FIAT PUNTO 1999 176 / 1.G Owners Manual

Manufacturer: FIAT, Model Year: 1999, Model line: PUNTO, Model: FIAT PUNTO 1999 176 / 1.GPages: 225, PDF Size: 18.54 MB

Page 91 of 225

2D*10 Engine removal and overhaul procedures

1 General information

Included In (his Part of Chapter 2 are details of removing the engine/transmission from the car and general overhaul procedures for tho cylinder head, cylinder block/crankca9e and all other engine internal components. The information given ranges from advice concerning preparation for an overhaul and the purchase of replacement parts, to detailed step-by-step procedures covering removal, inspection, renovation and refitting of engine Internal components. After Section 5, all instructions are based on the assumption that the engine has been removed from the car. For Information concerning in-car engine repair, as well as the removal and refitting of those external components necessary for full overhaul, refer to Part A, 8 or C of this Chapter (as applicable) and to Section 5. Ignore any preliminary dismantling operations described in Part A. B or C that are no longer relevant onca the engine has been removed from ihe car.

2 Engine overhaul -general information

1 It Is not always easy to determine when, or if, an engine should be completely overhauled, as a number of lectors must be considered. 2 High mileage Is not necessarily an Indication that an overhaul Is needed, while low mileage does not preclude the need for an overhaul. Frequency of servicing Is probably the most important consideration. An engine which has had regular and frequent oil and filter changes, as well as other required maintenance, should give many thousands of miles of reliable service. Conversely, a neglected engine may require an overhaul very early In its life. 3 Excessive oil consumption Is an Indication that piston rings, vaivo seals and/or valve guides are in need of attention. Make sure that oil leaks are not responsible before deciding that the rings and/or guides are worn Perform a compression test, as described In Parts A or B (petrol engines) or C (diesel engines) of this Chapter, to determine the likely cause of the problem. 4 Check the oil pressure with a gauge fitted In place of the oil pressure switch. If it Is extremely low. the main and big-end bearings, and/or the oil pump, are probably worn out. 5 Loss of power, rough running, knocking or metallic engine noises, excessive valve gear noise, and high fuel consumption may also point to Ihe need for an overhaul, especially if

they are all present at the same time. If a complete service does not remedy the situation, major mechanical work is the only solution. 6 An engine overhaul involves restoring ell Internal parts to the specification of a new engine. During an overhaul, the cylinders are rebored (where applicable), the pistons and the piston rings are renewed. New main and big-end bearings are generally fitted; If necessary, the crankshaft may be reground. to restore the journals. 7 The valves are also servrced as well, since they are usually In less-than-perfect condition at this point. While the engine is being overhauled, other components, such as the starter and alternator, can be overhauled as well. The end result should be an as-new engine that will give many trouble-free miles. Note: Critical cooling system components such as the hoses, thermostat and coolant pump should be renewed when an engine is overhauled. The radiator should be checked carefully, to ensure that it is not clogged or leaking. A/so. it Is a good Idea to renew the ofI pump whenever the engine i$ overhauled.

8 Before beginning the engine overhaul, read through tho entire procedure, to familiarise yourself with the scope and requirements of the job. Overhauling an engine is not difficult If you follow carefully all of the instructions, have the necessary tools and equipment, and pay close attention to all specifications. It can, however, be time-consuming. Plan on the car being off the road for a minimum of two weeks, especially If pans must be taken to an engineering wo'kd for repair or reconditioning.

9 Check on the availability of parts and make sure that any necessary special tools and equipment are obtained in advance. Most work can be done with typical hand lools, although a number of precision measuring tools are required (or Inspecting parts to determine if they must be renewed. Often the engineering works will handle the inspection of parts and offer advice concerning reconditioning and renewal, Note: Always wait unt'l the engine has been completely dismantled, and until all components (especially the cylinder block/crankcase and the crankshaft) have been inspected, before deciding what service and repair operations must be performed by an engineering works. The condition of these components will be the major factor to consider when determining whether to overhaul the original engine, or to buy a reconditioned unit. Do not. fh ere tore, purchase parts or have overhaul work done on other components until they have been thoroughly Inspected. As a general rule, time is the primary cost of an overhaul, so it does not pay to fit worn or sub-standard parts.

10 As a final note, to ensure maximum life and minimum trouble from a reconditioned engine, everything must be assembled wilh care, in a spotlessly-clean environment.

3 Engine and transmission removal -methods

and

precautions

1 If you have decided that the engine must be removed for overhaul or major repair work, several preliminary steps should be taken. 2 Locating a suitable place to work is extremely important. Adequate work space, along with storage space for the car, will be needed. If a workshop or garage Is not available, at the very least, a flat, level, clean work surface Is required. 3 Cleaning the engine compartment and engine/transmission before beginning the removal procedure wilt help keep tools clean and organised. 4 An engine hoist or A-frame will also be necessary. Make sure the equipment is rated In excess of the combined weight of the engine and transmission, Safety Ib of primary Importance, considering the potential hazards involved in lifting the engine/transmission out of the car. 5 If this is Ihe first time you have removed

an

engine, an assistant Bhould Ideally be available. Advice and aid from someone more experienced would also be helpful. There are many instances when one person cannot simultaneously perform all of the operations required when lifting the engine out of Ihe vehicle. 6 Plan the operation ahead of time. Before starting work, arrange for the hire of or obtain all of the tools and equipment you will need. Some of the equipment necessary to perform engine/transmission removal and Installation safely and wilh relative ease On addition to an engine hoist) Is as follows: a heavy duly trolley jack, complete sets of spanners and sockets as described in the reference section of this manual, wooden blocks, and plenty of rags and cleaning solvent for mopping up spitted oil, coolant and fuel. If the hoist must be hired, make sure that you arrange for it In advance, and perform all of the operations possible without it beforehand. This will save you money and time.

7 Plan for the car to be out of use for quite a while. An engineering works will be required to perform some of the work which the do-it-yourselfer cannot accomplish without special equipment. These places often have a busy schedule, so it would be a good idea to consul! them before removing the engine, in order to accurately estimate the amount of time required to rebuild or repair components that may need work, 9 Always be extremely careful when removing and refitting the engine/transmission. Serious injury can result from careless actions. Plan ahead and take your time, and a job of this nature, although major, can be accomplished successfully.

Page 92 of 225

2D*10 Engine removal and overhaul procedures

Engine and transmission -removal, separation, connection and refitting

Note: The engine Is lowered from the engine compartment as a complete unit with the transmission; tho two are then separated for overhaul.

Removal 1 Remove the bonnet and disconnect the washer tubing as described in Chapter 11 (see illustrations). 2 Apply the handbrake, then jack up the front of the vehicle and support on axle stands (see Jacking and vehicle support). Remove both front wheels. In order to remove tne engine/transmission assembly in an upright position from under the vehicle, there must be a minimum clearance of 660 mm between the floor and the front crossmember. Additional height Is necessary if the assembly is to be lowered onto a trolley. 3 Where fitted, unbolt and remove the engine compartment lower cover. 4 Remove the auxiliary drivebelt(s) with reference to Chapter 1A or 1B. 5 Dram the engine oil. transmission oil/fluid and coolant with reference to Chapter 1A or 1B. 6 Remove the battery (see Chapter 5A). 7 On manual transmission models with a cable dutch, disconnect the clutch cable from the transmission (refer to Chapter 6). On manual transmission models with a hydraulic clutch unbolt the clutch slave cylinder from the top of the transmission then fit a cable-tie around it to prevent the piston coming out (see Illustration). Position the cylinder to one side. 8 Unscrew the nut and disconnect the earth lead from the transmission (see illustration). Petrol engines 9 Unbolt and remove the battery tray. 10 Disconnect the wiring from the reversing light switch. 11 On manual transmission models disconnect the reverse Inhibition cable from the transmission then disconnect the gear selector rod from the lever on the transmission. 12 Remove the air cleaner and ducting as descnbed In Chapter 4A or 4B. 13 On automatic transmission models disconnect the kickdown cable and gear selector cable as described in Chapter 7B. Also disconnect the wiring for the electro-magnetic clutch. 14 Unbolt and remove the cover from the bulkhead then disconnect the oxygen sensor wiring. 15 Disconnect the remaining wiring at the bulkhead and release the fuse holders at the mounting. 16 Disconnect the vacuum pipe from the inlet manifold, and also disconnect the wiring connector located next to it.

