dashboard FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 7 of 171

Fluid levels (if included) are monitored by LEDs f, o and

p, indicating the levels of the fluid reservoirs.

A red LED illuminates at the position on the check panel

corresponding to a side door or a hatchback/tailgate

that is not properly closed.

SIDE AND TAIL LIGHTS

When the side and tail lights are turned on, the check

panel monitors the light bulbs, fuses and circuits.

• LED g monitors the front side lights.

• LED i monitors the tail lights.

If one of the two fuses protecting the following bulbs

blows, LEDs g, i, and m illuminate.

NUMBER PLATE LIGHTS

• LED m indicates when one or both of the number

plate light bulbs have burnt out.

REAR FOG LIGHTS

• When the fog-guard lights are turned on, LED h

monitors the light bulbs.

• When the fuse blows or a circuit malfunction occurs,

LED h illuminates, but not the panel indicator.

STOP LIGHTS

If one or both stop lights burn out, the fuse blows or a

circuit malfunction occurs, LED I or n illuminates when

braking.

• LED n monitors the left stop light.

• LED I monitors the right stop light.

If both bulbs burn out at the same time or brake pedal

switch malfunction occurs, both LEDs I and n

illuminate.

ENGINE OIL LEVEL

• LED f illuminates when the engine oil level is low (key

at MAR,engine not running).

The oil level monitoring system does not operate when

the engine is running. If the oil level warning LED

illuminates when driving, a circuit sensor malfunction

has occurred.

When starting the car on a hill or within 10 minutes of

switching off the engine the warning light may

illuminate (event will be stored in system memory). Start

the engine again on level ground to ensure the oil level

is sufficient.

COOLANT

A low coolant level is indicated by LED o (key at MAR).

The LED also illuminates when a sensor or circuit

malfunction occurs.

WINDSCREEN AND REAR SCREEN WASH LEVELS

• LED p illuminates (key at MAR) when the level in the

windscreen or rear screen wash reservoirs are low.

• The LED also indicates when a circuit or sensor

malfunction occurs.

