Temperature Lock icon in the rear temperature

knob.

• Rotate the Rear Blower, Rear Temperature and the Rear Mode Control knobs to suit your comfort

needs.

• ATC is selected by adjusting the rear blower knob counterclockwise to AUTO.

Once the desired temperature is displayed, the ATC

System will automatically achieve and maintain that

comfort level. When the system is set up for your

comfort level, it is not necessary to change the settings.

You will experience the greatest efficiency by simply

allowing the system to function automatically.

(fig. 55) Uconnect® 8.4 Automatic Rear Climate Button On The Touchscreen

1 — Rear Auto Button 2 — Rear Lock Button

3 — Front Climate Button 4 —Temperature Up Button5— Temperature Down

Button 6 — Blower Up Button

7 — Mode Button 8 — Blower Down Button

9 — Rear Off Button

87

KNOWING

YOUR

VEHICLE

SAFETY

STAR

TING

AND

DRIVING

WARNING

LIGHTS

AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND CARE

TECHNICAL

SPECIFICATIONS

CONTENTS

Page 94 of 412

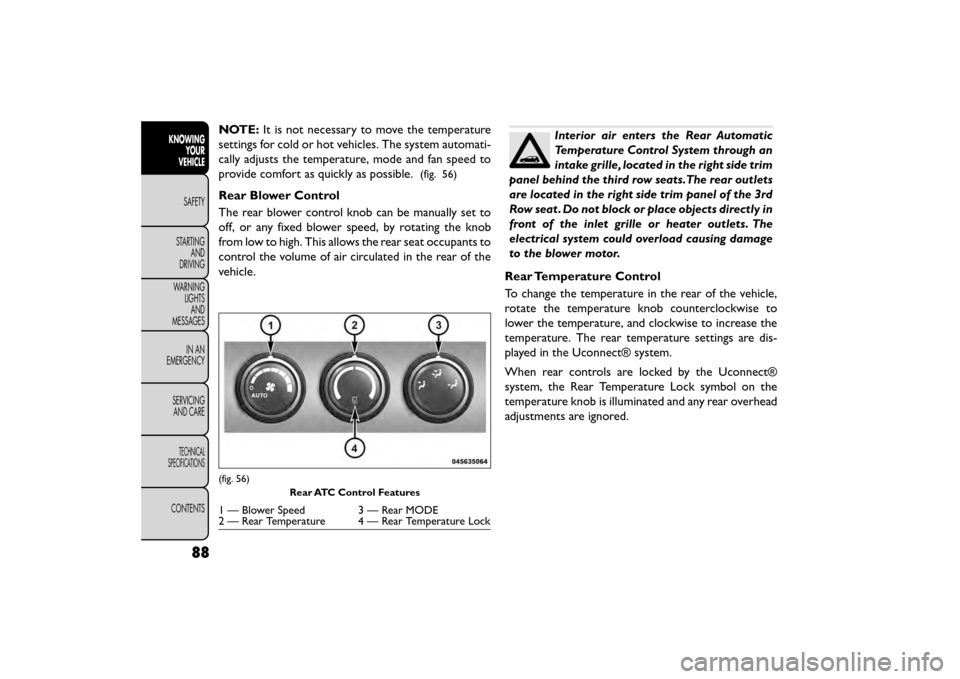

NOTE:It is not necessary to move the temperature

settings for cold or hot vehicles. The system automati-

cally adjusts the temperature, mode and fan speed to

provide comfort as quickly as possible.

(fig. 56)

Rear Blower Control

The rear blower control knob can be manually set to

off, or any fixed blower speed, by rotating the knob

from low to high. This allows the rear seat occupants to

control the volume of air circulated in the rear of the

vehicle.

Interior air enters the Rear Automatic

Temperature Control System through an

intake grille, located in the right side trim

panel behind the third row seats.The rear outlets

are located in the right side trim panel of the 3rd

Row seat . Do not block or place objects directly in

front of the inlet grille or heater outlets. The

electrical system could overload causing damage

to the blower motor.

Rear Temperature Control

To change the temperature in the rear of the vehicle,

rotate the temperature knob counterclockwise to

lower the temperature, and clockwise to increase the

temperature. The rear temperature settings are dis-

played in the Uconnect® system.

