lug pattern FIAT TEMPRA 1988 Service And Repair Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 1988, Model line: TEMPRA, Model: FIAT TEMPRA 1988Pages: 171, PDF Size: 18.05 MB

Page 115 of 171

Job 6. Accelerator cable, petrol

injection engines - replacement

and adjustment.

Q Step 2: From inside the car,

unhook the cable nipple from the

fork (arrowed) at the top of the

pedal arm.

• Step 3: Pull out the bulkhead

grommet and release the cable.

^ • There are many different

cables, so take your old

cable as a pattern when

buying a replacement to make sure the new one is

exactly

the same.

Q Step 4: Refit in the reverse order

-

not forgetting the

grommet in the bulkhead!

Q Step 5: Check that, when the new cable is fitted:

• there

is

just the slightest amount of free-play in the cable

with the throttle closed.

• the carburettor lever is back against its stop with the throttle

fully open.

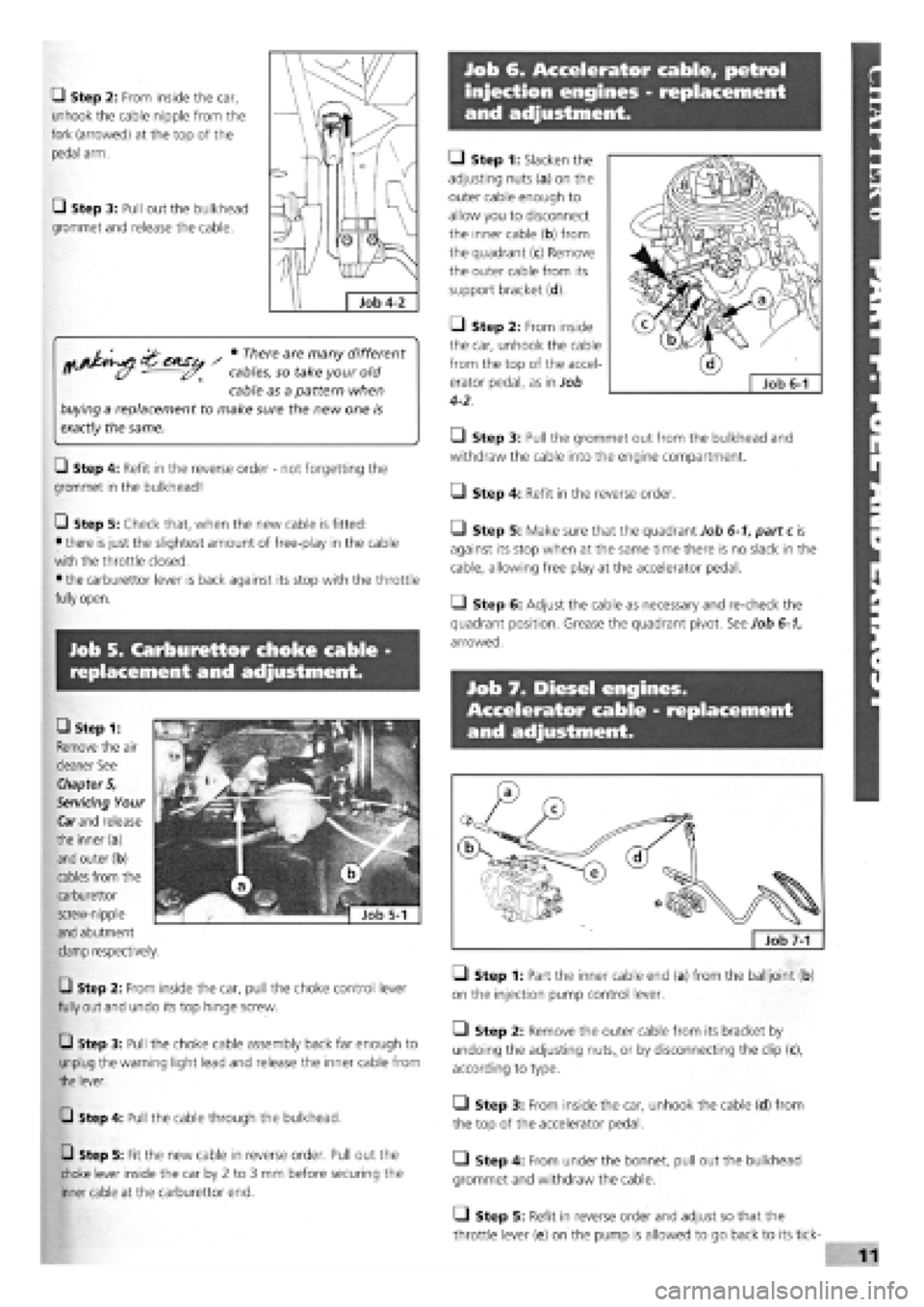

• Step 1: Slacken the

adjusting nuts (a) on the

outer cable enough to

allow you to disconnect

the inner cable (b) from

the quadrant (c) Remove

the outer cable from its

support bracket (d).

