torque FIAT PANDA 2016 319 / 3.G Owners Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: PANDA, Model: FIAT PANDA 2016 319 / 3.GPages: 204, PDF Size: 18.77 MB

Page 63 of 204

ACTIVE SAFETY

SYSTEMS

ABS (Anti-lock Braking

System)

This system, which is an integral part of

the braking system, prevents one or

more wheels from locking and slipping

in all road surface conditions,

irrespective of the intensity of the

braking action, ensuring that the vehicle

can be controlled even during

emergency braking.

IMPORTANT To obtain the maximum

efficiency of the braking system, a

bedding-in period of about 500 km is

needed: during this period it is better to

avoid sharp, repeated and prolonged

braking.

The ABS also includes the following

systems: EBD (Electronic Braking Force

Distribution), MSR (Motor

Schleppmoment Regelung) and MBA

(Mechanical Brake Assist) (for

versions/markets, where provided).

System intervention

The driver can feel that the ABS system

has come into action because the

brake pedal pulsates slightly and the

system gets noisier: this is entirely

normal with the system operating.ESC SYSTEM (Electronic

Stability Control)

(for versions/markets, where provided)

This is an electronic system that

controls vehicle stability in the event of

tyre grip loss, helping maintain

directional control. The system is

capable of recognising potentially

dangerous situations in terms of the

stability and intervenes automatically on

the brakes in a differentiated manner

for the four wheels in order to provide a

stabilising torque.

The ESC system switches on

automatically when the engine is

started and cannot be switched off.

System intervention

The intervention of the system is

indicated by the flashing of theESC

warning light on the instrument panel,

to inform the driver that the vehicle is in

critical stability and grip conditions.

56) 57) 58) 59) 60) 61)

HH (Hill Holder) SYSTEM

This system is an integral part of the

ESC system and facilitates starting on

slopes.

It is automatically activated in the

following conditions:

❒uphill: vehicle stationary on a road

with a gradient higher than 5%, engine

running, brake pressed and

transmission in neutral or gear other

than reverse engaged;❒downhill: vehicle stationary on a road

with a gradient higher than 5%, engine

running, brake pressed and reverse

gear engaged.

When setting off, the ESC system

control unit maintains the braking

pressure on the wheels until the torque

necessary for starting is reached, or

in any case for a maximum of 2

seconds, allowing your right foot to be

moved easily from the brake pedal to

the accelerator.

When two seconds have elapsed,

without starting, the system is

automatically deactivated, gradually

releasing the braking pressure. During

this release stage, the typical

mechanical brake release noise can be

heard, indicating that the vehicle is

about to move.

NOTE: the Hill Holder system is not

active with parking brake engaged.

IMPORTANT The Hill Holder system is

not a parking brake, therefore do not

leave the vehicle without activating the

handbrake, switching off the engine,

and engaging first gear, with the vehicle

parked in safe conditions.

61

47) 48) 49) 50) 51) 52) 53) 54) 55)

Page 65 of 204

The activation of the ELD system

involves the following functions being

switched on:

❒inhibition of the ASR function, in

order to fully exploit the engine torque;

❒differential lock effect on the front and

rear axles, via the braking system, to

improve drive on uneven surfaces.