When rear controls are locked by the Uconnect®

system, the Rear Temperature Lock symbol on the

temperature knob is illuminated and any rear overhead

adjustments are ignored.

(fig. 56) Rear ATC Control Features

1 — Blower Speed 3 — Rear MODE

2 — Rear Temperature 4 — Rear Temperature Lock

88

KNOWINGYOUR

VEHICLE

SAFETY

STAR

TINGAND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENCY

SERVICINGAND CARE

TECHNICAL

SPECIFICATIONS

CONTENTS

Page 98 of 412

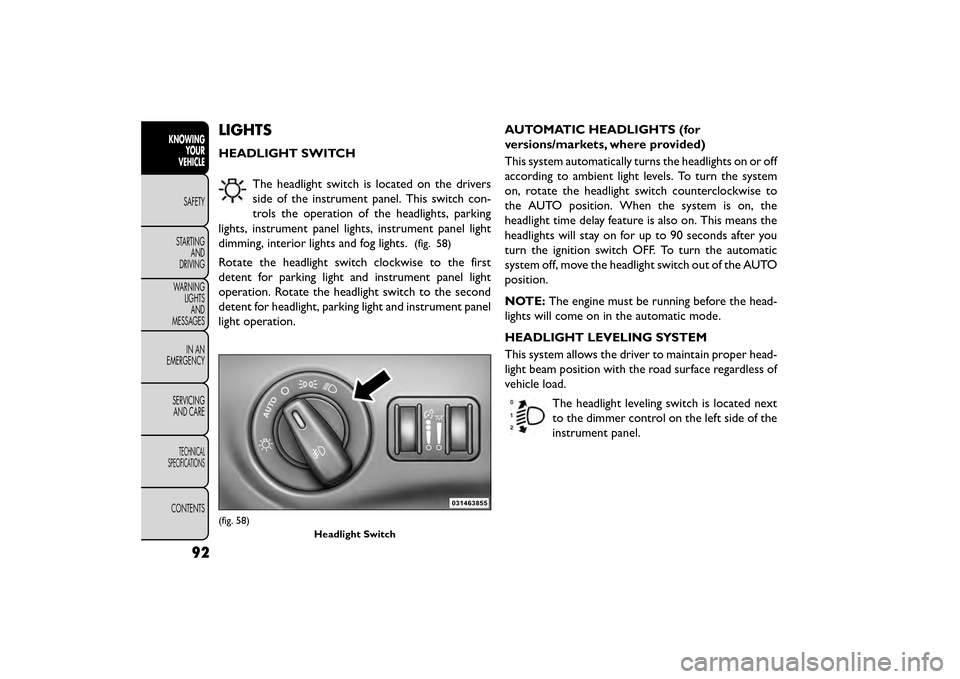

LIGHTS

HEADLIGHT SWITCHThe headlight switch is located on the drivers

side of the instrument panel. This switch con-

trols the operation of the headlights, parking

lights, instrument panel lights, instrument panel light

dimming, interior lights and fog lights.

(fig. 58)

Rotate the headlight switch clockwise to the first

detent for parking light and instrument panel light

operation. Rotate the headlight switch to the second

detent for headlight, parking light and instrument panel

light operation. AUTOMATIC HEADLIGHTS (for

versions/markets, where provided)

This system automatically turns the headlights on or off

according to ambient light levels. To turn the system

on, rotate the headlight switch counterclockwise to

the AUTO position. When the system is on, the

headlight time delay feature is also on. This means the

headlights will stay on for up to 90 seconds after you

turn the ignition switch OFF. To turn the automatic

system off, move the headlight switch out of the AUTO

position.

NOTE:

The engine must be running before the head-

lights will come on in the automatic mode.

HEADLIGHT LEVELING SYSTEM

This system allows the driver to maintain proper head-

light beam position with the road surface regardless of

vehicle load.

The headlight leveling switch is located next

to the dimmer control on the left side of the

instrument panel.

