OBD FIAT MAREA 2000 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2000, Model line: MAREA, Model: FIAT MAREA 2000 1.GPages: 330

Page 69 of 330

Marea- Marea Weekend • ^ Engine

2000 range (Q) Fuel feed system

10.

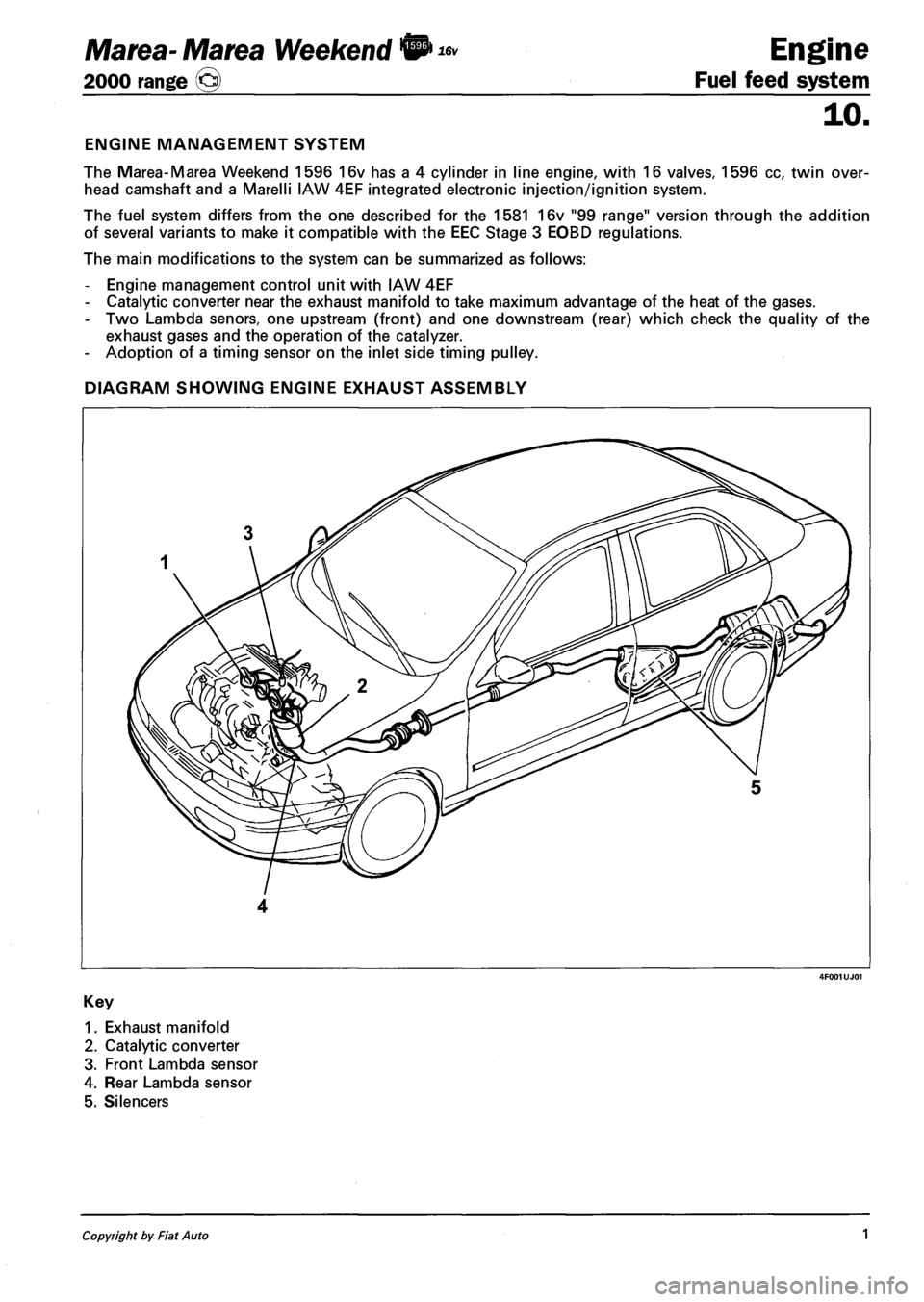

ENGINE MANAGEMENT SYSTEM

The Marea-Marea Weekend 1596 16v has a 4 cylinder in line engine, with 16 valves, 1596 cc, twin over

head camshaft and a Marelli IAW 4EF integrated electronic injection/ignition system.

The fuel system differs from the one described for the 1581 16v "99 range" version through the addition

of several variants to make it compatible with the EEC Stage 3 EOBD regulations.

The main modifications to the system can be summarized as follows:

- Engine management control unit with IAW 4EF

- Catalytic converter near the exhaust manifold to take maximum advantage of the heat of the gases.

- Two Lambda senors, one upstream (front) and one downstream (rear) which check the quality of the

exhaust gases and the operation of the catalyzer.

- Adoption of a timing sensor on the inlet side timing pulley.

