warning FIAT TEMPRA 1988 Service And User Guide

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 48 of 171

• Job 32. Change petrol fuel filter. IMPORTANT NOTES:

• Wear plastic gloves and goggles and have a large rag

and a suitable fire extinguisher ready.

• Place a container beneath the filter to catch fuel

spillage.

• After fitting the new filter in place, refit the casing,

ensure no traces of fuel are left, reconnect the battery and

restart the engine.

• Check carefully to ensure there are no leaks before

refitting the cover.

• Job 33. Drain diesel fuel filter.

IMPORTANT NOTE: Some models are fitted with a water-

in-fuel sensor. Drain the filter when the warning light

comes on. Unplug the sensor from the base of the filter,

first.

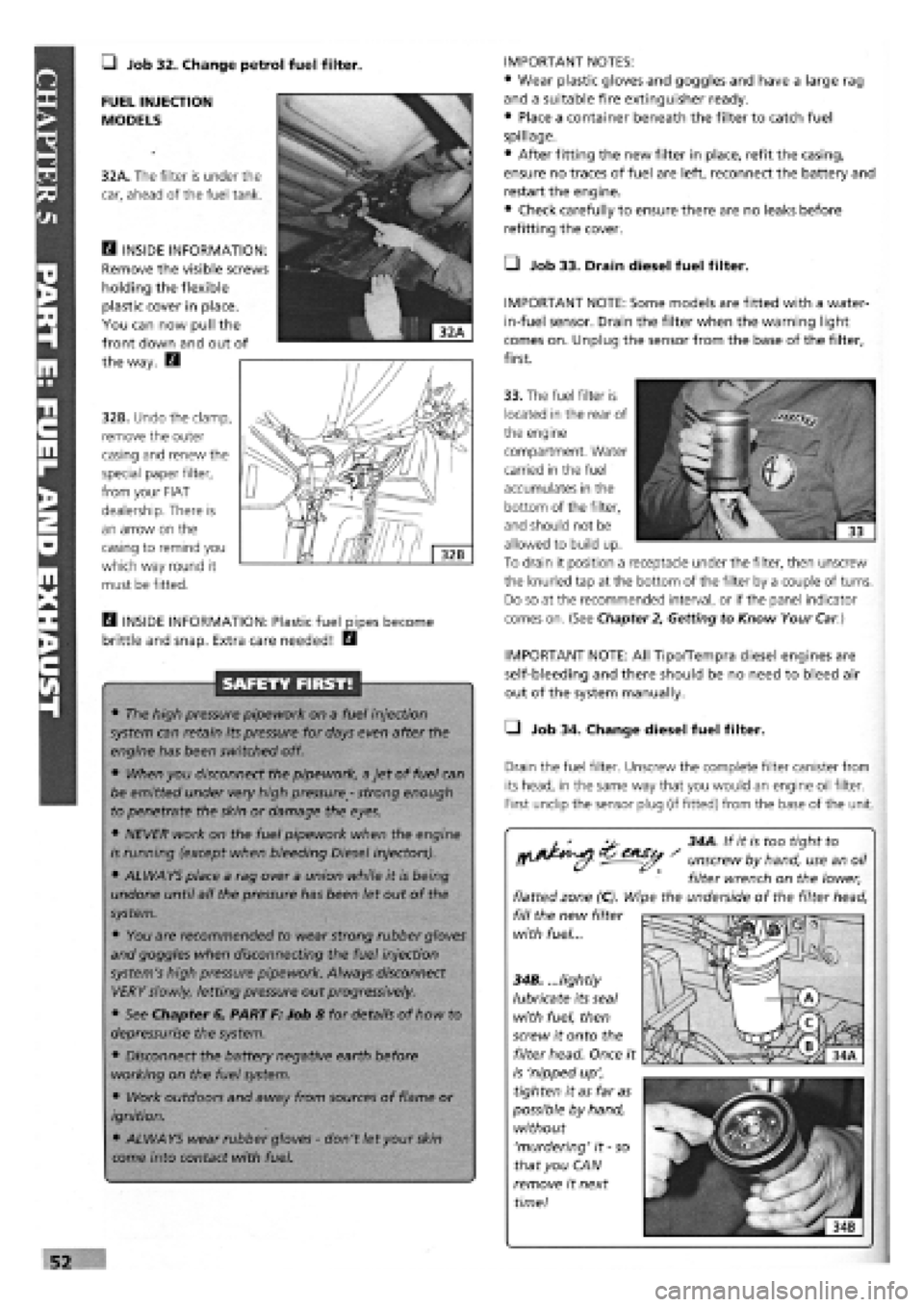

FUEL INJECTION

MODELS

32A. The filter is under the

car, ahead of the fuel tank.

E3 INSIDE INFORMATION:

Remove the visible screws

holding the flexible

plastic cover in place.

You can now pull the

front down and out of

the way. E3

32B. Undo the clamp,

remove the outer

casing and renew the

special paper filter,

from your FIAT

dealership. There is

an arrow on the

casing to remind you

which way round it

must be fitted.

33. The fuel filter is

located in the rear of

the engine

compartment. Water

carried in the fuel

accumulates in the

bottom of the filter,

and should not be

allowed to build up.

To drain it position a receptacle under the filter, then unscrew

the knurled tap at the bottom of the filter by a couple of turns.

Do so at the recommended interval, or if the panel indicator

comes on. (See Chapter

2,

Getting to Know Your

Car.)

H INSIDE INFORMATION: Plastic fuel pipes become

brittle and snap. Extra care needed! E3

SAFETY FIRST!

• The high pressure pipework on a fuel injection

system can retain its pressure for days even after the

engine has been switched off.

• When you disconnect the pipework, a jet of fuel can

be emitted under very high pressure

-

strong enough

to penetrate the skin or damage the eyes.

• NEVER work on the fuel pipework when the engine

is running (except when bleeding Diesel injectors).

• ALWAYS place a rag over a union while it is being

undone until all the pressure has been let out of the

system.

• You are recommended to wear strong rubber gloves

and goggles when disconnecting the fuel injection

system's high pressure pipework. Always disconnect

VERY slowly, letting pressure out progressively.

• See Chapter 6, PART F: Job 8 for details of how to

depressurise the system.

• Disconnect the battery negative earth before

working on the fuel system.

• Work outdoors and away from sources of flame or

ignition.

• ALWAYS wear rubber gloves

-

don't let your

skin

come into contact with fuel.

IMPORTANT NOTE: All Tipo/Tempra diesel engines are

self-bleeding and there should be no need to bleed air

out of the system manually.

• Job 34. Change diesel fuel filter.

Drain the fuel filter. Unscrew the complete filter canister from

its head, in the same way that you would an engine oil filter.

First undip the sensor plug (if fitted) from the base of the unit.

^ 34A. If it is too tight to

^^ - unscrew by hand, use an oil

filter wrench on the lower,

flatted zone (C). Wipe the underside of the filter head,

fill the new filter

with fuel...

34B. ...lightly

lubricate its seal

with fuel, then

screw it onto the

filter head. Once it

is 'nipped up',

tighten it as far as

possible by hand,

without

'murdering' it

-

so

that you CAN

remove it next

time!

Page 74 of 171

• Step 30: Fit

the crankshaft

pulley and

tighten. See

Chapter 3,

Facts and

Figures.

• Step 31: Fit the

water pump and

distribution pipe.

