engine FIAT IDEA 2009 1.G Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2009, Model line: IDEA, Model: FIAT IDEA 2009 1.GPages: 210, PDF Size: 3.62 MB

Page 175 of 210

174

STARTING

AND DRIVING

IN AN

EMERGENCY

TECHNICAL

SPECIFICATIONS

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

IMPORTANT A battery which is kept at

a charge of less than 50% for any length of

time will be damaged by sulphation leading

to a reduction in cranking power.

The battery will also be more at risk of

freezing (already at –10 °C).

Refer to the paragraph “Car inactivity” in

“Starting and driving” if the car is left

parked for a long time.

If after buying the car, you want to install

electric accessories which require per-

manent electric supply (alarm, etc.) con-

tact Fiat Dealership whose qualified per-

sonnel, in addition to suggesting the mo-

st suitable devices from Lineaccessori Fiat,

will evaluate the overall electric absorp-

tion, checking whether the car’s electric

system is capable of withstanding the load

required, or whether it should be inte-

grated with a more powerful battery.

Since these devices continue absorbing

energy even when the ignition key is off,

they gradually run down the battery. USEFUL ADVICE FOR

LENGTHENING THE LIFE OF

YOUR BATTERY

To avoid draining your battery and

lengthen its life, observe the following in-

dications:

❒when the car is parked, make sure that

the doors, bonnet and tailgate are clo-

sed properly to make sure that the li-

ghts inside the passenger compart-

ment go out;

❒switch off all lights inside the vehicle:

the car is however equipped with a sy-

stem which switches all internal lights

off automatically;

❒do not keep devices (e.g. sound sy-

stem, hazard lights, etc.) on for a long

time with the engine off;

❒before performing any operation on the

electrical system, disconnect the bat-

tery negative cable;

❒battery terminals shall always be per-

fectly tightened.Batteries contain very dange-

rous substances for the envi-

ronment. You are recommen-

ded to go to a Fiat Dealership

to have the battery replaced where the

old battery will be disposed of respec-

ting both the environment and the laws

in force.

If the vehicle needs to be off

the road for a long period

under conditions of intense cold, re-

move the battery and take it to a

heated place, otherwise it may free-

ze.

WARNING

When performing any ope-

ration on the battery or near

it, always protect your eyes with the

special goggles.

WARNING

Page 179 of 210

178

STARTING

AND DRIVING

IN AN

EMERGENCY

TECHNICAL

SPECIFICATIONS

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

BODYWORK

PROTECTION FROM

ATMOSPHERIC AGENTS

The main causes of corrosion are the fol-

lowing:

❒atmospheric pollution;

❒salty air and humidity (coastal areas,

or hot humid climates);

❒seasonal environment conditions.

Not to be underestimated is also the abra-

sive action of wind-borne atmospheric du-

st and sand and mud and gravel raised by

other cars.

On your car, Fiat implemented the best

manufacturing technologies to effectively

protect the bodywork against corrosion.

These are the most important:

❒painting products and systems which

give the car particular resistance to

corrosion and abrasion;

❒use of galvanised (or pre-treated) steel

sheets, with high resistance to corro-

sion;

❒spraying of plastic parts with a pro-

tective function in the more exposed

points: under door, inner wing parts,

edges, etc.;

❒boxed parts are designed to prevent

condensation and pooling of water

which can cause corrosion from the

inside.BODY AND UNDERBODY

WARRANTY

Your car is covered by warranty against

perforation due to rust of any original ele-

ment of the structure or body. For the ge-

neral terms of this warranty, refer to your

“FIAT SERVICE” Booklet.

ADVICE FOR PRESERVING THE

BODYWORK

Paint

Paintwork does not only serve an aesthe-

tic purpose, but also protects the un-

derlying sheet metal.

Touch up abrasions and scratches imme-

diately to prevent the formation of rust.

