hose FIAT MAREA 2001 1.G Workshop Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2001, Model line: MAREA, Model: FIAT MAREA 2001 1.GPages: 330

Page 11 of 330

Introduction

Performance - Fuel consumption

Marea-Marea Weekend

2000 range ©

OO.o

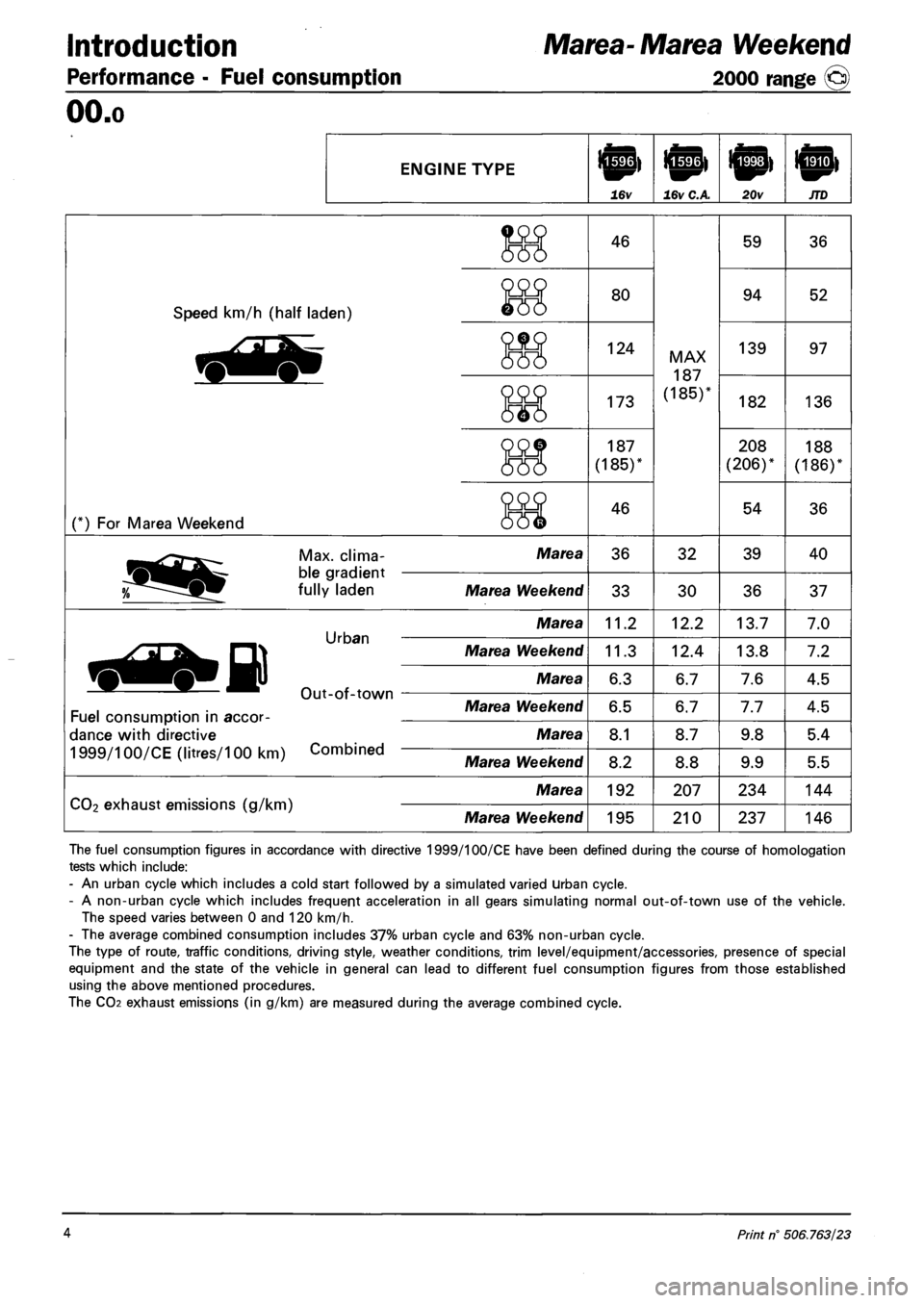

ENGINE TYPE

16v 16v C.A 20v JTD

Speed km/h (half laden)

(*) For Marea Weekend

46

80

124

173

187

(185)'

46

MAX

187

(185)*

59

94

139

182

208

(206)*

54

Max. clima-

ble gradient

fully laden

Marea 36 32 39

Marea Weekend 33 30 36

Urban

Out-of-town

Marea 11.2 12.2 13.7

Marea Weekend 11.3 12.4 13.8

Marea 6.3 6.7 7.6

Fuel consumption in accor

dance with directive

1999/100/CE (litres/100 km) Combined

Marea Weekend 6.5 6.7 7.7

Marea 8.1 8.7 9.8

Marea Weekend 8.2 8.8 9.9

CO2 exhaust emissions (g/km)

Marea 192 207 234

Marea Weekend 195 210 237

The fuel consumption figures in accordance with directive 1999/100/CE have been defined during the course of homologation

tests which include:

- An urban cycle which includes a cold start followed by a simulated varied urban cycle.

- A non-urban cycle which includes frequent acceleration in all gears simulating normal out-of-town use of the vehicle.

The speed varies between 0 and 120 km/h.

- The average combined consumption includes 37% urban cycle and 63% non-urban cycle.

The type of route, traffic conditions, driving style, weather conditions, trim level/equipment/accessories, presence of special

equipment and the state of the vehicle in general can lead to different fuel consumption figures from those established

using the above mentioned procedures.

The CO2 exhaust emissions (in g/km) are measured during the average combined cycle.

