Bar FIAT MAREA 2001 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2001, Model line: MAREA, Model: FIAT MAREA 2001 1.GPages: 330

Page 63 of 330

Marengo 0 ™ Technical Data

2000 range Suspension and wheels

OO.o

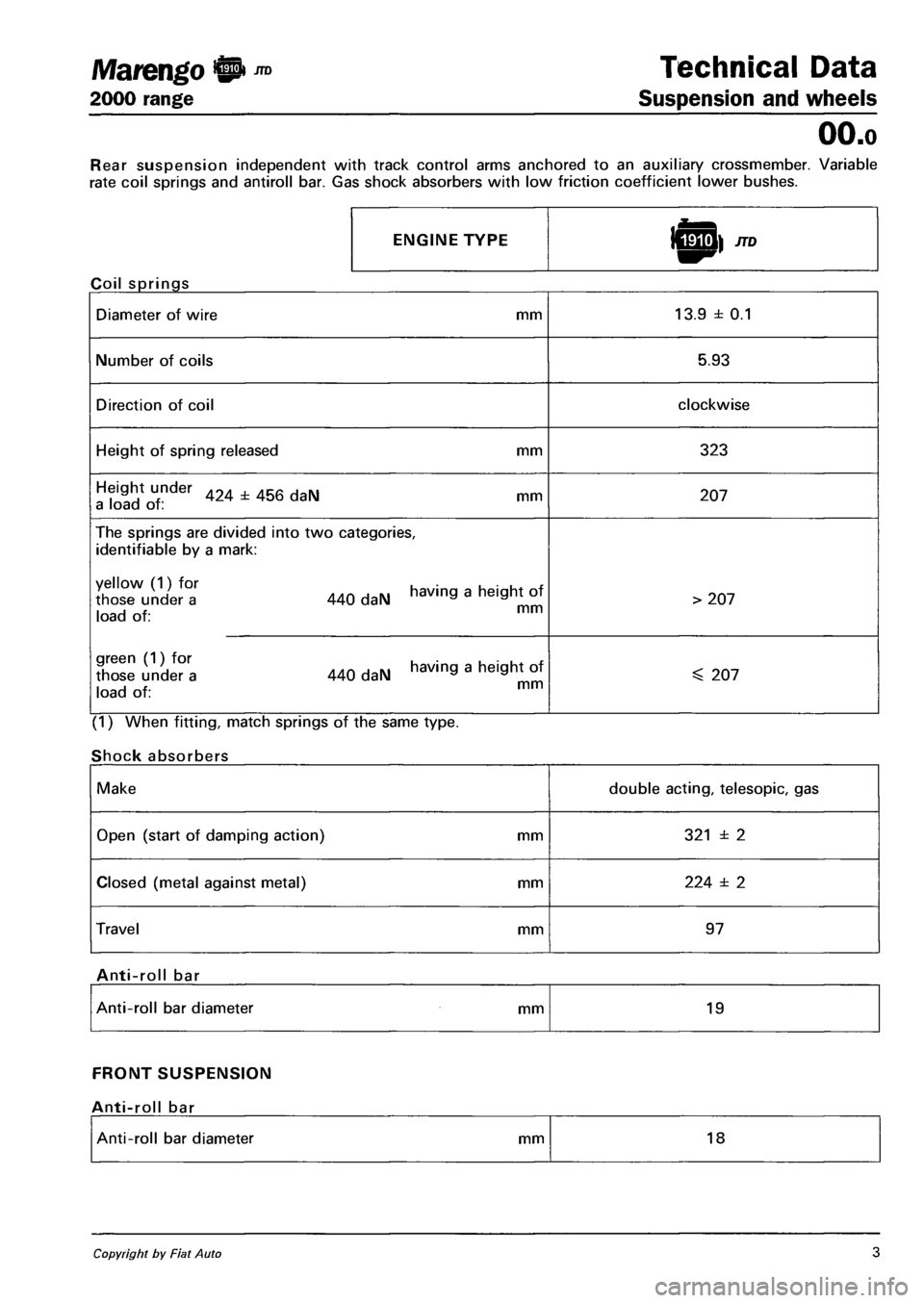

Rear suspension independent with track control arms anchored to an auxiliary crossmember. Variable

rate coil springs and antiroll bar. Gas shock absorbers with low friction coefficient lower bushes.

ENGINE TYPE

Coil springs

Diameter of wire mm 13.9 ± 0.1

Number of coils 5.93

Direction of coil clockwise

Height of spring released mm 323

Height under 424 ± 456 daN mm a load of : 207

The springs are divided into two categories,

identifiable by a mark:

XX°l 440 daN having a heigh, of i -i x mm load of:

> 207

green (1) for having a height of those under a 440 daN a a i J x. mm load of:

^ 207

(1) When fitting, match springs of the same type.

Shock absorbers

Make double acting, telesopic, gas

Open (start of damping action) mm 321 ± 2

Closed (metal against metal) mm 224 ± 2

Travel mm 97

Anti-roll bar

Anti-roll bar diameter mm 19

FRONT SUSPENSION

Anti-roll bar

Anti-roll bar diameter mm 18

Copyright by Fiat Auto 3

Page 87 of 330

Marea- Marea Weekend © ™ Engine

2000 range Q Fuel feed system

10.