(fig. 58) Headlight Switch

92

KNOWINGYOUR

VEHICLE

SAFETY

STAR

TINGAND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENCY

SERVICINGAND CARE

TECHNICAL

SPECIFICATIONS

CONTENTS

Page 189 of 412

System Information

Information Mode Display

When information mode is active, the current mode

setting for both audio channels is displayed. In addition

to the items called out by number, the remaining

information displays the current status of the source

(such as station frequency, name, preset or track num-

ber, song title, artist name, album name, etc.).

• Channel 1 Mode – Displays the current source forChannel 1.

• Channel 1 Audio Only/Mute — Audio: The audio only icon is not used on Channel 1, in a single screen

system. Mute: when the Mute icon is displayed, the

audio for Channel 1 has been muted using the re-

mote control’s MUTE button.

• Channel 2 Audio Only/Mute — Audio: Only in a single screen system: The audio only icon is displayed

on Channel 2 when Channel 1 is in a video mode.

Mute: when the Mute icon is displayed, the audio for

Channel 2 has been muted using the remote con-

trol’s MUTE button. • Channel 2 Mode — Displays the current source for

Channel 2.

• Channel 2 ENTER Button Action — When the ENTER button on the remote control is pressed

with the "INPUT FILE #" button visible on the

screen, the screen shows a numeric entry keypad

which allows you to enter a specific track number on

data discs and HDD (see Numeric Keypad Menu

section of this manual). Also, Enter Button Action –

“INPUT TRK #” to enter a specific track number on

audio discs.

• Remote Locked Out — When the icon is displayed, the remote control functions are disabled.

• Clock — Displays the time.

• Channel 1 Shared Status — When the icon is dis- played, the audio for Channel 1 is also shared with

the radio and playing through the cabin speakers.

183

KNOWING

YOUR

VEHICLE

SAFETY

STAR

TING

AND

DRIVING

WARNING

LIGHTS

AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND CARE

TECHNICAL

SPECIFICATIONS

CONTENTS

Page 291 of 412

SPARE TIRE REMOVAL

NOTE:On seven-passenger models, fold the third-

row passenger seats flat. This will provide more space

when accessing the jacking tools and when operating

the winch mechanism.

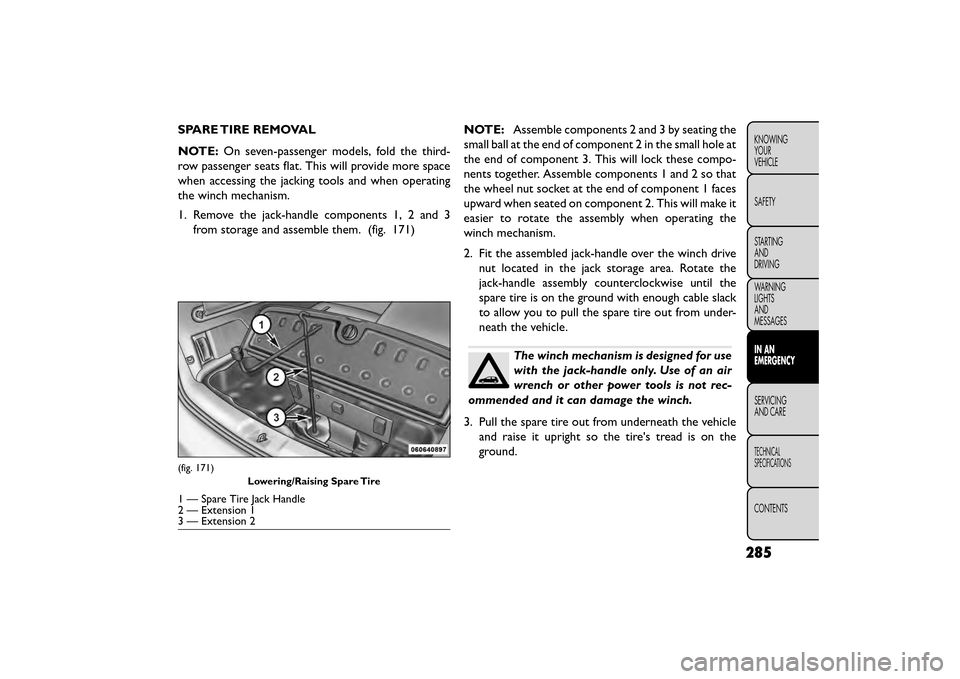

1. Remove the jack-handle components 1, 2 and 3 from storage and assemble them. (fig. 171) NOTE:

Assemble components 2 and 3 by seating the

small ball at the end of component 2 in the small hole at

the end of component 3. This will lock these compo-

nents together. Assemble components 1 and 2 so that

the wheel nut socket at the end of component 1 faces

upward when seated on component 2. This will make it

easier to rotate the assembly when operating the

winch mechanism.

