ECO mode FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 5 of 171

Please read the whole of the CHAPTER 1, SAFETY FIRST! before carrying out any work on your car.

CHAPTER 2

USING YOUR CAR

This Chapter is taken from

FIAT's own official Handbooks

on the Tipo and Tempra. It

contains important and

helpful information for the

operation of your FIAT Tipo or

Tempra.

KEYS AND LOCKS

• 1. DOORS AMD BONNET

DOOR LOCKS

Most FIAT Tipos and Tempras have manual locking. You

turn the key in the lock in the normal way to lock and

unlock the door.

CHILDPROOF LOCKS

1 A.

Some models are

fitted with childproof

locks. You will find them

in the ends of the rear

doors, when open.

• Place your ignition key in

notch A, in the end of the

door, when open.

• Turn to the right to lock the childproof rear door

locks; turn to the left to unlock.

REMOTE LOCKING/UNLOCKING

1B. A

directional

signal is

emitted

when you

press button

C on your

remote unit

(early

models) or

on your

ignition key

(later

models).

IMPORTANT NOTE: The presence of dirt, snow or

ice on the side windows may prevent operation.

We recommend that you

read this chapter

carefully, so that you will

become familiar with your

vehicle's controls and

instruments.

Receiving Unit In Car: The receiving unit can store up

to 6 codes. Tag D, supplied with every receiver, has a

code number stamped on it. Keep this tag in a safe

place

-

replacements are very expensive.

To Store the Code of Your Transmitter:

• Press and hold down button A with a ball-point pen.

The red LED B illuminates, indicating that the receiving

unit is ready to store the code.

• Hold down button C on your remote unit/ignition key.

• The LED at B turns off, indicating that the receiver has

stored the code.

• Release Button A. Red LED B flashes for about 8

seconds to confirm that the code has been stored.

If you press button A again within 8 seconds, the red

LED B illuminates indicating that the receiving unit is

ready to store another code. Repeat the procedure.

If you lose a remote unit there are two ways to store a

new code:

Using a Remote Unit With Code Already Stored:

• Press and hold down button A. After about 2 seconds

red LED B flashes once.

• Press button C on the remote whose code has been

stored. Red LED B illuminates.

• Release button A. Red LED B flashes for 8 seconds

indicating new code has been stored.

Manual Operation: Have tag D ready. The four

numbers stamped on the tag will be used in this

procedure:

• Press Button A twice. Red LED B flashes 3 times and

then turns off for about 2 seconds.

• When LED B lights up again, press button A the

number of times indicated by the first code number on

tag D (if 0 do not press the button). Two seconds after

pressing button A , LED B will turn off for 2 seconds.

Page 6 of 171

• Repeat this operation three more times until the

complete code number has been entered, if the code

has been entered in correctly LED B will start flashing.

• Release button A (see illustration

1B).

Red LED B

flashes for 8 seconds indicating the new remote unit's

code has been stored.

IMPORTANT NOTE: If the LED does not illuminate

when remote unit button (illustration 1B, button

O is pressed, change the remote unit's battery.

• Insert the emergency key A into the emergency switch

slot in the glove compartment turn the key to the left to

switch the alarm off (see inset).

• Turn the key back towards its original position to

switch the alarm system back on.

IMPORTANT NOTE: As the alarm system absorbs

energy, if you are not planning on using the car

for a long period of time, turn the alarm exclusion

key to the off position, so as not to run the vehicle

battery down.

• 2. IGNITION SWITCH AND

STEERING COLUMN LOCK

IGNITION SWITCH

2. The ignition/steering column lock key, once inserted

in the ignition lock, can be placed in any of the

following four positions:

• PARK

-

With the key in this

position the side and tail lights

can be turned on, the steering

column locked and the keys

can be removed. Press button

A to turn the key to PARK.

• STOP

-

When the key is

turned to the STOP position the steering column will be

locked, and the keys can be removed.

• MAR

-

This is the driving position. When the key is in

this position all the electrical devices are energised.

• AW

-

Turning the key to this position starts the

engine.

STEERING COLUMN LOCK

• LOCKING

-

To apply the steering wheel lock turn the

steering wheel slightly to the left or right when the key is

at STOP or PARK.

• UNLOCKING

-

Rocking the steering wheel gently back

and forth while turning the ignition key to MAR unlocks

the steering wheel.

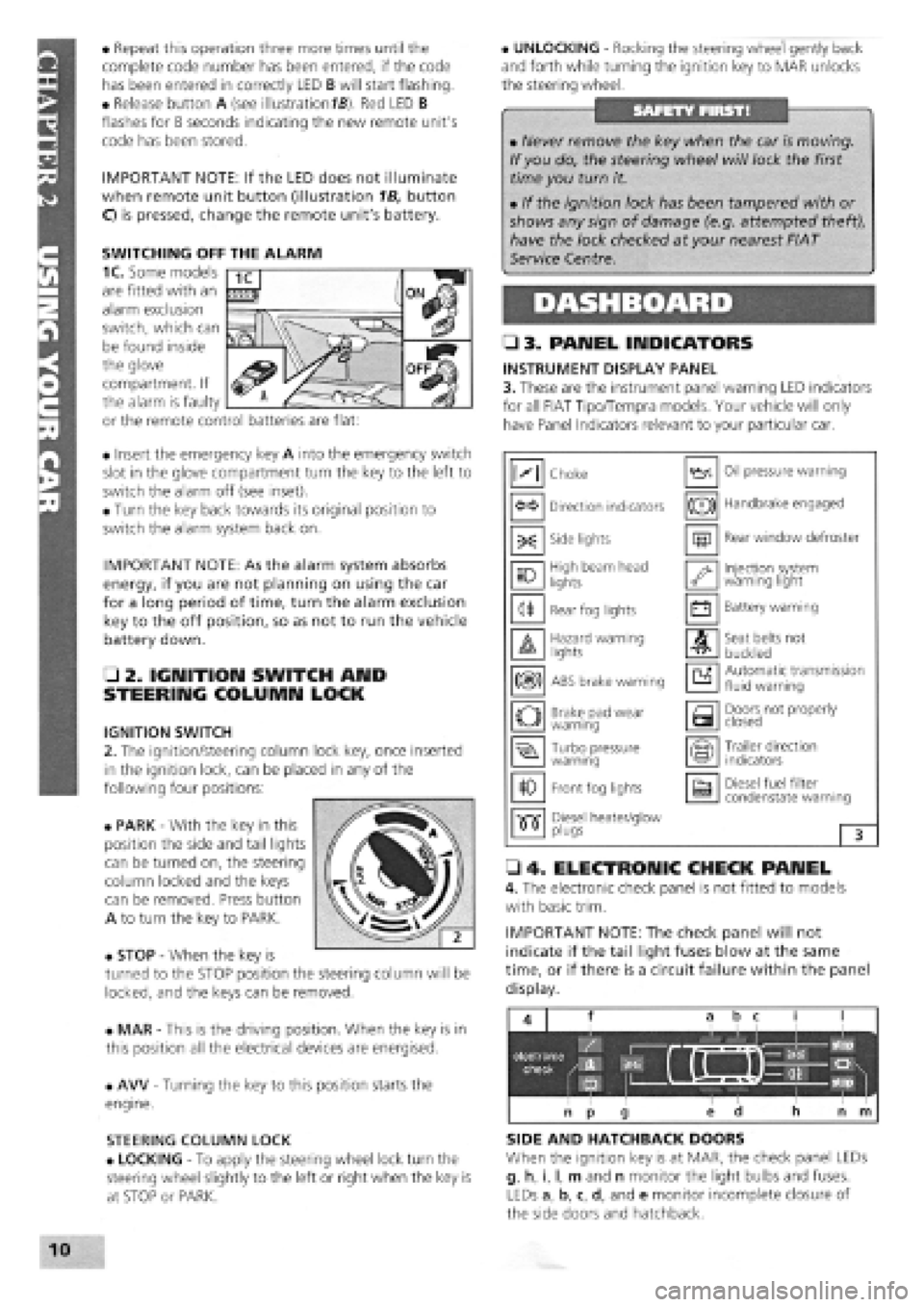

• 3. PANEL INDICATORS

INSTRUMENT DISPLAY PANEL

3. These are the instrument panel warning LED indicators

for all FIAT Tipo/Tempra models. Your vehicle will only

have Panel Indicators relevant to your particular car.