FUEL SYSTEM

INTRODUCTION

Marea and Marea Weekend 1.9 JTD cars are equipped with a 4 cylinder in line, 1910 cc turbodiesel en

gine with two valves per cylinder, an overhead camshaft, turbocharger and intercooler and electronic in

jection.

The fuel system ensures correct engine operation and can be divided into the following subsystems:

- Fuel feed circuit with common rail injection;

- air feed circuit;

- exhaust circuit;

- blow by vapour recirculation circuit;

- Exhaust Gas Recirculation (EGR) circuit

Operation of the various circuits making up the fuel system is optimised by an electronic control system

managed by a special control unit.

The main feature of the fuel system is common rail fuel injection. Common rail is a higher pressure elec

tronic injection system for fast direct injection diesel engines.

The main features of the common rail system are as follows:

- availability of high injection pressures (up to 1350 bars);

- possibility of modulating these pressures (from a minimum of 150 bars to a maximum of 1350 bars)

independently of engine speed (rpm) and engine load;

- ability to operate at high engine speeds (up to 6000 rpm);

- precise injection control (injection advance and duration);

- reduced fuel consumption;

- reduced emissions.

FUEL SYSTEM MANAGEMENT STRATEGIES

The management program (software) is stored inside the control unit memory and consists of a series of

strategies, each of which manages a precise system control function.

Through the use of information providd by the various sensors (input), each strategy processes a set of

parameters based on data stored in special control unit memory areas. It then controls system actuators

(output), i.e. the devices that allow the engine to operate.

The main purpose of these management strategies is to determine the exact amount of fuel to be injected

into the cylinders with timing (injection advance) and pressure designed to achieve the best possible en

gine performance in terms of power, fuel consumption, fumes, emissions and handling.

The main system management strategies are essentially as follows:

contro

contro

contro

contro

contro

contro

contro

contro

contro

contro

contro

contro

contro

contro

contro

of injected fuel quantity;

of injection advance;

of injection pressure;

of auxiliary fuel pump;

of injection during over-run (cut-off);

of idle speed;

of maximum speed limitation;

of maximum torque limitation;

of fuel temperature;

of engine coolant temperature;

of air turbocharging pressure;

of glow plugs;

of exhaust fumes;

of exhaust gas recirculation (EGR);

of climate control system activation;

control of engine immobiliser operation (Fiat

CODE);

self-diagnosis

Copyright by Fiat Auto 1

Page 89 of 330

Ma tea- Marea Weekend 9 ™

2000 range (Q) Fuel feed system

Engine

10.

Control of injected fuel quantity

The control unit controls the fuel pressure regulator and injectors on the basis of output signals from the

accelerator pedal potentiometer, flow meter and rpm sensor.

The timing and thus the injection sequence are determined when the engine is started up using signals

from the rpm and timing sensor (synchronisation stage); injection timing is then implemented using the

rpm sensor signal alone and considering a injection sequence of 1 -3-4-2.

The control unit inhibits injection in the following cases:

- fuel pressure level greater than 1500 bars;

- fuel pressure level lower than 120 bars;

- engine speed higher than 6000 rpm.

When the engine has warmed up, maximum injection duration (injector opening time) is 1500 ns, but it

can reach 3000 ns during the start-up stage.

Control of injection advance

The electronic control unit determines injection advance mainly on the basis of the quantity of fuel to be

injected.

The injection advance is then corrected on the basis of coolant temperature and speed in order to com

pensate for ignition delays due to low temperatures in the combustion chamber during warm-up.

The optimum injection point is also processed to ensure driving comfort and emission limits laid down by

Euro 3 legislation.

Control of injection pressure

This control is of particular importance because injection pressure influences the following parameters:

- amount of fuel taken into the cylinders for the same injection time duration;

- injected fuel nebulation;

- spray penetration;

- lag between electrical control to injection and actual injection start and end times.

The above parameters engine behaviour significantly, particularly in terms of power output, exhaust emis

sions, noise levels and handling.

The injection control unit controls the pressure governor on the basis of engine load to obtain an optimal

line pressure at all times.

When the engine is cold, injection pressure is corrected on the basis of engine speed and engine coolant

temperature to meet engine needs at different operating temperatures.

Control of auxiliary fuel pump

The auxiliary fuel pump submerged in the tank is supplied by the injection control unit by means of a relay

when the ignition key is turned on.

Fuel supply to the pump is inhibited when one of the following condition occurs:

- when the ignition has been turned on for a certain length of time without the engine running;

- if the inertia switch cuts in.

Control of injection during over-run (cut-off)

The fuel cut-off strategy is implemented when the injection control unit receives information that the ac

celerator pedal has been released from the potentiometer.

Under these conditions, the control unit cuts off the fuel supply to the injectors and restores it before idle

speed is reached.