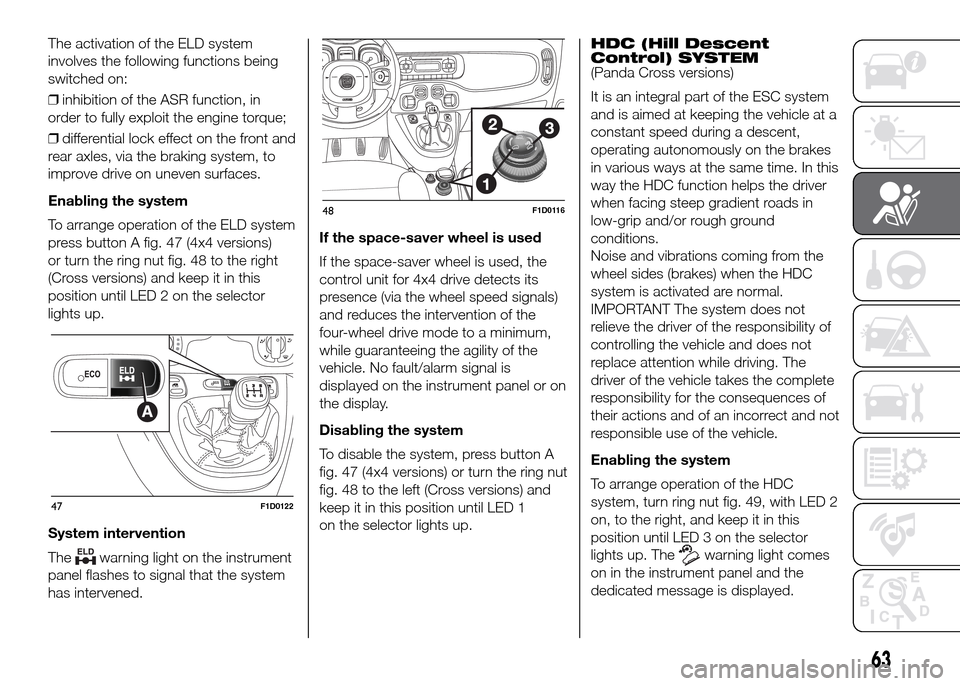

Enabling the system

To arrange operation of the ELD system

press button A fig. 47 (4x4 versions)

or turn the ring nut fig. 48 to the right

(Cross versions) and keep it in this

position until LED 2 on the selector

lights up.

System intervention

The

warning light on the instrument

panel flashes to signal that the system

has intervened.If the space-saver wheel is used

If the space-saver wheel is used, the

control unit for 4x4 drive detects its

presence (via the wheel speed signals)

and reduces the intervention of the

four-wheel drive mode to a minimum,

while guaranteeing the agility of the

vehicle. No fault/alarm signal is

displayed on the instrument panel or on

the display.

Disabling the system

To disable the system, press button A

fig. 47 (4x4 versions) or turn the ring nut

fig. 48 to the left (Cross versions) and

keep it in this position until LED 1

on the selector lights up.HDC (Hill Descent

Control) SYSTEM

(Panda Cross versions)

It is an integral part of the ESC system

and is aimed at keeping the vehicle at a

constant speed during a descent,

operating autonomously on the brakes

in various ways at the same time. In this

way the HDC function helps the driver

when facing steep gradient roads in

low-grip and/or rough ground

conditions.

Noise and vibrations coming from the

wheel sides (brakes) when the HDC

system is activated are normal.

IMPORTANT The system does not

relieve the driver of the responsibility of

controlling the vehicle and does not

replace attention while driving. The

driver of the vehicle takes the complete

responsibility for the consequences of

their actions and of an incorrect and not

responsible use of the vehicle.

Enabling the system

To arrange operation of the HDC

system, turn ring nut fig. 49, with LED 2

on, to the right, and keep it in this

position until LED 3 on the selector

lights up. Thewarning light comes

on in the instrument panel and the

dedicated message is displayed.

47F1D0122

48F1D0116

63

Page 97 of 204

The unstable positions, in other words

those that are abandoned as soon

as the lever is released, are the

positions for requesting a higher gear

(+), requesting a lower gear (–) and

requesting automatic operating mode

(A/M).

IMPORTANT With the engine started,

any error between the lever position

and the gear actually engaged is

signalled by a buzzer until consistency

is restored.

