Seat FIAT PUNTO 1995 176 / 1.G User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1995, Model line: PUNTO, Model: FIAT PUNTO 1995 176 / 1.GPages: 225, PDF Size: 18.54 MB

Page 73 of 225

2C«1

Chapter 2 PartC:

Diesel engine in-car repair procedures

Contents

Auxiliary drivebelts - removal and refitting See Chapter 1B Camshaft cover - removal and refitting 6 Camshaft oil seal - renewal 7 Camshaft - removal and refitting See Chapter 20 Crankshaft oil seats - renewal 8 Cylinder compression test « 3 Cylinder head - dismantling and overhaul See Chapter 20 Cylinder head - removal and refitting 9 Engine mountings - inspection and renewal 11 Engine oil and fitter - renewal See Chapter 18 Engine oil level check See Weekly checks

Degrees of difficulty

Flywheel * removal, inspection and refitting 10 General information 1 Location of TDC on No 1 cylinder 2 Oil cooler - removal and refitting 14 Oil pump and pick-up tube • removal, Inspection and refitting 13 Sump • removal and refitting 12 Timing belt and covers • removal and refitting 4 Timing belt tensioner and sprockets - removal, Inspection and refitting 5 Valve clearance check and adjustment See Chapter 1B

Easy,

suitable for novice

with Irttle

|| experience g^

FaMy

eesy,

suitable ^

forbeglnnerwilti

some experience ^

Falrtydfficult, ^ suitable

for

competent DIYmechanic ^

Difficult, suitable

for & experienced DIY mechanic ^

Very

difficult,

^ suitable

for

expert

DfY

jR or professional ^

Specifications

General Engine code:' 1698 cc non-turbo engine 176.B3.000 1698 cc turbo engine: Up to 1997 t76.A3.00aor176.A5.000 1997 onward 176.A3.000or176.B7.000 •Note: See Vehicle Identification for the location of the code marking on the engine. Bore 82.6 mm Stroke 79.2 mm Compression ratio: Non-turbo engine 20.5:1 Turbo engine 19:1 Firing order 1-3-4-2

No 1

cylinder location Timing belt end of engine Titling belt tension See text

Lubrication system Oi pump type By-rotor driven from front of crankshaft Outer rotor-to-houslng clearance 0.080 to 0.186 mm Axial clearance 0.025 to 0.056 mm

Torque wrench settings Nm ibf ft Camshaft cover 10 7 Camshaft sprocket 11B 87 Crankshaft sprocket centre bolt 190 140 Cylinder head: Stage 1 50 37 Stage 2 100 74 StageS Angle-tighten a furtfier 90" Stage 4 Angle-tighten a further 90° CySnder head front bolts 30 22 Flywheel 142 105

Fuel

injection pump sprocket 49 36 Inlet and exhaust manifolds 25 18 Sump 10 7 Timing belt tensioner and idler 44 32

Page 76 of 225

2C*2 Diesel engine in-car repair procedures

4.4a Unbolt the engine oil dipstick tube...

3 Cylinder compression test

Note: A compression tester specifically designed for diesef engines must be used for this test. 1 When engine performance Is down, or if misfiring occurs, a compression test can provide diagnostic clues as to the engine's condition, If the lest is performed regularly, it can give warning of trouble before any other symptoms become apparent. 2 A compression tester specifically Intended for diesel engines must be used, because of the higher pressures involved. The Ie6ter is connected to an adapler which screws Into the glow plug or injector hole. It is unlikely to be worthwhile buying such a tester for occasional use. but it may be possible to borrow or hire one • if not. have the test performed by a garage. 3 Unless specific instructions to the contrary are supplied with the tester, observe the following points: 9) The battery must bo in a good state of charge, the air titter must be clean, end the engine should be at normal operating temperature. b) AH the in/actors or glow plugs should be removed before starting the lest. If removing the injectors, also remove the flame shield washers, otherwise they may be blown out. c) The stop solenoid must be disconnected.

4.4b ... and remove it from the rubber grommet in the oil pump housing

fo prevent the engine from running or fuel from being discharged. 4 There is no need to hold the accelerator pedal down during the test, because the diesel engine air inlet is not throttled. 5 The cause of poor compression Is less easy to establish on a diesel engine than on a petrol one. The effect of introducing oil into the cylinders (wet testing) Is not conclusive, because there is a risk that the oil will sit in the recess on the piston crown, instead of passing to the rings. However the following can be used as a rough guide to diagnosis. 6 All cylinders should produce very similar pressures; a difference of more than 5 bars between any two cylinders Indicates the existence of a fault. Note that the compression should build up quickly In a healthy engine; low compression on the first stroke, followed by gradually-increasing pressure on successive strokes, indicates worn piston rings. A low compression reading on the first stroke, which does not build up during successive strokes, indicates leaking valves or a blown head gasket (a cracked hoad could also be the cause). 7 A low reading from two adjacent cylinders Is almost certainly due to the head gasket having blown between them: the presence of coolant In the engine oil will confirm this,

Leakdown test 8 A leakdown test measures the rate at which compressed air fed into the cylinder Is lost. It is an alternative to a compression test, and in many ways it is better, since the escaping air provides easy identification of where pressure loss is occurring (piston rings, valves or head gasket). 9 The equipment needed for leakdown testing is unlikely to be available to the home mechanic. If poor compression Is suspected, have the test performed by a suitably-equipped garage.

4 Timing belt and covers -removal

and

refitting

Note: Fiat specify the use of a spec/a/ timing belt tension measuring tool to correctly set the timing belt tension. If access to this equipment cannot be obtained, an approximate setting can be achieved using the method described below. If the method described is used, the tension must be checked using the special tool at the earliest possible opportunity. Do not drive the vehicle over large distances, or use high engine speeds, until the belt fens/on rs known to be correct. Refer to a Fiat dealer for advice.

General Information 1 The function of the timing belt is to drive the camshaft and fuel injection pump. Should the belt slip or break in service, the valve timing will be disturbed and piston-to-valve contact

will occur, resulting In serious engine damage. 2 The timing bolt should be renewed at the specified intervals (see Chapter 1B), or earlier If It is contaminated with oil. or If It is at al noisy In operation (a scraping noise due to uneven wear),

Removal 3 Set the engine at TDC on No 1 cylinder

as

described in Section 2. 4 Unbolt and remove tho engine oil dipstick tube and remove It from the rubber gromme! in the oil pump housing (see illustrations), 5 Before removing the timing belt check rts tension by turning the belt through 90" with finger and thumb midway between u* injection pump and camshaft sprockets. This will give you an Idea of the tension to apply when refitting, assuming the tension is already correct. Also note the position of the tensions pulley as a reference mark. 6 Release tho nut on the timing bea tensioner, move the tensioner pulley away from the belt and retlghten the nut to hold the pulley in the retracted position. 7 If the timing belt is to be re-used, use white paint or chalk to mark the direction of rotation on the belt (if markings do not already exist), then slip the belt off the camshaft, crankshaft and injection pump sprockets, and the idler and tensioner pulleys. Caution: If the belt appears to be In good condition and can be re-used, it fs essential that It Is refitted the same

wsy

round, otherwise accelerated wear will result, leading fo premature failure. 8 Check the timing belt carefully for any signs of uneven wear, splitting, or oil contamination. Pay particular attention to the roots of the teeth. Renew it if there is the slightest doutt about its condition. If the engine is undergoing an overhaul, renew the belt as a matter of course, regardless of its apparent conditio*. The cost of a new belt Is nothing compa/ed with the cost of repairs, should the belt freak in service. If signs of oil contamination art found, trace the source of the oil leak and rectify It. Wash down the engine timing baft area and all related components, to remove

sd

traces of oil.