4.1a Unscrewing the bonnet hinge bolts

17 Unscrewthenutsandseparatetheengine wiring harness lead from the battery positive cable terminal. 18 Disconnect the accelerator cable from the engine as described in Chapter 4A or 4B, 19 Loosen the clip and disconnect the radiator top hose from the elbow on the left-hand end of the cylinder head. Similarly disconnect the bottom hose. On 16-valve models, remove the radiator electric cooling fan as described in Chapter 3. 20 Identify the hoses connected to the throttle housing, then disconnect them. 21 Identify the coolant heater hoses on the bulkhead for position, then loosen the clips and disconnect the hoses. 22 Loosen the clip and disconnect the brake servo vacuum hose from the Inlet manifold. Where applicable, disconnect the remaining emission control system vacuum hoses from the Inlet manifold after Identifying their locations to aid refitting. 23 Disconnect tho fuel supply and return hoses from the throttle housing. 24 Release the connector from the ignition/fuel ECU located on the right-hand side of the engine compartment. 25 Unscrew the nut and detach the earth cable from its location near the ECU. 26 Disconnect the diagnostic connector located near the ECU. 27 On models fitted with power steering, refer to Chapter 10 and unbolt the power steering pump from the front of the engine without disconnecting the hydraulic fluid lines then tie It to one side so that it will not obstruct the removal of the engine. On

4.1b Disconnecting the washer tubing

models with air conditioning, similarly unbolt the air conditioning compressor and position it clear of the engine. Do not disconnect the air conditioning refngerant pipes/hoses. 26 On manual transmission models pull out the retaining plate and disconnect the gear selector cable from the lever on the transmission. 29 Unscrew the nuts retaining the track rod ends on the swivel hubs and use a balljoint separator tool to disconnect them. 30 Release the flexible brake fluid hoses and ABS system sensor wrring from the front suspension struts. 31 On manual transmission models, unscrew the nuts from the outer ends of each driveshaft. To prevent the hubs from turning either have an assistant depress the brake pedal, or temporarily Insert two wheel bolts and use a lever to hold the hub. 32 On automatic transmission models use a suitable drift to drive out Ihe roll pins securing 2D the inner ends of the drlveshafts to tho trans-mission output stubs. Turn the driveshalts as necossary to access the roll pins . 33 Unscrew the two bolts securing the right-hand swivel hub assembly to the front suspension strut, then move the hub assembly outwards. On manual transmission models release the outer end of the driveshaft from the hub assembly - on automatic transmission models slide the inner end of the driveshaft off the final drive output stub. Take care not to strain the flexible brake hose while doing this. Move the driveshaft to one side thon temporanly refit the hub assembly to the strut. On manual transmission models, make

^ - / //

4.7 Fit a cable tie around the dutch slave cylinder to prevent the piston coming out 4.8 Disconnecting the earth lead from the transmission

Page 93 of 225

2D*10 Engine removal and overhaul procedures

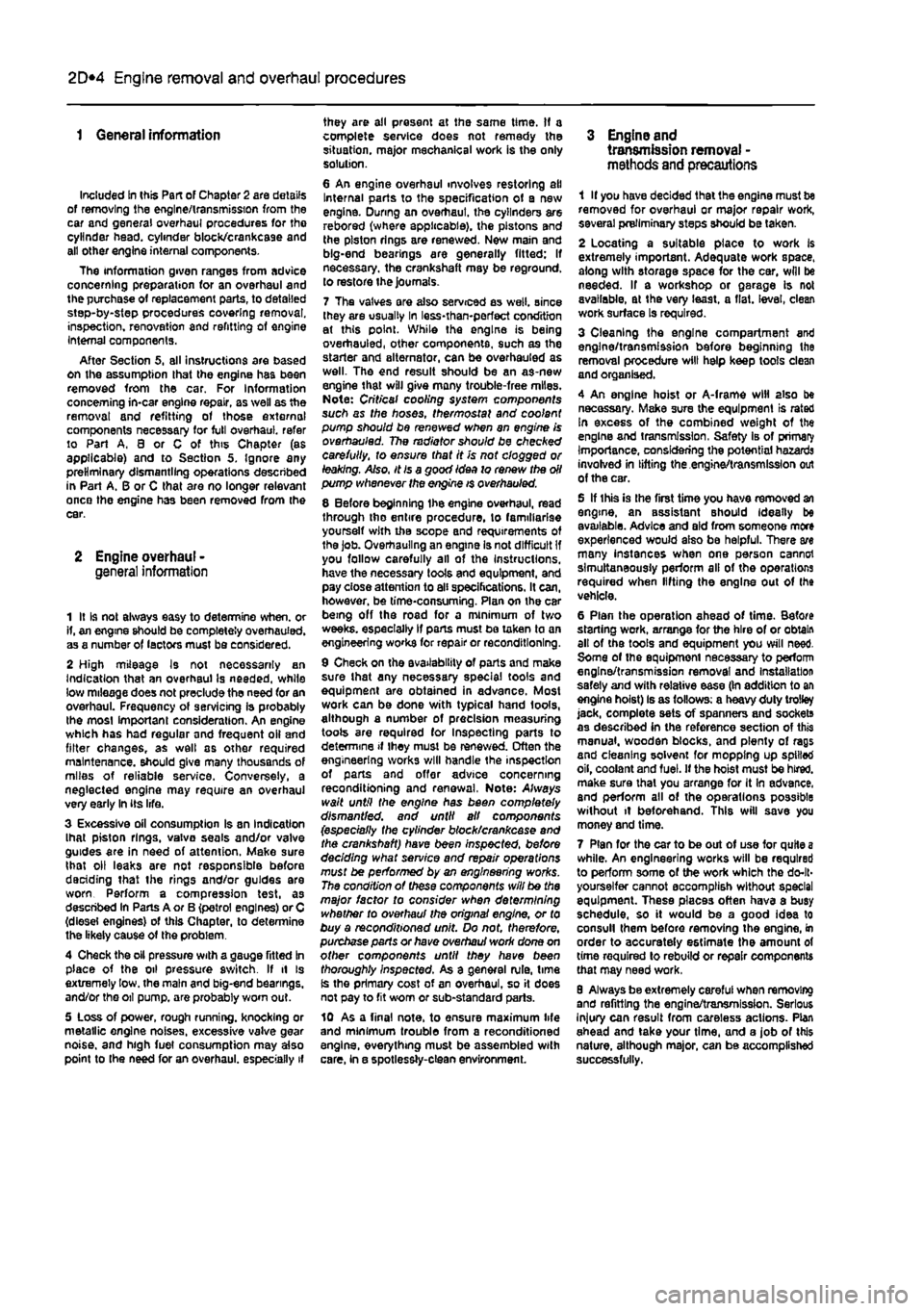

4.36a Relay guard mounting nuts 4.36b Battery tray and mounting bolts 4.36c Disconnect the engine wiring harness located above the transmission .

4.36d ... the inner wiring plug ...

sure that the dnveshaft is positioned to clear Ihe lower suspension arm when the engine is removed. 34 Disconnect the left-hand driveahaft using the same procedure

4.41 Engine wiring harness connections to the battery positive cable

4.36e ... and the outer wiring plug

35 Remove the exhaust front downpipe witfl reference to Chapter 4D. Diesel engines 36 Unbolt and remove the roiay guard then disconnect the wiring as applicable and unbolt the battery tray (see Illustrations). 37 Disconnect tho gear selector cable from the transmission by removing the retaining plate and prising the socket end off Ihe ball on the lever. Use a pair of pliors to pull out the plate. Tie the cable to the bulkhead (see illustration). 38 Unscrew the nut and disconnect the gear selector rod from the ievor on the top of the transmission, 39 Remove the air cleaner and air inlet duct by unscrewing the two bolls securing the duct to the valve cover and loosening the clip securing the duct to the air cleaner. Refer to Chapter 4C if necessary.

