spare wheel FIAT STRADA 2015 Owner handbook (in English)

[x] Cancel search | Manufacturer: FIAT, Model Year: 2015, Model line: STRADA, Model: FIAT STRADA 2015Pages: 187, PDF Size: 8.06 MB

Page 111 of 187

109

If alloy wheels are

purchased to replace

the steel wheels, we

suggest that you retain 4

original bolts for use only with

the spare wheel. There is a risk

of damaging the wheel hubs.

Indicate the presence

of the stationary

vehicle in accordance with

current regulations: hazard

warning lights, warning triangle

etc. Passengers should get out

of the vehicle and wait until

replacement is concluded,

avoiding the risk of traffic. If

you are on a slope or uneven

surface, place wedges or other

suitable objects under the

wheels to secure the vehicle.

WARNINGCHANGING A WHEEL

Bear in mind that:

– the mass of the jack is 2.9 kg;

– the jack requires no adjustment;

– the jack cannot be repaired. It

must be replaced with an original

part if damaged;

– no tool other than the cranking

device illustrated in this section

may be fitted on the jack.

Never start the engine

when the vehicle is

jacked up.If a trailer is used,

detach the trailer before

raising the vehicle.

WARNING

107-132 STRADA LUM GB 1ed 9-01-2012 14:52 Pagina 109

Page 112 of 187

110

ACCESSING TOOLS, JACK

AND SPARE WHEEL

Fiat Strada, Short or

Extended Cab

The tool bag can be found behind

the driver’s seat. The bag may be

held with elastic straps or Velcro,

depending on the version.

The spare wheel may be housed

externally in the load compartment.Fiat Strada

Adventure Crew Cab

To access the tool bag, pull the

central handle and fold over the rear

cushion.

The spare wheel is housed

externally in the load compartment.

1) Remove the jack and its cranking

device.

2) Take the wheel wrench and,

depending on the version, the

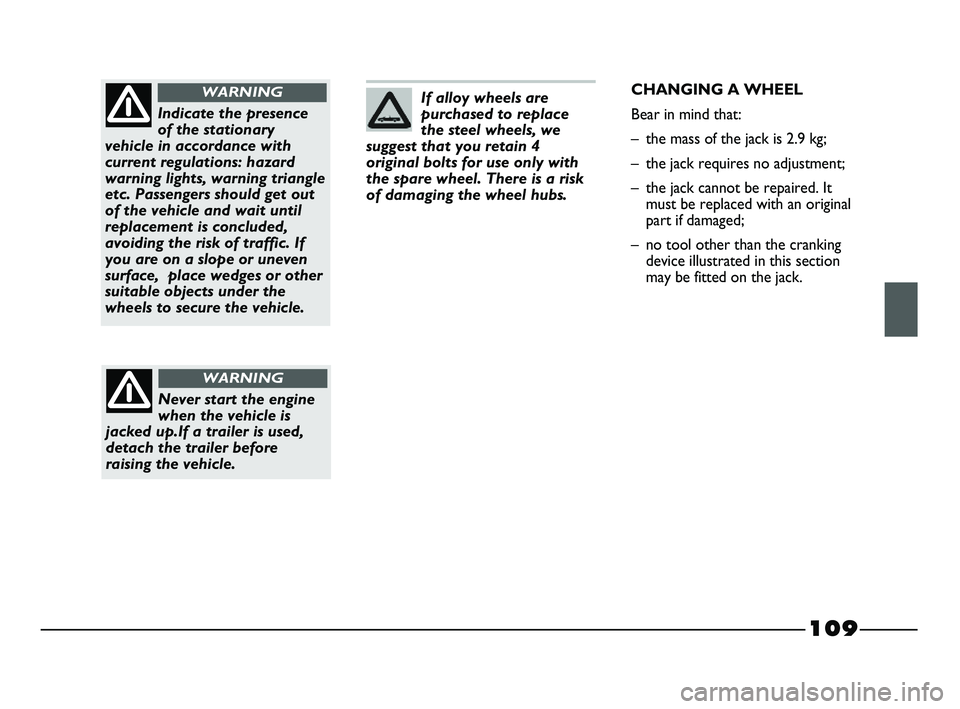

anti-theft bolt.3) Remove the spare wheel cover

canvas and completely unscrew

the ring nut A-fig. 112-113 using,

where necessary, the anti-theft

nut B-fig. 113.

fig. 113

F0X0094m

fig. 112

F0X0093m

fig. 110

F0X0091m

fig. 111

F0X0092m

107-132 STRADA LUM GB 1ed 9-01-2012 14:52 Pagina 110

Page 113 of 187

111

CHANGING THE WHEEL

1) Loosen the fixing bolts of the

wheel to be replaced by about

one turn.

