Rear FIAT MAREA 2001 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 2001, Model line: MAREA, Model: FIAT MAREA 2001 1.GPages: 330

Page 63 of 330

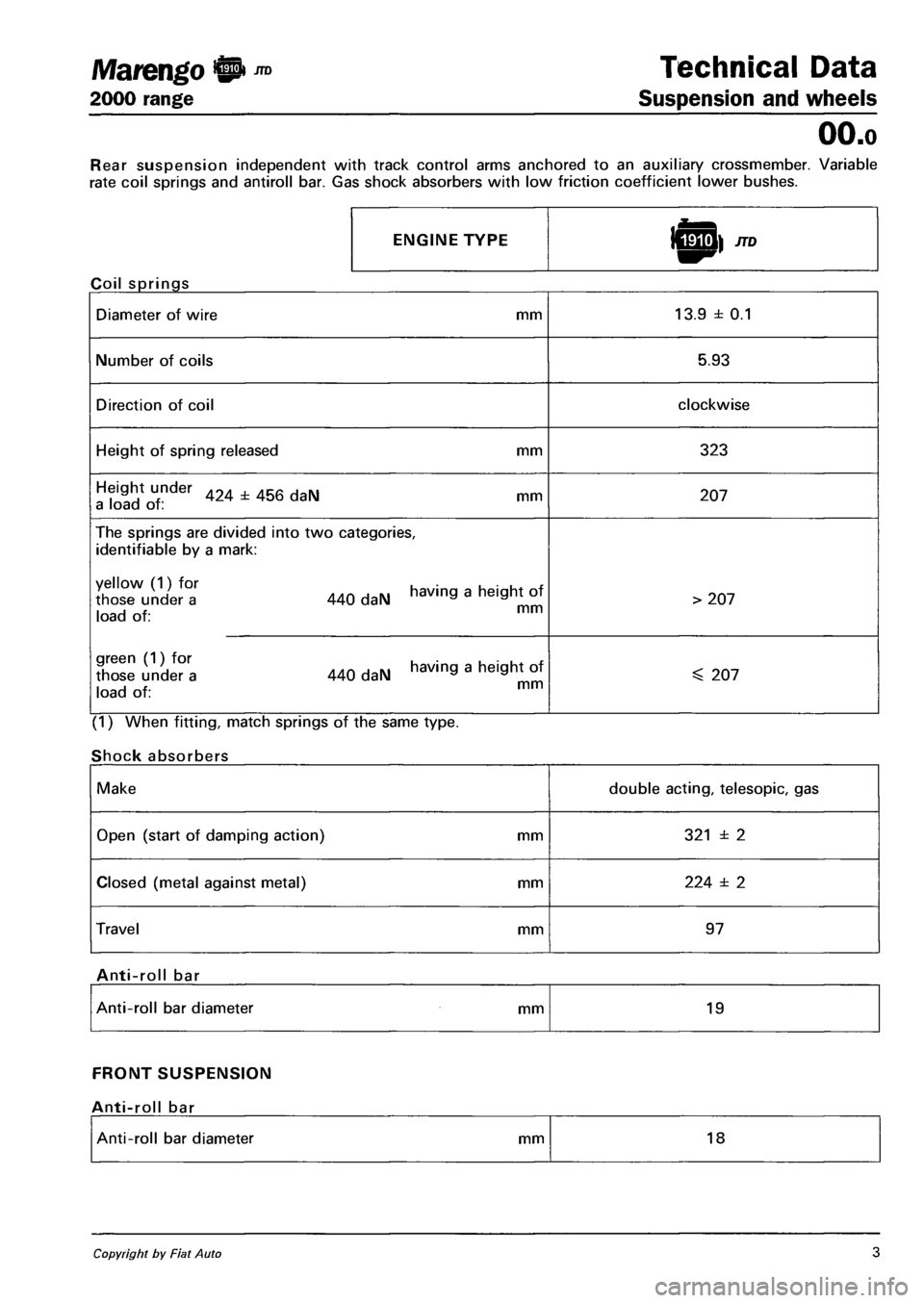

Marengo 0 ™ Technical Data

2000 range Suspension and wheels

OO.o

Rear suspension independent with track control arms anchored to an auxiliary crossmember. Variable

rate coil springs and antiroll bar. Gas shock absorbers with low friction coefficient lower bushes.

ENGINE TYPE

Coil springs

Diameter of wire mm 13.9 ± 0.1

Number of coils 5.93

Direction of coil clockwise

Height of spring released mm 323

Height under 424 ± 456 daN mm a load of : 207

The springs are divided into two categories,

identifiable by a mark:

XX°l 440 daN having a heigh, of i -i x mm load of:

> 207

green (1) for having a height of those under a 440 daN a a i J x. mm load of:

^ 207

(1) When fitting, match springs of the same type.

Shock absorbers

Make double acting, telesopic, gas

Open (start of damping action) mm 321 ± 2

Closed (metal against metal) mm 224 ± 2

Travel mm 97

Anti-roll bar

Anti-roll bar diameter mm 19

FRONT SUSPENSION

Anti-roll bar

Anti-roll bar diameter mm 18

Copyright by Fiat Auto 3

Page 68 of 330

Marea- Marea Weekend • *» Engine

2000 range (§) Fuel feed system

10.

Pages

FUEL FEED SYSTEM

- Engine management system 1

- Diagram showing engine exhaust assem

bly 1

- Fuel anti-evaporation system ~2

- Location of diagnostic socket 2

- Location of injection/ignition system

components in the engine compartment 3

- Front Lambda sensor . 4

- Rear Lambda sensor 4

- Catalytic converter heat shield 5

- Catalytic converter 5

- Exhaust manifold 6

- Electric fuel pump with level sender unit 7

Copyright by Fiat Auto

Page 69 of 330

Marea- Marea Weekend • ^ Engine

2000 range (Q) Fuel feed system

10.