4.37 Tie tho gear selector cable to the bulkhead

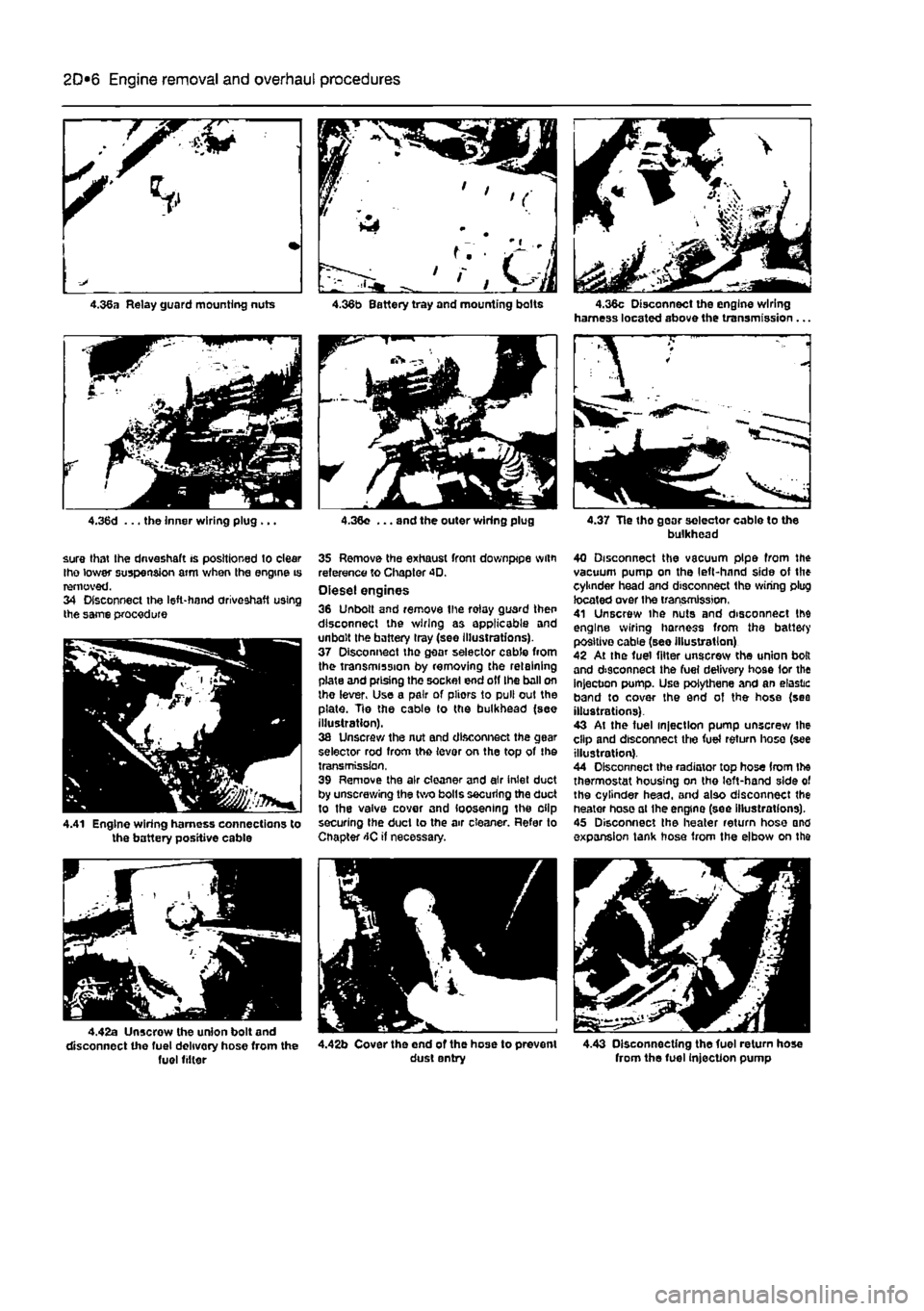

40 Disconnect the vacuum pipe from the vacuum pump on the left-hand side of the cylinder head and disconnect the wiring plug located over the transmission, 41 Unscrew ihe nuts and disconnect the engine wiring harness from the battery positive cable (see illustration) 42 At the fuel filter unscrew the union bolt and disconnect the fuei delivery hose lor the injection pump. Use polythene and an elastic band to cover the end of the hose (see illustrations). 43 At the fuel injection pump unscrew the clip and disconnect thie fuel return hose (see illustration). 44 Disconnect the radiator top hose from the thermostat housing on tho left-hand side of the cylinder head, and also disconnect the healer hose at Ihe engine (see illustrations). 45 Disconnect the heater return hose and expansion tank hose from the elbow on the

4.42a Unscrew the union bolt and disconnect the fuel delivery hose from the fuel filter 4.42b Cover the end of the hose to prevent dust entry 4.43 Disconnecting the fuel return hose from the fuel injection pump

Page 94 of 225

2D*10 Engine removal and overhaul procedures

4.44a Disconnecting tho radiator top hose from the thermostat housing

4.45b ... and expansion tank hose

lofi-nand side of the cylinder head, From the top ot the radiator and from the expansion tank (see Illustrations). 46 Disconnect the radiator bottom hose from the elbow on the cylinder head.

4.49e ... and the adjustment lockbolt...

4.44b Disconnecting the heater hose st the engine

4.49a Remove the front bracket bolt...

47 On models with a speedometer cable, disconnect the cable from the transmission. 48 On models with an electronic speedometer, if necessary disconnect the winng connector on the support bracket. The cable may be left

4.49f ... and tie the power steering pump to the bulkhead

. m " • V;

<4

4.45a Disconnecting the heater return hose...

4.49b ... the belt adjustment bolt...

attached if Ihe transmission Is not being detached from the engine. 49 On models fitted with power steering, unbolt the power steering pump from the rear right-hand side of the engine without disconnecting the hydraulic fluid lines then tie it to one side on the bulkhead so that it will not obstruct the removal of the engine. To do (his first remove the front bracket bolt, remove the belt adjustment bolt, remove the rear through-bolt, lift away the cover and remove the adjustment lockbolt (see illustrations). On models with air conditioning, similarly unbolt the air conditioning compressor and position It clear of the engine. Do not disconnect the air conditioning refrigerant pipes/hoses. 50 Disconnect the coolant purge hoses from the top of the radiator and expansion tank (seo illustrations). 51 Disconnect the accelerator cable from the injection pump (see Chapter 4Q.

4.50a Disconnecting the coolant purge hoses from the radiator...

