oil press FIAT MAREA 2000 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2000, Model line: MAREA, Model: FIAT MAREA 2000 1.GPages: 330

Page 31 of 330

Technical Data

Engine: lubrication

OO.io

Marea- Marea Weekend

2000 range ©

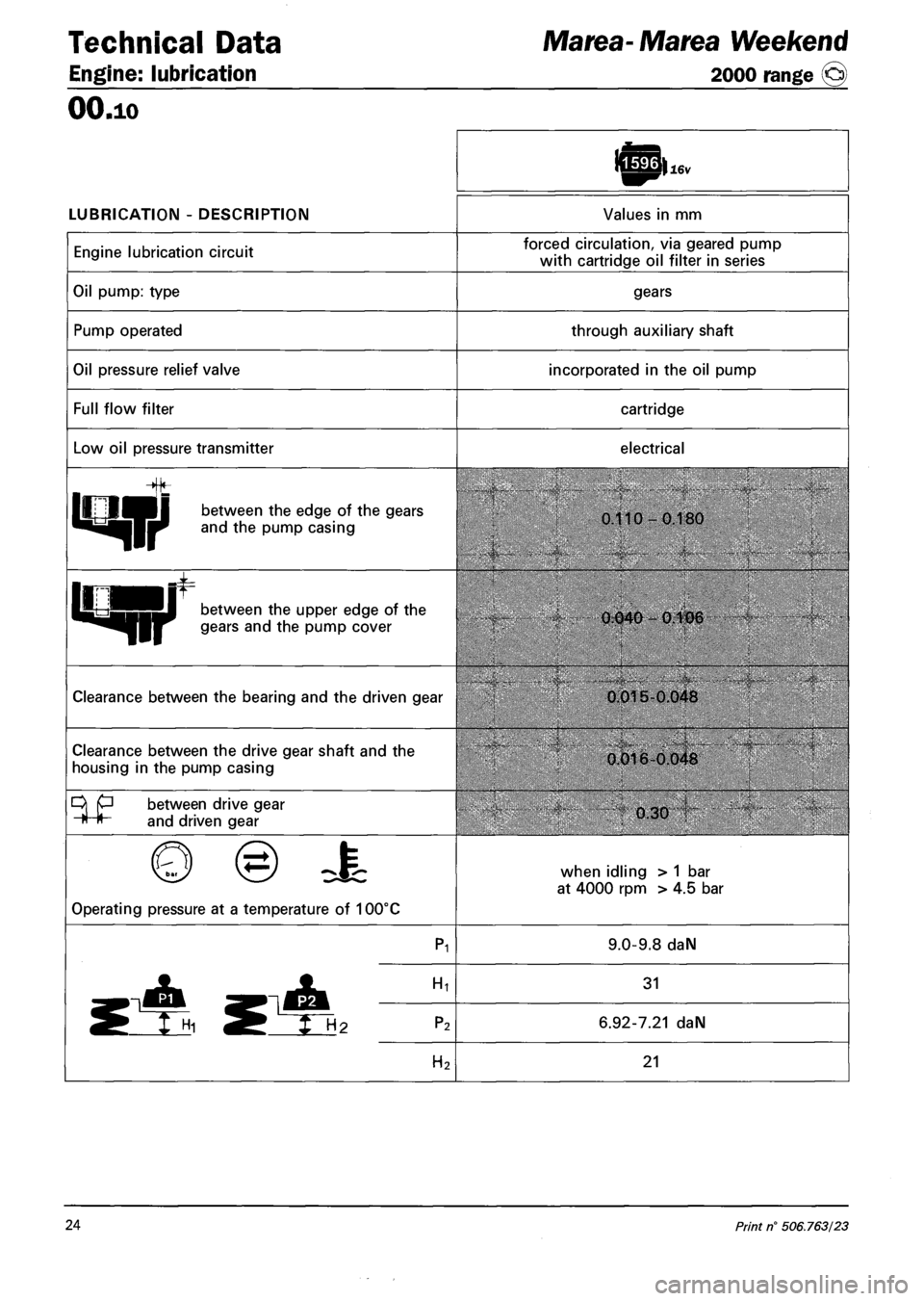

LUBRICATION - DESCRIPTION LUBRICATION - DESCRIPTION Values in mm

Engine lubrication circuit forced circulation, via geared pump

with cartridge oil filter in series

Oil pump: type gears

Pump operated through auxiliary shaft

Oil pressure relief valve incorporated in the oil pump

Full flow filter cartridge

Low oil pressure transmitter electrical

IlimBi between the edge of the gears

^^^•••F and the pump casing

JjOj^^^U between the upper edge of the

^^*^^B§ gears and the pump cover

Clearance between the bearing and the driven gear

Clearance between the drive gear shaft and the

housing in the pump casing

Oi p between drive gear

