gearbox FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 2 of 171

Running The Vehicle

NEVER start the engine unless the gearbox is in neutral (or

'Park' in the case of automatic transmission) and the hand

brake is fully applied.

NEVER run catalytic converter equipped vehicles without the

exhaust system heat shields in place.

TAKE CARE when parking vehicles fitted with catalytic

converters. The 'cat' reaches extremely high temperatures and

any combustible materials under the car, such as long dry

grass, could be ignited.

Personal Safety

NEVER siphon fuel, antifreeze, brake fluid or other such toxic

liquids by mouth, or allow contact with your skin. Use a

suitable hand pump and wear gloves.

BEFORE undertaking dirty jobs, use a barrier cream on your

hands as a protection against infection. Preferably, wear

suitable gloves, available from DIY outlets.

WEAR IMPERVIOUS GLOVES for sure when there is a risk of

used engine oil coming into contact with your skin. It can

cause cancer.

WIPE UP any spilt oil, grease or water off the floor

immediately.

MAKE SURE that spanners and all other tools are the right size

for the job and are not likely to slip. Never try to 'double-up'

spanners to gain more leverage.

SEEK HELP if you need to lift something heavy which may be

beyond your capability. Don't forget that when lifting a heavy

weight, you should keep your back straight and bend your

knees to avoid injuring your back.

NEVER take risky short-cuts or rush to finish a job. Plan ahead

and allow plenty of time.

BE METICULOUS and keep the work area tidy

-

you'll avoid

frustration, work better and lose less.

KEEP children and animals right-away from the work area and

from unattended vehicles.

ALWAYS tell someone what you're doing and have them

regularly check that all is well, especially when working alone

on, or under, the vehicle.

Fire!

Petrol (gasoline) is a dangerous and highly flammable liquid

requiring special precautions. When working on the fuel

system, disconnect the vehicle battery earth (ground) terminal

whenever possible and always work outside, or in a very well

ventilated area. Any form of spark, such as that caused by an

electrical fault, by two metal surfaces striking against each

other, by a central heating boiler in the garage 'firing up', or

even by static electricity built up in your clothing can, in a

confined space, ignite petrol vapour causing an explosion.

Take great care not to spill petrol on to the engine or exhaust

system, never allow any naked flame anywhere near the work

area and, above all, don't smoke.

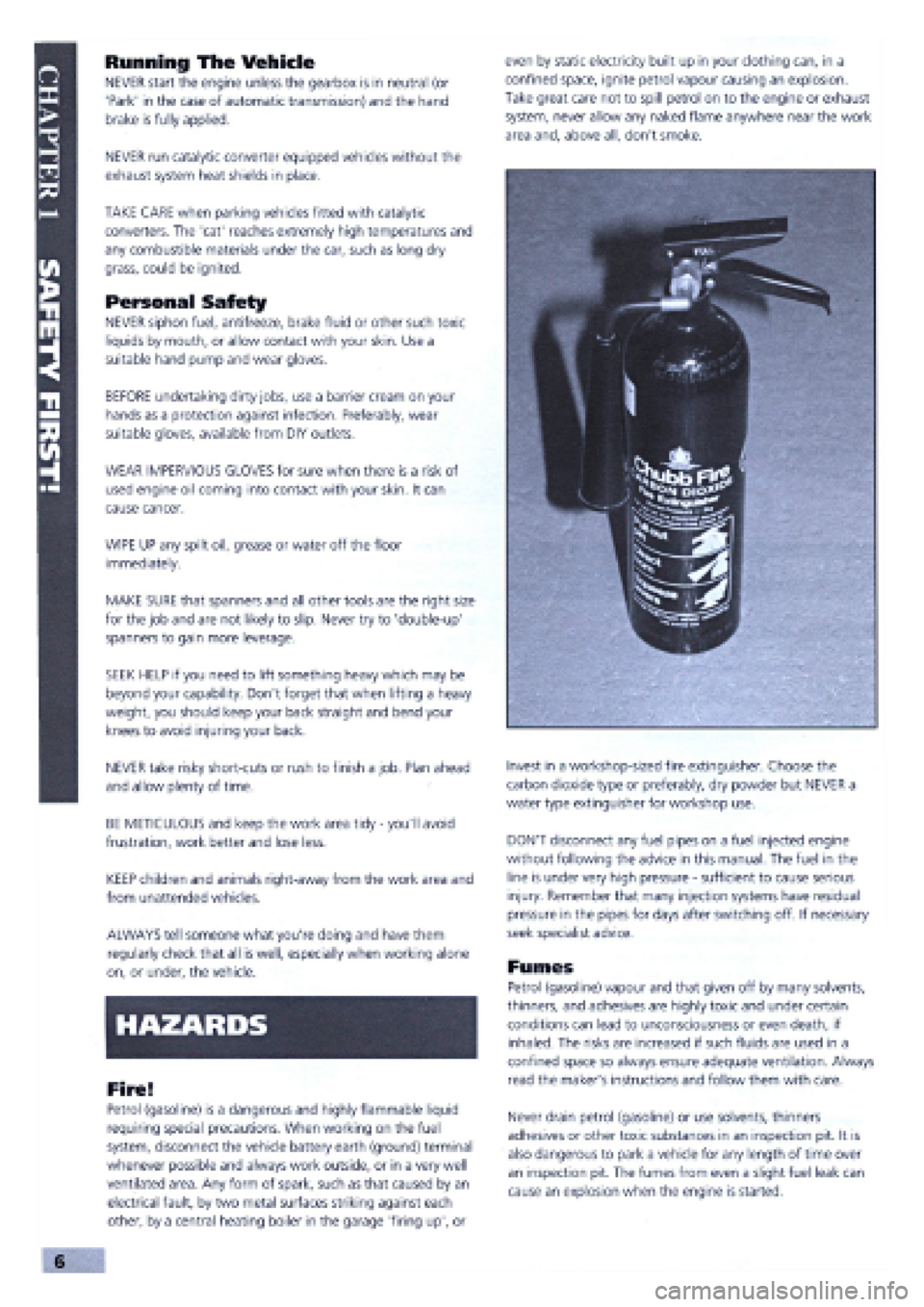

Invest in a workshop-sized fire extinguisher. Choose the

carbon dioxide type or preferably, dry powder but NEVER a

water type extinguisher for workshop use.

DON'T disconnect any fuel pipes on a fuel injected engine

without following the advice in this manual. The fuel in the

line is under very high pressure

-

sufficient to cause serious

injury. Remember that many injection systems have residual

pressure in the pipes for days after switching off. If necessary

seek specialist advice.

Fumes

Petrol (gasoline) vapour and that given off by many solvents,

thinners, and adhesives are highly toxic and under certain

conditions can lead to unconsciousness or even death, if

inhaled. The risks are increased if such fluids are used in a

confined space so always ensure adequate ventilation. Always

read the maker's instructions and follow them with care.

Never drain petrol (gasoline) or use solvents, thinners

adhesives or other toxic substances in an inspection pit. It is

also dangerous to park a vehicle for any length of time over

an inspection pit. The fumes from even a slight fuel leak can

cause an explosion when the engine is started.

v ,,, Oil;::;s

Page 4 of 171

and explosions. Do not allow resin or 2-pack adhesive hardener,

or that supplied with filler or 2-pack stopper, to come into

contact with skin or eyes. Read carefully the safety notes

supplied on the can, tube or packaging and always wear

impervious gloves and goggles when working with them.

Fluoroelastomers

Fluoroelastomers are commonly used for oil seals, wiring and

cabling, bearing surfaces, gaskets, diaphragms, hoses and '0'

rings. If they are subjected to temperatures greater than 315

degrees C, they will decompose and can be potentially

hazardous. Some decomposition may occur at temperatures

above 200 degrees C, and it is obvious that when a car has

been in a fire or has been dismantled with the assistance of a

cutting torch or blow torch, the fluoroelastomers can

decompose in the manner indicated above.

According to the Health and Safety Executive, "Skin contact

with this liquid or decomposition residues can cause painful and

penetrating burns. Permanent irreversible skin and tissue

damage can occur". Damage can also be caused to eyes or by

the inhalation of fumes created as fluoroelastomers are burned

or heated.

After a vehicle has been exposed to fire or high temperatures:

1. Do not touch blackened or charred seals or equipment.

2. Preferably, don't handle parts containing decomposed

fluoroelastomers, but if you must, wear goggles and PVC

(polyvinyl chloride) or neoprene protective gloves whilst doing

so. Never handle such parts unless they are completely cool.

3. Contaminated parts, residues, materials and clothing,

including protective clothing and gloves, should be disposed of

by an approved contractor to landfill or by incineration

according to national or local regulations. Oil seals, gaskets and

'0' rings, along with contaminated material, must not

be burned.