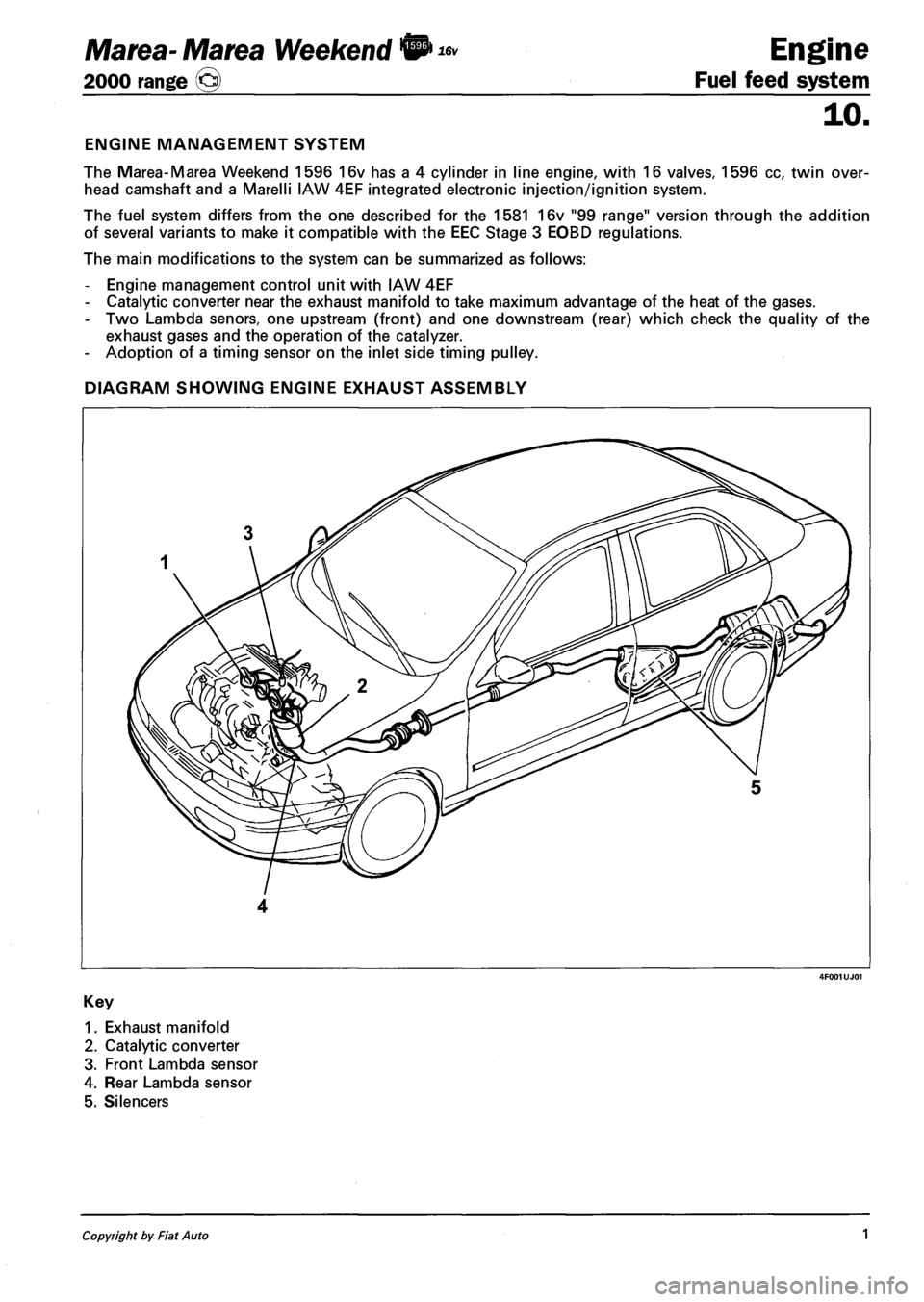

ENGINE MANAGEMENT SYSTEM

The Marea-Marea Weekend 1596 16v has a 4 cylinder in line engine, with 16 valves, 1596 cc, twin over

head camshaft and a Marelli IAW 4EF integrated electronic injection/ignition system.

The fuel system differs from the one described for the 1581 16v "99 range" version through the addition

of several variants to make it compatible with the EEC Stage 3 EOBD regulations.

The main modifications to the system can be summarized as follows:

- Engine management control unit with IAW 4EF

- Catalytic converter near the exhaust manifold to take maximum advantage of the heat of the gases.

- Two Lambda senors, one upstream (front) and one downstream (rear) which check the quality of the

exhaust gases and the operation of the catalyzer.

- Adoption of a timing sensor on the inlet side timing pulley.

