ignition FIAT SPIDER ABARTH 2017 Manual Online

[x] Cancel search | Manufacturer: FIAT, Model Year: 2017, Model line: SPIDER ABARTH, Model: FIAT SPIDER ABARTH 2017Pages: 292, PDF Size: 9.24 MB

Page 191 of 292

6. Disconnect the bulb from the

socket.

7. Install the new bulb in the reverse

order of the removal procedure. Fog Lights

Proceed as follows:

1. If you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left.

2. Make sure the ignition is switched

off, and the headlight switch is off.

3. Remove the fasteners in the five

locations and partially peel back the

mud guard.

4. Disconnect the connector from the

unit by pressing the tab on the

connector with your finger and pulling

the connector.

5. Turn the socket and bulb assembly

counterclockwise, extract the bulb and

remove it.

6. Disconnect the bulb from the

socket.

7. Install the new bulb in the reverse

order of the removal procedure.

Brake lights / Tail lights

Go to your authorized dealer when the

replacement of this lights is necessary. Side Direction Indicator Lights

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and the headlight

switch is off.

2. If you are changing the right bulb,

start the engine, turn the steering wheel

all the way to the right, and turn off

engine. If you are changing the left bulb,

turn the steering wheel to the left.

3. Remove the fasteners in the five

locations and partially peel back the

mud guard.

4. Disconnect the electrical connector

from the bulb by pressing the tab on

the connector with your finger and

pulling the connector.

5. Remove the lens assembly by

pressing the tab on the unit with your

finger and pulling the unit forward to

compress in the internal catch, then pull

the cluster outwards.

6. Lift up the lens assembly, and then

remove the cluster and install the new

side direction indicator lens assembly in

the reverse order of the removal

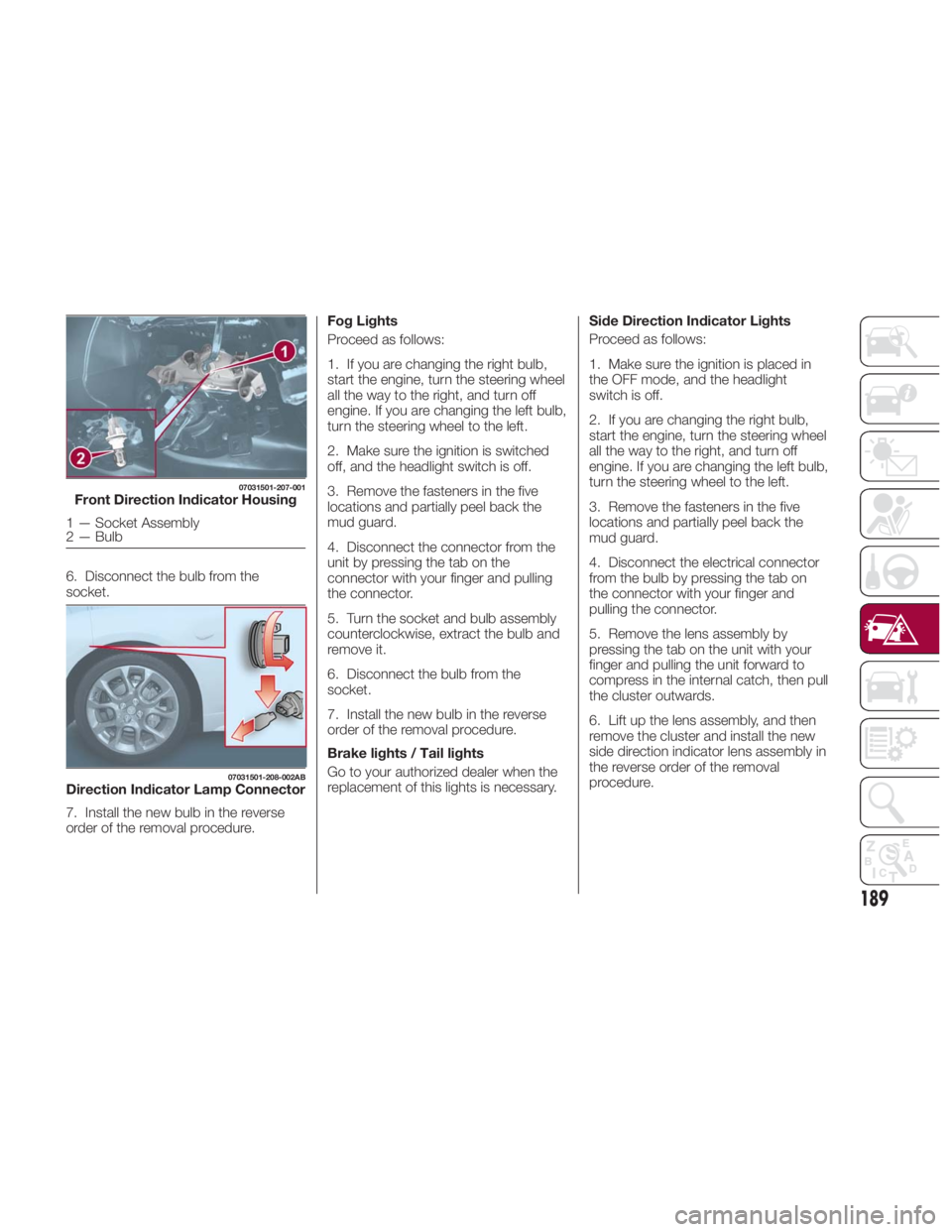

procedure.07031501-207-001

Front Direction Indicator Housing

1 — Socket Assembly

2 — Bulb 07031501-208-002AB

Direction Indicator Lamp Connector

189

Page 194 of 292

5. Turn the socket and bulb assembly

counterclockwise to remove from

taillight housing, and remove bulb.

6. Install the new bulb in the reverse

order of the removal procedure. Reverse Light

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and the headlight

switch is off.

2. Turn the socket assembly

counterclockwise to remove, and

remove bulb.