• 4. ELECTRONIC CHECK PANEL

4. The electronic check panel is not fitted to models

with basic trim.

IMPORTANT NOTE: The check panel will not

indicate if the tail light fuses blow at the same

time, or if there is a circuit failure within the panel

display.

SIDE AND HATCHBACK DOORS

When the ignition key is at MAR, the check panel LEDs

g, h, i, I, m and n monitor the light bulbs and fuses.

LEDs a, b, c, d, and e monitor incomplete closure of

the side doors and hatchback.

• Never remove the key when the car is moving.

If you do, the steering wheel will lock the first

time you turn it.

• If the ignition lock has been tampered with or

shows any sign of damage (e.g. attempted theft),

have the lock checked at your nearest FIAT

Service Centre.

M Choke Oil pressure warning

Direction indicators (®) Handbrake engaged

-X: Side lights m Rear window defroster

10 High beam head

lights '•y Injection system warning light

<1* Rear fog lights • Battery warning

A Hazard warning lights A Seat belts not

buckled

m ABS brake warning a Automatic transmission fluid warning

o Brake pad wear warning a Doors not properly closed

Turbo pressure warning Trailer direction indicators

10 Front fog lights a Diesel fuel filter condenstate warning

•515" Diesel heater/glow •515" plugs 3

SWITCHING OFF THE ALARM

1C. Some models

are fitted with an

alarm exclusion

switch, which can

be found inside

the glove

compartment. If

the alarm is faulty

or the remote control batteries are flat:

Page 8 of 171

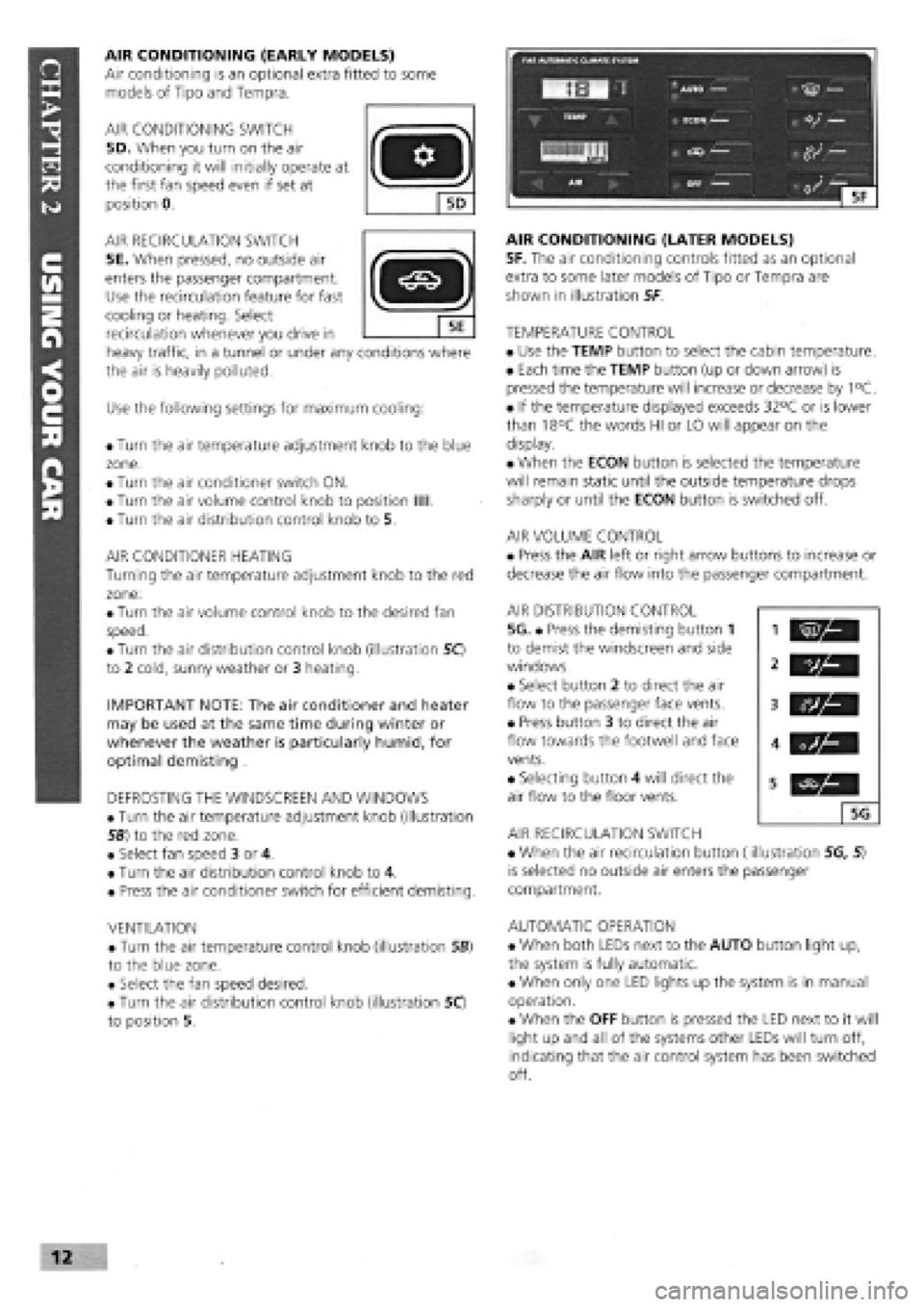

AIR CONDITIONING (EARLY MODELS)

Air conditioning is an optional extra fitted to some

models of Tipo and Tempra.

AIR CONDITIONING SWITCH

5D. When you turn on the air

conditioning it will initially operate at

the first fan speed even if set at

position 0.

AIR RECIRCULATION SWITCH

5E. When pressed, no outside air

enters the passenger compartment.

Use the recirculation feature for fast

cooling or heating. Select

recirculation whenever you drive in

heavy traffic, in a tunnel or under any conditions where

the air is heavily polluted.

Use the following settings for maximum cooling:

• Turn the air temperature adjustment knob to the blue

zone.

• Turn the air conditioner switch ON.

• Turn the air volume control knob to position Mil.

• Turn the air distribution control knob to 5.

AIR CONDITIONER HEATING

Turning the air temperature adjustment knob to the red

zone:

• Turn the air volume control knob to the desired fan

speed.

• Turn the air distribution control knob (illustration 50

to 2 cold, sunny weather or 3 heating.

IMPORTANT NOTE: The air conditioner and heater

may be used at the same time during winter or

whenever the weather is particularly humid, for

optimal demisting .

DEFROSTING THE WINDSCREEN AND WINDOWS

• Turn the air temperature adjustment knob (illustration

56) to the red zone.

• Select fan speed 3 or 4.

• Turn the air distribution control knob to 4.

• Press the air conditioner switch for efficient demisting.

VENTILATION

• Turn the air temperature control knob (illustration SB)

to the blue zone.

• Select the fan speed desired.

• Turn the air distribution control knob (illustration 50

to position 5.

AIR CONDITIONING (LATER MODELS)

5F. The air conditioning controls fitted as an optional

extra to some later models of Tipo or Tempra are

shown in illustration 5F

TEMPERATURE CONTROL

• Use the TEMP button to select the cabin temperature.

• Each time the TEMP button (up or down arrow) is

pressed the temperature will increase or decrease by 1°C.

• If the temperature displayed exceeds 32°C or is lower

than 18°C the words HI or LO will appear on the

display.

• When the ECON button is selected the temperature

will remain static until the outside temperature drops

sharply or until the ECON button is switched off.

AIR VOLUME CONTROL

• Press the AIR left or right arrow buttons to increase or

decrease the air flow into the passenger compartment.

AIR DISTRIBUTION CONTROL

5G. • Press the demisting button 1

to demist the windscreen and side

windows.

• Select button 2 to direct the air

flow to the passenger face vents.

• Press button 3 to direct the air

flow towards the footwell and face

vents.

• Selecting button 4 will direct the

air flow to the floor vents.