MANUAL MODE

Proceed as follows:

❒press the brake pedal and start the

engine;

❒if AUTO appears on the display,

move the lever A fig. 80 to A/M

to select MANUAL mode;

❒push gear lever A towards (+) to

engage first gear (if starting from N or

R, simply place the lever in the middle

position) or R to engage reverse;

❒release the brake pedal and press

the accelerator pedal;

❒in driving conditions, push lever A of

the gearbox towards (+) to engage

the next gear up or towards (–) to

engage the next gear down.AUTOMATIC MODE

Proceed as follows:

❒press the brake pedal;

❒start the engine;

❒if AUTO does not appear on the

display, move the gear lever A fig. 80 to

A/M to select AUTOMATIC mode;

❒push the gear lever towards (+) to

engage 1st gear (if starting from N or R,

simply place the lever in the middle

position) or R to engage reverse;

❒release the brake pedal and press

the accelerator pedal: the gear most

suited to the vehicle speed will be

engaged.

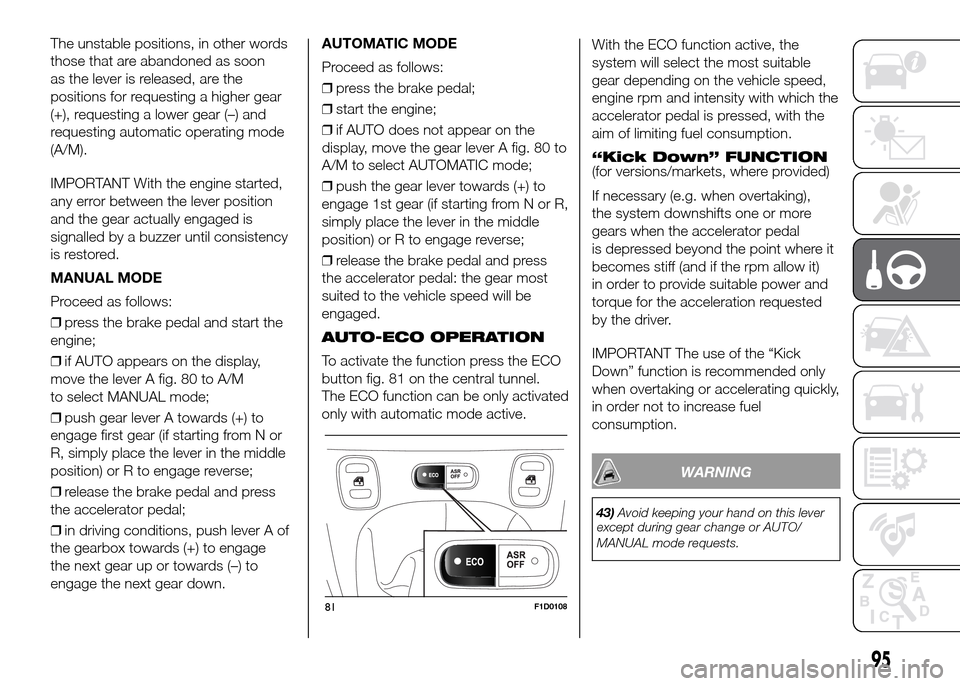

AUTO-ECO OPERATION

To activate the function press the ECO

button fig. 81 on the central tunnel.

The ECO function can be only activated

only with automatic mode active.

81F1D0108

95

With the ECO function active, the

system will select the most suitable

gear depending on the vehicle speed,

engine rpm and intensity with which the

accelerator pedal is pressed, with the

aim of limiting fuel consumption.

“Kick Down” FUNCTION

(for versions/markets, where provided)

If necessary (e.g. when overtaking),

the system downshifts one or more

gears when the accelerator pedal

is depressed beyond the point where it

becomes stiff (and if the rpm allow it)

in order to provide suitable power and

torque for the acceleration requested

by the driver.

IMPORTANT The use of the “Kick

Down” function is recommended only

when overtaking or accelerating quickly,

in order not to increase fuel

consumption.

WARNING

43)Avoid keeping your hand on this lever

except during gear change or AUTO/

MANUAL mode requests.