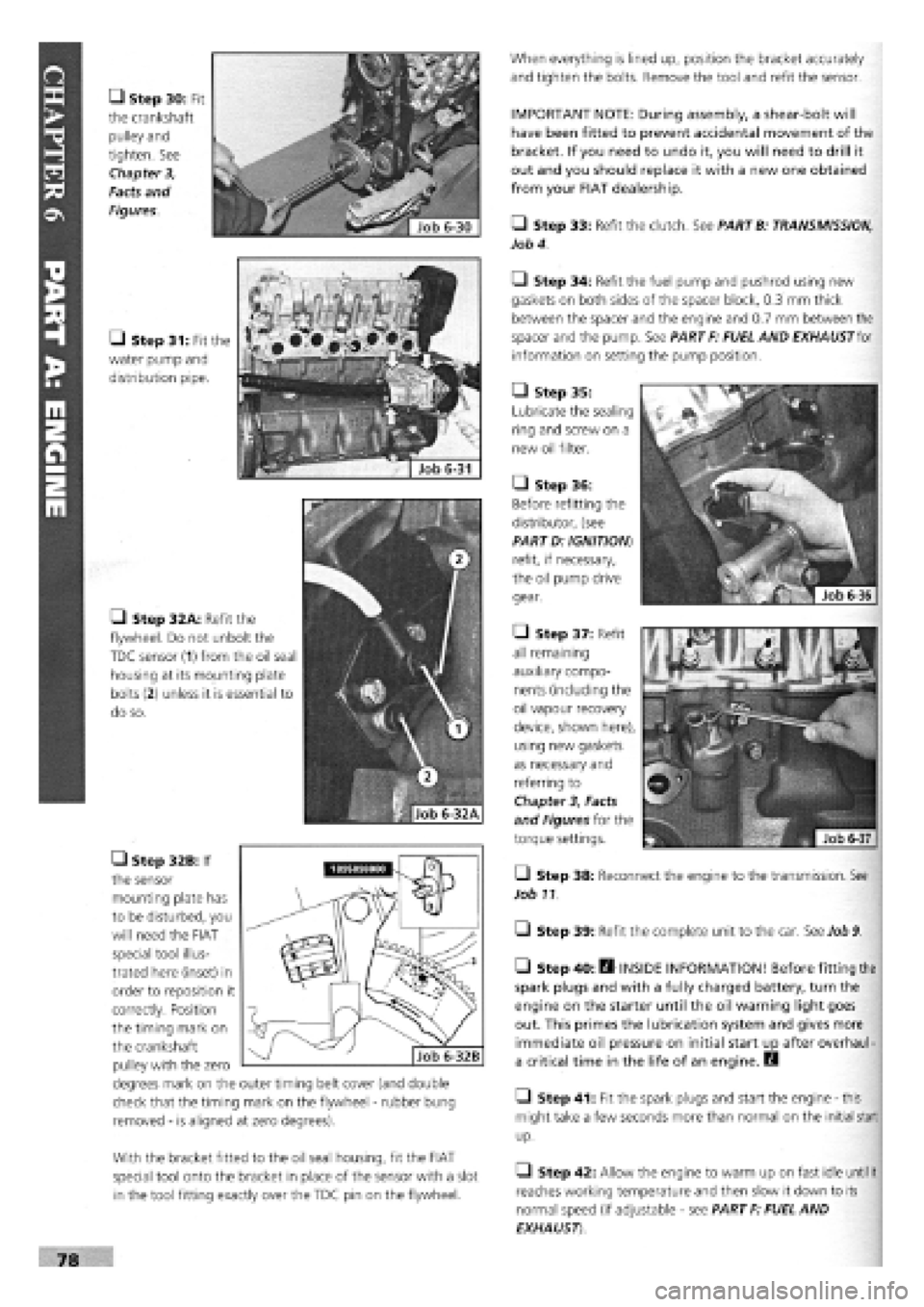

• Step 32A: Refit the

flywheel. Do not unbolt the

TDC sensor (1) from the oil seal

housing at its mounting plate

bolts

(2)

unless it is essential to

do so.

• Step 32B: If

the sensor

mounting plate has

to be disturbed, you

will need the FIAT

special tool illus-

trated here (inset) in

order to reposition it

correctly. Position

the timing mark on

the crankshaft

pulley with the zero

degrees mark on the outer timing belt cover (and double

check that the timing mark on the flywheel

-

rubber bung

removed

-

is aligned at zero degrees).

With the bracket fitted to the oil seal housing, fit the FIAT

special tool onto the bracket in place of the sensor with a slot

in the tool fitting exactly over the TDC pin on the flywheel.

When everything is lined up, position the bracket accurately

and tighten the bolts. Remove the tool and refit the sensor.

IMPORTANT NOTE: During assembly, a shear-bolt will

have been fitted to prevent accidental movement of the

bracket. If you need to undo it, you will need to drill it

out and you should replace it with a new one obtained

from your FIAT dealership.

• Step 33: Refit the clutch. See PARTB: TRANSMISSION,

Job 4.

Q Step 34: Refit the fuel pump and pushrod using new

gaskets on both sides of the spacer block, 0.3 mm thick

between the spacer and the engine and 0.7 mm between the

spacer and the pump. See PART F: FUEL AND EXHAUST for

information on setting the pump position.

• Step 35:

Lubricate the sealing

ring and screw on a

new oil filter.

• Step 36:

Before refitting the

distributor, (see

PART D: IGNITION)

refit, if necessary,

the oil pump drive

gear.

• Step 37: Refit

all remaining

auxiliary compo-

nents (including the

oil vapour recovery

device, shown here),

using new gaskets

as necessary and

referring to

Chapter

3,

Facts

and Figures for the

torque settings.

Q Step 38: Reconnect the engine to the transmission. See

Job 11.

Q Step 39: Refit the complete unit to the car. See Job

9.

• Step 40: fl INSIDE INFORMATION! Before fitting the

spark plugs and with a fully charged battery, turn the

engine on the starter until the oil warning light goes

out. This primes the lubrication system and gives more

immediate oil pressure on initial start up after overhaul-

a critical time in the life of an engine. B

• Step 41: Fit the spark plugs and start the engine

-

this

might take a few seconds more than normal on the initial start

up.

• Step 42: Allow the engine to warm up on fast idle

until

it

reaches working temperature and then slow it down to its

normal speed (if adjustable

-

see PART F: FUEL AND

EXHAUST)

Page 84 of 171

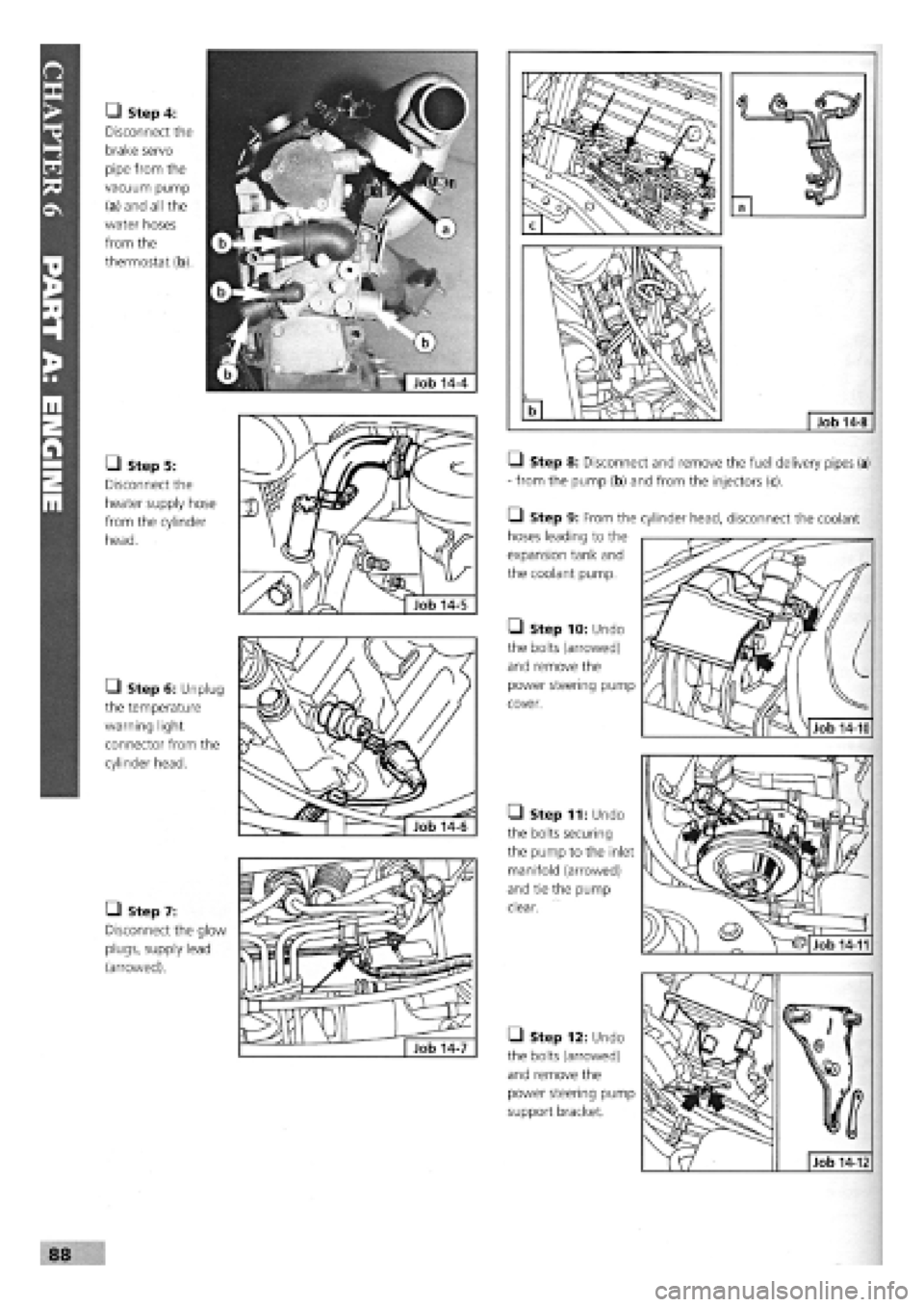

• Step 4:

Disconnect the

brake servo

pipe from the

vacuum pump

(a) and all the

water hoses

from the

thermostat (b).