AIR RECIRCULATION SWITCH

• When the air recirculation button (illustration 5G, 5)

is selected no outside air enters the passenger

compartment.

AUTOMATIC OPERATION

• When both LEDs next to the AUTO button light up,

the system is fully automatic.

• When only one LED lights up the system is in manual

operation.

• When the OFF button is pressed the LED next to it will

light up and all of the systems other LEDs will turn off,

indicating that the air control system has been switched

off.

vh

5G

Page 12 of 171

EMERGENCY STARTING

To release the spare

wheel, jack and tool kit:

16A. Undo strap A to

release the jack from the support. Unscrew nut B, to

remove the spare wheel.

16B. Release the jack from the tool stand by lifting tab C.

The arrangement of the tools in their holder might have

one of the configurations shown in illustration 16B.

• 17. RAISING

THE VEHICLE

17A. To raise the vehicle,

position the jack under

the side member, about

20 cm from the wheel

arch. Turn the jack

handle until the its

grooved head (see inset)

fits the flange at the base of the sill.

REMOVING A WHEEL

17B. Loosen all the wheel bolts in the

order shown.

• Lift the car until the wheel is about

25 mm

(1

in.) off the ground.

• The hub cap is secured by only three wheel bolts.

• Remove the hub cap, then unscrew the fourth wheel

bolt, and remove the wheel.

• Put the spare wheel on, making sure that the aligning

peg or pegs on the hub fits into the hole/s in the rim.

• Attach the wheel with a single bolt and then put the

wheel cover back on so that the largest hole fits over

the bolt holding on the wheel. Screw in the other three

bolts, which also hold on the wheel cover.

• Lower the car and remove the jack. Tighten the wheel

bolts evenly in a criss-cross fashion, as shown in

illustration 17C.

RAISING THE VEHICLE WITH A TROLLEY JACK

• 17C. FROM THE FRONT

-

Place a hardwood board

between the jack and the car, see inset. The jack must

ONLY be positioned under the gearbox case support on

the side of the differential gears.

• 17D. FROM THE REAR

-

Put a hardwood board

between the jack and the car ONLY at the back of the

spare wheel housing.

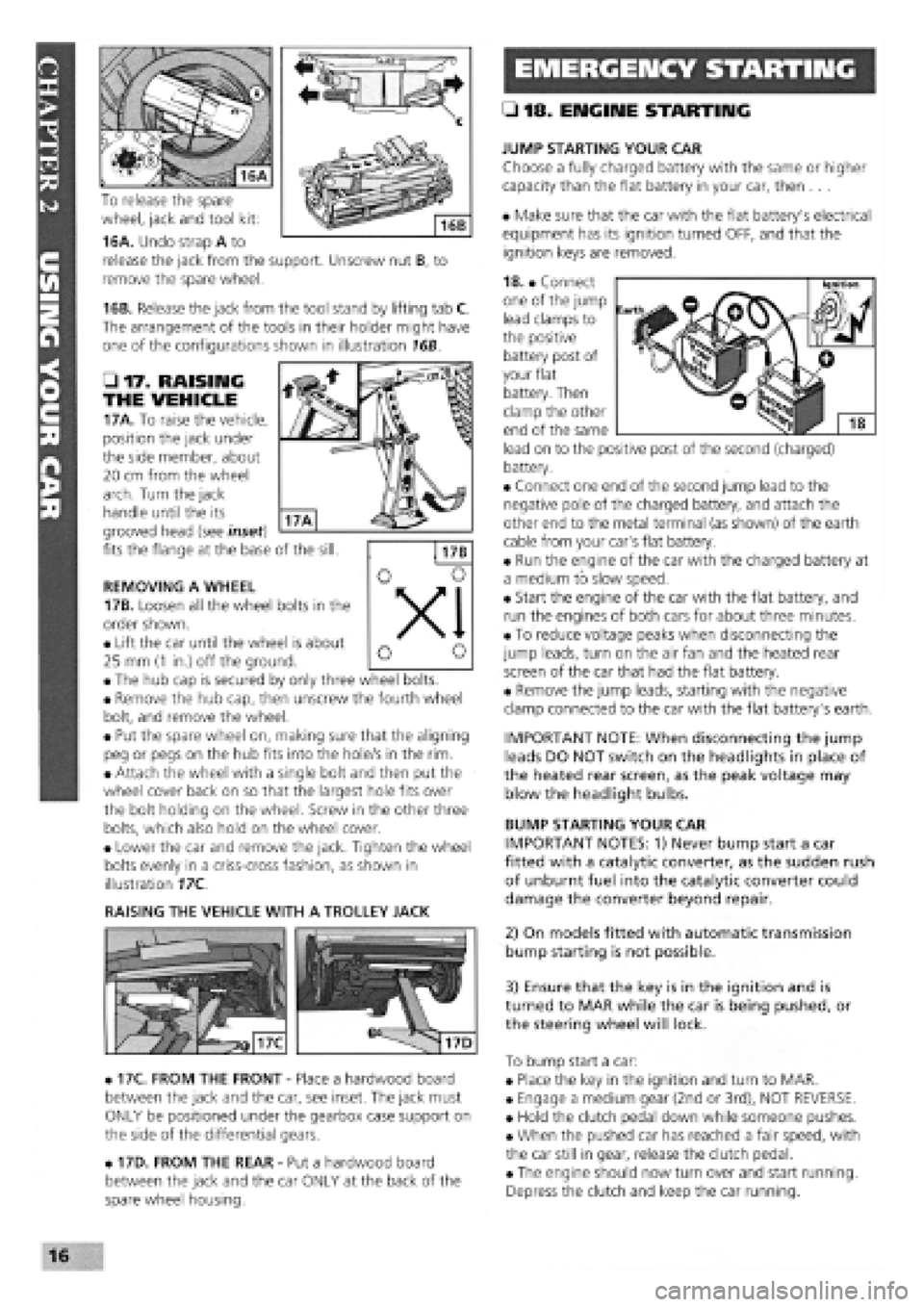

• 18. ENGINE STARTING

JUMP STARTING YOUR CAR

Choose a fully charged battery with the same or higher

capacity than the flat battery in your car, then ...

• Make sure that the car with the flat battery's electrical

equipment has its ignition turned OFF, and that the

ignition keys are removed.

18. • Connect

one of the jump

lead clamps to

the positive

battery post of

your flat

battery. Then

clamp the other

end of the same

lead on to the positive post of the second (charged)

battery.

• Connect one end of the second jump lead to the

negative pole of the charged battery, and attach the

other end to the metal terminal (as shown) of the earth

cable from your car's flat battery.

• Run the engine of the car with the charged battery at

a medium to slow speed.

• Start the engine of the car with the flat battery, and

run the engines of both cars for about three minutes.

• To reduce voltage peaks when disconnecting the

jump leads, turn on the air fan and the heated rear

screen of the car that had the flat battery.

• Remove the jump leads, starting with the negative

clamp connected to the car with the flat battery's earth.

IMPORTANT NOTE: When disconnecting the jump

leads DO NOT switch on the headlights in place of

the heated rear screen, as the peak voltage may

blow the headlight bulbs.

BUMP STARTING YOUR CAR

IMPORTANT NOTES: 1) Never bump start a car

fitted with a catalytic converter, as the sudden rush

of unburnt fuel into the catalytic converter could

damage the converter beyond repair.

2) On models fitted with automatic transmission

bump starting is not possible.

3) Ensure that the key is in the ignition and is

turned to MAR while the car is being pushed, or

the steering wheel will lock.

To bump start a car:

• Place the key in the ignition and turn to MAR.

• Engage a medium gear (2nd or 3rd), NOT REVERSE.

• Hold the clutch pedal down while someone pushes.

• When the pushed car has reached a fair speed, with

the car still in gear, release the clutch pedal.

• The engine should now turn over and start running.

Depress the clutch and keep the car running.

16

Page 14 of 171

October 1991 2.0 i.e. 16v introduced, with 1995cc, 16 valve

high-performance DOHC engine, catalytic converter, sports

suspension, front and rear disc brakes. ABS available as

option.

January 1992 Existing Tipo models lightly facelifted and

redesignated 1.4 Formula, 1.45, 1.6S, 1.6SX, 1.9TD SX,

1.8 i.e. SX. 1.7D discontinued. SX versions with digital

instruments.