3. Install the new bulb in the reverse

order of the removal procedure. Rear Side Marker

Proceed as follows:

1. Push the lens assembly rearward to

compress the internal catch, then pull

the lens assembly outwards.

2. Turn the socket and bulb assembly

counterclockwise to remove, and

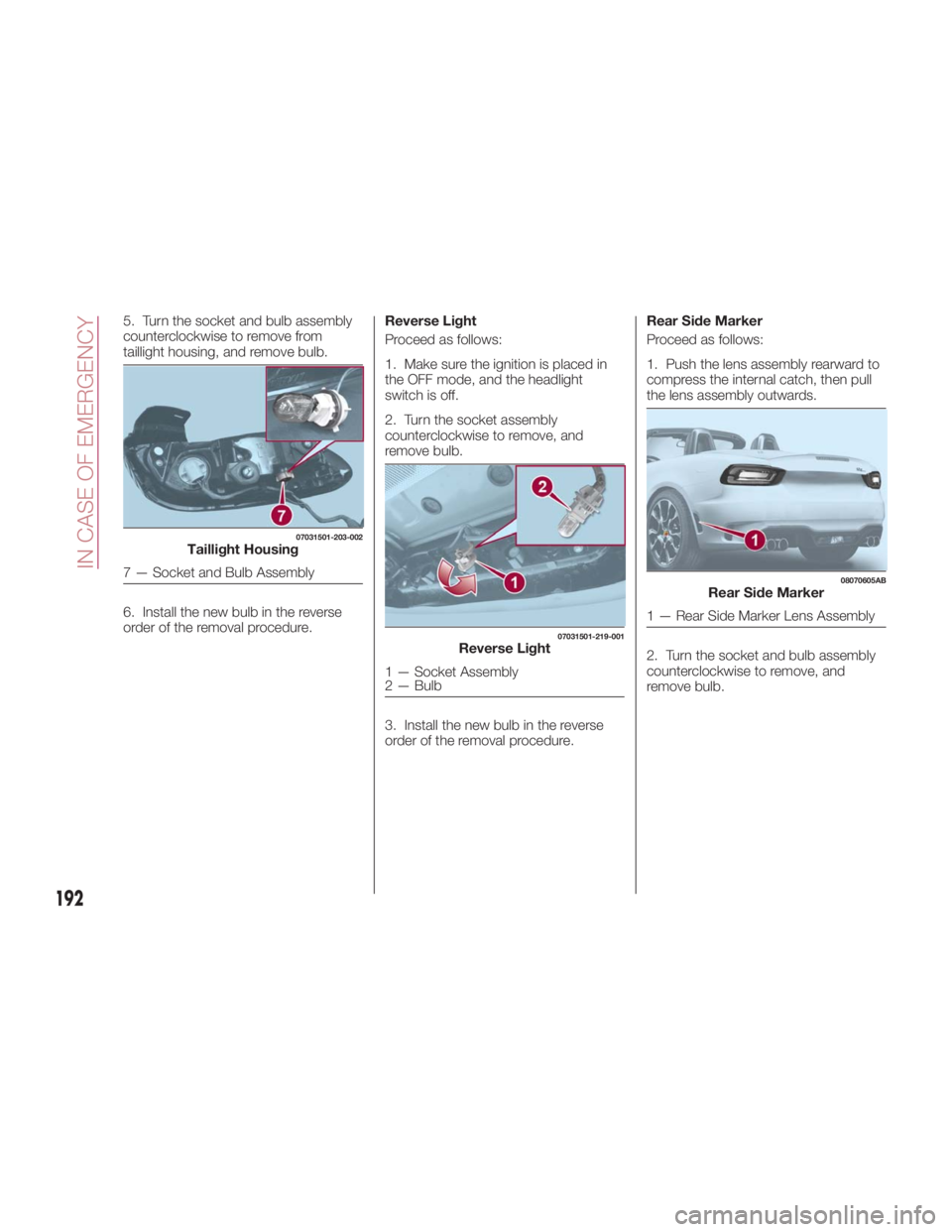

remove bulb.07031501-203-002

Taillight Housing

7 — Socket and Bulb Assembly 07031501-219-001

Reverse Light

1 — Socket Assembly

2 — Bulb 08070605AB

Rear Side Marker

1 — Rear Side Marker Lens Assembly

192

IN CASE OF EMERGENCY

Page 195 of 292

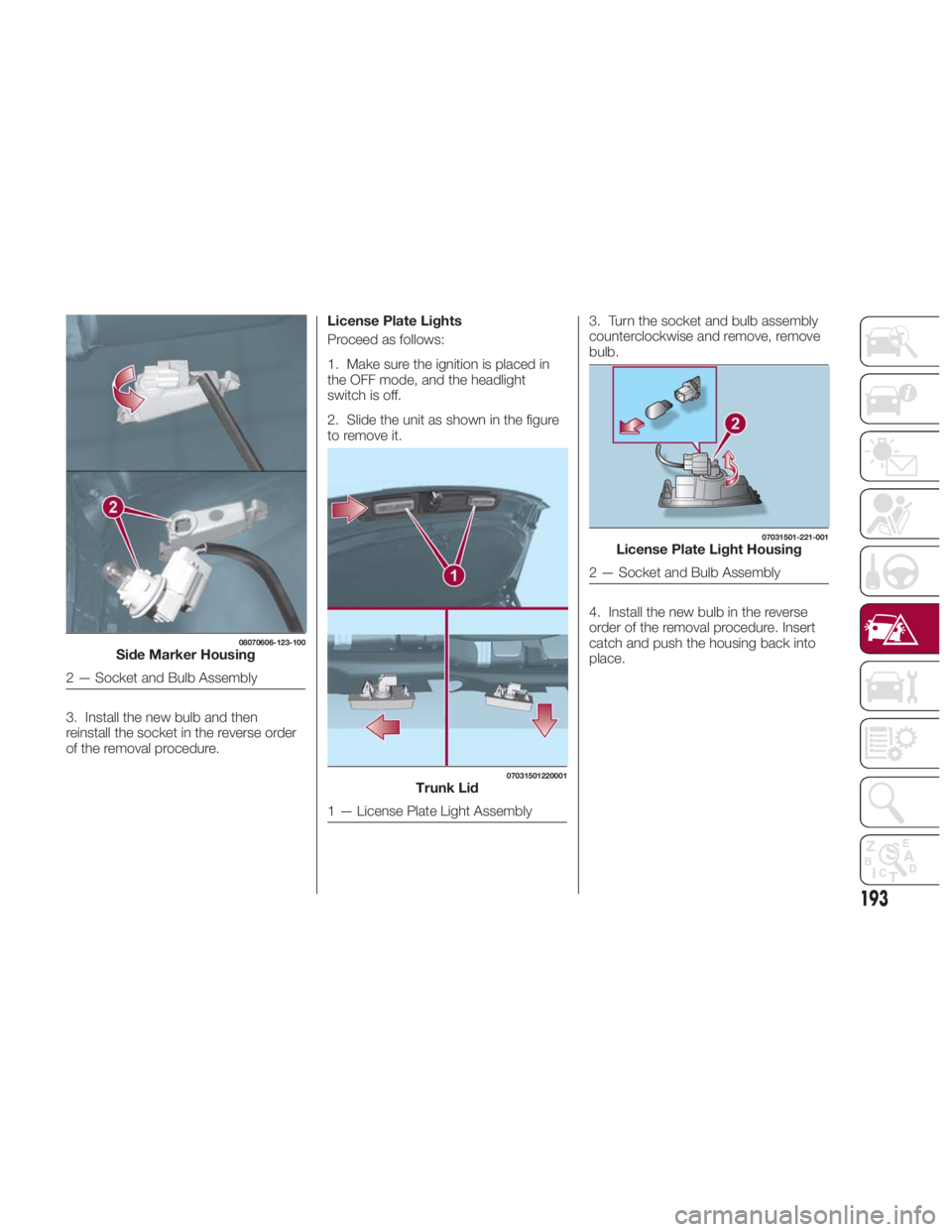

3. Install the new bulb and then

reinstall the socket in the reverse order

of the removal procedure. License Plate Lights