4 Print n° 506.763/23

Page 18 of 330

Marea- Marea Weekend

2000 range ©

Technical Data

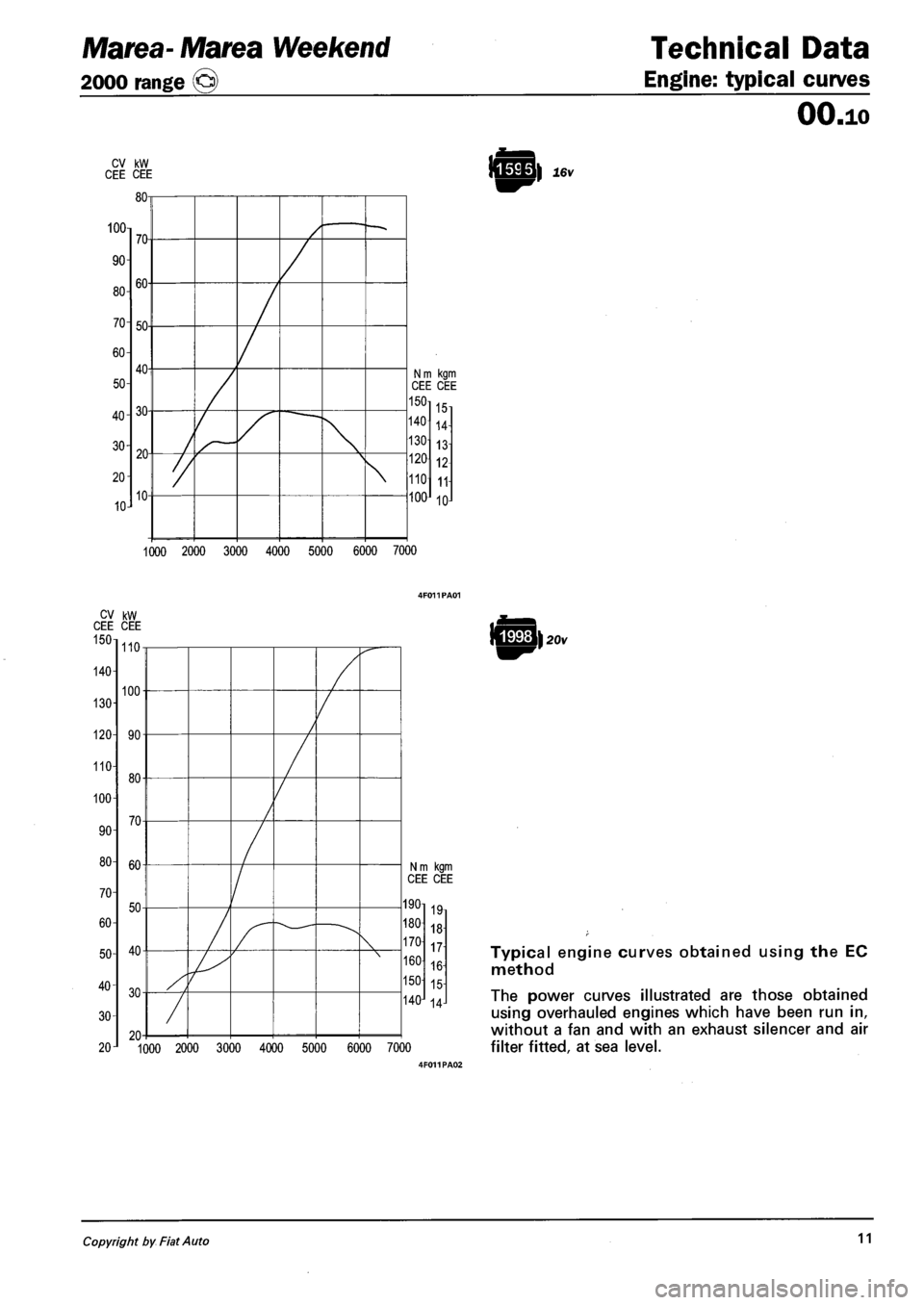

Engine: typical curves

CV kW CEE CEE

OO.10

ICEEEI \ 16v

1000 2000 3000 4000 5000 6000 7000

CV kW CEE CEE 150

140

130H

120

110

100

90

80

70

60

50

40

30

20

l| 20v

N m kgm CEE CEE

1000 2000 3000 4000 5000 6000 7000

Typical engine curves obtained using the EC

method

The power curves illustrated are those obtained

using overhauled engines which have been run in,

without a fan and with an exhaust silencer and air

filter fitted, at sea level.