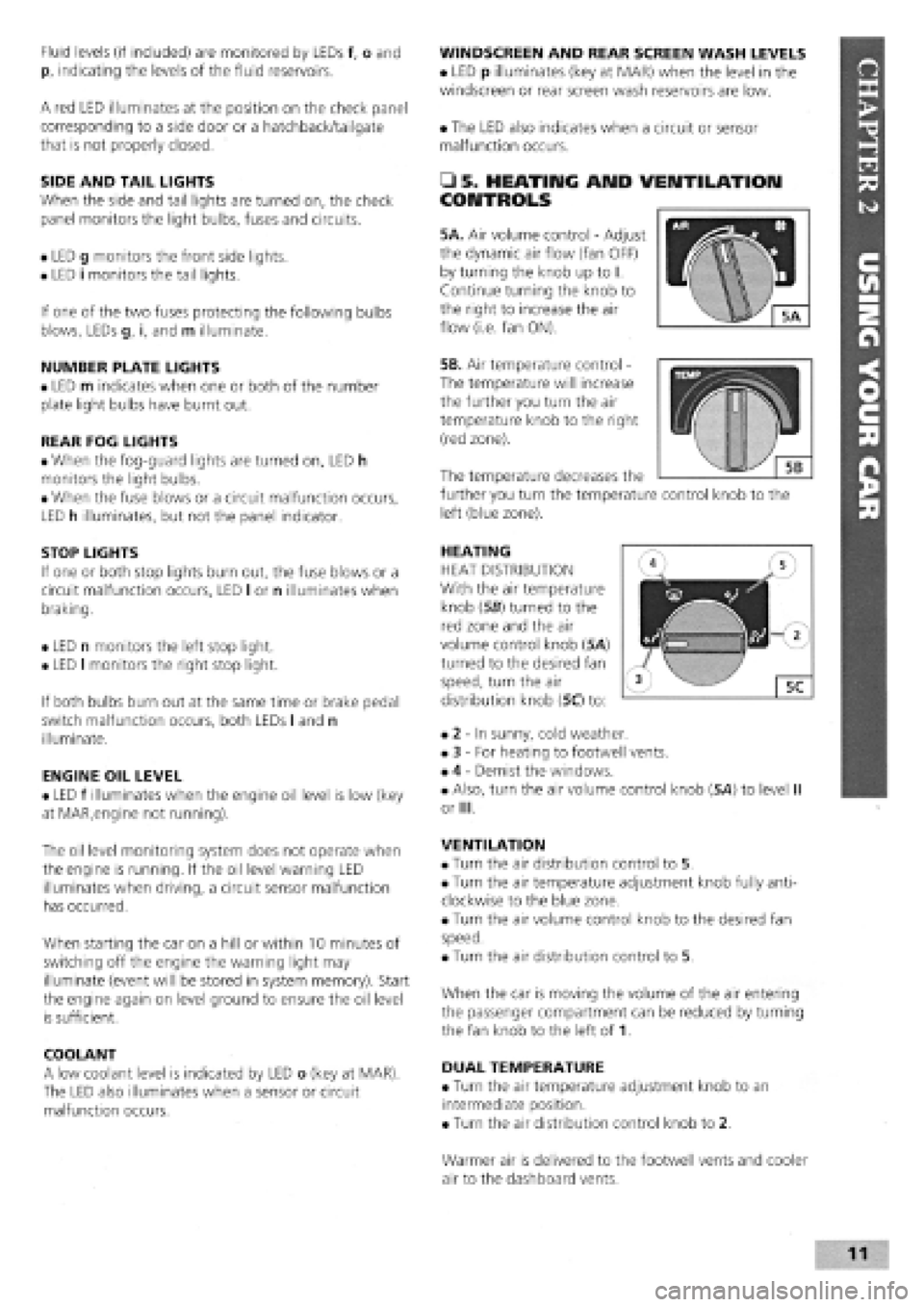

• 5. HE ATI IMG AMD VENTILATION

CONTROLS

5A. Air volume control

-

Adjust

the dynamic air flow (fan OFF)

by turning the knob up to I.

Continue turning the knob to

the right to increase the air

flow (i.e. fan ON).

5B. Air temperature control -

The temperature will increase

the further you turn the air

temperature knob to the right

(red zone).

HEATING

HEAT DISTRIBUTION

With the air temperature

knob (56) turned to the

red zone and the air

volume control knob (5A)

turned to the desired fan

speed, turn the air

distribution knob (5C) to:

• 2

-

In sunny, cold weather.

• 3

-

For heating to footwell vents.

• 4

-

Demist the windows.

• Also, turn the air volume control knob (5A) to level II

or III.

VENTILATION

• Turn the air distribution control to 5.

• Turn the air temperature adjustment knob fully anti-

clockwise to the blue zone.

• Turn the air volume control knob to the desired fan

speed.

• Turn the air distribution control to 5.

When the car is moving the volume of the air entering

the passenger compartment can be reduced by turning

the fan knob to the left of 1.

DUAL TEMPERATURE

• Turn the air temperature adjustment knob to an

intermediate position.

• Turn the air distribution control knob to 2.

The temperature decreases the

further you turn the temperature control knob to the

left (blue zone).

Warmer air is delivered to the footwell vents and cooler

air to the dashboard vents.