1. Always have a fire extinguisher of the correct type at arm's

length when working on the fuel system. If you do have a fire,

DON'T PANIC. Use the extinguisher effectively by directing it at

the base of the fire.

2. NEVER use a naked flame anywhere in the workplace.

3. KEEP your inspection lamp well away from any source of

petrol (gasoline) such as when disconnecting a carburettor float

bowl or fuel line.

4. NEVER use petrol (gasoline) to clean parts. Use paraffin

(kerosene), white spirits, or, a proprietary degreaser.

5. NO SMOKING. There's a risk of fire or of transferring

dangerous substances to your mouth and, in any case, ash

falling into mechanical components is to be avoided.

FACT FILE: FOUR WHEEL DRIVE CARS

• Whenever you have to raise a wheel off the

ground and turn it by hand, always ensure that

the opposite-side's wheel to the one being lifted is

also off the ground and free to turn and that both wheels remaining

on the ground are held by the parking brake (if possible) and

securely chocked in both directions.

• ALWAYS have the gearbox in neutral (or 'N' in the case of

automatics). In the case of

some

4 wheel drive automatics and those

with permanent 4WD, it is necessary to disengage the 4WD system

by special means.

• Consult your handbook or seek advice from your main dealer.

6. BE METHODICAL in everything you do, use common sense,

and think of safety at all times.

ENVIRONMENT FIRST!

The used oil from the sump of

just

one car

can

cover

an

area of

water the size of two football pitches, cutting off the oxygen

supply

and

harming swans, ducks, fish and other river lift.

When you drain your engine oil

-

don't oil the drain!

Pouring oil

down the

drain will

cause

pollution. It is

also an

offense.

Don't mix used

oil with other

materials, such

as paint and

solvents,

because this

makes

recycling

difficult.

Take used oil

to an oil

recycling bank.

Telephone

FREE on 0800 663366 to find the location of your nearest oil

bank, or contact you local authority recycling officer.

OIL POLLUTES WATER

USE YOUR BRAIN-

NOT THE DRAIN!

Page 12 of 171

EMERGENCY STARTING

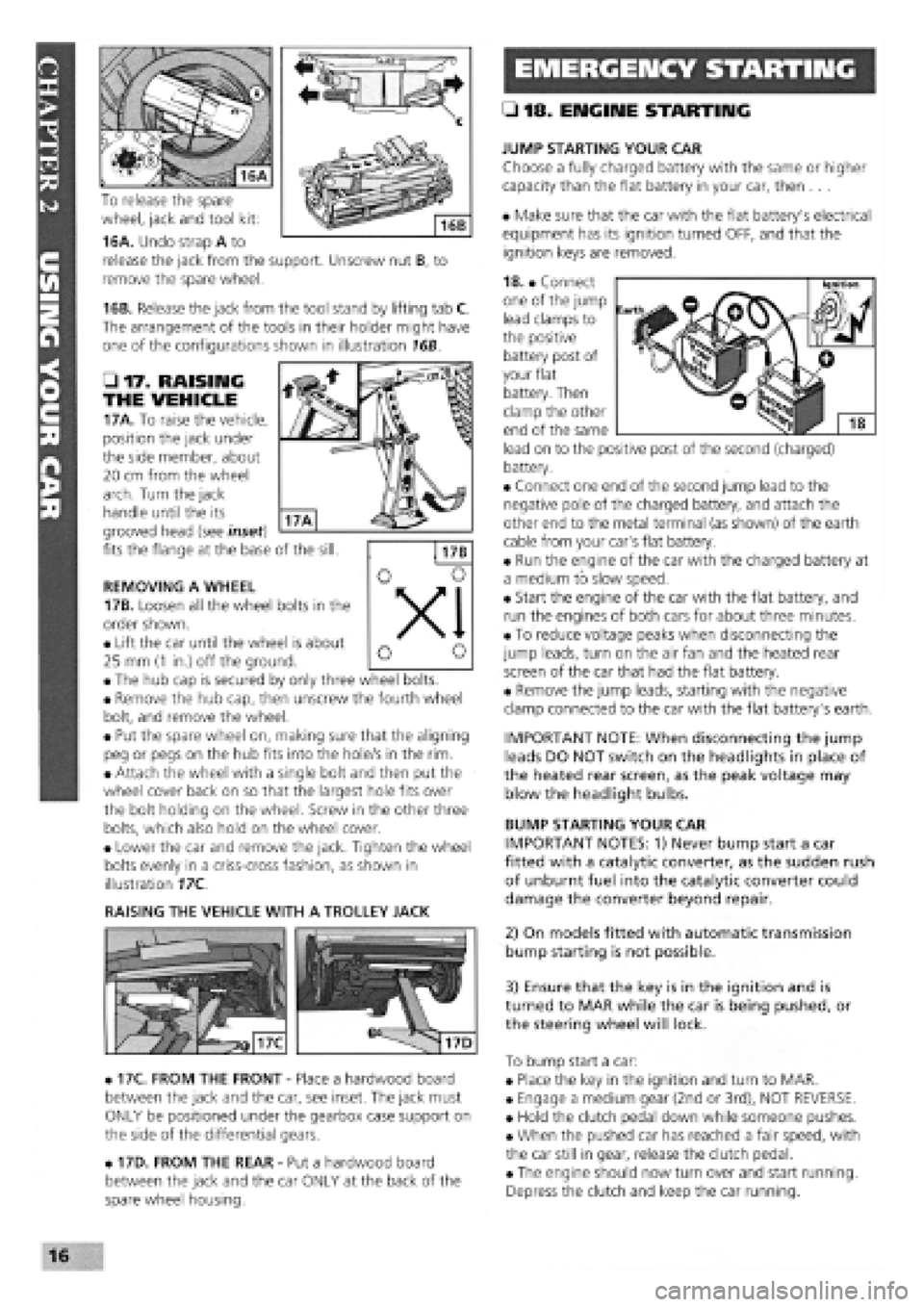

To release the spare

wheel, jack and tool kit:

16A. Undo strap A to

release the jack from the support. Unscrew nut B, to

remove the spare wheel.

16B. Release the jack from the tool stand by lifting tab C.

The arrangement of the tools in their holder might have

one of the configurations shown in illustration 16B.

• 17. RAISING

THE VEHICLE

17A. To raise the vehicle,

position the jack under

the side member, about

20 cm from the wheel

arch. Turn the jack

handle until the its

grooved head (see inset)

fits the flange at the base of the sill.

REMOVING A WHEEL

17B. Loosen all the wheel bolts in the

order shown.

• Lift the car until the wheel is about

25 mm

(1

in.) off the ground.

• The hub cap is secured by only three wheel bolts.

• Remove the hub cap, then unscrew the fourth wheel

bolt, and remove the wheel.

• Put the spare wheel on, making sure that the aligning

peg or pegs on the hub fits into the hole/s in the rim.

• Attach the wheel with a single bolt and then put the

wheel cover back on so that the largest hole fits over

the bolt holding on the wheel. Screw in the other three

bolts, which also hold on the wheel cover.

• Lower the car and remove the jack. Tighten the wheel

bolts evenly in a criss-cross fashion, as shown in

illustration 17C.

RAISING THE VEHICLE WITH A TROLLEY JACK

• 17C. FROM THE FRONT

-

Place a hardwood board

between the jack and the car, see inset. The jack must

ONLY be positioned under the gearbox case support on

the side of the differential gears.

• 17D. FROM THE REAR

-

Put a hardwood board

between the jack and the car ONLY at the back of the

spare wheel housing.

• 18. ENGINE STARTING

JUMP STARTING YOUR CAR

Choose a fully charged battery with the same or higher

capacity than the flat battery in your car, then ...

• Make sure that the car with the flat battery's electrical

equipment has its ignition turned OFF, and that the

ignition keys are removed.

18. • Connect

one of the jump

lead clamps to

the positive

battery post of

your flat

battery. Then

clamp the other

end of the same

lead on to the positive post of the second (charged)

battery.

• Connect one end of the second jump lead to the

negative pole of the charged battery, and attach the

other end to the metal terminal (as shown) of the earth

cable from your car's flat battery.

• Run the engine of the car with the charged battery at

a medium to slow speed.

• Start the engine of the car with the flat battery, and

run the engines of both cars for about three minutes.

• To reduce voltage peaks when disconnecting the

jump leads, turn on the air fan and the heated rear

screen of the car that had the flat battery.

• Remove the jump leads, starting with the negative

clamp connected to the car with the flat battery's earth.

IMPORTANT NOTE: When disconnecting the jump

leads DO NOT switch on the headlights in place of

the heated rear screen, as the peak voltage may

blow the headlight bulbs.