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and the headlight

switch is off.

2. Slide the unit as shown in the figure

to remove it. 3. Turn the socket and bulb assembly

counterclockwise and remove, remove

bulb.

4. Install the new bulb in the reverse

order of the removal procedure. Insert

catch and push the housing back into

place.08070606-123-100

Side Marker Housing

2 — Socket and Bulb Assembly 07031501220001

Trunk Lid

1 — License Plate Light Assembly 07031501-221-001

License Plate Light Housing

2 — Socket and Bulb Assembly

193

Page 196 of 292

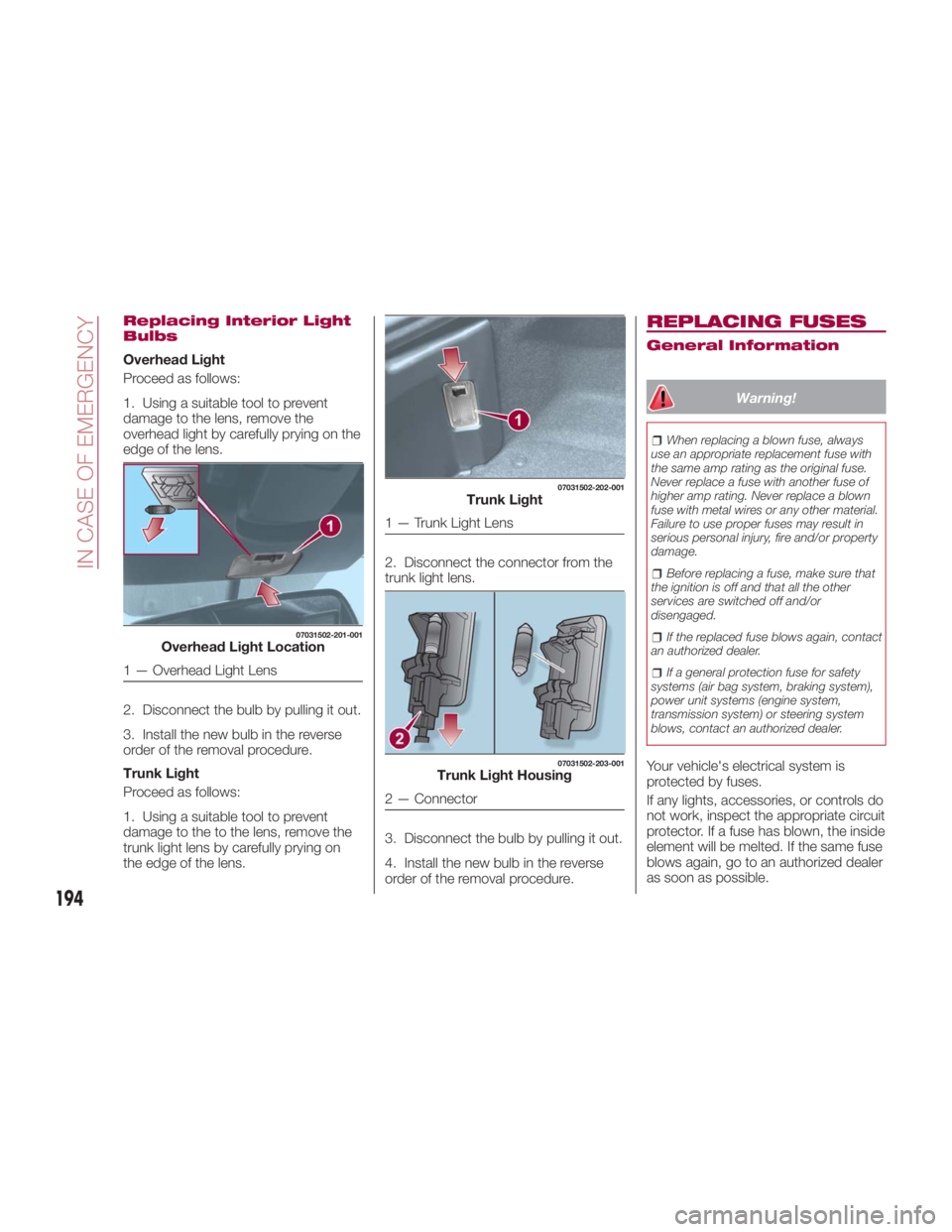

Replacing Interior Light

Bulbs

Overhead Light

Proceed as follows:

1. Using a suitable tool to prevent

damage to the lens, remove the

overhead light by carefully prying on the

edge of the lens.