Only use genuine spare paint products for

touch-ups (see “Bodywork paint identifi-

cation plate” in the “Technical Specifica-

tions” section).Normal maintenance of paintwork consi-

sts in washing the vehicle: the frequency

depends on the conditions and environ-

ment where the vehicle is used. For exam-

ple, it is advisable to wash the car more

often in areas with a high environmental

pollution or on roads sprinkled with salt.

To correctly wash the car:

❒remove the aerial from the roof to

prevent damage to it if the car is wa-

shed in an automatic system;

❒wash the body using a low pressure jet

of water;

❒wipe a sponge with a slightly soapy so-

lution over the bodywork, frequently

rinsing with the sponge;

❒rinse well with water and dry with a

jet of air or a chamois leather.

Dry the parts less in sight particularly ca-

refully, such as the door frames and the

headlight frames, where water may sta-

gnate more easily. It is a good idea to lea-

ve the car in the open for a while after wa-

shing it to give time for the water to eva-

porate.

Do not wash the car after it has been

parked in the sun or when the engine is

bonnet is hot: this could take the shine off

the paint.

Page 180 of 210

179

STARTING

AND DRIVING

IN AN

EMERGENCY

TECHNICAL

SPECIFICATIONS

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

Exterior plastic parts must be cleaned in

the same way as the rest of the car.

Where possible, do not park under trees;

the resinous substance many species re-

lease give the paint a dull appearance and

increase the possibility of triggering rust

processes.

IMPORTANT Bird droppings must be wa-

shed off immediately and thoroughly as the

acid they contain is particularly aggressi-

ve.

Windows

Use specific window cleaner products. Al-

so use clean cloths to avoid scratching the

glass or damaging the transparency.

IMPORTANT Wipe the rear window in-

side gently with a cloth in the direction

of the filaments to avoid damaging the hea-

ting device.Front headlights

IMPORTANT Never use aromatic sub-

stances (e.g.: petrol) or ketenes (e.g.: ace-

tone) for cleaning front headlight plastic

lens.

Engine compartment

At the end of every winter, wash the en-

gine compartment thoroughly, taking ca-

re not to aim the jet of water directly at

the electronic control units or at the

windscreen wiper motors. Have this ope-

ration performed at a specialised work-

shop.

IMPORTANT Perform this operation on

a cold engine and with the key at STOP.

After the washing operation, make sure

that the various protections (e.g. rubber

caps and guards) have not removed or da-

maged.Detergents pollute the envi-

ronment. The vehicle should

be washed in areas equipped

for collecting and purifying

the liquid used in the washing process.

Never use flammable pro-

ducts, such as petrol ether or

rectified petrol to clean inside the car.

The electrostatic charges which are

generated by rubbing during the clea-

ning operation may cause a fire.