• Step 5:

Disconnect the

heater supply hose

from the cylinder

head.

• Step 6: Unplug

the temperature

warning light

connector from the

cylinder head.

• Step 7:

Disconnect the glow

plugs, supply lead

(arrowed).

Q Step 8: Disconnect and remove the fuel delivery pipes (a)

- from the pump (b) and from the injectors (c).

• Step 9: From the

hoses leading to the

expansion tank and

the coolant pump.

• Step 10: Undo

the bolts (arrowed)

and remove the

power steering pump

cover.

• Step 11: Undo

the bolts securing

the pump to the inlet

manifold (arrowed)

and tie the pump

clear.

• Step 12: Undo

the bolts (arrowed)

and remove the

power steering pump

support bracket.

88

cylinder head, disconnect the coolant

Job 14-10

Job 14-12

Job 14-11

Page 89 of 171

Job 17. Diesel engine.

Valve clearances - adjustment.

D INSIDE INFORMATION! After carrying out Job 16,

valve clearance measurement and adjustment is now

needed. Both measurement and shim replacement are

carried out in the same manner as for the petrol engine

(.Job

7), so refer to this and also to Chapter 3, Facts

and Figures for specifications. B

Job 18. Diesel engine - removal.

moving parts with engine oil during assembly. See Chapter 3,

Facts

and Figures for specified tightening torques.

luei suppiy diiu leium pipe;>

at the injection pump...

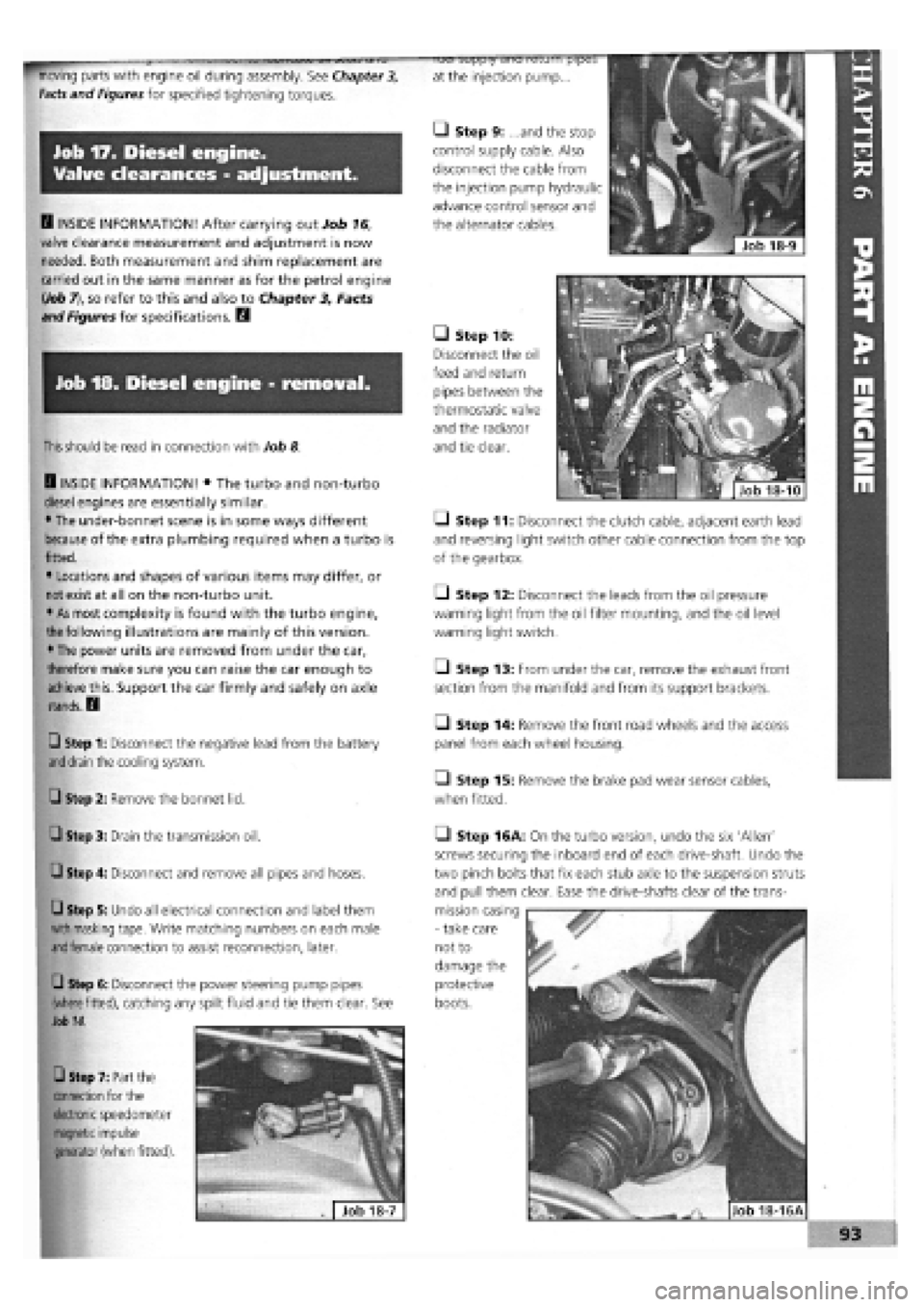

• Step 9: ...and the stop

control supply cable. Also

disconnect the cable from

the injection pump hydraulic

advance control sensor and

the alternator cables.

• Step 10:

Disconnect the oil

feed and return

pipes between the

thermostatic valve

and the radiator

and tie clear.

I

This should

be read in connection with Job 8

Q INSIDE INFORMATION! • The turbo and non-turbo

diesel engines are essentially similar.

• The under-bonnet scene is in some ways different

because of the extra plumbing required when a turbo is

fitted.

• Locations and shapes of various items may differ, or

not exist at all on the non-turbo unit.

• As most complexity is found with the turbo engine,

I

the

following illustrations are mainly of this version.

• The power units are removed from under the car,

therefore make sure you can raise the car enough to

achieve this. Support the car firmly and safely on axle

stands. D

Q Step 1: Disconnect the negative lead from the battery

and drain

the cooling system. Q Step 2: Remove the bonnet lid.

• Step 3: Drain the transmission oil.

Q Step 4: Disconnect and remove all pipes and hoses.

Q Step 5: Undo all electrical connection and label them

with masking

tape. Write matching numbers on each male

and female

connection to assist reconnection, later.

Q Step 6: Disconnect the power steering pump pipes

(where fitted),

catching any spilt fluid and tie them clear. See

Job 14.

• Step 7: Part the

connection for the

electronic

speedometer

magnetic impulse

generator

(when fitted).

Q Step 11: Disconnect the clutch cable, adjacent earth lead

and reversing light switch other cable connection from the top

of the gearbox.

• Step 12: Disconnect the leads from the oil pressure

warning light from the oil filter mounting, and the oil level

warning light switch.

• Step 13: From under the car, remove the exhaust front

section from the manifold and from its support brackets.

O Step 14: Remove the front road wheels and the access

panel from each wheel housing.

• Step 15: Remove the brake pad wear sensor cables,

when fitted.

Q Step 16A: On the turbo version, undo the six 'Allen'

screws securing the inboard end of each drive-shaft. Undo the

two pinch bolts that fix each stub axle to the suspension struts

and pull them clear. Ease the drive-shafts clear of the trans-

mission casing

-

take care

not to

damage the

protective

boots.