* * and driven gear

0 © J±

Operating pressure at a temperature of 100°C

when idling > 1 bar

at 4000 rpm > 4.5 bar

Pi 9.0-9.8 daN

31

9 1 Hi I H? P2 6.92-7.21 daN

H2 21

24 Print n° 506.763/23

Page 32 of 330

Marea-Marea Weekend

2000 range ©

Technical Data

Engine: lubrication

OO.io

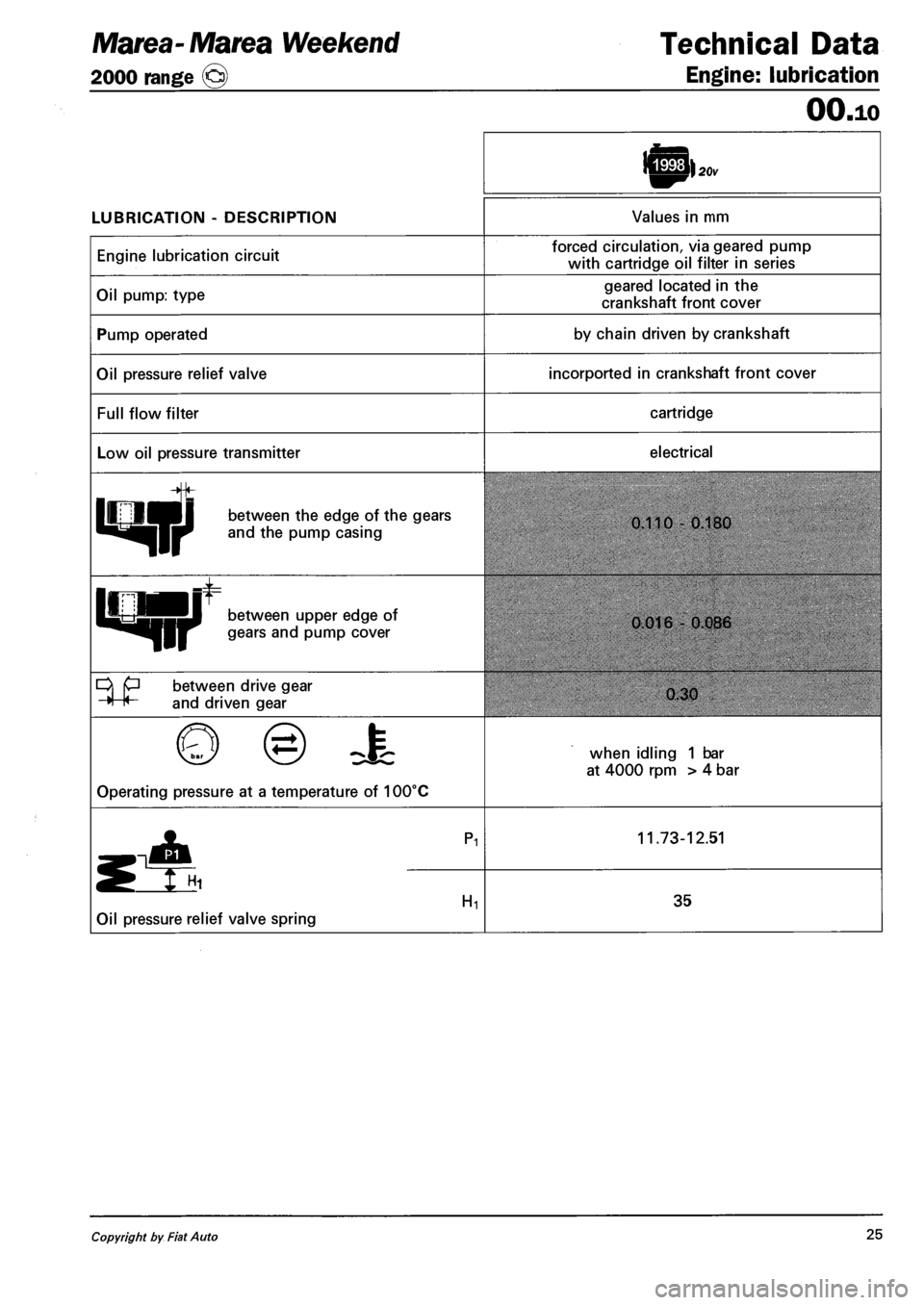

LUBRICATION - DESCRIPTION Values in mm

Engine lubrication circuit forced circulation, via geared pump

with cartridge oil filter in series

Oil pump: type geared located in the

crankshaft front cover

Pump operated by chain driven by crankshaft

Oil pressure relief valve incorported in crankshaft front cover

Full flow filter cartridge

Low oil pressure transmitter electrical

llOmH between the edge of the gears

^^^•••F and the pump casing

(EQi^^^U between upper edge of

^^^^BBf gears and pump cover

Oi 0 between drive gear

-*r-H- and driven gear

© © J:

Operating pressure at a temperature of 100°C

when idling 1 bar

at 4000 rpm > 4 bar

11.73-12.51

2 J*

Hi

Oil pressure relief valve spring

35

Copyright by Fiat Auto 25

Page 34 of 330

Marea-Marea Weekend Technical Data

2000 range (j§) Engine: fuel system - special tools

OO.io

INTEGRATED ELECTRONIC INJECTION/IGNITION SYSTEM

COMPONENTS

Electronic control unit

Manual gearbox I.A.W. 4EF. B3

Electronic control unit

Automatic transmission I.A.W. 4EF. L1

Air pressure sensor M. Marelli TPRT 05

Fuel vapour solenoid valve M. Marelli EC2

Throttle case M. Marelli 46 SX F2

Idle adjustment actuator M. Marelli IB 02

Injector M. Marelli IWP 109

Fuel pressure regulator MARWALL RPM 84

Coolant temperature sender unit SYLEA 402.386.01

Top Dead Centre and rpm sensor M. Marelli CVM 02

Throttle position sensor (potentiometer) M. Marelli IPF 2C

Detonation sensor NGK KNE 11

Electric fuel pump (*) MARWALL ESS 291

Lambda sensor upstream of catalyzer NTK OZA 534 A1

Lambda sensor downstream of catalyzer NTK OZA 532 A1

Fuel filter MARWALL FA 5325 IN

Timing sensor SYLEA SFA 200

Ignition coil Champion BAE 920A/

BERU 0.040.100.029

SPECIAL TOOLS

(*) Use tool 1870736000 for removing-refitting the fuel pump retaining ring nut

Copyright by Fiat Auto 27

Page 38 of 330

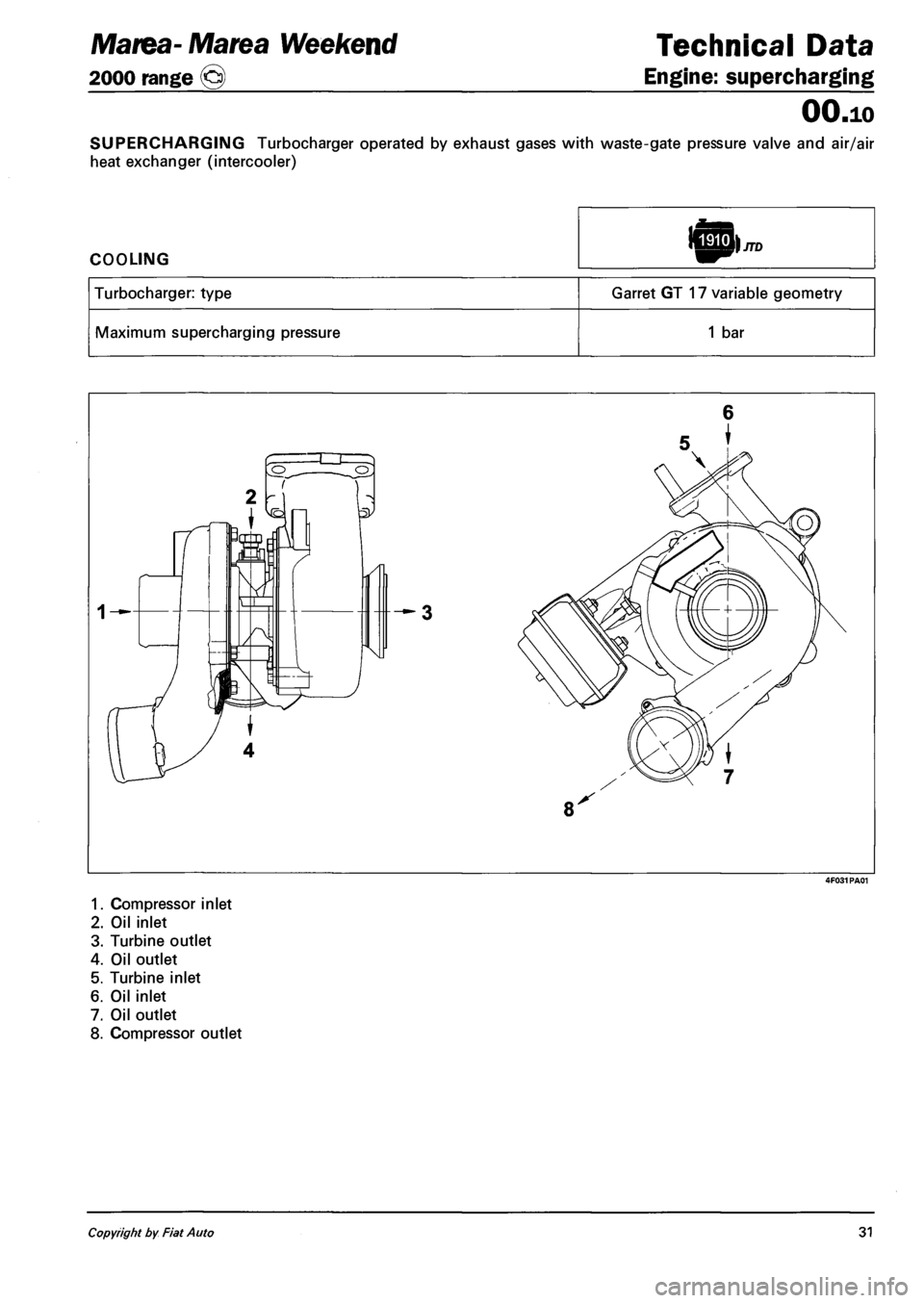

Marea- Marea Weekend Technical Data

2000 range (§) Engine: supercharging

OO.io

SUPERCHARGING Turbocharger operated by exhaust gases with waste-gate pressure valve and air/air

heat exchanger (intercooler)

COOLING

Turbocharger: type Garret GT 17 variable geometry

Maximum supercharging pressure 1 bar

6

5

1. Compressor inlet

2. Oil inlet

3. Turbine outlet

4. Oil outlet

5. Turbine inlet

6. Oil inlet

7. Oil outlet

8. Compressor outlet

Copyright by Fiat Auto 31

Page 71 of 330

Marea- Marea Weekend 9* Engine

2000 range (Q) Fuel feed system

10.