Copyright by Fiat Auto 3

Page 105 of 330

Marea- Marea Weekend 9 ™

2000 range (Q)

4F019XJ01

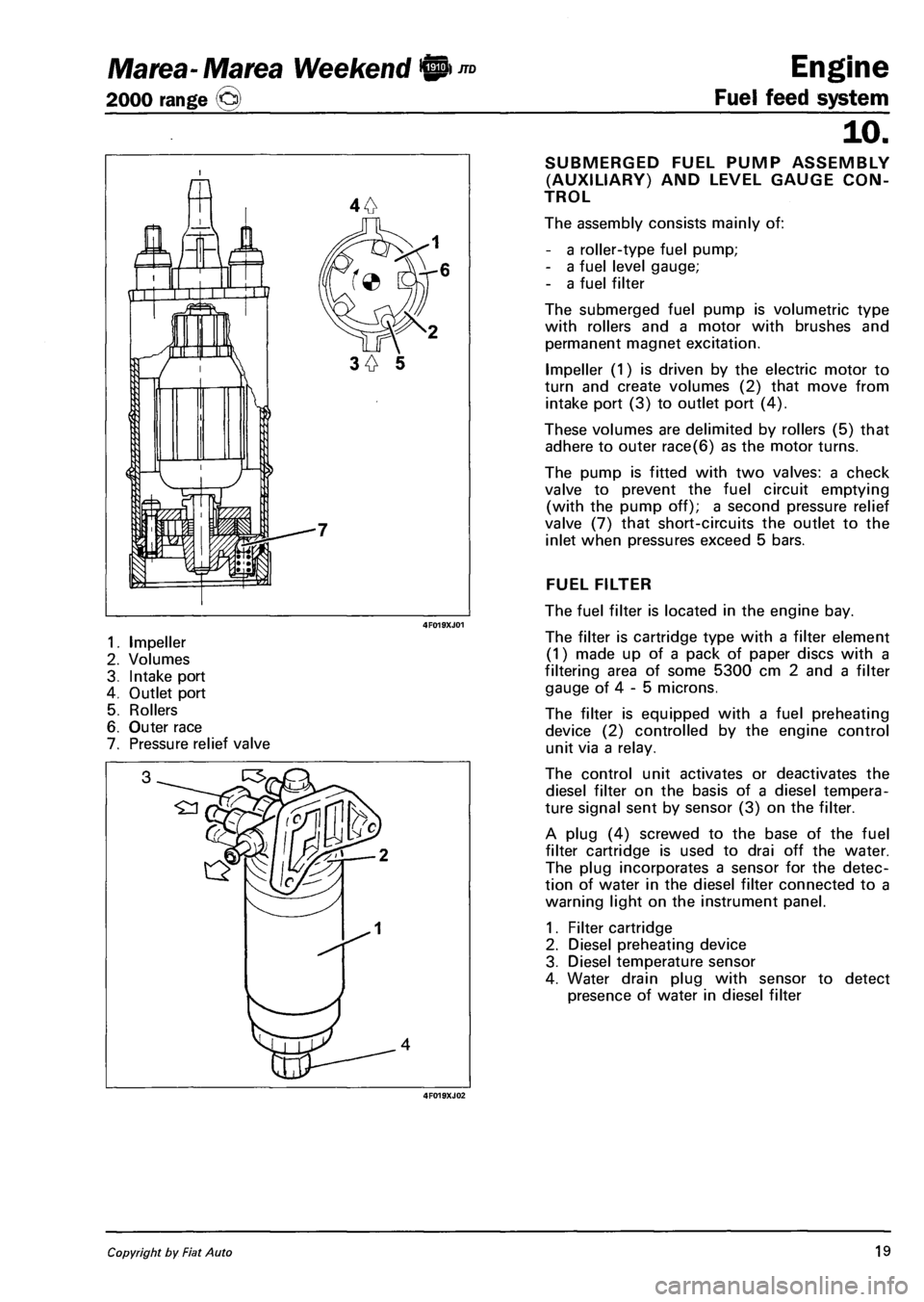

1. Impeller

2. Volumes

3. Intake port

4. Outlet port

5. Rollers

6. Outer race

7. Pressure relief valve

4F019XJ02

Engine

Fuel feed system

10.

SUBMERGED FUEL PUMP ASSEMBLY

(AUXILIARY) AND LEVEL GAUGE CON

TROL

The assembly consists mainly of:

- a roller-type fuel pump;

- a fuel level gauge;

- a fuel filter

The submerged fuel pump is volumetric type

with rollers and a motor with brushes and

permanent magnet excitation.

Impeller (1) is driven by the electric motor to

turn and create volumes (2) that move from

intake port (3) to outlet port (4).

These volumes are delimited by rollers (5) that

adhere to outer race(6) as the motor turns.

The pump is fitted with two valves: a check

valve to prevent the fuel circuit emptying

(with the pump off); a second pressure relief

valve (7) that short-circuits the outlet to the

inlet when pressures exceed 5 bars.

FUEL FILTER

The fuel filter is located in the engine bay.

The filter is cartridge type with a filter element

(1) made up of a pack of paper discs with a

filtering area of some 5300 cm 2 and a filter

gauge of 4 - 5 microns.

The filter is equipped with a fuel preheating

device (2) controlled by the engine control

unit via a relay.

The control unit activates or deactivates the

diesel filter on the basis of a diesel tempera

ture signal sent by sensor (3) on the filter.

A plug (4) screwed to the base of the fuel

filter cartridge is used to drai off the water.