Copyright by Fiat Auto 11

Page 49 of 330

Technical Data

Front suspension

Marea- Marea Weekend

2000 range @

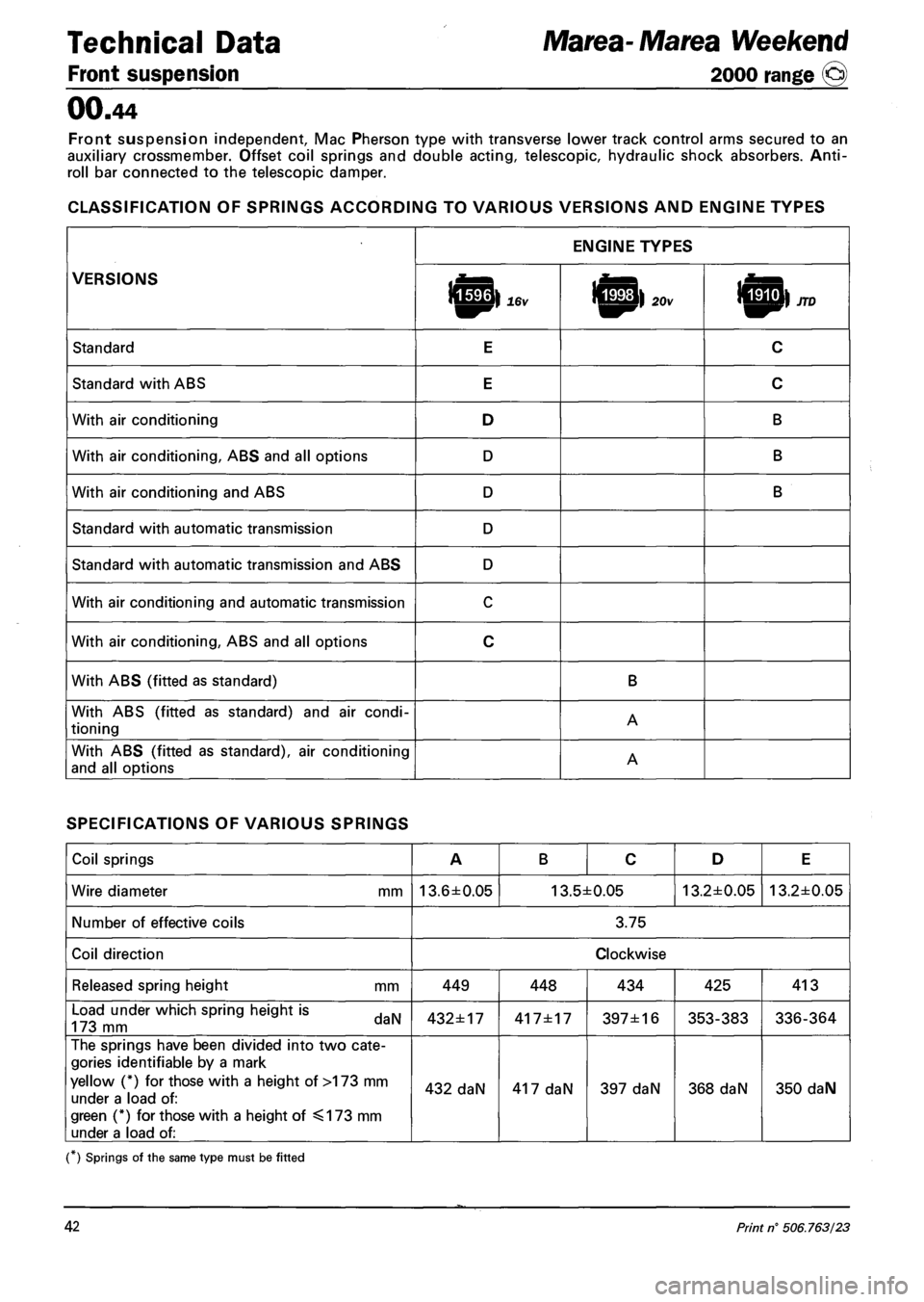

00.44

Front suspension independent, Mac Pherson type with transverse lower track control arms secured to an

auxiliary crossmember. Offset coil springs and double acting, telescopic, hydraulic shock absorbers. Anti-

roll bar connected to the telescopic damper.

CLASSIFICATION OF SPRINGS ACCORDING TO VARIOUS VERSIONS AND ENGINE TYPES

VERSIONS

ENGINE TYPES

VERSIONS

Standard E C

Standard with ABS E C

With air conditioning D B

With air conditioning, ABS and all options D B

With air conditioning and ABS D B

Standard with automatic transmission D

Standard with automatic transmission and ABS D

With air conditioning and automatic transmission C

With air conditioning, ABS and all options C

With ABS (fitted as standard) B

With ABS (fitted as standard) and air condi

tioning A

With ABS (fitted as standard), air conditioning

and all options A

SPECIFICATIONS OF VARIOUS SPRINGS

Coil springs A B C D E

Wire diameter mm 13.6±0.05 13.5±0.05 13.2±0.05 13.2±0.05

Number of effective coils 3.75

Coil direction Clockwise

Released spring height mm 449 448 434 425 413

Load under which spring height is .

173 mm am 432±17 417±17 397±16 353-383 336-364

The springs have been divided into two cate

gories identifiable by a mark

yellow (*) for those with a height of >173 mm

under a load of:

green (*) for those with a height of <173 mm

under a load of:

432 daN 417 daN 397 daN 368 daN 350 daN

( ) Springs of the same type must be fitted

42 Print n° 506.763/23

Page 51 of 330

Technical Data Marea

Rear suspension 2000 range (§)