Page 95 of 225

2D*10 Engine removal and overhaul procedures

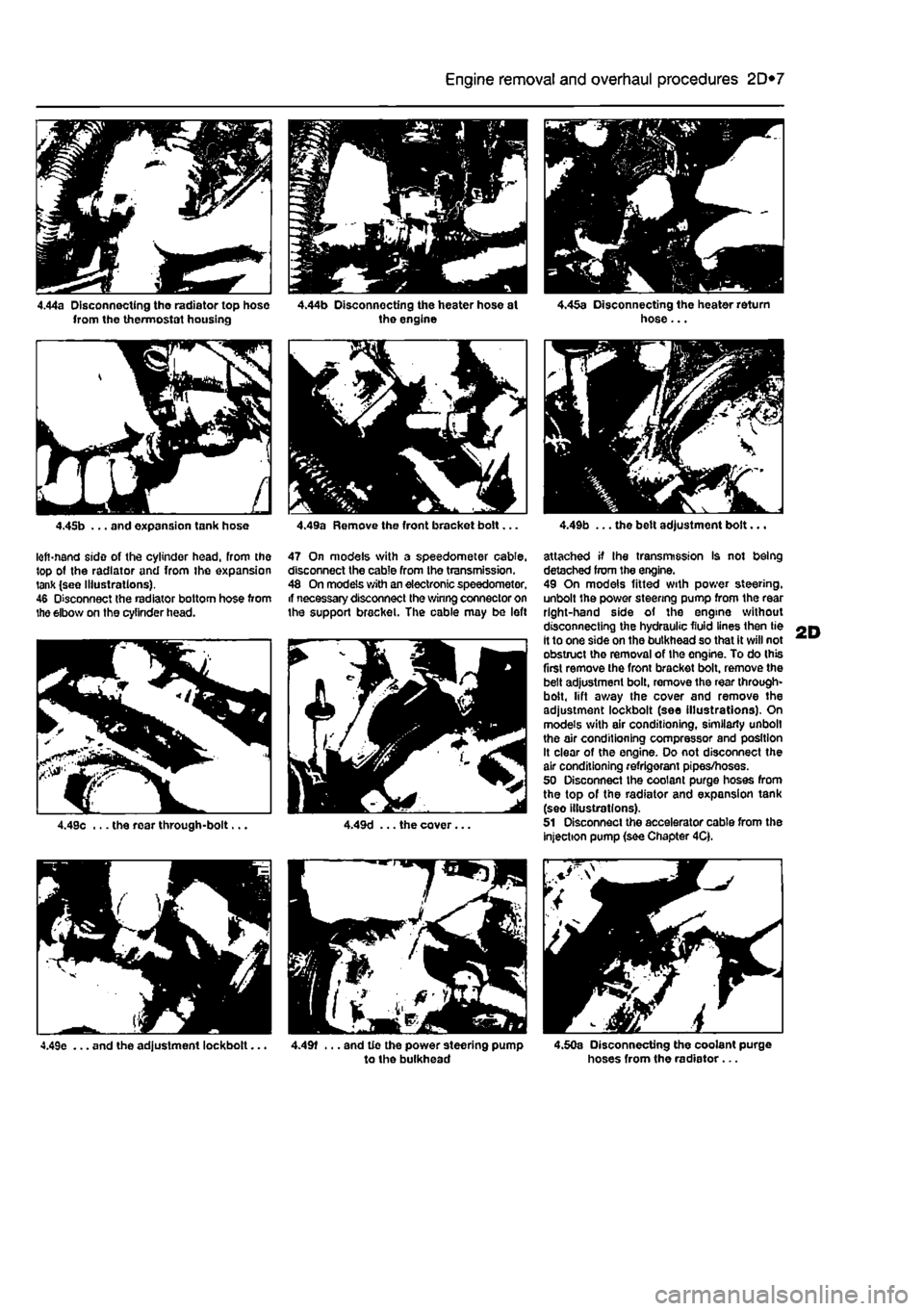

4.50b ... and expansion tank 4.S2 Disconnecting the radiator coolant temperature sensor wiring plug

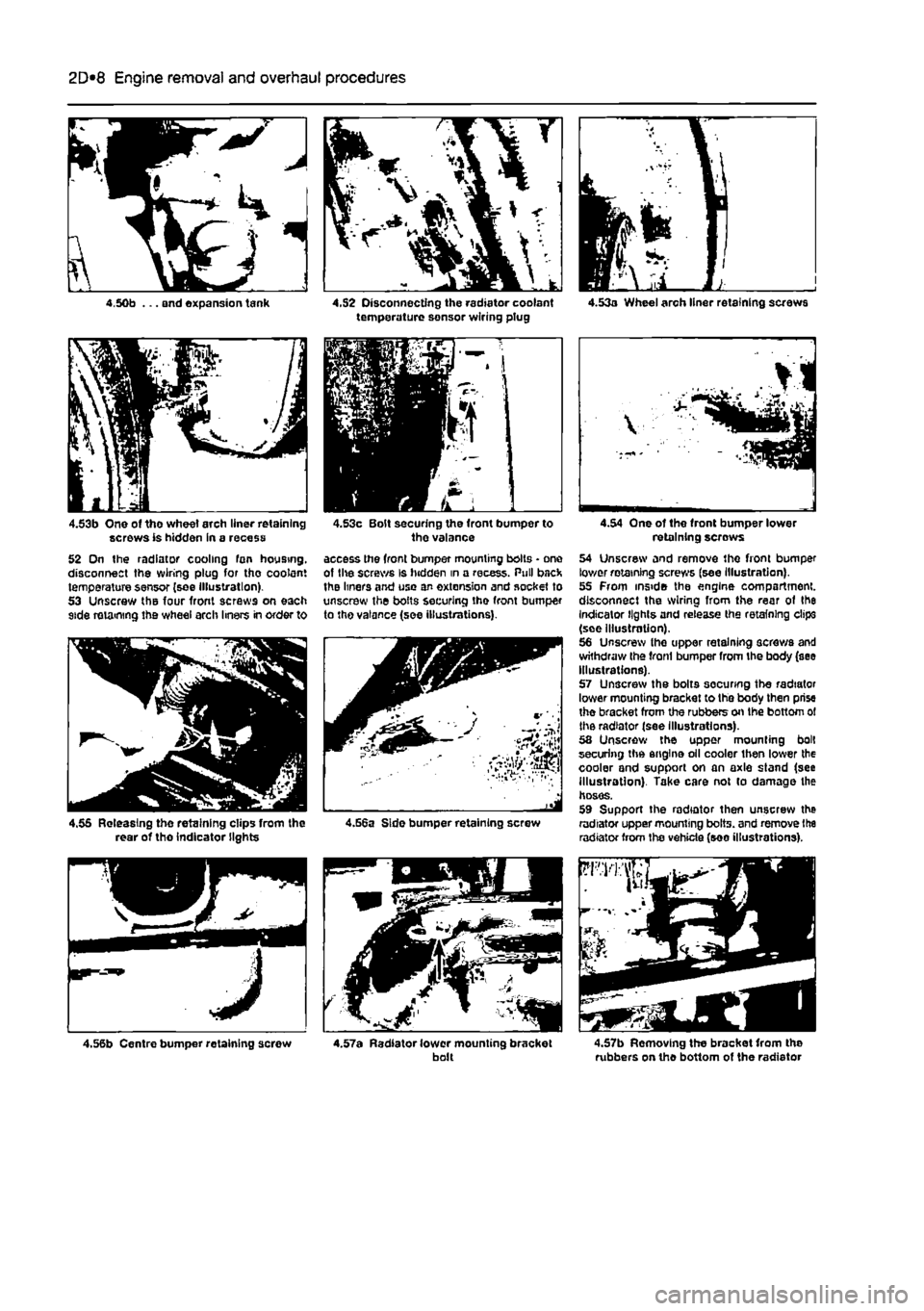

4.53b One of tho wheel arch liner retaining screws is hidden in a recess 52 On the radiator cooling fan housing, disconnect the wiring plug for tho coolant temperature sensor (see illustration). 53 Unscrew the four front screws on each side retaining the wheel arch liners in order to

4.53c Bolt securing the front bumper to the valance access the front bumper mounting bolts • one of lite screws is hidden in a recess. Pull back the liners and use an extension and socket to unscrew the bolts securing the front bumper to tho valance (see illustrations).

4.55 Releasing the retaining clips from the rear of tho indicator lights 4.56a Side bumper retaining screw

4.56b Centre bumper retaining screw 4.57a Radiator lower mounting bracket bolt

4.54 One of the front bumper lower retaining screws 54 Unscrew and remove the front bumper lower retaining screws (see Illustration). 55 From inside the engine compartment, disconnect the wiring from the rear of the Indicator lights and release the retaining clips (see illustration). 56 Unscrew the upper retaining screws and withdraw the front bumper from the body (see Illustrations). 57 Unscrew the bolts socunng the radiator lower mounting bracket to the body then prise the bracket from the rubbers on the bottom ol the radiator (see Illustrations). 58 Unscrew the upper mounting bolt securing the engine oil cooler then lower the cooler and support on an axle stand (see illustrotion). Take care not to damage the hoses. 59 Support the radiator then unscrew the radiator upper mounting bolts, and remove the radiator from the vehicle (see illustrations).

