Pressure regulator FIAT MAREA 2000 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2000, Model line: MAREA, Model: FIAT MAREA 2000 1.GPages: 330

Page 95 of 330

Marea- Marea Weekend 9 ™

2000 range ©) Fuel feed system

Engine

10.

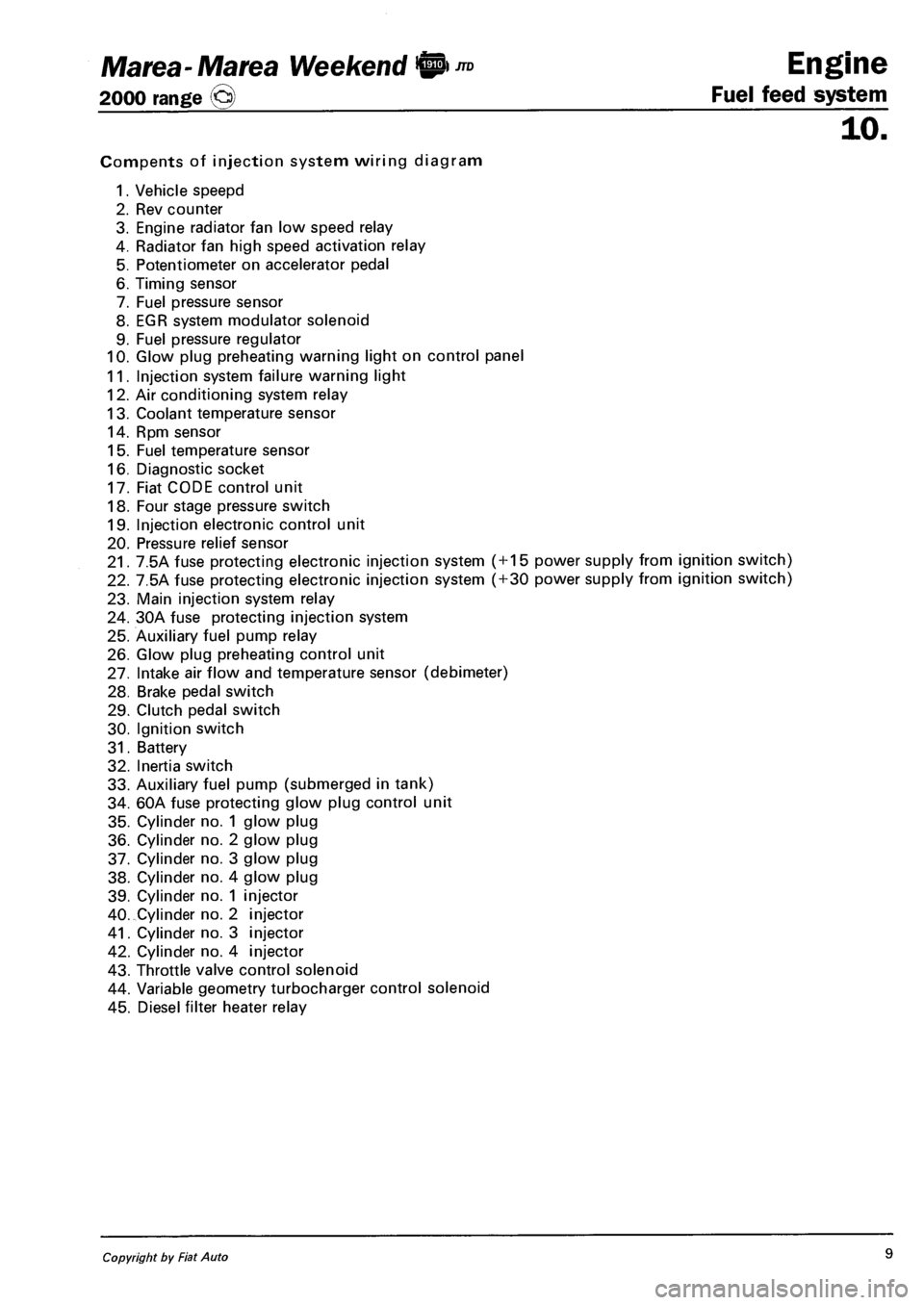

Compents of injection system wiring diagram

1. Vehicle speepd

2. Rev counter

3. Engine radiator fan low speed relay

4. Radiator fan high speed activation relay

5. Potentiometer on accelerator pedal

6. Timing sensor

7. Fuel pressure sensor

8. EGR system modulator solenoid

9. Fuel pressure regulator

10. Glow plug preheating warning light on control panel

11. Injection system failure warning light

12. Air conditioning system relay

13. Coolant temperature sensor

14. Rpm sensor

15. Fuel temperature sensor

16. Diagnostic socket

17. Fiat CODE control unit

18. Four stage pressure switch

19. Injection electronic control unit

20. Pressure relief sensor

21. 7.5A fuse protecting electronic injection system ( + 15 power supply from ignition switch)

22. 7.5A fuse protecting electronic injection system ( + 30 power supply from ignition switch)

23. Main injection system relay

24. 30A fuse protecting injection system

25. Auxiliary fuel pump relay

26. Glow plug preheating control unit

27. Intake air flow and temperature sensor (debimeter)

28. Brake pedal switch

29. Clutch pedal switch

30. Ignition switch

31. Battery

32. Inertia switch

33. Auxiliary fuel pump (submerged in tank)

34. 60A fuse protecting glow plug control unit

35. Cylinder no. 1 glow plug

36. Cylinder no. 2 glow plug

37. Cylinder no. 3 glow plug

38. Cylinder no. 4 glow plug

39. Cylinder no. 1 injector

40. Cylinder no. 2 injector

41. Cylinder no. 3 injector

42. Cylinder no. 4 injector

43. Throttle valve control solenoid

44. Variable geometry turbocharger control solenoid

45. Diesel filter heater relay

Copyright by Fiat Auto 9

Page 96 of 330

Engine Marea- Marea Weekend 9 ™

Fuel feed system 2000 range @

10.