2. Fit the assembled jack-handle over the winch drive nut located in the jack storage area. Rotate the

jack-handle assembly counterclockwise until the

spare tire is on the ground with enough cable slack

to allow you to pull the spare tire out from under-

neath the vehicle.

The winch mechanism is designed for use

with the jack-handle only. Use of an air

wrench or other power tools is not rec-

ommended and it can damage the winch.

3. Pull the spare tire out from underneath the vehicle and raise it upright so the tire's tread is on the

ground.

(fig. 171)

Lowering/Raising Spare Tire

1 — Spare Tire Jack Handle

2 — Extension 1

3 — Extension 2

285

KNOWING

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS

AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

CARE

TECHNICAL

SPECIFICATIONS

CONTENTS

Page 292 of 412

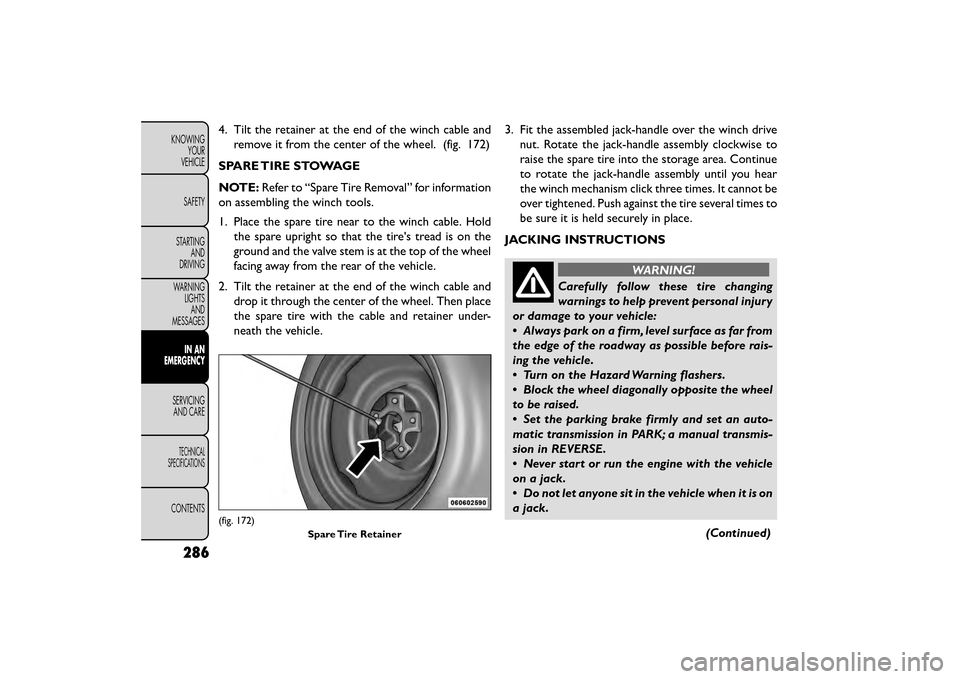

4. Tilt the retainer at the end of the winch cable andremove it from the center of the wheel. (fig. 172)

SPARE TIRE STOWAGE

NOTE: Refer to “Spare Tire Removal” for information

on assembling the winch tools.

1. Place the spare tire near to the winch cable. Hold the spare upright so that the tire's tread is on the

ground and the valve stem is at the top of the wheel

facing away from the rear of the vehicle.

2. Tilt the retainer at the end of the winch cable and drop it through the center of the wheel. Then place

the spare tire with the cable and retainer under-

neath the vehicle. 3. Fit the assembled jack-handle over the winch drive

nut. Rotate the jack-handle assembly clockwise to

raise the spare tire into the storage area. Continue

to rotate the jack-handle assembly until you hear

the winch mechanism click three times. It cannot be

over tightened. Push against the tire several times to

be sure it is held securely in place.