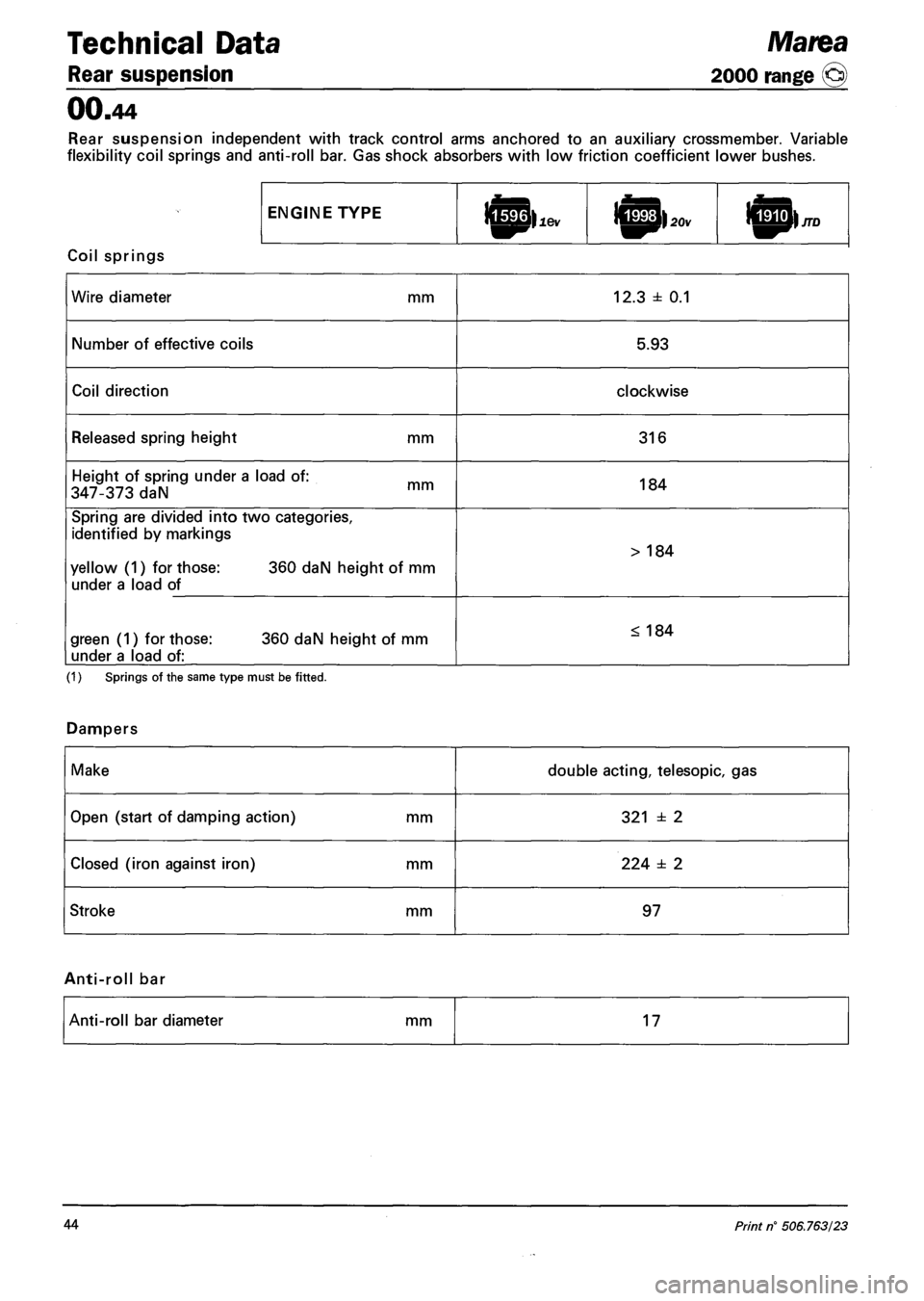

00.44

Rear suspension independent with track control arms anchored to an auxiliary crossmember. Variable

flexibility coil springs and anti-roll bar. Gas shock absorbers with low friction coefficient lower bushes.

ENGINE TYPE lopi lev ICphov

Coil springs

Wire diameter mm 12.3 ± 0.1

Number of effective coils 5.93

Coil direction clockwise

Released spring height mm 316

Height of spring under a load of:

347-373 daN mm 184

Spring are divided into two categories,

identified by markings

yellow (1) for those: 360 daN height of mm

under a load of

> 184

green (1) for those: 360 daN height of mm

under a load of:

< 184

(1) Springs of the same type must be fitted.

Dampers

Make double acting, telesopic, gas

Open (start of damping action) mm 321 ± 2

Closed (iron against iron) mm 224 ± 2

Stroke mm 97

Anti-roll bar

Anti-roll bar diameter mm 17

44 Print n° 506.763/23

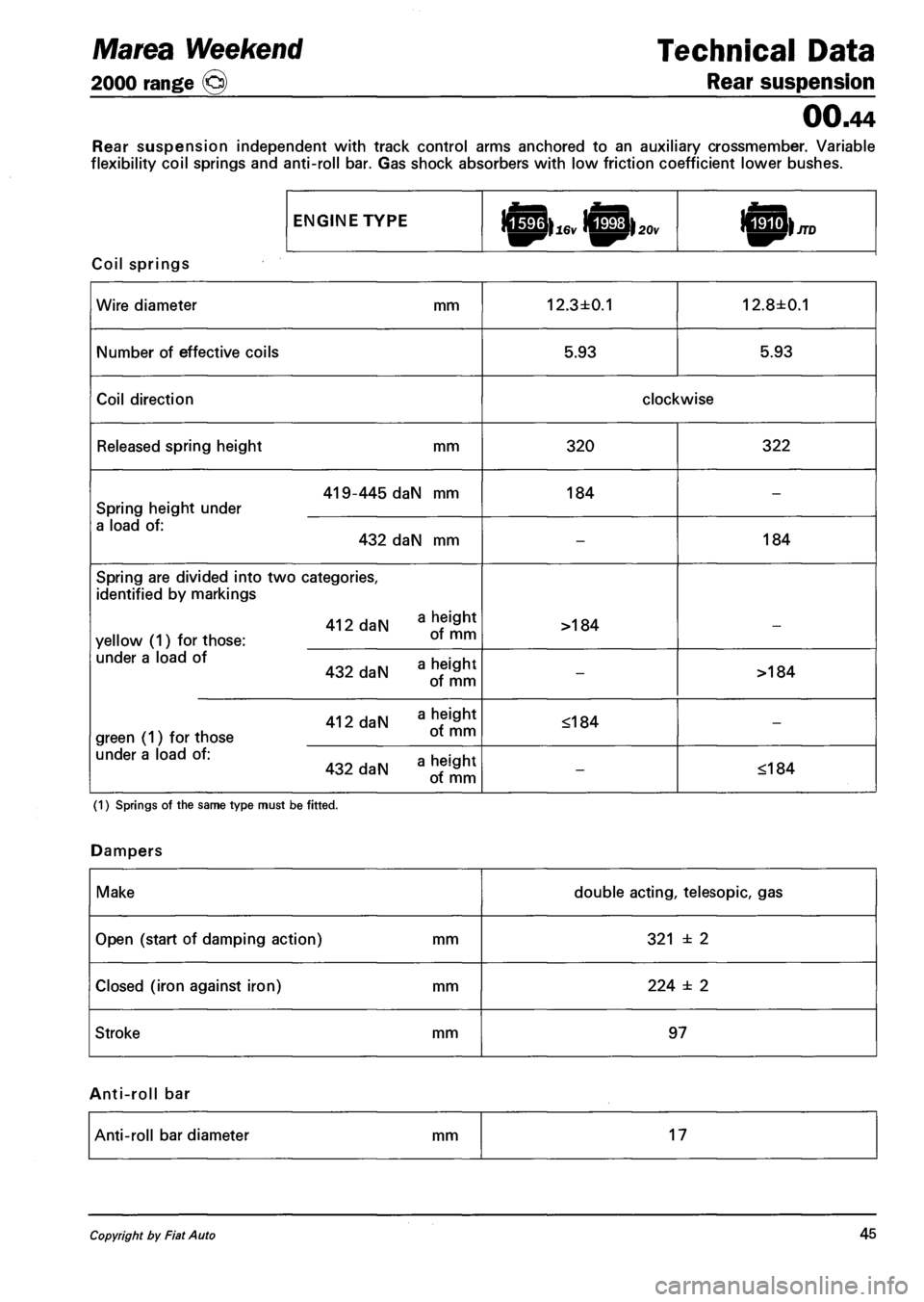

Page 52 of 330

Marea Weekend Technical Data

2000 range o Rear suspension

00.44

Rear suspension independent with track control arms anchored to an auxiliary crossmember. Variable

flexibility coil springs and anti-roll bar. Gas shock absorbers with low friction coefficient lower bushes.