DIAGRAM SHOWING ENGINE EXHAUST ASSEMBLY

1. Exhaust manifold

2. Catalytic converter

3. Front Lambda sensor

4. Rear Lambda sensor

5. Silencers

Copyright by Fiat Auto 1

Page 78 of 330

Marea- Marea Weekend & Engine

2000 range (§) Fuel feed system

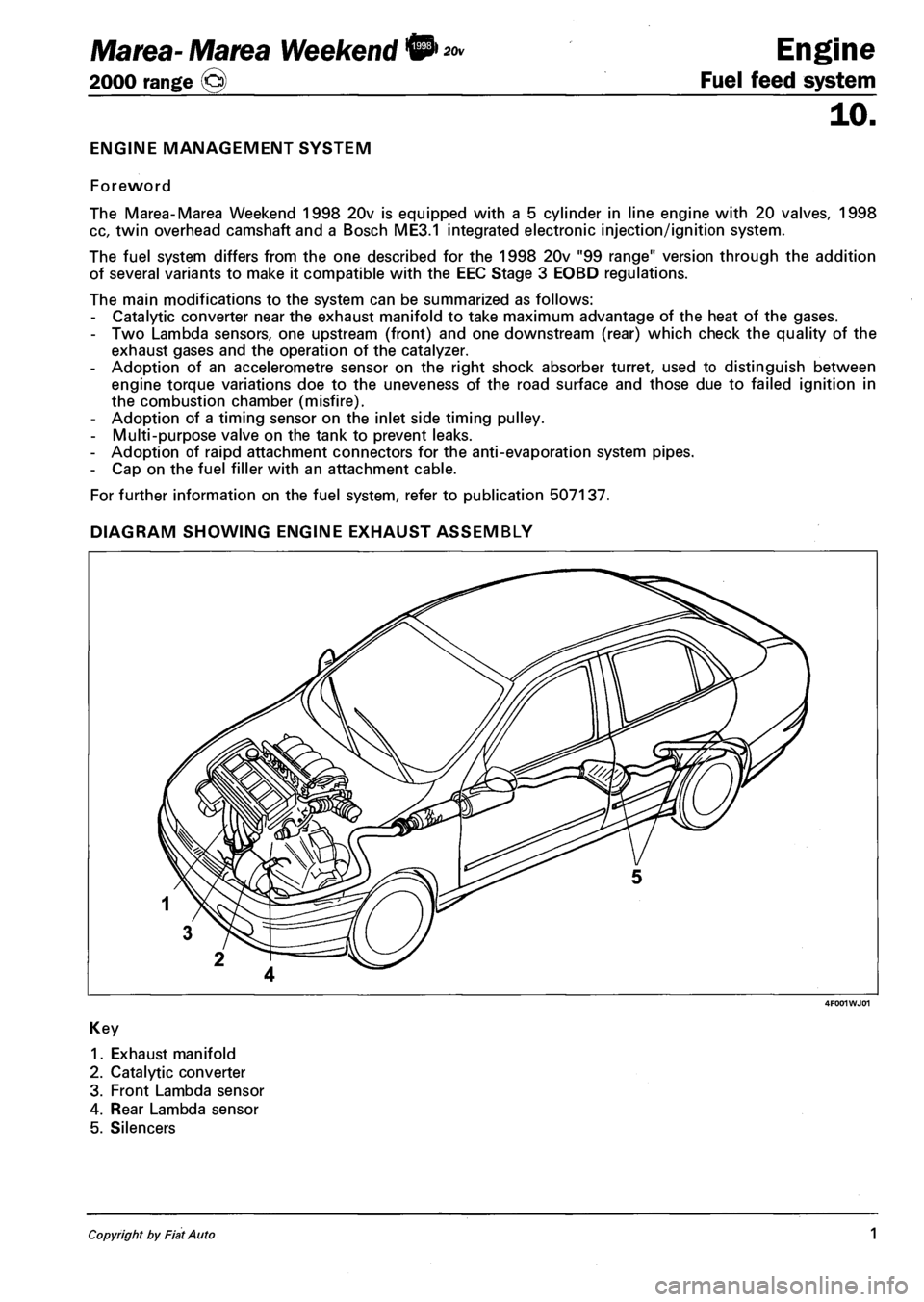

ENGINE MANAGEMENT SYSTEM

Foreword

The Marea-Marea Weekend 1998 20v is equipped with a 5 cylinder in line engine with 20 valves, 1998

cc, twin overhead camshaft and a Bosch ME3.1 integrated electronic injection/ignition system.

The fuel system differs from the one described for the 1998 20v "99 range" version through the addition

of several variants to make it compatible with the EEC Stage 3 EOBD regulations.

The main modifications to the system can be summarized as follows:

- Catalytic converter near the exhaust manifold to take maximum advantage of the heat of the gases.

- Two Lambda sensors, one upstream (front) and one downstream (rear) which check the quality of the

exhaust gases and the operation of the catalyzer.

- Adoption of an accelerometre sensor on the right shock absorber turret, used to distinguish between

engine torque variations doe to the uneveness of the road surface and those due to failed ignition in

the combustion chamber (misfire).