Page 22 of 171

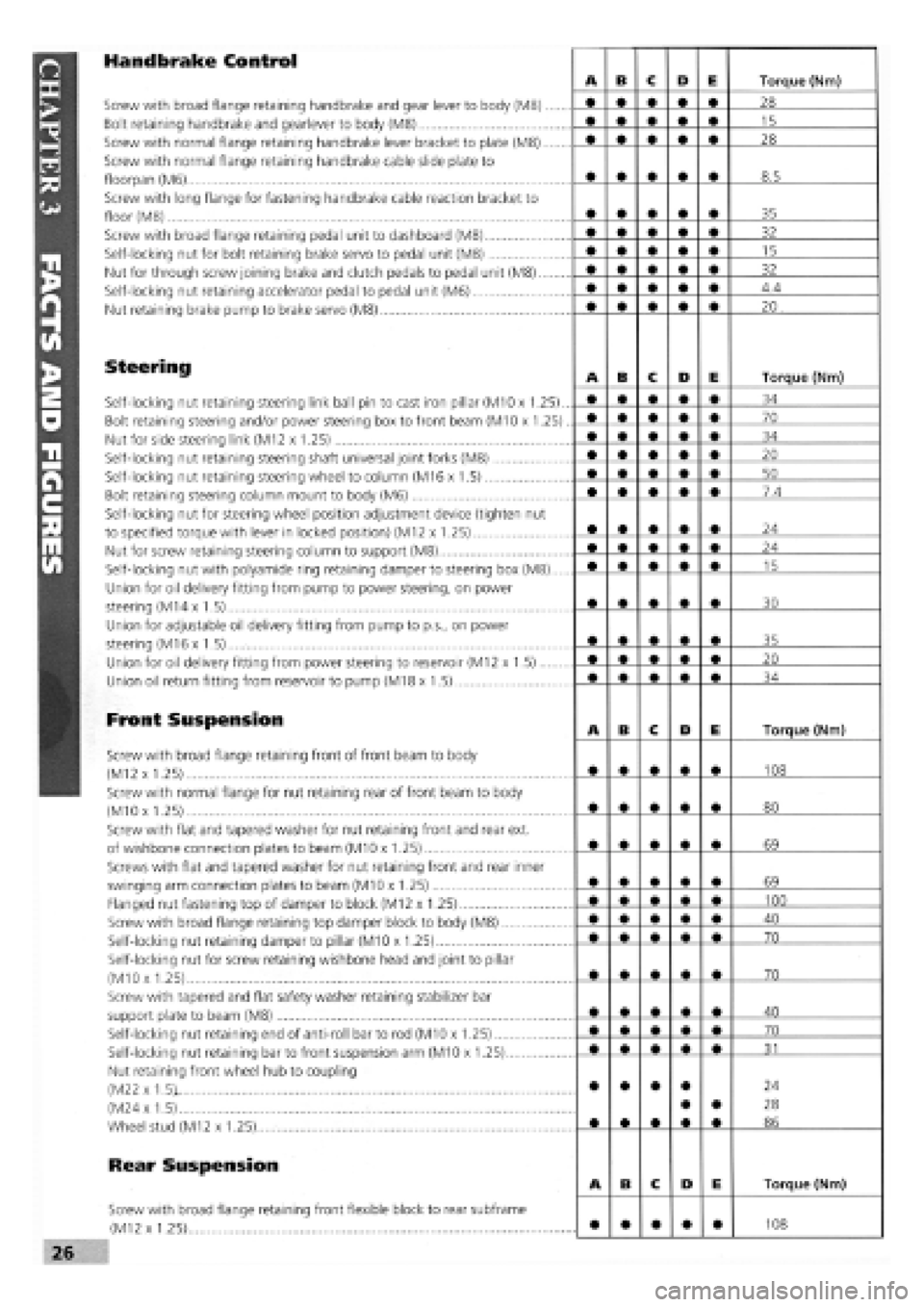

Handbrake Control

Screw with broad flange retaining handbrake and gear lever to body (M8)

Bolt retaining handbrake and gearlever to body (M8)

Screw with normal flange retaining handbrake lever bracket to plate (M8)

Screw with normal flange retaining handbrake cable slide plate to

floorpan (M6)

Screw with long flange for fastening handbrake cable reaction bracket to

floor (M8)

Screw with broad flange retaining pedal unit to dashboard (M8)

Self-locking nut for bolt retaining brake servo to pedal unit (M8)

Nut for through screw joining brake and clutch pedals to pedal unit (M8).

Self-locking nut retaining accelerator pedal to pedal unit (M6)

Nut retaining brake pump to brake servo (M8)

Steering

Self-locking nut retaining steering link ball pin to cast iron pillar (M10 x 1.25)..

Bolt retaining steering and/or power steering box to front beam (M10 x 1.25).

Nut for side steering link (M12 x 1.25)

Self-locking nut retaining steering shaft universal joint forks (M8)

Self-locking nut retaining steering wheel to column (M16 x 1.5)

Bolt retaining steering column mount to body (M6)

Self-locking nut for steering wheel position adjustment device (tighten nut

to specified torque with lever in locked position) (M12 x 1.25)

Nut for screw retaining steering column to support (M8)

Self-locking nut with polyamide ring retaining damper to steering box (M8)

Union for oil delivery fitting from pump to power steering, on power

steering (M14 x 1.5)

Union for adjustable oil delivery fitting from pump to p.s., on power

steering (M16 x 1.5)

Union for oil delivery fitting from power steering to reservoir (M12 x 1.5)

Union oil return fitting from reservoir to pump (M18 x 1.5)

Front Suspension

Screw with broad flange retaining front of front beam to body

(M12 x 1.25)

Screw with normal flange for nut retaining rear of front beam to body

(M10

x

1.25)

Screw with flat and tapered washer for nut retaining front and rear ext.

of wishbone connection plates to beam (M10 x 1.25)

Screws with flat and tapered washer for nut retaining front and rear inner

swinging arm connection plates to beam (M10 x 1.25)

Flanged nut fastening top of damper to block (M12 x 1.25)

Screw with broad flange retaining top damper block to body (M8)

Self-locking nut retaining damper to pillar (M10 x 1.25)

Self-locking nut for screw retaining wishbone head and joint to pillar

(M10

x

1.25)

Screw with tapered and flat safety washer retaining stabilizer bar

support plate to beam (M8)

Self-locking nut retaining end of anti-roll bar to rod (M10 x 1.25)

Self-locking nut retaining bar to front suspension arm (M10 x 1.25)

Nut retaining front wheel hub to coupling

(M22 x 1.5)i

(M24

x

1.5)

Wheel stud (M12 x 1.25).....

