lights FIAT TIPO 4DOORS 2016 1.G Owner's Manual

[x] Cancel search | Manufacturer: FIAT, Model Year: 2016, Model line: TIPO 4DOORS, Model: FIAT TIPO 4DOORS 2016 1.GPages: 204, PDF Size: 4.94 MB

Page 57 of 204

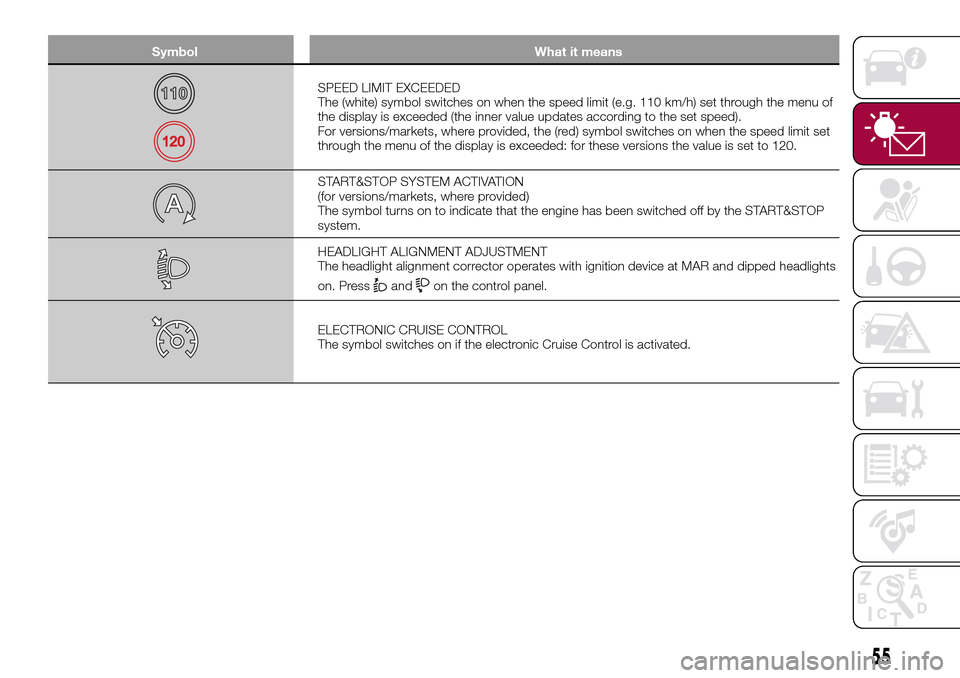

Symbol What it means

SPEED LIMIT EXCEEDED

The (white) symbol switches on when the speed limit (e.g. 110 km/h) set through the menu of

the display is exceeded (the inner value updates according to the set speed).

For versions/markets, where provided, the (red) symbol switches on when the speed limit set

through the menu of the display is exceeded: for these versions the value is set to 120.

START&STOP SYSTEM ACTIVATION

(for versions/markets, where provided)

The symbol turns on to indicate that the engine has been switched off by the START&STOP

system.

HEADLIGHT ALIGNMENT ADJUSTMENT

The headlight alignment corrector operates with ignition device at MAR and dipped headlights

on. Press

andon the control panel.

ELECTRONIC CRUISE CONTROL

The symbol switches on if the electronic Cruise Control is activated.

55

Page 97 of 204

TOWING TRAILERS

IMPORTANT NOTES

115) 116)

For towing caravans or trailers the

vehicle must be fitted with an approved

tow hook and an adequate electrical

system. Should aftermarket installation

be requested, this must be carried out

by specialists.

Install any specific and/or additional

door mirrors as specified by the

Highway Code.

Remember that, when towing a trailer,

steep hills are harder to climb, braking

distances increase and overtaking takes

longer depending on the overall weight

of the trailer.

Engage a low gear when driving

downhill, rather than constantly using

the brake.