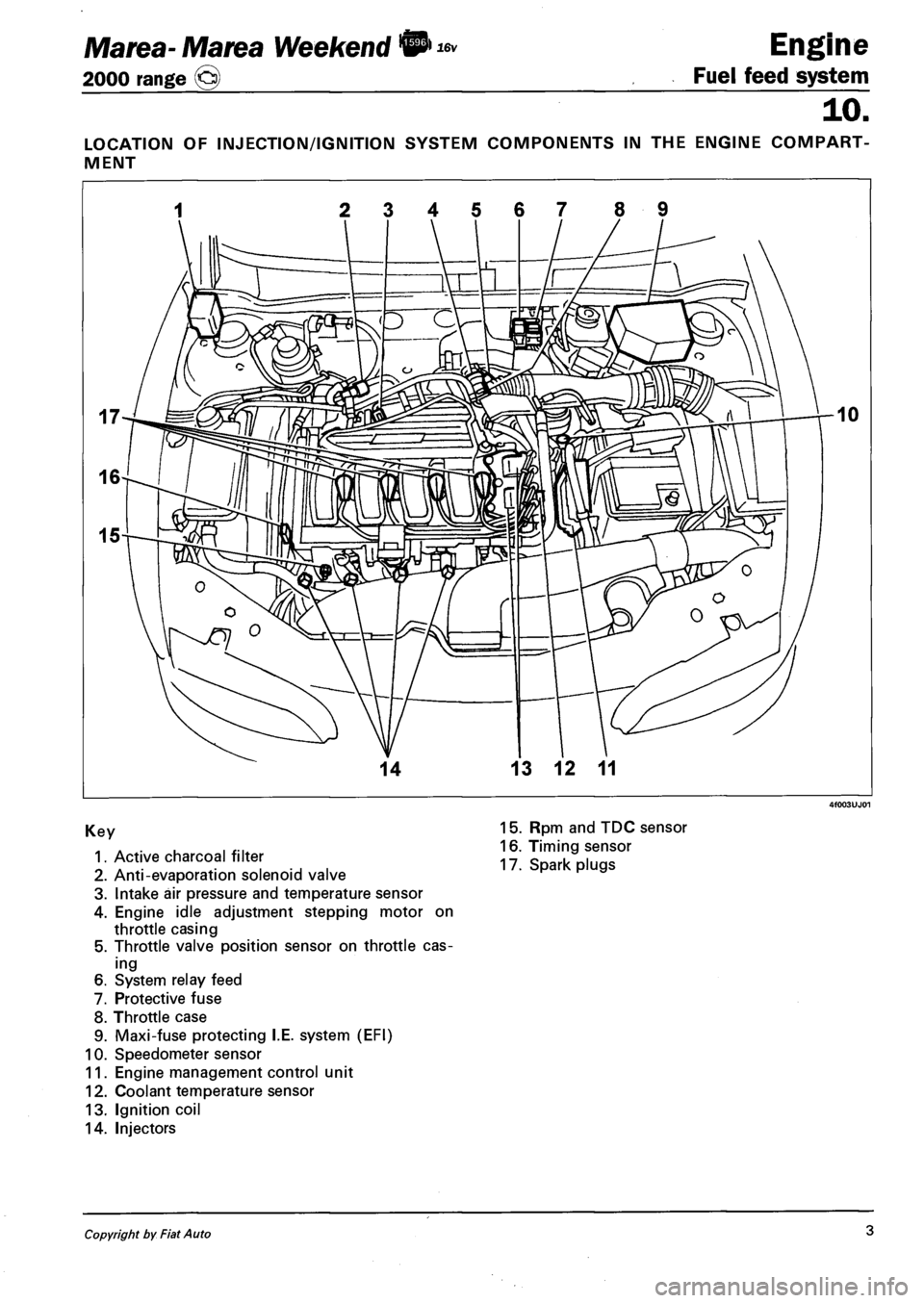

LOCATION OF INJECTION/IGNITION SYSTEM COMPONENTS IN THE ENGINE COMPART

MENT

1 2345678 9

Key

1. Active charcoal filter

2. Anti-evaporation solenoid valve

3. Intake air pressure and temperature sensor

4. Engine idle adjustment stepping motor on

throttle casing

5. Throttle valve position sensor on throttle cas

ing

6. System relay feed

7. Protective fuse

8. Throttle case

9. Maxi-fuse protecting I.E. system (EFI)

10. Speedometer sensor

11. Engine management control unit

12. Coolant temperature sensor

13. Ignition coil

14. Injectors

15. Rpm and TDC sensor

16. Timing sensor

17. Spark plugs

Copyright by Fiat Auto 3

Page 99 of 330

Marea- Marea Weekend 9"°

2000 range ©

Engine

Fuel feed system

10.

TIMING SENSOR

The Hall effect sensor is fitted to the cylinder head and faces the camshaft pulley.

An opening on the pulley allows the timing sensor to detect the engine timing position and indicate it to

the injection control unit.

The injection control unit uses the timing sensor signal to detect TDC at the end of compression.

Operation

A semi-condulator layer, through which a current passes, immersed in a magnetic field (lines of force per

pendicular to the direction of the current), produces a difference in power, known as Hall voltage.

If the intensity of the current remains constant, the voltage produced only depends on the intensity of the

magnetic field. The intensity of the field can simply be altered periodically to produce a modulated electri

cal signal. Signal frequency is proportional to the speed with which the magnetic field changes.

To achieve this change, the sensor is crossed by a metal ring (inner part of the pulley) with an opening.

When it moves, the metal part of the ring covers the sensor to magnetic field and the output signal is

therefore low; Conversely, the sensor generates a high signal at the opening when the magnetic field is

present.

This signal, together with the rpm and TDC signals, allows the injection control unit to identify piston po

sition and determine injection point.