Rear Suspension

Screw with broad flange retaining front flexible block to rear subframe

(M12 x 1.25)

A B C D E Torque (Nm)

• • • • • 28

• • • • • 15

• • • • • 28

8.5

35

32

15

32

4.4

20 .

A B C D E Torque (Nm)

• • • • • 34

70

34

• • • • • 20

50

7.4

24

24

15

30

35

20

34

A B c D E Torque (Nm)

108

80

69

69

100

40

70

70

40

70

31

• • • • • •

24

28

86

A B c D E Torque (Nm)

108

Page 36 of 171

LUGGAGE COMPARTMENT LIGHT

7b. TIPO: Pull the lens

downwards to remove

it. Remove and replace

the 5W tubular bulb.

7c. TEMPRA SALOON:

From inside the boot,

lever the light unit out

of its slot with a screw-

driver. Remove and

replace the 5W tubular

bulb (A).

DASH BULBS

See Chapter 6, Repairs and Replacements for details of

instrument panel removal for access to its light bulbs. The

bulbs are a quarter-turn fit in the back of the panel.

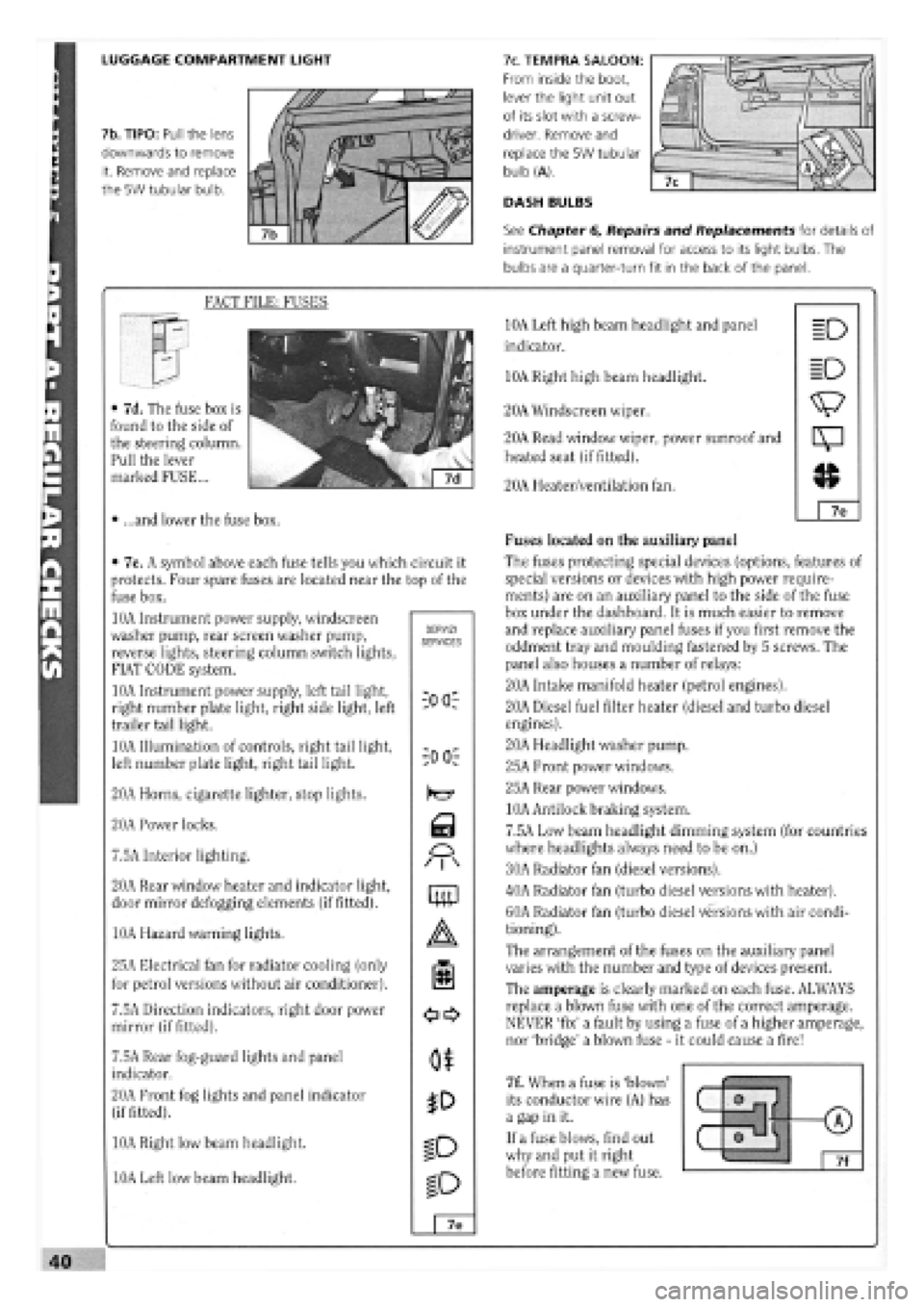

FACT FILE: FUSES

• 7d. The fuse box is

found to the side of

the steering column.

Pull the lever

marked FUSE...

• ...and lower the fuse box.

• 7e. A symbol above each fuse tells you which circuit it

protects. Four spare fuses are located near the top of the

fuse box.

10A Instrument power supply, windscreen

washer pump, rear screen washer pump,

reverse lights, steering column switch lights,

FIAT CODE system.

10A Instrument power supply, left tail light,

right number plate light, right side light, left

trailer tail light.

10A Illumination of controls, right tail light,

left number plate light, right tail light.

20A Horns, cigarette lighter, stop lights.

20A Power locks.

7.5A Interior lighting.

20A Rear window heater and indicator light,

door mirror defogging elements (if fitted).

10A Hazard warning lights.

25A Electrical fan for radiator cooling (only

for petrol versions without air conditioner).