Page 127 of 204

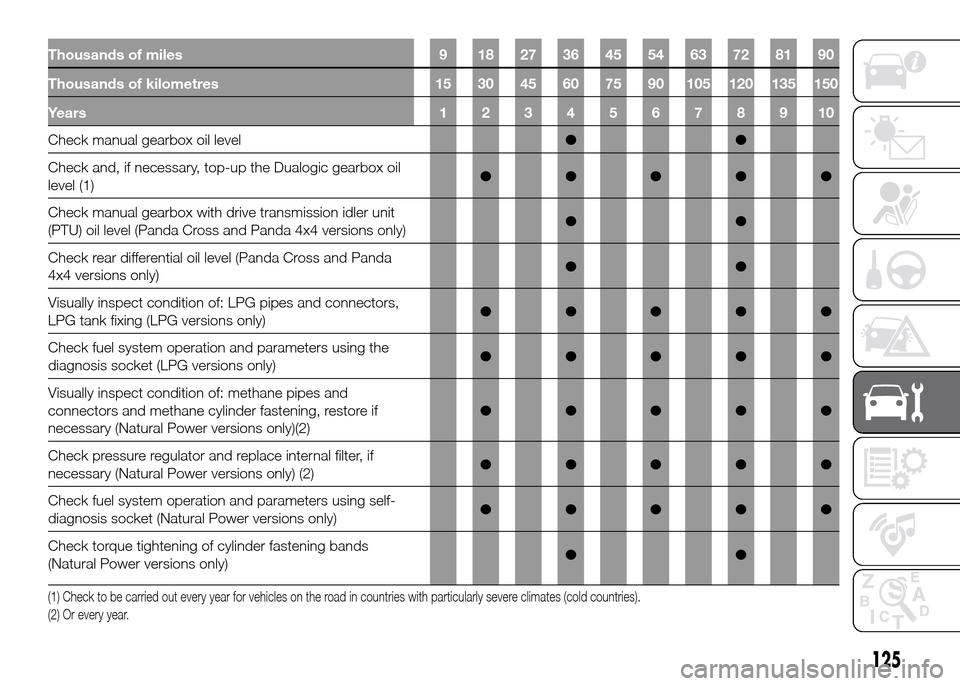

Thousands of miles 9 18 27 36 45 54 63 72 81 90

Thousands of kilometres 15 30 45 60 75 90 105 120 135 150

Years12345678910

Check manual gearbox oil level●●

Check and, if necessary, top-up the Dualogic gearbox oil

level (1)●●●●●

Check manual gearbox with drive transmission idler unit

(PTU) oil level (Panda Cross and Panda 4x4 versions only)●●

Check rear differential oil level (Panda Cross and Panda

4x4 versions only)●●

Visually inspect condition of: LPG pipes and connectors,

LPG tank fixing (LPG versions only)●●●●●

Check fuel system operation and parameters using the

diagnosis socket (LPG versions only)●●●●●

Visually inspect condition of: methane pipes and

connectors and methane cylinder fastening, restore if

necessary (Natural Power versions only)(2)●●●●●

Check pressure regulator and replace internal filter, if

necessary (Natural Power versions only) (2)●●●●●

Check fuel system operation and parameters using self-

diagnosis socket (Natural Power versions only)●●●●●

Check torque tightening of cylinder fastening bands

(Natural Power versions only)●●

(1) Check to be carried out every year for vehicles on the road in countries with particularly severe climates (cold countries).

(2) Or every year.