2. Disconnect the bulb by pulling it out.

3. Install the new bulb in the reverse

order of the removal procedure.

Trunk Light

Proceed as follows:

1. Using a suitable tool to prevent

damage to the to the lens, remove the

trunk light lens by carefully prying on

the edge of the lens. 2. Disconnect the connector from the

trunk light lens.

3. Disconnect the bulb by pulling it out.

4. Install the new bulb in the reverse

order of the removal procedure. REPLACING FUSES General Information

Warning! When replacing a blown fuse, always

use an appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a blown

fuse with metal wires or any other material.

Failure to use proper fuses may result in

serious personal injury, fire and/or property

damage.

Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or

disengaged.

If the replaced fuse blows again, contact

an authorized dealer.

If a general protection fuse for safety

systems (air bag system, braking system),

power unit systems (engine system,

transmission system) or steering system

blows, contact an authorized dealer.

Your vehicle's electrical system is

protected by fuses.

If any lights, accessories, or controls do

not work, inspect the appropriate circuit

protector. If a fuse has blown, the inside

element will be melted. If the same fuse

blows again, go to an authorized dealer

as soon as possible.07031502-201-001

Overhead Light Location

1 — Overhead Light Lens 07031502-202-001

Trunk Light

1 — Trunk Light Lens 07031502-203-001

Trunk Light Housing

2 — Connector

194

IN CASE OF EMERGENCY

Page 197 of 292

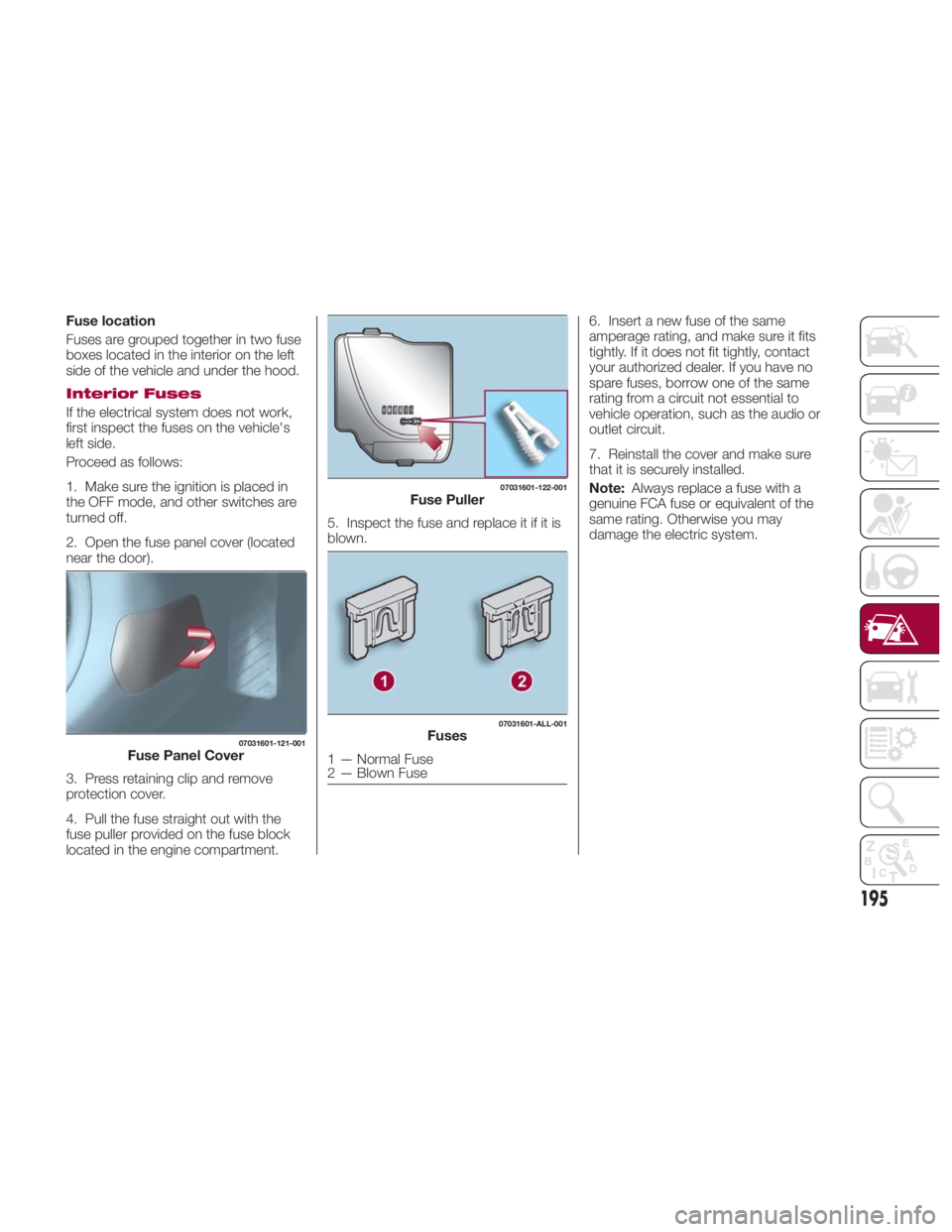

Fuse location

Fuses are grouped together in two fuse

boxes located in the interior on the left

side of the vehicle and under the hood.

Interior Fuses

If the electrical system does not work,

first inspect the fuses on the vehicle's

left side.