DIAGRAM SHOWING ENGINE EXHAUST ASSEMBLY

1. Exhaust manifold

2. Catalytic converter

3. Front Lambda sensor

4. Rear Lambda sensor

5. Silencers

Copyright by Fiat Auto 1

Page 72 of 330

Engine

Fuel feed system

Marea- Marea Weekend •

2000 range @

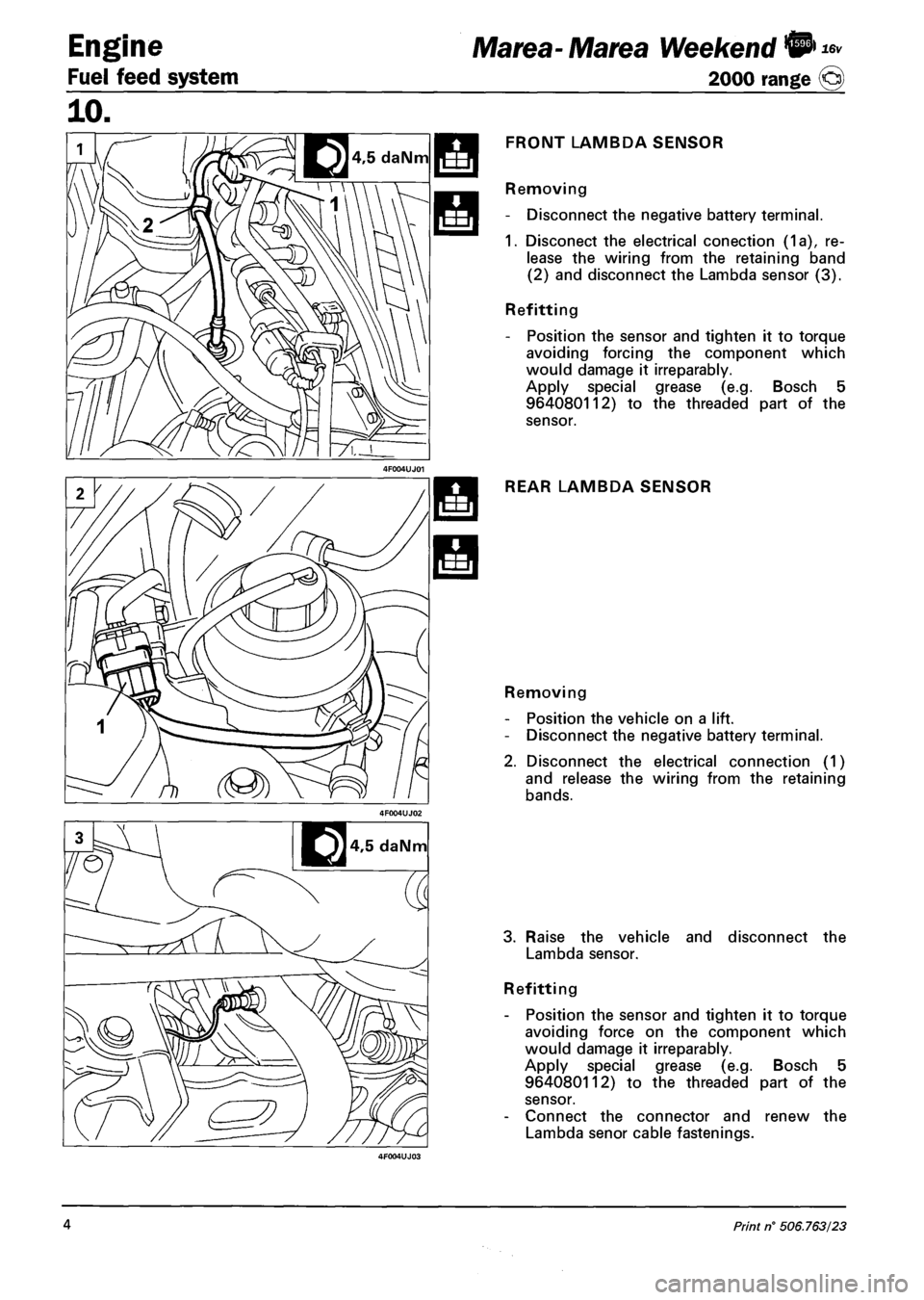

FRONT LAMBDA SENSOR

Removing

- Disconnect the negative battery terminal.

1. Disconect the electrical conection (1a), re

lease the wiring from the retaining band

(2) and disconnect the Lambda sensor (3).

Refitting

- Position the sensor and tighten it to torque

avoiding forcing the component which

would damage it irreparably.

Apply special grease (e.g. Bosch 5

964080112) to the threaded part of the

sensor.

REAR LAMBDA SENSOR

Removing

- Position the vehicle on a lift.

- Disconnect the negative battery terminal.

2. Disconnect the electrical connection (1)

and release the wiring from the retaining

bands.

3. Raise the vehicle and disconnect the

Lambda sensor.

Refitting

- Position the sensor and tighten it to torque

avoiding force on the component which

would damage it irreparably.

Apply special grease (e.g. Bosch 5

964080112) to the threaded part of the

sensor.

- Connect the connector and renew the

Lambda senor cable fastenings.