JACKING INSTRUCTIONS

WARNING!

Carefully follow these tire changing

warnin gs

to help prevent personal injury

or damage to your vehicle:

• Always park on a firm, level surface as far from

the edge of the roadway as possible before rais-

ing the vehicle.

• Turn on the Hazard Warning flashers.

• Block the wheel diagonally opposite the wheel

to be raised.

• Set the parking brake firmly and set an auto-

matic transmission in PARK; a manual transmis-

sion in REVERSE.

• Never start or run the engine with the vehicle

on a jack.

• Do not let anyone sit in the vehicle when it is on

a jack.

(Continued)

(fig. 172)Spare Tire Retainer

286

KNOWINGYOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENCY

SER VICING

AND

CARE

TECHNICAL

SPECIFICATIONS

CONTENTS

Page 293 of 412

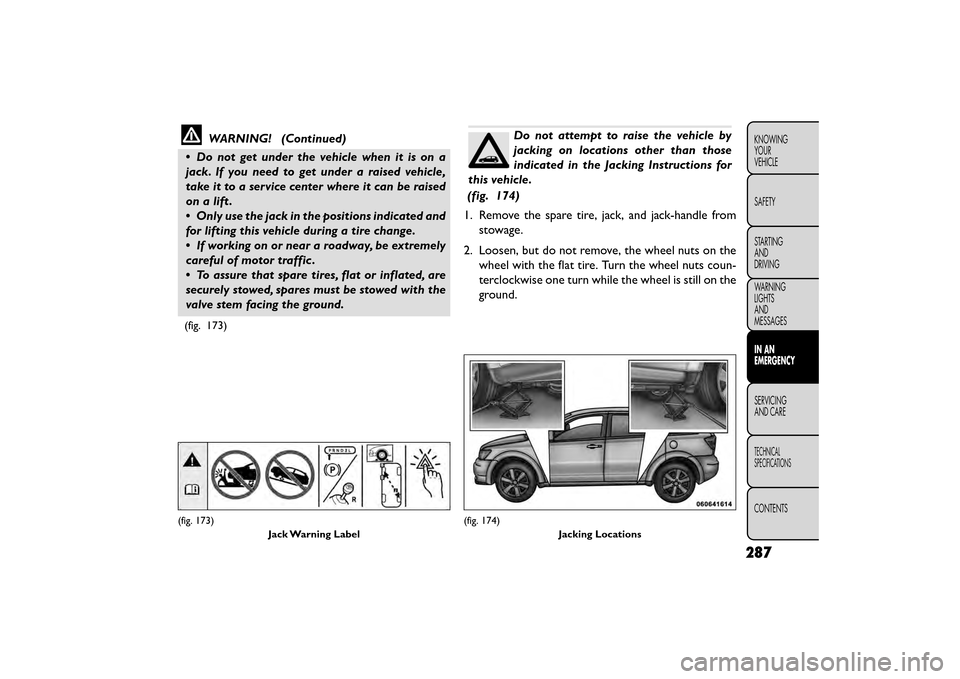

WARNING! (Continued)

• Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be raised

on a lift .

• Only use the jack in the positions indicated and

for lifting this vehicle during a tire change.

• If working on or near a roadway, be extremely

careful of motor traffic .

• To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with the

valve stem facing the ground.

(fig. 173)

Do not attempt to raise the vehicle by

jacking on locations other than those

indicated in the Jacking Instructions for

this vehicle.

(fig. 174)

1. Remove the spare tire, jack, and jack-handle from stowage.

2. Loosen, but do not remove, the wheel nuts on the wheel with the flat tire. Turn the wheel nuts coun-

terclockwise one turn while the wheel is still on the

ground.