ENGINE TYPE

Coil springs

Wire diameter mm 12.3±0.1 12.8±0.1

Number of effective coils 5.93 5.93

Coil direction clockwise

Released spring height mm 320 322

419-445 daN mm

Spring height under

184 -

a load of:

432 daN mm -184

Spring are divided into two categories,

identified by markings

412 daN

yellow (1) for those: oT mm

>184 _

under a load of hpinht

432 daN a

of mm

->184

412 daN aJS* green (1) for those ot mm

<184 -

under a load of: _ hpiflht 432 daN a "eif£J ot mm -<184

(1) Springs of the same type must be fitted.

Dampers

Make double acting, telesopic, gas

Open (start of damping action) mm 321 ± 2

Closed (iron against iron) mm 224 ± 2

Stroke mm 97

Anti-roll bar

Anti-roll bar diameter mm 17

Copyright by Fiat A uto 45

Page 63 of 330

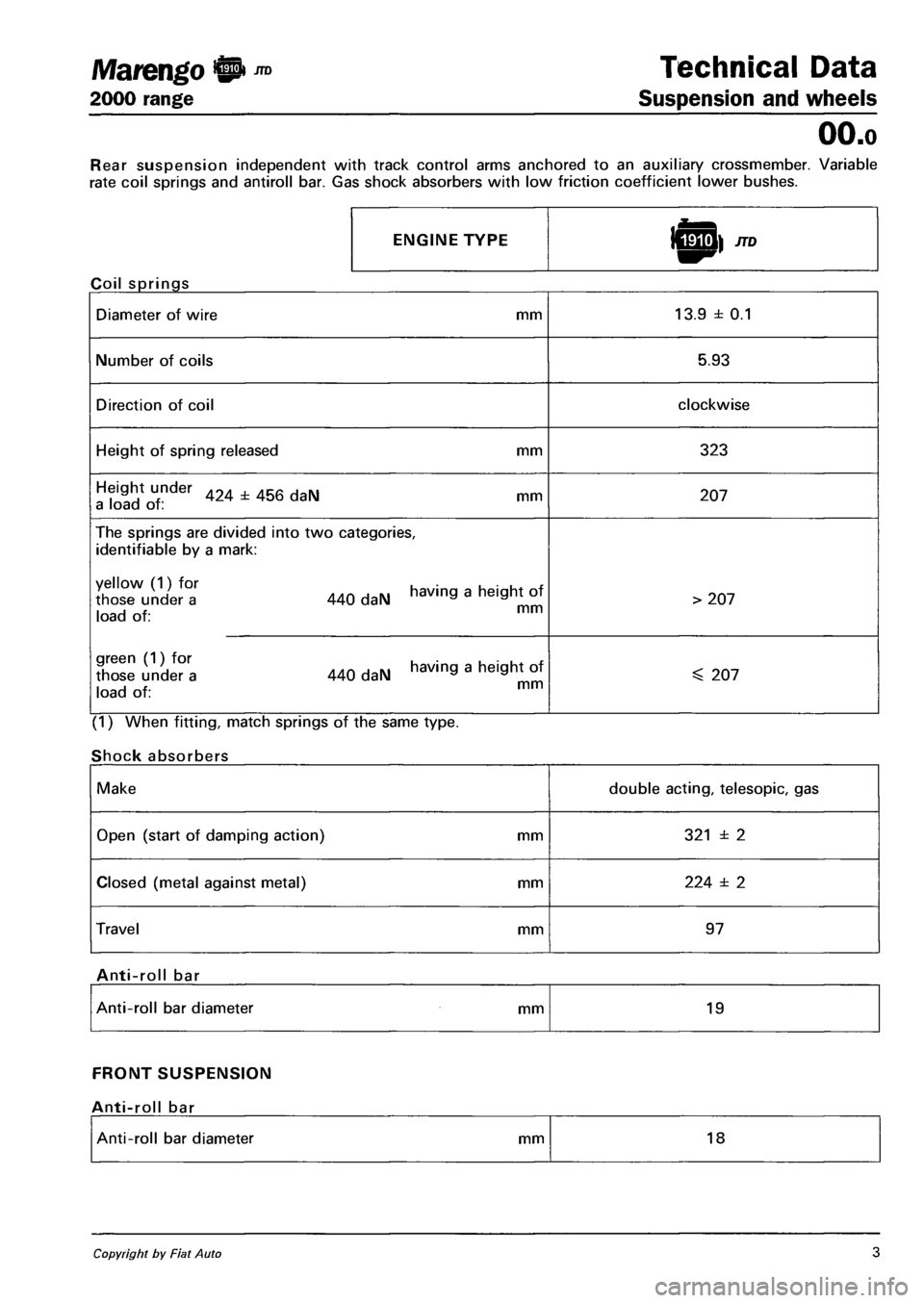

Marengo 0 ™ Technical Data

2000 range Suspension and wheels

OO.o

Rear suspension independent with track control arms anchored to an auxiliary crossmember. Variable

rate coil springs and antiroll bar. Gas shock absorbers with low friction coefficient lower bushes.

ENGINE TYPE

Coil springs

Diameter of wire mm 13.9 ± 0.1

Number of coils 5.93

Direction of coil clockwise

Height of spring released mm 323

Height under 424 ± 456 daN mm a load of : 207

The springs are divided into two categories,

identifiable by a mark:

XX°l 440 daN having a heigh, of i -i x mm load of:

> 207

green (1) for having a height of those under a 440 daN a a i J x. mm load of:

^ 207

(1) When fitting, match springs of the same type.