125

Page 145 of 204

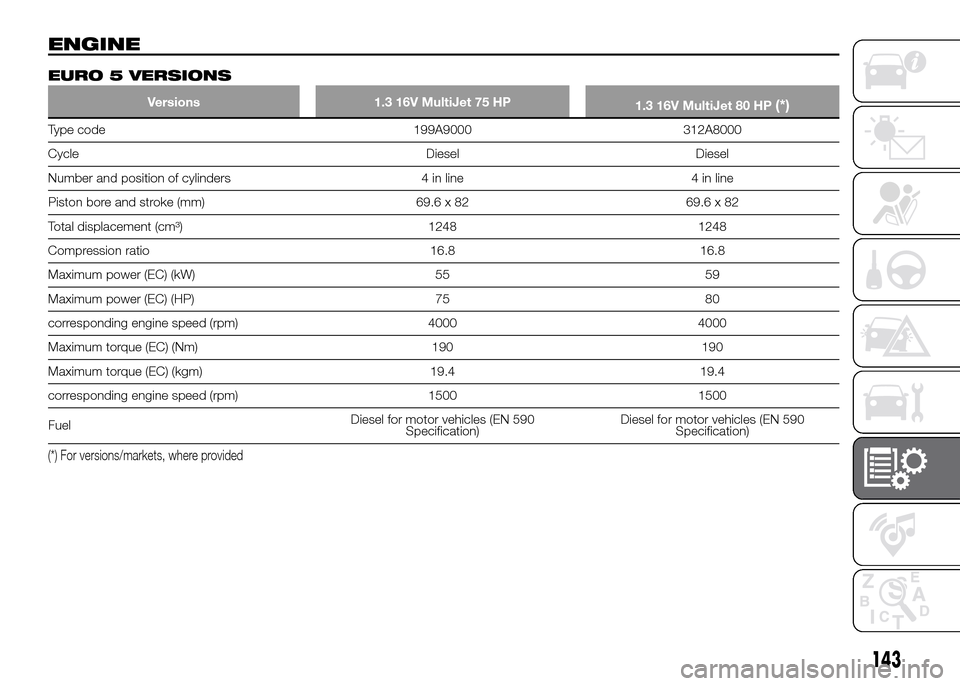

ENGINE

EURO 5 VERSIONS

Versions 1.3 16V MultiJet 75 HP

1.3 16V MultiJet 80 HP(*)

Type code 199A9000 312A8000

Cycle Diesel Diesel

Number and position of cylinders 4 in line 4 in line

Piston bore and stroke (mm) 69.6 x 82 69.6 x 82

Total displacement (cm³) 1248 1248

Compression ratio 16.8 16.8

Maximum power (EC) (kW) 55 59

Maximum power (EC) (HP) 75 80

corresponding engine speed (rpm) 4000 4000

Maximum torque (EC) (Nm) 190 190

Maximum torque (EC) (kgm) 19.4 19.4

corresponding engine speed (rpm) 1500 1500

FuelDiesel for motor vehicles (EN 590

Specification)Diesel for motor vehicles (EN 590

Specification)