Tempra 1.9 TDS (turbo diesel) Station Wagon introduced. 1.4

and 1.9D saloons discontinued.

May 1992 Tempra 1.8 i.e. SX Saloon and Station Wagon

discontinued.

June 1992 Tempra 2.0 i.e. SX saloon and station wagon

models introduced, with high performance 1995cc DOHC fuel

injected engine, catalytic converter and disc brakes front and

rear.

Tipo 1.4 and all Tipo and Tempra 1.6 models (except Selecta)

now with a catalytic converter and fuel injection in place of

Weber twin-choke carburettor. Designated i.e. in badging.

December 1992 Tipo 1.8 i.e. and 1.6 Selecta discontinued.

February 1993 Tipo 2.0 i.e. GT introduced. Slightly lower

performance and spec, version of the 16v model.

July 1993 Tipo 1.4 now available as a 3-door or 5-door

hatchback. 2.0 i.e. 16v now only available as 3-door. Tipo 2.0

i.e. GT replaced by similar spec. 2.0 i.e. SLX.

Tempra 2.0 i.e. SX saloons and estates now only available

with auto, gearbox. Otherwise, SX models become known as

SLX, with colour-coded mirrors and ABS brakes. Most Tempras

now with body-coloured bumpers. 1.9D (non turbo Diesel re-

introduced).

All Tipo and Tempra models now with revised front-end

styling

-

narrower headlights and revised grille. Improved crash

protection, including side impact beams, safety steering wheel

and uprated brakes. Power steering, central locking, electric

windows all standard.

February 1994 Tipo 1.7 non-turbo diesel re-introduced as

1.7 DS.

May 1994 Tempra 1.9DS Station Wagon introduced.

September 1994 Most models available with driver's airbag,

fire prevention system and seat belt pre-tensioners.

December 1994 Tempra 1.6 i.e. versions get M.P.I, engine.

February/March 1995 All models with VIN number window

etching and immobiliser standard on all Tempra petrol models.

October 1995 Immobiliser fitted to Tempra D and TD models.

End of 1995 Tipo discontinued.

Mid-1996 Tempra discontinued.

PART B: VITAL STATISTICS

All Tipo models

-

55 litres, except petrol with catalytic converter

- 51

litres.

All Tempra models

-

65 litres, except petrol with catalytic converter

-

62 litres.

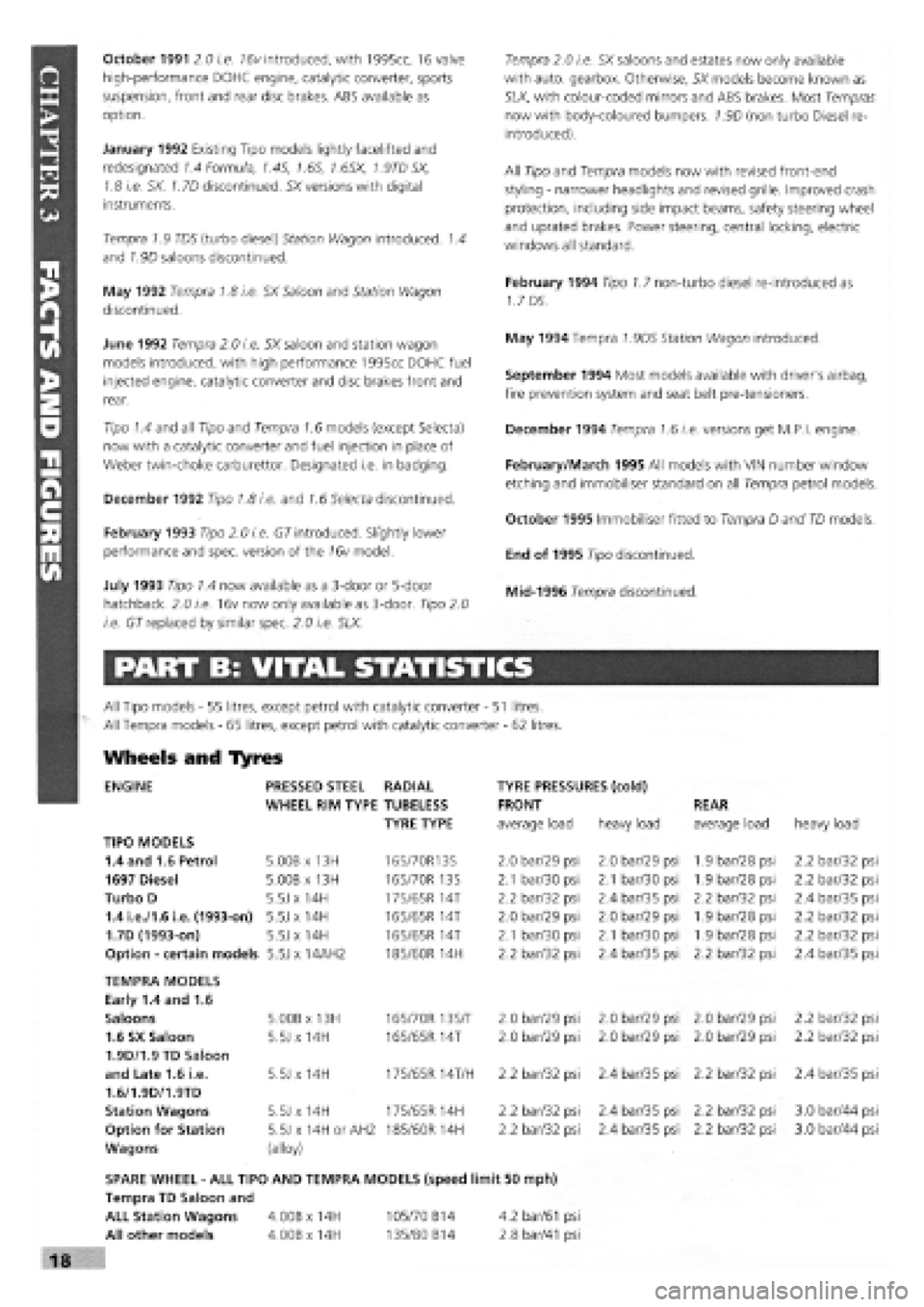

Wheels and Tyres

ENGINE PRESSED STEEL RADIAL TYRE PRESSURES (cold)

WHEEL RIM TYPE TUBELESS FRONT REAR

TYRE TYPE average load heavy load average load heavy load

TIPO MODELS

1.4 and 1.6 Petrol 5.00B x 13H 165/70R13S 2.0 bar/29 psi 2.0 bar/29 psi 1.9 bar/28 psi 2.2 bar/32 psi

1697 Diesel 5.00B x 13H 165/70R 13S 2.1 bar/30 psi 2.1 bar/30 psi 1.9 bar/28 psi 2.2 bar/32 psi

Turbo D 5.5J x 14H

175/65 R

14T 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

1.4 i.e./1.6 i.e. (1993-on) 5.5J x 14H

165/65 R

14T 2.0 bar/29 psi 2.0 bar/29 psi 1.9 bar/28 psi 2.2 bar/32 psi

1.7D (1993-on) 5.5J x 14H 165/65R 14T 2.1 bar/30 psi 2.1 bar/30 psi 1.9 bar/28 psi 2.2 bar/32 psi

Option

-

certain models 5.5J x 14AH2 185/60R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

TEMPRA MODELS

Early 1.4 and 1.6

Saloons 5.00B x 13H 165/70R 13S/T 2.0 bar/29 psi 2.0 bar/29 psi 2.0 bar/29 psi 2.2 bar/32 psi

1.6 SX Saloon 5.5J x 14H 165/65R 14T 2.0 bar/29 psi 2.0 bar/29 psi 2.0 bar/29 psi 2.2 bar/32 psi

1.9D/1.9 TD Saloon

and Late 1.6 i.e. 5.5J x 14H 175/65R 14T/H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

1.6/1.9D/1.9TD

Station Wagons 5.5J x 14H 175/65R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 3.0 bar/44 psi

Option for Station 5.5J x 14H or AH2 185/60 R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 3.0 bar/44 psi