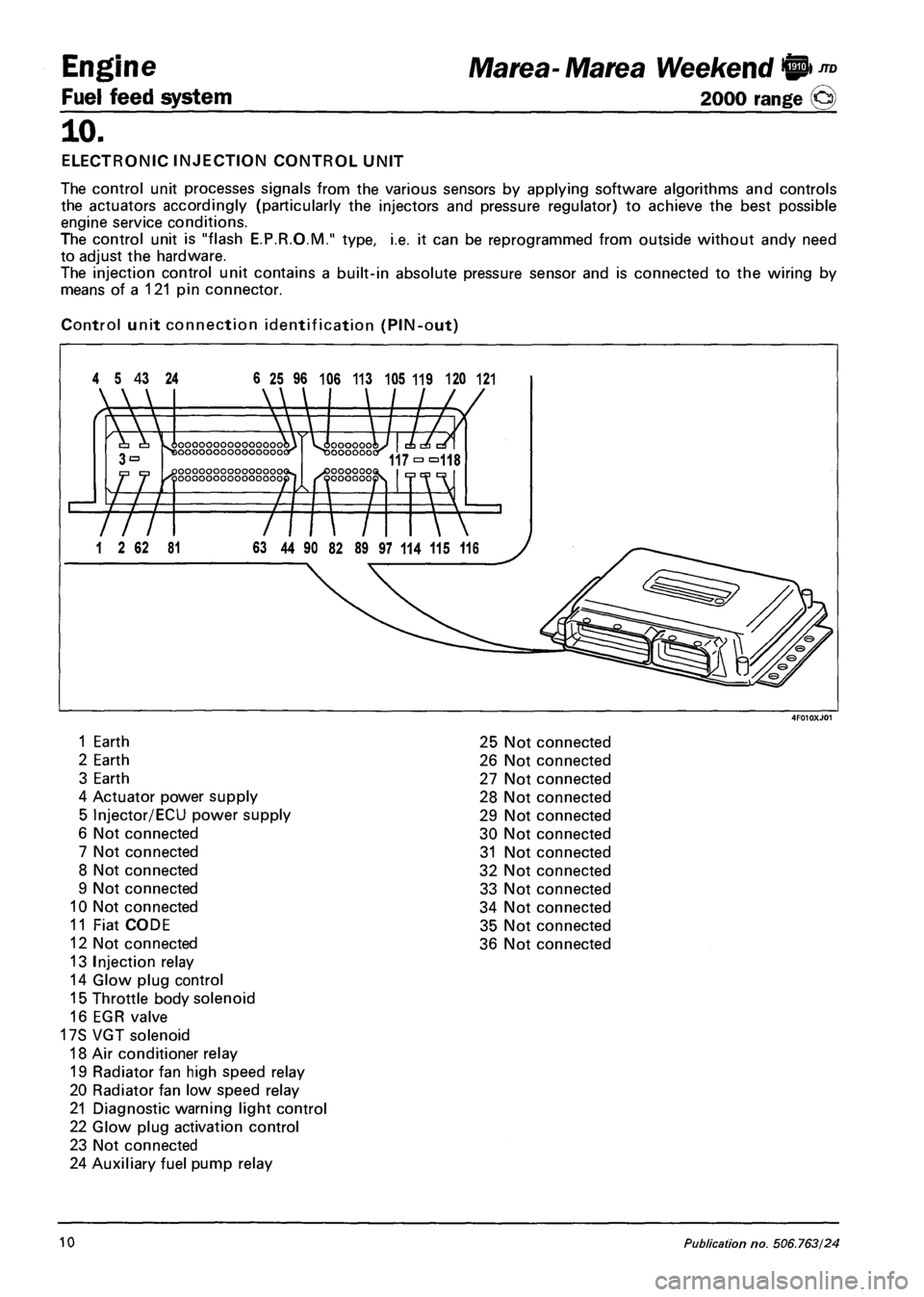

ELECTRONIC INJECTION CONTROL UNIT

The control unit processes signals from the various sensors by applying software algorithms and controls

the actuators accordingly (particularly the injectors and pressure regulator) to achieve the best possible

engine service conditions.

The control unit is "flash E.P.R.O.M." type, i.e. it can be reprogrammed from outside without andy need

to adjust the hardware.

The injection control unit contains a built-in absolute pressure sensor and is connected to the wiring by

means of a 121 pin connector.

Control unit connection identification (PIN-out)

4 5 43 24 6 25 96 106 113 105 119 120 121

1 Earth 25 Not connected

2 Earth 26 Not connected

3 Earth 27 Not connected

4 Actuator power supply 28 Not connected

5 Injector/ECU power supply 29 Not connected

6 Not connected 30 Not connected

7 Not connected 31 Not connected

8 Not connected 32 Not connected

9 Not connected 33 Not connected

10 Not connected 34 Not connected

11 Fiat CODE 35 Not connected

12 Not connected 36 Not connected

13 Injection relay

14 Glow plug control

15 Throttle body solenoid

16 EGR valve

17S VGT solenoid

18 Air conditioner relay

19 Radiator fan high speed relay

20 Radiator fan low speed relay

21 Diagnostic warning light control

22 Glow plug activation control

23 Not connected

24 Auxiliary fuel pump relay

10 Publication no. 506.763/24

Page 97 of 330

Ma tea- Ma tea Weekend !@ ™

2000 range ©

Engine

Fuel feed system

10.