(fig. 173)

Jack Warning Label(fig. 174) Jacking Locations

287

KNOWING

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS

AND

MESSAGES

IN AN

EMERGENCY

SERVICING

AND

CARE

TECHNICAL

SPECIFICATIONS

CONTENTS

Page 294 of 412

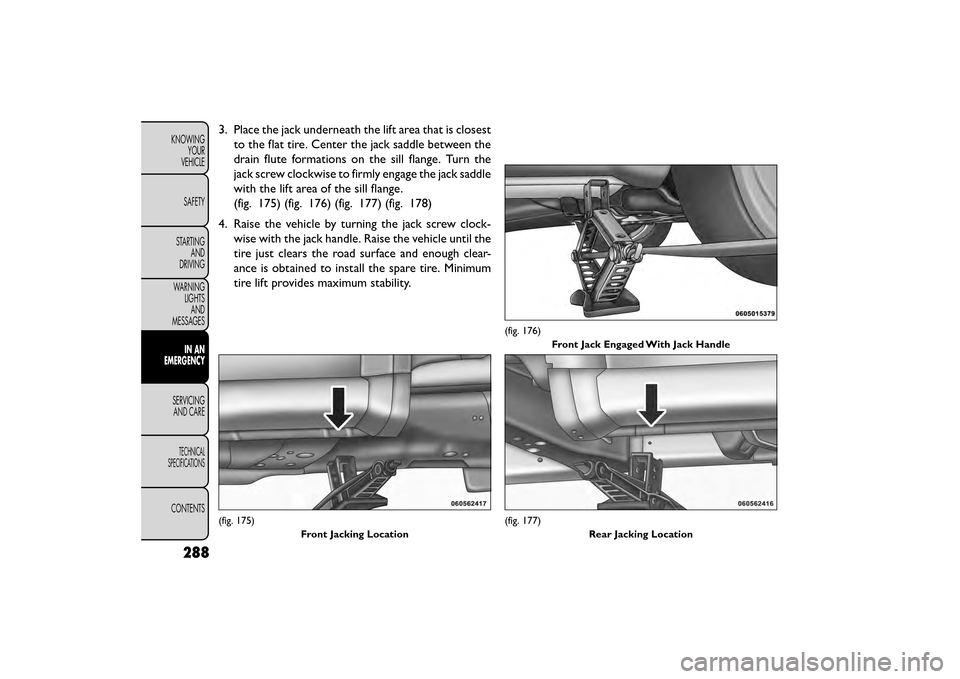

3. Place the jack underneath the lift area that is closestto the flat tire. Center the jack saddle between the

drain flute formations on the sill flange. Turn the

jack screw clockwise to firmly engage the jack saddle

with the lift area of the sill flange.

(fig. 175) (fig. 176) (fig. 177) (fig. 178)

4. Raise the vehicle by turning the jack screw clock- wise with the jack handle. Raise the vehicle until the

tire just clears the road surface and enough clear-

ance is obtained to install the spare tire. Minimum

tire lift provides maximum stability.

(fig. 175)

Front Jacking Location

(fig. 176)Front Jack Engaged With Jack Handle

(fig. 177) Rear Jacking Location

288

KNOWINGYOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENCY

SER VICING

AND

CARE

TECHNICAL

SPECIFICATIONS

CONTENTS

Page 296 of 412

NOTE:

• For vehicles so equipped, do not attempt to install acenter cap or wheel cover on the compact spare.

• Refer to “Compact Spare Tire” and to “Limited-Use Spare” under “Tires — General Information” in

“Technical Specifications” for additional warnings,

cautions, and information about the spare tire, its

use, and operation.

7. Install the wheel nuts with the cone-shaped end of the nut toward the wheel. Lightly tighten the wheel

nuts.

WARNING!

To avoid the risk of forcing the vehicle

off t

he jack, do not tighten the wheel

nuts fully until the vehicle has been lowered.

Failure to follow this warning may result in per-

sonal injury.

8. Lower the vehicle by turning the jack screw coun- terclockwise with the jack handle. 9. Finish tightening the lug nuts. Push down on the

wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. Refer to “Torque

Specifications” in this section for proper lug nut

torque. If in doubt about the correct tightness, have

them checked with a torque wrench by your autho-

rized dealer or service station.

10. Lower the jack to its fully closed position.

11. Place the deflated (flat) tire in the cargo area. Do

not stow the deflated tire in the spare tire

stowage location. Have the deflated (flat) tire

repaired or replaced as soon as possible.