2) With alloy wheels, shake the

vehicle to detach the rim from

the wheel hub more easily.

3) Turn the jack’s cranking device in

order to open it partially.

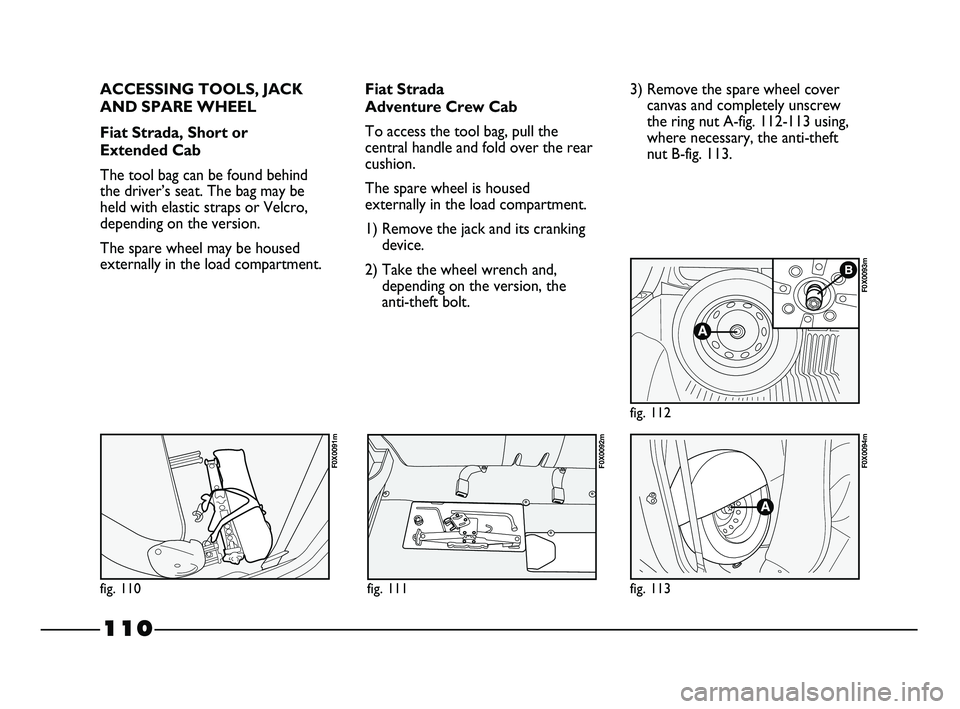

4) Arrange the jack at symbol B-fig. 114

close to the wheel to be replaced

and make sure than the groove A

of the jack is fitted firmly into side

member C.5) Warn any bystanders that the

vehicle is about to be lifted. They

must stay clear and be warned

not to touch the vehicle until it is

back on the ground.

6) Operate the jack’s cranking device

and lift the vehicle until the wheel

is several centimetres off the

ground. When turning the

cranking device, make sure that it

can turn freely without scraping

your hand against the ground. The

moving components of the jack

(screw and joints) can also cause

injuries: do not touch them.

If you come into contact with

lubricating grease, clean yourself

thoroughly.7) Completely unscrew the 4 bolts

and remove the hub cap (where

provided) and the wheel to be

replaced.

8) Make sure that the spare wheel

contact surfaces are clean and

that impurities are not present so

that the fixing bolts will not come

loose. Fit the spare wheel, aligning

the holes A-fig. 115 with the pins

B as appropriate.

9) Tighten one of the bolts A-fig. 116

near inflation valve B.