BUMP STARTING YOUR CAR

IMPORTANT NOTES: 1) Never bump start a car

fitted with a catalytic converter, as the sudden rush

of unburnt fuel into the catalytic converter could

damage the converter beyond repair.

2) On models fitted with automatic transmission

bump starting is not possible.

3) Ensure that the key is in the ignition and is

turned to MAR while the car is being pushed, or

the steering wheel will lock.

To bump start a car:

• Place the key in the ignition and turn to MAR.

• Engage a medium gear (2nd or 3rd), NOT REVERSE.

• Hold the clutch pedal down while someone pushes.

• When the pushed car has reached a fair speed, with

the car still in gear, release the clutch pedal.

• The engine should now turn over and start running.

Depress the clutch and keep the car running.

16

Page 13 of 171

CHAPTER 3

FACTS ARID FIGURES

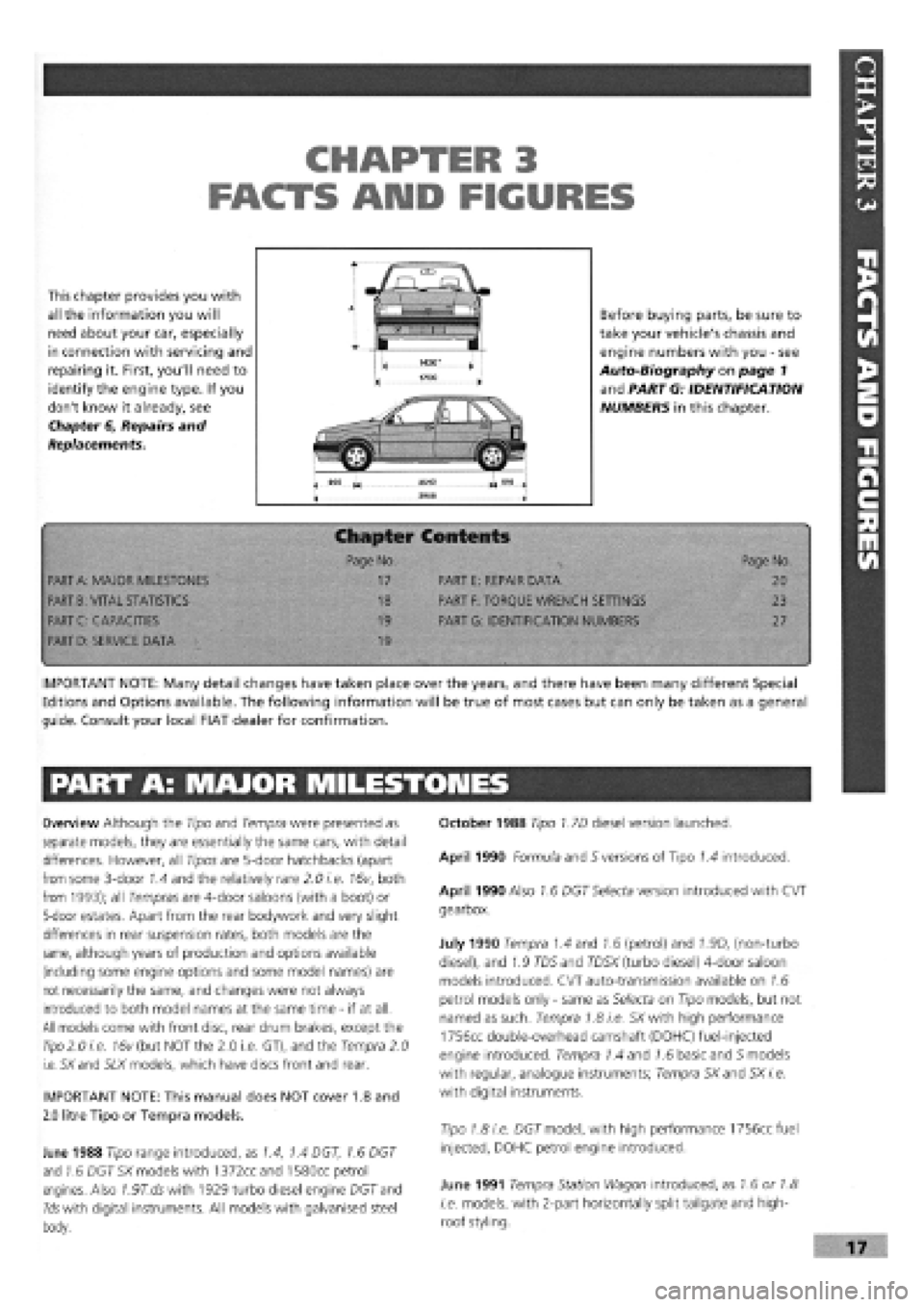

This chapter provides you with

all the information you will

need about your car, especially

in connection with servicing and

repairing it. First, you'll need to

identify the engine type. If you

don't know it already, see

Chapter 6, Repairs and

Replacements.

Before buying parts, be sure to

take your vehicle's chassis and

engine numbers with you

-

see

Auto-Biography on page 1

and PART G: IDENTIFICATION

NUMBERS in this chapter.

Chapter Contents

• -< Page No. Page No.

PART

A:

MAJOR MILESTONES 17 PART E: REPAIR DATA 20

PART

B:

VITAL STATISTICS 18 PART

F:

TORQUE WRENCH SETTINGS 23

PART C: CAPACITIES 19 PART G: IDENTIFICATION NUMBERS 27

PART

D:

SERVICE DATA 19

•

IMPORTANT NOTE: Many detail changes have taken place over the years, and there have been many different Special

Editions and Options available. The following information will be true of most cases but can only be taken as a general

guide. Consult your local FIAT dealer for confirmation.

PART A: MAJOR MILESTONES

Overview Although the Tipo and Tempra were presented as

separate models, they are essentially the same cars, with detail

differences. However, all Tipos are 5-door hatchbacks (apart

from some 3-door 1.4 and the relatively rare 2.0 i.e. 16v, both

from 1993); all Tempras are 4-door saloons (with a boot) or

5-door estates. Apart from the rear bodywork and very slight

differences in rear suspension rates, both models are the

same, although years of production and options available

(including some engine options and some model names) are

not necessarily the same, and changes were not always

introduced to both model names at the same time

-

if at all.

All models come with front disc, rear drum brakes, except the

Tipo

2.0 i.e. 16v (but NOT the 2.0 i.e. GT), and the Tempra 2.0

i.e. SXand SLX models, which have discs front and rear.

IMPORTANT NOTE: This manual does NOT cover 1.8 and

2.0 litre Tipo or Tempra models.

June 1988 Tipo range introduced, as 1.4, 1.4 DGT, 1.6 DGT

and 1.6 DGT SX models with 1372ccand 1580cc petrol

engines. Also 7.97".dswith 1929 turbo diesel engine DGT and

Ids with digital instruments. All models with galvanised steel

body.

October 1988 Tipo 1.7D diesel version launched.

April 1990 Formula and S versions of Tipo 1.4 introduced.

April 1990 Also 1.6 DGT Selecta version introduced with CVT

gearbox.

July 1990 Tempra 1.4 and 1.6 (petrol) and 1.9D, (non-turbo

diesel), and 1.9 TD5 and TD5X (turbo diesel) 4-door saloon

models introduced. CVT auto-transmission available on 1.6

petrol models only

-

same as Selecta on Tipo models, but not

named as such. Tempra 1.8 i.e. SX with high performance

1756cc double-overhead camshaft (DOHC) fuel-injected

engine introduced. Tempra 1.4 and 1.6 basic and 5 models

with regular, analogue instruments; Tempra SXand SX i.e.

with digital instruments.

Tipo 1.8 i.e. DGT model, with high performance 1756cc fuel

injected, DOHC petrol engine introduced.

June 1991 Tempra Station Wagon introduced, as 1.6 or 1.8

i.e. models, with 2-part horizontally split tailgate and high-

roof styling.

Page 14 of 171

October 1991 2.0 i.e. 16v introduced, with 1995cc, 16 valve

high-performance DOHC engine, catalytic converter, sports

suspension, front and rear disc brakes. ABS available as

option.

January 1992 Existing Tipo models lightly facelifted and

redesignated 1.4 Formula, 1.45, 1.6S, 1.6SX, 1.9TD SX,

1.8 i.e. SX. 1.7D discontinued. SX versions with digital

instruments.

Tempra 1.9 TDS (turbo diesel) Station Wagon introduced. 1.4

and 1.9D saloons discontinued.

May 1992 Tempra 1.8 i.e. SX Saloon and Station Wagon

discontinued.

June 1992 Tempra 2.0 i.e. SX saloon and station wagon

models introduced, with high performance 1995cc DOHC fuel

injected engine, catalytic converter and disc brakes front and

rear.