(*) For versions/markets, where provided

143

Page 146 of 204

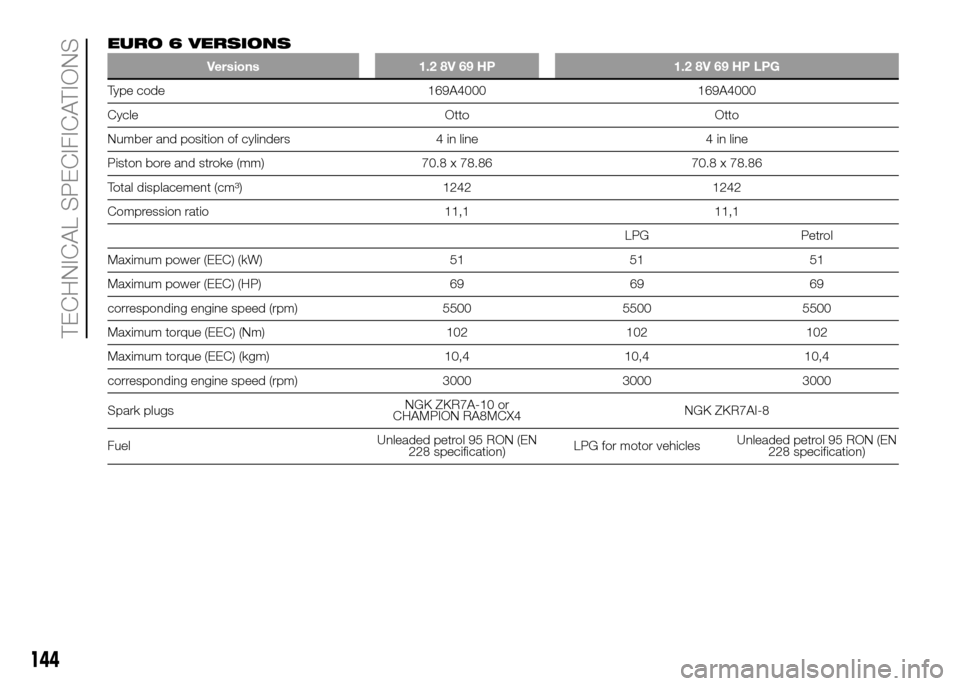

EURO 6 VERSIONS

Versions 1.2 8V 69 HP 1.2 8V 69 HP LPG

Type code 169A4000 169A4000

Cycle Otto Otto

Number and position of cylinders 4 in line 4 in line

Piston bore and stroke (mm) 70.8 x 78.86 70.8 x 78.86

Total displacement (cm³) 1242 1242

Compression ratio 11,1 11,1

LPG Petrol

Maximum power (EEC) (kW) 51 51 51

Maximum power (EEC) (HP) 69 69 69

corresponding engine speed (rpm) 5500 5500 5500

Maximum torque (EEC) (Nm) 102 102 102

Maximum torque (EEC) (kgm) 10,4 10,4 10,4

corresponding engine speed (rpm) 3000 3000 3000

Spark plugsNGK ZKR7A-10 or

CHAMPION RA8MCX4NGK ZKR7AI-8

FuelUnleaded petrol 95 RON (EN

228 specification)LPG for motor vehiclesUnleaded petrol 95 RON (EN

228 specification)