Q Step 2: From inside

the car, unhook the cable

from the top of the accel-

erator pedal, as in Job

4-2.

• Step 3: Pull the grommet out from the bulkhead and

withdraw the cable into the engine compartment.

O Step 4: Refit in the reverse order.

• Step 5: Make sure that the quadrant Job 6-1, part c is

against its stop when at the same time there is no slack in the

cable, allowing free play at the accelerator pedal.

• Step 6: Adjust the cable as necessary and re-check the

quadrant position. Grease the quadrant pivot. See Job 6-1,

arrowed.

Job 7. Diesel engines.

Accelerator cable - replacement

and adjustment.

Job 5. Carburettor choke cable -

replacement and adjustment.

Q Step 2: From inside the car, pull the choke control lever

fully out and undo its top hinge screw.

Q Step 3: Pull the choke cable assembly back far enough to

unplug the warning light lead and release the inner cable from

the lever.

Q Step 4: Pull the cable through the bulkhead.

Q Step 5: Fit the new cable in reverse order. Pull out the

choke lever inside the car by 2 to 3 mm before securing the

inner cable at the carburettor end.

Q Step 1: Part the inner cable end (a) from the balljoint (b)

on the injection pump control lever.

• Step 2: Remove the outer cable from its bracket by

undoing the adjusting

nuts,,

or by disconnecting the clip (c),

according to type.

• Step 3: From inside the car, unhook the cable (d) from

the top of the accelerator pedal.

• Step 4: From under the bonnet, pull out the bulkhead

grommet and withdraw the cable.

Q Step 5: Refit in reverse order and adjust so that the

throttle lever (e) on the pump is allowed to go back to its tick-

CD Step 1:

Remove the air

cleaner See

Chapter 5,

Servicing Your

Car

and

release

the inner(a)

and outer (b)

cables from the

carburettor

screw-nipple

and abutment

clamp respectively.

Page 137 of 171

Job 15. Flexible hoses -

replacement.

• Step 8: Bleed the brakes, see Job

17

H INSIDE INFORMATION: When disconnecting brake

pipes or hoses, it is helpful to minimise brake fluid loss.

This can be done by unscrewing the master cylinder

reservoir cap, laying a sheet of plastic across the

opening, and refitting the cap. This will prevent atmos-

pheric pressure from pushing the fluid out of opened

lines. D

/ • If a rigid pipe starts to

twist with the union, grip

the pipe as lightly as

possible, and see if you can stop it from turning.

• If not, cut through the pipe with a junior hacksaw

and replace the length of rigid pipe.

Job 16. Metal pipes -

replacement.

B INSIDE INFORMATION: When disconnecting brake

pipes or hoses, it is helpful to minimise brake fluid loss.

This can be done by unscrewing the master cylinder

reservoir cap, laying a sheet of plastic across the

opening, and refitting the cap. This will prevent atmos-

pheric pressure from pushing the fluid out of opened

lines. A pipe spanner makes the job much easier! B

Step 1: Undo the unions at each end of a pipe length.

Patience is often required because of the union seizing both in

its threads and on the pipe. See MAKING IT EASY! after Job

15,

Step 8 Use penetrating oil to help free seized unions, and

use a split-ring spanner rather than an open-ended one, to

reduce the risk of rounding off the union nuts.

• Step 2: Detach the pipe length from its securing clips and

remove it.

i^vj ens s * ^ step 3: where possible, use the old pipe as

a pattern to shape the new

one prior to fitting.

• Step 4: Follow the original route and secure the pipe in

the body clips.

Q Step 5: Connect the unions and bleed the system. See

Job

17

Job 17. Brake bleeding.