4 Print n° 506.763/23

Page 74 of 330

Engine

Fuel feed system

16v Marea- Marea Weekend ©

2000 range @

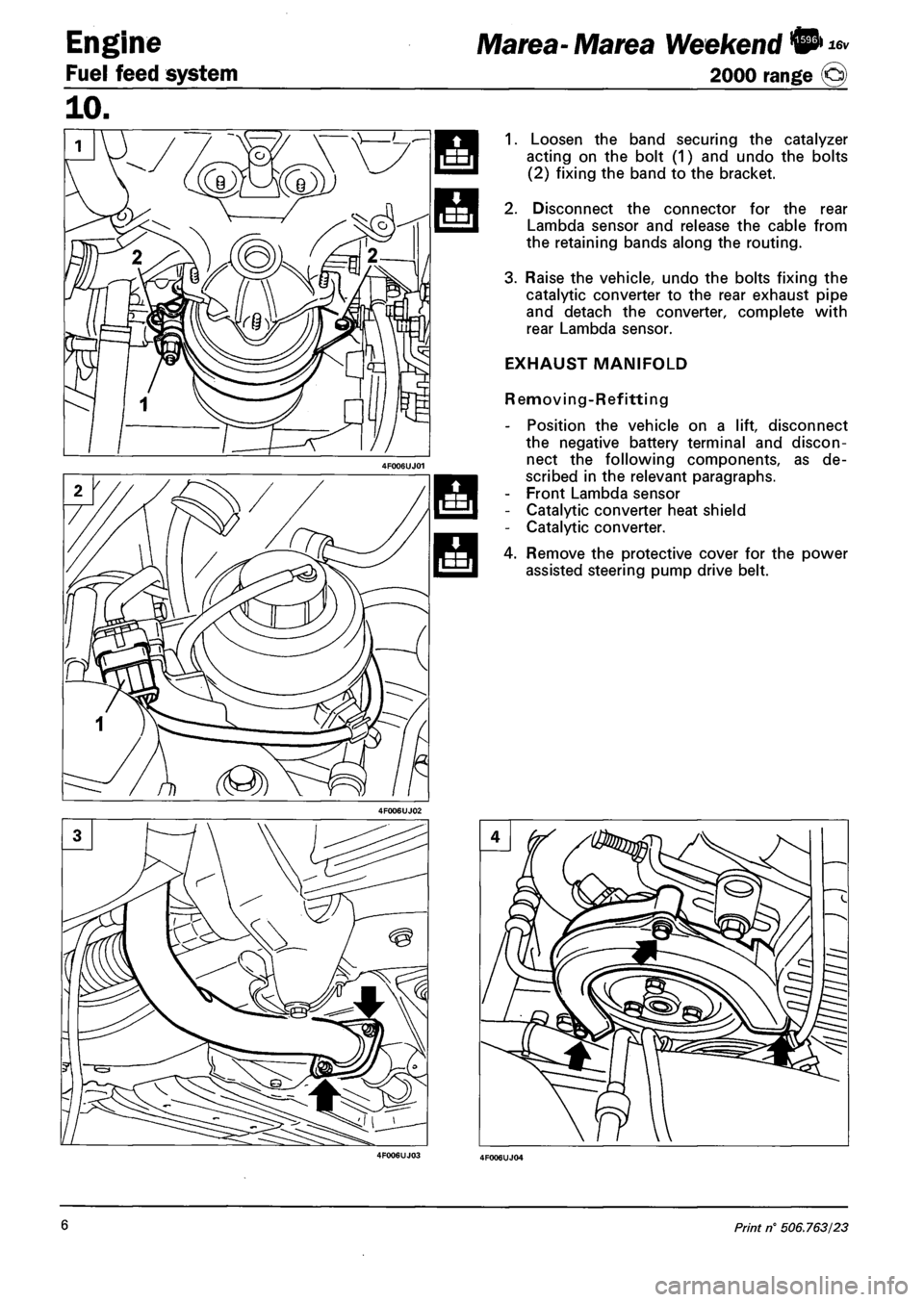

1. Loosen the band securing the catalyzer

acting on the bolt (1) and undo the bolts

(2) fixing the band to the bracket.

2. Disconnect the connector for the rear

Lambda sensor and release the cable from

the retaining bands along the routing.

3. Raise the vehicle, undo the bolts fixing the

catalytic converter to the rear exhaust pipe

and detach the converter, complete with

rear Lambda sensor.

EXHAUST MANIFOLD

Removing-Refitting

- Position the vehicle on a lift, disconnect

the negative battery terminal and discon

nect the following components, as de

scribed in the relevant paragraphs.

- Front Lambda sensor

- Catalytic converter heat shield

- Catalytic converter.

4. Remove the protective cover for the power

assisted steering pump drive belt.

6 Print n° 506.763/23

Page 77 of 330

Marea- MareaWeekend • ** Engine

2000 range @ . . Index

10.