The weight the trailer exerts on the

vehicle tow hook reduces the vehicle's

loading capacity by the same amount.

To make sure that the maximum

towable weight is not exceeded (given

in the vehicle registration document)

account should be taken of the fully

laden trailer, including accessories and

luggage.

Do not exceed the speed limits specific

to each country you are driving in, in thecase of vehicles towing trailers. In any

case, the top speed must not exceed

100 km/h.

Any electric brake must be powered

directly by the battery through a cable

with a cross-section of no less than 2.5

mm

2.

In addition to the electrical branches,

the vehicle electrical system can only be

connected to the supply cable for an

electric brake and to the cable for an

internal light for the trailer, not

exceeding 15 W. For connections, use

the preset control unit with a battery

cable with section not less than 2.5 mm

2.

IMPORTANT The use of auxiliary loads

other than external lights (e.g. electric

brake) must take place with engine

running.

INSTALLING A TOW

HOOK

The towing device should be fastened

to the body by specialised personnel

according to any additional and/or

integrative information supplied by the

Manufacturer of the device.

The towing device must meet current

regulations with reference to Directive

94/20/EC and subsequent

amendments.For any version the towing device used

must be right for the towable weight of

the vehicle on which it is to be installed.

For the electrical connection a standard

connector should be used which is

generally placed on a special bracket

normally fastened to the towing device,

and a special ECU for external trailer

light control must be installed on the

vehicle.

Seven or thirteen pin 12 V DC

connections should be used

(CUNA/UNI and ISO/DIN Standards).

Follow any instructions provided by the

vehicle manufacturer and/or the towing

device manufacturer.

WARNING

115)The ABS with which the car is

equipped will not control the braking

system of the trailer. Particular caution is

required on slippery roads.

116)Never modify the braking system of

the vehicle to control the trailer brake. The

trailer braking system must be fully

independent of the car’s hydraulic system.

95

Page 100 of 204

IN AN EMERGENCY

A punctured tyre or a burnt-out bulb?

At times, a problem may interfere with

our journey.

The pages on emergencies can help

you to deal with critical situations

independently and with calm.

In an emergency we recommend that

you call the freephone number found in

the Warranty Booklet.