WARNING

Page 182 of 210

181

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

IDENTIFICATION DATA ................................................. 182

ENGINE CODES - BODYWORK VERSIONS ............. 184

ENGINE ................................................................................. 185

FUEL FEED/IGNITION ....................................................... 187

TRANSMISSION UNIT ...................................................... 187

BRAKES .................................................................................. 188

SUSPENSIONS ..................................................................... 188

STEERING SYSTEM ............................................................. 188

WHEELS ................................................................................. 189

DIMENSIONS ....................................................................... 193

PERFORMANCE .................................................................. 193

WEIGHTS .............................................................................. 194

CAPACITIES ......................................................................... 195

FLUIDS AND LUBRICANTS ............................................ 196

FUEL CONSUMPTION ...................................................... 198

CO

2EMISSIONS .................................................................. 199

T T

E E

C C

H H

N N

I I

C C

A A

L L

S S

P P

E E

C C

I I

F F

I I

C C

A A

T T

I I

O O

N N

S S

Page 183 of 210

182

STARTING

AND DRIVING

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

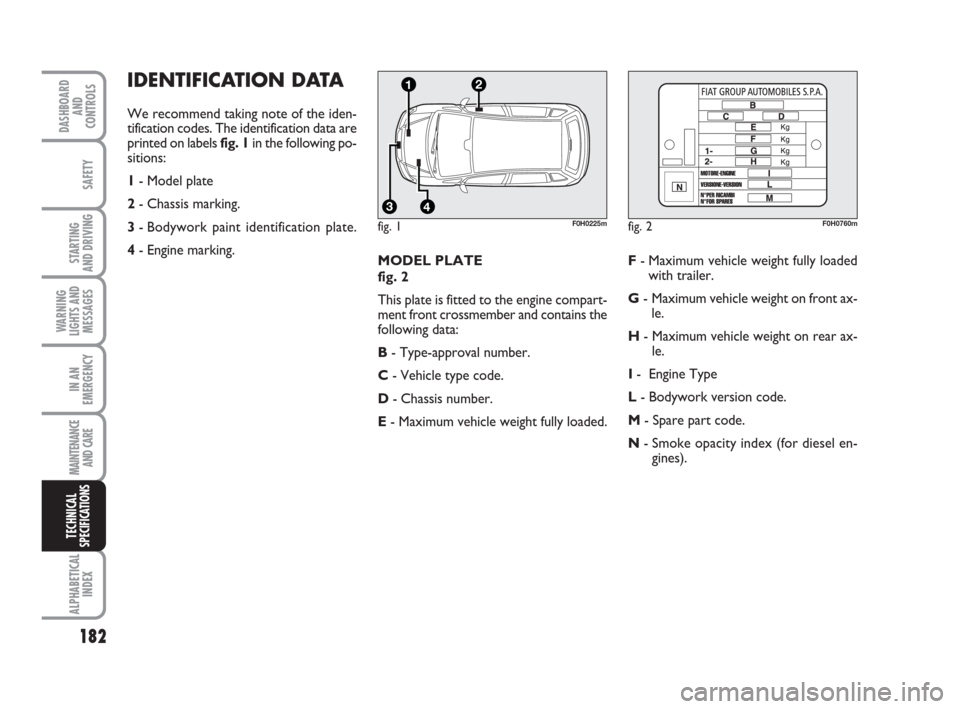

IDENTIFICATION DATA

We recommend taking note of the iden-

tification codes. The identification data are

printed on labels fig. 1in the following po-

sitions:

1- Model plate

2- Chassis marking.

3- Bodywork paint identification plate.

4- Engine marking.

MODEL PLATE

fig. 2

This plate is fitted to the engine compart-

ment front crossmember and contains the

following data:

B- Type-approval number.

C- Vehicle type code.

D- Chassis number.

E- Maximum vehicle weight fully loaded.F- Maximum vehicle weight fully loaded

with trailer.

G- Maximum vehicle weight on front ax-

le.

H- Maximum vehicle weight on rear ax-

le.

I- Engine Type

L- Bodywork version code.

M- Spare part code.

N- Smoke opacity index (for diesel en-

gines).