- Adoption of a timing sensor on the inlet side timing pulley.

- Multi-purpose valve on the tank to prevent leaks.

- Adoption of raipd attachment connectors for the anti-evaporation system pipes.

- Cap on the fuel filler with an attachment cable.

For further information on the fuel system, refer to publication 507137.

DIAGRAM SHOWING ENGINE EXHAUST ASSEMBLY

4F001WJ01

Key

1. Exhaust manifold

2. Catalytic converter

3. Front Lambda sensor

4. Rear Lambda sensor

5. Silencers

Copyright by Fiat Auto 1

Page 91 of 330

![FIAT MAREA 2000 1.G Workshop Manual Marea-Marea Weekend 9]

2000 range (j§)

I) JTD

Fuel feed system

Engine

10.

Exhaust fumes control

Through this function the injection control unit limits any exhaust fumes that could be produce FIAT MAREA 2000 1.G Workshop Manual Marea-Marea Weekend 9]

2000 range (j§)

I) JTD

Fuel feed system

Engine

10.

Exhaust fumes control

Through this function the injection control unit limits any exhaust fumes that could be produce](/img/10/4653/w960_4653-90.png)

Marea-Marea Weekend 9]

2000 range (j§)

I) JTD

Fuel feed system

Engine

10.

Exhaust fumes control

Through this function the injection control unit limits any exhaust fumes that could be produced during

transition speeds.

To satisy these requirements the control unit processes the signals supplied by the accelerator pedal po

tentiometer, the rpm sensor and the air flow meter and controls the fuel pressure regulator and the injec

tors to meter the correct amount of fuel to inject.

Exhaust gas recirculation control

On the basis of the signals supplied by the rpm sensor, intake air quantity sensor, engine coolant tempe

rature sensor and accelerator pedal position sensor, the control unit calculates the operating times for the

EGR valve so that the exhaust gases are partly recirculated in certain engine operating conditions in line

with Euro 3 pollution control standards.

Air conditioning system engagement control

The injection control unit manages the operation of the air conditioning system compressor electro

magnet coupling following a logic aimed at preventing operating conditions that would adversely affect

engine performance.

- When the compressor is switched on the injection control unit increases the quantity of fuel during

idling to allow the engine to adjust to the increased power requirements and momentarily interrupts the

supply to the compressor in high engine power requirement conditions (strong acceleration).

Engine immobilizer function control

The system is equipped with an engine immobilizer function. This function is achieved through the pre

sence of a specific control unit (Fiat CODE), capable of conversing with the injection control unit and an

electronic key with a special transmitter for sending a recognition code.

Each time the key is turned to the OFF position, the Fiat CODE system completely deactivates the injecti

on control unit.

When the key is turned to the ON position the following operations take place, in order:

1. the injection control unit (whose memory contains a secret code) sends the Fiat CODE control unit a

request to send the secret code to deactivate the immobilizer functions;

2. the Fiat CODE control unit responds by only sending the secret code after, in turn, having received the

recognition code transmitted by the ignition key;

3. the recognition of the secret code allows the deactivation of the injection control unit immobilizer func

tion and its normal operation.

Autodiagnosis

The complete electronic fault diagnosis of the injection system is carried out by connecting the special

equipment (EXAMINER or EXAMINER PLUS) to the standardized diagnostic socket (EOBD).

The system is also equipped with a self-diagnostic function which recognizes, memorizes and signals any

faults.

If a fault is detected in the sensors or actuators, the recovery strategy is immediately activated in order to

ensure that the engine functions at an acceptable level. The vehicle can be driven to a service centre for

the appropriate repairs to be carried out.