Shock absorbers

Make double acting, telesopic, gas

Open (start of damping action) mm 321 ± 2

Closed (metal against metal) mm 224 ± 2

Travel mm 97

Anti-roll bar

Anti-roll bar diameter mm 19

FRONT SUSPENSION

Anti-roll bar

Anti-roll bar diameter mm 18

Copyright by Fiat Auto 3

Page 66 of 330

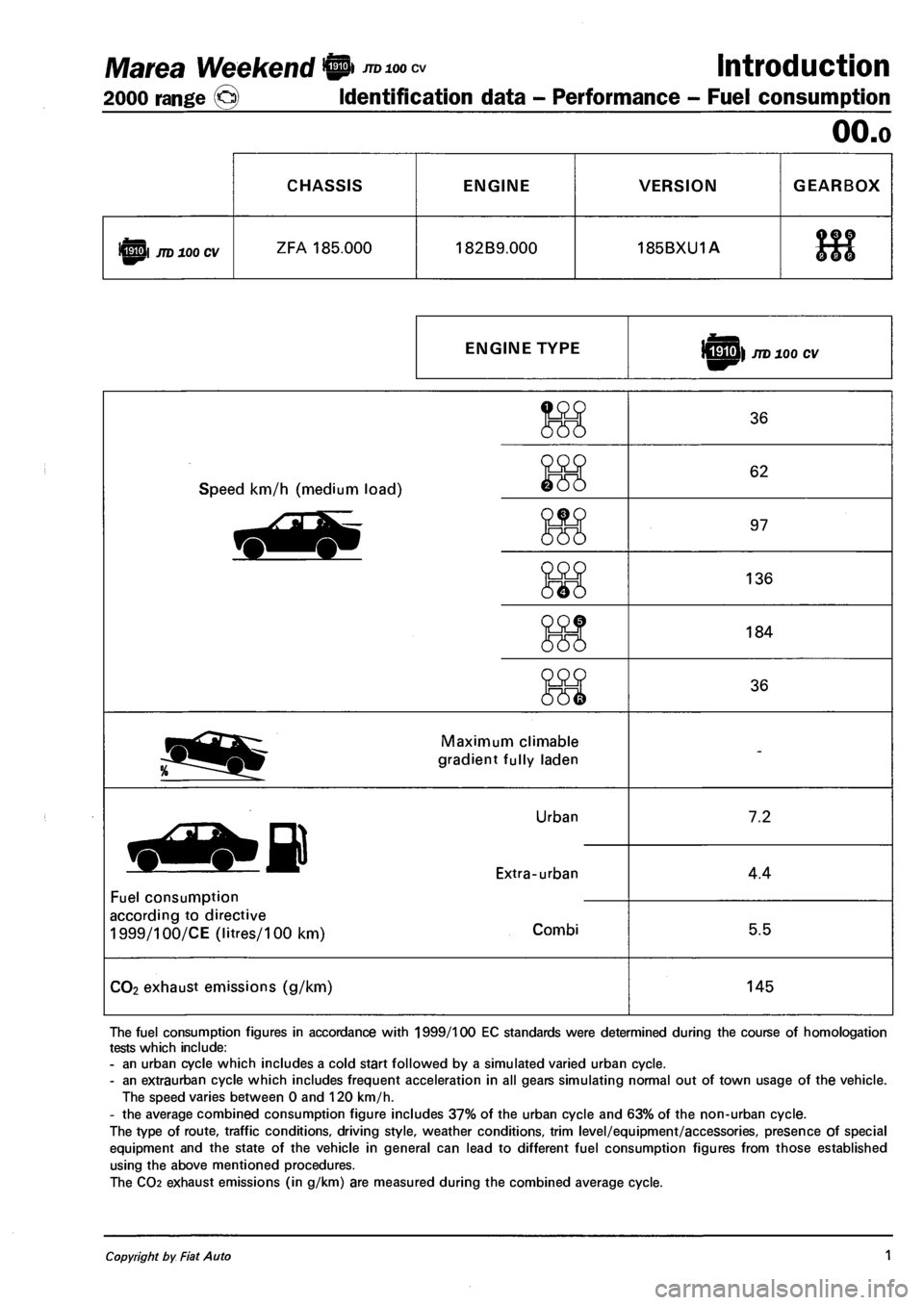

Marea Weekend 9 mnoocv Introduction

2000 range @> Identification data - Performance - Fuel consumption

OO.o

CHASSIS ENGINE VERSION GEARBOX

iQpl JTD 100 CV ZFA 185.000 182B9.000 185BXU1A 9f ?

666

ENGINE TYPE sHU) JTD 100 CV

Speed km/h (medium load)

36

62

97

136

184

36

Maximum climable

gradient fully laden

Fuel consumption

according to directive

1999/100/CE (litres/100 km)

Urban

Extra-urban

Combi

7.2

4.4

5.5

CO2 exhaust emissions (g/km) 145

The fuel consumption figures in accordance with 1999/100 EC standards were determined during the course of homologation

tests which include:

- an urban cycle which includes a cold start followed by a simulated varied urban cycle.

- an extraurban cycle which includes frequent acceleration in all gears simulating normal out of town usage of the vehicle.

The speed varies between 0 and 120 km/h.

- the average combined consumption figure includes 37% of the urban cycle and 63% of the non-urban cycle.

The type of route, traffic conditions, driving style, weather conditions, trim level/equipment/accessories, presence of special

equipment and the state of the vehicle in general can lead to different fuel consumption figures from those established

using the above mentioned procedures.

The CO2 exhaust emissions (in g/km) are measured during the combined average cycle.