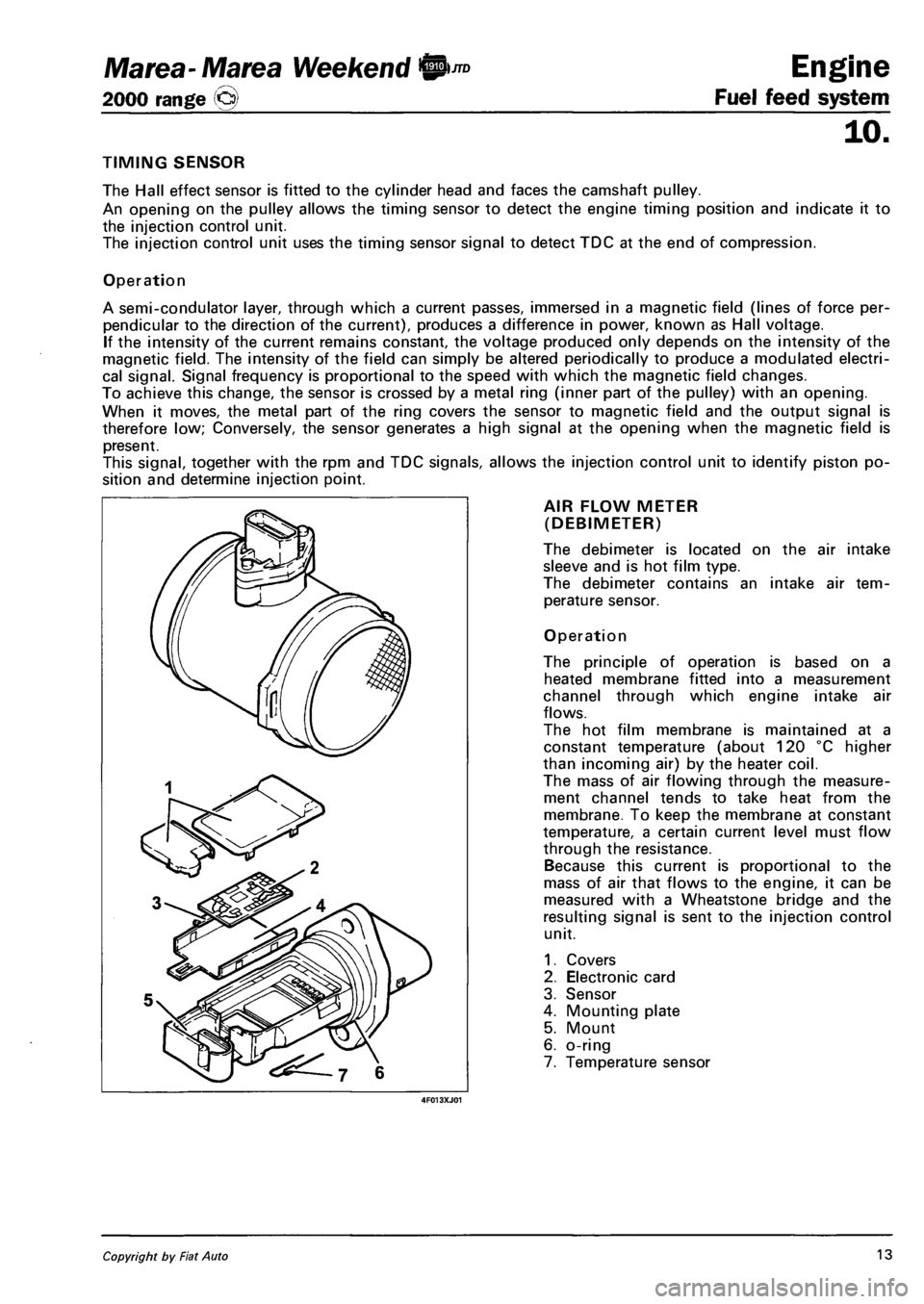

AIR FLOW METER

(DEBIMETER)

The debimeter is located on the air intake

sleeve and is hot film type.

The debimeter contains an intake air tem

perature sensor.

Operation

The principle of operation is based on a

heated membrane fitted into a measurement

channel through which engine intake air

flows.

The hot film membrane is maintained at a

constant temperature (about 120 °C higher

than incoming air) by the heater coil.

The mass of air flowing through the measure

ment channel tends to take heat from the

membrane. To keep the membrane at constant

temperature, a certain current level must flow

through the resistance.

Because this current is proportional to the

mass of air that flows to the engine, it can be

measured with a Wheatstone bridge and the

resulting signal is sent to the injection control

unit.

1. Covers

2. Electronic card

3. Sensor

4. Mounting plate

5. Mount

6. o-ring

7. Temperature sensor

Copyright by Fiat Auto 13

Page 100 of 330

Engine

Fuel feed system

10.