Refitting 9 Before refitting, thoroughly clean the tknmg belt sprockets. Check that the tensioner and idler pulleys rotate freely, without any sign ol roughness. If necessary, renew them as described in Section 5. 10 Ensure that the crankshaft, camshaft and injection pump sprockets are still at their TDC positions as described In Section 2. 11 Engage the timing belt with the crankshaft sprocket, then locate it around the idler pufiey and onto the Injection pump sprocket making sure that it is kept taught. Continue to locate! around the camshaft sprocket and finally around Ihe tensioner pulley (see Illustration) Ensure the belt teeth seat correctly on Ihe sprockets.

Page 80 of 225

2C*2 Diesel engine in-car repair procedures

Refitting 6 Locate a new gasket on the cylinder head and make sure tt Is correctly seated. 7 Lower the cover onto the gasket making sure the gasket Is not displaced, 8 Insert the mounting bolts and tighten them securely In a progressive sequence. Position Ihe support brackets as noted during removal. 9 Clip ihe coolant hoses in position then refil the air ducting.

7 Camshaft oil seal -renewal

8 Crankshaft oil seals -renswal I

9 Cylinder head -

removal

and refitting

1 Remove the timing belt and camshaft sprocket as descnbed in Sections 4 and 5. 2 Using a suitable hooked instrument, remove tho oil seal from the cylinder head taking care nol to damage the surface of the camshafl. Alternatively drill a small hole In tho oil seal and Insert a self-topping screw - the seal can then be removed by pulling on the screw with a pair of pliers. 3 Clean the seating In the cylinder head and tho end of the camshaft To prevent damage to the new oil seal as It is being fitted, wrap some adhesive tape around the end ol the camshaft and lightJy oil it. 4 Dip tho new ail s«al In oil then locate it over Ihe camshaft making sure that the sealing lips are facing inwards. 5 Using a suitable tubular drift, drive the oil seal squarely into the cylinder h*ad. Remove the adhesive tap© 6 Refit the camshaft sprocket and timing belt with reference to Sections 6 and 4.

Front (right-hand side) oil seal t The front oil seal is located in the oil pump casing on the front of the crankshaft. Remove the timing belt as described in Section 4 and the crankshaft sprocket as described in Section 5, 2 Using a suitable hooked instrument, remove the oil seal from the oil pump casing taking care not to damage the surface of the crankshaft. Alternatively drill a small hole In the oil soal and insert a self-tapping screw - the seal can then be removed by pulling on the screw with a pair of pliers. 3 Clean the seating in the oH pump and the surface of the crankshaft. To prevent damage to the new off seal as It Is being fitted, wrap some adhesive tape around the end of tha crankshaft and lightly oil it. 4 Oip the new oii seal In oil then otter it up to the oil pump casing making sure that the sealing Hps are facing inwards,

8.Ba Rear oil soal and housing

5 Using a suitable tubular drift, driva the oil sea! squarely into the casing. Remove the adhesive tape. 6 Refit the crankshaft sprocket and timing belt with reference to Sections 5 and 4.

Rear (left-hand side) oil seal Note: The following paragraphs describe renewal of the rear oil seal leaving the housing In position. The alternative mathod is to remove the housing and renew the oil seel on the bench, however there is then the possibility of damaging the sump gasket. Refer to Chapter 2D for details of removing the mar oil sea! housing. 7 Ramove the flywheel as described in Section 10. 8 Using a suitable hooked Instrument. remove 1he oil seat from the roar oil seal housing taking care not to damage Ihe surface of Ihe crankshaft. Alternatively dnll a small hole In the o» seal and insert a self-tapping screw - the seal can ihan be removed by pulling on the screw with a pair of pliers (see Illustrations), 9 Clean the seating in the housing and the surface of the crankshaft. Check the crankshaft for burrs which may damage the oil seal tip of tno new saal, and It necessary use a Una file to removothem. 10 Dip the new soal in clean engine oil and carefully tocato it over tho crankshafl rear Range making sure that

H

the correct way round. 11 Progressively tap the oH seal into the housing keepfng it square to prevent distortion. A block of wood is useful for this purpose. 12 Refit the flywheel with reference to Section 10.

I

5.8b Using a self-tapping screw and pliers to remove the rear oil seal

Removal Note: The cylinder head bolts are of special splined design and a Fiat tool should be obtained to unscrew them. A Torn key will

not

fit however In practise It was found that a close-fitting Allen key could bo used as an alternative. 1 Disconnect the battery negative terminal (refer to Disconnecting the battery in the Reference Section of this manual), 2 Remove tha battery as described In Chapter 5A. 3 Refer to Chapter IB and carry out the following: o) Drain the engine oil, b) Drain the cooling system. 4 Remove the timing belt as described in Section 4. 5 Unbolt and remova the relay guard and bracket from the left-hand side of the engine. 6 Unbolt and remove the battery mounting tray and disconnect the wiring and lines from the modulator valva and relays. 7 Remove the air eleanar assembly and air duct with reference lo Chapter 4C. 8 Loosen the clip and disconnect the vacuum hosa from the vacuum pump on the left-hand end of the cylinder head. 9 Loosen Ihe clips and disconnect the radiator top hose from the cylinder head outlet. Also disconnect the heater inlet hose from the thermostat housing, 10 Loosen the clips and disconnect the expansion tank and heater outlet hoses. 11 Identify all wiring connectors then disconnect them from the cylinder head, 12 Unscrew the expansion tank mounting screws, then disconnect tha expansion tank hoses at their connections to the engine. Remove the expansion tank from tha engine compartment. 13 Release tha clip and disconnect ihe crankcase breather from the left-hand rear of the cylinder head. 14 Unbolt the power steering pump uppar cover bracket then unscrew the pivot ana adjustment bolts while leaving ihe tMd lioses still attached. Release the drivebelt (if still In place) then tie the pump to the bulkhead. 15 Loosen tha clips and disconnect Ihe short coolant hose from the cylinder head outlet to the coolant pump (soe illustration). 18 At the rear of the engine, unbolt and disconnect the oil delivery pipe from the turbocharger (where applicable) and crankcase (see Illustrations). 17 Disconnect the return hose from tha thermostat housing to the coolant pump (see Illustration), 18 Unbolt the metal coolant return pipe and pull it out from the coolant pump inlet elbow (see Illustrations).