Page 114 of 171

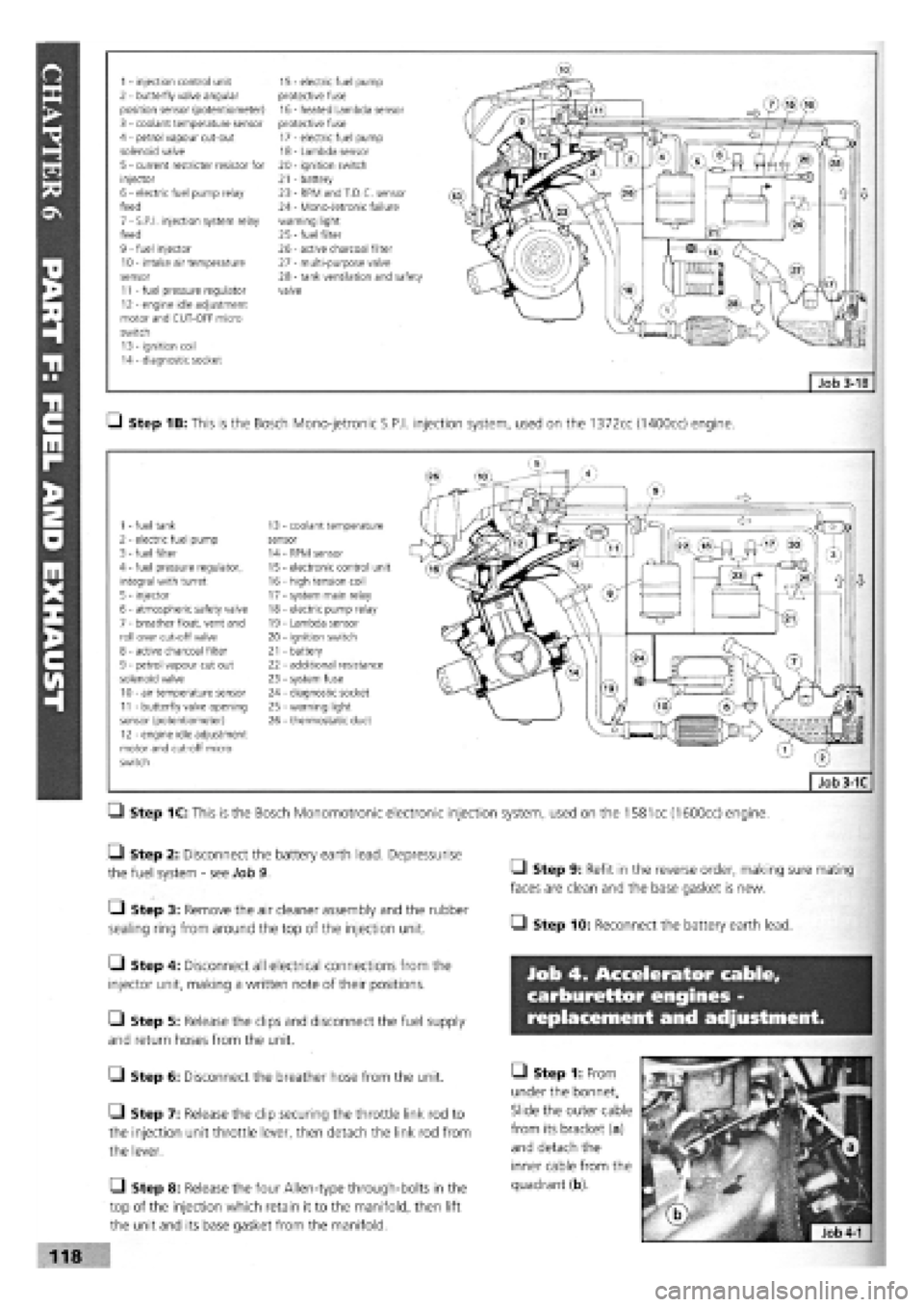

1 - injection control unit 15 - electric fuel pump 2 - butterfly valve angular protective fuse position sensor (potentiometer) 16 - heated Lambda sensor 3 - coolant temperature sensor protective fuse 4 - petrol vapour cut-out 17 - electric fuel pump solenoid valve 18 - Lambda sensor 5 - current restricter resistor for 20 - ignition switch injector 21 - battery 6 - electric fuel pump relay 23 - RPM and T.D.C. sensor feed 24 - Mono-Jetronic failure 7 - S.P.I, injection system relay warning light feed 25

-

fuel filter 9 - fuel injector 26 - active charcoal filter 10 - intake air temperature 27 - multi-purpose valve sensor 28 - tank ventilation and safety 11 - fuel pressure regulator valve 12 - engine idle adjustment motor and CUT-OFF micro switch 13 - ignition coil 14 - diagnostic socket

Q Step 1B: This is the Bosch Mono-jetronic S.P.I, injection system, used on the 1372cc (1400cc) engine.

1 - fuel tank 13 coolant temperature 2 - electric fuel pump sensor 3 - fuel filter 14 RPM sensor 4 - fuel pressure regulator, 15 electronic control unit integral with turret 16 - high tension coil 5 - injector 17 - system main relay 6 - atmospheric safety valve 18 - electric pump relay 7 - breather float, vent and 19 - Lambda sensor roll over cut-off valve 20 - ignition switch 8 - active charcoal filter 21 - battery 9 - petrol vapour cut out 22 - additional resistance solenoid valve 23 - system fuse 10 - air temperature sensor 24 - diagnostic socket 11 - butterfly valve opening 25 - warning light sensor (potentiometer) 26 - thermostatic duct 12 - engine idle adjustment motor and cut-off micro switch

Q Step 1C: This is the Bosch Monomotronic electronic injection system, used on the

1581

cc (1600cc) engine.

• Step 2: Disconnect the battery earth lead. Depressurise

the fuel system

-

see Job 9.

• Step 3: Remove the air cleaner assembly and the rubber

sealing ring from around the top of the injection unit.

Q Step 4: Disconnect all electrical connections from the

injector unit, making a written note of their positions.

Q Step 5: Release the clips and disconnect the fuel supply

and return hoses from the unit.

G Step 6: Disconnect the breather hose from the unit.

• Step 7: Release the clip securing the throttle link rod to

the injection unit throttle lever, then detach the link rod from

the lever.

Q Step 8: Release the four Allen-type through-bolts in the

top of the injection which retain it to the manifold, then lift

the unit and its base gasket from the manifold.

• Step 9: Refit in the reverse order, making sure mating

faces are clean and the base gasket is new.

• Step 10: Reconnect the battery earth lead.

Job 4. Accelerator cable,

carburettor engines -

replacement and adjustment.

• Step 1: From

under the bonnet,

Slide the outer cable

from its bracket (a)

and detach the

inner cable from the

quadrant (b).