It is also possible to call the national or

international universal freephone

number to search for the nearest Fiat

Dealership.HAZARD WARNING LIGHTS......99

BULB REPLACEMENT.........99

REPLACING FUSES..........106

CHANGING A WHEEL.........111

FIX&GO AUTOMATIC KIT.......115

EMERGENCY STARTING.......117

FUEL CUT-OFF SYSTEM.......119

AUTOMATIC TRANSMISSION. . . .119

TOWING THE VEHICLE........121

98

IN AN EMERGENCY

Page 101 of 204

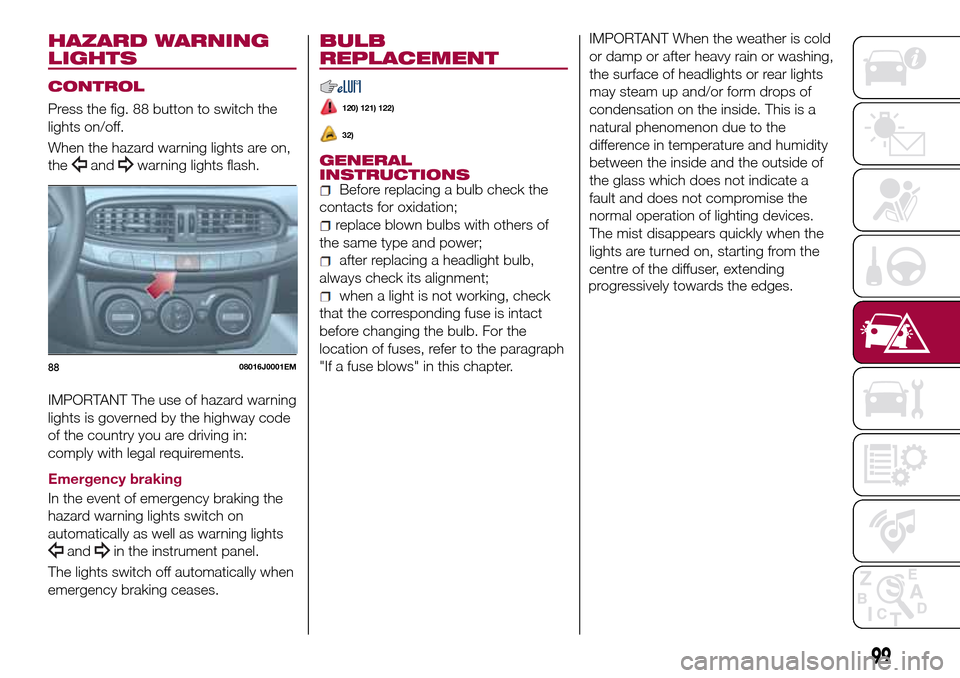

HAZARD WARNING

LIGHTS

CONTROL

Press the fig. 88 button to switch the

lights on/off.

When the hazard warning lights are on,

the

andwarning lights flash.

IMPORTANT The use of hazard warning

lights is governed by the highway code

of the country you are driving in:

comply with legal requirements.

Emergency braking

In the event of emergency braking the

hazard warning lights switch on

automatically as well as warning lights

andin the instrument panel.

The lights switch off automatically when

emergency braking ceases.

BULB

REPLACEMENT

120) 121) 122)

32)

GENERAL

INSTRUCTIONS

Before replacing a bulb check the

contacts for oxidation;

replace blown bulbs with others of

the same type and power;

after replacing a headlight bulb,

always check its alignment;

when a light is not working, check

that the corresponding fuse is intact

before changing the bulb. For the

location of fuses, refer to the paragraph

"If a fuse blows" in this chapter.

IMPORTANT When the weather is cold

or damp or after heavy rain or washing,

the surface of headlights or rear lights

may steam up and/or form drops of

condensation on the inside. This is a

natural phenomenon due to the

difference in temperature and humidity

between the inside and the outside of

the glass which does not indicate a

fault and does not compromise the

normal operation of lighting devices.

The mist disappears quickly when the

lights are turned on, starting from the

centre of the diffuser, extending

progressively towards the edges.