expert22 flna http://rutracker.org

Page 83 of 225

Diesel engine in-car repair procedures 2C*11

r

<3^

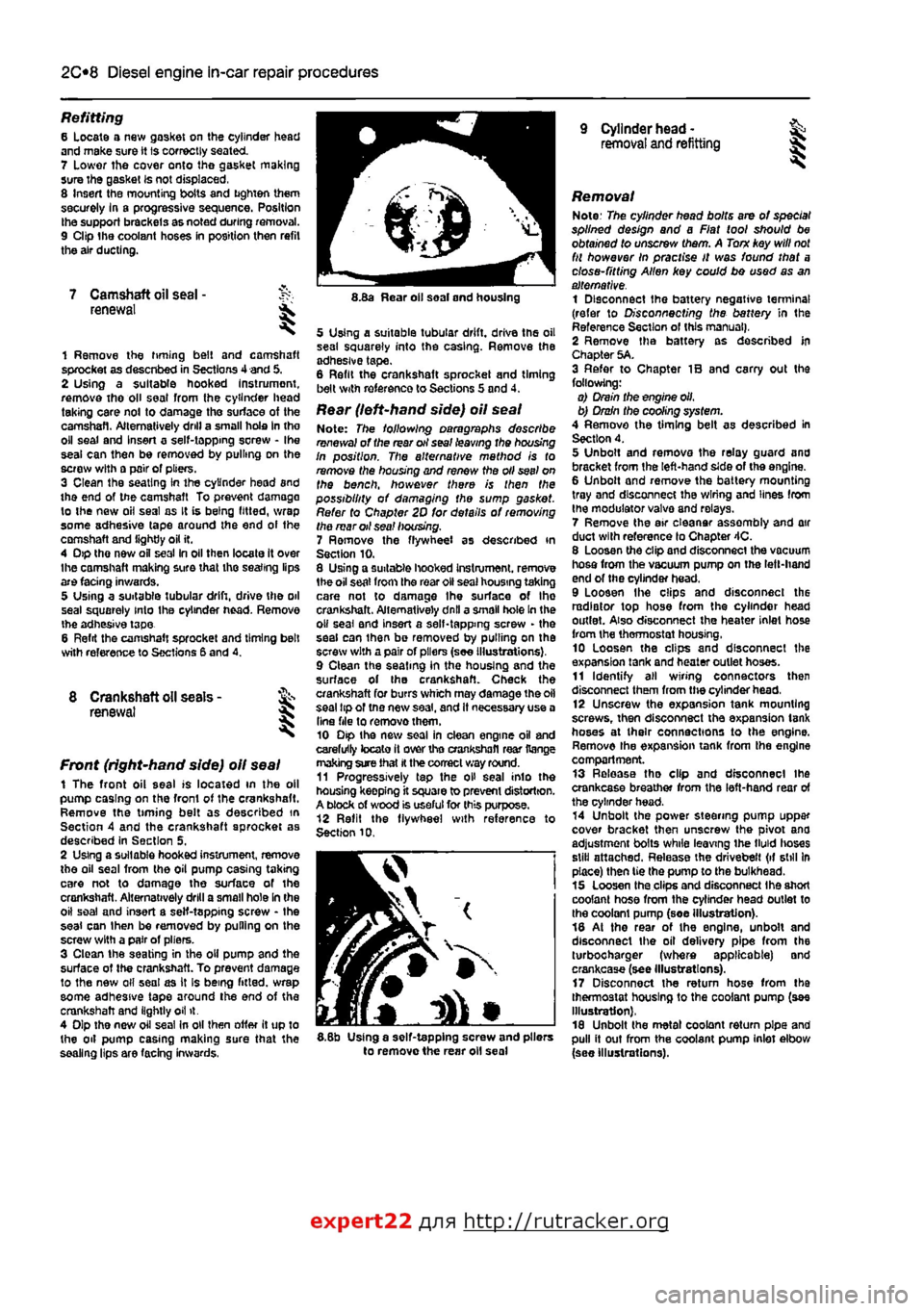

9.46a The locating dowel in the cylinder block 43 It is possible for the ptston crowns to stnke and damage the valve heads, if the camshaft is rotated v/ith the timing belt removed and the crankshaft set to TDC. For this reason, the crankshaft must be set to a position other than TDC on No t cylinder before the cylinder head is refitted. Use a socket on the crankshaft pulley centre bolt to turn the crankshaft in its normal direction of rotation, until all four pistons are positioned Halfway down their bores, v/ith No 1 piston on lis upstroke - approximately 90° before TDC.

Refitting 44 If the manifolds are being refitted before refitting the cylinder head proceed as follows, otherwise fit the manifolds later when the head is refitted. Ensure thai the inlet and exhaust manifold mating surfaces are completely clean, then locale the new gasket on the studs. 45 Locate the inlet and exhaust manifolds together with the turbocharger, where applicable, on the studs. Refit the nuts and washers and tighten to the specified torque.

sequence

f^/f

9.52b Tighten the cylinder head bolts to the Stage 1 and Stage 2 settings using a torque wrench

on the block 46 Lay the new head gasket on the cylinder block engaging it with the locating dowel. The word ALTO must be uppermost (see illustrations). 47 As a means of locating Ihe cylinder head accurately, cut the heads from two of the old cylinder head bolts. Cut a slot, big enough for a screwdriver blade, in the end of each bolt. These can be used as alignment dowels to assist in cylinder head refitting, however If the head is being refitted without the manifolds it is not necessary to take this action. 48 With the help of an assistant, place the cylinder head assembly centrally on the cylinder block ensuring thai the locating dowels engage with Ihe holes in the cylinder head. Check that the head gasket Is correctly seatod before allowing the full weight of the cylinder head to rest on it. 49 Where necessary, unscrew the home-made alignment dowels, using a flat bladed screwdriver. 50 The oyllnder head bolt threads must be clean. Dip the bolts in engine oil. and allow them to drain for thirty minutes. 51 Carefully enter each bolt with washer into its relevant hole (do not drop them in) and screw in, by hand only, until finger-tight. 52 Working progressively and In the sequence shown, first tighten the cylinder head bolts to their Stage 1 torque setting, using a torque wrench and suitable socket (see illustrations). Go round again, in the sequence shown, and tighten the bolls to the Stage 2 torque setting. 53 Once all the bolts have been tightened to their Stage 2 setting, working again in the

bolts to the Stage 3 and Stage 4 settings

9.46c The word ALTO must be uppermost

given sequence, angle-tighten the bolts through the specified Stage 3 angle, using a socket and extension bar (see illustration). It Is recommended that an angle-measuring gauge is used during this stage of the tightening, to ensure accuracy. If a gauge is not available, use white paint to make alignment marks between the bolt head and cylinder head prior to tightening; the marks can then be used to check tho bolt has been rotated through the correct angle during tightening. Repeat for the Stage 4 setting. 54 Refit the cylinder head front retaining bolts and tighten lo the specified torque. 55 Refit the camshaft cover together with a new gasket and tighten the bolts progressively to the specified torque. 56 The remaining procedure is a reversal of the removal procedure noting the following points. a) Tighten all nut and bolts to the specified torque where given. b) When refitting the metal coolant pipe to the coolant pump, use a new O-ring (see illustration). cj Refit the timing belt with reference to Section 4. d) Use a new exhaust front pipe gasket. e) Refit the auxiliary dhvebeltfs) as described in Chapter 1B. f) Refer to Chapter 4C when refitting the

air

cleaner and air duct. g) Refill the cooling system and fill the engine with new oil with reference to Chapter 1B. 57 Refer to Chapter 20 when starting the engine for the first time.