Tipo 1.4 and all Tipo and Tempra 1.6 models (except Selecta)

now with a catalytic converter and fuel injection in place of

Weber twin-choke carburettor. Designated i.e. in badging.

December 1992 Tipo 1.8 i.e. and 1.6 Selecta discontinued.

February 1993 Tipo 2.0 i.e. GT introduced. Slightly lower

performance and spec, version of the 16v model.

July 1993 Tipo 1.4 now available as a 3-door or 5-door

hatchback. 2.0 i.e. 16v now only available as 3-door. Tipo 2.0

i.e. GT replaced by similar spec. 2.0 i.e. SLX.

Tempra 2.0 i.e. SX saloons and estates now only available

with auto, gearbox. Otherwise, SX models become known as

SLX, with colour-coded mirrors and ABS brakes. Most Tempras

now with body-coloured bumpers. 1.9D (non turbo Diesel re-

introduced).

All Tipo and Tempra models now with revised front-end

styling

-

narrower headlights and revised grille. Improved crash

protection, including side impact beams, safety steering wheel

and uprated brakes. Power steering, central locking, electric

windows all standard.

February 1994 Tipo 1.7 non-turbo diesel re-introduced as

1.7 DS.

May 1994 Tempra 1.9DS Station Wagon introduced.

September 1994 Most models available with driver's airbag,

fire prevention system and seat belt pre-tensioners.

December 1994 Tempra 1.6 i.e. versions get M.P.I, engine.

February/March 1995 All models with VIN number window

etching and immobiliser standard on all Tempra petrol models.

October 1995 Immobiliser fitted to Tempra D and TD models.

End of 1995 Tipo discontinued.

Mid-1996 Tempra discontinued.

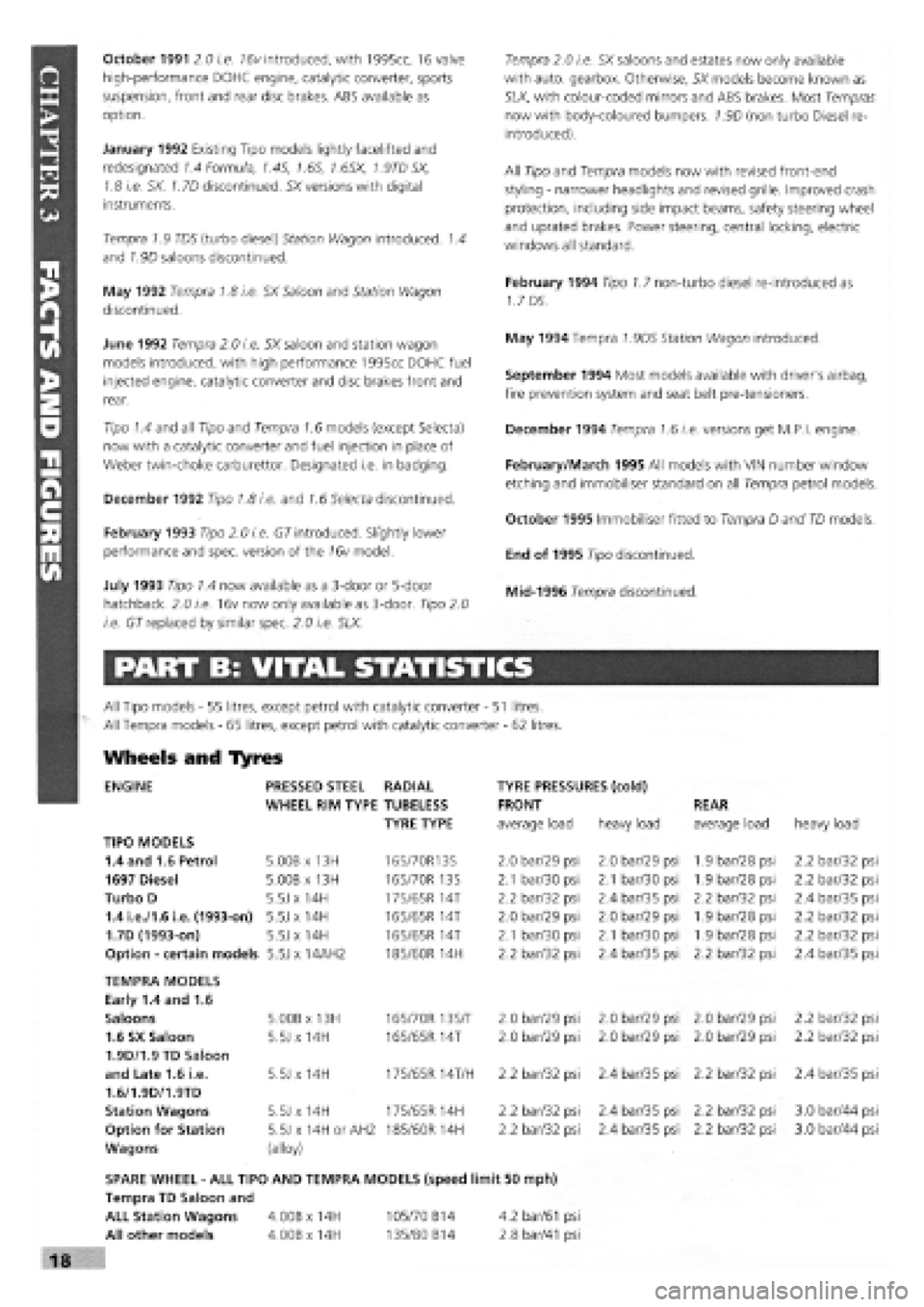

PART B: VITAL STATISTICS

All Tipo models

-

55 litres, except petrol with catalytic converter

- 51

litres.

All Tempra models

-

65 litres, except petrol with catalytic converter

-

62 litres.

Wheels and Tyres

ENGINE PRESSED STEEL RADIAL TYRE PRESSURES (cold)

WHEEL RIM TYPE TUBELESS FRONT REAR

TYRE TYPE average load heavy load average load heavy load

TIPO MODELS

1.4 and 1.6 Petrol 5.00B x 13H 165/70R13S 2.0 bar/29 psi 2.0 bar/29 psi 1.9 bar/28 psi 2.2 bar/32 psi

1697 Diesel 5.00B x 13H 165/70R 13S 2.1 bar/30 psi 2.1 bar/30 psi 1.9 bar/28 psi 2.2 bar/32 psi

Turbo D 5.5J x 14H

175/65 R

14T 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

1.4 i.e./1.6 i.e. (1993-on) 5.5J x 14H

165/65 R

14T 2.0 bar/29 psi 2.0 bar/29 psi 1.9 bar/28 psi 2.2 bar/32 psi

1.7D (1993-on) 5.5J x 14H 165/65R 14T 2.1 bar/30 psi 2.1 bar/30 psi 1.9 bar/28 psi 2.2 bar/32 psi

Option

-

certain models 5.5J x 14AH2 185/60R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

TEMPRA MODELS

Early 1.4 and 1.6

Saloons 5.00B x 13H 165/70R 13S/T 2.0 bar/29 psi 2.0 bar/29 psi 2.0 bar/29 psi 2.2 bar/32 psi

1.6 SX Saloon 5.5J x 14H 165/65R 14T 2.0 bar/29 psi 2.0 bar/29 psi 2.0 bar/29 psi 2.2 bar/32 psi

1.9D/1.9 TD Saloon

and Late 1.6 i.e. 5.5J x 14H 175/65R 14T/H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 2.4 bar/35 psi

1.6/1.9D/1.9TD

Station Wagons 5.5J x 14H 175/65R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 3.0 bar/44 psi

Option for Station 5.5J x 14H or AH2 185/60 R 14H 2.2 bar/32 psi 2.4 bar/35 psi 2.2 bar/32 psi 3.0 bar/44 psi

Wagons (alloy)

SPARE WHEEL

-

ALL TIPO AND TEMPRA MODELS (speed limit 50 mph)