118

Page 115 of 171

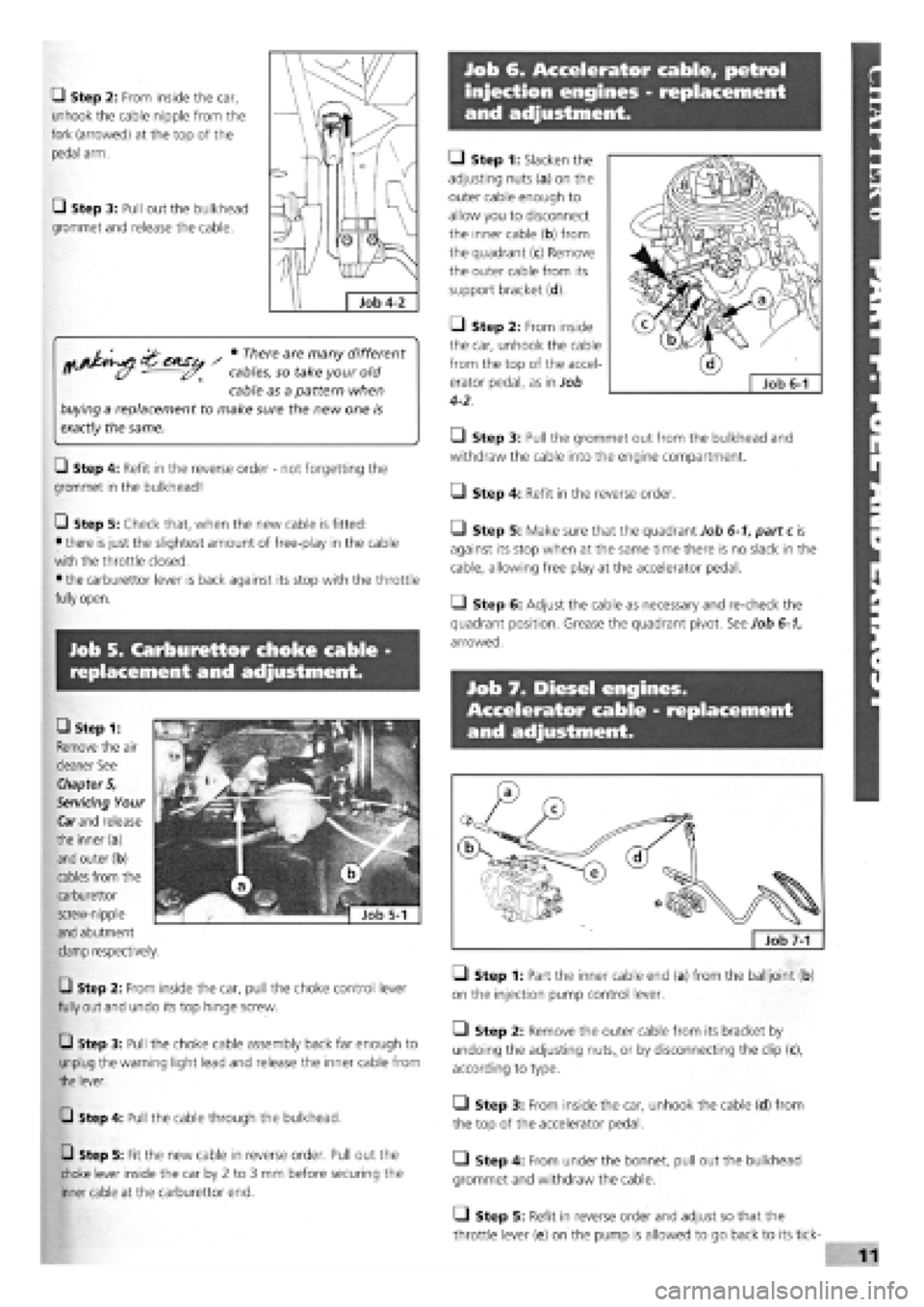

Job 6. Accelerator cable, petrol

injection engines - replacement

and adjustment.

Q Step 2: From inside the car,

unhook the cable nipple from the

fork (arrowed) at the top of the

pedal arm.

• Step 3: Pull out the bulkhead

grommet and release the cable.

^ • There are many different

cables, so take your old

cable as a pattern when

buying a replacement to make sure the new one is

exactly

the same.

Q Step 4: Refit in the reverse order

-

not forgetting the

grommet in the bulkhead!

Q Step 5: Check that, when the new cable is fitted:

• there

is

just the slightest amount of free-play in the cable

with the throttle closed.

• the carburettor lever is back against its stop with the throttle

fully open.

• Step 1: Slacken the

adjusting nuts (a) on the

outer cable enough to

allow you to disconnect

the inner cable (b) from

the quadrant (c) Remove

the outer cable from its

support bracket (d).

Q Step 2: From inside

the car, unhook the cable

from the top of the accel-

erator pedal, as in Job

4-2.

• Step 3: Pull the grommet out from the bulkhead and

withdraw the cable into the engine compartment.

O Step 4: Refit in the reverse order.

• Step 5: Make sure that the quadrant Job 6-1, part c is

against its stop when at the same time there is no slack in the

cable, allowing free play at the accelerator pedal.

• Step 6: Adjust the cable as necessary and re-check the

quadrant position. Grease the quadrant pivot. See Job 6-1,

arrowed.

Job 7. Diesel engines.

Accelerator cable - replacement

and adjustment.

Job 5. Carburettor choke cable -

replacement and adjustment.

Q Step 2: From inside the car, pull the choke control lever

fully out and undo its top hinge screw.

Q Step 3: Pull the choke cable assembly back far enough to

unplug the warning light lead and release the inner cable from

the lever.

Q Step 4: Pull the cable through the bulkhead.

Q Step 5: Fit the new cable in reverse order. Pull out the

choke lever inside the car by 2 to 3 mm before securing the

inner cable at the carburettor end.

Q Step 1: Part the inner cable end (a) from the balljoint (b)

on the injection pump control lever.

• Step 2: Remove the outer cable from its bracket by

undoing the adjusting

nuts,,

or by disconnecting the clip (c),

according to type.

• Step 3: From inside the car, unhook the cable (d) from

the top of the accelerator pedal.

• Step 4: From under the bonnet, pull out the bulkhead

grommet and withdraw the cable.

Q Step 5: Refit in reverse order and adjust so that the

throttle lever (e) on the pump is allowed to go back to its tick-

CD Step 1:

Remove the air

cleaner See

Chapter 5,

Servicing Your

Car

and

release

the inner(a)

and outer (b)

cables from the

carburettor

screw-nipple

and abutment

clamp respectively.

Page 119 of 171

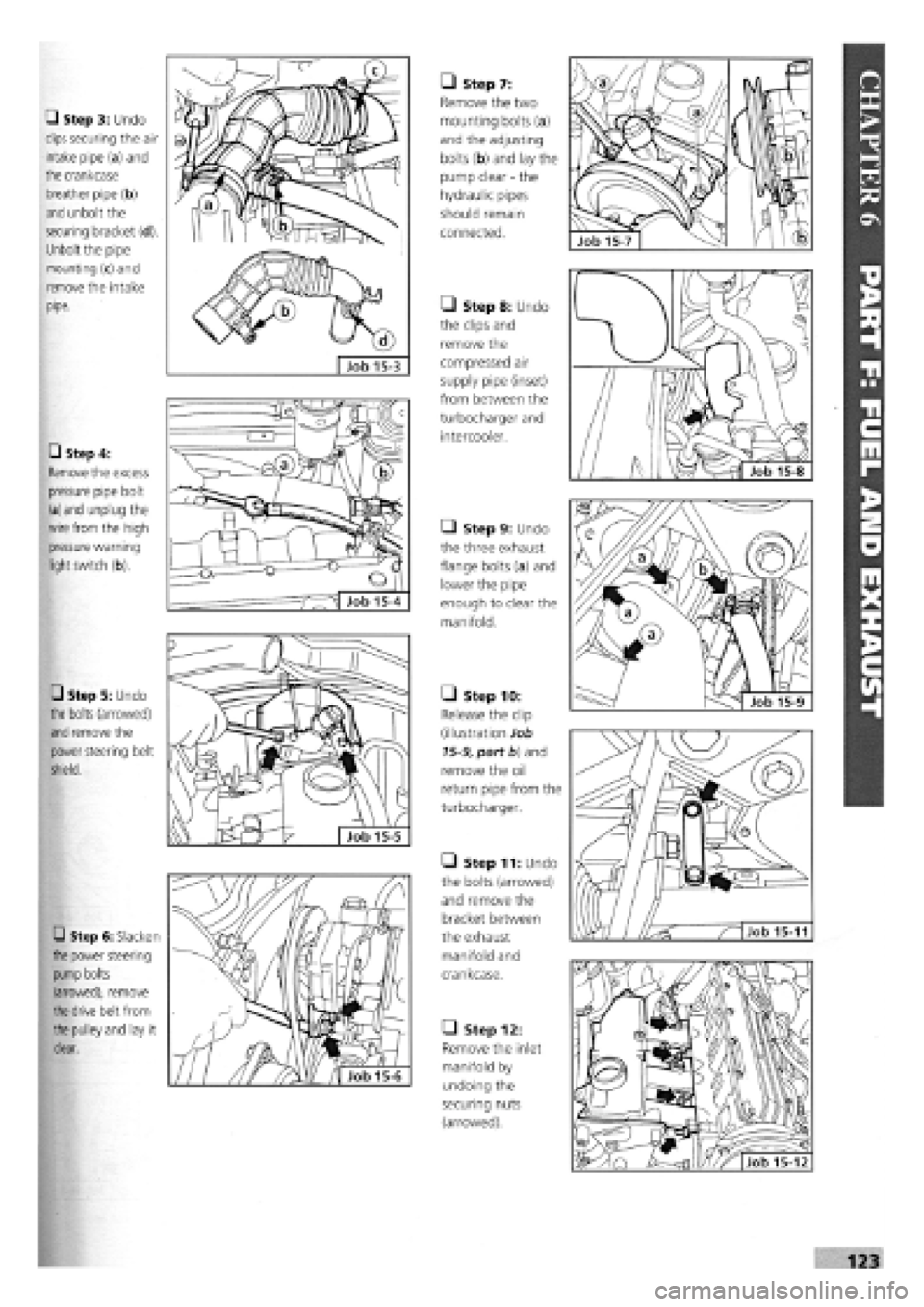

• Step 3: Undo

clips securing the air

intake pipe (a) and

the crankcase

breather pipe (b)

and unbolt the

securing bracket (d).