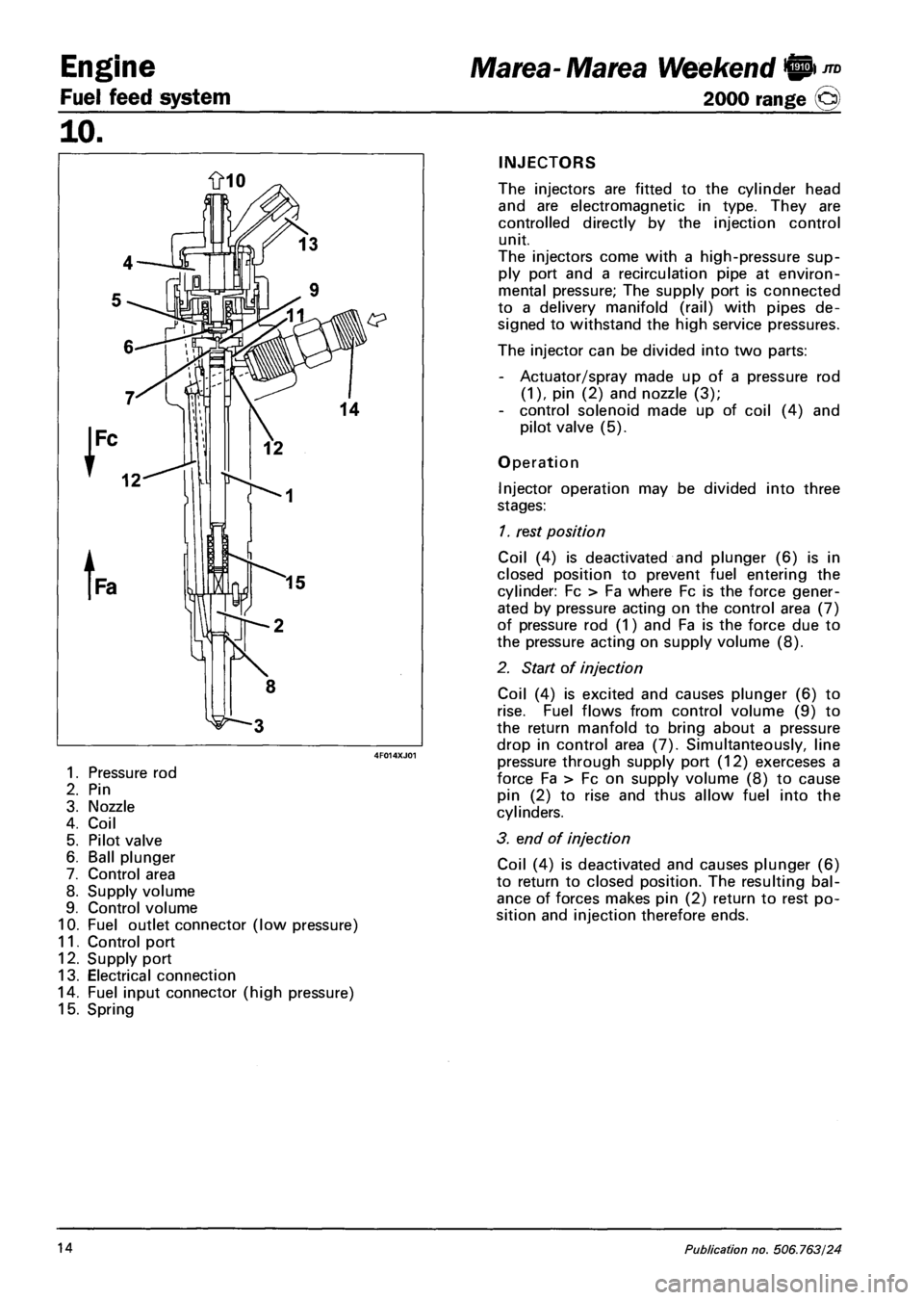

1. Pressure rod

2. Pin

3. Nozzle

4. Coil

5. Pilot valve

6. Ball plunger

7. Control area

8. Supply volume

9. Control volume

10. Fuel outlet connector (low pressure)

11. Control port

12. Supply port

13. Electrical connection

14. Fuel input connector (high pressure)

15. Spring

Marea- Marea Weekend 9 ™

2000 range (Q)

INJECTORS

The injectors are fitted to the cylinder head

and are electromagnetic in type. They are

controlled directly by the injection control

unit.

The injectors come with a high-pressure sup

ply port and a recirculation pipe at environ

mental pressure; The supply port is connected

to a delivery manifold (rail) with pipes de

signed to withstand the high service pressures.

The injector can be divided into two parts:

- Actuator/spray made up of a pressure rod

(1), pin (2) and nozzle (3);

- control solenoid made up of coil (4) and

pilot valve (5).

Operation

Injector operation may be divided into three

stages:

1. rest position

Coil (4) is deactivated and plunger (6) is in

closed position to prevent fuel entering the

cylinder: Fc > Fa where Fc is the force gener

ated by pressure acting on the control area (7)

of pressure rod (1) and Fa is the force due to

the pressure acting on supply volume (8).

2. Start of injection

Coil (4) is excited and causes plunger (6) to

rise. Fuel flows from control volume (9) to

the return manfold to bring about a pressure

drop in control area (7). Simultanteously, line

pressure through supply port (12) exerceses a

force Fa > Fc on supply volume (8) to cause

pin (2) to rise and thus allow fuel into the

cylinders.

3. end of injection

Coil (4) is deactivated and causes plunger (6)

to return to closed position. The resulting bal

ance of forces makes pin (2) return to rest po

sition and injection therefore ends.

14 Publication no. 506.763/24

Page 102 of 330

![FIAT MAREA 2000 1.G Workshop Manual Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1 <fi=2 1 1 15J

GLOW PLUG PREHEATING CONTROL

UNIT

The glow plugs are controlled by mea FIAT MAREA 2000 1.G Workshop Manual Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1 <fi=2 1 1 15J

GLOW PLUG PREHEATING CONTROL

UNIT

The glow plugs are controlled by mea](/img/10/4653/w960_4653-101.png)

Engine

Fuel feed system

JTD Marea-Marea Weekend ©

2000 range ©

10.

iH

ft

B I 0 ] I D

[ 0 0 1 1

D

0 1

UNIT

The glow plugs are controlled by means of a

preheating control unit under the direct con

trol of the injection control unit.

The preheating control unit contains a smart

relay that sends a return response (feedback)

to the injection control unit, which is thus in

formed of faults in the preheating control unit

or glow plug short-circuits to earth.

The figure shows the connectors on the base

of the preheating control unit and the pin-out

1. Earth

2. Injection control unit (pin 22)

3. Power supply from main injection relay

4. Not connected

5. Injection control unit (pin 62)

8. Positive from battery (+30)

G. Glow plugs (only four outputs are used)

ACCELERATOR

PEDAL POTENTIOMETER

Accelerator pedal position is converted to an

electrical voltage signal and send to the injec

tion control unit by a potentiometer connected

to the accelerator pedal.

Accelerator pedal position is processed to

gether with rpm information to provide injec

tion times and pressure.