Tempra TD Saloon and

ALL Station Wagons 4.00B x 14H 105/70 B14 4.2

bar/61

psi

All other models 4.00Bx14H 135/80 B14 2.8

bar/41

psi

Page 20 of 171

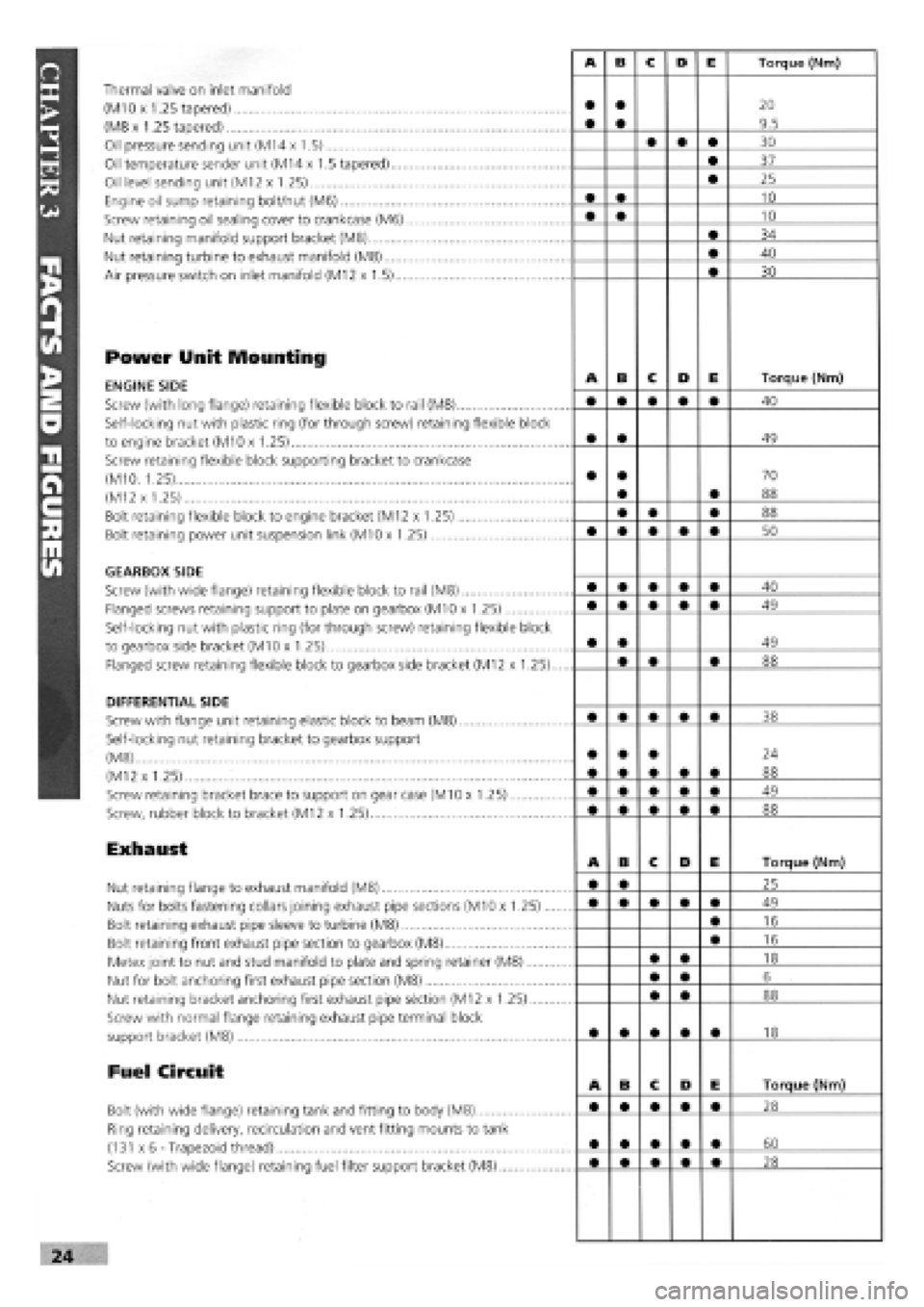

Thermal valve on inlet manifold

(M10 x 1.25 tapered)

(M8 x 1.25 tapered)

Oil pressure sending unit (M14 x 1.5)

Oil temperature sender unit (M14 x 1.5 tapered)....

Oil level sending unit (M12 x 1.25)

Engine oil sump retaining bolt/nut (M6)

Screw retaining oil sealing cover to crankcase (M6)

Nut retaining manifold support bracket (M8)

Nut retaining turbine to exhaust manifold (M8)

Air pressure switch on inlet manifold (M12 x 1.5)...

Power Unit Mounting

ENGINE SIDE

Screw (with long flange) retaining flexible block to rail (M8)

Self-locking nut with plastic ring (for through screw) retaining flexible block

to engine bracket (M10 x 1.25)

Screw retaining flexible block supporting bracket to crankcase

(M10. 1.25)

(M12 x 1.25)

Bolt retaining flexible block to engine bracket (M12 x 1.25)

Bolt retaining power unit suspension link (M10 x 1.25)

GEARBOX SIDE

Screw (with wide flange) retaining flexible block to rail (M8)

Flanged screws retaining support to plate on gearbox (M10 x 1.25)

Self-locking nut with plastic ring (for through screw) retaining flexible block

to gearbox side bracket (M10 x 1.25)

Flanged screw retaining flexible block to gearbox side bracket (M12 x 1.25).

DIFFERENTIAL SIDE

Screw with flange unit retaining elastic block to beam (M8)

Self-locking nut retaining bracket to gearbox support

(M8)

(M12 x 1.25)

Screw retaining bracket brace to support on gear case (M10 x 1.25)

Screw, rubber block to bracket (M12 x 1.25)

Exhaust

Nut retaining flange to exhaust manifold (M8)

Nuts for bolts fastening collars joining exhaust pipe sections (M10 x 1.25)...

Bolt retaining exhaust pipe sleeve to turbine (M8)

Bolt retaining front exhaust pipe section to gearbox (M8)

Metex joint to nut and stud manifold to plate and spring retainer (M8)

Nut for bolt anchoring first exhaust pipe section (M8)

Nut retaining bracket anchoring first exhaust pipe section (M12 x 1.25)

Screw with normal flange retaining exhaust pipe terminal block

support bracket (M8)

Fuel Circuit

Bolt (with wide flange) retaining tank and fitting to body (M8)

Ring retaining delivery, recirculation and vent fitting mounts to tank

(131 x 6-Trapezoid thread)

Screw (with wide flange) retaining fuel filter support bracket (M8)

Page 21 of 171

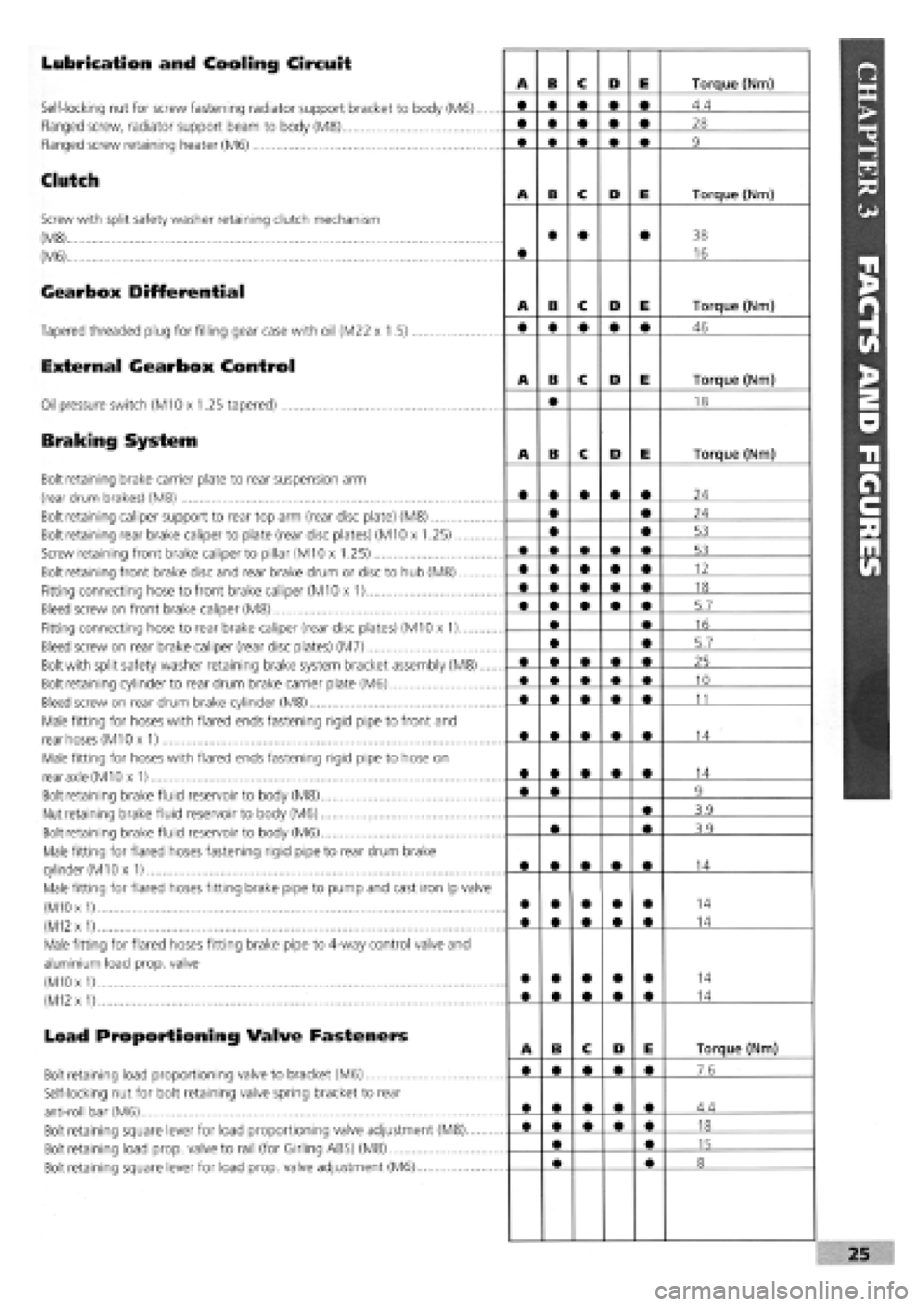

Lubrication and Cooling Circuit

Self-locking nut for screw fastening radiator support bracket to body (M6)....