Wagons (alloy)

SPARE WHEEL

-

ALL TIPO AND TEMPRA MODELS (speed limit 50 mph)

Tempra TD Saloon and

ALL Station Wagons 4.00B x 14H 105/70 B14 4.2

bar/61

psi

All other models 4.00Bx14H 135/80 B14 2.8

bar/41

psi

Page 15 of 171

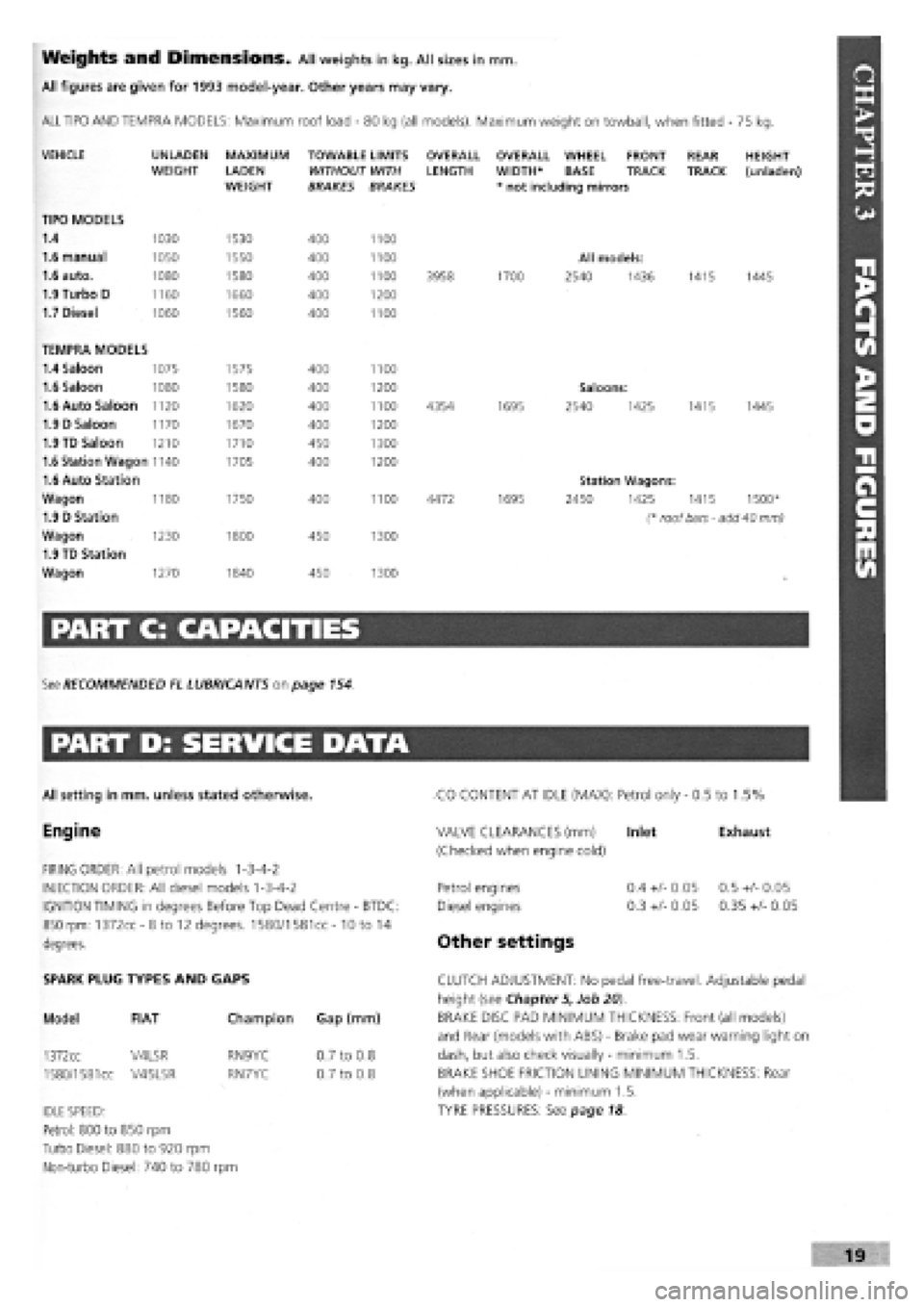

Weights and Dimensions. All weights in kg. All sizes in mm.

All figures are given for 1993 model-year. Other years may vary.

ALL TIPO AND TEMPRA MODELS: Maximum roof load

-

80 kg (all models). Maximum weight on towball, when fitted - 75 kg.

VEHICLE

TIPO MODELS

1.4

1.6 manual

1.6 auto.

1.9 Turbo D

1.7 Diesel

UNLADEN WEIGHT

1030

1050

1080

1160

1060

MAXIMUM

LADEN WEIGHT

1530

1550

1580

1660

1560

TOWABLE LIMITS WITHOUT WITH BRAKES BRAKES

400

400

400

400

400

1100

1100

1100

1200

1100

OVERALL LENGTH

3958

OVERALL WHEEL FRONT WIDTH* BASE TRACK * not including mirrors

1700

All models:

2540 1436

REAR TRACK

1415

HEIGHT (unladen)

1445

TEMPRA MODELS

1.4 Saloon 1075 1575 400 1100

1.6 Saloon 1080 1580 400 1200 Saloons:

1.6 Auto Saloon 1120 1620 400 1100 4354 1695 2540 1425 1415 1445

1.9 D Saloon 1170 1670 400 1200

1.9 TD Saloon 1210 1710 450 1300

1.6 Station Wagon 1140 1705 400 1200

1.6 Auto Station Station Wagons:

Wagon 1180 1750 400 1100 4472 1695 2450 1425 1415 1500*

1.9 D Station (* roof bars - add 40 mm)

Wagon 1230 1800 450 1300

1.9 TD Station

Wagon 1270 1840 450 1300

PART C: CAPACITIES

See RECOMMENDED EL LUBRICANTS on page 154.

PART D: SERVICE DATA

All setting in mm. unless stated otherwise.

Engine

FIRING ORDER: All petrol models 1-3-4-2

INJECTION ORDER: All diesel models 1-3-4-2

IGNITION TIMING in degrees Before Top Dead Centre

-

BTDC:

850 rpm: 1372cc-8to 12 degrees. 1580/1581cc- 10 to 14

degrees.

CO CONTENT AT IDLE (MAX): Petrol only

-

0.5 to 1.5%

Exhaust VALVE CLEARANCES (mm) Inlet

(Checked when engine cold)

Petrol engines

Diesel engines

Other settings

0.4

+/-

0.05

0.3

+/-

0.05

0.5

+/-

0.05

0.35

+/-

0.05

SPARK PLUG TYPES AND GAPS

Model FIAT

1372cc V4LSR

1580/1581

cc V45LSR

Champion Gap (mm)

RN9YC

RN7YC

IDLE SPEED:

Petrol: 800 to 850 rpm

Turbo Diesel: 880 to 920 rpm

Non-turbo Diesel: 740 to 780 rpm

0.7 to 0.8

0.7 to 0.8

CLUTCH ADJUSTMENT: No pedal free-travel. Adjustable pedal

height (see Chapter 5, Job 20).

BRAKE DISC PAD MINIMUM THICKNESS: Front (all models)

and Rear (models with ABS)

-

Brake pad wear warning light on

dash, but also check visually

-

minimum 1.5.

BRAKE SHOE FRICTION LINING MINIMUM THICKNESS: Rear

(when applicable)

-

minimum 1.5.