B INSIDE INFORMATION: Unless the master cylinder or

pressure regulating valve has been disturbed, it will only

be necessary to bleed the end of the braking system

which has been opened. If bleeding the whole system,

start bleeding at the left-hand rear brake. B

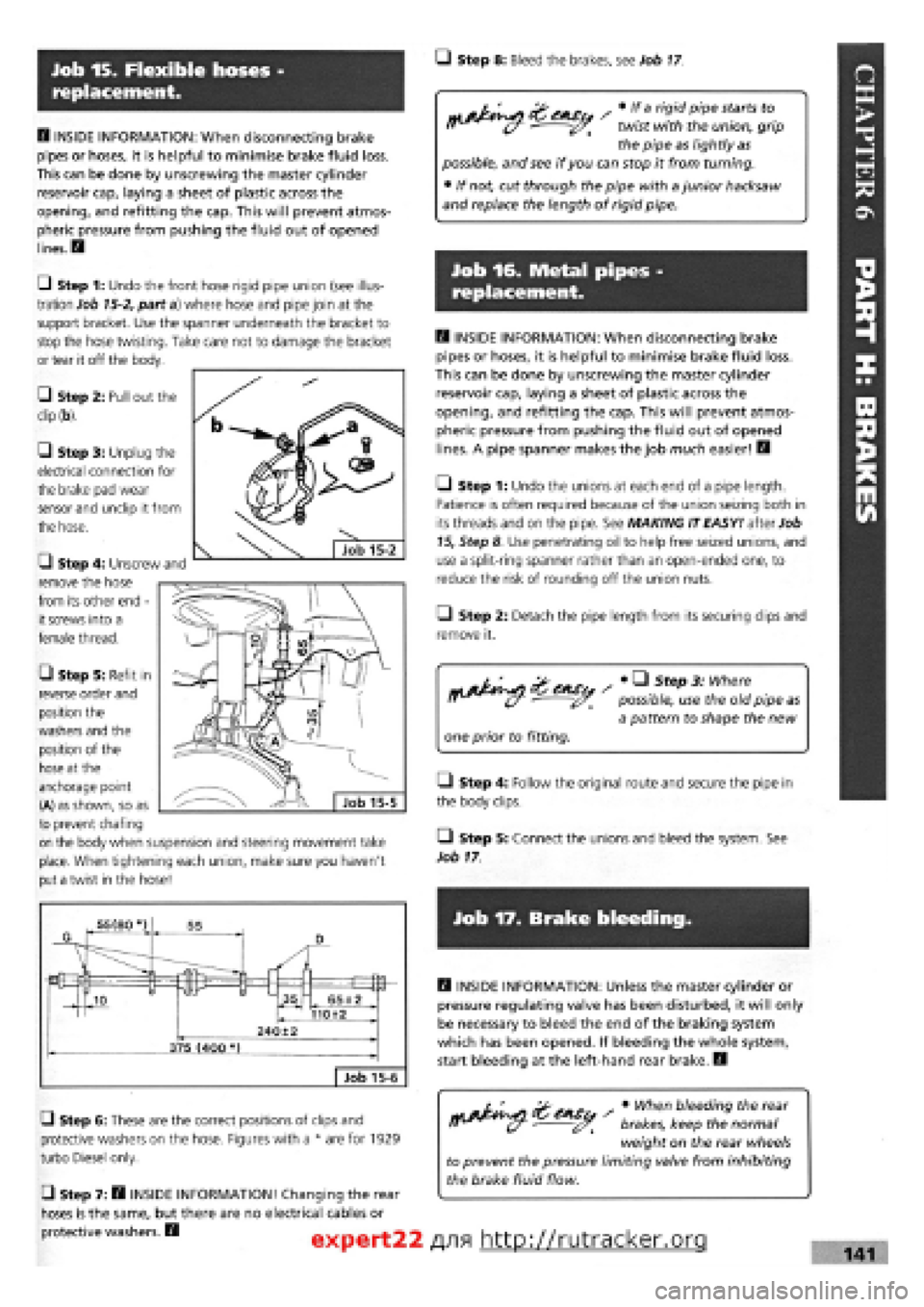

G Step 6: These are the correct positions of clips and

protective washers on the hose. Figures with a * are for 1929

turbo Diesel only.

• Step 7: B INSIDE INFORMATION! Changing the rear

hoses is the same, but there are no electrical cables or

protective washers. B

s • When bleeding the rear

brakes, keep the normal

weight on the rear wheels

to prevent the pressure limiting valve from inhibiting

the brake fluid flow.

expert22 f

\9\ http://rutracker.org 141

Ul Step 1: Undo the front hose rigid pipe union (see illus-

tration Job

15-2,

part a) where hose and pipe join at the

support bracket. Use the spanner underneath the bracket to

stop the hose twisting. Take care not to damage the bracket

or tear it off the body.

• Step 2: Pull out the

dip (b).

G Step 3: Unplug the

electrical connection for

the brake pad wear

sensor and unclip it from

the hose.

G Step 4: Unscrew and

remove the hose

from its other end -

it screws into a

female thread.

• Step 5: Refit in

reverse order and

position the

washers and the

position of the

hose at the

anchorage point

(A) as shown, so as

to prevent chafing

on the body when suspension and steering movement take

place. When tightening each union, make sure you haven't

put a twist in the hose!