Proceed as follows:

1. Make sure the ignition is placed in

the OFF mode, and other switches are

turned off.

2. Open the fuse panel cover (located

near the door).

3. Press retaining clip and remove

protection cover.

4. Pull the fuse straight out with the

fuse puller provided on the fuse block

located in the engine compartment. 5. Inspect the fuse and replace it if it is

blown. 6. Insert a new fuse of the same

amperage rating, and make sure it fits

tightly. If it does not fit tightly, contact

your authorized dealer. If you have no

spare fuses, borrow one of the same

rating from a circuit not essential to

vehicle operation, such as the audio or

outlet circuit.

7. Reinstall the cover and make sure

that it is securely installed.

Note: Always replace a fuse with a

genuine FCA fuse or equivalent of the

same rating. Otherwise you may

damage the electric system.07031601-121-001

Fuse Panel Cover 07031601-122-001

Fuse Puller 07031601-ALL-001

Fuses

1 — Normal Fuse

2 — Blown Fuse

195

Page 198 of 292

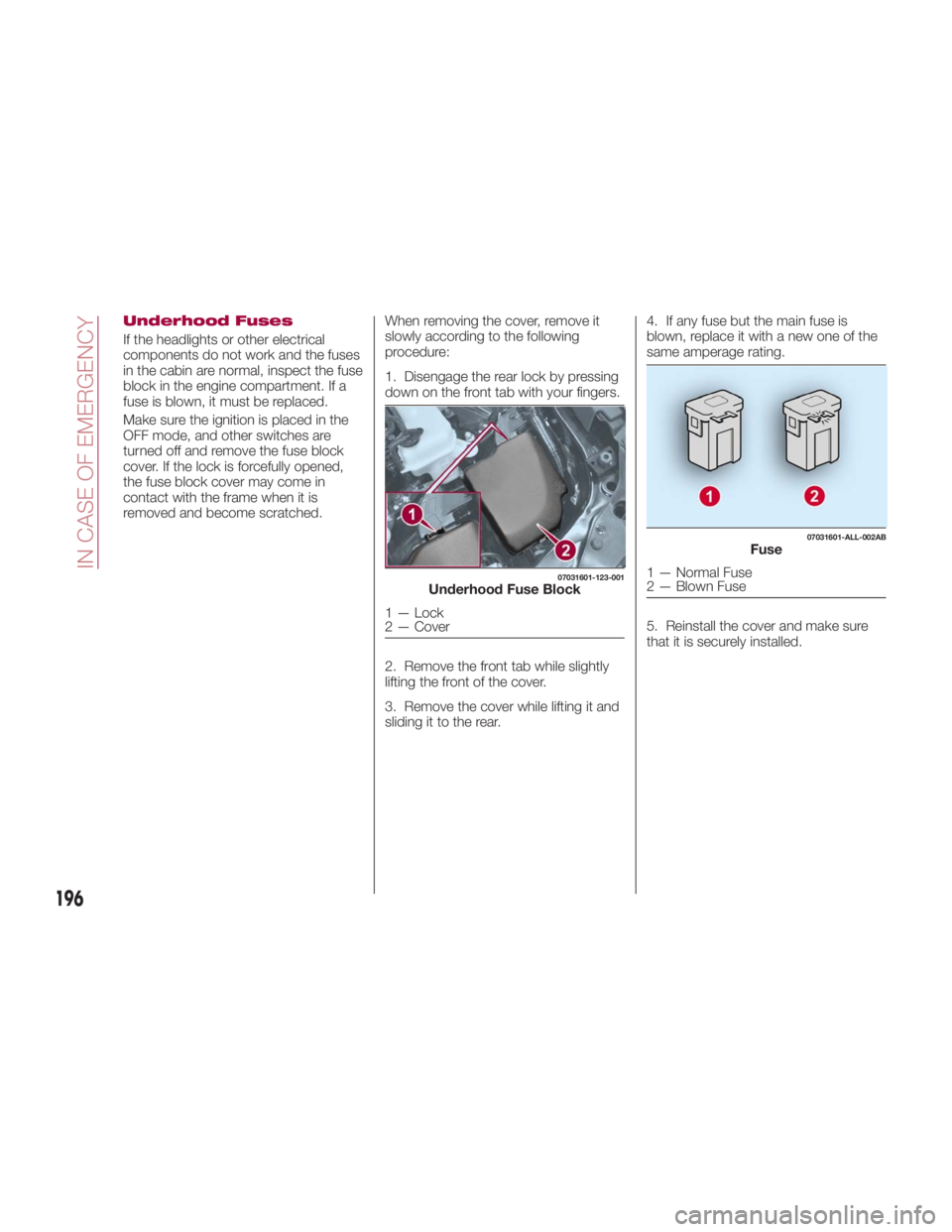

Underhood Fuses

If the headlights or other electrical

components do not work and the fuses

in the cabin are normal, inspect the fuse

block in the engine compartment. If a

fuse is blown, it must be replaced.

Make sure the ignition is placed in the

OFF mode, and other switches are

turned off and remove the fuse block

cover. If the lock is forcefully opened,

the fuse block cover may come in

contact with the frame when it is

removed and become scratched. When removing the cover, remove it

slowly according to the following

procedure:

1. Disengage the rear lock by pressing

down on the front tab with your fingers.

2. Remove the front tab while slightly

lifting the front of the cover.

3. Remove the cover while lifting it and

sliding it to the rear. 4. If any fuse but the main fuse is

blown, replace it with a new one of the

same amperage rating.