Copyright by Fiat Auto 1

Page 73 of 330

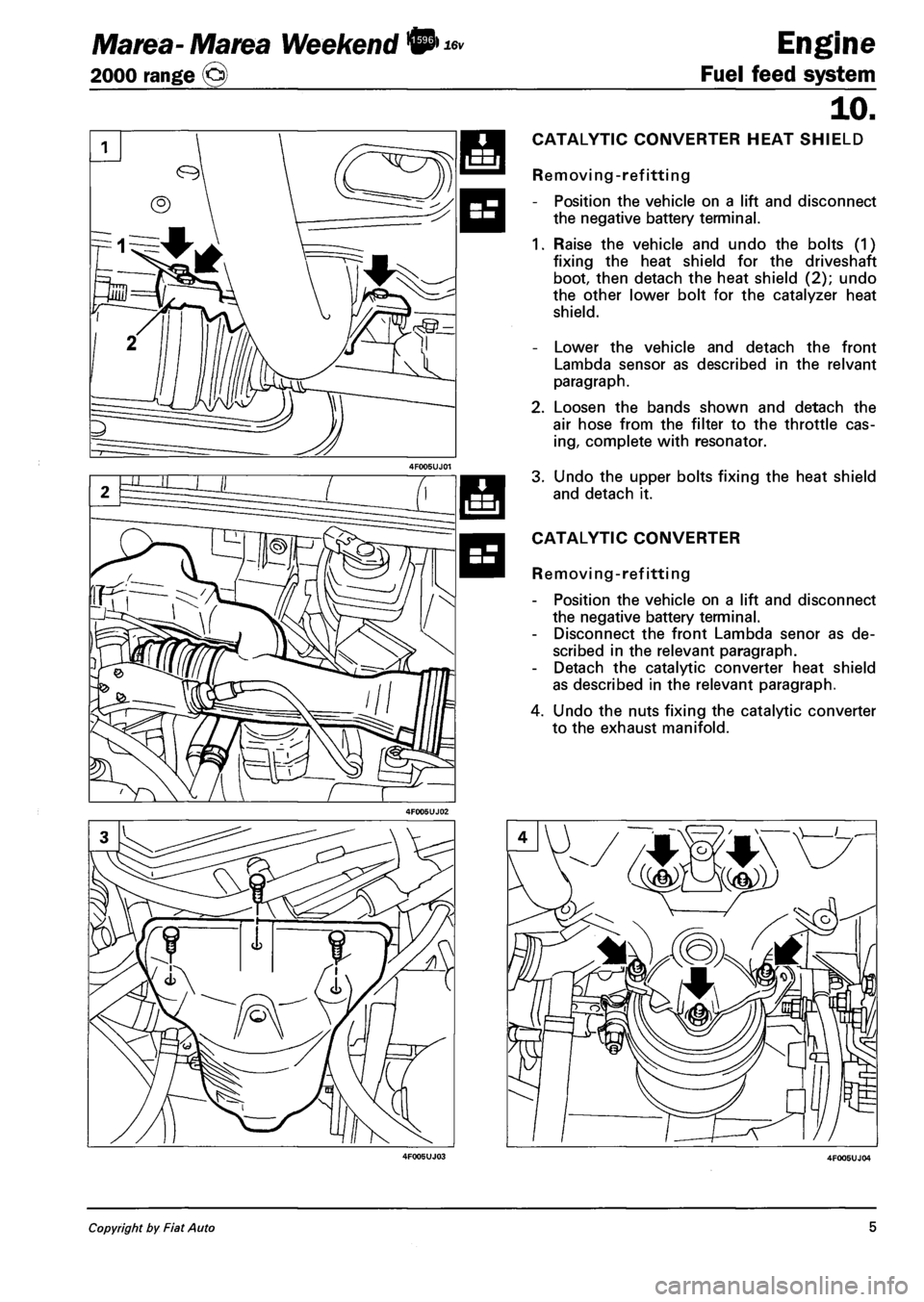

Marea-Marea Weekend

2000 range ©

Engine

Fuel feed system

10.

CATALYTIC CONVERTER HEAT SHIELD

Removing-refitting

- Position the vehicle on a lift and disconnect

the negative battery terminal.

1. Raise the vehicle and undo the bolts (1)

fixing the heat shield for the driveshaft

boot, then detach the heat shield (2); undo

the other lower bolt for the catalyzer heat

shield.

- Lower the vehicle and detach the front

Lambda sensor as described in the relvant

paragraph.

2. Loosen the bands shown and detach the

air hose from the filter to the throttle cas

ing, complete with resonator.

3. Undo the upper bolts fixing the heat shield

and detach it.

CATALYTIC CONVERTER

Removing-refitting

- Position the vehicle on a lift and disconnect

the negative battery terminal.

- Disconnect the front Lambda senor as de

scribed in the relevant paragraph.

- Detach the catalytic converter heat shield

as described in the relevant paragraph.

4. Undo the nuts fixing the catalytic converter

to the exhaust manifold.

Copyright by Fiat Auto 5

Page 78 of 330

Marea- Marea Weekend & Engine

2000 range (§) Fuel feed system

ENGINE MANAGEMENT SYSTEM

Foreword

The Marea-Marea Weekend 1998 20v is equipped with a 5 cylinder in line engine with 20 valves, 1998

cc, twin overhead camshaft and a Bosch ME3.1 integrated electronic injection/ignition system.

The fuel system differs from the one described for the 1998 20v "99 range" version through the addition

of several variants to make it compatible with the EEC Stage 3 EOBD regulations.

The main modifications to the system can be summarized as follows:

- Catalytic converter near the exhaust manifold to take maximum advantage of the heat of the gases.

- Two Lambda sensors, one upstream (front) and one downstream (rear) which check the quality of the

exhaust gases and the operation of the catalyzer.

- Adoption of an accelerometre sensor on the right shock absorber turret, used to distinguish between

engine torque variations doe to the uneveness of the road surface and those due to failed ignition in

the combustion chamber (misfire).

- Adoption of a timing sensor on the inlet side timing pulley.

- Multi-purpose valve on the tank to prevent leaks.

- Adoption of raipd attachment connectors for the anti-evaporation system pipes.

- Cap on the fuel filler with an attachment cable.

For further information on the fuel system, refer to publication 507137.