fig. 1

4

21

3

F0H0225mfig. 2F0H0760m

IN AN

EMERGENCY

Page 184 of 210

183

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

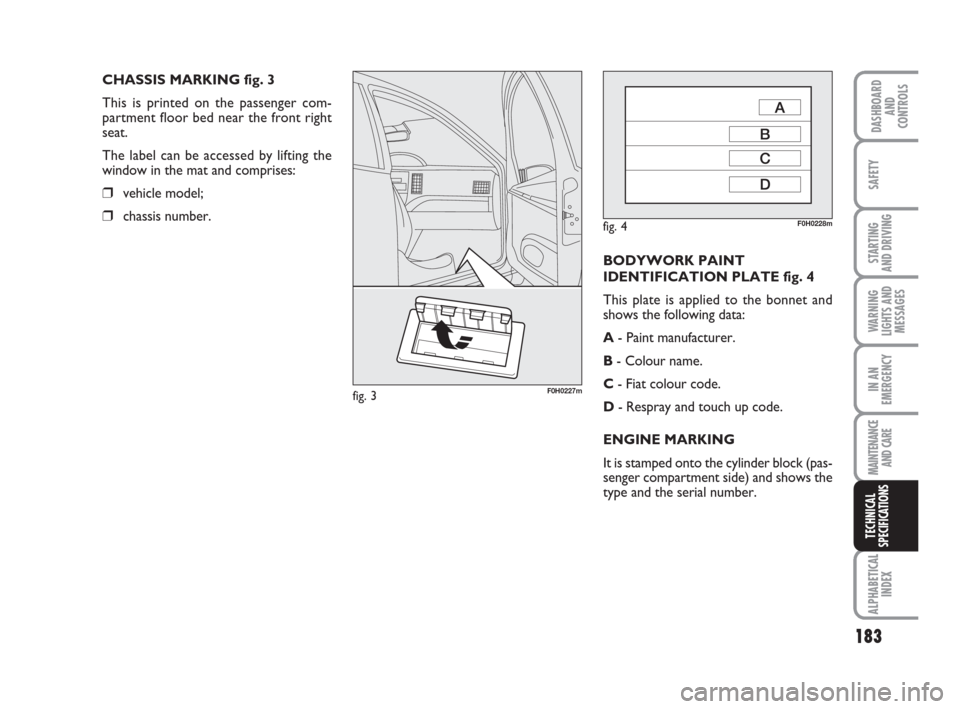

CHASSIS MARKING fig. 3

This is printed on the passenger com-

partment floor bed near the front right

seat.

The label can be accessed by lifting the

window in the mat and comprises:

❒vehicle model;

❒chassis number.

fig. 3F0H0227m

fig. 4F0H0228m

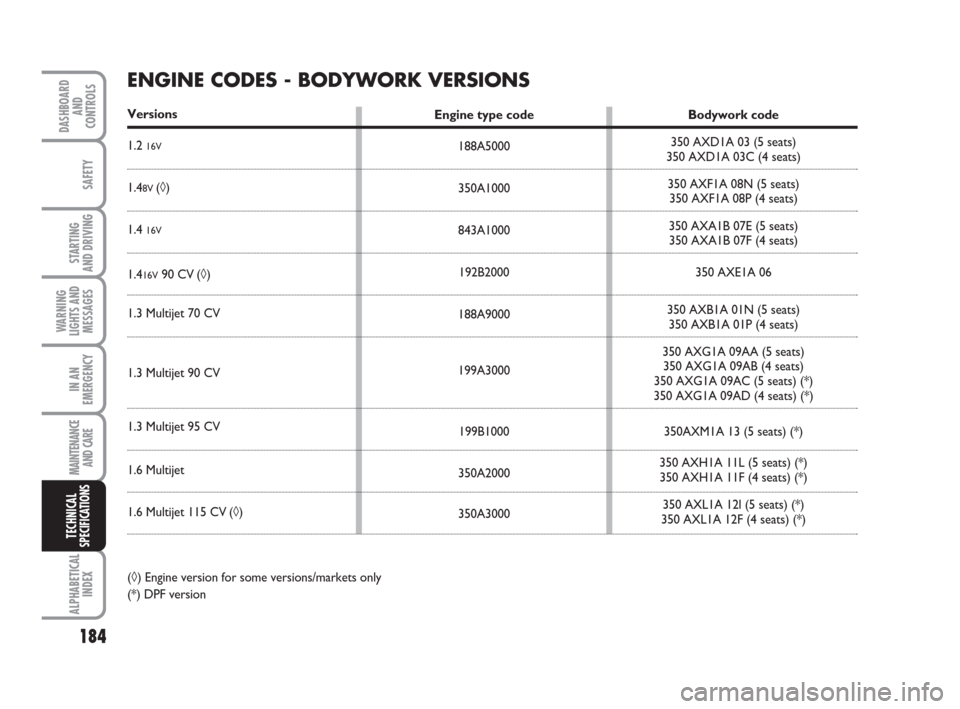

BODYWORK PAINT

IDENTIFICATION PLATE fig. 4

This plate is applied to the bonnet and

shows the following data:

A- Paint manufacturer.

B- Colour name.

C- Fiat colour code.

D- Respray and touch up code.

ENGINE MARKING

It is stamped onto the cylinder block (pas-

senger compartment side) and shows the

type and the serial number.