5. Reinstall the cover and make sure

that it is securely installed. 07031601-123-001

Underhood Fuse Block

1 — Lock

2 — Cover 07031601-ALL-002AB

Fuse

1 — Normal Fuse

2 — Blown Fuse

196

IN CASE OF EMERGENCY

Page 213 of 292

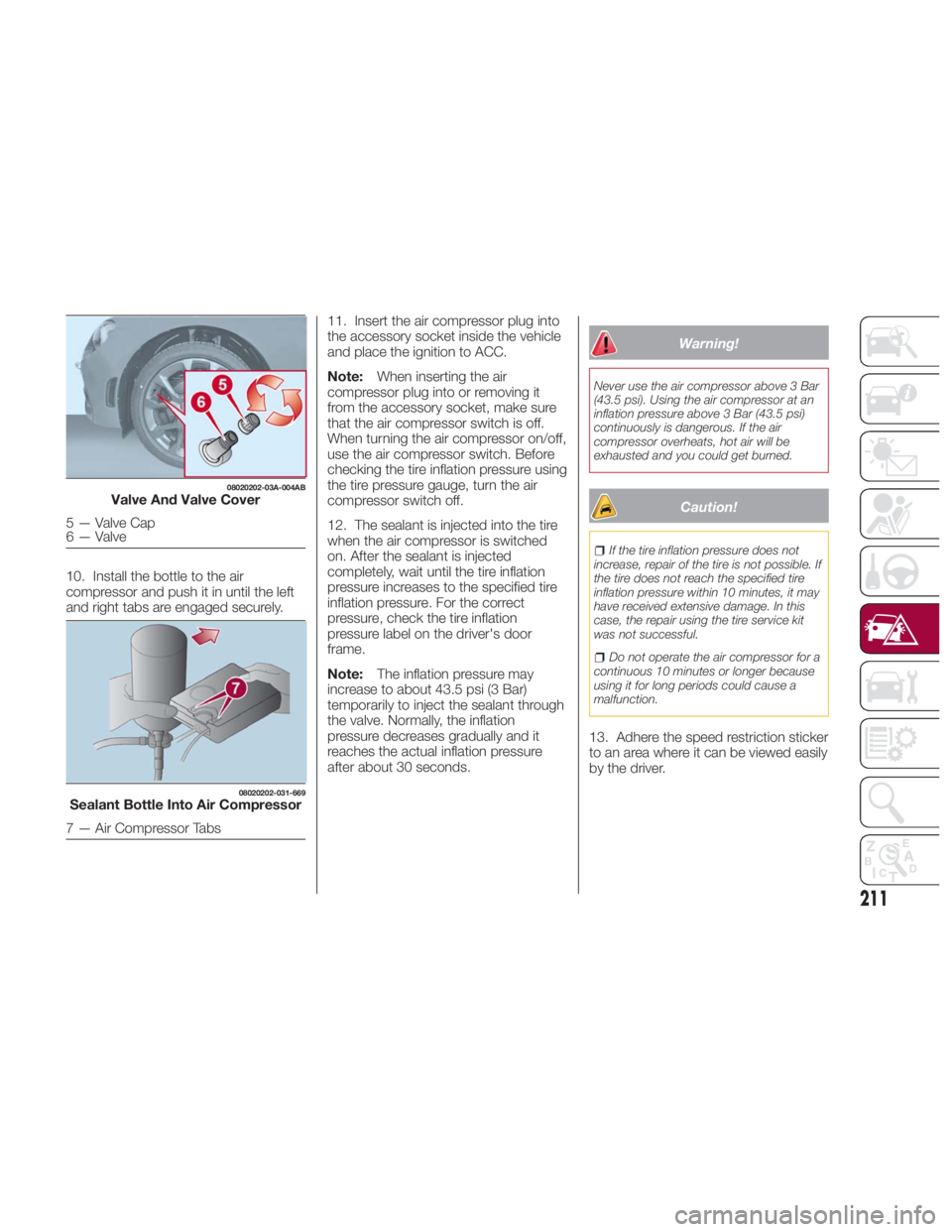

10. Install the bottle to the air

compressor and push it in until the left

and right tabs are engaged securely. 11. Insert the air compressor plug into

the accessory socket inside the vehicle

and place the ignition to ACC.

Note: When inserting the air

compressor plug into or removing it

from the accessory socket, make sure

that the air compressor switch is off.

When turning the air compressor on/off,

use the air compressor switch. Before

checking the tire inflation pressure using

the tire pressure gauge, turn the air

compressor switch off.

12. The sealant is injected into the tire

when the air compressor is switched

on. After the sealant is injected

completely, wait until the tire inflation

pressure increases to the specified tire

inflation pressure. For the correct

pressure, check the tire inflation

pressure label on the driver's door

frame.

Note: The inflation pressure may

increase to about 43.5 psi (3 Bar)

temporarily to inject the sealant through

the valve. Normally, the inflation

pressure decreases gradually and it

reaches the actual inflation pressure

after about 30 seconds. Warning!Never use the air compressor above 3 Bar

(43.5 psi). Using the air compressor at an

inflation pressure above 3 Bar (43.5 psi)

continuously is dangerous. If the air

compressor overheats, hot air will be

exhausted and you could get burned.

Caution! If the tire inflation pressure does not

increase, repair of the tire is not possible. If

the tire does not reach the specified tire

inflation pressure within 10 minutes, it may

have received extensive damage. In this

case, the repair using the tire service kit

was not successful.

Do not operate the air compressor for a

continuous 10 minutes or longer because

using it for long periods could cause a

malfunction.