37 Not connected

38 Not connected

39 Not connected

40 Not connected

41 Not connected

42 Not connected

43 Not connected

44 Not connected

45 Not connected

46 Not connected

47 Engine rpm signal output

48 Diagnostic line k

49 Vehicle speed signal input

50 Not connected

51 Activation signal from 4-stage pressure switch

52 Activation signal from 3-stage pressure switch

53 Not connected

54 Not connected

55 Not connected

56 Not connected

57 Not connected

58 Key ON signal

59 Brake switch

60 Air conditioner activation request

61 Clutch switch

62 Glow plug diagnosis

63 Not connected

64 Not connected

65 Not connected

66 Not connected

67 Not connected

68 Not connected

69 Not connected

70 Not connected

71 Not connected

72 Not connected

73 Not connected

74 Not connected

75 Not connected

76 Accelerator pedal 1 earth

77 Accelerator pedal 1 signal

78 Accelerator pedal 1 power supply

79 Accelerator pedal 2 earth

80 Accelerator pedal 2 signal

81 Accelerator pedal 2 power supply

82 Diesel temperature sensor (pin 1)

83 Diesel temperature sensor (pin 2)

84 Coolant temperature sensor (pin 1)

85 Coolant temperature sensor (pin 2)

86 Air flow meter (pin 1)

87 Not connected

88 Air flow meter (pin 3)

89 Air flow meter (pin 5)

90 Fuel pressure sensor (pin 3)

91 Fuel pressure sensor (pin 2)

92 Fuel pressure sensor (pin 1)

93 Turbo pressure sensor (pin 1)

94 Turbo pressure sensor (pin 3)

95 Turbo pressure sensor (pin 2)

96 Not connected

97 Air flow meter (pin 4)

98 Not connected

99 RPM sensor (pin 1)

100 RPM sensor (pin 2)

101 RPM sensor (pin 3)

102 RPM sensor (pin 1)

103 Timing sensor (pin 2)

104 Timing sensor (pin 3)

105 Not connected

106 Not connected

107 Not connected

108 Fuel pressure regulator

109 Fuel pressure regulator

110 Not connected

111 Heater relay control Fuel filter

112 Not connected

113 Not connected

114 Cylinder 4 injector control

115 Not connected

116 Not connected

117 Cylinder 1 and 2 injector power supply

118 Cylinder 3 and 4 injector power supply

119 Cylinder 1 injector control

120 Cylinder 2 injector control

121 Cylinder 3 injector control

Copyright by Fiat Auto 11

Page 101 of 330

Marea- Marea Weekend 9™

2000 range (§)

4F015XJ03

Engine

Fuel feed system

ijo.

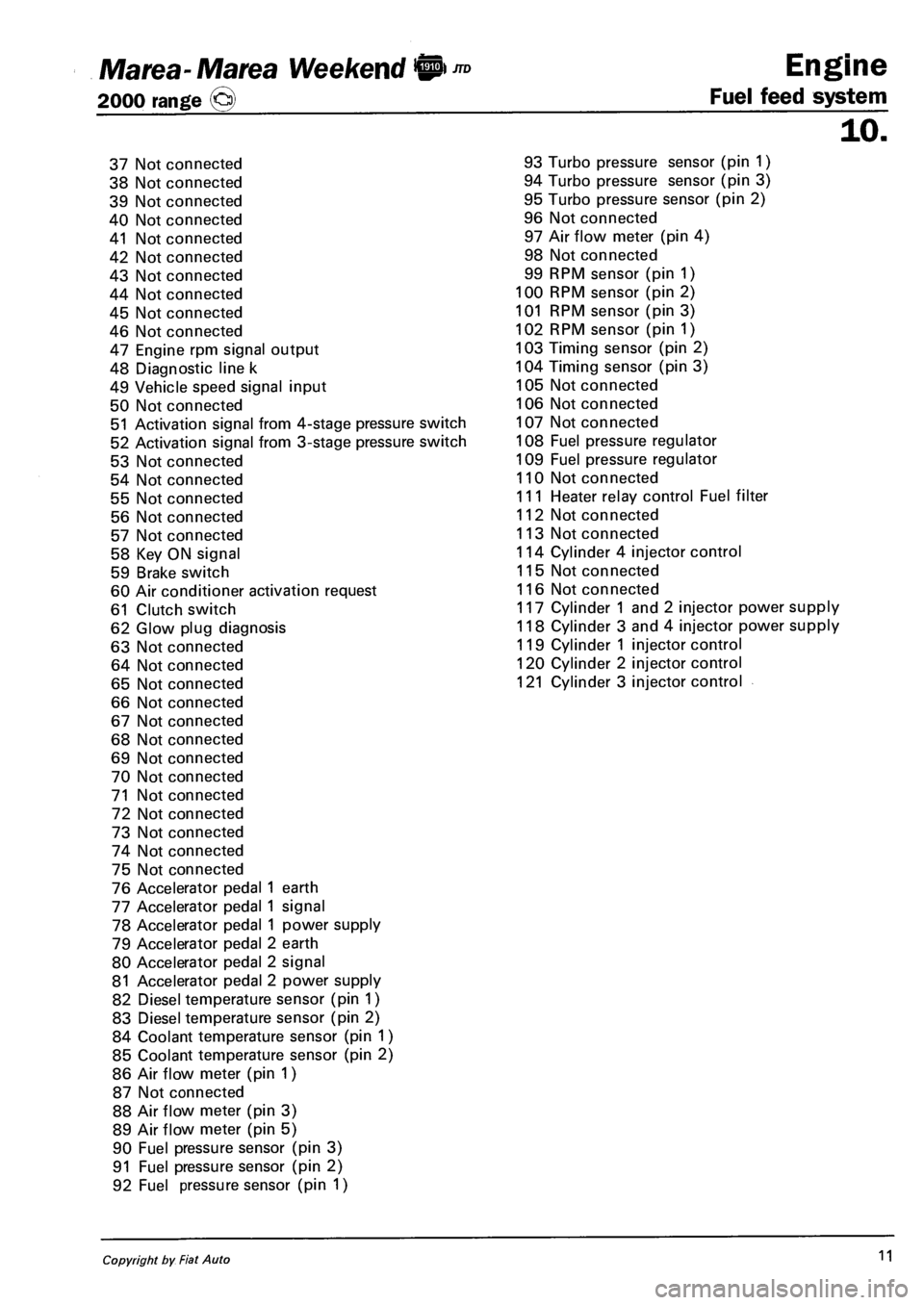

ENGINE COOLANT TEMPERATURE

SENSOR

The sensor is fitted to the thermostat and

measures the temperature of the engine cool

ant by means of an NTC thermistor with a

negative resistance coefficient.

Because the sensor is made using semicon

ductor technology, the resistance falls if sen

sor element temperature rises with increasing

coolant temperature.

Because resistance does not change in linear

manner, it is higher at low temperatures than

at high temperatures for the same temperature

increase.

1. NTC resistance

2. Sensor case

3. Electrical connector

FUEL TEMPERATURE

SENSOR

The sensor is fitted on the return manifold and

measures fuel temperature by means of an

NTC thermistor with a negative resistance co

efficient.

Refer to the previous description of the cool

ant temperature sensor for sensor operation.

FUEL PRESSURE SENSOR

The sensor is fitted in the middle of the fuel

delivery manifold (rail) and is responsible for

providing a return signal (feedback) to the

control unit in order to:

- adjust injection pressure;

- regulator injection duration.