The sensor consists of a case (1) secured to

the pedal by a flange, which contains an axi-

ally-positioned shaft (2) connected to two

potentiometers (3): main and safety potenti

ometers.

A coil spring on the shaft ensures the correct

resistance to pressure while a second spring

ensures return upon release.

16 Publication no. 506.763/24

Page 106 of 330

Engine

Fuel feed system

JTD Marea-Marea Weekend @

2000 range ©

10.

7^ £3

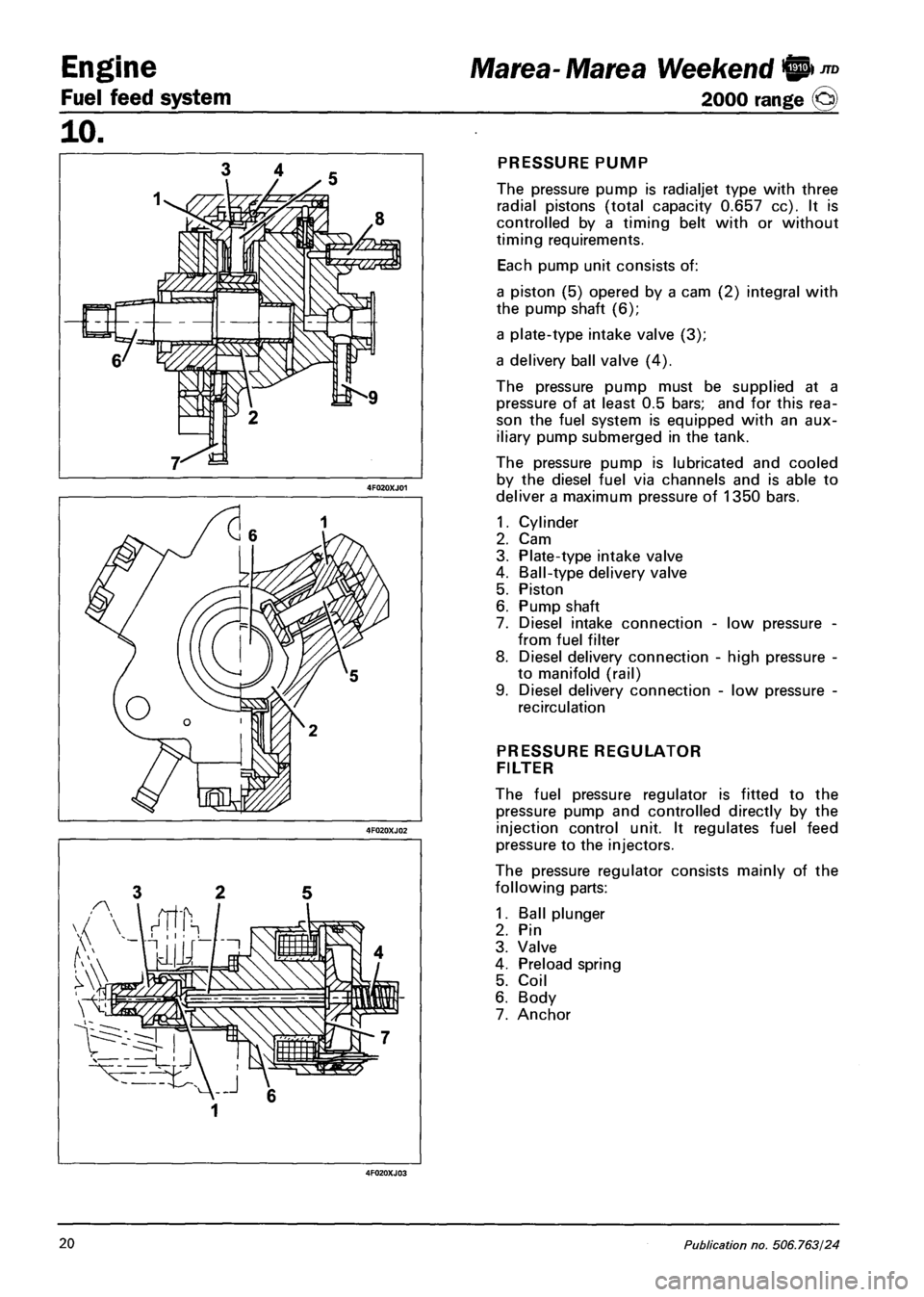

PRESSURE PUMP

The pressure pump is radialjet type with three

radial pistons (total capacity 0.657 cc). It is

controlled by a timing belt with or without

timing requirements.

Each pump unit consists of:

a piston (5) opered by a cam (2) integral with

the pump shaft (6);

a plate-type intake valve (3);

a delivery ball valve (4).

The pressure pump must be supplied at a

pressure of at least 0.5 bars; and for this rea

son the fuel system is equipped with an aux

iliary pump submerged in the tank.

The pressure pump is lubricated and cooled

by the diesel fuel via channels and is able to

deliver a maximum pressure of 1350 bars.

1.

2.

3.

4.

5.

6.

7.

8.

Cylinder

Cam

Plate-type intake valve

Ball-type delivery valve

Piston

Pump shaft

Diesel intake connection -

from fuel filter

Diesel delivery connection

to manifold (rail)

Diesel delivery connection

recirculation

low pressure

high pressure

low pressure

PRESSURE REGULATOR

FILTER

The fuel pressure regulator is fitted to the

pressure pump and controlled directly by the

injection control unit. It regulates fuel feed

pressure to the injectors.

The pressure regulator consists mainly of the

following parts:

1. Ball plunger

2. Pin

3. Valve

4. Preload spring

5. Coil

6. Body

7. Anchor

20 Publication no. 506.763/24

Page 112 of 330

Engine

Fuel feed system

JTD Marea- Marea Weekend 9

2000 range @

10.