Page 185 of 210

184

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

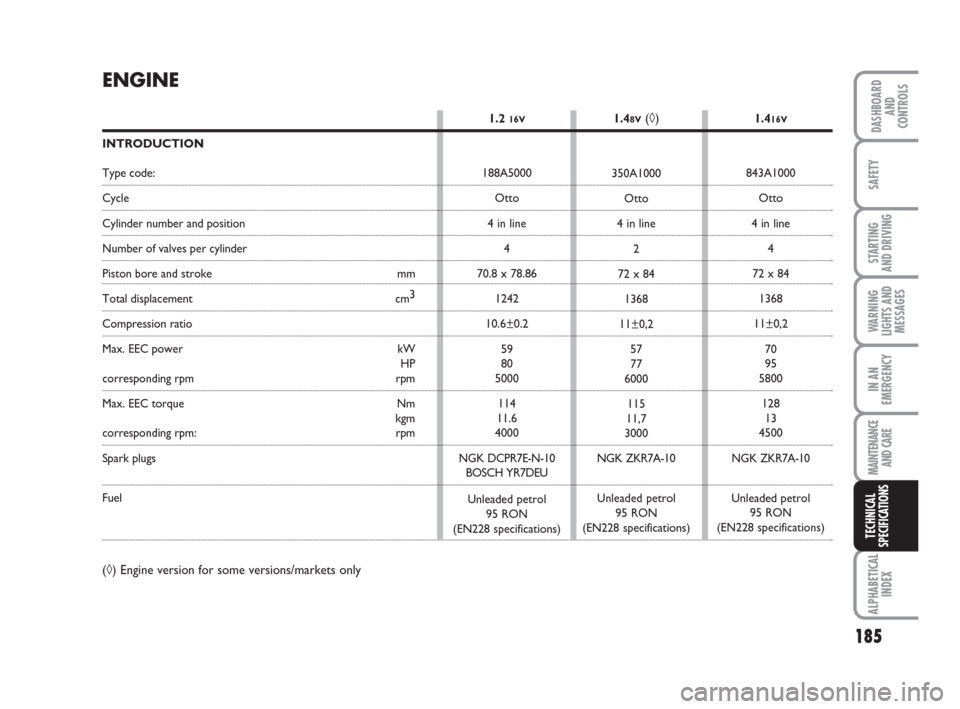

ENGINE CODES - BODYWORK VERSIONS

Versions

1.2

16V

1.48V (◊)

1.4 16V

1.416V90 CV (◊)

1.3 Multijet 70 CV

1.3 Multijet 90 CV

1.3 Multijet 95 CV

1.6 Multijet

1.6 Multijet 115 CV (◊)

Bodywork code

350 AXD1A 03 (5 seats)

350 AXD1A 03C (4 seats)

350 AXF1A 08N (5 seats)

350 AXF1A 08P (4 seats)

350 AXA1B 07E (5 seats)

350 AXA1B 07F (4 seats)

350 AXE1A 06

350 AXB1A 01N (5 seats)

350 AXB1A 01P (4 seats)

350 AXG1A 09AA (5 seats)

350 AXG1A 09AB (4 seats)

350 AXG1A 09AC (5 seats) (*)

350 AXG1A 09AD (4 seats) (*)

350AXM1A 13 (5 seats) (*)