The plug incorporates a sensor for the detec

tion of water in the diesel filter connected to a

warning light on the instrument panel.

1. Filter cartridge

2. Diesel preheating device

3. Diesel temperature sensor

4. Water drain plug with sensor to detect

presence of water in diesel filter

Copyright by Fiat Auto 19

Page 106 of 330

Engine

Fuel feed system

JTD Marea-Marea Weekend @

2000 range ©

10.

7^ £3

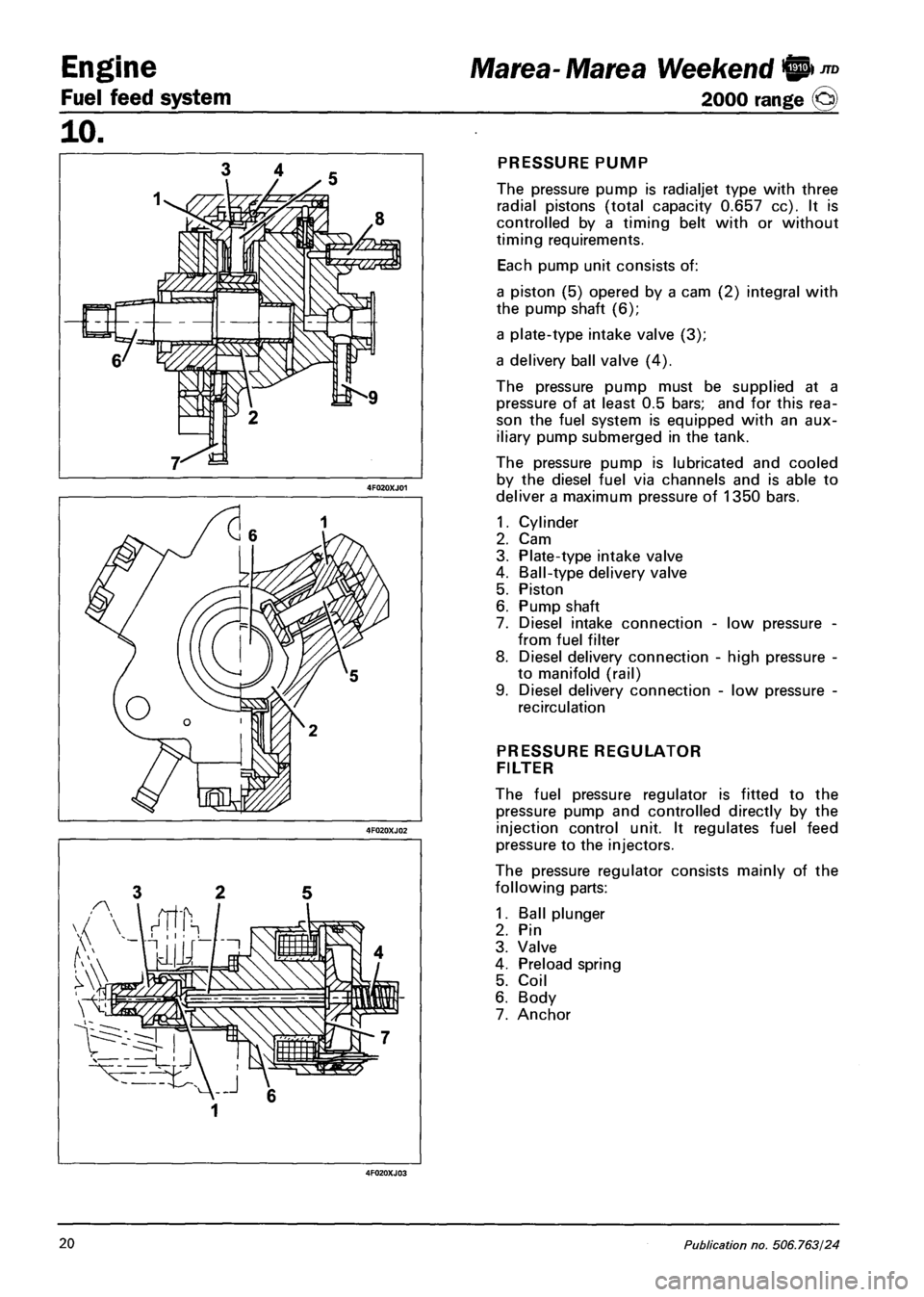

PRESSURE PUMP

The pressure pump is radialjet type with three

radial pistons (total capacity 0.657 cc). It is

controlled by a timing belt with or without

timing requirements.

Each pump unit consists of:

a piston (5) opered by a cam (2) integral with

the pump shaft (6);

a plate-type intake valve (3);

a delivery ball valve (4).

The pressure pump must be supplied at a

pressure of at least 0.5 bars; and for this rea

son the fuel system is equipped with an aux

iliary pump submerged in the tank.

The pressure pump is lubricated and cooled

by the diesel fuel via channels and is able to

deliver a maximum pressure of 1350 bars.

1.

2.

3.

4.

5.

6.

7.

8.