8808016J0001EM

99

Page 103 of 204

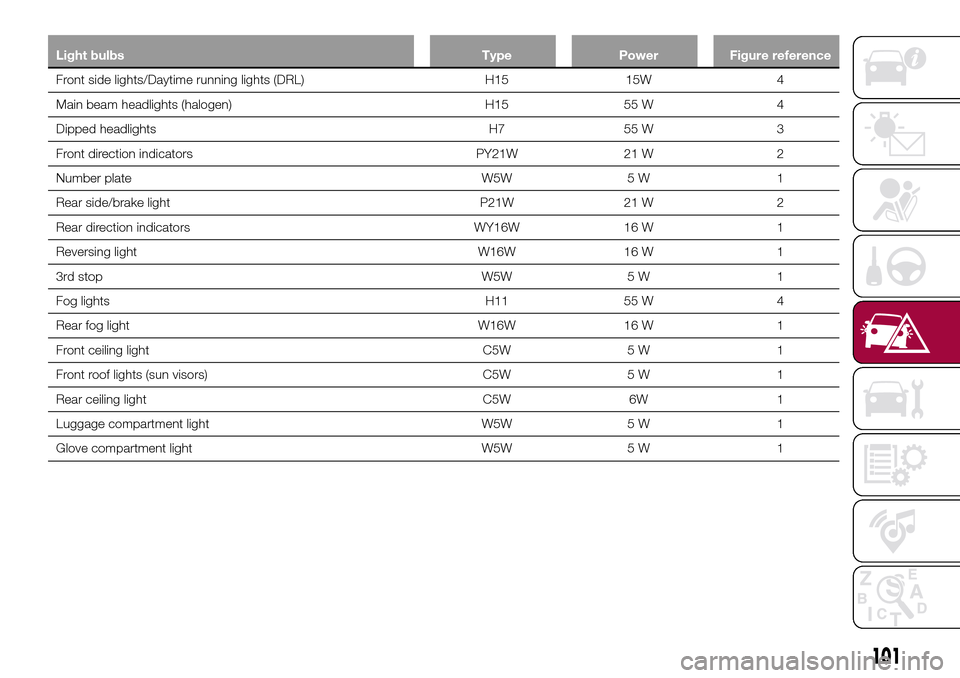

Light bulbs Type Power Figure reference

Front side lights/Daytime running lights (DRL) H15 15W 4

Main beam headlights (halogen) H15 55 W 4

Dipped headlights H7 55 W 3

Front direction indicators PY21W 21 W 2

Number plate W5W 5 W 1

Rear side/brake light P21W 21 W 2

Rear direction indicators WY16W 16 W 1

Reversing light W16W 16 W 1

3rd stop W5W 5 W 1

Fog lights H11 55 W 4

Rear fog light W16W 16 W 1

Front ceiling light C5W 5 W 1

Front roof lights (sun visors) C5W 5 W 1

Rear ceiling light C5W 6W 1

Luggage compartment light W5W 5 W 1

Glove compartment light W5W 5 W 1

101

Page 104 of 204

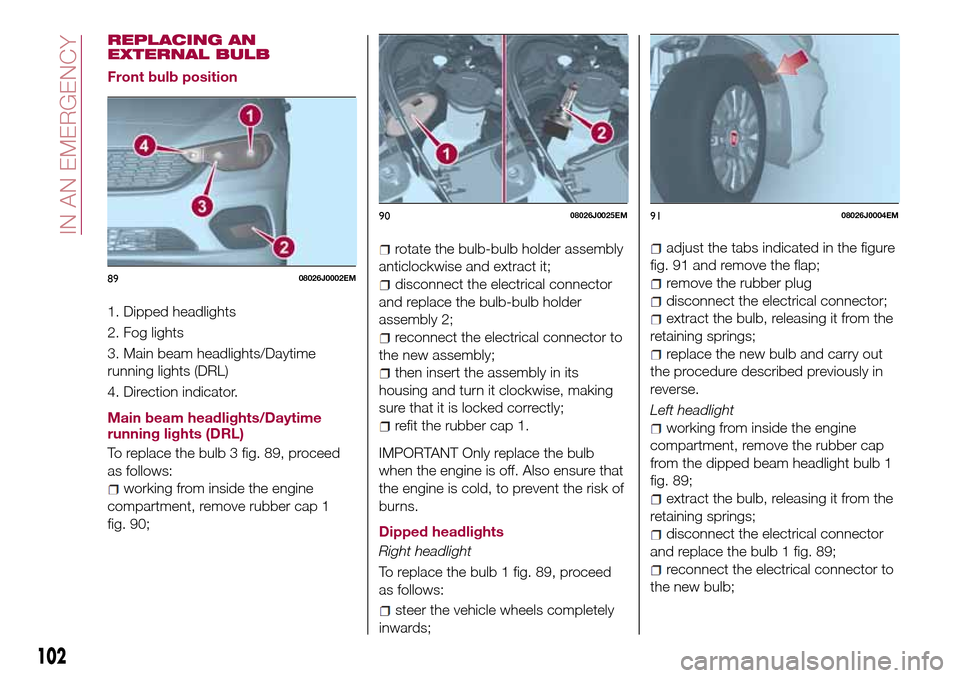

REPLACING AN

EXTERNAL BULB

Front bulb position

1. Dipped headlights

2. Fog lights

3. Main beam headlights/Daytime

running lights (DRL)

4. Direction indicator.

Main beam headlights/Daytime

running lights (DRL)

To replace the bulb 3 fig. 89, proceed

as follows:

working from inside the engine

compartment, remove rubber cap 1

fig. 90;

rotate the bulb-bulb holder assembly

anticlockwise and extract it;

disconnect the electrical connector

and replace the bulb-bulb holder

assembly 2;

reconnect the electrical connector to

the new assembly;

then insert the assembly in its

housing and turn it clockwise, making

sure that it is locked correctly;

refit the rubber cap 1.