Copyright by Fiat Auto 15

Page 104 of 330

Engine

Fuel feed system

JTD Marea- Marea Weekend 0

2000 range ©

10.

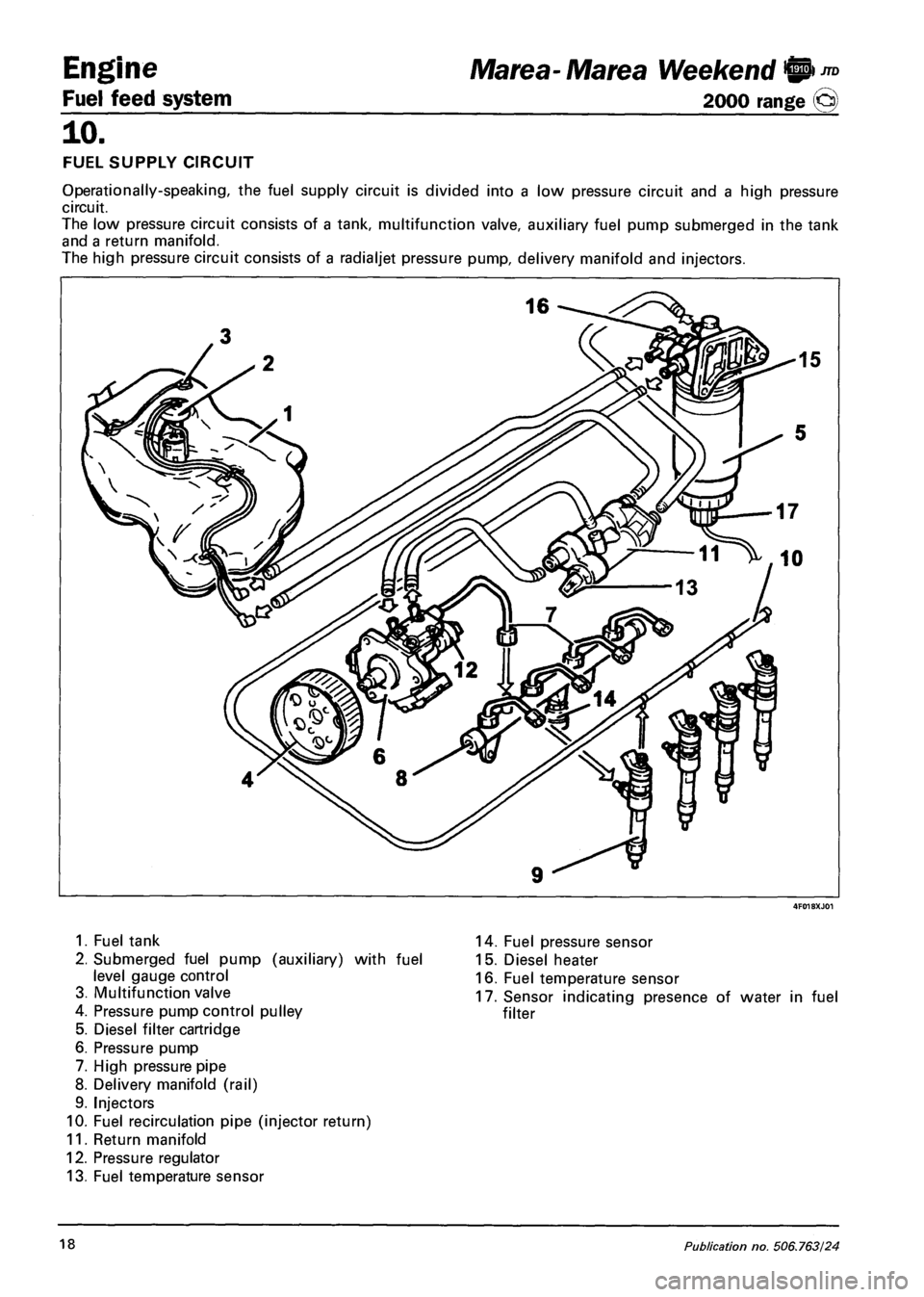

FUEL SUPPLY CIRCUIT

Operationally-speaking, the fuel supply circuit is divided into a low pressure circuit and a high pressure

circuit.

The low pressure circuit consists of a tank, multifunction valve, auxiliary fuel pump submerged in the tank

and a return manifold.

The high pressure circuit consists of a radialjet pressure pump, delivery manifold and injectors.

1. Fuel tank

2. Submerged fuel pump (auxiliary) with fuel

level gauge control

3. Multifunction valve

4. Pressure pump control pulley

5. Diesel filter cartridge

6. Pressure pump

7. High pressure pipe

8. Delivery manifold (rail)

9. Injectors

10. Fuel recirculation pipe (injector return)

11. Return manifold

12. Pressure regulator

13. Fuel temperature sensor

14. Fuel pressure sensor

15. Diesel heater

16. Fuel temperature sensor

17. Sensor indicating presence of water in fuel

filter

18 Publication no. 506.763/24

Page 106 of 330

Engine

Fuel feed system

JTD Marea-Marea Weekend @

2000 range ©

10.