Unbolt the pipe

mounting (c) and

remove the intake

pipe.

• Step 4:

Remove the excess

pressure pipe bolt

(a)

and

unplug the

wire from

the high

pressure warning

light

switch (b).

• Step 5: Undo

the

bolts (arrowed)

and

remove the

power steering belt

shield.

• Step 6: Slacken

the

power steering

pump

bolts

(arrowed), remove

the

drive belt from

the

pulley and lay it

clear.

7"

e

L Job 15-5

• Step 7:

Remove the two

mounting bolts (a)

and the adjusting

bolts (b) and lay the

pump clear

-

the

hydraulic pipes

should remain

connected.

• Step 8: Undo

the clips and

remove the

compressed air

supply pipe (inset)

from between the

turbocharger and

intercooler.

• Step 9: Undo

the three exhaust

flange bolts (a) and

lower the pipe

enough to clear the

manifold.

• Step 10:

Release the clip

(illustration Job

15-9, part fa) and

remove the oil

return pipe from the

turbocharger.

• Step 11: Undo

the bolts (arrowed)

and remove the

bracket between

the exhaust

manifold and

crankcase.

• Step 12:

Remove the inlet

manifold by

undoing the

securing nuts

(arrowed).

O)

T'

123

Page 130 of 171

• Step 8:

Support the

axle beam with

the jack and

undo the

mounting bolts

(arrowed and

indicated by

operator with

socket bar).

Lower the

complete unit

from the car.

IMPORTANT NOTE: In this shot, the top shock absorber

mountings have been disconnected, leaving the shock

absorber fitted to the suspension and the coil springs in

place. We recommend 'our' approach, covered in Step 7!

• Step 9: Undo the bolts securing the anti-roll bar and

remove it. (See Job 9.) Disconnect the brake pipes from the

side to be worked on and remove the brake drum.

Q Step 10: Remove the hub cap (see illustration Job 1-1D,

part 13) by carefully tapping and levering with a screwdriver.

• Step 11: Undo the hub nut (see illustration Job 1-1D,

part

10).

PART H: BRAKES

• Step 12: A special tool

(1857508000) or a VERY

strong Allen key (a) will be

required to reach into the

hub (b), and plenty of

leverage!

Q Step 13: Remove the

hub and inspect the bearing

for roughness or noise or

roughness when turning it by hand.

E3 INSIDE INFORMATION! The bearing is lubricated for

life and is only supplied as an assembly with the hub. B

• Step 14: Inspect the stub axle pin (see illustration Job

1-

1D, part

12)

for any signs of damage or distortion. Replace if

in doubt.

Q Step 15: Refitting is the reverse of removal but note the

following:

• See Chapter

3,

Facts and Figures for all tightening

torques as you progress through the assembling.

• Use new hub nuts and fully tighten once the suspension is

mounted to give you stability.

• Refer to PART H: BRAKES when refitting the brake parts

and bleeding the brakes.

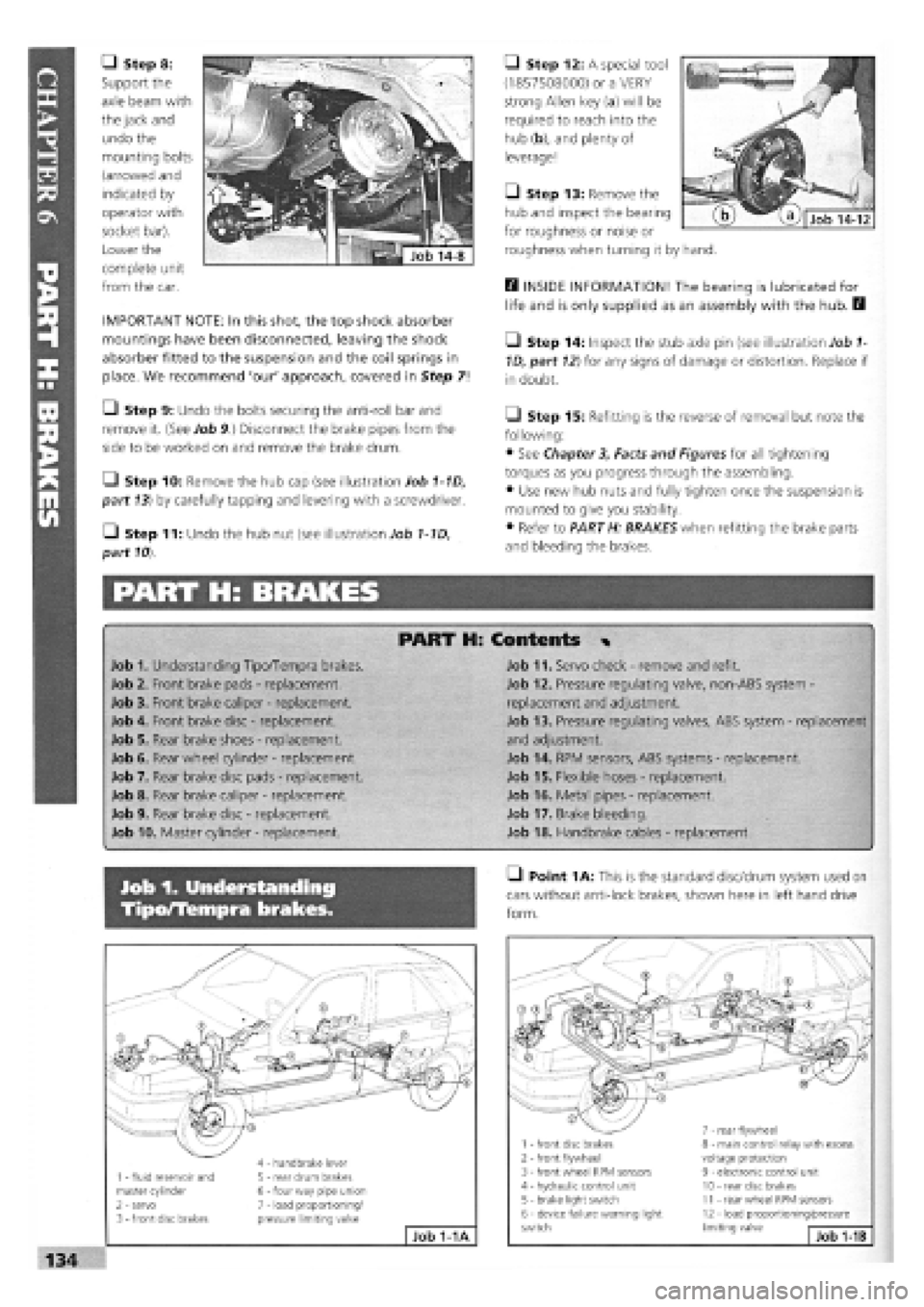

PART H: Contents %

Job 1. Understanding Tipo/Tempra brakes.

Job 2. Front brake pads

-

replacement.

Job 3. Front brake caliper

-

replacement.

Job 4. Front brake disc

-

replacement.

Job 5. Rear brake shoes

-

replacement.

Job 6. Rear wheel cylinder

-

replacement.

Job 7. Rear brake disc pads

-

replacement.

Job 8. Rear brake caliper

-

replacement.

Job 9. Rear brake disc

-

replacement.

Job 10. Master cylinder

-

replacement.

Job 11. Servo check

-

remove and refit.

Job 12. Pressure regulating valve, non-ABS system -

replacement and adjustment.

Job 13. Pressure regulating valves, ABS system

-

replacement

and adjustment.

Job 14. RPM sensors, ABS systems

-

replacement.

Job 15. Flexible hoses

-

replacement.

Job 16. Metal pipes

-

replacement.

Job 17. Brake bleeding.

Job 18. Handbrake cables

-

replacement.

Job 1. Understanding

Tipo/Tempra brakes.

• Point

1

A: This is the standard disc/drum system used on

cars without anti-lock brakes, shown here in left hand drive

form.