144

TECHNICAL SPECIFICATIONS

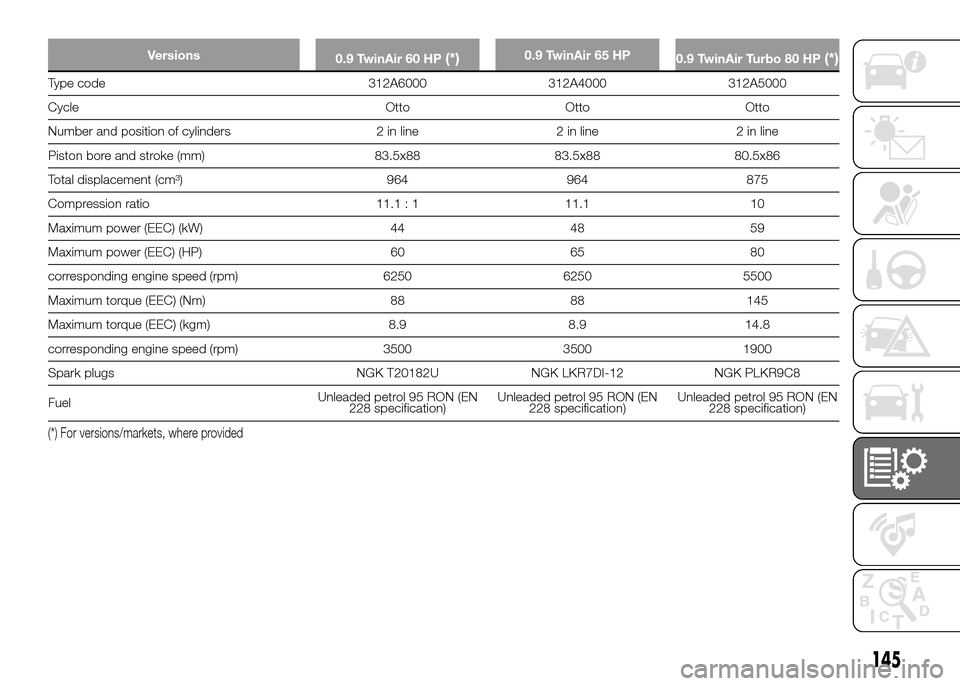

Page 147 of 204

Versions

0.9 TwinAir 60 HP(*)0.9 TwinAir 65 HP

0.9 TwinAir Turbo 80 HP(*)

Type code 312A6000 312A4000 312A5000

Cycle Otto Otto Otto

Number and position of cylinders 2 in line 2 in line 2 in line

Piston bore and stroke (mm) 83.5x88 83.5x88 80.5x86

Total displacement (cm³) 964 964 875

Compression ratio 11.1 : 1 11.1 10

Maximum power (EEC) (kW) 44 48 59

Maximum power (EEC) (HP) 60 65 80

corresponding engine speed (rpm) 6250 6250 5500

Maximum torque (EEC) (Nm) 88 88 145

Maximum torque (EEC) (kgm) 8.9 8.9 14.8

corresponding engine speed (rpm) 3500 3500 1900

Spark plugs NGK T20182U NGK LKR7DI-12 NGK PLKR9C8

FuelUnleaded petrol 95 RON (EN

228 specification)Unleaded petrol 95 RON (EN

228 specification)Unleaded petrol 95 RON (EN

228 specification)

(*) For versions/markets, where provided

145

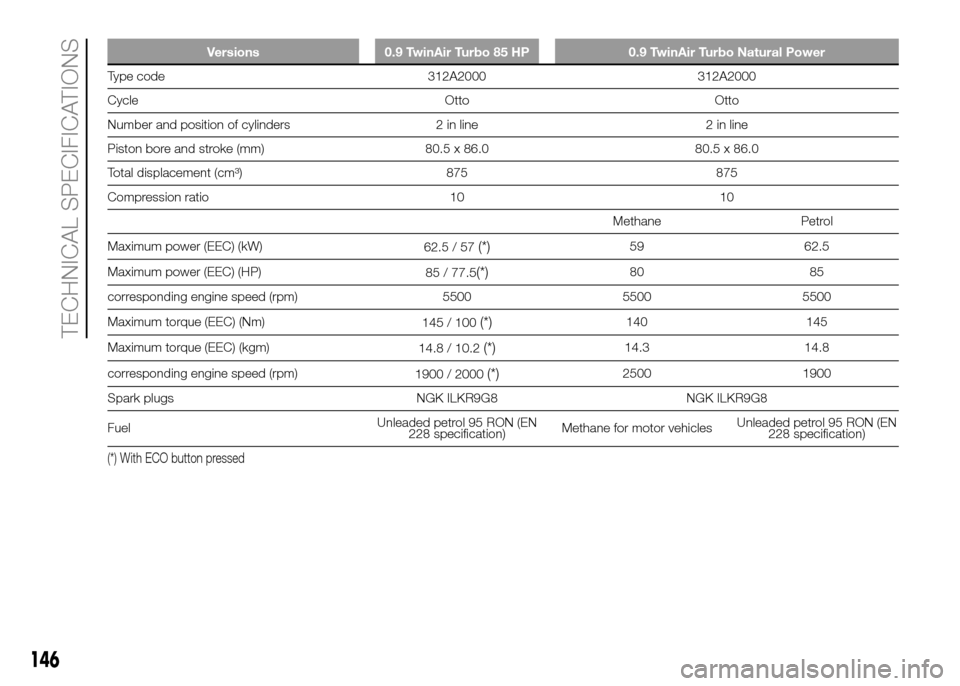

Page 148 of 204

Versions 0.9 TwinAir Turbo 85 HP 0.9 TwinAir Turbo Natural Power

Type code 312A2000 312A2000

Cycle Otto Otto

Number and position of cylinders 2 in line 2 in line

Piston bore and stroke (mm) 80.5 x 86.0 80.5 x 86.0

Total displacement (cm³) 875 875

Compression ratio 10 10

Methane Petrol

Maximum power (EEC) (kW)

62.5 / 57

(*)59 62.5

Maximum power (EEC) (HP)

85 / 77.5

(*)80 85

corresponding engine speed (rpm) 5500 5500 5500

Maximum torque (EEC) (Nm)

145 / 100

(*)140 145

Maximum torque (EEC) (kgm)