7^ £3

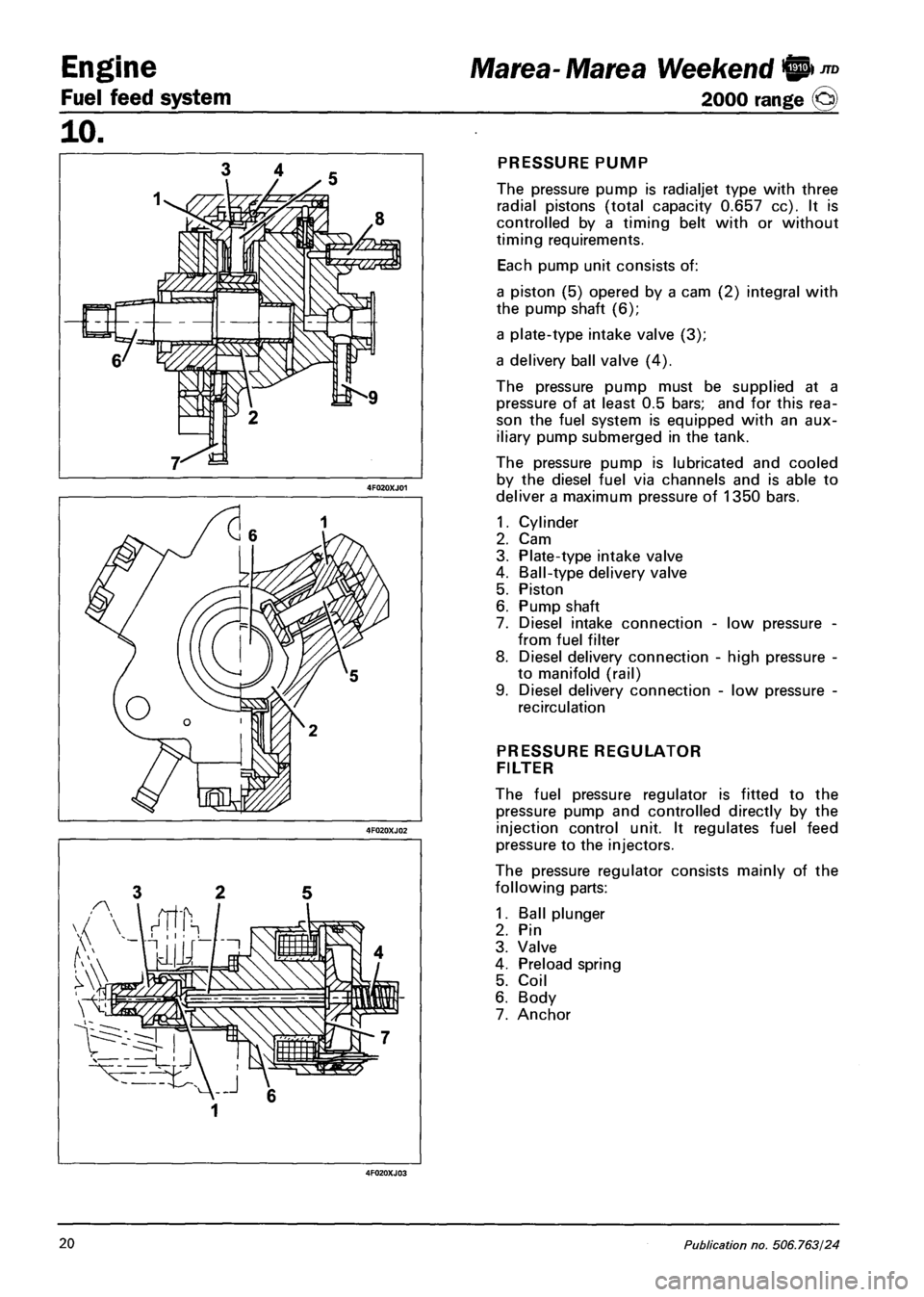

PRESSURE PUMP

The pressure pump is radialjet type with three

radial pistons (total capacity 0.657 cc). It is

controlled by a timing belt with or without

timing requirements.

Each pump unit consists of:

a piston (5) opered by a cam (2) integral with

the pump shaft (6);

a plate-type intake valve (3);

a delivery ball valve (4).

The pressure pump must be supplied at a

pressure of at least 0.5 bars; and for this rea

son the fuel system is equipped with an aux

iliary pump submerged in the tank.

The pressure pump is lubricated and cooled

by the diesel fuel via channels and is able to

deliver a maximum pressure of 1350 bars.

1.

2.

3.

4.

5.

6.

7.

8.

Cylinder

Cam

Plate-type intake valve

Ball-type delivery valve

Piston

Pump shaft

Diesel intake connection -

from fuel filter

Diesel delivery connection

to manifold (rail)

Diesel delivery connection

recirculation

low pressure

high pressure

low pressure

PRESSURE REGULATOR

FILTER

The fuel pressure regulator is fitted to the

pressure pump and controlled directly by the

injection control unit. It regulates fuel feed

pressure to the injectors.

The pressure regulator consists mainly of the

following parts:

1. Ball plunger

2. Pin

3. Valve

4. Preload spring

5. Coil

6. Body

7. Anchor

20 Publication no. 506.763/24

Page 122 of 330

Engine

Fuel feed system

Marea- Marea Weekend @ ™

2000 range ©

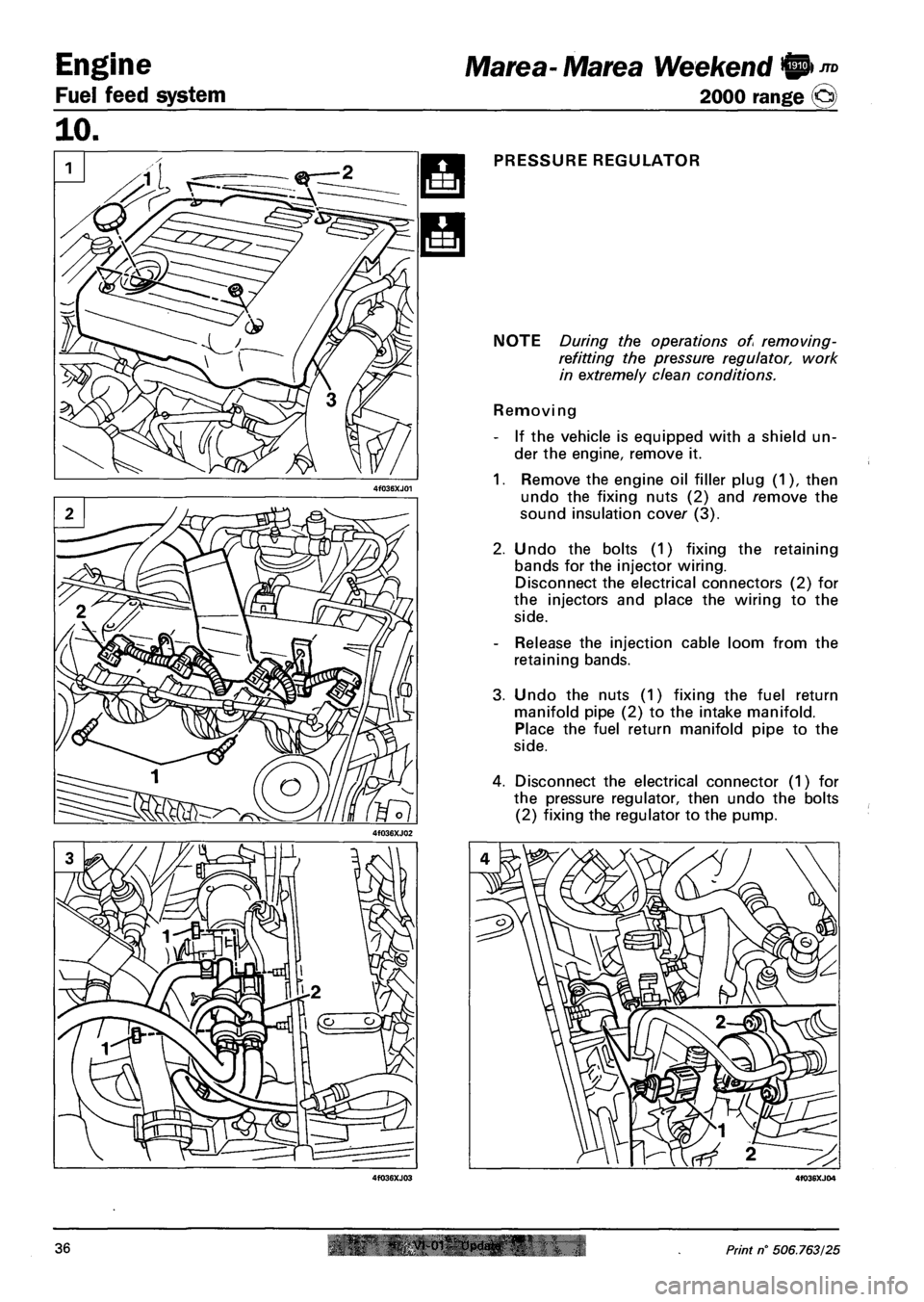

PRESSURE REGULATOR

NOTE During the operations of removing-

refitting the pressure regulator, work

in extremely clean conditions.

Removing

- If the vehicle is equipped with a shield un

der the engine, remove it.

1. Remove the engine oil filler plug (1), then

undo the fixing nuts (2) and remove the

sound insulation cover (3).

2. Undo the bolts (1) fixing the retaining

bands for the injector wiring.

Disconnect the electrical connectors (2) for

the injectors and place the wiring to the

side.

- Release the injection cable loom from the

retaining bands.

3. Undo the nuts (1) fixing the fuel return

manifold pipe (2) to the intake manifold.

Place the fuel return manifold pipe to the

side.

4. Disconnect the electrical connector (1) for

the pressure regulator, then undo the bolts

(2) fixing the regulator to the pump.

36 Print n° 506.763/25

Page 123 of 330

Marea-Marea Weekend H nD Engine

2000 range (Q) Fuel feed system

10.

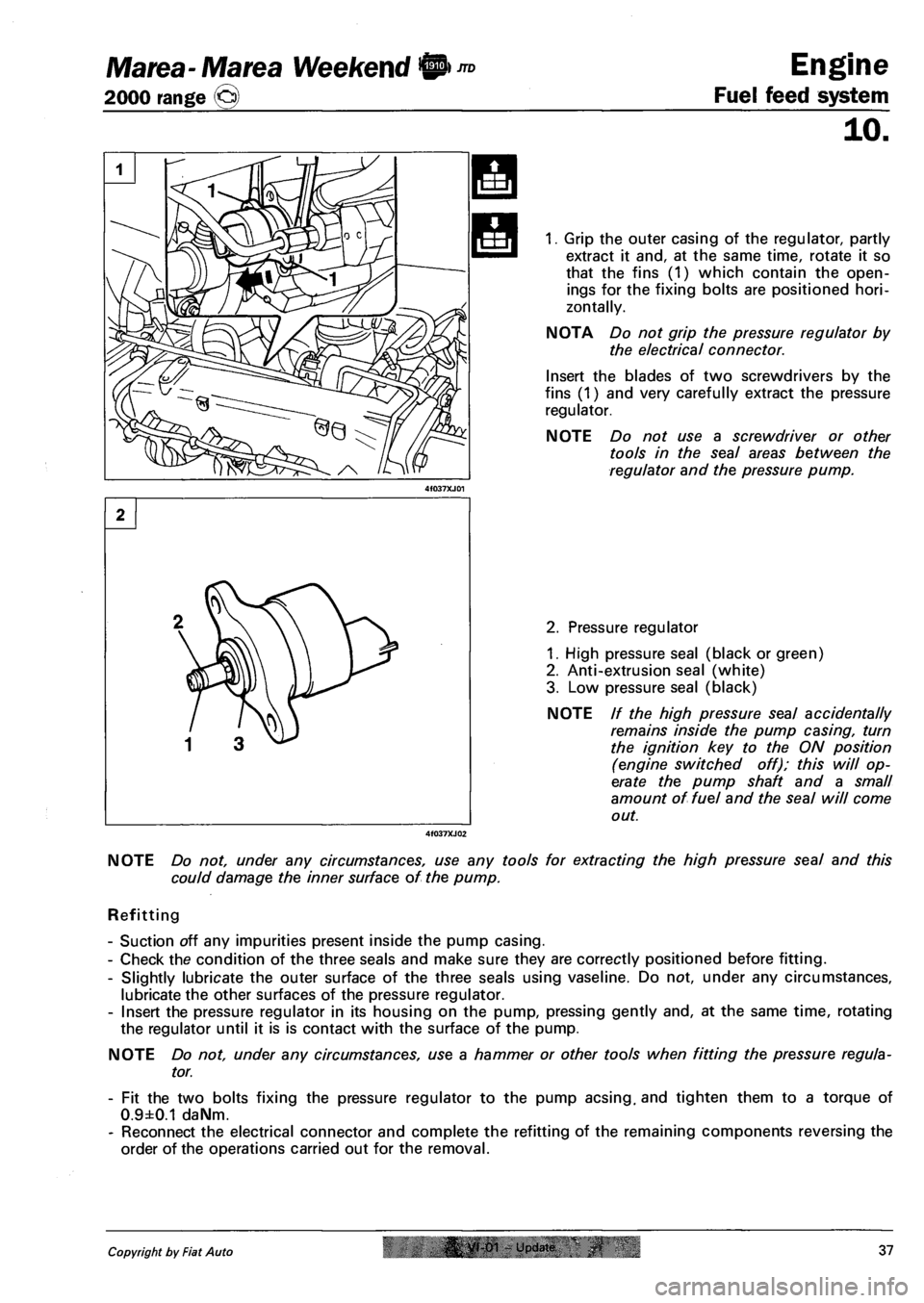

1. Grip the outer casing of the regulator, partly

extract it and, at the same time, rotate it so

that the fins (1) which contain the open

ings for the fixing bolts are positioned hori

zontally.