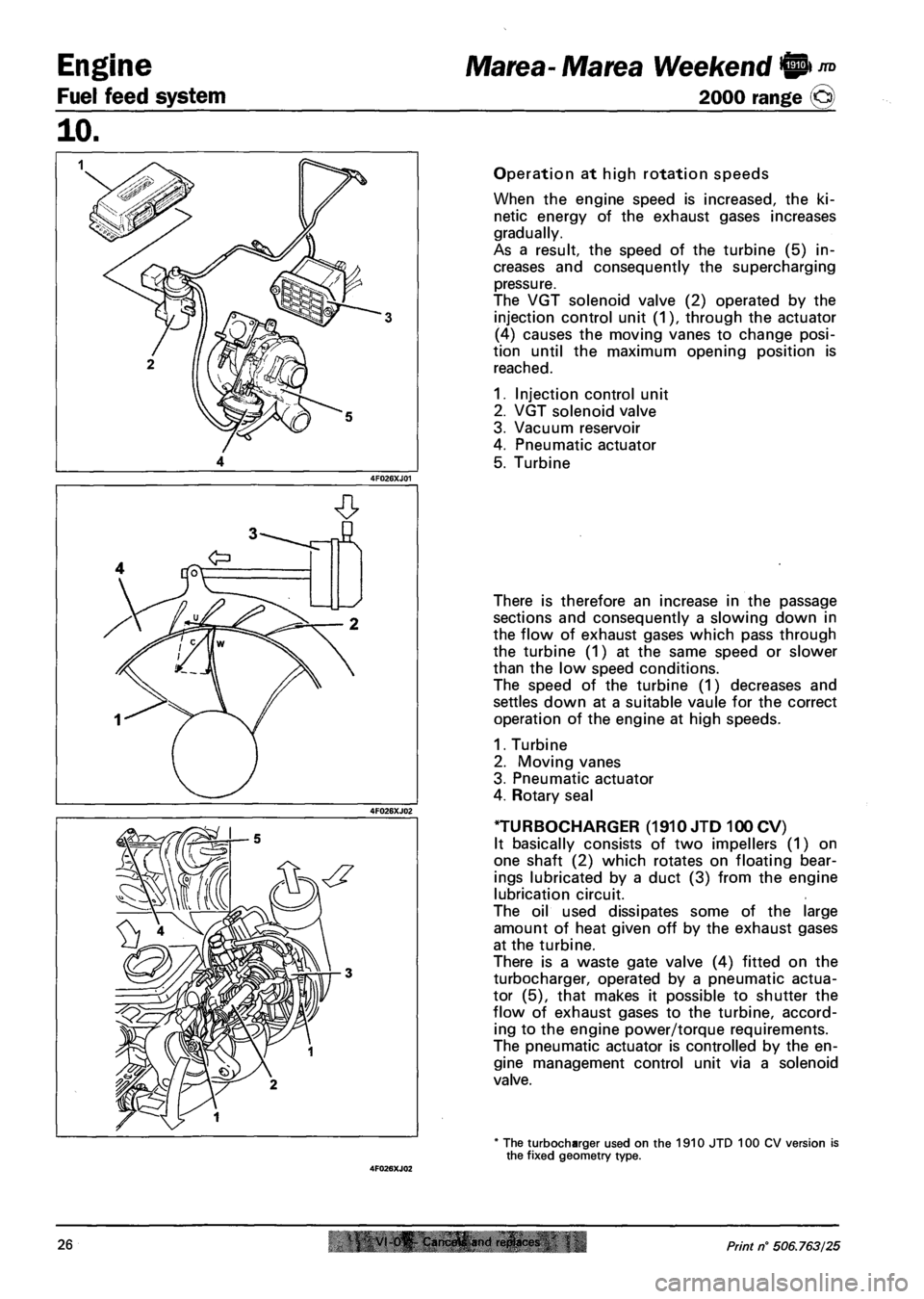

Operation at high rotation speeds

When the engine speed is increased, the ki

netic energy of the exhaust gases increases

gradually.

As a result, the speed of the turbine (5) in

creases and consequently the supercharging

pressure.

The VGT solenoid valve (2) operated by the

injection control unit (1), through the actuator

(4) causes the moving vanes to change posi

tion until the maximum opening position is

reached.

1. Injection control unit

2. VGT solenoid valve

3. Vacuum reservoir

4. Pneumatic actuator

5. Turbine

There is therefore an increase in the passage

sections and consequently a slowing down in

the flow of exhaust gases which pass through

the turbine (1) at the same speed or slower

than the low speed conditions.

The speed of the turbine (1) decreases and

settles down at a suitable vaule for the correct

operation of the engine at high speeds.

1. Turbine

2. Moving vanes

3. Pneumatic actuator

4. Rotary seal

TURBOCHARGER (1910 JTD 100 CV)

It basically consists of two impellers (1) on

one shaft (2) which rotates on floating bear

ings lubricated by a duct (3) from the engine

lubrication circuit.

The oil used dissipates some of the large

amount of heat given off by the exhaust gases

at the turbine.

There is a waste gate valve (4) fitted on the

turbocharger, operated by a pneumatic actua

tor (5), that makes it possible to shutter the

flow of exhaust gases to the turbine, accord

ing to the engine power/torque requirements.

The pneumatic actuator is controlled by the en

gine management control unit via a solenoid

valve.

* The turbocharger used on the 1910 JTD 100 CV version is the fixed geometry type.

26 VI 0^ Cam.frtfi and ri!plact<& Print n° 506.763/25