350 AXH1A 11L (5 seats) (*)

350 AXH1A 11F (4 seats) (*)

350 AXL1A 12l (5 seats) (*)

350 AXL1A 12F (4 seats) (*)

(◊) Engine version for some versions/markets only

(*) DPF versionEngine type code

188A5000

350A1000

843A1000

192B2000

188A9000

199A3000

199B1000

350A2000

350A3000

Page 186 of 210

185

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

(◊) Engine version for some versions/markets only

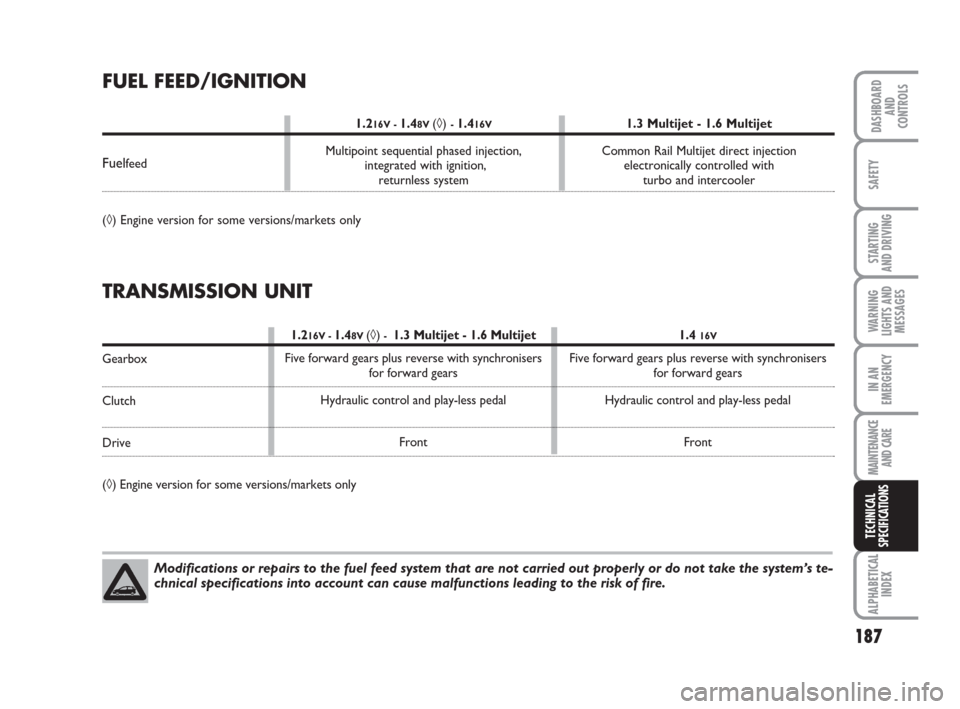

ENGINE

INTRODUCTION

Type code:

Cycle

Cylinder number and position

Number of valves per cylinder

Piston bore and stroke mm

Total displacement cm3

Compression ratio

Max. EEC power kW

HP

corresponding rpm rpm

Max. EEC torque Nm

kgm

corresponding rpm: rpm

Spark plugs

Fuel

1.2 16V

188A5000

Otto

4 in line

4

70.8 x 78.86

1242

10.6±0.2

59

80

5000

114

11.6

4000

NGK DCPR7E-N-10

BOSCH YR7DEU

Unleaded petrol

95 RON

(EN228 specifications)1.4

16V

843A1000

Otto

4 in line

4

72 x 84

1368

11±0,2

70

95

5800

128

13

4500

NGK ZKR7A-10

Unleaded petrol

95 RON

(EN228 specifications) 1.4

8V(◊)

350A1000

Otto

4 in line

2

72 x 84

1368

11±0,2

57

77

6000

115

11,7

3000

NGK ZKR7A-10

Unleaded petrol

95 RON

(EN228 specifications)

Page 188 of 210

187

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

FUEL FEED/IGNITION

Fuelfeed

(◊) Engine version for some versions/markets only

TRANSMISSION UNIT

Gearbox

Clutch

Drive

(◊) Engine version for some versions/markets only1.3 Multijet - 1.6 Multijet

Common Rail Multijet direct injection

electronically controlled with

turbo and intercooler 1.2

16V - 1.48V (◊) - 1.416V

Multipoint sequential phased injection,

integrated with ignition,

returnless system

1.2

16V - 1.48V (◊) - 1.3 Multijet - 1.6 Multijet

Five forward gears plus reverse with synchronisers

for forward gears

Hydraulic control and play-less pedal

Front1.4 16V

Five forward gears plus reverse with synchronisers

for forward gears

Hydraulic control and play-less pedal

Front

Modifications or repairs to the fuel feed system that are not carried out properly or do not take the system’s te-

chnical specifications into account can cause malfunctions leading to the risk of fire.