Cylinder

Cam

Plate-type intake valve

Ball-type delivery valve

Piston

Pump shaft

Diesel intake connection -

from fuel filter

Diesel delivery connection

to manifold (rail)

Diesel delivery connection

recirculation

low pressure

high pressure

low pressure

PRESSURE REGULATOR

FILTER

The fuel pressure regulator is fitted to the

pressure pump and controlled directly by the

injection control unit. It regulates fuel feed

pressure to the injectors.

The pressure regulator consists mainly of the

following parts:

1. Ball plunger

2. Pin

3. Valve

4. Preload spring

5. Coil

6. Body

7. Anchor

20 Publication no. 506.763/24

Page 107 of 330

Marea- Marea Weekend <§l ™

2000 range ©

Engine

Fuel feed system

TZZZZZZZZZZZZZZZZZZb

TZZZZZZZZZZZZZZ*

10.

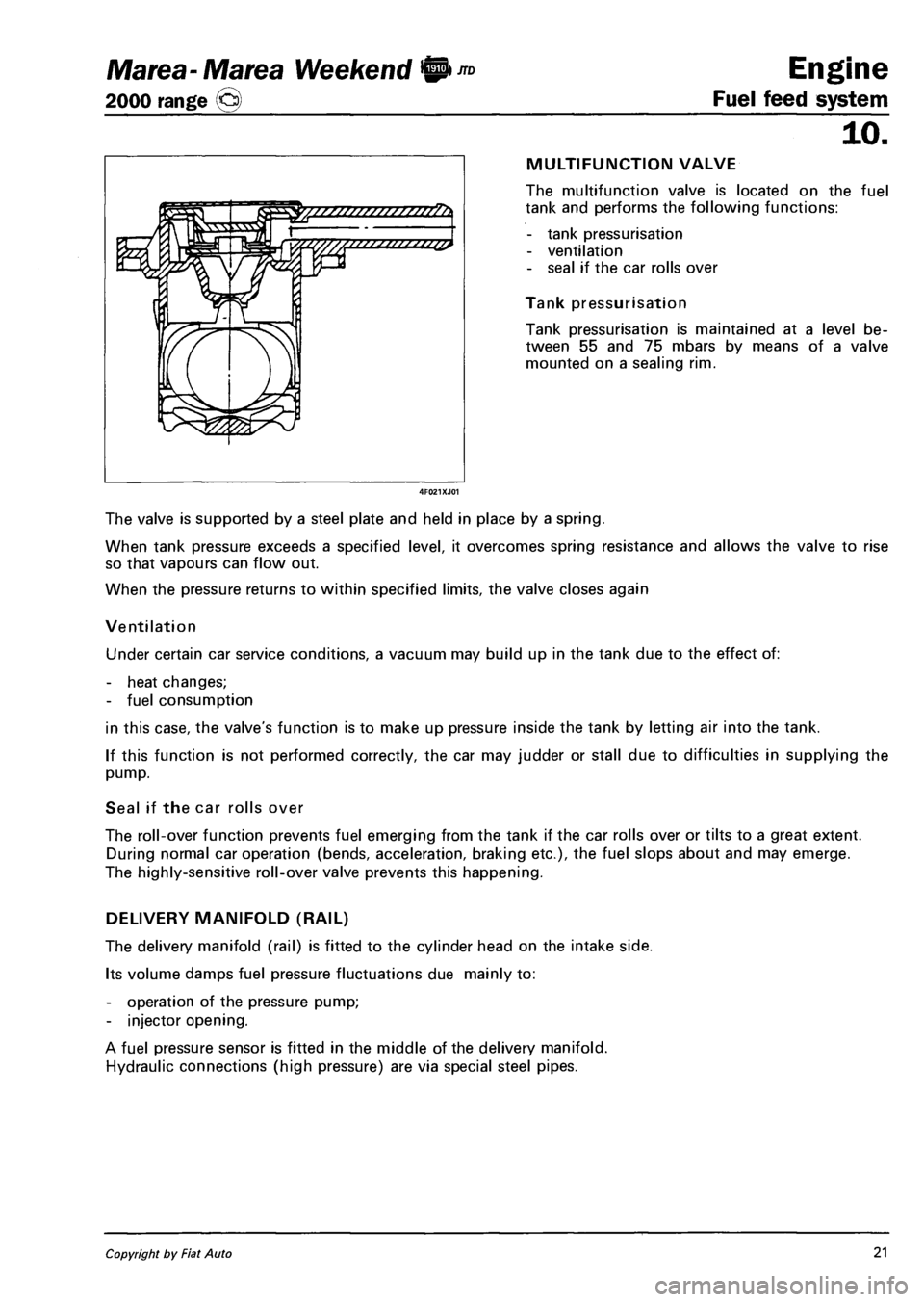

MULTIFUNCTION VALVE

The multifunction valve is located on the fuel

tank and performs the following functions:

- tank pressurisation

- ventilation

- seal if the car rolls over

Tank pressurisation

Tank pressurisation is maintained at a level be

tween 55 and 75 mbars by means of a valve

mounted on a sealing rim.

The valve is supported by a steel plate and held in place by a spring.

When tank pressure exceeds a specified level, it overcomes spring resistance and allows the valve to rise

so that vapours can flow out.