. Page

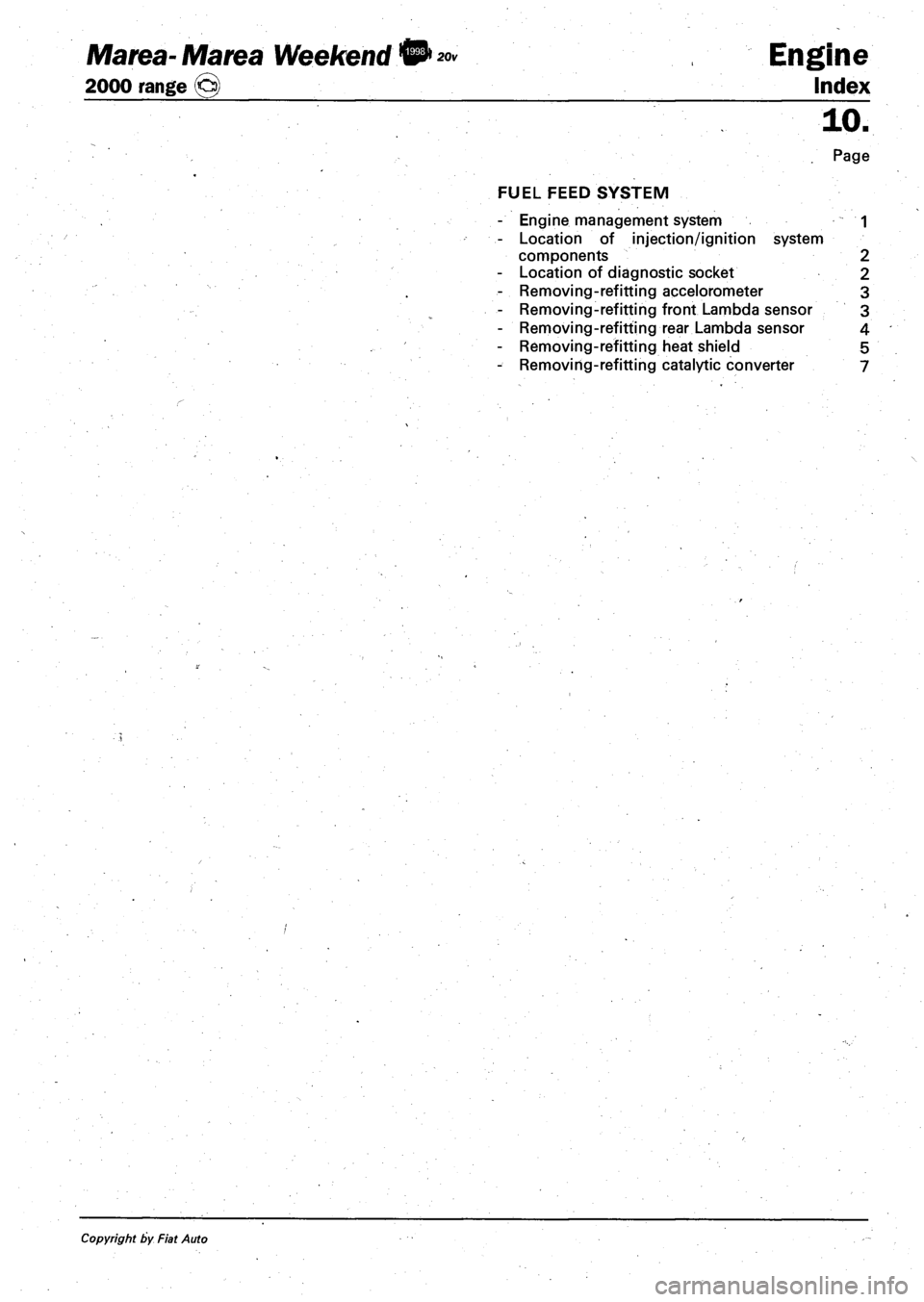

FUEL FEED SYSTEM

- Engine management system 1

- Location of injection/ignition system

components 2

- Location of diagnostic socket 2

- Removing-refitting accelorometer 3

- Removing-refitting front Lambda sensor 3

- Removing-refitting rear Lambda sensor 4

- Removing-refitting heat shield 5

- Removing-refitting catalytic converter 7

Copyright by Fiat Auto

Page 78 of 330

Marea- Marea Weekend & Engine

2000 range (§) Fuel feed system

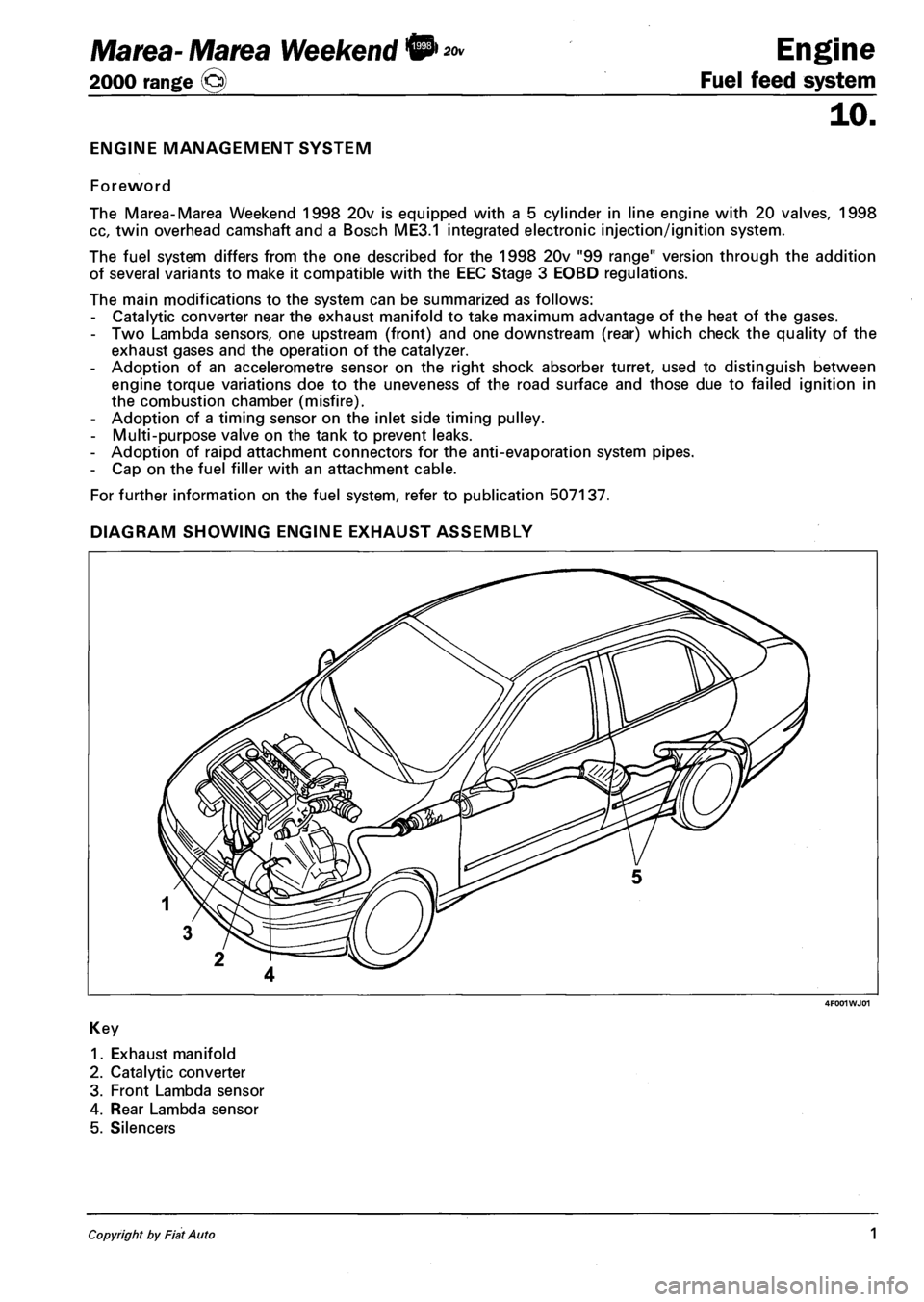

ENGINE MANAGEMENT SYSTEM

Foreword

The Marea-Marea Weekend 1998 20v is equipped with a 5 cylinder in line engine with 20 valves, 1998

cc, twin overhead camshaft and a Bosch ME3.1 integrated electronic injection/ignition system.