9.56 Use a new O-ring on the coolant pipe before refitting it to the pump

Page 86 of 225

2014 Diesel engine in-car repair procedures

^ ^^ i > ; v. » •

•

.

r, ^

W

(fM

•

;

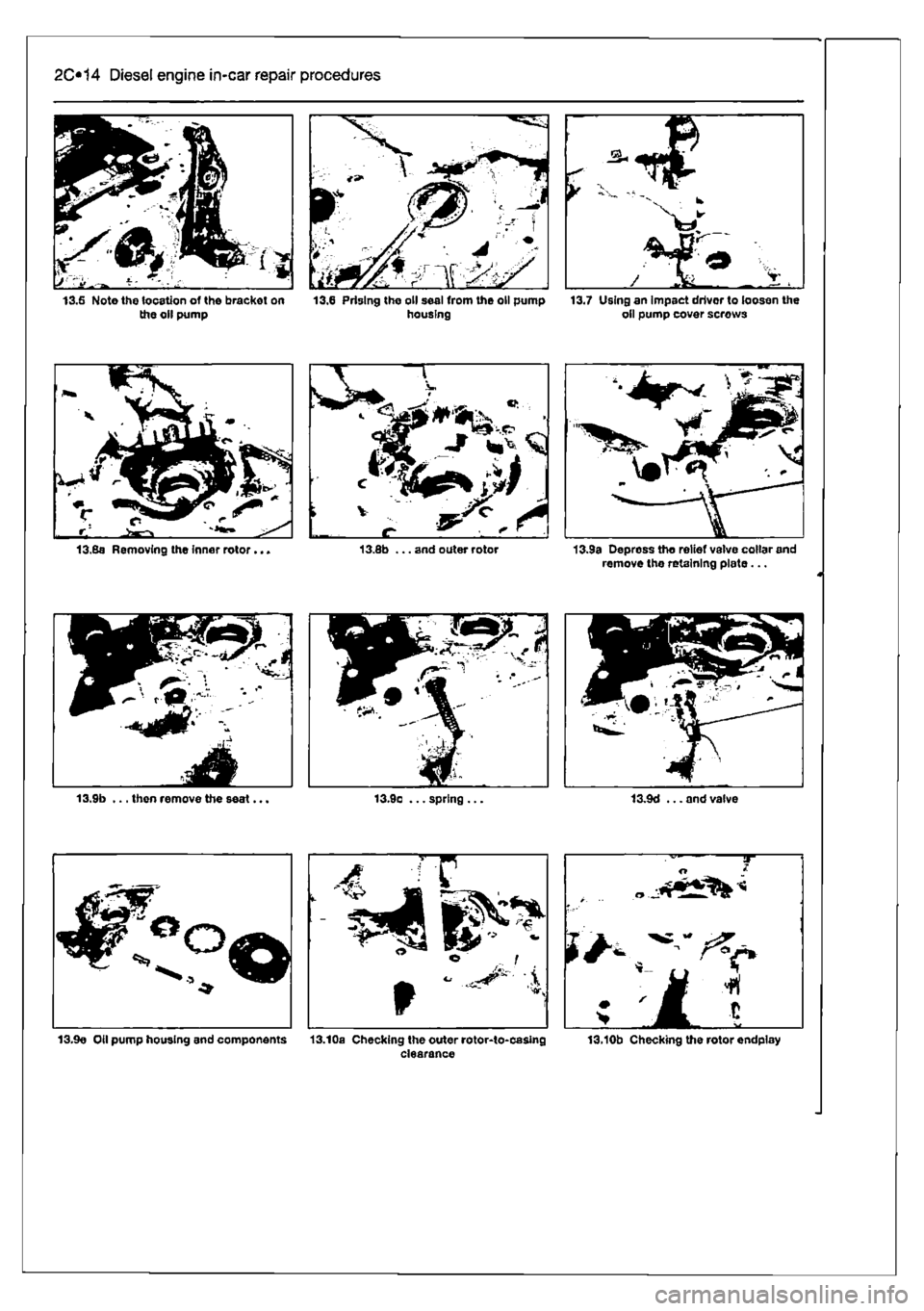

13.5 Note the location of the bracket on the oil pump 13.6 Prising the oil seal from the oil pump housing 13.7 Using an impact drivor to loosen the oil pump cover screws

'' r' -*•<- ^

- •

• J

; v _Vc >•

13.6a Removing the inner rotor... 13.8b ... and outer rotor 13.9a Depress tho relief valve collar and remove the retaining plate...

JB <0

1MU55U

13.9b ... then remove the seat... 13.9c ... spring ... 13.9d ... and valve

. ' IT

® f

9 ; I 1 13.9e Oil pump housing and components 13.10a Checking the outer rotor-to-casing clearance 13.10b Checking the rotor endplay

Page 87 of 225

Diesel engine in-car repair procedures 2C*11

X

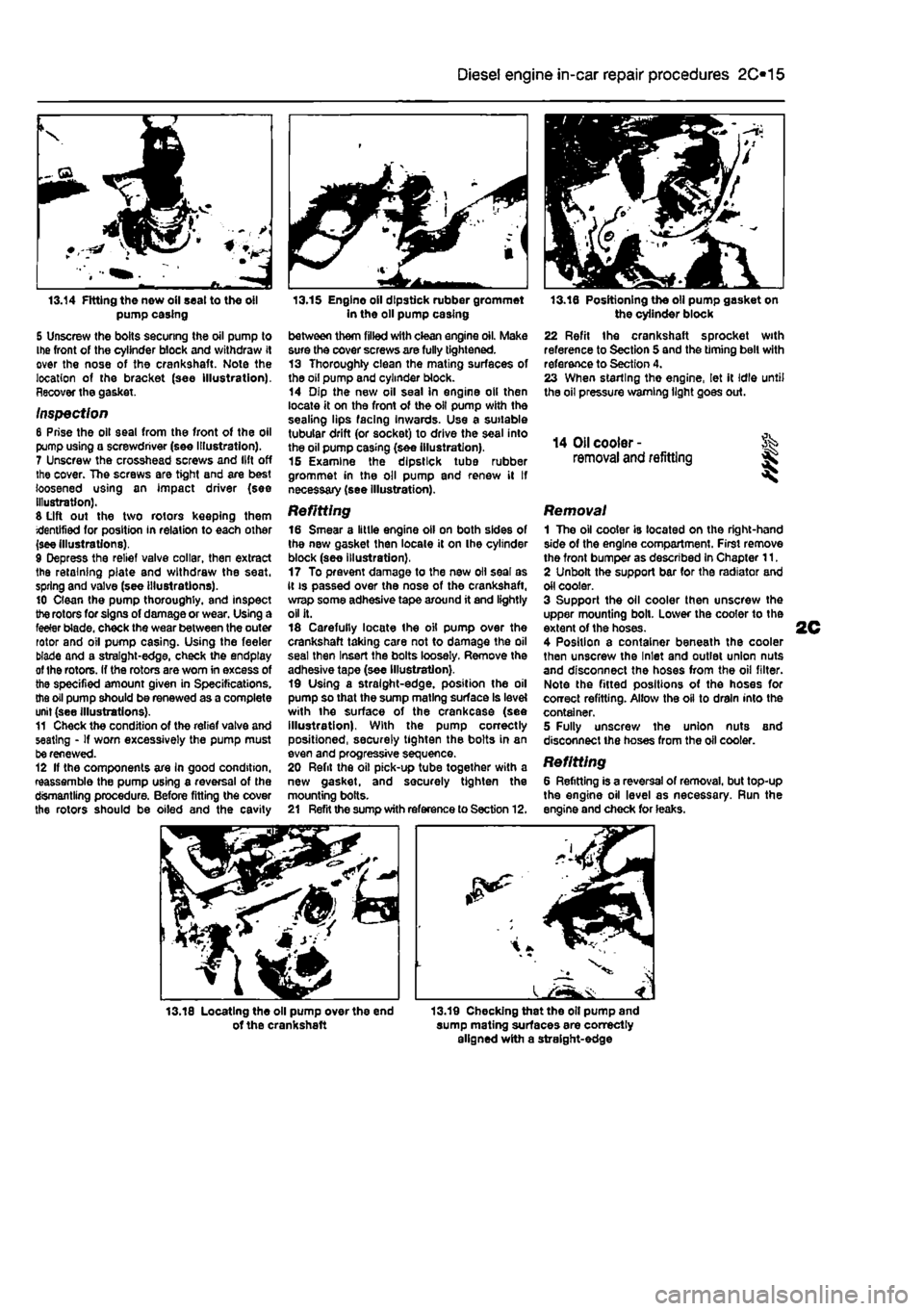

a 13.14 Fitting the new oil seal to the oil pump casing

S Unscrew the bolts securing the oil pump to Ihe front of the cylinder block and withdraw it over the nose of the crankshaft. Note the location of the bracket (see Illustration). Recover the gasket.