When the pressure returns to within specified limits, the valve closes again

Ventilation

Under certain car service conditions, a vacuum may build up in the tank due to the effect of:

- heat changes;

- fuel consumption

in this case, the valve's function is to make up pressure inside the tank by letting air into the tank.

If this function is not performed correctly, the car may judder or stall due to difficulties in supplying the

pump.

Seal if the car rolls over

The roll-over function prevents fuel emerging from the tank if the car rolls over or tilts to a great extent.

During normal car operation (bends, acceleration, braking etc.), the fuel slops about and may emerge.

The highly-sensitive roll-over valve prevents this happening.

DELIVERY MANIFOLD (RAIL)

The delivery manifold (rail) is fitted to the cylinder head on the intake side.

Its volume damps fuel pressure fluctuations due mainly to:

- operation of the pressure pump;

- injector opening.

A fuel pressure sensor is fitted in the middle of the delivery manifold.

Hydraulic connections (high pressure) are via special steel pipes.

Copyright by Fiat Auto 21

Page 226 of 330

Electrical equipment

Component location

Marea- Marea Weekend

2000 range ©

55.

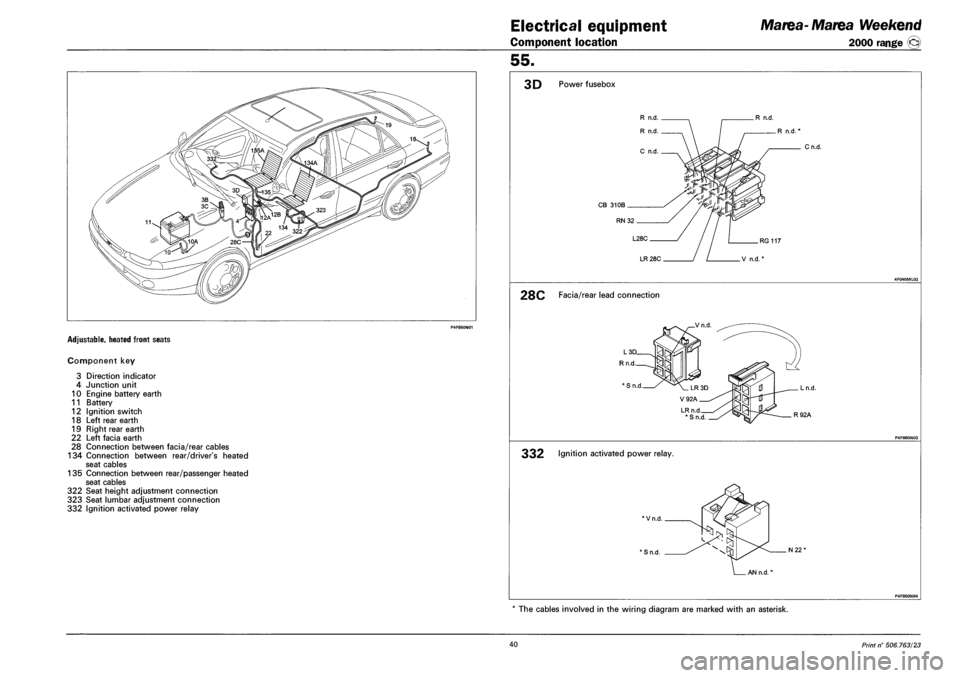

ADJUSTABLE, HEATED FRONT SEATS

Component key

3 Direction indicator

4 Junction unit

10 Engine battery earth

11 Battery

12 Ignition switch

18 Left rear earth

19 Right rear earth

22 Left facia earth

28 Connection between facia/rear cables

134 Connection between rear/driver's heated

seat cables

135 Connection between rear/passenger heated

seat cables

322 Seat height adjustment connection

323 Seat lumbar adjustment connection

332 Ignition activated power relay

3D Power fusebox

R n.d.

R n.d.

C n.d.

R n.d.

CB 31 OB .

RN 32.

L28C .

LR 28C

.R n.d.

Cn.d.

.RG 117

V n.d.

28C Facia/rear lead connection

_Vn.d

LRn.d *Sn.d

. Ln.d.

. R92A

332 Ignition activated power relay.

*Vn.d.

' S n.d. N22"

AN n.d.

P4F850N04

* The cables involved in the wiring diagram are marked with an asterisk.

40 Print n° 506.763/23

Page 319 of 330

Marea- Marea Weekend

2000 range ©

Electrical equipment

Connector blocks

55.