Copyright by Fiat Auto 5

Page 143 of 330

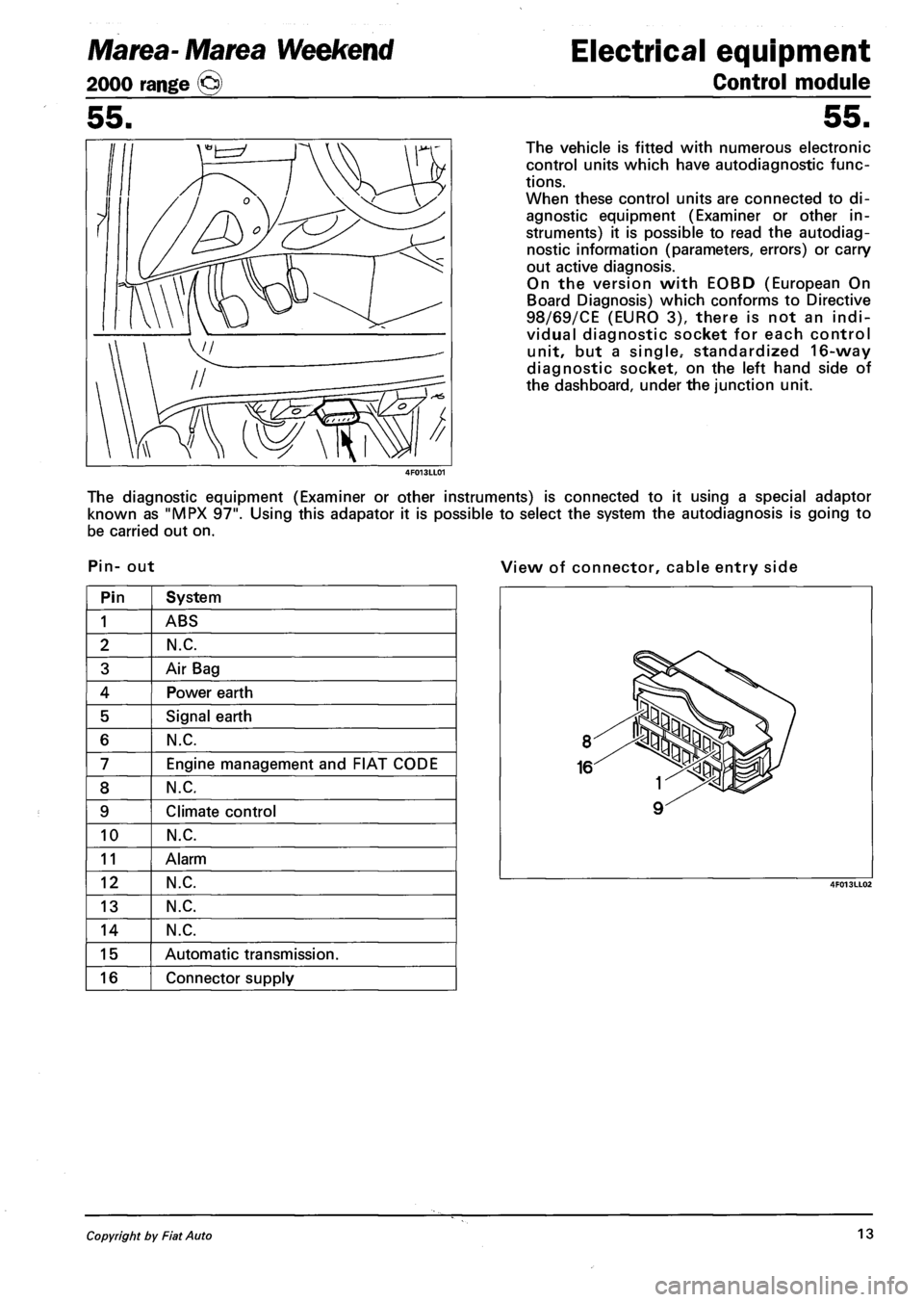

Marea- Marea Weekend

2000 range ©

Electrical equipment

Control module

55.

The vehicle is fitted with numerous electronic

control units which have autodiagnostic func

tions.

When these control units are connected to di

agnostic equipment (Examiner or other in

struments) it is possible to read the autodiag

nostic information (parameters, errors) or carry

out active diagnosis.

On the version with EOBD (European On

Board Diagnosis) which conforms to Directive

98/69/CE (EURO 3), there is not an indi

vidual diagnostic socket for each control

unit, but a single.- standardized 16-way

diagnostic socket, on the left hand side of

the dashboard, under the junction unit.

The diagnostic equipment (Examiner or other instruments) is connected to it using a special adaptor

known as "MPX 97". Using this adapator it is possible to select the system the autodiagnosis is going to

be carried out on.