Page 189 of 210

188

STARTING

AND DRIVING

IN AN

EMERGENCY

MAINTENANCE

AND CARE

ALPHABETICAL

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

WARNING

LIGHTS AND

MESSAGES

TECHNICAL

SPECIFICATIONS

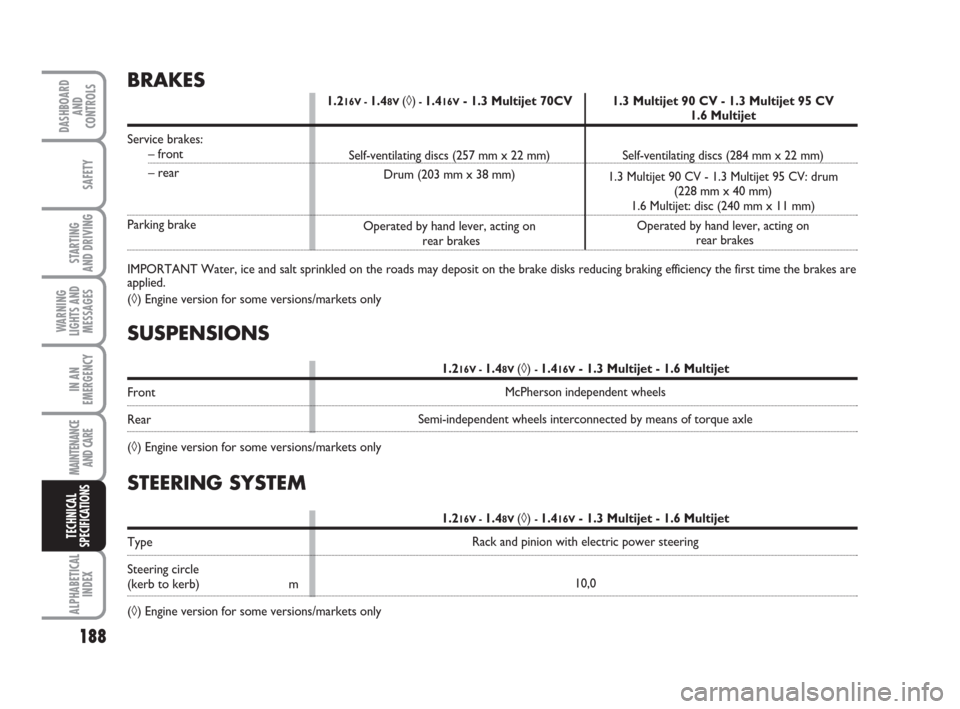

SUSPENSIONS

Front

Rear

(◊) Engine version for some versions/markets only1.2

16V - 1.48V (◊) - 1.416V- 1.3 Multijet - 1.6 Multijet

McPherson independent wheels

Semi-independent wheels interconnected by means of torque axle

STEERING SYSTEM

Type

Steering circle

(kerb to kerb) m

(◊) Engine version for some versions/markets only1.2

16V - 1.48V (◊) - 1.416V- 1.3 Multijet - 1.6 Multijet

Rack and pinion with electric power steering

10,0

BRAKES

Service brakes:– front

– rear

Parking brake

IMPORTANT Water, ice and salt sprinkled on the roads may deposit on the brake disks reducing braking efficiency the first time the brakes are

applied.

(◊) Engine version for some versions/markets only1.2

16V - 1.48V (◊)- 1.416V- 1.3 Multijet 70CV

Self-ventilating discs (257 mm x 22 mm)

Drum (203 mm x 38 mm)

Operated by hand lever, acting on

rear brakes1.3 Multijet 90 CV - 1.3 Multijet 95 CV

1.6 Multijet

Self-ventilating discs (284 mm x 22 mm)

1.3 Multijet 90 CV - 1.3 Multijet 95 CV: drum

(228 mm x 40 mm)

1.6 Multijet: disc (240 mm x 11 mm)

Operated by hand lever, acting on

rear brakes