12. To stow the winch cable and retainer, fit the assembled jack-handle over the winch drive nut.

Rotate the jack-handle assembly clockwise until

you hear the winch mechanism click three times. It

cannot be over tightened.

13. Stow the jack-handle and jack. Remove the wheel blocks from the vehicle and release the park brake.

14. Check the tire pressure as soon as possible. Adjust the tire pressure as required.

290

KNOWING YOUR

VEHICLE

SAFETY

STARTING AND

DRIVING

WARNING LIGHTSAND

MESSAGES

IN AN

EMERGENCY

SER VICING

AND

CARE

TECHNICAL

SPECIFICATIONS

CONTENTS

Page 297 of 412

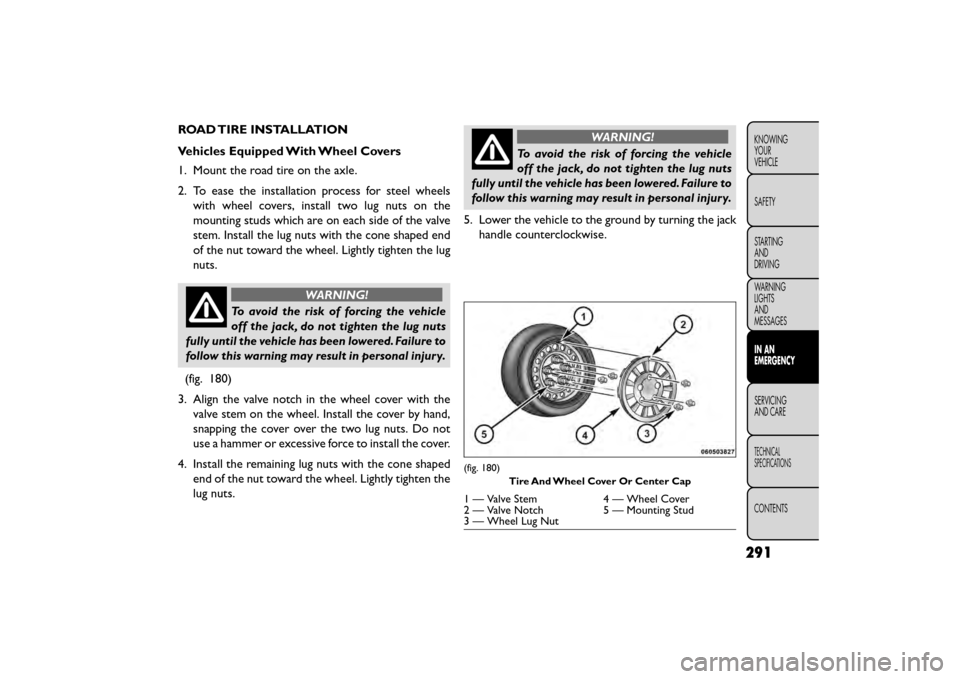

ROAD TIRE INSTALLATION

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheelswith wheel covers, install two lug nuts on the

mounting studs which are on each side of the valve

stem. Install the lug nuts with the cone shaped end

of the nut toward the wheel. Lightly tighten the lug

nuts.

WARNING!

To avoid the risk of forcing the vehicle

off t

he jack, do not tighten the lug nuts

fully until the vehicle has been lowered. Failure to

follow this warning may result in personal injury.

(fig. 180)

3. Align the valve notch in the wheel cover with the valve stem on the wheel. Install the cover by hand,

snapping the cover over the two lug nuts. Do not

use a hammer or excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the

lug nuts.

WARNING!

To avoid the risk of forcing the vehicle

off t

he jack, do not tighten the lug nuts

fully until the vehicle has been lowered. Failure to

follow this warning may result in personal injury.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

(fig. 180)

Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Mounting Stud

3 — Wheel Lug Nut

291

KNOWING

YOUR

VEHICLE

SAFETY

STARTING

AND

DRIVING

WARNING

LIGHTS

AND

MESSAGES

IN AN

EMERGENCY

SER VICING

AND

CARE

TECHNICAL

SPECIFICATIONS

CONTENTS