4.57b Removing the bracket from the rubbers on the bottom of the radiator

Page 96 of 225

2D*10 Engine removal and overhaul procedures

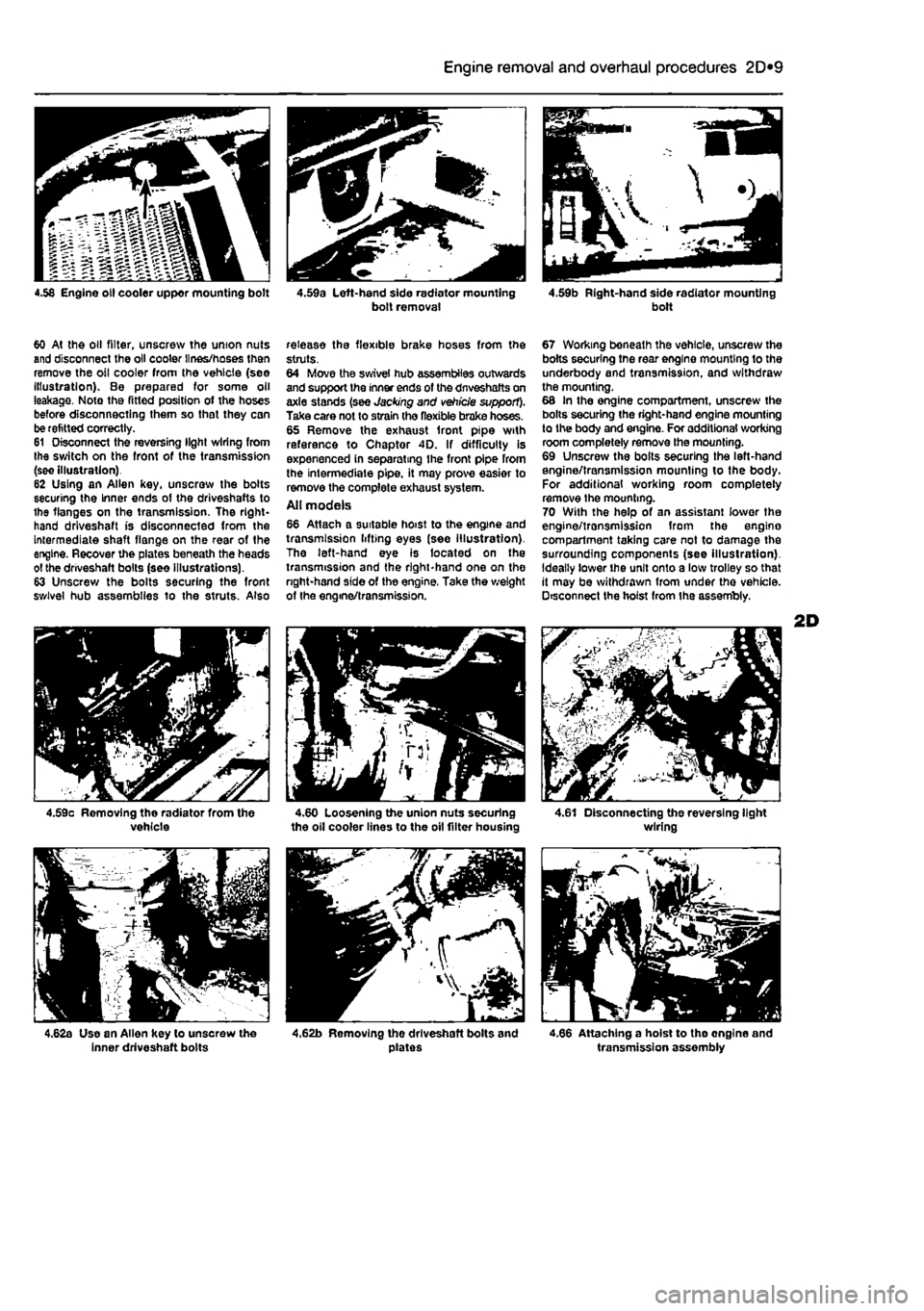

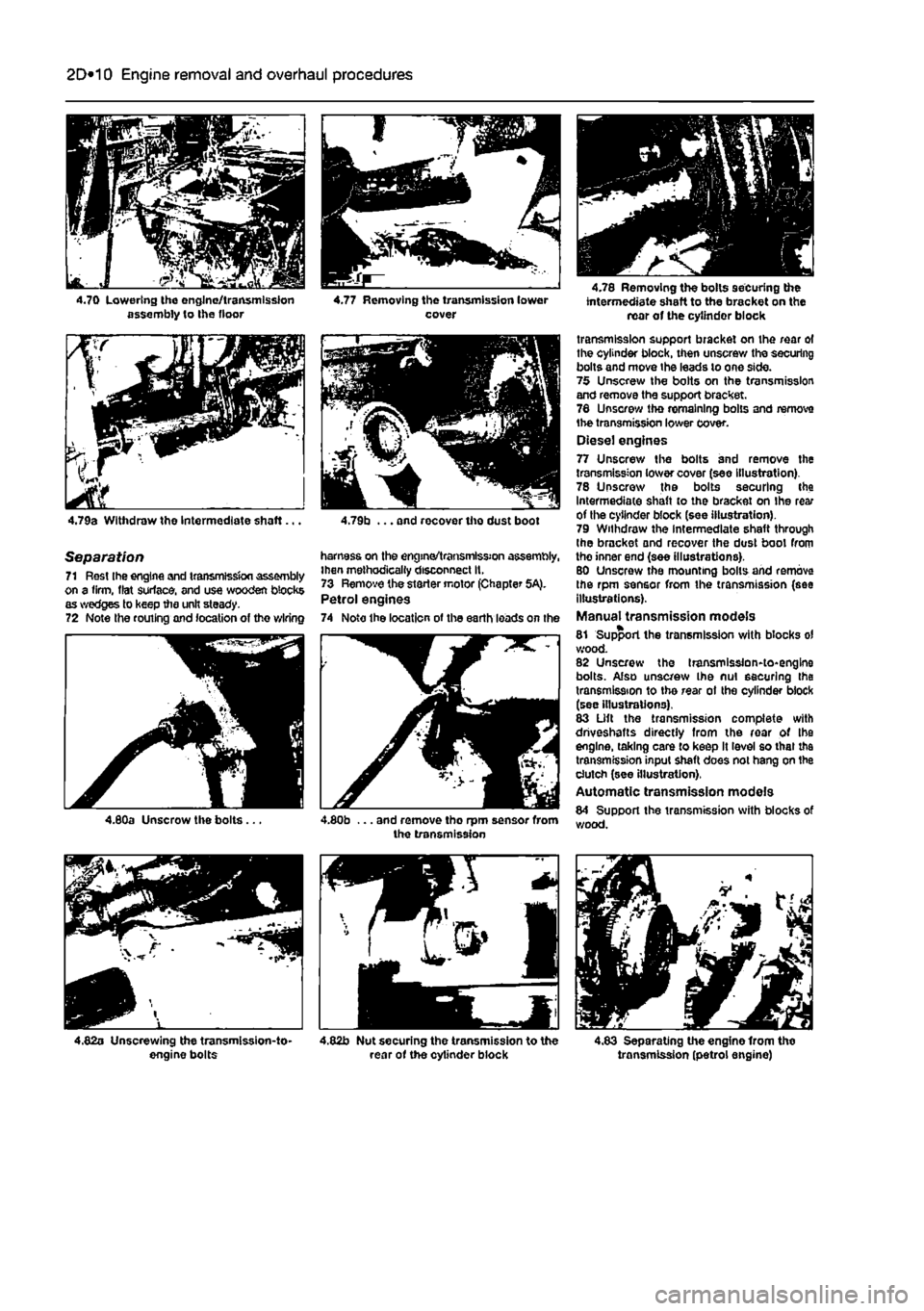

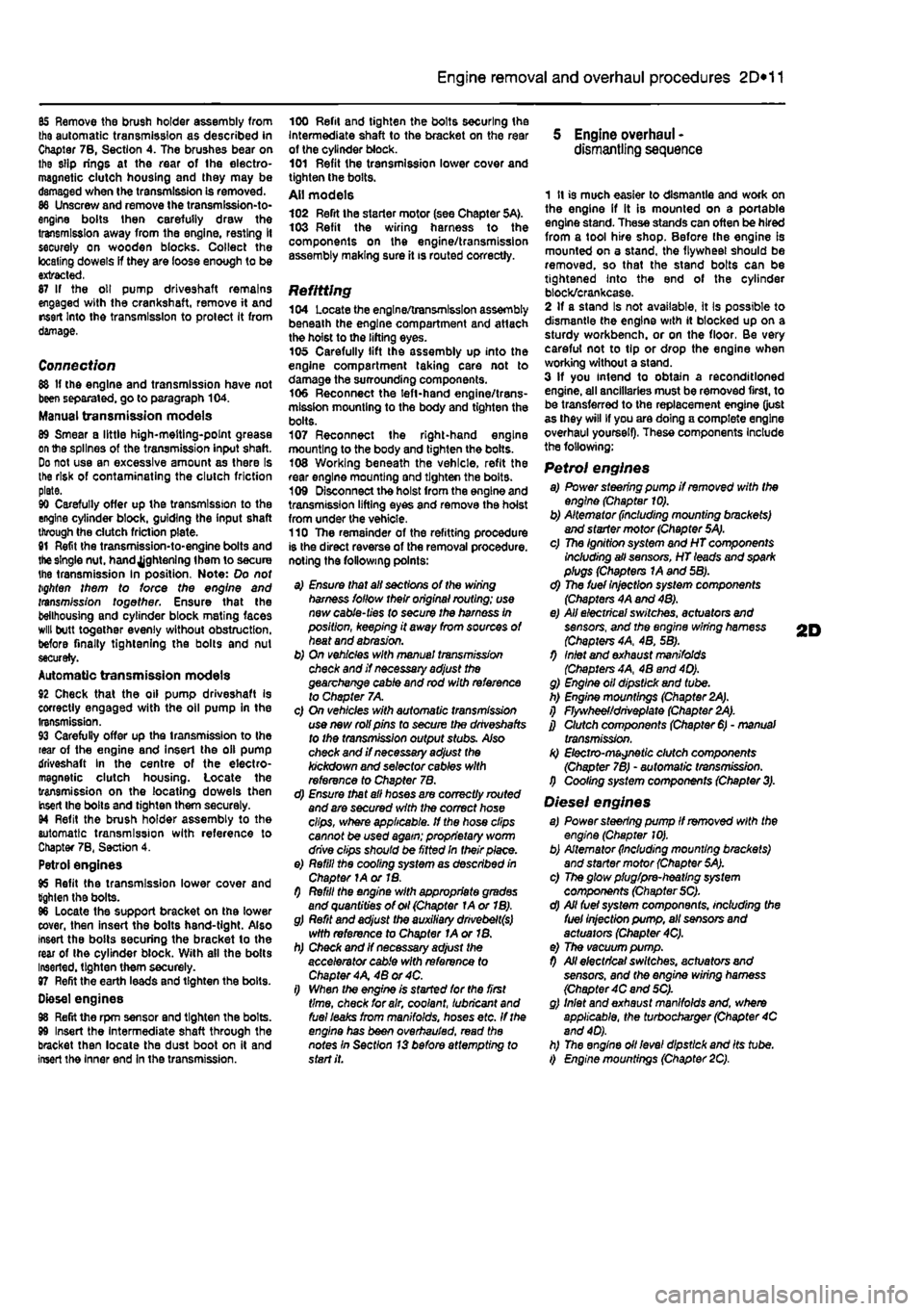

60 At the otl filter, unscrew the union nuts and disconnect the oil cooler lines/hoses then remove the oil cooler from the vehicle (see Illustration). Be prepared for some oil leakage. Note the fitted position of the hoses before disconnecting them so that they can be refitted correctly. 61 Disconnect the reversing light wiring from Ihe switch on the front of the transmission (see illustration) 82 Using an Allen key, unscrew the bolts securing the inner ends of the driveshafts to the flanges on the transmission. The right-hand driveshaft is disconnected from the Intermediate shaft flange on the rear of the engine. Recover the plates beneath the heads ol the driveshaft bolls (see illustrations). 63 Unscrew the bolts securing the front sv/lvel hub assemblies to the struts. Also

4.59c Removing the radiator from the vehicle

4.62a Use an Allen key to unscrew the inner driveshaft bolts

release the flexible brake hoses from the struts. 64 Move the swivel hub assemblies outwards and support the inner ends of the dnveshafts on axle stands (see Jacking and vehicle support). Take care not to strain the flexible brake hoses. 