IMPORTANT Only replace the bulb

when the engine is off. Also ensure that

the engine is cold, to prevent the risk of

burns.

Dipped headlights

Right headlight

To replace the bulb 1 fig. 89, proceed

as follows:

steer the vehicle wheels completely

inwards;

adjust the tabs indicated in the figure

fig. 91 and remove the flap;

remove the rubber plug

disconnect the electrical connector;

extract the bulb, releasing it from the

retaining springs;

replace the new bulb and carry out

the procedure described previously in

reverse.

Left headlight

working from inside the engine

compartment, remove the rubber cap

from the dipped beam headlight bulb 1

fig. 89;

extract the bulb, releasing it from the

retaining springs;

disconnect the electrical connector

and replace the bulb 1 fig. 89;

reconnect the electrical connector to

the new bulb;

8908026J0002EM

9008026J0025EM9108026J0004EM

102

IN AN EMERGENCY

Page 105 of 204

reposition the assembly in the seat;

refit the rubber cap.

IMPORTANT Only replace the bulb

when the engine is off. Also ensure that

the engine is cold, to prevent the risk of

burns.

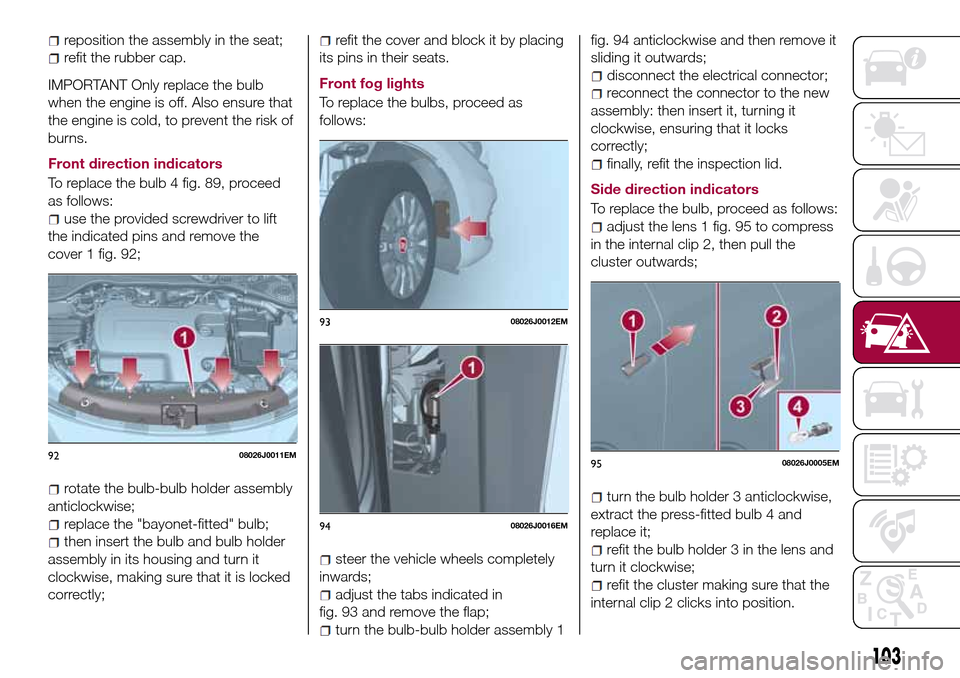

Front direction indicators

To replace the bulb 4 fig. 89, proceed

as follows:

use the provided screwdriver to lift

the indicated pins and remove the

cover 1 fig. 92;

rotate the bulb-bulb holder assembly

anticlockwise;

replace the "bayonet-fitted" bulb;

then insert the bulb and bulb holder

assembly in its housing and turn it

clockwise, making sure that it is locked

correctly;

refit the cover and block it by placing

its pins in their seats.