14.8 / 10.2

(*)14.3 14.8

corresponding engine speed (rpm)

1900 / 2000

(*)2500 1900

Spark plugs NGK ILKR9G8 NGK ILKR9G8

FuelUnleaded petrol 95 RON (EN

228 specification)Methane for motor vehiclesUnleaded petrol 95 RON (EN

228 specification)

(*) With ECO button pressed

146

TECHNICAL SPECIFICATIONS

Page 149 of 204

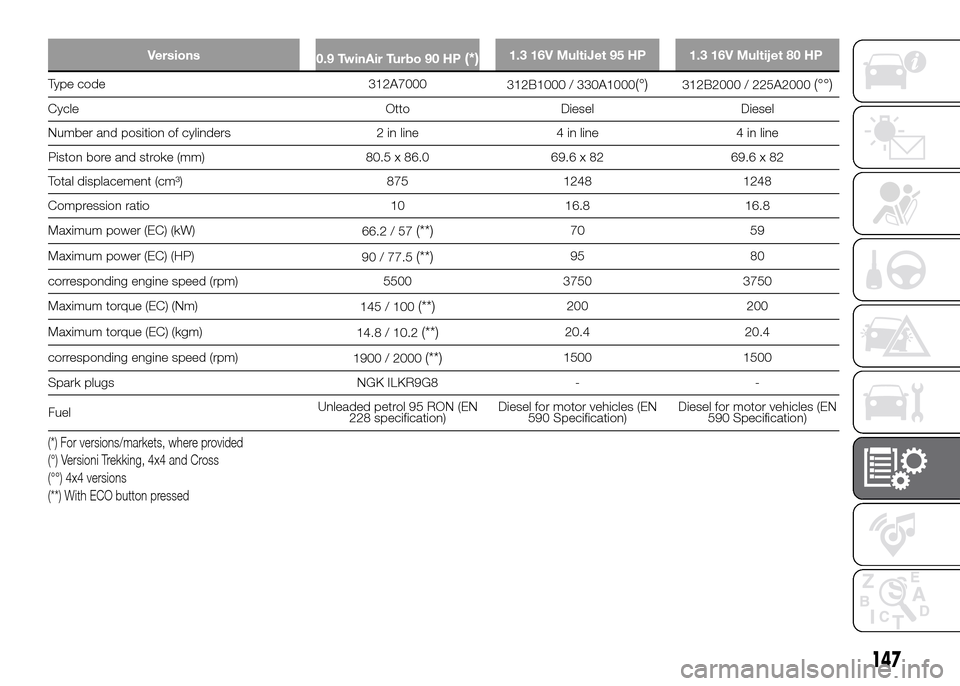

Versions

0.9 TwinAir Turbo 90 HP(*)1.3 16V MultiJet 95 HP 1.3 16V Multijet 80 HP

Type code 312A7000

312B1000 / 330A1000(°)312B2000 / 225A2000(°°)

Cycle Otto Diesel Diesel

Number and position of cylinders 2 in line 4 in line 4 in line

Piston bore and stroke (mm) 80.5 x 86.0 69.6 x 82 69.6 x 82

Total displacement (cm³) 875 1248 1248

Compression ratio 10 16.8 16.8

Maximum power (EC) (kW)

66.2 / 57

(**)70 59

Maximum power (EC) (HP)

90 / 77.5

(**)95 80

corresponding engine speed (rpm) 5500 3750 3750

Maximum torque (EC) (Nm)

145 / 100

(**)200 200

Maximum torque (EC) (kgm)

14.8 / 10.2

(**)20.4 20.4

corresponding engine speed (rpm)

1900 / 2000

(**)1500 1500

Spark plugs NGK ILKR9G8 - -

FuelUnleaded petrol 95 RON (EN

228 specification)Diesel for motor vehicles (EN

590 Specification)Diesel for motor vehicles (EN

590 Specification)

(*) For versions/markets, where provided

(°) Versioni Trekking, 4x4 and Cross

(°°) 4x4 versions

(**) With ECO button pressed

147