Pin- out View of connector, cable entry side

Pin System

1 ABS

2 N.C.

3 Air Bag

4 Power earth

5 Signal earth

6 N.C.

7 Engine management and FIAT CODE

8 N.C.

9 Climate control

10 N.C.

11 Alarm

12 N.C.

13 N.C.

14 N.C.

15 Automatic transmission.

16 Connector supply

Copyright by Fiat Auto 13

Page 144 of 330

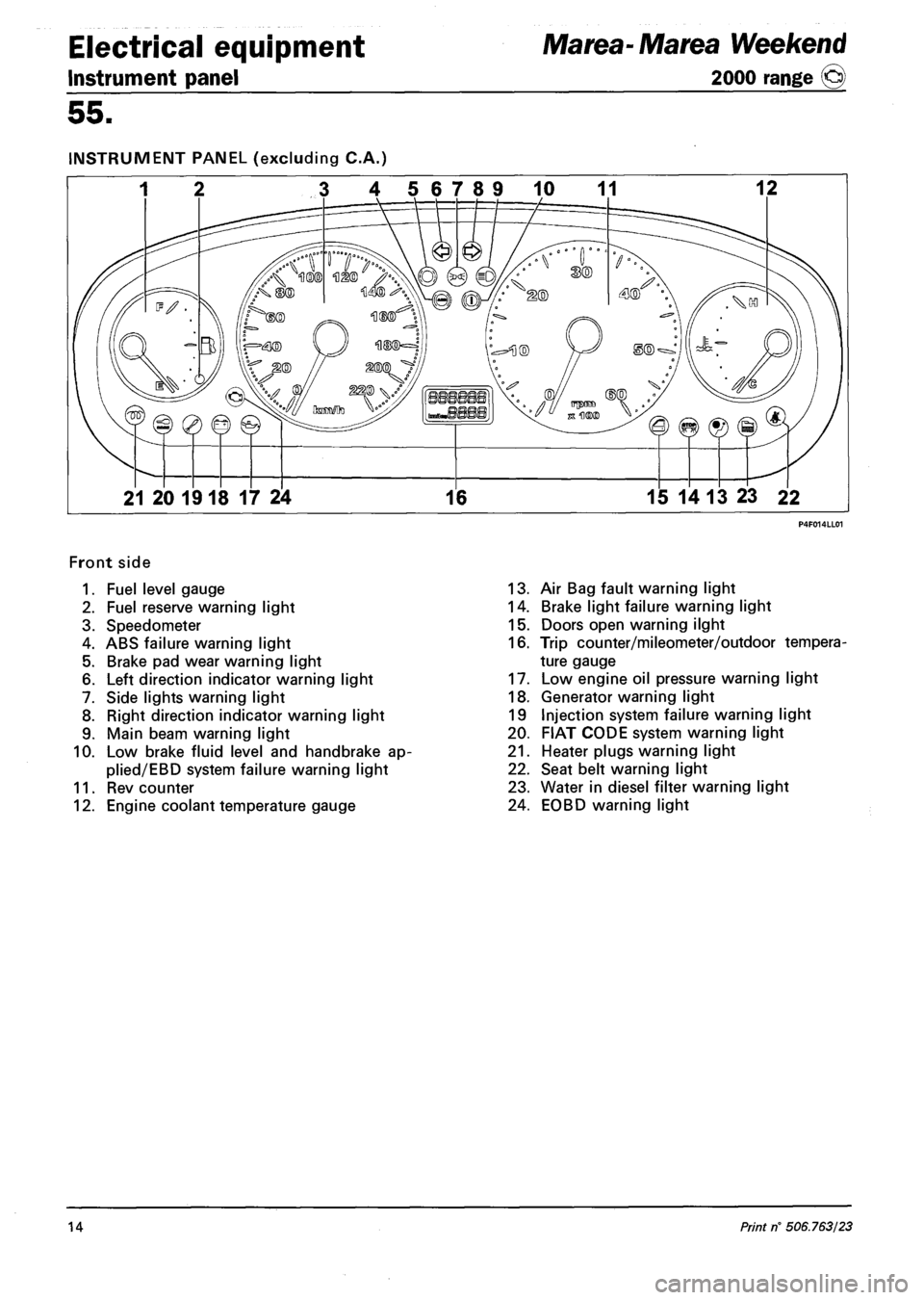

Electrical equipment

Instrument panel

Marea-Marea Weekend

2000 range ©

55.

INSTRUMENT PANEL (excluding C.A.)

3 4 56789 10 11 12

21 20 1918 17 24 16 15 14 13 23 22

Front side

1. Fuel level gauge

2. Fuel reserve warning light

3. Speedometer

4. ABS failure warning light

5. Brake pad wear warning light

6. Left direction indicator warning light

7. Side lights warning light

8. Right direction indicator warning light

9. Main beam warning light

10. Low brake fluid level and handbrake ap-

plied/EBD system failure warning light

11. Rev counter

12. Engine coolant temperature gauge

13. Air Bag fault warning light

14. Brake light failure warning light

15. Doors open warning ilght

16. Trip counter/mileometer/outdoor tempera

ture gauge

17. Low engine oil pressure warning light

18. Generator warning light

19 Injection system failure warning light

20. FIAT CODE system warning light

21. Heater plugs warning light

22. Seat belt warning light

23. Water in diesel filter warning light

24. EOBD warning light

14 Print rf 506.763/23

Page 145 of 330

Marea- Marea Weekend

2000 range ©

Electrical equipment

Control module

55.