Front fog lights

To replace the bulbs, proceed as

follows:

steer the vehicle wheels completely

inwards;

adjust the tabs indicated in

fig. 93 and remove the flap;

turn the bulb-bulb holder assembly 1fig. 94 anticlockwise and then remove it

sliding it outwards;

disconnect the electrical connector;

reconnect the connector to the new

assembly: then insert it, turning it

clockwise, ensuring that it locks

correctly;

finally, refit the inspection lid.

Side direction indicators

To replace the bulb, proceed as follows:

adjust the lens 1 fig. 95 to compress

in the internal clip 2, then pull the

cluster outwards;

turn the bulb holder 3 anticlockwise,

extract the press-fitted bulb 4 and

replace it;

refit the bulb holder 3 in the lens and

turn it clockwise;

refit the cluster making sure that the

internal clip 2 clicks into position.

9208026J0011EM

9308026J0012EM

9408026J0016EM

9508026J0005EM

103

Page 106 of 204

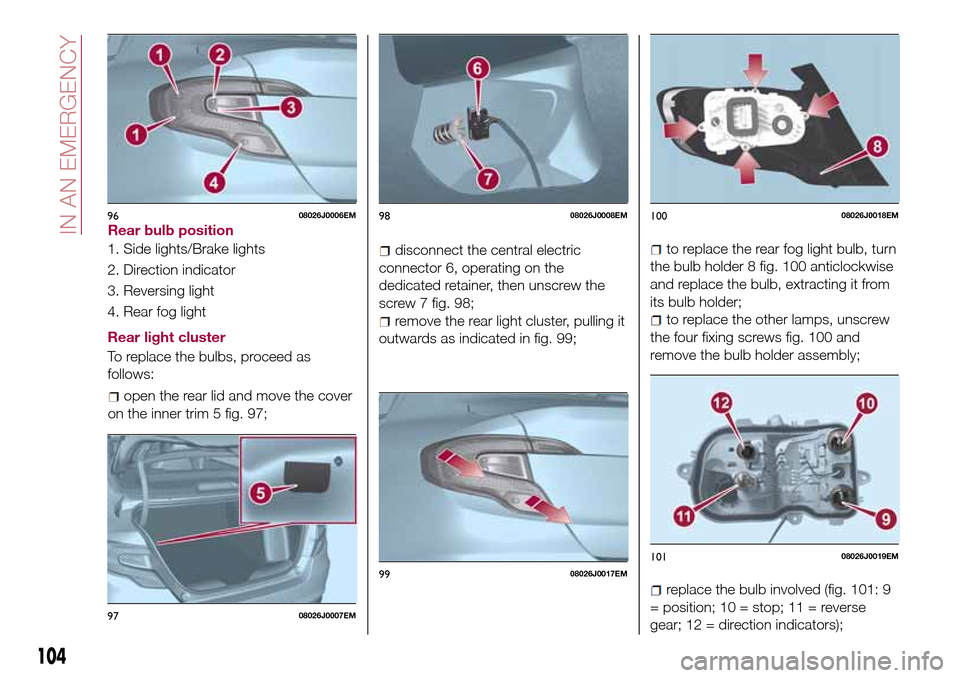

1. Side lights/Brake lights

2. Direction indicator

3. Reversing light

4. Rear fog light

Rear light cluster

To replace the bulbs, proceed as

follows:

open the rear lid and move the cover

on the inner trim 5 fig. 97;

disconnect the central electric

connector 6, operating on the

dedicated retainer, then unscrew the

screw 7 fig. 98;

remove the rear light cluster, pulling it

outwards as indicated in fig. 99;

to replace the rear fog light bulb, turn

the bulb holder 8 fig. 100 anticlockwise

and replace the bulb, extracting it from

its bulb holder;

to replace the other lamps, unscrew

the four fixing screws fig. 100 and

remove the bulb holder assembly;

replace the bulb involved (fig. 101: 9

= position; 10 = stop; 11 = reverse

gear; 12 = direction indicators);