7.5A Direction indicators, right door power

mirror (if fitted).

7.5A Rear fog-guard lights and panel

indicator.

20A Front fog lights and panel indicator

(if fitted).

10A Right low beam headlight.

10A Left low beam headlight.

SERVIZI SERVICES

iOO:

-00 r

Q

M

mp

o$

ID

ID

7e

10A Left high beam headlight and panel

indicator.

10A Right high beam headlight.

20A Windscreen wiper.

20A Read window wiper, power sunroof and

heated seat (if fitted).

20A Heater/ventilation fan.

Fuses located on the auxiliary panel

The fuses protecting special devices (options, features of

special versions or devices with high power require-

ments) are on an auxiliary panel to the side of the fuse

box under the dashboard. It is much easier to remove

and replace auxiliary panel fuses if you first remove the

oddment tray and moulding fastened by 5 screws. The

panel also houses a number of relays:

20A Intake manifold heater (petrol engines).

20A Diesel fuel filter heater (diesel and turbo diesel

engines).

20A Headlight washer pump.

25A Front power windows.

25A Rear power windows.

10A Antilock braking system.

7.5A Low beam headlight dimming system (for countries

where headlights always need to be on.)

30A Radiator fan (diesel versions).

40A Radiator fan (turbo diesel versions with heater).

60A Radiator fan (turbo diesel versions with air condi-

tioning).

The arrangement of the fuses on the auxiliary panel

varies with the number and type of devices present.

The amperage is clearly marked on each fuse. ALWAYS

replace a blown fuse with one of the correct amperage.

NEVER 'fix' a fault by using a fuse of a higher amperage,

nor 'bridge' a blown fuse

-

it could cause a fire!

7f. When a fuse is 'blown'

its conductor wire (A) has

a gap in it.

If a fuse blows, find out

why and put it right

before fitting a new fuse.

(7)

o m f (7) (7)