The fuel system differs from the one described for the 1998 20v "99 range" version through the addition

of several variants to make it compatible with the EEC Stage 3 EOBD regulations.

The main modifications to the system can be summarized as follows:

- Catalytic converter near the exhaust manifold to take maximum advantage of the heat of the gases.

- Two Lambda sensors, one upstream (front) and one downstream (rear) which check the quality of the

exhaust gases and the operation of the catalyzer.

- Adoption of an accelerometre sensor on the right shock absorber turret, used to distinguish between

engine torque variations doe to the uneveness of the road surface and those due to failed ignition in

the combustion chamber (misfire).

- Adoption of a timing sensor on the inlet side timing pulley.

- Multi-purpose valve on the tank to prevent leaks.

- Adoption of raipd attachment connectors for the anti-evaporation system pipes.

- Cap on the fuel filler with an attachment cable.

For further information on the fuel system, refer to publication 507137.

DIAGRAM SHOWING ENGINE EXHAUST ASSEMBLY

4F001WJ01

Key

1. Exhaust manifold

2. Catalytic converter

3. Front Lambda sensor

4. Rear Lambda sensor

5. Silencers

Copyright by Fiat Auto 1

Page 79 of 330

Engine

Fuel feed system

Marea-Marea Weekend ®> *»

2000 range @)

10.