65 Remove the exhaust front pipe with reference to Chaptor 4D. If difficulty is expenenced in separating Ihe front pipe from the intermediate pipe, it may prove easier to remove the complete exhaust system. Ail models 66 Attach a suitable hoist to the engine and transmission lifting eyes (see illustration). The left-hand eye is located on the transmission and the right-hand one on the right-hand side of the engine, Take the weight of the engine/transmission.

4.60 Loosening the union nuts securing the oil cooler lines to the oil filter housing

4.62b Removing the driveshaft bolts and plates

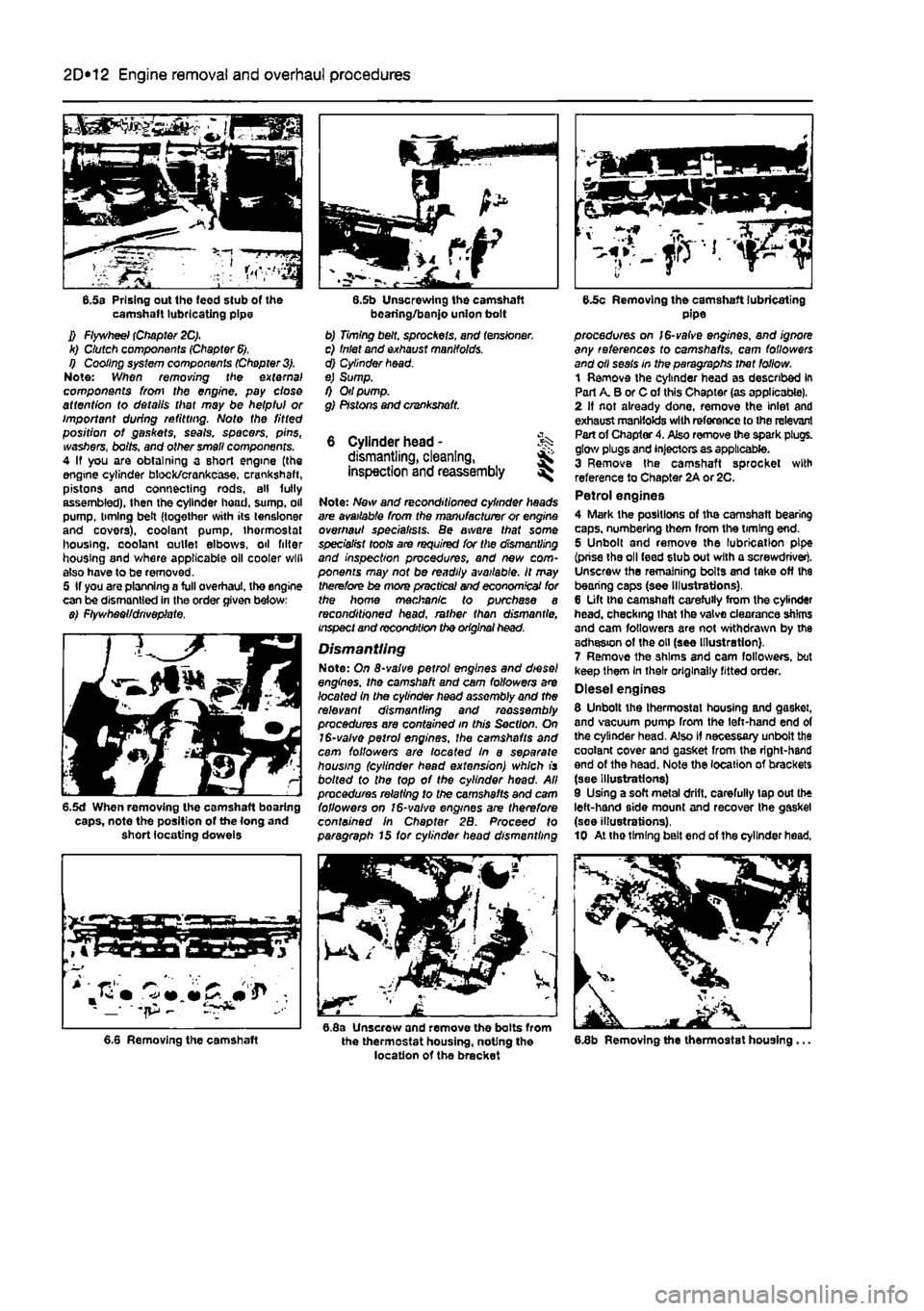

67 Working boneath the vehicle, unscrew the bolts securing tne rear engine mounting to the underbody and transmission, and withdraw the mounting. 68 In the engine compartment, unscrew the bolts securing the right-hand engine mounting to the body and engine. For additional working room completely remove the mounting. 69 Unscrew the boils securing the left-hand engine/transmission mounting to the body. For additional working room completely remove Ihe mounting. 70 With the help of an assistant lower the engine/transmission from the engino compartment taking care not to damage the surrounding components (see illustration). Ideally lower the unit onto a low trolley so that it may be withdrawn from under the vehicle. Disconnect the hoist from ihe assembly.