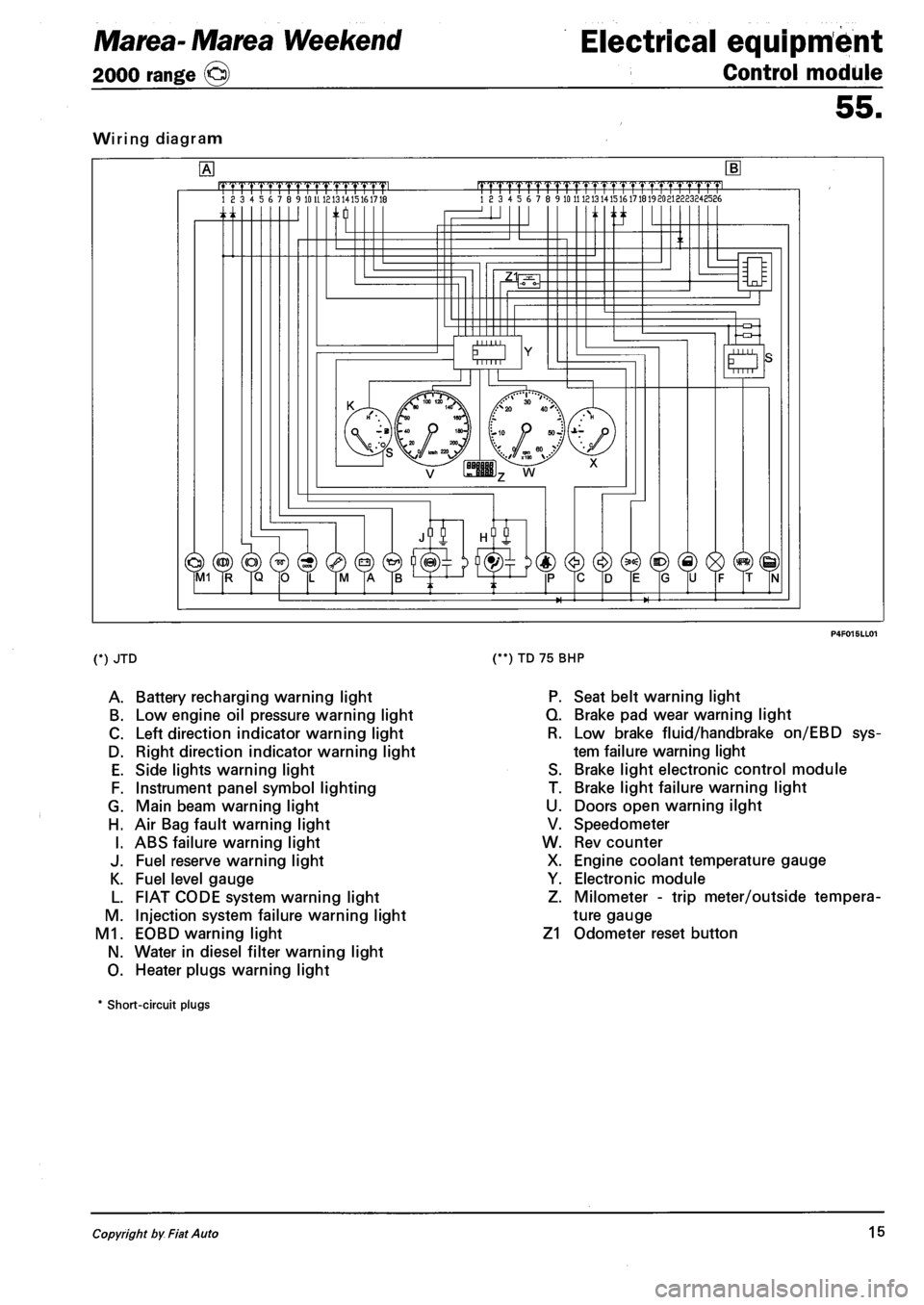

Wiring diagram

.mrmmmL 18 3 4 5 6 7 8 9 10 U 1213 1415161718 |TTTTrTrrrrTTTTT1.TTTTT1pmL 18 3 4 5 6 7 8 9 10 11 121314151617181920213223248586