TYRE PRESSURES: See page 18

Page 16 of 171

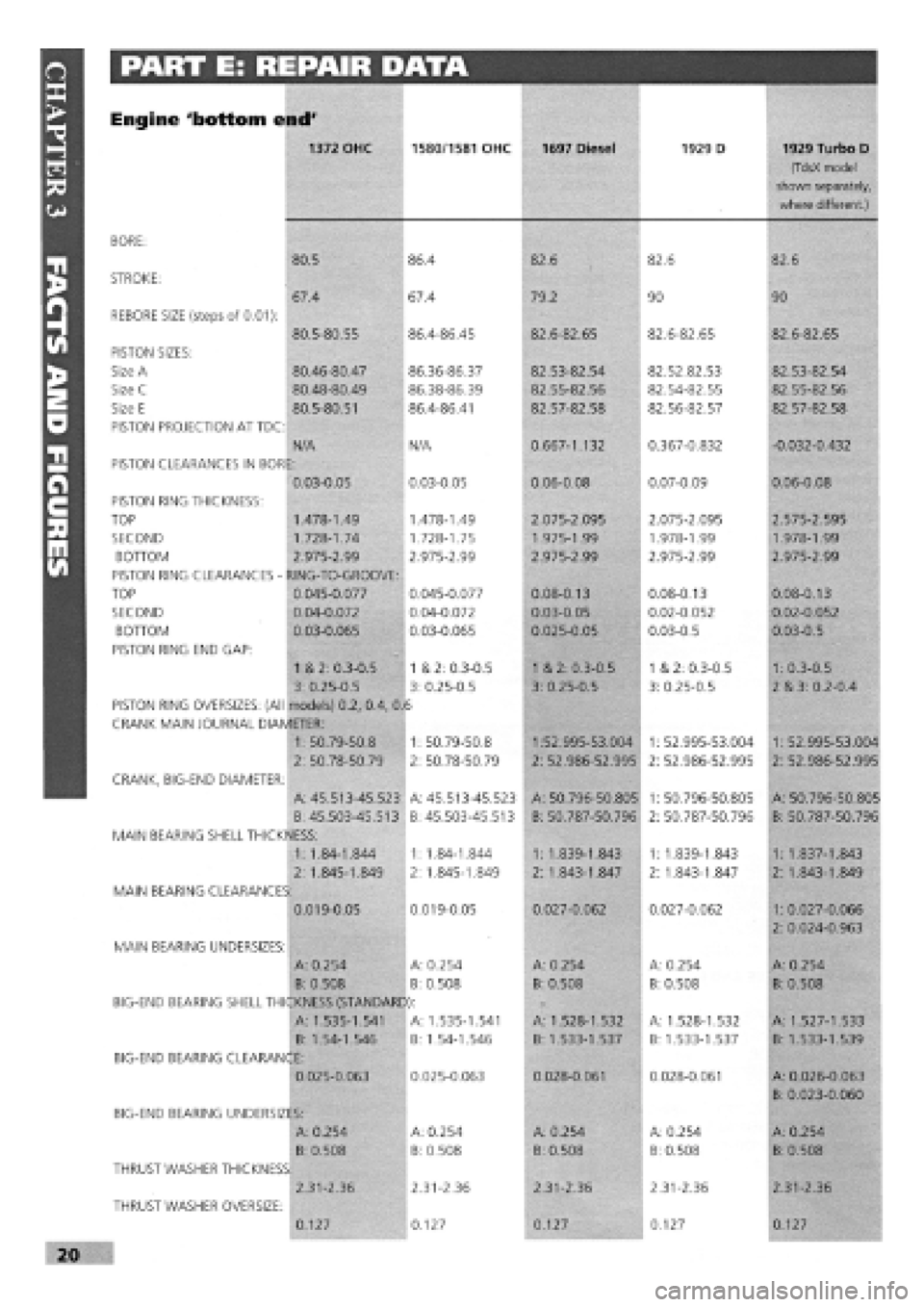

PART E: REPAIR DATA 1

Engine 'bottom end'

1372 OHC 1580/1581 OHC 1697 Diesel 1929 D 1929 Turbo D

(TdsX model

shown separately,

where different.)

BORE:

80.5 86.4 82.6 82.6 82.6

STROKE:

67.4 67.4 79.2 90 90

REBORE SIZE (steps of 0.01):

80.5-80.55 86.4-86.45 82.6-82.65 82.6-82.65 82.6-82.65

PISTON SIZES:

Size A 80.46-80.47 86.36-86.37 82.53-82.54 82.52.82.53 82.53-82.54

Size C 80.48-80.49 86.38-86.39 82.55-82.56 82.54-82.55 82.55-82.56

Size E 80.5-80.51 86.4-86.41 82.57-82.58 82.56-82.57 82.57-82.58

PISTON PROJECTION AT TDC:

N/A N/A 0.667-1.132 0.367-0.832 -0.032-0.432

PISTON CLEARANCES IN BORE:

0.03-0.05 0.03-0.05 0.06-0.08 0.07-0.09 0.06-0.08

PISTON RING THICKNESS: S^MRttffl

TOP 1.478-1.49 1.478-1.49 2.075-2.095 2.075-2.095 2.575-2.595

SECOND 1.728-1.74 1.728-1.75 1.975-1.99 1.978-1.99 1.978-1.99

BOTTOM 2.975-2.99 2.975-2.99 2.975-2.99 2.975-2.99 2.975-2.99

PISTON RING CLEARANCES -RING-TO-GROOVE:

TOP 0.045-0.077 0.045-0.077 0.08-0.13 0.08-0.13 0.08-0.13

SECOND 0.04-0.072 0.04-0.072 0.03-0.05 0.02-0.052 0.02-0.052

BOTTOM 0.03-0.065 0.03-0.065 0.025-0.05 0.03-0.5 0.03-0.5

PISTON RING END GAP:

1 & 2: 0.3-0.5 1 & 2: 0.3-0.5 1 & 2: 0.3-0.5 1 & 2: 0.3-0.5 1: 0.3-0.5

3: 0.25-0.5 3: 0.25-0.5 3: 0.25-0.5 3: 0.25-0.5 2 & 3: 0.2-0.4

PISTON RING OVERSIZES: (All models) 0.2, 0.4, 0. 6

CRANK MAIN JOURNAL DIAMETER:

1: 50.79-50.8 1: 50.79-50.8 1:52.995-53.004 1: 52.995-53.004 1: 52.995-53.004

2: 50.78-50.79 2: 50.78-50.79 2: 52.986-52.995 2: 52.986-52.995 2: 52.986-52.995

CRANK, BIG-END DIAMETER:

A: 45.513-45.523 A: 45.513-45.523 A: 50.796-50.805 1: 50.796-50.805 A: 50.796-50.805

B: 45.503-45.513 B: 45.503-45.513 B: 50.787-50.796 2: 50.787-50.796 B: 50.787-50.796

MAIN BEARING SHELL THICKNESS:

1: 1.84-1.844 1: 1.84-1.844 1: 1.839-1.843 1: 1.839-1.843 1: 1.837-1.843

2: 1.845-1.849 2: 1.845-1.849 2: 1.843-1.847 2: 1.843-1.847 2: 1.843-1.849

MAIN BEARING CLEARANCES

0.019-0.05 0.019-0.05 0.027-0.062 0.027-0.062 1: 0.027-0.066

2: 0.024-0.963

MAIN BEARING UNDERSIZES:

A: 0.254 A: 0.254 A: 0.254 A: 0.254 A: 0.254

B: 0.508 B: 0.508 B: 0.508 B: 0.508 B: 0.508

BIG-END BEARING SHELL THICKNESS (STANDARC ):

A: 1.535-1.541 A: 1.535-1.541 A: 1.528-1.532 A: 1.528-1.532 A: 1.527-1.533

B: 1.54-1.546 B: 1.54-1.546 B: 1.533-1.537 B: 1.533-1.537 B: 1.533-1.539

BIG-END BEARING CLEARANCE:

0.025-0.063 0.025-0.063 0.028-0.061 0.028-0.061 A: 0.026-0.063

B: 0.023-0.060

BIG-END BEARING UNDERSIZES:

A: 0.254 A: 0.254 A: 0.254 A: 0.254 A: 0.254

B: 0.508 B: 0.508 B: 0.508 B: 0.508 B: 0.508

THRUST WASHER THICKNESS

2.31-2.36 2.31-2.36 2.31-2.36 2.31-2.36 2.31-2.36

THRUST WASHER OVERSIZE:

0.127 0.127 0.127 0.127 0.127

20

Page 23 of 171

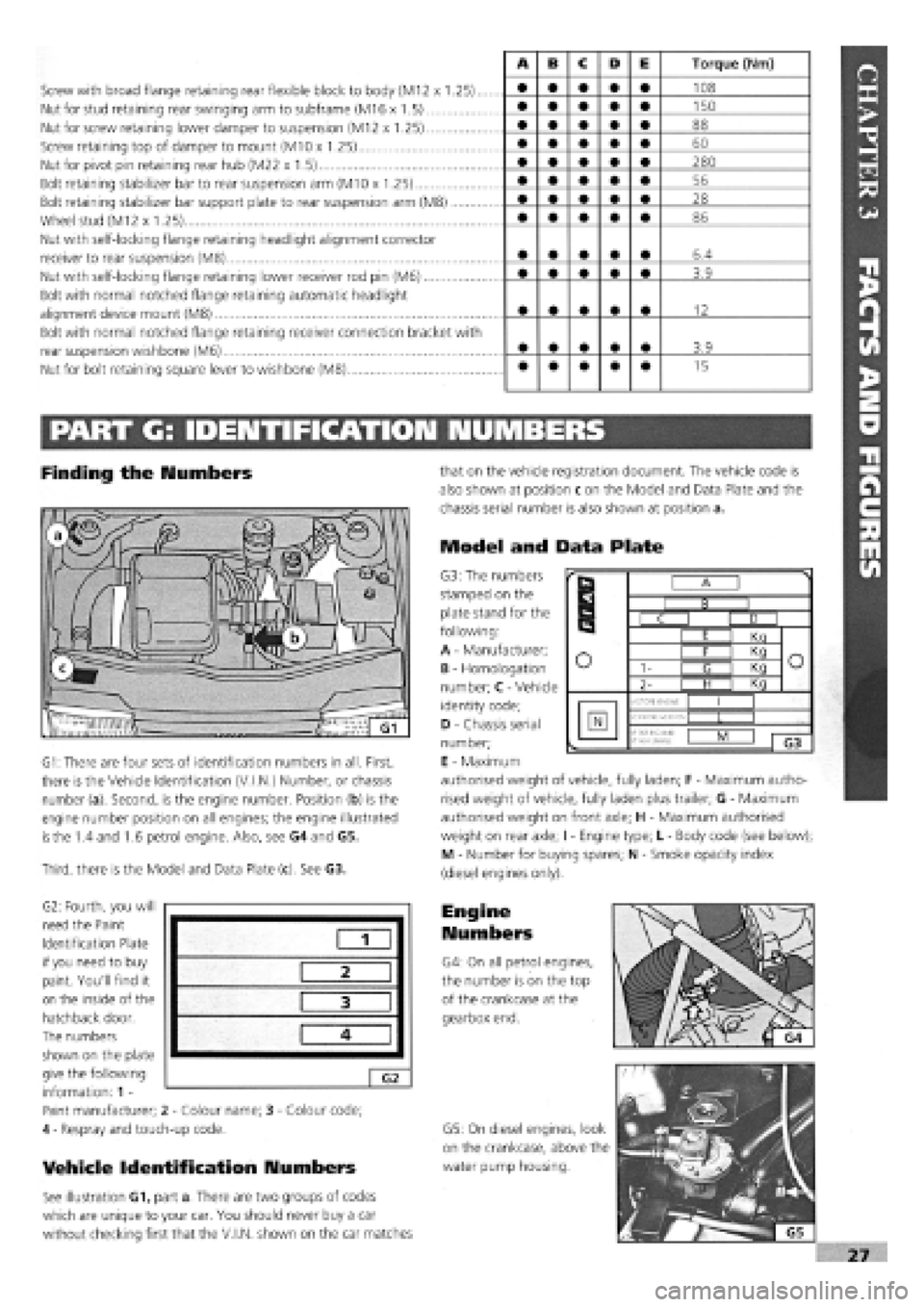

Screw with broad flange retaining rear flexible block to body (M12 x 1.25)..

Nut for stud retaining rear swinging arm to subframe (M16 x 1.5)

Nut for screw retaining lower damper to suspension (M12 x 1.25)

Screw retaining top of damper to mount (M10 x 1.25)

Nut for pivot pin retaining rear hub (M22 x 1.5)

Bolt retaining stabilizer bar to rear suspension arm (M10 x 1.25)

Bolt retaining stabilizer bar support plate to rear suspension arm (M8)

Wheel stud (M12 x 1.25)

Nut with self-locking flange retaining headlight alignment corrector

receiver to rear suspension (M8)

Nut with self-locking flange retaining lower receiver rod pin (M6)

Bolt with normal notched flange retaining automatic headlight

alignment device mount (M8)

Bolt with normal notched flange retaining receiver connection bracket with

rear suspension wishbone (M6)

Nut for bolt retaining square lever to wishbone (M8)

A B c D E Torque (Nm)

• • • • • 108

• • • • • 150

• • • • • 88

• • • • • 60

• • • • • 280

• • • • • 56

• • • • • 28

• • • • • 86

• • • • • 6.4

• • • • • 3.9

• • • • • 12

• • • • • 3.9

• • • • • 15

PART G: IDENTIFICATION NUMBERS

Finding the Numbers

G1: There are four sets of identification numbers in all. First,

there is the Vehicle Identification (V.I.N.) Number, or chassis

number (a). Second, is the engine number. Position (b) is the

engine number position on all engines; the engine illustrated

is

the 1.4 and 1.6 petrol engine. Also, see G4 and G5.

Third, there is the Model and Data Plate (c). See G3.

G2: Fourth, you will

need the Paint

Identification Plate

if you need to buy

paint. You'll find it

on the inside of the

hatchback door.

The numbers

shown on the plate

give the following

information: 1 -

Paint manufacturer; 2

-

Colour name; 3

-

Colour code;

4

-

Respray and touch-up code.

Vehicle Identification Numbers

See illustration G1, part a. There are two groups of codes

which are unique to your car. You should never buy a car

without checking first that the V.I.N, shown on the car matches

that on the vehicle registration document. The vehicle code is

also shown at position c on the Model and Data Plate and the

chassis serial number is also shown at position a.

Model and Data Plate

G3: The numbers

stamped on the

plate stand for the

following:

A

-

Manufacturer;

B

-

Homologation

number; C

-

Vehicle

identity code;

D

-

Chassis serial

number;

E

-

Maximum

authorised weight of vehicle, fully laden; F

-

Maximum autho-

rised weight of vehicle, fully laden plus trailer; G

-

Maximum

authorised weight on front axle; H

-

Maximum authorised

weight on rear axle; I

-

Engine type; L

-

Body code (see below);

M - Number for buying spares; N

-

Smoke opacity index

(diesel engines only).

Engine

Numbers

G4: On all petrol engines,

the number is on the top

of the crankcase at the

gearbox end.

G5: On diesel engines, look

on the crankcase, above the

water pump housing.

1

2

3

4

G2

r

B

r

B I B I

r

B

C I D I

r

B

I E I Kn

o o I F I Kq o o 1- I <3 I Kq o o

2- | H I Kq

o

MOTORE ENGINE

I I

N VERSIONE-VERSION •f

PER RICAM8:

N*

FOR SPARED

L I

1 G3

Page 28 of 171

Please read the whole of the Introduction to this Chapter before carrying out any work on your car.

CHAPTER 5

SERVICING YOUR CAR

Everyone wants to own a

car that starts first time,

runs reliably and lasts

longer than the average.

And it's all a question of

thorough maintenance!

If you follow the FIAT-

approved Service Jobs

listed here you can almost

guarantee that your car will

still be going strong when

others have fallen by the

wayside

-

or the hard

shoulder.

How To Use This Chapter

This chapter contains all of the servicing Jobs recommended

by FIAT for all models of Tipo and Tempra imported into the

UK except cars with 1.8 and 2 litre DOHC petrol engines. To

use the schedule, note that:

• Each letter code tells you the Service Interval at which you

should carry out each Service Job.

• Each Service Job has a Job number.

• Look up the number in the relevant part of this chapter and

you will see a complete explanation of the work.

SAFETY FIRST!

SAFETY FIRST information must always be read with

care and always taken seriously.

• In addition, please read the whole of Chapter 1,

Safety First! before carrying out any work on your

car.

• There are many hazards associated with working on

a car but all of them can be avoided by adhering

strictly to the safety rules.

• Don't skimp on safety!