0 tJ 7f

Page 52 of 171

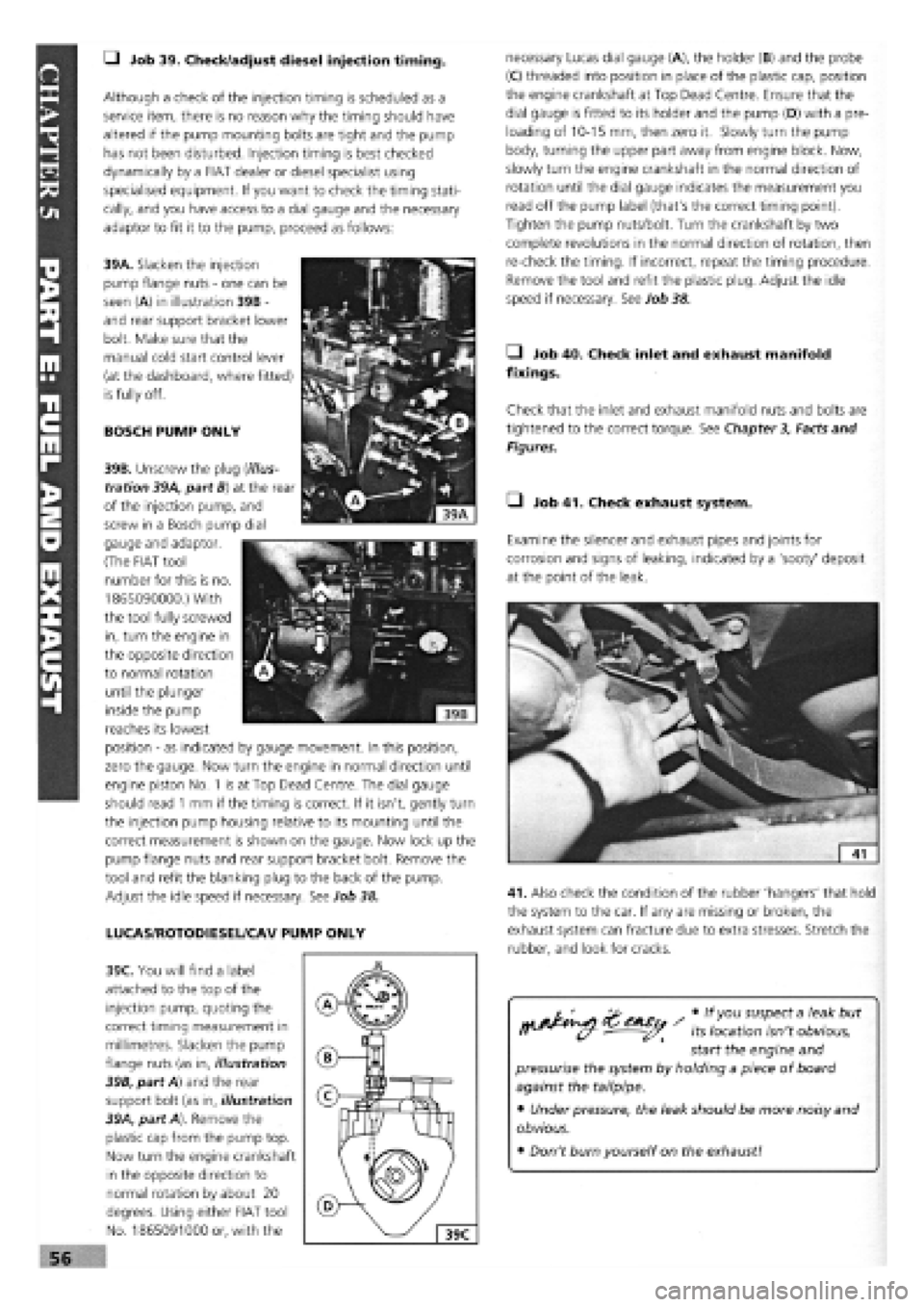

• Job 39. Check/adjust diesel injection timing.

Although a check of the injection timing is scheduled as a

service item, there is no reason why the timing should have

altered if the pump mounting bolts are tight and the pump

has not been disturbed. Injection timing is best checked

dynamically by a FIAT dealer or diesel specialist using

specialised equipment. If you want to check the timing stati-

cally, and you have access to a dial gauge and the necessary

adaptor to fit it to the pump, proceed as follows:

39A. Slacken the injection

pump flange nuts

-

one can be

seen (A) in illustration 39B -

and rear support bracket lower

bolt. Make sure that the

manual cold start control lever

(at the dashboard, where fitted)

is fully off.

BOSCH PUMP ONLY

necessary Lucas dial gauge (A), the holder (B) and the probe

(C) threaded into position in place of the plastic cap, position

the engine crankshaft at Top Dead Centre. Ensure that the

dial gauge is fitted to its holder and the pump (D) with a pre-

loading of 10-15 mm, then zero it. Slowly turn the pump

body, turning the upper part away from engine block. Now,

slowly turn the engine crankshaft in the normal direction of

rotation until the dial gauge indicates the measurement you

read off the pump label (that's the correct timing point).

Tighten the pump nuts/bolt. Turn the crankshaft by two

complete revolutions in the normal direction of rotation, then

re-check the timing. If incorrect, repeat the timing procedure.