A

B

fig. 116

F0X0097m

fig. 114

F0X0095m

fig. 115

F0X0096m

107-132 STRADA LUM GB 1ed 9-01-2012 14:52 Pagina 111

Page 114 of 187

112

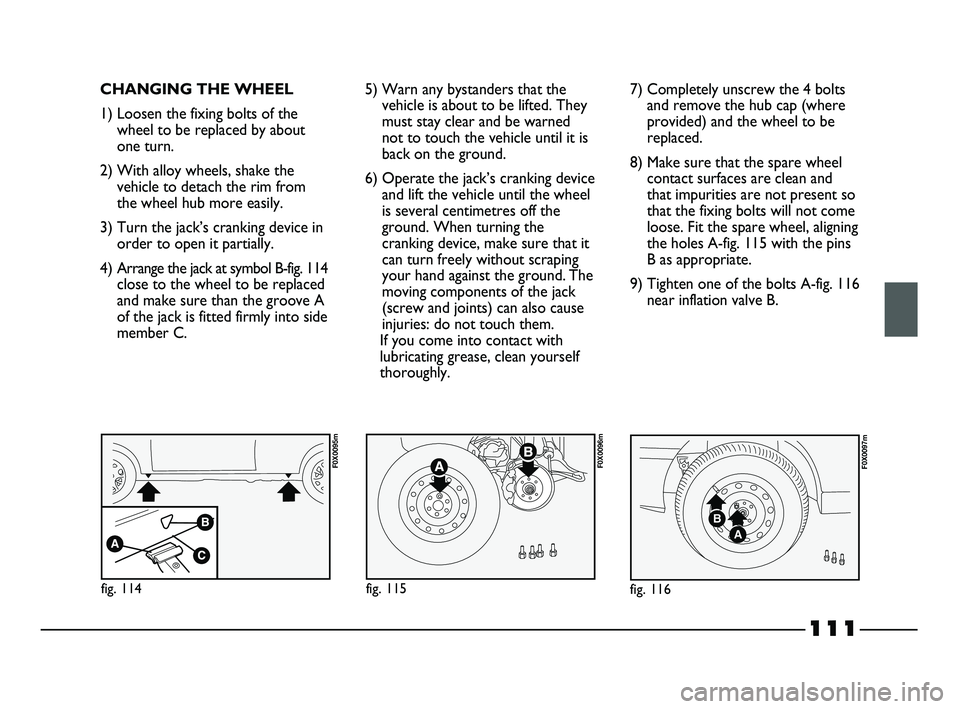

10) Fit the hub cap (where provided)

so that the largest hole A-fig.

117 is aligned with the bolt

which is already fixing the wheel.

11) Insert the remaining 3 bolts.

12) Tighten the bolts, using the

wrench provided.

13) Turn the jack’s cranking device

to lower the vehicle and remove

the jack.14) Fully tighten the bolts, passing

alternately from one bolt to the

opposite one, following the

order illustrated in fig. 118.

15) Unscrew the jack completely

and separate it from the

operating lever.

16) Place the cranking device back in

its housing.

17) Place the punctured wheel in the

spare wheel compartment and

fix it using the ring nut.

fig. 117

F0X0098m

fig. 118

F0X0099m

18) Position jack and tools in their

housings, fixing with the

appropriate retaining devices.

IMPORTANT As soon as possible:

have the punctured wheel repaired

and refit it on the vehicle, thereby

avoiding driving on the spare wheel.

IMPORTANT Check the pressure of

the tyres and the spare wheel

regularly.

107-132 STRADA LUM GB 1ed 9-01-2012 14:52 Pagina 112

Page 150 of 187

148

Tyres age even if they are not used

much. Cracks in the tread and on

the sidewalls are a sign of ageing. In

any event, have the tyres checked by

specialised personnel if they have

been fitted for longer than 6 years,

so that they can determine whether

they can still be used. Remember to

check the spare wheel with

particular care.

Always fit new replacement tyres.

Do not use any of dubious origin.

The Fiat Strada uses tubeless tyres.

Do not use inner tubes with these

tyres.

If a tyre is changed, also change the

inflation valve.