Inspection 8 Prise the oil seal from the front of the oil pump using a screwdriver (see Illustration). 7 Unscrew the crosshead screws and lift off the cover. The screws are tight and are best loosened using an impact driver (see illustration). S Lift out the two rotors keeping them identified for position in relation to each other (see illustrations). 9 Depress the relief valve collar, then extract the retaining plate and withdraw the seat, spring and valve (see illustrations). 10 Clean the pump thoroughly, and Inspect the rotors for signs of damage or wear. Using a feeler blade, check the wear between the outer rotor and oil pump casing. Using the feeler blade and a straight-edge, check the endptay of Ihe rotors. If the rotors are worn in excess of the specified amount given in Specifications, the oil pump should be renewed as a complete unit (see Illustrations). 11 Check the condition of the relief valve and seating - If worn excessively the pump must be renewed. 12 If the components are In good condition, reassemble the pump using a reversal of the dismantling procedure. Before fitting the cover the rotors should be oiled and the cavity

13.15 Engine oil dipstick rubber grommet in the oil pump casing between them filled with clean engine oil. Make sure the cover screws are fully tightened. 13 Thoroughly clean the mating surfaces of the oil pump and cylinder block. 14 Dip the new oil seal in engine oil then locate it on the front of the oil pump with the sealing lips facing Inwards. Use a suitable tubular drift (or socket) to drive the seal into the oil pump casing (see illustration). 16 Examine the dipstick tube rubber grommet in the oil pump and renew il If necessary (see illustration).

Refitting 16 Smear a little engine oil on both sides of the new gasket then locate it on the cylinder block (see illustration), 17 To prevent damage to the new oil seal as it is passed over the nose of the crankshaft, wrap some adhesive tape around it and lightly oil it. 18 Carefully locate the oil pump over the crankshaft taking care not to damage the oil seal then Insert the bolts loosely. Remove the adhesive tape (see Illustration). 19 Using a straight-edge, position the oil pump so that the sump mating surface Is level with the surface of the crankcase (see illustration). With the pump correctly positioned, securely tighten the bolts in an even and progressive sequence. 20 Refit the oil pick-up tube together with a new gasket, and securely tighten the mounting bolts. 21 Refit the sump with reference to Section 12.

13.16 Positioning the oil pump gasket on the cylinder block 22 Refit the crankshaft sprocket with reference to Section 5 and the timing belt with reference to Section 4. 23 When starling the engine, let it Idle until the oil pressure warning light goes out.

14 Oil cooler -removal and refitting I I

Removal 1 The oil cooler is located on the right-hand side of the engine compartment. First remove the front bumper as described In Chapter 11. 2 Unbolt the support bar for the radiator and oil cooler. 3 Support the oil cooler then unscrew the upper mounting boll. Lower the cooler to the extent of the hoses. 4 Position a container beneath the cooler then unscrew the Inlet and outlet union nuts and disconnect the hoses from the oil filter. Note the fitted positions of the hoses for correct refitting. Allow the oil to drain into the container. 5 Fully unscrew the union nuts and disconnect the hoses from the oil cooler.

Refitting 6 Refitting is a reversal of removal, but top-up the engine oil level as necessary. Run the engine and check for leaks.

13.18 Locating the oil pump over the end of the crankshaft 13.19 Checking that the oil pump and sump mating surfaces are correctly aligned with a straight-edge

Page 88 of 225

2D»1

Chapter 2 Part D:

Engine removal and overhaul procedures

Contents

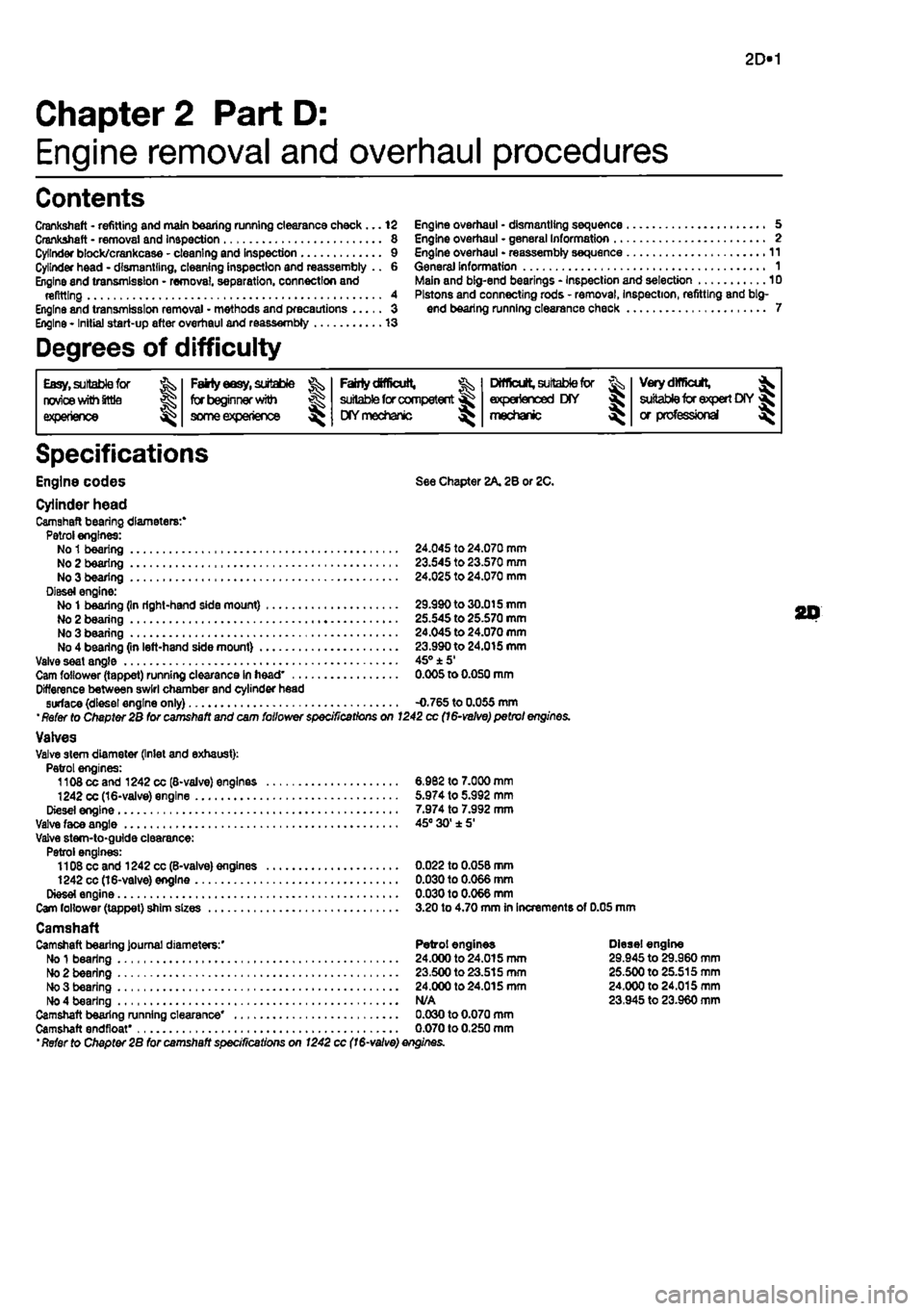

Crankshaft - refitting and main bearing running clearance check... 12 Engine overhaul • dismantling sequence 5 Crankshaft • removal and inspection 8 Engine overhaul • general Information .. Cylinder block/crankcase - cleaning and Inspection 9 Engine overhaul - reassembly sequence Cylinder head - dismantling, cleaning inspection and reassembly .. 6 General Information Engine and transmission - removal, separation, connection and refitting 4 Engine and transmission removal • methods and precautions 3 Engine * Initial start-up after overhaul and reassembly 13

Degrees of difficulty

Engine overhaul - general Information 2 11 1 Main and big-end bearings - Inspection and selection 10 Pistons and connecting rods - removal, inspection, refitting and big-end bearing running clearance check 7

Easy, suftable for FaHy easy, suitable ^ FaMy difficult, ^ Difficult, suitable for % Very difficult, ^ novice with littla | for beginner with suitable for competent ^ experienced DIY suitable for expert DIY « experience | some experience ^ HYmechanic mechanic or professional ^

Specifications

Engine codes See Chapter 2A. 2B or ZC.

Cylinder head Camshaft bearing diameters:* Petrol engines: No

1

bearing 24.045 to 24.070 mm No 2 bearing 23.S45 to 23.570 mm No 3 bearing 24.025 to 24.070 mm Diesel engine: No

1

bearing (In right-hand side mount) 29.990to30.015mm No 2 bearing 25.545 to 25.570 mm No 3 bearing 24.045 to 24.070 mm No 4 bearing (in left-hand side mount) 23.990 to 24.015 mm Valve seat angle 45° ±5' Cam follower (tappet) running clearance In head' 0.005 to 0.050 mm Difference between swirl chamber and cylinder head surface (diesel engine only) -0.765 to 0.055 mm '

Refer

to Chapter 2B for camshaft and cam follower specifications on 1242 cc

(16-velve)

petrol engines. Valves Valve stem diameter (Inlet and exhaust): Petrol engines: 1108 cc and 1242 cc (8-valve) engines 6.982 to 7.000 mm 1242

CC

(16-valve) engine 5.974 to 5.992 mm Diesel engine 7.974 to 7.992 mm Valve face angle 45° 30'±5' Valve stem-to-guide clearance: Petrol engines: 1108 cc and 1242 cc(B-valve) engines 0.022 to 0.05B mm 1242 cc (16-valve) engine 0.030 to 0.066 mm Diesel engine 0.030 to 0.066 mm Cam follower (tappet) sJiim sizes 3.20 to 4.70 mm In Increments of 0.05 mm Camshaft Camshaft bearing Journal diameters:' Petrol engines Diesel engine No

1

bearing 24.000 to 24.015 mm 29.945 to 29.960 mm No 2 bearing 23.500 to 23.515 mm 25.500 to 25.515 mm No 3 bearing 24.000 to 24.015 mm 24.000 to 24.015 mm No 4 bearing N/A 23.945 to 23.960 mm Camshaft bearing running clearance* 0.030 to 0.070 mm Camshaft endfloat* 0.070 to 0.250 mm 'Refer to Chapter 2B for camshaft specifications on 1242 cc

(16-valve)

enginss.

20

Page 101 of 225

2D*10 Engine removal and overhaul procedures

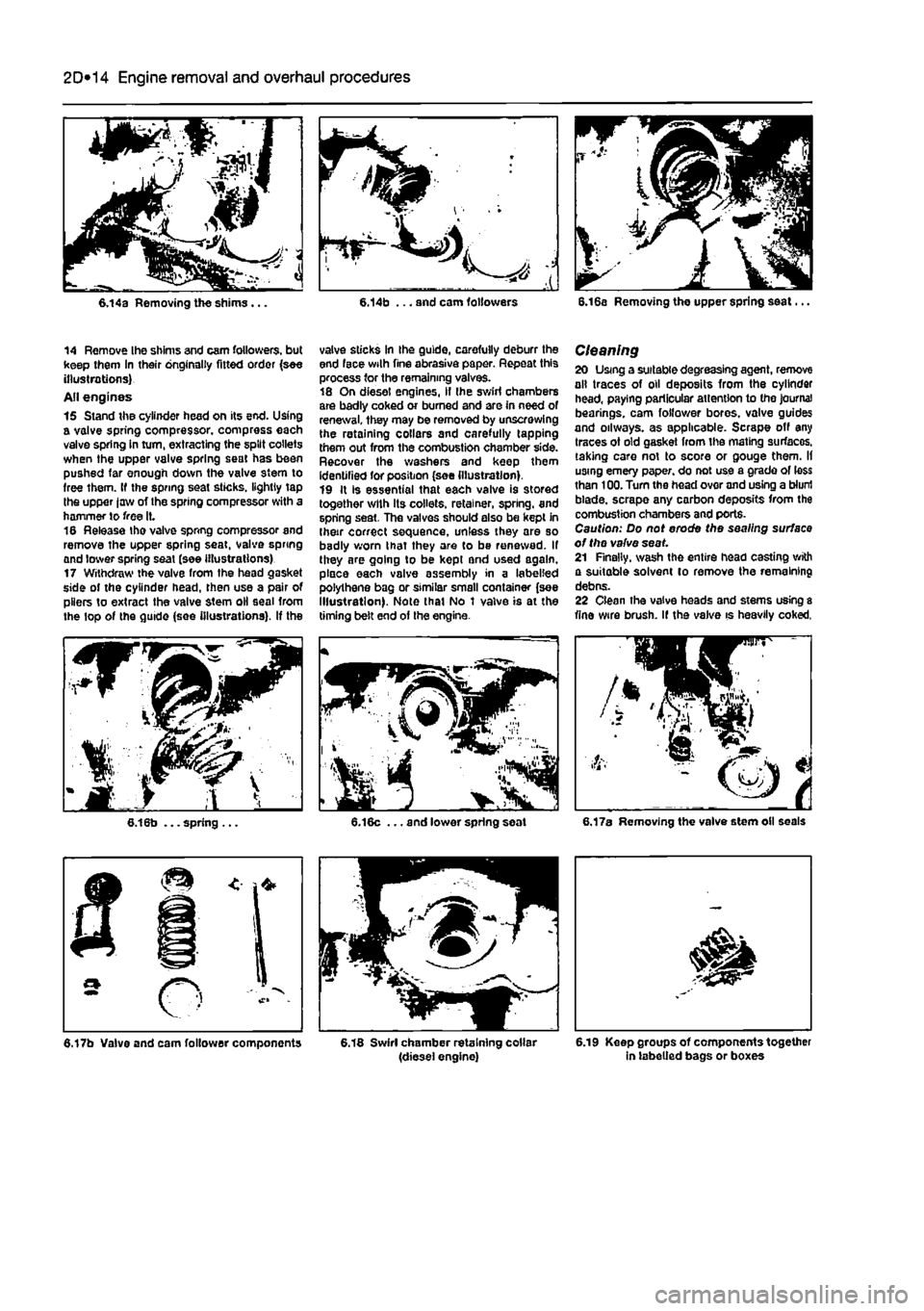

6,14a Removing the shims... 6.14b ... and cam followers 6.16a Removing the upper spring seat...