1 - fluid reservoir and master cylinder 2 - servo 3

-

front disc brakes

4 - handbrake lever 5 - rear drum brakes 6

-

four way pipe union 7 - load proportioning/ pressure limiting valve

Job 1-1A

1 - front disc brakes 2

-

front flywheel 3 - front wheel RPM sensors 4 - hydraulic control unit 5 - brake light switch 6 - device failure warning light switch

7 - rear flywheel 8 - main control relay with excess voltage protection 9 - electronic control unit 10 - rear disc brakes 11 - rear wheel RPM sensors 12 - load proportioning/pressure limiting valve Job

1-1B

Page 140 of 171

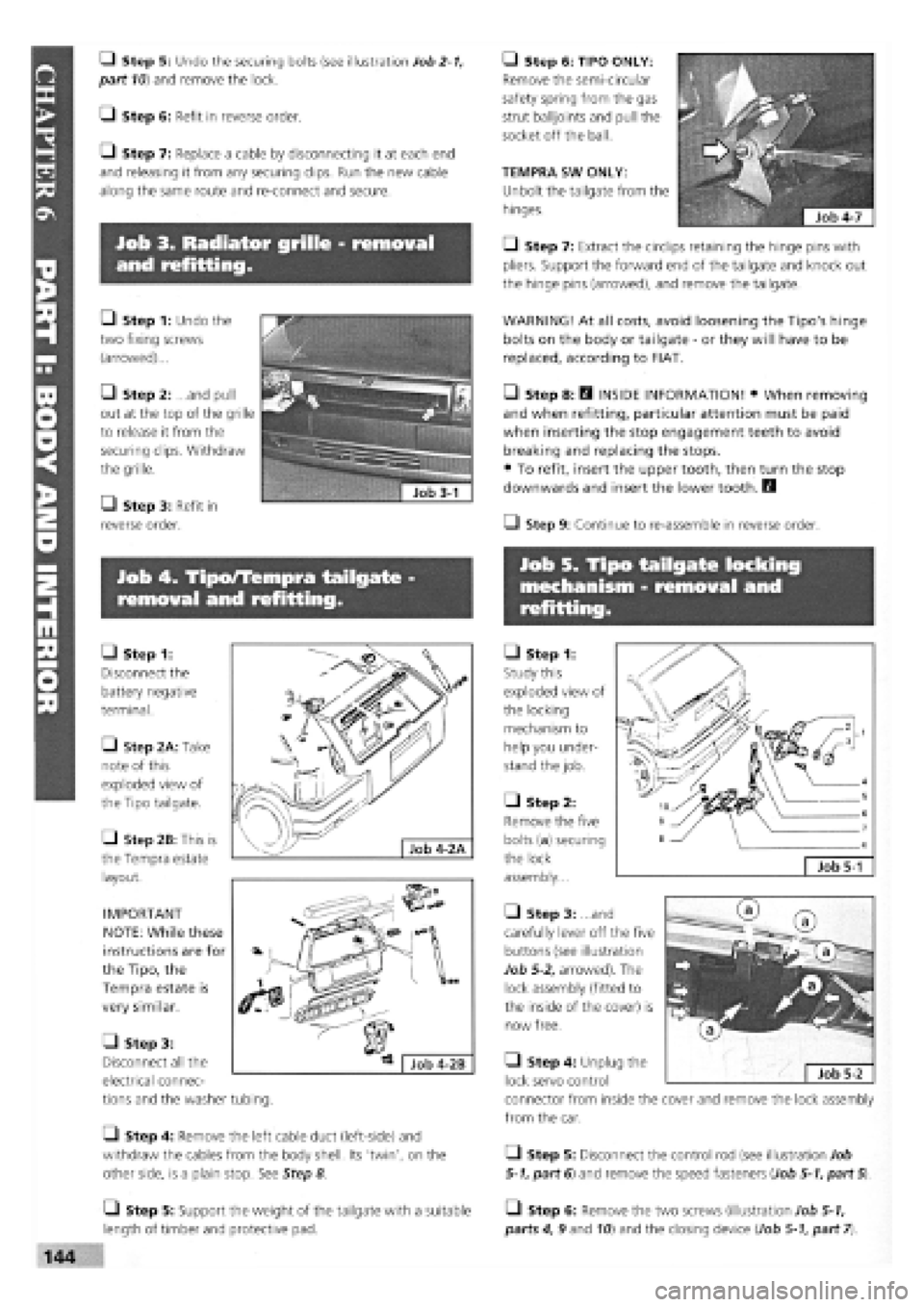

Job 3. Radiator grille - removal

and refitting.

Job 5. Tipo tailgate locking

mechanism - removal and

refitting.

Job 4. Tipo/Tempra tailgate -

removal and refitting.

Q Step 5: Undo the securing bolts (see illustration Job

2-1,

part

10)

and remove the lock.

Q Step 6: Refit in reverse order.

Q Step 7: Replace a cable by disconnecting it at each end

and releasing it from any securing clips. Run the new cable

along the same route and re-connect and secure.

• Step 1: Undo the

two fixing screws

(arrowed)...

Q Step 2: ...and pull

out at the top of the grille

to release it from the

securing clips. Withdraw

the grille.

• Step 3: Refit in

reverse order.

• Step 1:

Disconnect the

battery negative

terminal.

• Step 2A: Take

note of this

exploded view of

the Tipo tailgate.

• Step 2B: This is

the Tempra estate

layout.

IMPORTANT

NOTE: While these

instructions are for

the Tipo, the

Tempra estate is

very similar.

• Step 1:

Study this

exploded view of

the locking

mechanism to

help you under-

stand the job.

• Step 2:

Remove the five

bolts (a) securing

the lock

assembly...

• Step 3: ...and

carefully lever off the five

buttons (see illustration

Job

5-2,

arrowed). The

lock assembly (fitted to

the inside of the cover) is

now free.

• Step 6: TIPO ONLY:

Remove the semi-circular

safety spring from the gas

strut balljoints and pull the

socket off the ball.

TEMPRA SW ONLY:

Unbolt the tailgate from the

hinges.

• Step 7: Extract the circlips retaining the hinge pins with

pliers. Support the forward end of the tailgate and knock out

the hinge pins (arrowed), and remove the tailgate.

WARNING! At all costs, avoid loosening the Tipo's hinge

bolts on the body or tailgate

-

or they will have to be

replaced, according to FIAT.

• Step 8: H INSIDE INFORMATION! • When removing

and when refitting, particular attention must be paid

when inserting the stop engagement teeth to avoid

breaking and replacing the stops.

• To refit, insert the upper tooth, then turn the stop

downwards and insert the lower tooth. B

Q Step 9: Continue to re-assemble in reverse order.

Job 5-1

• Step 3:

Disconnect all the

electrical connec-

tions and the washer tubing.

• Step 4: Remove the left cable duct (left-side) and

withdraw the cables from the body shell. Its 'twin', on the

other side, is a plain stop. See Step 8

• Step 4: Unplug the

lock servo control

connector from inside the cover and remove the lock assembly

from the car.

Q Step 5: Disconnect the control rod (see illustration Job

5-1,

part 6) and remove the speed fasteners (Job

5-1,

part

5).

• Step 5: Support the weight of the tailgate with a suitable

length of timber and protective pad.

• Step 6: Remove the two screws (illustration Job

5-1,

parts 4, 9 and

10)

and the closing device (Job

5-1,

part

7).