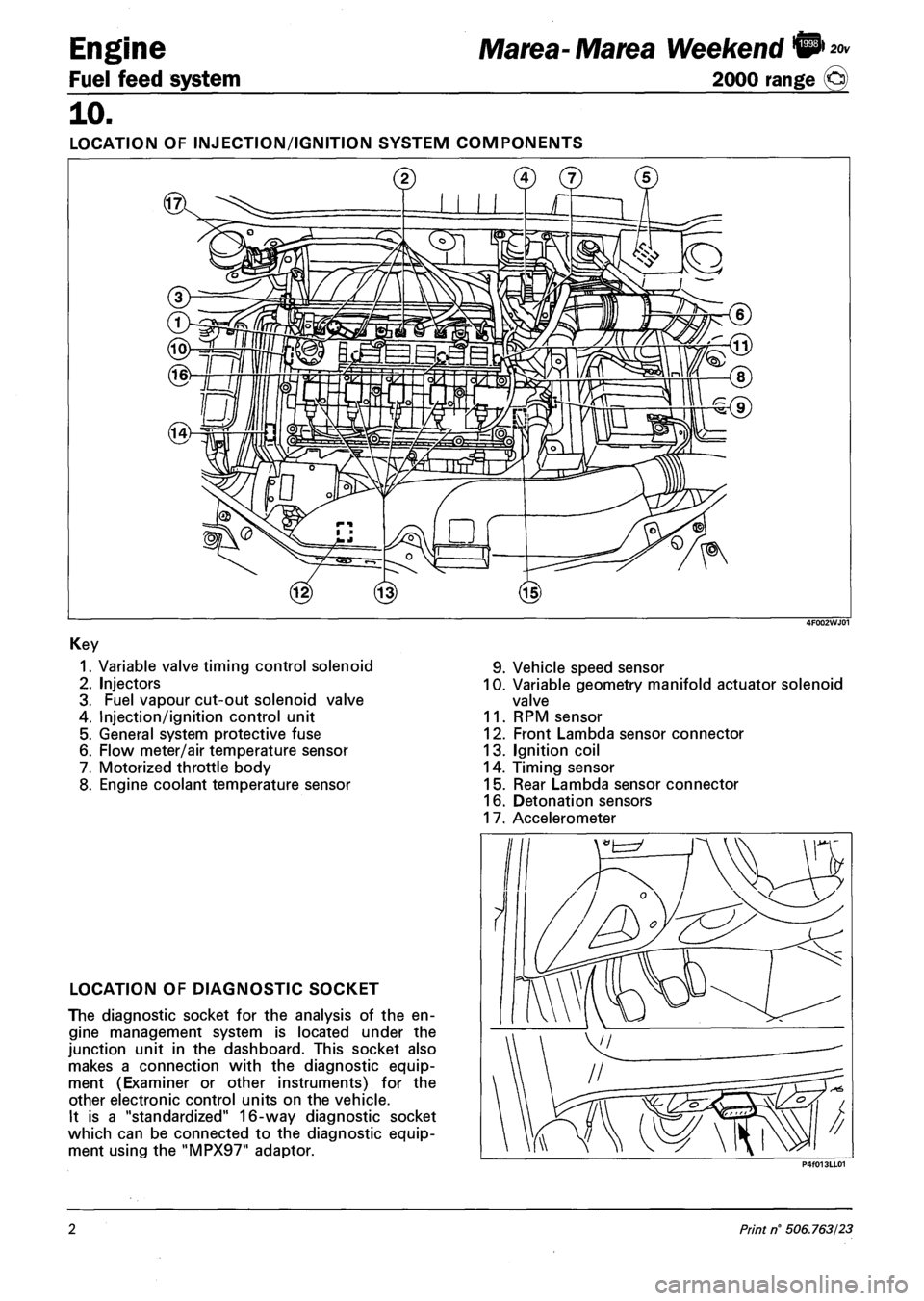

LOCATION OF INJECTION/IGNITION SYSTEM COMPONENTS

Key

1. Variable valve timing control solenoid

2. Injectors

3. Fuel vapour cut-out solenoid valve

4. Injection/ignition control unit

5. General system protective fuse

6. Flow meter/air temperature sensor

7. Motorized throttle body

8. Engine coolant temperature sensor

9. Vehicle speed sensor

10. Variable geometry manifold actuator solenoid

valve

11. RPM sensor

12. Front Lambda sensor connector

13. Ignition coil

14. Timing sensor

15. Rear Lambda sensor connector

16. Detonation sensors

17. Accelerometer

LOCATION OF DIAGNOSTIC SOCKET

The diagnostic socket for the analysis of the en

gine management system is located under the

junction unit in the dashboard. This socket also

makes a connection with the diagnostic equip

ment (Examiner or other instruments) for the

other electronic control units on the vehicle.

It is a "standardized" 16-way diagnostic socket

which can be connected to the diagnostic equip

ment using the "MPX97" adaptor.

2 Print n° 506.763/23

Page 81 of 330

Engine

Fuel feed system

Marea- Marea Weekend 9

2000 range ©

- Release the electrical wiring for the front

Lambda sensor from the retaining bands

and remove the sensor.

Refitting

NOTE Apply special grease (e.g. Bosch VS

14016- FT) to the threaded part ot

the sensor

- Place the Lambda sensor in position and

tighten to torque.

E Lambda sensor : 4.5 daNm

Reverse the order of the operations de

scribed for the removal.

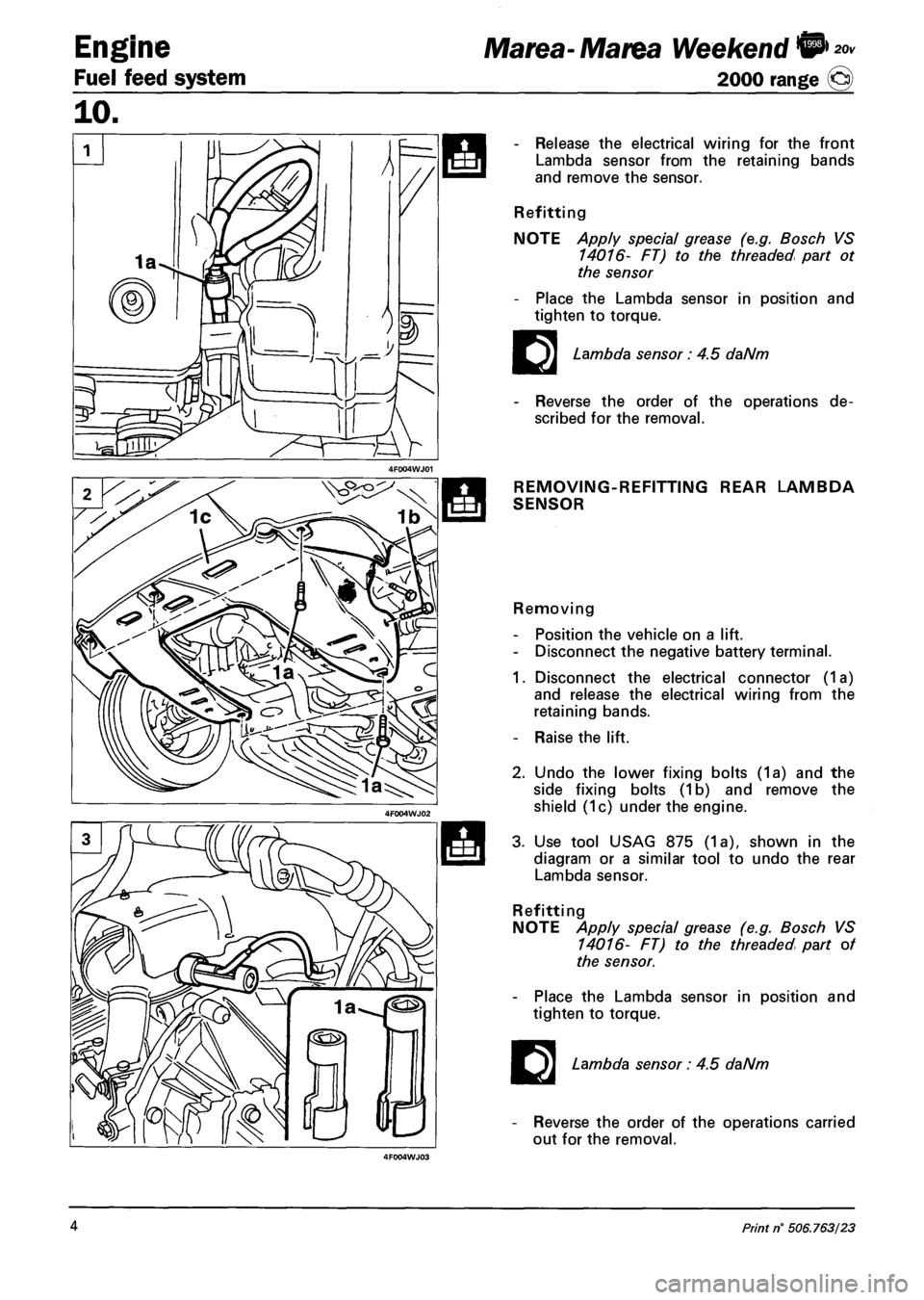

REMOVING-REFITTING REAR LAMBDA

SENSOR

Removing

- Position the vehicle on a lift.