Remove the tool and refit the plastic plug. Adjust the idle

speed if necessary. See Job 38.

• Job 40. Check inlet and exhaust manifold

fixings.

Check that the inlet and exhaust manifold nuts and bolts are

tightened to the correct torque. See Chapter

3,

Facts and

Figures.

• Job 41. Check exhaust system.

Examine the silencer and exhaust pipes and joints for

corrosion and signs of leaking, indicated by a 'sooty' deposit

at the point of the leak.

41. Also check the condition of the rubber 'hangers' that hold

the system to the car. If any are missing or broken, the

exhaust system can fracture due to extra stresses. Stretch the

rubber, and look for cracks.

39B. Unscrew the plug (illus-

tration 39A, part B) at the rear

of the injection pump, and

screw in a Bosch pump dial

gauge and adaptor.

(The FIAT tool

number for this is no.

1865090000.) With

the tool fully screwed

in, turn the engine in

the opposite direction

to normal rotation

until the plunger

inside the pump

reaches its lowest

position

-

as indicated by gauge movement. In this position,

zero the gauge. Now turn the engine in normal direction until

engine piston No. 1 is at Top Dead Centre. The dial gauge

should read

1

mm if the timing is correct. If it isn't, gently turn

the injection pump housing relative to its mounting until the

correct measurement is shown on the gauge. Now lock up the

pump flange nuts and rear support bracket bolt. Remove the

tool and refit the blanking plug to the back of the pump.

Adjust the idle speed if necessary. See Job 38.

LUCAS/ROTODIESEL/CAV PUMP ONLY

39C. You will find a label

attached to the top of the

injection pump, quoting the

correct timing measurement in

millimetres. Slacken the pump

flange nuts (as in, illustration

39B, part A) and the rear

support bolt (as in, illustration

39A, part A). Remove the

plastic cap from the pump top.

Now turn the engine crankshaft

in the opposite direction to

normal rotation by about 20

degrees. Using either FIAT tool

No. 1865091000 or, with the

cos / * susPect a but

fl^^^Cf- ^^ its location isn't obvious,

start the engine and

pressurise the system by holding a piece of board

against the tailpipe.

• Under pressure, the leak should be more noisy and

obvious.

• Don't burn yourself on the exhaust!

Page 146 of 171

B INSIDE INFORMATION! As an alternative to steps A1

and A2 you can disconnect all the electrical plugs under

the dashboard, which have wires which go through to

the door. B

LI Step A3: Support the door using a trolley jack with a

wad of rag on its pad for protection.