Page 151 of 171

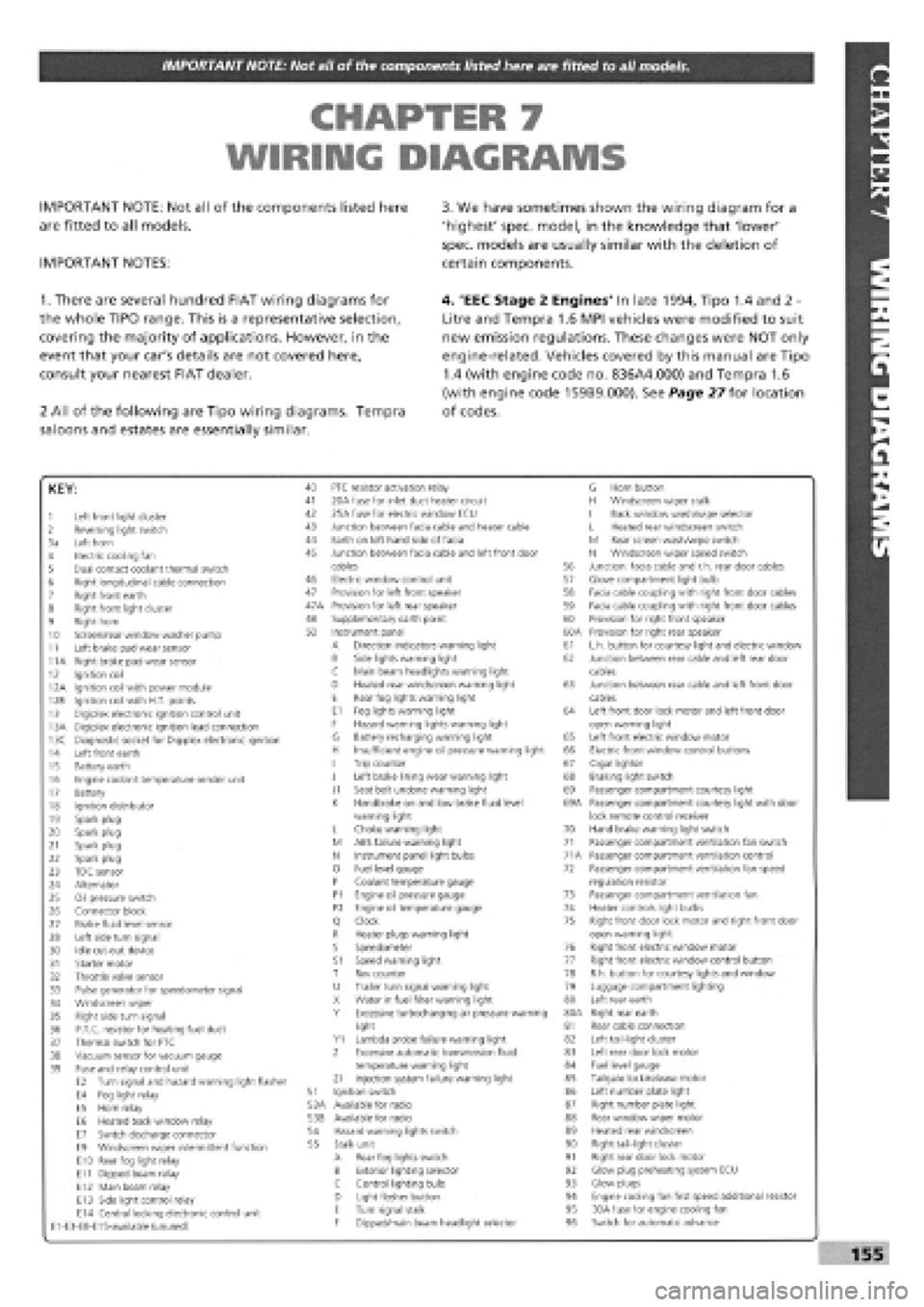

IMPORTANT NOTE: Not all of the components listed here are fitted to all models.

CHAPTER 7

WIRING DIAGRAMS

IMPORTANT NOTE: Not all of the components listed here

are fitted to all models.

IMPORTANT NOTES:

3. We have sometimes shown the wiring diagram for a

'highest' spec, model, in the knowledge that 'lower'

spec, models are usually similar with the deletion of

certain components.

1. There are several hundred FIAT wiring diagrams for

the whole TIPO range. This is a representative selection,

covering the majority of applications. However, in the

event that your car's details are not covered here,

consult your nearest FIAT dealer.

2 All of the following are Tipo wiring diagrams. Tempra

saloons and estates are essentially similar.

4. 'EEC Stage 2 Engines' In late 1994, Tipo 1.4 and 2 -

Litre and Tempra 1.6 MPI vehicles were modified to suit

new emission regulations. These changes were NOT only

engine-related. Vehicles covered by this manual are Tipo

1.4 (with engine code no. 836A4.000) and Tempra 1.6

(with engine code 159B9.000). See Page 27 for location

of codes.

KEY:

1 Left front light cluster 2 Reversing light switch 3a Left horn 4 Electric cooling fan 5 Dual contact coolant thermal switch 6 Right longitudinal cable connection 7 Right front earth 8 Right front light cluster 9 Right horn 10 Screen/rear window washer pump 11 Left brake pad wear sensor 11A Right brake pad wear sensor 12 Ignition coil 12A Ignition coil with power module 12B Ignition coil with H.T. points 13 Digiplex electronic ignition control unit 13A Digiplex electronic ignition lead connection 13C Diagnostic socket for Digiplex electronic ignition 14 Left front earth 15 Battery earth 16 Engine coolant temperature sender unit 17 Battery 18 Ignition distributor 19 Sparkplug 20 Spark plug 21 Sparkplug 22 Spark plug 23 TDC sensor 24 Alternator 25 Oil pressure switch 26 Connector block 27 Brake fluid level sensor 28 Left side turn signal 30 Idle cut-out device 31 Starter motor 32 Throttle valve sensor 33 Pulse generator for speedometer signal 34 Windscreen wiper 35 Right side turn signal 36 P.T.C. resistor for heating fuel duct 37 Thermal switch for PTC 38 Vacuum sensor for vacuum gauge 39 Fuse and relay control unit E2 Turn signal and hazard warning light flasher E4 Fog light relay E5 Horn relay E6 Heated back window relay E7 Switch discharge connector E9 Windscreen wiper intermittent function E10 Rear fog light relay E11 Dipped beam relay E12 Main beam relay E13 Side light control relay E14 Central locking electronic control unit E1-E3-E8-E15-available (unused)

40 PTC resistor activation relay 41 20A fuse for inlet duct heater circuit 42 25A fuse for electric window ECU 43 Junction between facia cable and heater cable 44 Earth on left hand side of facia 45 Junction between facia cable and left front door

G Horn button H Windscreen wiper stalk I Back window wash/wipe selector L Heated rear windscreen switch M Rear screen wash/wipe switch N Windscreen wiper speed switch cables 56 Junction: facia cable and r.h. rear door cables Electric window control unit 57 Glove compartment light bulb Provision for left front speaker 58 Facia cable coupling with right front door cables Provision for left rear speaker 59 Facia cable coupling with right front door cables Supplementary earth point 60 Provision for right front speaker Instrument panel 60A Provision for right rear speaker A Direction indicators warning light 61 L.h. button for courtesy light and electric window B Side lights warning light 62 Junction between rear cable and left rear door C Main beam headlights warning light cables D Heated rear windscreen warning light 63 Junction between rear cable and left front door E Rear fog lights warning light cables E1 Fog lights warning light 64 Left front door lock motor and left front door F Hazard warning lights warning light open warning light G Battery recharging warning light 65 Left front electric window motor H Insufficient engine oil pressure warning light 66 Electric front window control buttons I Trip counter 67 Cigar lighter J Left brake lining wear warning light 68 Braking light switch J1 Seat belt undone warning light 69 Passenger compartment courtesy light K Handbrake on and low brake fluid level 69A Passenger compartment courtesy light with door warning light lock remote control receiver L Choke warning light 70 Hand brake warning light switch M ABS failure warning light 71 Passenger compartment ventilation fan switch N Instrument panel light bulbs 71A Passenger compartment ventilation control 0 Fuel level gauge 72 Passenger compartment ventilation fan speed P Coolant temperature gauge regulation resistor P1 Engine oil pressure gauge 73 Passenger compartment ventilation fan P2 Engine oil temperature gauge 74 Heater controls light bulbs Q Clock 75 Right front door lock motor and right front door R Heater plugs warning light open warning light S Speedometer 76 Right front electric window motor S1 Speed warning light 77 Right front electric window control button T Rev counter 78 R.h. button for courtesy lights and window U Trailer turn signal warning light 79 Luggage compartment lighting X Water in fuel filter warning light 80 Left rear earth Y Excessive turbocharging air pressure warning 80A Right rear earth light 81 Rear cable connection Y1 Lambda probe failure warning light 82 Left tail-light cluster Z Excessive automatic transmission fluid 83 Left rear door lock motor temperature warning light 84 Fuel level gauge Z1 Injection system failure warning light 85 Tailgate lock/release motor Ignition switch 86 Left number plate light Available for radio 87 Right number plate light Available for radio 88 Rear window wiper motor Hazard warning lights switch 89 Heated rear windscreen Stalk unit 90 Right tail-light cluster A Rear fog lights switch 91 Right rear door lock motor B Exterior lighting selector 92 Glow plug preheating system ECU c Control lighting bulb 93 Glow plugs D Light flasher button 94 Engine cooling fan first speed additional resistor E Turn signal stalk 95 30A fuse for engine cooling fan F Dipped/main beam headlight selector 96 Switch for automatic advance

155