SERVICE INTERVALS - INTRODUCTION

• We think it is very

important to keep things as

straightforward as possible.

And where you see this heading, you'll know there's

an extra tip to help 'make it easy' for you!

Over the years, FIAT, in common with all other manufacturers,

have lengthened their recommended service intervals. For

instance, oil changes on later FIATs don't have to take place as

often as earlier ones. In the main, these changes have not

come about because of specific modifications to the cars

themselves. They have come about because of a number of

factors: Lubricants, spark plugs, seals and other components

have improved and mechanical parts are better made due to

improved materials and production techniques.

As a result, you are recommended to follow the maker's

recommendations on how often to service your car. If your car

lies right on a change-over point, the choice of which

schedule to follow will be yours, unless the specific advice

given here recommends otherwise

-

as we said earlier, most

change points came about for a number of reasons, so it

generally isn't necessary to identify with pinpoint accuracy

which bracket your car belongs to, if it isn't obvious.

32

Page 31 of 171

TOPPING-UP

1D. On petrol

engines the oil

filler cap is pull-

out rectangular

plug at the end

of the rocker

On diesel engines, the round cap is near the same end of the

cam cover. This cap is removed by turning a quarter-turn to

the left and lifting.

DIESEL ENGINES

Top-up, if necessary using a 50:50 mixture of distilled water

and Paraflu anti-freeze.

cover adjacent to

the distributor.

Note that on some models, the cap is circular.

1E. Pour in the

fresh oil carefully,

preferably using a

funnel. A clean

plastic bottle with

the bottom cut

off is ideal!

IMPORTANT NOTE: Regularly check the ground over

which the car has been parked for traces of oil or other

fluid leaks. If a leak is found, don't drive the car without

first finding out where the leak is from, and ideally,

repairing it.

G Job 2. Cooling system

-

check level.

SAFETY FIRST!

• ALWAYS check the coolant level with the engine

COLD

• If the engine is hot there is a real danger of

scalding

from boiling coolant gushing from the tank

when the cap is removed.

Never allow the coolant level to fall below the MIN (or UVELLO

A FREDDO) mark on the expansion tank. It is vitally important

that all engines have the correct proportion of anti-freeze in

the coolant all year round to prevent corrosion. A 50% mix of

distilled water with FL Paraflu coolant gives the best

protection.

• Job 3. Brake/dutch fluid

-

check level/s.

IMPORTANT NOTE: On later models, a hydraulic clutch is

fitted. The same fluid reservoir serves both brakes and

clutch.

SAFETY FIRST!

• If brake fluid should come into contact with skin or

eyes, rinse immediately with plenty of water.

• It is acceptable for the brake fluid level to fall

slightly during normal use, but if it falls significantly

below the MIN mark on the reservoir there is probably

a leak or internal seal failure. Stop using the car until

the problem has been put right.

• If you let dirt get into the hydraulic system it can

cause brake failure. Wipe the filler cap clean before

removing it.

• You should only ever use new brake fluid from a

sealed container

-

FIAT recommend FL Tutela Top 4

brake fluid. Old fluid absorbs moisture and this could

cause the brakes to fail when carrying out an

emergency stop or during another heavy use of the

brakes

-

just when you need them most and are least

able to do anything about it, in fact!

On all models the brake fluid reservoir is positioned above the

master cylinder either in the rear right-hand or rear left-hand

corner of the engine bay, according to model. The reservoir is

semi-transparent so the level can be checked without

disturbing the cap.

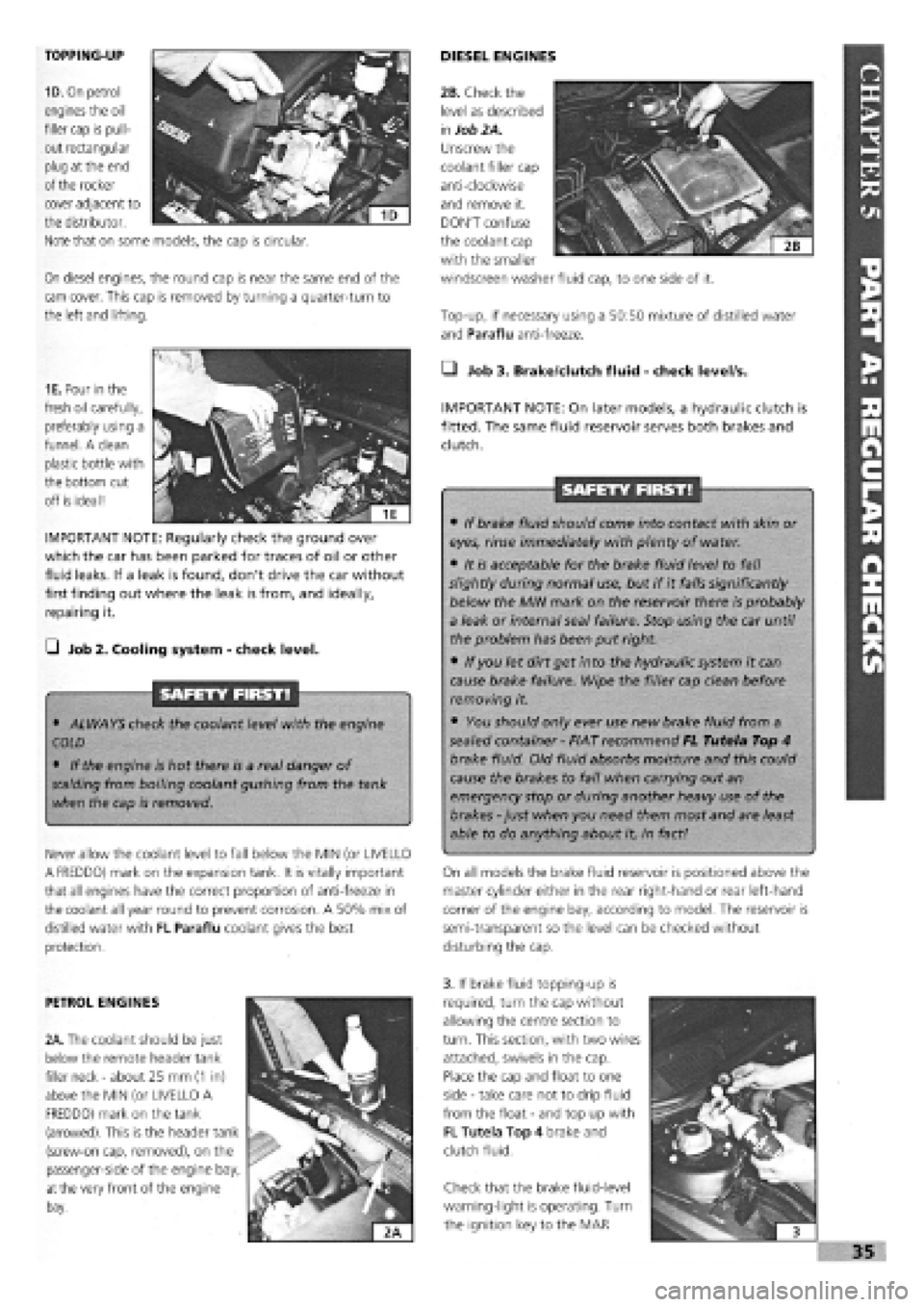

PETROL ENGINES

2A. The coolant should be just

below the remote header tank

filler neck

-

about 25 mm

(1

in)

above the MIN (or UVELLO A

FREDDO) mark on the tank

(arrowed). This is the header tank

(screw-on cap, removed), on the

passenger-side of the engine bay,

at

the very front of the engine

bay.

3. If brake fluid topping-up is

required, turn the cap without

allowing the centre section to

turn. This section, with two wires

attached, swivels in the cap.

Place the cap and float to one

side

-

take care not to drip fluid

from the float

-

and top up with

FL Tutela Top 4 brake and

clutch fluid.

Check that the brake fluid-level

warning-light is operating. Turn

the ignition key to the MAR

I

i 3

»35

2B. Check the

level as described

in

Job 2A.

Unscrew the

coolant filler cap

anti-clockwise

and remove it.

DON'T confuse

the coolant cap

with the smaller

windscreen washer fluid cap, to one side of it.