14 Remove Ihe shims and cam followers, but keep them In their onginally fitted order (see illustrations) All engines 15 Stand the cylinder head on its end. Using a valve spring compressor, compress each valve spring in turn, extracting the split collets when the upper valve spring seat has been pushed far enough down the valve stem to free them. If the spring seat sticks, lightly lap Ihe upper |aw of the spring compressor with a hammer to free It. 16 Release tho valve spnng compressor and remove the upper spring seat, valve spring and lower spring seat (see illustrations) 17 Withdraw the valve from the head gasket side of the cylinder head, then use a pair of pliers to extract the valve stem oil seal from the top of the guide (see illustrations). If the

valve slicks In the guide, carefully deburr the end face wilh fine abrasive paper. Repeat this process for the remaining valves. 18 On diesel engines, if Ihe swiri chambers are badly coked or burned and are in need of renewal, they may be removed by unscrewing the retaining collars and carefully tapping them out from the combustion chamber side. Recover the washers and keep them identified for position (see illustration). 19 It is essential that each valve is stored together with Its collets, retainer, spring, and spring seat. The valves should also be kept in (heir correct sequence, unless they are so badly worn that they are to be renewed. If they are going to be kepi and used again, place each valve assembly in a labelled polythene bag or similar small container (see Illustration). Note that No 1 valve is at the timing belt end of Ihe engine.

Cleaning 20 Using a suitable degreasing agent, remove all traces of oil deposits from the cylinder head, paying particular attention to tho journal bearings, cam follower bores, valve guides and oilways. as applicable. Scrape off any traces ot old gasket from the mating surfaces, taking care not to score or gouge them. If using emery paper, do not use a grade of (ess than 100. Turn the head over and using a blunt blade, scrape any carbon deposits from the combustion chambers and ports. Caution: Do not erode the seeling surface of tho valve seat. 21 Finally, wash the entire head casting with a suitable solvent to remove the remaining debns. 22 Clean the valve heads and stems using 8 fine wire brush. If the valve is heavily coked,

5.18 Swirl chamber retaining collar (diesel engine) 6.19 Keep groups of components together in labelled bags or boxes

Page 102 of 225

2D*10 Engine removal and overhaul procedures

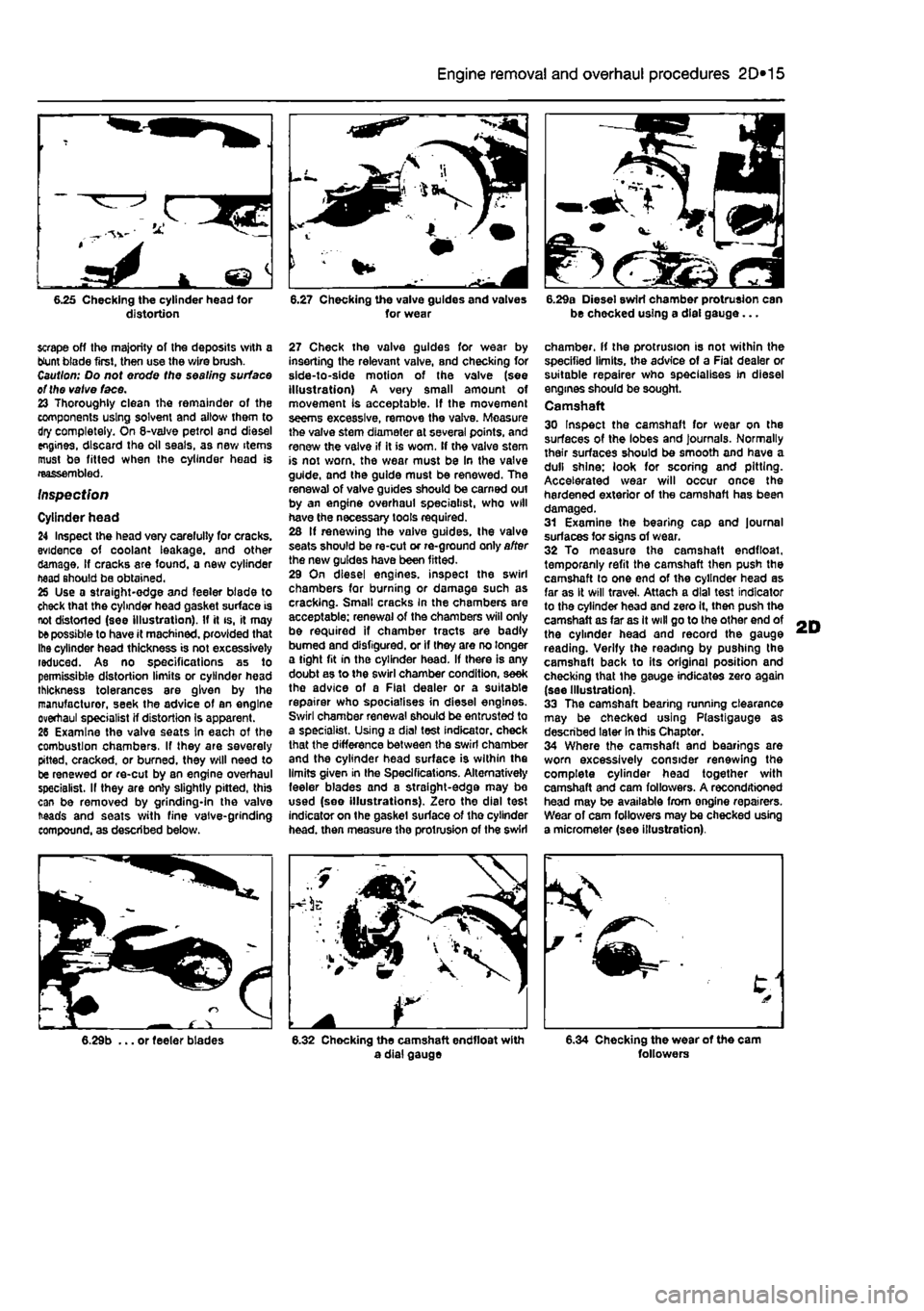

6.25 Checking the cylinder head for distortion 6.27 Checking the valve guides and valves for wear B.29a Diesel swirl chamber protrusion can be checked using a dial gauge...

scrape off the majority of the deposits with a blunt biade first, then use the wire brush. Caution: Do not erode the sealing surface ot the valve face. 23 Thoroughly clean the remainder of the components using solvent and allow them to dry completely. On 6-valve petrol and diesel engines, discard the oil seals, as new items must be fitted when the cylinder head is reassembled.