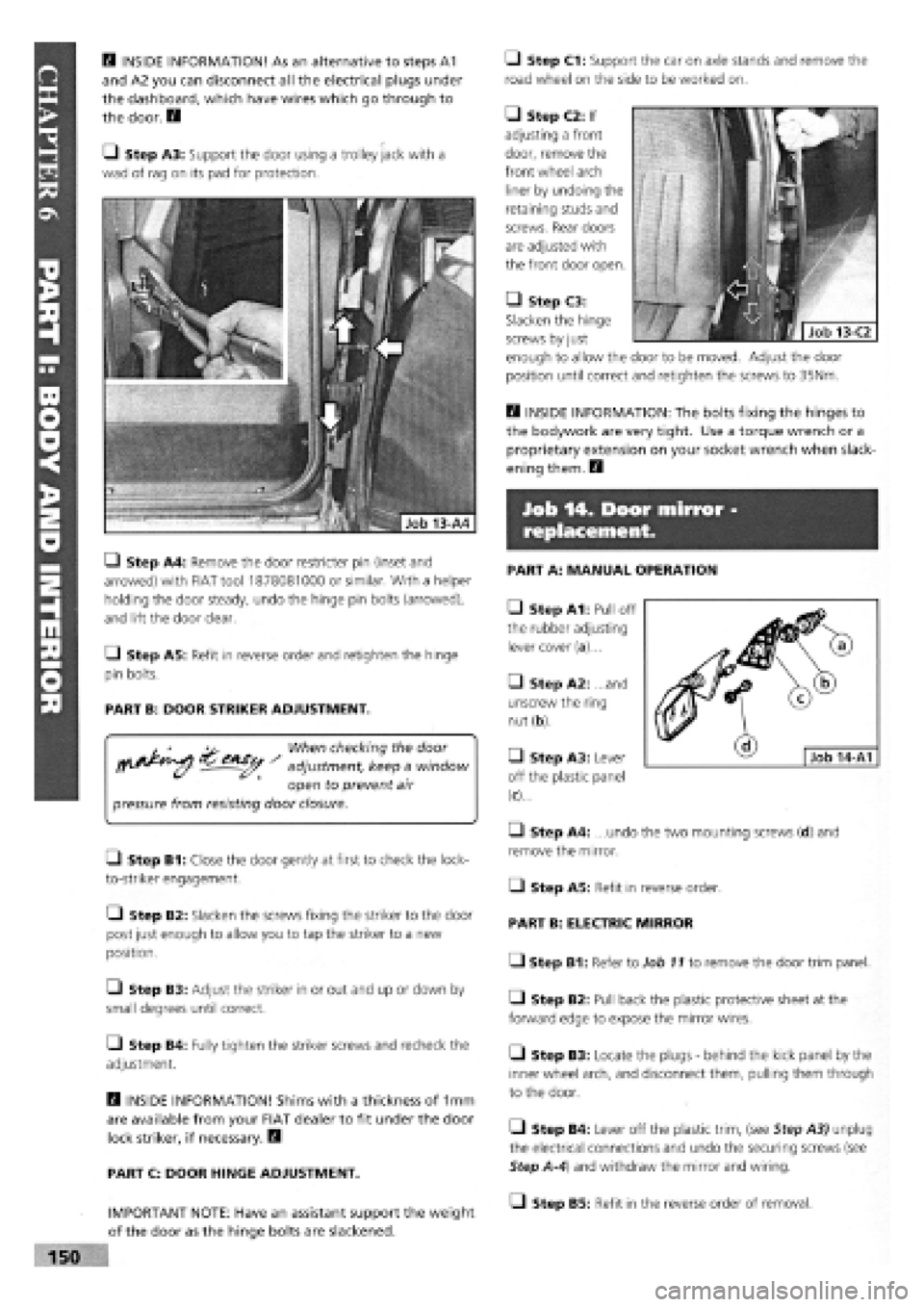

LI Step A4: Remove the door restricter pin (inset and

arrowed) with FIAT tool 1878081000 or similar. With a helper

holding the door steady, undo the hinge pin bolts (arrowed),

and lift the door clear.

• Step A5: Refit in reverse order and retighten the hinge

pin bolts.

PART B: DOOR STRIKER ADJUSTMENT.

, ' -u. When checking the door

jpj^ adjustment, keep a window

open to prevent air

pressure from resisting door closure.

• Step B1: Close the door gently at first to check the lock-

to-striker engagement.

• Step B2: Slacken the screws fixing the striker to the door

post just enough to allow you to tap the striker to a new

position.

L) Step B3: Adjust the striker in or out and up or down by

small degrees until correct.

Q Step B4: Fully tighten the striker screws and recheck the

adjustment.

B INSIDE INFORMATION! Shims with a thickness of 1mm

are available from your FIAT dealer to fit under the door

lock striker, if necessary. B

PART C: DOOR HINGE ADJUSTMENT.

IMPORTANT NOTE: Have an assistant support the weight

of the door as the hinge bolts are slackened.

• Step C1: Support the car on axle stands and remove the

road wheel on the side to be worked on.

• Step C2: If

adjusting a front

door, remove the

front wheel arch

liner by undoing the

retaining studs and

screws. Rear doors

are adjusted with

the front door open.

B INSIDE INFORMATION: The bolts fixing the hinges to

the bodywork are very tight. Use a torque wrench or a

proprietary extension on your socket wrench when slack-

ening them. B

Job 14. Door mirror -

replacement.

PART A: MANUAL OPERATION

• Step A1: Pull off

the rubber adjusting

lever cover (a)...

• Step A2: and

unscrew the ring

nut (b).

• Step A3: Lever

off the plastic panel

(c)...

• Step A4: ...undo the two mounting screws (d) and

remove the mirror.

D Step A5: Refit in reverse order.

PART B: ELECTRIC MIRROR

• Step B1: Refer to Job 11 to remove the door trim panel.

• Step B2: Pull back the plastic protective sheet at the

forward edge to expose the mirror wires.

• Step B3: Locate the plugs

-

behind the kick panel by the

inner wheel arch, and disconnect them, pulling them through

to the door.

• Step B4: Lever off the plastic trim, (see Step A3) unplug

the electrical connections and undo the securing screws (see

Step A-4) and withdraw the mirror and wiring.

LI Step B5: Refit in the reverse order of removal.

• Step C3:

Slacken the hinge

screws by just

enough to allow the door to be moved. Adjust the door

position until correct and retighten the screws to 35Nm.