- Disconnect the negative battery terminal.

1. Disconnect the electrical connector (1a)

and release the electrical wiring from the

retaining bands.

- Raise the lift.

2. Undo the lower fixing bolts (1a) and the

side fixing bolts (1b) and remove the

shield (1c) under the engine.

3. Use tool USAG 875 (1a), shown in the

diagram or a similar tool to undo the rear

Lambda sensor.

Refitting

NOTE Apply special grease (e.g. Bosch VS

14016- FT) to the threaded part of

the sensor.

- Place the Lambda sensor in position and

tighten to torque.

E Lambda sensor: 4.5 daNm

Reverse the order of the operations carried

out for the removal.

4 Print n° 506.763/23

Page 84 of 330

Marea- Marea Weekend 9

2000 range ©

Engine

Fuel feed system

10.

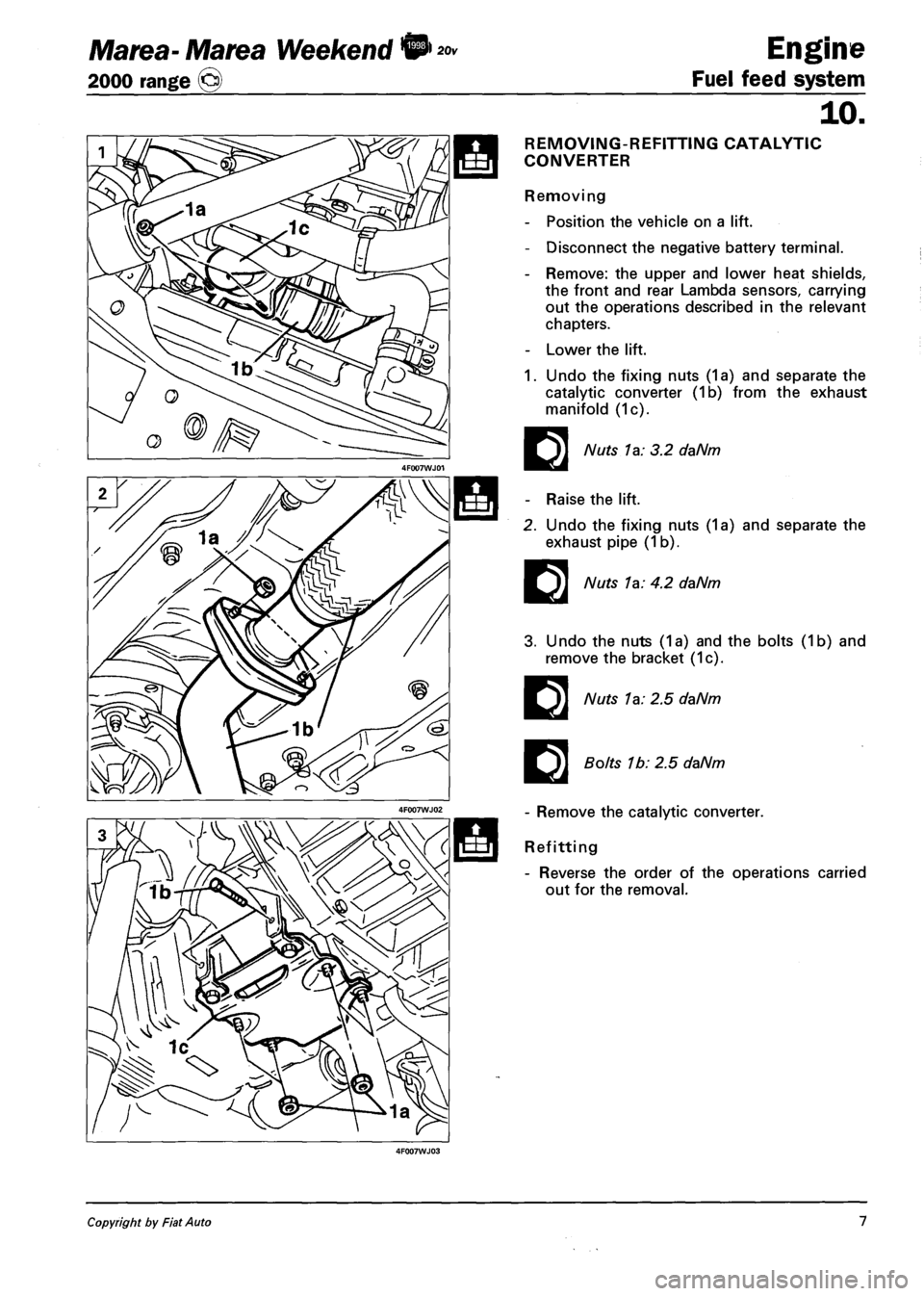

REMOVING-REFITTING CATALYTIC

CONVERTER

Removing

- Position the vehicle on a lift.

- Disconnect the negative battery terminal.

- Remove: the upper and lower heat shields,

the front and rear Lambda sensors, carrying

out the operations described in the relevant

chapters.

- Lower the lift.

1. Undo the fixing nuts (1a) and separate the

catalytic converter (1b) from the exhaust

manifold (1c).

E

Nuts la: 3.2 daNm

- Raise the lift.

2. Undo the fixing nuts (1a) and separate the

exhaust pipe (1 b).

EI

Nuts 1a: 4.2 daNm

3. Undo the nuts (1a) and the bolts (1b) and

remove the bracket (1c).

E

E

Nuts 1a: 2.5 daNm

Bolts 1b: 2.5 daNm

- Remove the catalytic converter.

Refitting

- Reverse the order of the operations carried

out for the removal.

Copyright by Fiat Auto 7