To allow even wear between the

front and rear tyres, it is advisable to

change them over every 10-15

thousand kilometres, keeping them

on the same side of the vehicle so as

not to reverse the direction of

rotation.RUBBER HOSES

For the rubber hoses of the brake,

power steering and supply system,

follow the Scheduled Servicing Plan

precisely. Ozone, high temperatures

and prolonged lack of fluid in the

system may cause hardening and

cracking of the hoses, with possible

leaks. Careful checking is therefore

necessary.Do not switch tyres

from the right hand side

of the vehicle to the left hand

side, and vice versa.

WARNING

Do not re coat alloy

wheel rims at

temperatures above 150°C. The

mechanical characteristics of

the wheels could be

compromised.

WARNING

133-154 STRADA LUM GB 1ed 9-01-2012 14:53 Pagina 148

Page 153 of 187

151

– spraying the underbody, engine

compartment, inside of wheel

arches and other parts with highly

protective wax products;

– spraying of plastic materials for

protective purposes in the most

exposed points: under the doors,

inside the wings, along the edges,

etc.;

– use of “open” boxed sections to

prevent condensation and pockets

of moisture from triggering rust

inside.

VEHICLE BODY AND

UNDERBODY WARRANTY

Your vehicle is covered by warranty

against perforation due to corrosion

of any original element of the

structure or body.

For the general terms of this

warranty, refer to the Warranty

Booklet.ADVICE FOR PRESERVING

THE BODYWORK

Paintwork

Paintwork does not only serve an

aesthetic purpose, but also protects

the underlying sheet metal.

Touch up abrasions and scratches

immediately to prevent the

formation of rust. Only use genuine

spare paint products for touch-ups

(see “Bodywork paint identification

plate” in the “Technical

Specifications” section).

Normal maintenance of paintwork

consists in washing the car: the

frequency depends on the conditions

and environment where the car is

used.

For example, it is advisable to wash

the vehicle more often in areas with

high levels of environmental

pollution or on roads spread with

salt.To correctly wash the vehicle,

proceed as follows:

– wash the body using a low

pressure jet of water;

– wipe a sponge with a slightly soapy

solution over the bodywork,

frequently rinsing the sponge;

– rinse well with water and dry with

a jet of air or a chamois leather.

If you put the vehicle through a car

wash, follow these

recommendations:

– remove the aerial from the roof so

that it does not get damaged;

– the vehicle should be washed with

water added to a soapy solution;

– rinse thoroughly to avoid soap

marks remaining on the bodywork

or less visible parts.