4.61 Disconnecting the reversing light wiring

4.66 Attaching a hoist to tho ongine and transmission assembly

Page 97 of 225

2D*10 Engine removal and overhaul procedures

4.70 Lowering the engine/transmission assembly to Ihe floor

4.79a Withdraw the Intermediate shaft...

Separation 71 Rest Ihe engine and transmission assembly on a firm, flat surface, and use wooden blocks as wedges to keep the unit steady. 72 Note the routing and location of the wiring

4.77 Removing the transmission lower cover

4.79b ... and recover the dust boot

harness on the engine/transmission assembly, Ihen methodically disconnect It. 73 Remove the starter motor (Chapter 5A). Petrol engines 74 Noto the location of the earth loads on the

4.78 Removing the bolts securing the intermediate shaft to the bracket on the rear of the cylinder block

transmission support bracket on the rear of the cylinder block, then unscrew the securing bolts and move the leads to one side. 75 Unscrew the bolts on the transmission and remove the support bracket. 78 Unscrew tho remaining bolts and remove the transmission lower cover. Diesel engines 77 Unscrew the bolts and remove the transmission lower cover (see Illustration). 78 Unscrew the bolts securing the Intermediate shaft to the bracket on Ihe rear of the cylinder block (see illustration). 79 Withdraw the Intermediate shaft through the bracket and recover the dust boot from tho inner end (see illustrations). 80 Unscrew the mounting bolts and remove the rpm sensor from the transmission (see illustrations). Manual transmission models 81 Support the transmission with blocks ol wood. 82 Unscrew the transmission-to-engine bolts. Also unscrew Ihe nut securing the transmission to the rear ot the cylinder block (see illustrations). 83 Lift the transmission complete with driveshafts directly from the roar of Ihe engine, taking care to keep It level so that the transmission input shaft does not hang on the clutch (see illustration), Automatic transmission models 84 Support the transmission with blocks of wood.

4.83 Separating the engine from tho transmission (petrol engine)

Page 98 of 225

2D*10 Engine removal and overhaul procedures

05 Remove the brush holder assembly from the automatic transmission as described in Chapter 7B, Section 4. The brushes bear on the slip rings at the rear of the electro-magnetic clutch housing and they may be damaged when the transmission is removed. 86 Unscrew and remove the transmission-to-engine bolts then carefully draw the transmission away from the engine, resting It securely on wooden blocks. Collect the locating dowels If they are loose enough to be extracted, 87 If the oil pump driveshaft remains engaged with the crankshaft, remove it and reert Into the transmission to protect It from damage.

Connection 86 If the engine and transmission have not been separated, go to paragraph 104. Manual transmission models 89 Smear a little high-melting-point grease

on

the splines of the transmission input shaft. Do not use an excessive amount as there Is the risk of contaminating the clutch friction plate. 90 Carefully offer up the transmission to the engine cylinder block, guiding the input shaft through the clutch friction plate. 91 Refit the transmission-to-engine bolts and

the

single nut. hand^jghtenlng 1hem to secure the transmission in position. Note: Do not hghten them to force the engine and transmission together. Ensure that the beilhousing and cylinder block mating faces will butt together evenly without obstruction, before finally tightening the bolts and nut securely. Automatic transmission models 92 Check that the oil pump driveshaft is correctly engaged with the oil pump in the transmission. 93 Carefully offer up the transmission to Ihe rear of the engine and insert the oil pump driveshaft In the centre of the electro-magnetic clutch housing. Locate the transmission on the locating dowels then Insert the bolts and tighten them securely. 94 Refit the brush holder assembly to the automatic transmission with reference to Chapter 7B, Section 4. Petrol engines 96 Refit the transmission lower cover and tighten the bolts. 96 Locate the support bracket on the lower cover, then insert the bolts hand-tight. Also Insert the bolts securing the bracket lo the rear of Ihe cylinder block. With all the bolts Inserted, tighten them securely. 97 Refit the earth leads and tighten the bolts. Diesel engines 98 Refit the rpm sensor and tighten the bolts. 99 Insert the Intermediate shaft through the bracket then locate the dust boot on it and insert the Inner end in the transmission.

100 Refit and tighten the bolts securing the Intermediate shaft to the bracket on the rear of the cylinder block. 101 Refit the transmission lower cover and tighten the bolts. Ail models 102 Refit the starter motor (see Chapter 5A). 103 Refit the wiring harness to the components on the engine/transmission assembly making sure it is routed correctly.

Refitting 104 Locate the engine/transmission assembly beneath the engine compartment and attach the hoist to the lifting eyes. 105 Carefully lift the assembly up into the engine compartment taking care not to damage the surrounding components. 106 Reconnect the left-hand engine/trans-mission mounting to the body and tighten the bolts. 107 Reconnect Ihe right-hand engine mounting to the body and tighten the bolts. 108 Working beneath the vehicle, refit the rear engine mounting and tighten the bolts. 109 Disconnect the hoist from the engine and transmission lifting eyes and remove the hoist from under the vehicle. 110 The remainder of the refitting procedure is the direct reverse of the removal procedure, noting the following points:

a) Ensure that alf sections of the wiring harness follow their original routing; use new cable-ties to secure the harness In position, keeping it away from sources

of

heat and abrasion. b) On vehicles with manual transmission check and if necessary adjust the gearchenge cable and rod with reference to Chapter 7A. c) On vehicles with automatic transmission use new ro//p/ns fo secure the driveshafts to the transmission output stubs. Also check and if necessary adjust the kickdown end selector cables with reference to Chapter 78. d) Ensure that afi hoses are correctly routed and are secured with the correct hose clips, where applicable. If the hose clips cannot be used again; proprietary worm drive clips should be fitted

In

their place. e) Refill the cooling system as described in Chapter 1A or 18. f) Refill the engine with appropriate grades and quantities of oil (Chapter

1A

or 1B). g) Refit and adjust the auxiliary drivebelt(s) wfth reference fo Chapter 1A or 1B. h) Check and If necessary adjust the accelerator cable with reference to Chapter

AA,

48 or

AC.

i) When the engine is started for the first time, check for

air,

coolant, lubricant and fuel leaks from manifolds, hoses etc. If

the

engine has been overhauled, read

the

notes In Section 13 before attempting to starlit.

5 Engine overhaul • dismantling sequence

1 It is much easier to dismantle and work on the engine if it is mounted on a portable engine stand. These stands can often be hired from a tool hire shop. Before the engine is mounted on a stand, the flywheel should be removed, so that the stand bolts can be tightened Into the end of the cylinder block/crankcase. 2 If a stand Is not available, it Is possible to dismantle the engine with it blocked up on a sturdy workbench, or on the floor, Be very careful not to tip or drop the engine when working without a stand. 3 If you intend to obtain a reconditioned engine, all anclllarles must be removed first, to be transferred to the replacement engine (just as they will If you are doing a complete engine overhaul yourself). These components Include the following:

Petroi engines a) Power steering pump if removed with the engine (Chapter

10).

b) Alternator fmcluding mounting brackets) and starter motor (Chapter

SA).

c) The Ignition system and HT components including ail sensors, HT leads and

spark

plugs (Chapters 1A and

SB).

d) The fuel injection system components (Chapters A A and

AB).

e) All electrical switches, actuators and sensors, and the engine wiring harness (Chapters 4A, AB, SB). f) Inlet and exhaust manifolds (Chapters 4A, AB end

AD).

g) Engine oil dipstick and tube. h) Engine mountings (Chapter

2A).

i) Flywheef/driveptate (Chapter

2A).

j) Clutch components (Chapter

6)

- manual transmission. k) Electro-magnetic clutch components (Chapter 7B) - automatic transmission. I) Cooling system components (Chapter

3).

Diesei engines a) Power steering pump //removed with the engine (Chapter

10).

b) Alternator (Including mounting brackets) and starter motor (Chapter 5A). c) The glow plugfpre-heatlng system components (Chapter

SC).

d) Ait fuel system components, including the fuel injection pump, all sensors and actuators (Chapter

AC).

e) The vacuum pump. f) Ail electrical switches, actuators and sensors, and the engine wiring harness (Chapter 4C and 5C). g) Inlet and exhaust manifolds and, where applicable, the turbocharger (Chapter

AC

and 4D). h) The engine oil level dipstick and its tube. i) Engine mountings (Chapter

2C).

Page 99 of 225

2D*10 Engine removal and overhaul procedures

6.5s Prising out the feed stub of the camshaft lubricating pipe J) Flywheel (Chapter 2C). k) Clutch components (Chapter

6).