Flanged screw, radiator support beam to body (M8)

Flanged screw retaining heater (M6)

Clutch

Screw with split safety washer retaining clutch mechanism

(M8)

(M6)

Gearbox Differential

Tapered threaded plug for filling gear case with oil (M22 x 1.5)

External Gearbox Control

Oil pressure switch (M10 x 1.25 tapered)

Braking System

Bolt retaining brake carrier plate to rear suspension arm

(rear drum brakes) (M8)

Bolt retaining caliper support to rear top arm (rear disc plate) (M8)

Bolt retaining rear brake caliper to plate (rear disc plates) (M10 x 1.25)

Screw retaining front brake caliper to pillar (M10 x 1.25)

Bolt retaining front brake disc and rear brake drum or disc to hub (M8)

Fitting connecting hose to front brake caliper (M10 x 1)

Bleed screw on front brake caliper (M8)

Fitting connecting hose to rear brake caliper (rear disc plates) (M10 x 1)

Bleed screw on rear brake caliper (rear disc plates) (M7)

Bolt with split safety washer retaining brake system bracket assembly (M8)....

Bolt retaining cylinder to rear drum brake carrier plate (M6)

Bleed screw on rear drum brake cylinder (M8)

Male fitting for hoses with flared ends fastening rigid pipe to front and

rear hoses (M10 x 1)

Male fitting for hoses with flared ends fastening rigid pipe to hose on

rear axle (M10 x 1)

Bolt retaining brake fluid reservoir to body (M8)

Nut retaining brake fluid reservoir to body (M6)

Bolt retaining brake fluid reservoir to body (M6)

Male fitting for flared hoses fastening rigid pipe to rear drum brake

cylinder

(M1

Ox 1)

Male fitting for flared hoses fitting brake pipe to pump and cast iron Ip valve

(M10

x

1)

(M12

x

1)

Male fitting for flared hoses fitting brake pipe to 4-way control valve and

aluminium load prop, valve

(M10 x

1)

(M12

x

1)

Load Proportioning Valve Fasteners

Bolt retaining load proportioning valve to bracket (M6)

Self-locking nut for bolt retaining valve spring bracket to rear

anti-roll bar (M6)

Bolt retaining square lever for load proportioning valve adjustment (M8)

Bolt retaining load prop, valve to rail (for Girling ABS) (M8)

Bolt retaining square lever for load prop, valve adjustment (M6)

Page 23 of 171

Screw with broad flange retaining rear flexible block to body (M12 x 1.25)..

Nut for stud retaining rear swinging arm to subframe (M16 x 1.5)

Nut for screw retaining lower damper to suspension (M12 x 1.25)

Screw retaining top of damper to mount (M10 x 1.25)

Nut for pivot pin retaining rear hub (M22 x 1.5)

Bolt retaining stabilizer bar to rear suspension arm (M10 x 1.25)

Bolt retaining stabilizer bar support plate to rear suspension arm (M8)

Wheel stud (M12 x 1.25)

Nut with self-locking flange retaining headlight alignment corrector

receiver to rear suspension (M8)

Nut with self-locking flange retaining lower receiver rod pin (M6)

Bolt with normal notched flange retaining automatic headlight

alignment device mount (M8)

Bolt with normal notched flange retaining receiver connection bracket with

rear suspension wishbone (M6)

Nut for bolt retaining square lever to wishbone (M8)

A B c D E Torque (Nm)

• • • • • 108

• • • • • 150

• • • • • 88

• • • • • 60

• • • • • 280

• • • • • 56

• • • • • 28

• • • • • 86

• • • • • 6.4

• • • • • 3.9

• • • • • 12

• • • • • 3.9

• • • • • 15

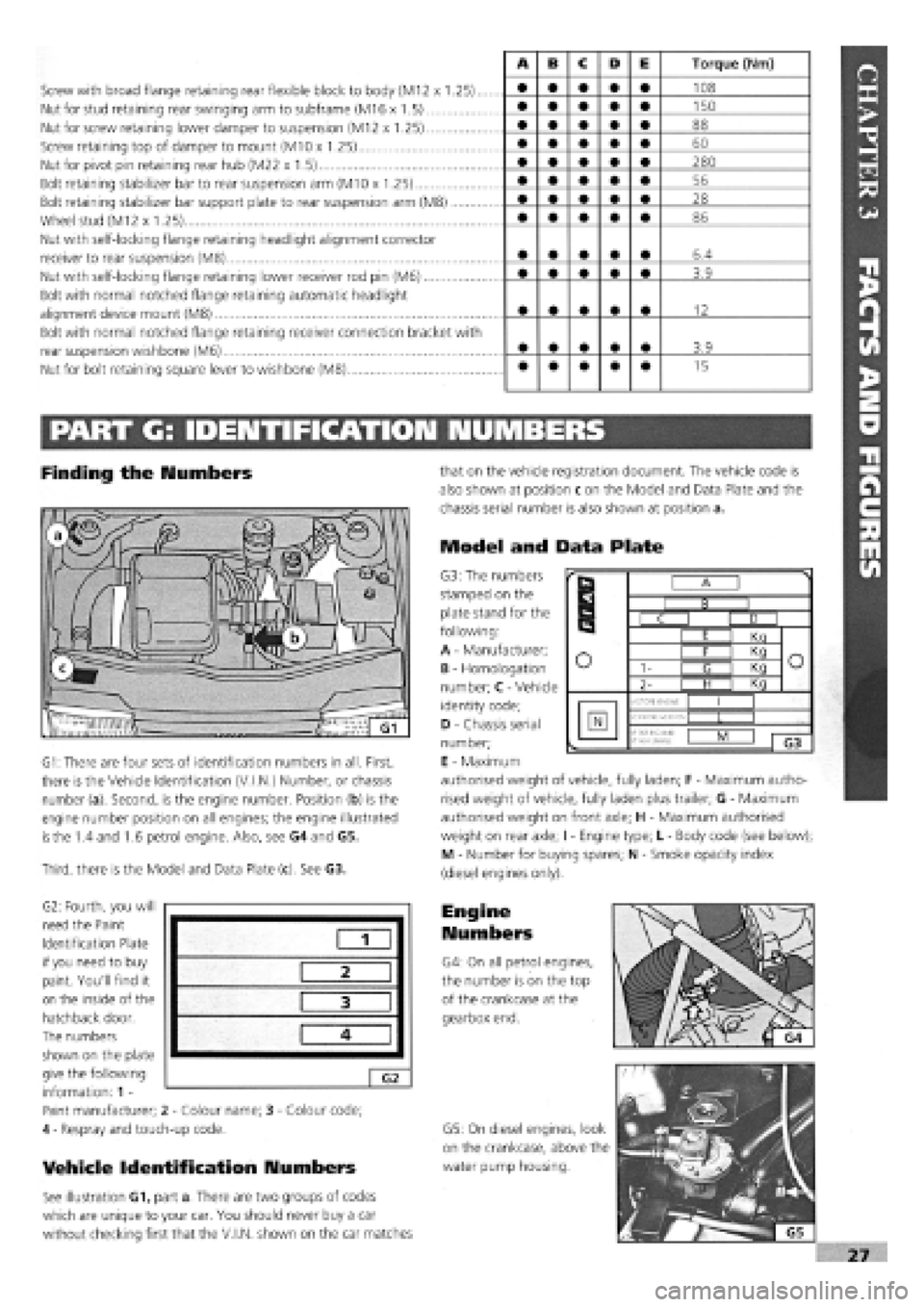

PART G: IDENTIFICATION NUMBERS

Finding the Numbers

G1: There are four sets of identification numbers in all. First,

there is the Vehicle Identification (V.I.N.) Number, or chassis

number (a). Second, is the engine number. Position (b) is the

engine number position on all engines; the engine illustrated

is

the 1.4 and 1.6 petrol engine. Also, see G4 and G5.