133-154 STRADA LUM GB 1ed 9-01-2012 14:53 Pagina 151

Page 163 of 187

161

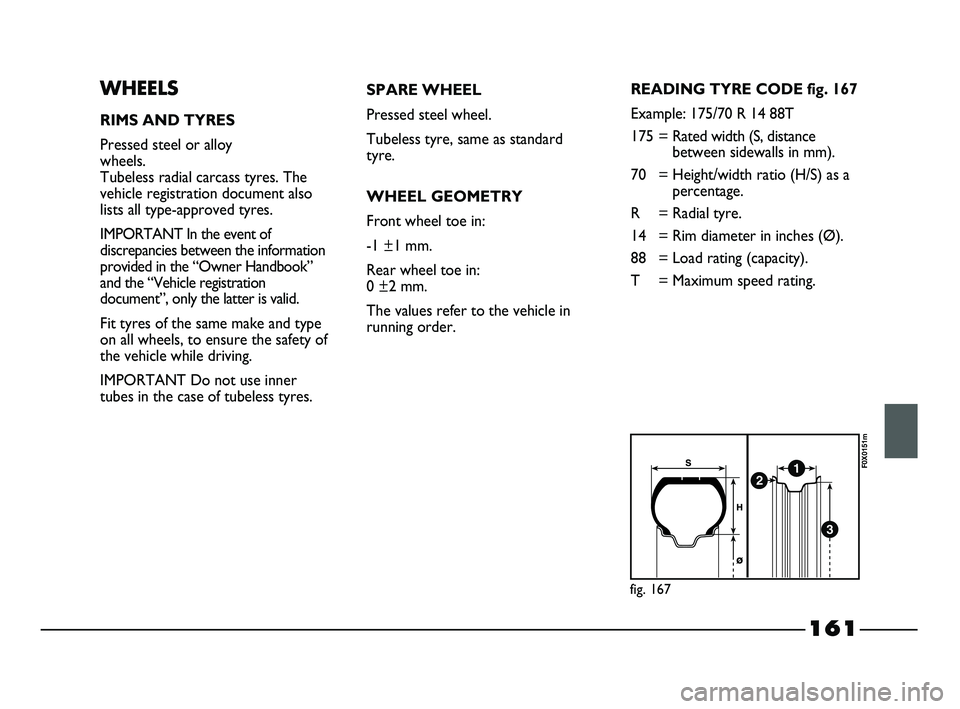

WHEELS

RIMS AND TYRES

Pressed steel or alloy

wheels.

Tubeless radial carcass tyres. The

vehicle registration document also

lists all type-approved tyres.

IMPORTANT In the event of

discrepancies between the information

provided in the “Owner Handbook”

and the “Vehicle registration

document”, only the latter is valid.

Fit tyres of the same make and type

on all wheels, to ensure the safety of

the vehicle while driving.

IMPORTANT Do not use inner

tubes in the case of tubeless tyres.

21

3

fig. 167

F0X0151m

SPARE WHEEL

Pressed steel wheel.

Tubeless tyre, same as standard

tyre.

WHEEL GEOMETRY

Front wheel toe in:

-1 ±1 mm.

Rear wheel toe in:

0 ±2 mm.

The values refer to the vehicle in

running order.READING TYRE CODE fig. 167

Example: 175/70 R 14 88T

175 = Rated width (S, distance

between sidewalls in mm).

70 = Height/width ratio (H/S) as a

percentage.

R = Radial tyre.

14 = Rim diameter in inches (Ø).

88 = Load rating (capacity).

T = Maximum speed rating.

155-184 STRADA LUM GB 1ed 20-01-2012 9:34 Pagina 161

Page 186 of 187

Fiat Group Automobiles S.p.A. - Parts & Services - Technical Services - \

Service EngineeringLargo Senatore G. Agnelli, 3 - 10040 Volvera - Torino (Italia)Print no. 603.99.088 - 04/2012 - 2 Edition

Technical specifications .................................................... 155

Third brake light ........................................................................\

.. 119

Topping up the en gine oil ........................................................... 139

Towing the vehicle....................................................................... 130

Towing tra ilers........................................................................\

...... 104

Trailers ( towing)........................................................................\

... 104

Transmi ssion........................................................................\

.......... 159

Trip compu ter ........................................................................\

...... 42

Tyre pr essure........................................................................\

........ 164

Tyres - inflation pressure............................................................. 147-164

- mainten ance........................................................................\

... 147

- reading rim code................................................................... 163

- reading t yre code .................................................................. 161

- Rim pr otector........................................................................\

162

- snow ........................................................................\

.......... 99-163

- spare wheel........................................................................\

.... 161

- specificati ons........................................................................\

.. 163

Using the gearbox .................................................................. 99

Vehicle inact ivity ..................................................................... 105

Vehicle lift ing ........................................................................\

... 128-129

Vehicle maintenance ........................................................ 133

Ventilati on ........................................................................\

........ 56-58

Warning lights and messages ................................................ 45

Warning lights and messages ..................................................... 45

Weight s ........................................................................\

.................. 167

Wheel geom etry ........................................................................\

. 161

Wheels - chang ing ........................................................... 109-110-111-112

- mainten ance........................................................................\

... 147

- specificati ons........................................................................\

.. 163

- wheel trim........................................................................\

...... 161

Window clea ning ........................................................................\

. 62

Windows - clea ning ........................................................................\

............ 62

- elect ric........................................................................\

............. 70

- manua l ........................................................................\

............. 70

- rear window ........................................................................\

... 77

Windscreen washer fluid level................................................... 141

Windscreen washer - contro l ......................................................................\

............. 62

- fluid le vel ........................................................................\

........ 141

Windscreen wiper - blade repla cement................................................................. 149

- contro l ........................................................................\

............. 62

- nozzle s ........................................................................\

............. 150

- smart w ashing........................................................................\

62

155-184 STRADA LUM GB 2ed 3-04-2012 15:00 Pagina 184