13. Adhere the speed restriction sticker

to an area where it can be viewed easily

by the driver.08020202-03A-004AB

Valve And Valve Cover

5 — Valve Cap

6 — Valve 08020202-031-669

Sealant Bottle Into Air Compressor

7 — Air Compressor Tabs

211

Page 217 of 292

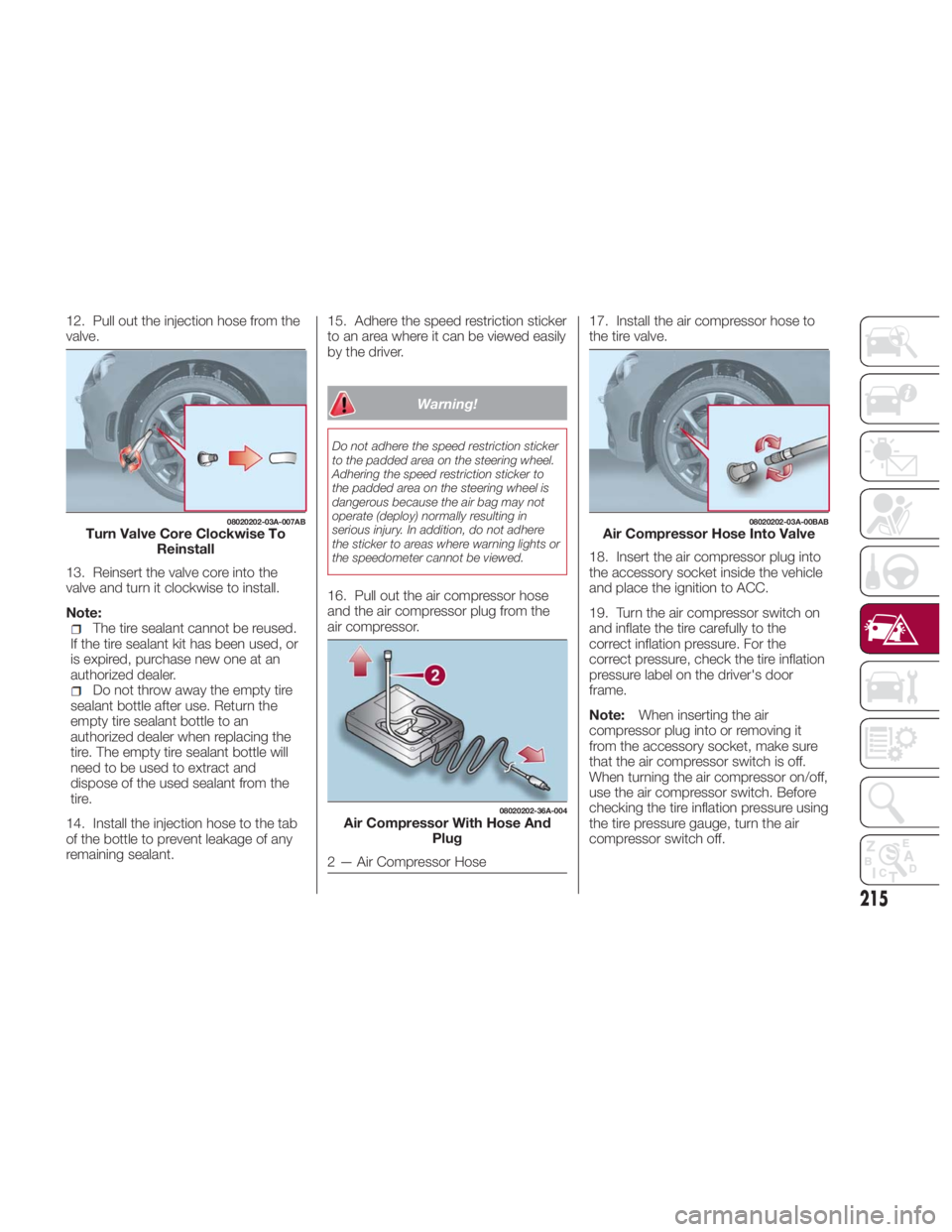

12. Pull out the injection hose from the

valve.

13. Reinsert the valve core into the

valve and turn it clockwise to install.

Note:

The tire sealant cannot be reused.

If the tire sealant kit has been used, or

is expired, purchase new one at an

authorized dealer.

Do not throw away the empty tire

sealant bottle after use. Return the

empty tire sealant bottle to an

authorized dealer when replacing the

tire. The empty tire sealant bottle will

need to be used to extract and

dispose of the used sealant from the

tire.

14. Install the injection hose to the tab

of the bottle to prevent leakage of any

remaining sealant. 15. Adhere the speed restriction sticker

to an area where it can be viewed easily

by the driver.

Warning!Do not adhere the speed restriction sticker

to the padded area on the steering wheel.

Adhering the speed restriction sticker to

the padded area on the steering wheel is

dangerous because the air bag may not

operate (deploy) normally resulting in

serious injury. In addition, do not adhere

the sticker to areas where warning lights or

the speedometer cannot be viewed.

16. Pull out the air compressor hose

and the air compressor plug from the

air compressor. 17. Install the air compressor hose to

the tire valve.

18. Insert the air compressor plug into

the accessory socket inside the vehicle

and place the ignition to ACC.

19. Turn the air compressor switch on

and inflate the tire carefully to the

correct inflation pressure. For the

correct pressure, check the tire inflation

pressure label on the driver's door

frame.

Note: When inserting the air

compressor plug into or removing it

from the accessory socket, make sure

that the air compressor switch is off.

When turning the air compressor on/off,

use the air compressor switch. Before

checking the tire inflation pressure using

the tire pressure gauge, turn the air

compressor switch off.08020202-03A-007AB

Turn Valve Core Clockwise To

Reinstall 08020202-36A-004

Air Compressor With Hose And

Plug

2 — Air Compressor Hose 08020202-03A-00BAB

Air Compressor Hose Into Valve

215

Page 224 of 292

If towing service is not available in an

emergency, the vehicle may be towed

with all four wheels on the ground using

the towing hook at the front of the

vehicle. Only tow the vehicle on paved

surfaces for short distances at low

speeds.

Follow these instructions when towing

the vehicle with all wheels on the

ground:

1. Shift to NEUTRAL for manual

transmission or automatic transmission.

2. Place the ignition to ACC.

3. Release the parking brake.

Note: Remember that power assist for

the brakes and steering will not be

available when the engine is not

running. EVENT DATA

RECORDER (EDR) This vehicle is equipped with an Event

Data Recorder (EDR). The main

purpose of an EDR is to record data

that will assist in understanding how a

vehicle’s systems performed under

certain crash or near crash-like

situations, such as an air bag

deployment or hitting a road obstacle.

Please refer to “Occupant Restraint

Systems” in “Safety” for further

information on the Event Data Recorder

(EDR).