Inspection

Cylinder head 24 Inspect the head very carelully for cracks, evidence of coolant leakage, and other damage. If cracks are found, a new cylinder head should be obtained. 25 Use a straight-edge and feeler blade to check that the cylinder head gasket surface is not distorted (see illustration). If it is, it may

be

possible to have it machined, provided that Ihe cylinder head thickness is not excessively reduced. As no specifications as to permissible distortion limits or cylinder head thickness tolerances are given by ihe manufacturer, seek the advice of an engine overhaul specialist if distortion Is apparent. 26 Examine the valve seats In each of the combustion chambers, If they are severely pitted, cracked, or burned, they will need to be renewed or re-cut by an engine overhaul specialist. If they are only slightly pitted, this can be removed by grinding-in the valve heads and seats with fine valve-grinding compound, as described below.

27 Check the valve guides for wear by inserting the relevant valve, and checking for side-to-side motion of the valve (see illustration) A very small amount of movement Is acceptable. If the movement seems excessive, remove the valve. Measure the valve stem diameter at several points, and renew the valve if it is worn. If the valve stem is not worn, the wear must be In the valve guide, and the guide must be renewed. The renewal of valve guides should be earned out by an engine overhaul specialist, who will have the necessary tools required. 26 If renewing the vaive guides, the valve seats should be re-cut or re-ground only after the new guides have been fitted. 29 On diesel engines, inspect the swirl chambers for burning or damage such as cracking. Smalt cracks in the chambers are acceptable: renewal of the chambers will only be required if chamber tracts are badly burned and disfigured, or if they are no longer a tight fit in the cylinder head. If there is any doubt as to the swirl chamber condition, seek the advice of a Flat dealer or a suitable repairer who specialises in diesel engines. Swirl chamber renewal should be entrusted to a specialist. Using a dial test indicator, check that the difference between the swirl chamber and the cylinder head surface is within the limits given in Ihe Specifications. Alternatively feeler blades and a straight-edge may bo used (see illustrations). Zero the dial test indicator on the gaskel surface of tho cylinder head, then measure the protrusion of the swirl

chamber, if the protrusion is not within the specified limits, the advice of a Fiat dealer or suitable repairer who specialises in diesel engines should be sought. Camshaft 30 Inspect the camshaft for wear on the surfaces of the lobes and journals. Normally their surfaces should be smooth and have a dull shine: look for scoring and pitting. Accelerated wear will occur once the hardened exterior of the camshaft has been damaged. 31 Examine the bearing cap and journal surfaces for signs of wear. 32 To measure the camshaft endfloat, temporanly refit the camshaft then push the camshaft lo one end of the cylinder head as far as It will travel. Attach a dial test indicator to the cylinder head and zero it, then push the camshaft as far as It will go to the other end of the cylinder head and record the gauge reading. Verify the reading by pushing the camshaft back to its original position and checking that the gauge indicates zero again (see Illustration). 33 The camshaft bearing running clearance may be checked using Plastigauge as described later in this Chapter. 34 Where the camshaft and bearings are worn excessively consider renewing the complete cylinder head together with camshaft and cam followers. A reconditioned head may be available from ongine repairers. Wear of cam followers may be checked using a micrometer (see illustration).

6.29b ... or feeler blades 6.32 Chocking the camshaft endfloat with a dial gauge 6.34 Checking the wear of the cam followers

Page 103 of 225

2D*10 Engine removal and overhaul procedures

Valves and associated components 35 Examine the head of each vaive for pitting, burning, cracks, and general wear. Check the valve stem for scoring and wear ridges. Rotate the valve, and check lor any obvious indication that it Is bent. Look tor pits or excessive wear on the tip of each valve stem. Renew any valve that shows any such signs of wear or damage. 36 if the valve appears satisfactory at this stage, measure the vaive stem diameter at several points using a micrometer. Any significant difference in the readings obtained Indicates wear of the valve stem. Should any of these conditions be apparent, the valve(s) must be renewed. 37 If the valves are In satisfactory condition, they should be ground (lapped) into their respective seats, to ensure a smooth, gas-tight seal. If the seat is only tightly pitted, or if it has been re-cut, fine grinding compound only should be used to produce the required finish. Coarse valve-grinding compound should nor be used, unless a seat is badly bumed or deeply pitted, If this is the case, the cylinder head and valves should be Inspected by an expert, to decldo whether seat re-cutting, or even the renewal of the valve or seat insert (where possible) is required. 38 Valve grinding Is carried out as follows. Place the cylinder head upside-down on blocks on a bench. 39 Smear a trace of (the appropriate grade of) valve-gnndtng compound on the seat face, and press a suction grinding tool onto the valve head. With a semi-rotary action, grind

6.48 Compressing the vaive spring and fitting the split collets

them

the valve head to its seat, lifting the valve occasionally to redistribute tho grinding compound (see Illustration). A light spring placed under the valve head will greatly ease this operation 40 If coarse grinding compound Is being used, v/ork only until a dull, matt even surface Is produced on both the valve seal and the valve, then wipe off tho used compound, and repeat the process with fine compound. When a smooth unbroken ring ol light grey malt finish Is produced on both the valve and seat, the grinding operation is complete. Do not grind-In the valves any further than absolutely necessary, or the seat will be prematurely sunk into the cylinder head. 41 When all the valves have been ground-m, carefully wash off all traces of grinding compound using paraffin or a suitable solvent, before reassembling the cylinder head. 42 Examine the valve springs for signs of damage ano discoloration, If possible compare the length of the springs with new ones and renew them if necessary. 43 Stand each spring on a flat surface, and check ft tor squareness. If any of the springs are damaged, distorted or have lost mar tension, obtain a complete new set of springs. It Is normal to renew the valve springs as a matter of course if a major overhaul is being earned out. 44 Renew (he valve stem oil seals regardless of their apparent condition.

Reassembly 45 Lubricate the stems of the valves, and insert the valves into their original locations

6.53 Tightening the camshaft bearing cap nuts (diesel engines)

6.46 Using a socket to press the valve stem seals onto the guides

(see illustration). If new valves are being fitted, insert them Into the locations to which they have been ground. 46 Refit the spring sea( then, working on the first valve, dip the new valve stem sesl in fresh engine oil. Carefully locate it over the valve and onto the guide. Take care not to damage the seal as it Is passed over the valve stem. Use a suitable socket or metal tube to press the seal firmly onto the guide (sea Illustration). 47 Locate the valve spring on top of its seat, then refit the spring retainer. 48 Compress the valve spring, and locate the split collets in the recess in the valve stem. Release the compressor, then repeat the procedure on the remaining valves (see illustration)

Use a dab o) grease to hold Uiejitts* the collets In position on the HlNT valve stem while the spring compressor is released.

49 With ail the valves Installed, place the cylinder head on blocks on the bench and, using a hammer and Interposed block ol wood, top the end of each valve stem to settle the components. 50 On diesel engines, refit the swirl chambers together with their washers and tighten the retaining collars to the specified torque. 51 Oil the cam followers and locate them In their correct positions in the cylinder head. Locate the shims In the cam followers making sure they are in their original positions. 52 Oil the journals then locate the camshaft m the cylinder head with the cam lobes of No 1 cylinder facing upwards (ie No 1 cylinder at TDC). 53 Refit the bearing caps In their correct positions and progressively tighten the nuts/bolts to the specified torque (sea illustration). On petrol engines locate the lubrication pipe on Ihe head and press in the oil feed stub before refitting the bolts. 54 On diesel engines fit a new oil sea) to the right-hand side mount, then refit both side mounts together with new gaskets, Tighten the right-hand mount bolts. Also refit the coolant cover and thermostat housing together with new gaskets (see illustrations).