Third, there is the Model and Data Plate (c). See G3.

G2: Fourth, you will

need the Paint

Identification Plate

if you need to buy

paint. You'll find it

on the inside of the

hatchback door.

The numbers

shown on the plate

give the following

information: 1 -

Paint manufacturer; 2

-

Colour name; 3

-

Colour code;

4

-

Respray and touch-up code.

Vehicle Identification Numbers

See illustration G1, part a. There are two groups of codes

which are unique to your car. You should never buy a car

without checking first that the V.I.N, shown on the car matches

that on the vehicle registration document. The vehicle code is

also shown at position c on the Model and Data Plate and the

chassis serial number is also shown at position a.

Model and Data Plate

G3: The numbers

stamped on the

plate stand for the

following:

A

-

Manufacturer;

B

-

Homologation

number; C

-

Vehicle

identity code;

D

-

Chassis serial

number;

E

-

Maximum

authorised weight of vehicle, fully laden; F

-

Maximum autho-

rised weight of vehicle, fully laden plus trailer; G

-

Maximum

authorised weight on front axle; H

-

Maximum authorised

weight on rear axle; I

-

Engine type; L

-

Body code (see below);

M - Number for buying spares; N

-

Smoke opacity index

(diesel engines only).

Engine

Numbers

G4: On all petrol engines,

the number is on the top

of the crankcase at the

gearbox end.

G5: On diesel engines, look

on the crankcase, above the

water pump housing.

1

2

3

4

G2

r

B

r

B I B I

r

B

C I D I

r

B

I E I Kn

o o I F I Kq o o 1- I <3 I Kq o o

2- | H I Kq

o

MOTORE ENGINE

I I

N VERSIONE-VERSION •f

PER RICAM8:

N*

FOR SPARED

L I

1 G3

Page 26 of 171

PART C: VEHICLE RAISED OFF THE GROUND

Bodywork Structure

01

.

Any sharp edges on the external bodywork, caused by damage or corrosion will cause the vehicle to fail.

02 . Check all load bearing areas for corrosion. Open the doors and check the sills inside and out, above and below. Any corrosion in structural metalwork within 30 cm (12 in.) of seat belt mounting, steering and suspension attachment points will cause the vehicle to fail.

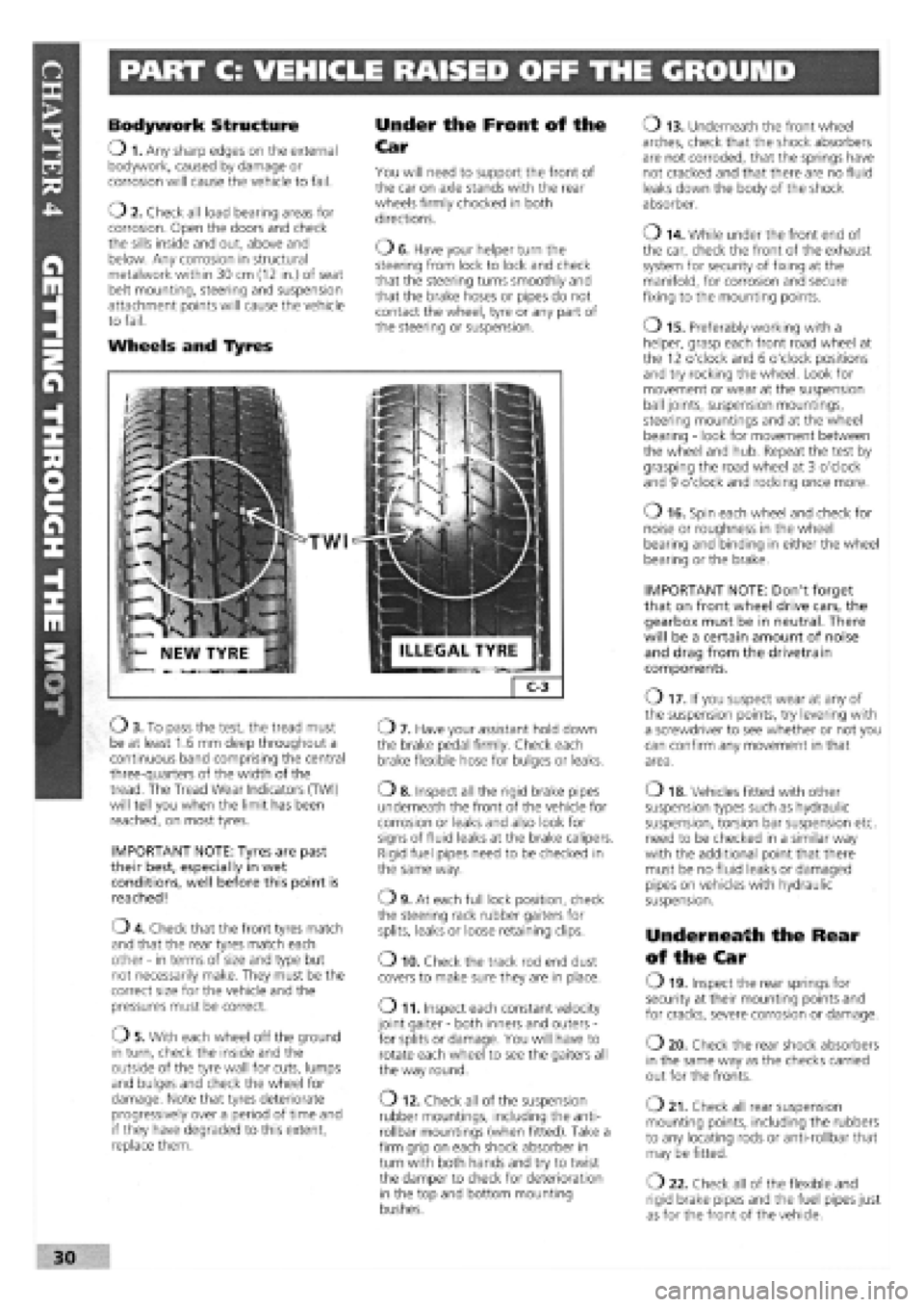

Wheels and Tyres

Under the Front of the

Car

You will need to support the front of the car on axle stands with the rear wheels firmly chocked in both directions.

OE . Have your helper turn the steering from lock to lock and check that the steering turns smoothly and that the brake hoses or pipes do not contact the wheel, tyre or any part of the steering or suspension.

TWI

Ob . To pass the test, the tread must be at least 1.6 mm deep throughout a continuous band comprising the central three-quarters of the width of the tread. The Tread Wear Indicators (TWI) will tell you when the limit has been reached, on most tyres.

IMPORTANT NOTE: Tyres are past their best, especially in wet conditions, well before this point is reached!

04 . Check that the front tyres match and that the rear tyres match each other

-

in terms of size and type but not necessarily make. They must be the correct size for the vehicle and the pressures must be correct.

05 . With each wheel off the ground in turn, check the inside and the outside of the tyre wall for cuts, lumps and bulges and check the wheel for damage. Note that tyres deteriorate progressively over a period of time and if they have degraded to this extent, replace them.

07 . Have your assistant hold down the brake pedal firmly. Check each brake flexible hose for bulges or leaks.

o 8. Inspect all the rigid brake pipes underneath the front of the vehicle for corrosion or leaks and also look for signs of fluid leaks at the brake calipers. Rigid fuel pipes need to be checked in the same way.

09 . At each full lock position, check the steering rack rubber gaiters for splits, leaks or loose retaining clips.

o 10. Check the track rod end dust covers to make sure they are in place.

o 11. Inspect each constant velocity joint gaiter

-

both inners and outers

-

for splits or damage. You will have to rotate each wheel to see the gaiters all the way round.

O 12. Check all of the suspension rubber mountings, including the anti-rollbar mountings (when fitted). Take a firm grip on each shock absorber in turn with both hands and try to twist the damper to check for deterioration in the top and bottom mounting bushes.

o 13. Underneath the front wheel arches, check that the shock absorbers are not corroded, that the springs have not cracked and that there are no fluid leaks down the body of the shock absorber.

o 14. While under the front end of the car, check the front of the exhaust system for security of fixing at the manifold, for corrosion and secure fixing to the mounting points.

o 15. Preferably working with a helper, grasp each front road wheel at the 12 o'clock and 6 o'clock positions and try rocking the wheel. Look for movement or wear at the suspension ball joints, suspension mountings, steering mountings and at the wheel bearing

-

look for movement between the wheel and hub. Repeat the test by grasping the road wheel at 3 o'clock and 9 o'clock and rocking once more.

o 16. Spin each wheel and check for noise or roughness in the wheel bearing and binding in either the wheel bearing or the brake.