222

IN CASE OF EMERGENCY

Page 234 of 292

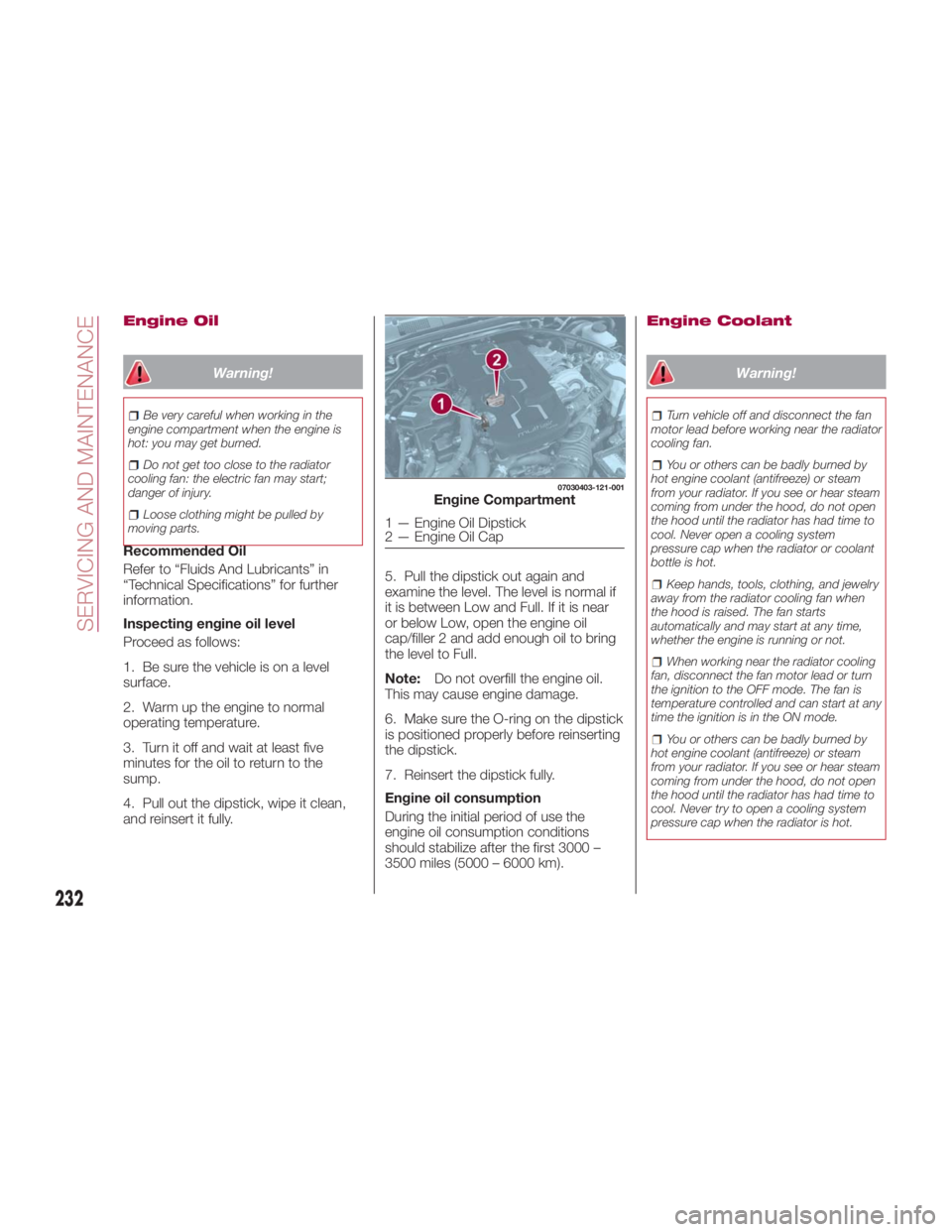

Engine Oil

Warning!Be very careful when working in the

engine compartment when the engine is

hot: you may get burned.

Do not get too close to the radiator

cooling fan: the electric fan may start;

danger of injury.

Loose clothing might be pulled by

moving parts.

Recommended Oil

Refer to “Fluids And Lubricants” in

“Technical Specifications” for further

information.

Inspecting engine oil level

Proceed as follows:

1. Be sure the vehicle is on a level

surface.

2. Warm up the engine to normal

operating temperature.

3. Turn it off and wait at least five

minutes for the oil to return to the

sump.

4. Pull out the dipstick, wipe it clean,

and reinsert it fully. 5. Pull the dipstick out again and

examine the level. The level is normal if

it is between Low and Full. If it is near

or below Low, open the engine oil

cap/filler 2 and add enough oil to bring

the level to Full.

Note: Do not overfill the engine oil.

This may cause engine damage.

6. Make sure the O-ring on the dipstick

is positioned properly before reinserting

the dipstick.

7. Reinsert the dipstick fully.

Engine oil consumption

During the initial period of use the

engine oil consumption conditions

should stabilize after the first 3000 –

3500 miles (5000 – 6000 km). Engine Coolant

Warning! Turn vehicle off and disconnect the fan

motor lead before working near the radiator

cooling fan.

You or others can be badly burned by

hot engine coolant (antifreeze) or steam

from your radiator. If you see or hear steam

coming from under the hood, do not open

the hood until the radiator has had time to

cool. Never open a cooling system

pressure cap when the radiator or coolant

bottle is hot.

Keep hands, tools, clothing, and jewelry

away from the radiator cooling fan when

the hood is raised. The fan starts

automatically and may start at any time,

whether the engine is running or not.

When working near the radiator cooling

fan, disconnect the fan motor lead or turn

the ignition to the OFF mode. The fan is

temperature controlled and can start at any

time the ignition is in the ON mode.

You or others can be badly burned by

hot engine coolant (antifreeze) or steam

from your radiator. If you see or hear steam

coming from under the hood, do not open

the hood until the radiator has had time to

cool. Never try to open a cooling system

pressure cap when the radiator is hot. 07030403-121-001

Engine Compartment

1 — Engine Oil Dipstick

2 — Engine Oil Cap

232

SERVICING AND MAINTENANCE