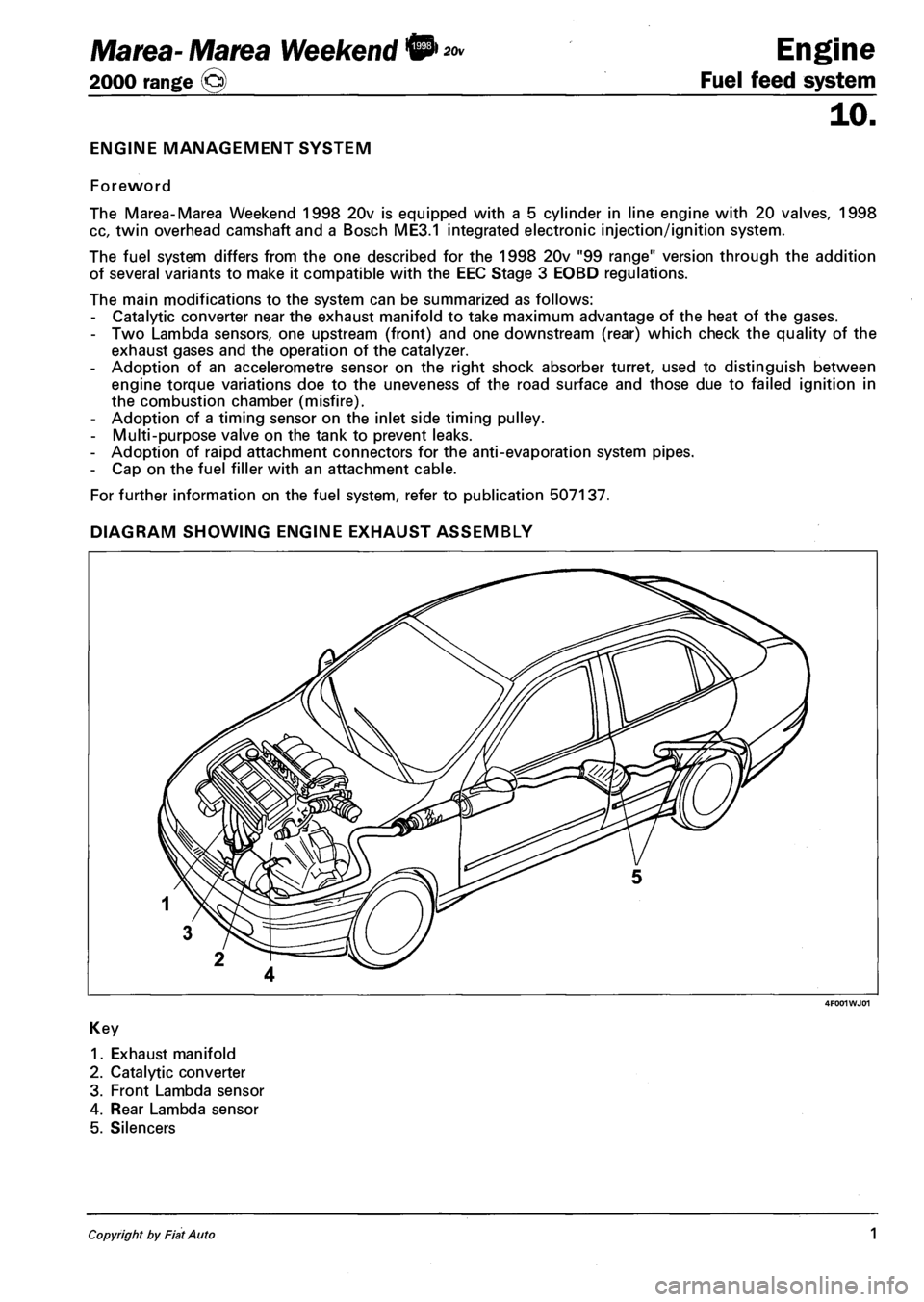

DIAGRAM SHOWING ENGINE EXHAUST ASSEMBLY

4F001WJ01

Key

1. Exhaust manifold

2. Catalytic converter

3. Front Lambda sensor

4. Rear Lambda sensor

5. Silencers

Copyright by Fiat Auto 1

Page 91 of 330

![FIAT MAREA 2001 1.G Workshop Manual Marea-Marea Weekend 9]

2000 range (j§)

I) JTD

Fuel feed system

Engine

10.

Exhaust fumes control

Through this function the injection control unit limits any exhaust fumes that could be produce FIAT MAREA 2001 1.G Workshop Manual Marea-Marea Weekend 9]

2000 range (j§)

I) JTD

Fuel feed system

Engine

10.

Exhaust fumes control

Through this function the injection control unit limits any exhaust fumes that could be produce](/img/10/4653/w960_4653-90.png)

Marea-Marea Weekend 9]

2000 range (j§)

I) JTD

Fuel feed system

Engine

10.

Exhaust fumes control

Through this function the injection control unit limits any exhaust fumes that could be produced during

transition speeds.

To satisy these requirements the control unit processes the signals supplied by the accelerator pedal po

tentiometer, the rpm sensor and the air flow meter and controls the fuel pressure regulator and the injec

tors to meter the correct amount of fuel to inject.

Exhaust gas recirculation control

On the basis of the signals supplied by the rpm sensor, intake air quantity sensor, engine coolant tempe

rature sensor and accelerator pedal position sensor, the control unit calculates the operating times for the

EGR valve so that the exhaust gases are partly recirculated in certain engine operating conditions in line

with Euro 3 pollution control standards.

Air conditioning system engagement control

The injection control unit manages the operation of the air conditioning system compressor electro

magnet coupling following a logic aimed at preventing operating conditions that would adversely affect

engine performance.

- When the compressor is switched on the injection control unit increases the quantity of fuel during

idling to allow the engine to adjust to the increased power requirements and momentarily interrupts the

supply to the compressor in high engine power requirement conditions (strong acceleration).

Engine immobilizer function control

The system is equipped with an engine immobilizer function. This function is achieved through the pre

sence of a specific control unit (Fiat CODE), capable of conversing with the injection control unit and an

electronic key with a special transmitter for sending a recognition code.

Each time the key is turned to the OFF position, the Fiat CODE system completely deactivates the injecti

on control unit.

When the key is turned to the ON position the following operations take place, in order:

1. the injection control unit (whose memory contains a secret code) sends the Fiat CODE control unit a

request to send the secret code to deactivate the immobilizer functions;

2. the Fiat CODE control unit responds by only sending the secret code after, in turn, having received the

recognition code transmitted by the ignition key;

3. the recognition of the secret code allows the deactivation of the injection control unit immobilizer func

tion and its normal operation.

Autodiagnosis

The complete electronic fault diagnosis of the injection system is carried out by connecting the special

equipment (EXAMINER or EXAMINER PLUS) to the standardized diagnostic socket (EOBD).

The system is also equipped with a self-diagnostic function which recognizes, memorizes and signals any

faults.

If a fault is detected in the sensors or actuators, the recovery strategy is immediately activated in order to

ensure that the engine functions at an acceptable level. The vehicle can be driven to a service centre for

the appropriate repairs to be carried out.

Copyright by Fiat Auto 5