NOTA Do not grip the pressure regulator by

the electrical connector.

Insert the blades of two screwdrivers by the

fins (1) and very carefully extract the pressure

regulator.

NOTE Do not use a screwdriver or other

tools in the seal areas between the

regulator and the pressure pump.

2. Pressure regulator

1. High pressure seal (black or green)

2. Anti-extrusion seal (white)

3. Low pressure seal (black)

NOTE // the high pressure seal accidentally

remains inside the pump casing, turn

the ignition key to the ON position

(engine switched off); this will op

erate the pump shaft and a small

amount of fuel and the seal will come

out.

NOTE Do not, under any circumstances, use any tools for extracting the high pressure seal and this

could damage the inner surface of the pump.

Refitting

- Suction off any impurities present inside the pump casing.

- Check the condition of the three seals and make sure they are correctly positioned before fitting.

- Slightly lubricate the outer surface of the three seals using vaseline. Do not, under any circumstances,

lubricate the other surfaces of the pressure regulator.

- Insert the pressure regulator in its housing on the pump, pressing gently and, at the same time, rotating

the regulator until it is is contact with the surface of the pump.

NOTE Do not, under any circumstances, use a hammer or other tools when fitting the pressure regula

tor.

- Fit the two bolts fixing the pressure regulator to the pump acsing. and tighten them to a torque of

0.9±0.1 daNm.

- Reconnect the electrical connector and complete the refitting of the remaining components reversing the

order of the operations carried out for the removal.

Copyright by Fiat Auto |& yt-01 - Update 37

Page 260 of 330

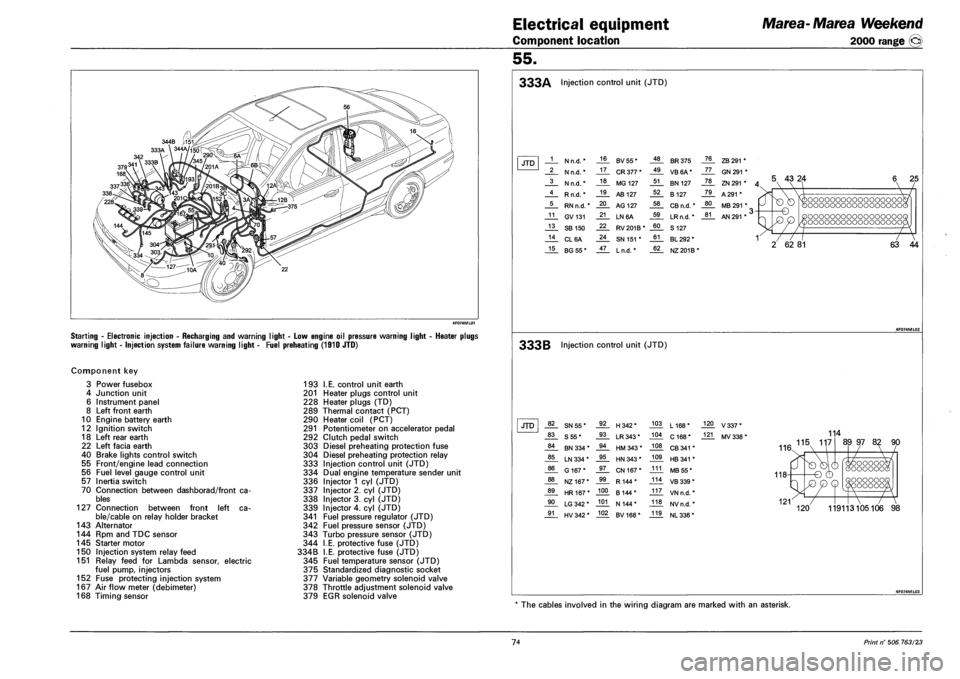

Electrical equipment

Component location

Marea-Marea Weekend

2000 range ©

55.

Starting - Electronic injection - Recharging and warning light - Low engine oil pressure warning

warning light - Injection system failure warning light - Fuel preheating (1910 JTD)

ight - Heater plugs

Component key

3 Power fusebox

4 Junction unit

6 Instrument panel

8 Left front earth

10 Engine battery earth

12 Ignition switch

18 Left rear earth

22 Left facia earth

40 Brake lights control switch

55 Front/engine lead connection

56 Fuel level gauge control unit

57 Inertia switch

70 Connection between dashborad/front ca

bles

127 Connection between front left ca

ble/cable on relay holder bracket

143 Alternator

144 Rpm and TDC sensor

145 Starter motor

150 Injection system relay feed

151 Relay feed for Lambda sensor, electric

fuel pump, injectors

152 Fuse protecting injection system

167 Air flow meter (debimeter)

168 Timing sensor

193 I.E. control unit earth

201 Heater plugs control unit

228 Heater plugs (TD)

289 Thermal contact (PCT)

290 Heater coil (PCT)

291 Potentiometer on accelerator pedal

292 Clutch pedal switch

303 Diesel preheating protection fuse

304 Diesel preheating protection relay

333 Injection control unit (JTD)

334 Dual engine temperature sender unit

336 Injector 1 cyl (JTD)

337 Injector 2. cyl (JTD)

338 Injector 3. cyl (JTD)

339 Injector 4. cyl (JTD)

341 Fuel pressure regulator (JTD)

342 Fuel pressure sensor (JTD)

343 Turbo pressure sensor (JTD)

344 I.E. protective fuse (JTD)

334B I.E. protective fuse (JTD)

345 Fuel temperature sensor (JTD)

375 Standardized diagnostic socket

377 Variable geometry solenoid valve

378 Throttle adjustment solenoid valve

379 EGR solenoid valve

333A Injection control unit (JTD)