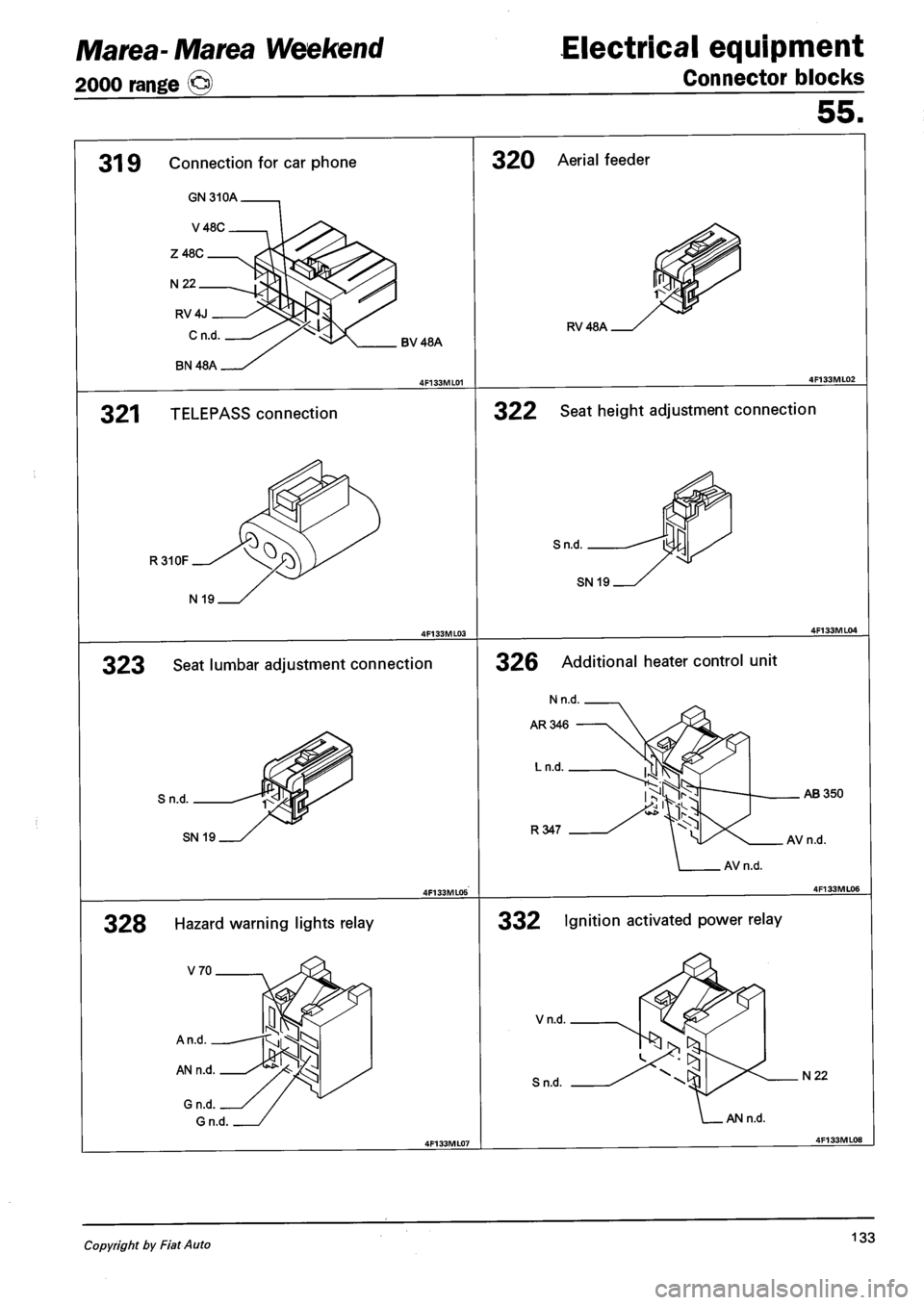

319 Connection for car phone

GN310A.

V48C.

Z48C.

N 22.

RV4J

BV48A

321 TELEPASS connection

R310F

320 Aerial feeder

RV48A

322 Seat height adjustment connection

N 19

323 Seat lumbar adjustment connection

Sn.d.

SN 19

328 Hazard warning lights relay

Sn.d.

SN 19

326 Additional heater control unit

AB350

R347 AV n.d.

332 Ignition activated power relay

Vn.d.

Sn.d. N22

AN n.d.