n ti

O Mill

(*) JTD

A. Battery recharging warning light

B. Low engine oil pressure warning light

C. Left direction indicator warning light

D. Right direction indicator warning light

E. Side lights warning light

F. Instrument panel symbol lighting

G. Main beam warning light

H. Air Bag fault warning light

I. ABS failure warning light

J. Fuel reserve warning light

K. Fuel level gauge

L. FIAT CODE system warning light

M. Injection system failure warning light

M1. EOBD warning light

N. Water in diesel filter warning light

O. Heater plugs warning light

(**) TD 75 BHP

P. Seat belt warning light

Q. Brake pad wear warning light

R. Low brake fluid/handbrake on/EBD sys

tem failure warning light

S. Brake light electronic control module

T. Brake light failure warning light

U. Doors open warning ilght

V. Speedometer

W. Rev counter

X. Engine coolant temperature gauge

Y. Electronic module

Z. Milometer - trip meter/outside tempera

ture gauge

Z1 Odometer reset button

* Short-circuit plugs

Copyright by Fiat Auto 15

Page 146 of 330

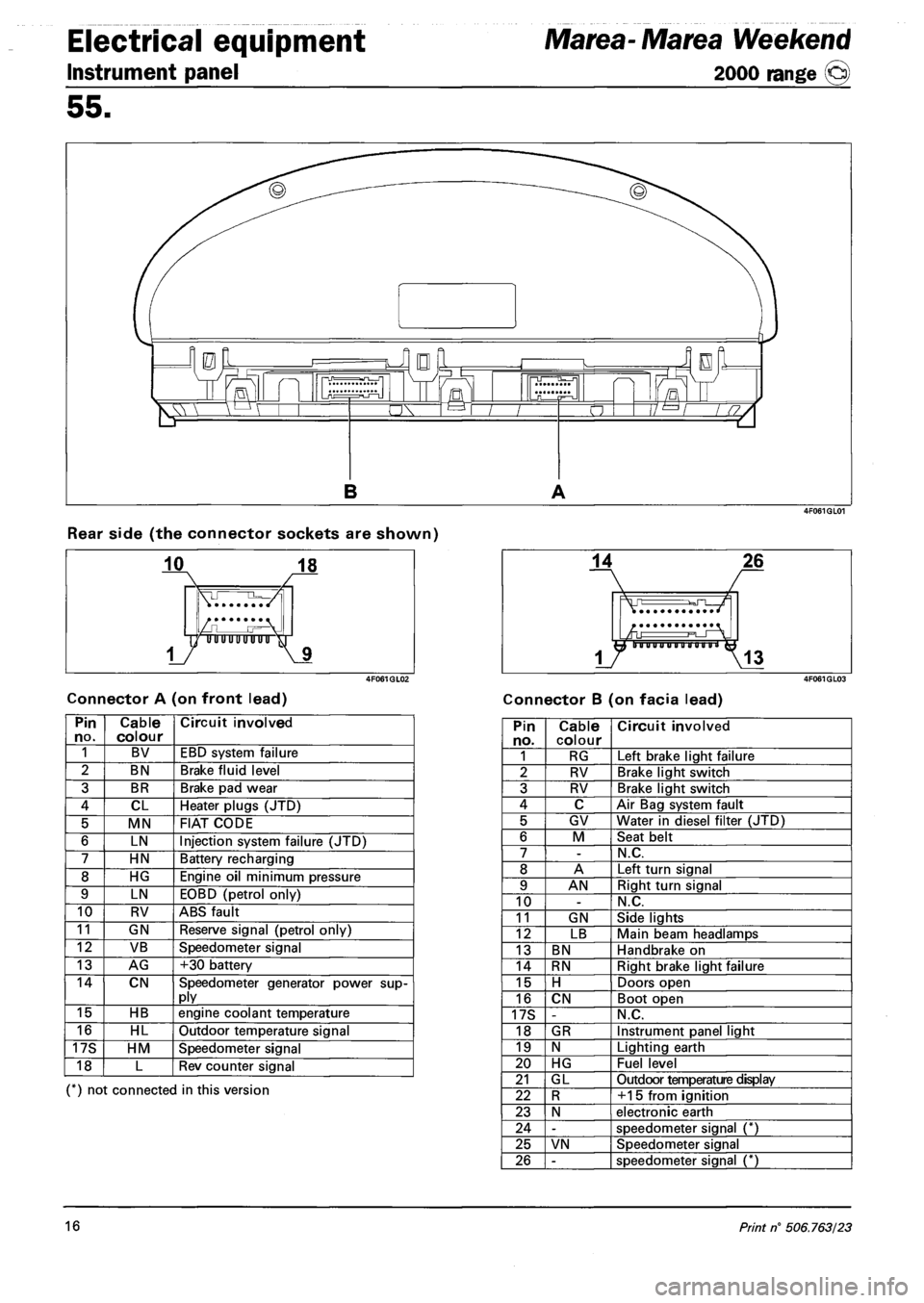

Electrical equipment

Instrument panel

Marea- Marea Weekend

2000 range ©

55.

Rear side (the connector sockets are shown)

Connector A (on front lead) Connector B (on facia lead)

Pin no. Cable colour Circuit involved

1 BV EBD system failure

2 BN Brake fluid level

3 BR Brake pad wear

4 CL Heater plugs (JTD)

5 MN FIAT CODE

6 LN Injection system failure (JTD)

7 HN Battery recharging

8 HG Engine oil minimum pressure

9 LN EOBD (petrol only)

10 RV ABS fault

11 GN Reserve signal (petrol only)

12 VB Speedometer signal

13 AG +30 battery

14 CN Speedometer generator power supply

15 HB engine coolant temperature

16 HL Outdoor temperature signal

17S HM Speedometer signal

18 L Rev counter signal

(*) not connected in this version

Pin no. Cable colour Circuit involved

1 RG Left brake light failure

2 RV Brake light switch

3 RV Brake light switch

4 C Air Bag system fault

5 GV Water in diesel filter (JTD)

6 M Seat belt

7 -N.C.

8 A Left turn signal

9 AN Right turn signal

10 -N.C.

11 GN Side lights

12 LB Main beam headlamps

13 BN Handbrake on

14 RN Right brake light failure

15 H Doors open

16 CN Boot open

17S -N.C.