IMPORTANT NOTE: Don't forget that on front wheel drive cars, the gearbox must be in neutral. There will be a certain amount of noise and drag from the drivetrain components.

O 17. If you suspect wear at any of the suspension points, try levering with a screwdriver to see whether or not you can confirm any movement in that area.

o 18. Vehicles fitted with other suspension types such as hydraulic suspension, torsion bar suspension etc. need to be checked in a similar way with the additional point that there must be no fluid leaks or damaged pipes on vehicles with hydraulic suspension.

Underneath the Rear

of the Car

O 19. Inspect the rear springs for security at their mounting points and for cracks, severe corrosion or damage.

o 20. Check the rear shock absorbers in the same way as the checks carried out for the fronts.

o 21. Check all rear suspension mounting points, including the rubbers to any locating rods or anti-rollbar that may be fitted.

O 22. Check all of the flexible and rigid brake pipes and the fuel pipes just as for the front of the vehicle.

30

Page 29 of 171

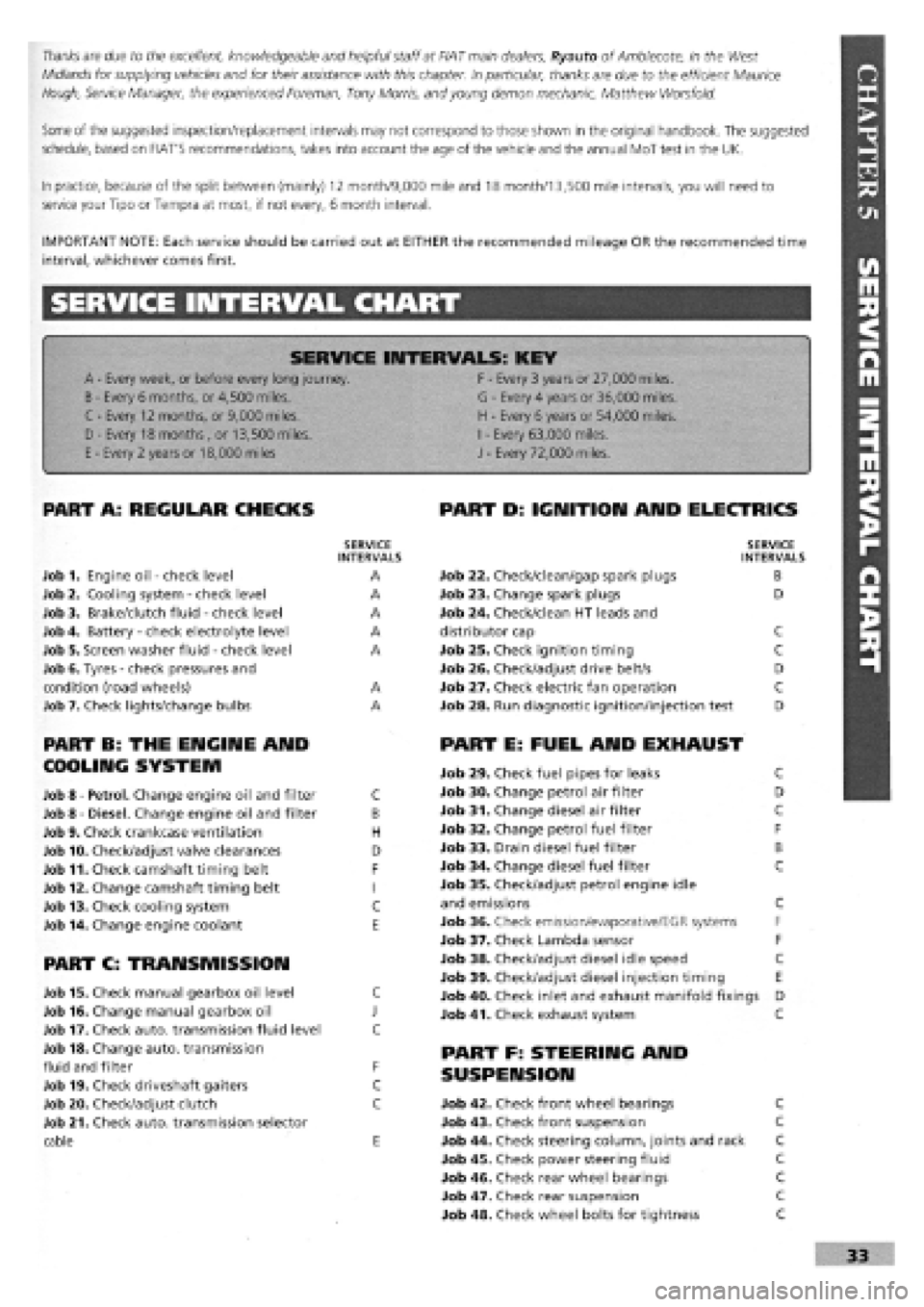

Thanks

are due to the excellent, knowledgeable and helpful staff at FIAT main dealers, Ryauto of Amblecote, in the West

Midlands for supplying vehicles and for their assistance with this chapter. In particular, thanks are due to the efficient Maurice

Hough, Service Manager, the experienced Foreman, Tony Morris, and young demon mechanic, Matthew Worsfold.

Some of the suggested inspection/replacement intervals may not correspond to those shown in the original handbook. The suggested

schedule, based on FIAT'S recommendations, takes into account the age of the vehicle and the annual MoT test in the UK.

In practice, because of the split between (mainly) 12 month/9,000 mile and 18 month/13,500 mile intervals, you will need to

service your Tipo or Tempra at most, if not every, 6 month interval.

IMPORTANT NOTE: Each service should be carried out at EITHER the recommended mileage OR the recommended time

interval, whichever comes first.

SERVICE INTERVAL CHART

SERVICE INTERVALS: KEY

A

-

Every week, or before every long journey. F

-

Every 3 years or 27,000 miles.

B

-

Every 6 months, or 4,500 miles. G

-

Every 4 years or 36,000 miles.

C - Every 12 months, or 9,000 miles. H

-

Every 6 years or 54,000 miles.

I

-

Every 63,000 miles. D - Every 18 months , or 13,500 miles.

H

-

Every 6 years or 54,000 miles.

I

-

Every 63,000 miles.

E

-

Every 2 years or 18,000 miles J

-

Every 72,000 miles.

PART A: REGULAR CHECKS

SERVICE INTERVALS

Job 1. Engine oil

-

check level A

Job 2. Cooling system

-

check level A

Job 3. Brake/clutch fluid

-

check level A

Job 4. Battery

-

check electrolyte level A

Job 5. Screen washer fluid

-

check level A

Job 6. Tyres

-

check pressures and

condition (road wheels) A

Job 7. Check lights/change bulbs A

PART B: THE ENGINE AND

COOLING SYSTEM

Job 8

-

Petrol. Change engine oil and filter C

Job 8

-

Diesel. Change engine oil and filter B

Job 9. Check crankcase ventilation H

Job 10. Check/adjust valve clearances D

Job 11. Check camshaft timing belt F

Job 12. Change camshaft timing belt I

Job 13. Check cooling system C

Job 14. Change engine coolant E

PART C: TRANSMISSION

Job 15. Check manual gearbox oil level C

Job 16. Change manual gearbox oil J

Job 17. Check auto, transmission fluid level C

Job 18. Change auto, transmission

fluid and filter F

Job 19. Check driveshaft gaiters C

Job 20. Check/adjust clutch C

Job 21. Check auto, transmission selector

cable E

PART D: IGNITION AND ELECTRICS

SERVICE INTERVALS

Job 22. Check/clean/gap spark plugs B

Job 23. Change spark plugs D

Job 24. Check/clean HT leads and

distributor cap C

Job 25. Check ignition timing C

Job 26. Check/adjust drive belt/s D

Job 27. Check electric fan operation C

Job 28. Run diagnostic ignition/injection test D

PART E: FUEL AND EXHAUST

Job 29. Check fuel pipes for leaks C

Job 30. Change petrol air filter D

Job 31. Change diesel air filter C

Job 32. Change petrol fuel filter F

Job 33. Drain diesel fuel filter B

Job 34. Change diesel fuel filter C

Job 35. Check/adjust petrol engine idle

and emissions C

Job 36. Check emission/evaporative/EGR systems F

Job 37. Check Lambda sensor F

Job 38. Check/adjust diesel idle speed C

Job 39. Check/adjust diesel injection timing E

Job 40. Check inlet and exhaust manifold fixings D

Job 41. Check exhaust system C

PART F: STEERING AND

SUSPENSION

Job 42. Check front wheel bearings C

Job 43. Check front suspension C

Job 44. Check steering column, joints and rack C

Job 45. Check power steering fluid C

Job 46. Check rear wheel bearings C

Job 47. Check rear suspension C

Job 48. Check wheel bolts for tightness C