Copyright by Fiat Auto 133

Page 330 of 330

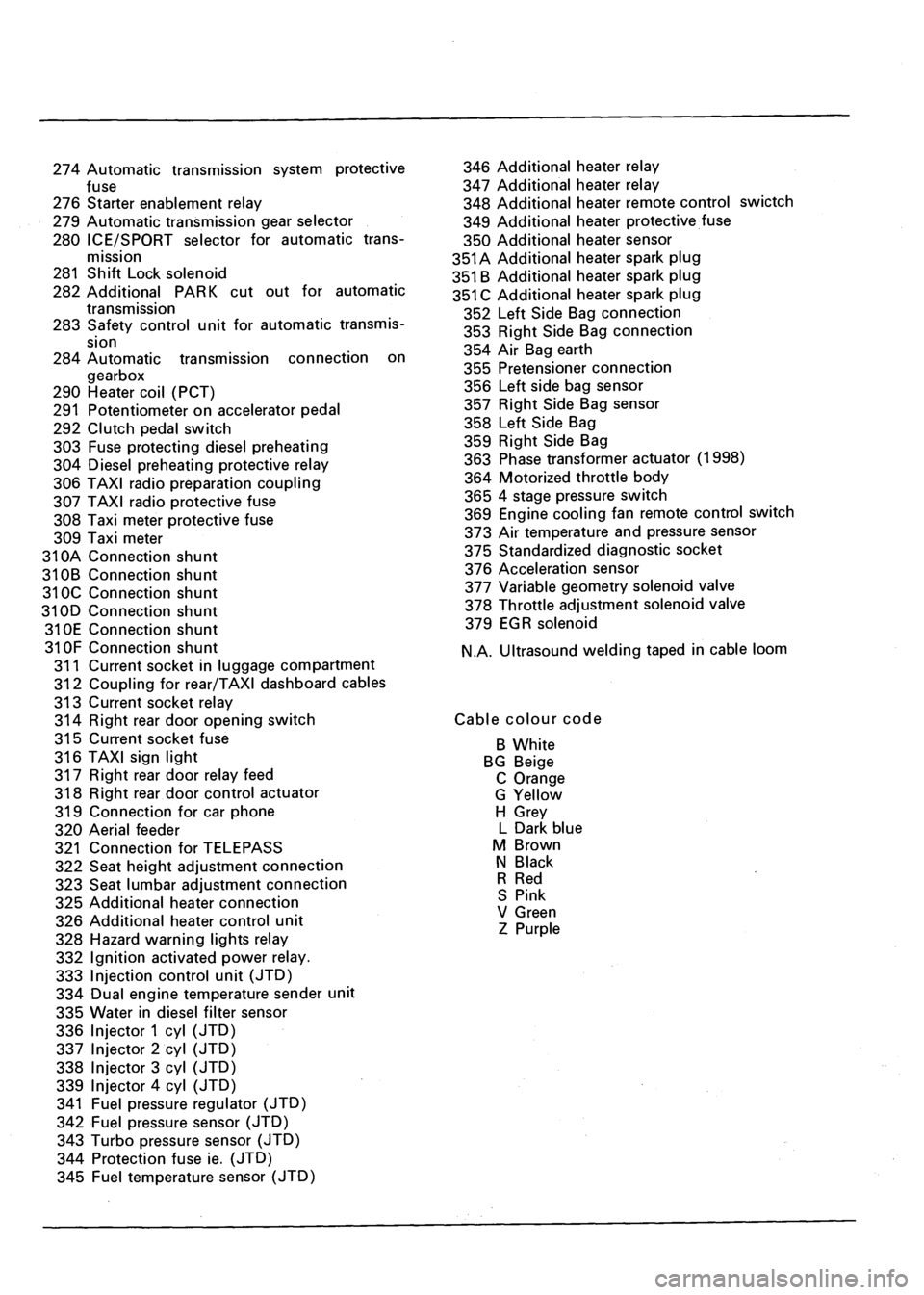

274 Automatic transmission system protective

fuse

276 Starter enablement relay

279 Automatic transmission gear selector

280 ICE/SPORT selector for automatic trans

mission

281 Shift Lock solenoid

282 Additional PARK cut out for automatic

transmission

283 Safety control unit for automatic transmis

sion

284 Automatic transmission connection on

gearbox

290 Heater coil (PCT)

291 Potentiometer on accelerator pedal

292 Clutch pedal switch

303 Fuse protecting diesel preheating

304 Diesel preheating protective relay

306 TAXI radio preparation coupling

307 TAXI radio protective fuse

308 Taxi meter protective fuse

309 Taxi meter

31 OA Connection shunt

310B Connection shunt

310C Connection shunt

310D Connection shunt

310E Connection shunt

31 OF Connection shunt

311 Current socket in luggage compartment

312 Coupling for rear/TAXI dashboard cables

313 Current socket relay

314 Right rear door opening switch

315 Current socket fuse

316 TAXI sign light

317 Right rear door relay feed

318 Right rear door control actuator

319 Connection for car phone

320 Aerial feeder

321 Connection for TELEPASS

322 Seat height adjustment connection

323 Seat lumbar adjustment connection

325 Additional heater connection

326 Additional heater control unit

328 Hazard warning lights relay

332 Ignition activated power relay.

333 Injection control unit (JTD)

334 Dual engine temperature sender unit

335 Water in diesel filter sensor

336 Injector 1 cyl (JTD)

337 Injector 2 cyl (JTD)

338 Injector 3 cyl (JTD)

339 Injector 4 cyl (JTD)

341 Fuel pressure regulator (JTD)

342 Fuel pressure sensor (JTD)

343 Turbo pressure sensor (JTD)

344 Protection fuse ie. (JTD)

345 Fuel temperature sensor (JTD)

346 Additional heater relay

347 Additional heater relay

348 Additional heater remote control swictch

349 Additional heater protective fuse

350 Additional heater sensor

351A Additional heater spark plug

351 B Additional heater spark plug

351 C Additional heater spark plug

352 Left Side Bag connection

353 Right Side Bag connection

354 Air Bag earth

355 Pretensioner connection

356 Left side bag sensor

357 Right Side Bag sensor

358 Left Side Bag

359 Right Side Bag

363 Phase transformer actuator (1998)

364 Motorized throttle body

365 4 stage pressure switch

369 Engine cooling fan remote control switch

373 Air temperature and pressure sensor

375 Standardized diagnostic socket

376 Acceleration sensor

377 Variable geometry solenoid valve

378 Throttle adjustment solenoid valve

379 EGR solenoid

N.A. Ultrasound welding taped in cable loom

Cable colour code

B White

BG Beige

C Orange

G Yellow

H Grey

L Dark blue

M Brown

N Black

R Red

S Pink

V Green

Z Purple