18 GR Instrument panel light

19 N Lighting earth

20 HG Fuel level

21 GL Outdoor temperature display

22 R +15 from ignition

23 N electronic earth

24 -speedometer signal (*)

25 VN Speedometer signal

26 -speedometer signal (*)

16 Print n° 506.763/23

Page 148 of 330

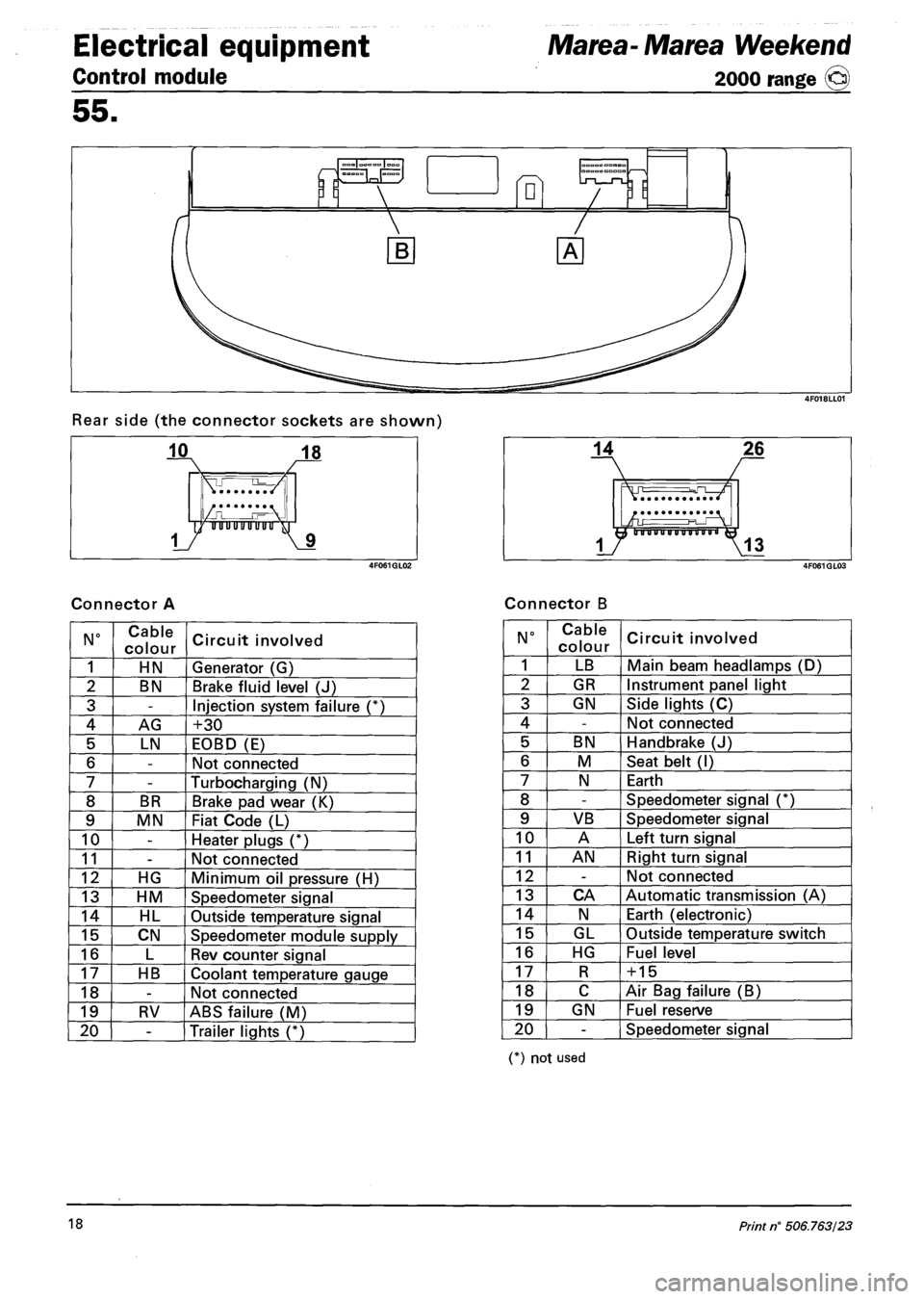

Electrical equipment

Control module

Marea- Marea Weekend

2000 range ©

55.

Rear side (the connector sockets are shown)

Connector A Connector B

N° Cable

colour Circuit involved

1 HN Generator (G)

2 BN Brake fluid level (J)

3 -Injection system failure (*)

4 AG +30

5 LN EOBD (E)

6 -Not connected

7 -Turbocharging (N)

8 BR Brake pad wear (K)

9 MN Fiat Code (L)

10 -Heater plugs (*)

11 -Not connected

12 HG Minimum oil pressure (H)

13 HM Speedometer signal

14 HL Outside temperature signal

15 CN Speedometer module supply

16 L Rev counter signal

17 HB Coolant temperature gauge

18 -Not connected

19 RV ABS failure (M)

20 -Trailer lights (*)

N° Cable

colour Circuit involved

1 LB Main beam headlamps (D)

2 GR Instrument panel light

3 GN Side lights (C)

4 -Not connected

5 BN Handbrake (J)

6 M Seat belt (I)

7 N Earth

8 -Speedometer signal (*)

9 VB Speedometer signal

10 A Left turn signal

11 AN Right turn signal

12 -Not connected

13 CA Automatic transmission (A)

14 N Earth (electronic)

15 GL Outside temperature switch

16 HG Fuel level

17 R + 15

18 C Air Bag failure (B)

19 GN Fuel reserve

20 -Speedometer signal

(*) not used

18 Print n° 506.763/23