JTD 1 N n.d. * 16 BV55* 48 BR 375 76 ZB 291 *

2 N n.d. * 17 CR 377 * 49 VB6A* 77 GN 291 *

3 N n.d. * 18 MG 127 51 BN 127 78 ZN 291 * A 4 Rn.d.* 19 AB 127 52 B 127 79 A 291 *

5 RN n.d. * 20 AG 127 58 CB n.d. * 80 MB 291 * ,

11 GV131 21 LN6A 59 LRn.d. * 81 AN 291 * ' >

13 SB 150 22 RV201B* 60 S 127

14 CL6A 24 SN 151 * 61 BL 292 * 1

15 BG55* 47 Ln.d. * 62 NZ 201B*

5 43 24

-o

T7

2 62 81

oooooooooooooooooc oooooooooooooooooc

oooooooooooooooooc oooooooooooooooooc

~7

63 44

333B Injection control unit (JTD)

JTD 82 SN55* 92 H342* 103 L168* 120 V337*

83 S55* 93 LR 343* 104 C 168* 121 MV 338 *

84 BN 334 * 94 HM 343 * 108 CB 341 *

85 LN 334 * 95 HN 343 * 109 HB 341 *

86 G 167* 97 CN 167* 111 MB 55*

88 NZ167* 99 R144* 114 VB 339 *

89 HR167* 100 B 144* 117 VN n.d. *

90 LG 342 * 101 N 144* 118 NVn.d. *

91 HV 342 * 102 BV168* 119 NL 336 *

114

AA 115 117

116.

89 97 82 90

oooooc OOOOOOG OOOOOOO 'OOOOOC

119113105106 98

* The cables involved in the wiring diagram are marked with an asterisk.

74 Print n° 506.763/23

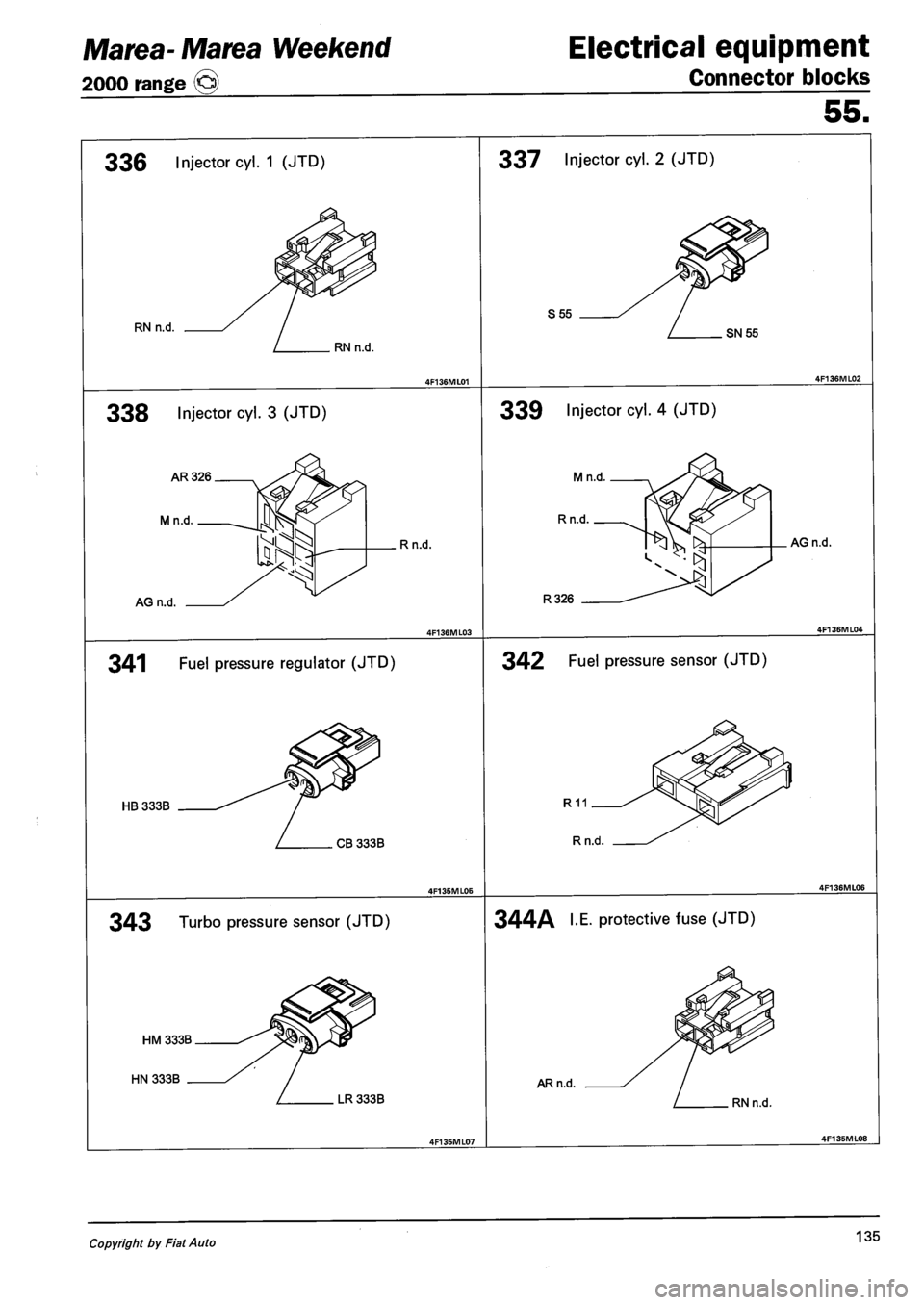

Page 321 of 330

Marea- Marea Weekend

2000 range ©

Electrical equipment

Connector blocks

55.

336 Injector cyl. 1 (JTD)

RN n.d.

RN n.d.

338 Injector cyl. 3 (JTD)

AR326

Mn.d.

AG n.d.

. R n.d.

337 Injector cyl. 2 (JTD)

S55

SN55

339 Injector cyl. 4 (JTD)

Mn.d

Rn.d.

341 Fuel pressure regulator (JTD)

HB 333B

CB 333B

343 Turbo pressure sensor (JTD)

LR 333B

R326

AG n.d.

342 Fuel pressure sensor (JTD)

344A I.E. protective fuse (JTD)

AR n.d.

RN n.d.

Copyright by Fiat Auto 135