I) Cooling system components (Chapter

3).

Note: When removing trie external components from the engine, pay close attention to details that may be helpful or important during refitting. Note the fitted position of gaskets, seals, spacers, pins, washers, bolts, and other small components. 4 If you are obtaining a short engine (the engine cylinder block/crankcase, crankshaft, pistons and connecting rods, all fully assembled), then the cylinder head, sump, oil pump, timing belt (together with its tensloner and covers), coolant pump, thermostat housing, coolant outlet elbows, oil filter housing and where applicable oil cooler will also have to be removed. 5 If you are planning a full overhaul, the engine can be dismantled in the order given below: $) Ftywhaoi/drivoplate.

6.5d When removing the camshaft bearing caps, note the position of the (ong and short locating dowels

bearing/banjo union bolt b) Timing belt, sprockets, and tensioner. c) Inlet and exhaust manifolds. d) Cylinder head. e) Sump. f) Oil pump. g) Pistons and crankshaft.

6 Cylinder head - % dismantling, cleaning, inspection and reassembly ^

Note: Now and reconditioned cylinder heads are available from the manufacturer or engine overhaul specialists. Be aware that some specialist tools are required for the dismantling and inspection procedures, and new com-ponents may not be readily available. It may therefore be mors practical and economical for the home mechanic to purchase a reconditioned head, rather than dismantle, inspect and recondition the original head.

Dismantling Note: On 8-valve petrol engines and diesel engines, the camshaft and cam followers are /oca fed In the cylinder head assembly and the relevant dismantling and reassembly procedures are contained in this Section. On 1$-valve petrol engines, the camshafts and cam followers are /oca fed In a separate housing (cylinder head extension) which is bo/fed fo the top of the cylinder head. All procedures relating to the camshafts and cam followers on 16-valve engines are therefore contained in Chapter 2B. Proceed fo paragraph 15 for cylinder head dismantling

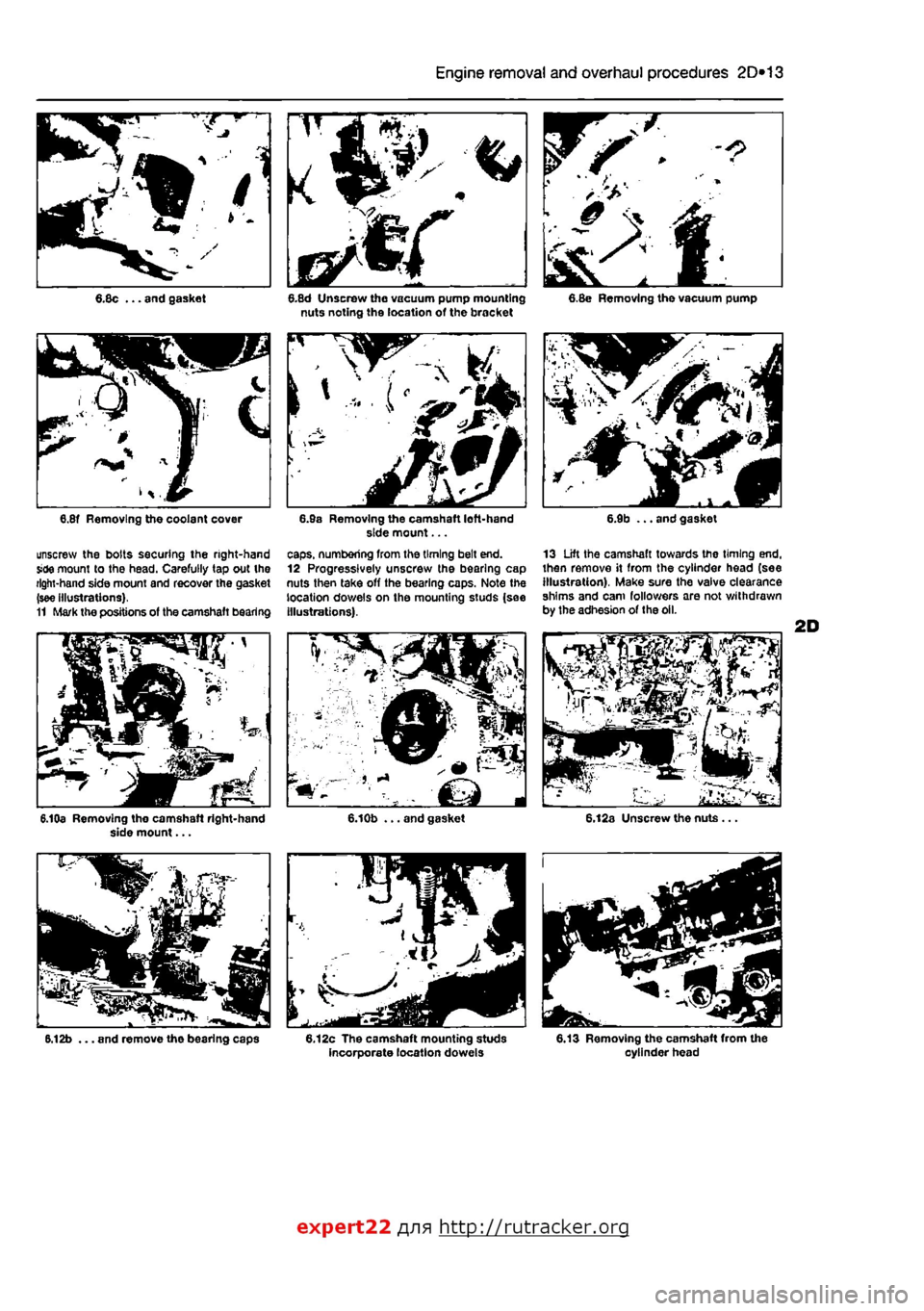

6.8a Unscrew and remove the bolts from the thermostat housing, noting the location of the bracket

6.5c Removing the camshaft lubricating pipe procedures on /6-vafve engines, and ignore any references to camshafts, cam followers and oil seals in the paragraphs that follow. 1 Remove the cylinder head as described in Part A. B or C of this Chapter (as applicable). 2 If not already done, remove the inlet and exhaust manifolds with reference to the relevant Part of Chapter 4. Also remove the spark plugs, glow plugs and injectors as applicable. 3 Remove the camshaft sprocket with reference to Chapter 2A or 2C. Petrol engines 4 Mark the positions of the camshaft bearing caps, numbering them from the timing end. 5 Unbolt and remove the lubrication pipe (prise the oil feed stub out with a screwdriver). Unscrew the remaining bolts and take off the bearing caps (see illustrations). 6 Lift the camshaft carefully from the cylinder head, checking lhat the valve clearance shims and cam followers are not withdrawn by the adhesion of the oil (see Illustration). 7 Remove the shims and cam followers, but keep them In their originally fitted order. Diesel engines 8 Unbolt the thermostat housing and gasket, and vacuum pump from the left-hand end of the cylinder head. Also if necessary unbolt the coolant cover and gasket from the right-hand end of the head. Note the location of brackets (see illustrations) 9 Using a soft metal drift, carefully lap out the left-hand side mount and recover the gasket (soe illustrations). 10 At tho timing bait end of the cylinder head.

6.8b Removing the thermostat housing ... 6.6 Removing the camshaft

Page 100 of 225

2D*10 Engine removal and overhaul procedures

V.

^

•

• - >v

4L

6.8c ... and gasket

unscrew the bolts securing the right-hand Side mount to the head. Carefully tap out the right-hand side mount and recover the gasket (see illustrations). 11 Mark the positions of the camshaft bearing

6.10a Removing tho camshaft right-hand side mount...

6.12b ... and remove the bearing caps

6.8d Unscrew the vacuum pump mounting nuts noting the location of the bracket

caps, numbering from the timing belt end. 12 Progressively unscrew the bearing cap nuts then take off the bearing caps. Note the location dowels on the mounting studs (sae Illustrations).

6.12c The camshaft mounting studs incorporate location dowels

6.8e Removing the vacuum pump

13 Lift the camshaft towards the timing end. then remove it from the cylinder head (see illustration). Make sure the valve clearance shims and cam followers are not withdrawn by the adhesion of the oil.

6.13 Removing the camshaft from the cylinder head

expert22 fl/in http://rutracker.org