9608026J0006EM

9708026J0007EM

9808026J0008EM

9908026J0017EM

10008026J0018EM

10108026J0019EM

104

IN AN EMERGENCYRear bulb position

Page 107 of 204

refit the bulb holder unit correctly on

the rear light cluster, fully tightening the

four fixing screws;

reposition the rear light cluster on the

vehicle;

fully tighten the rear light cluster fixing

device and reconnect the electrical

connector;

reposition the section of the inner

trim;

reclose the rear lid.

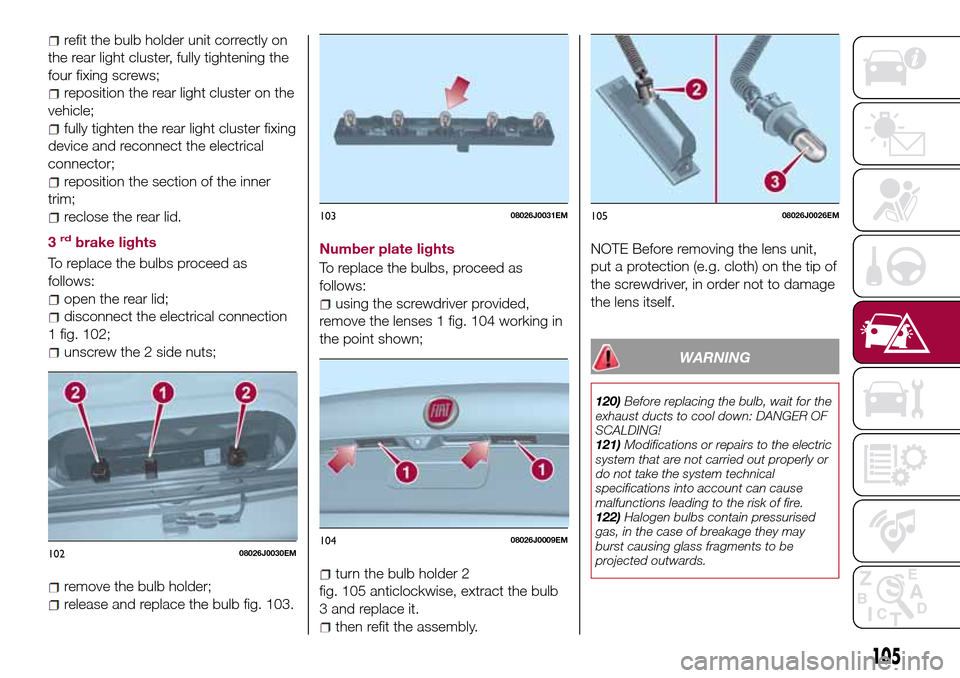

3

rdbrake lights

To replace the bulbs proceed as

follows:

open the rear lid;

disconnect the electrical connection

1 fig. 102;

unscrew the 2 side nuts;

remove the bulb holder;

release and replace the bulb fig. 103.Number plate lights

To replace the bulbs, proceed as

follows:

using the screwdriver provided,

remove the lenses 1 fig. 104 working in

the point shown;

turn the bulb holder 2

fig. 105 anticlockwise, extract the bulb

3 and replace it.

then refit the assembly.NOTE Before removing the lens unit,

put a protection (e.g. cloth) on the tip of

the screwdriver, in order not to damage

the lens itself.

WARNING

120)Before replacing the bulb, wait for the

exhaust ducts to cool down: DANGER OF

SCALDING!

121)Modifications or repairs to the electric

system that are not carried out properly or

do not take the system technical

specifications into account can cause

malfunctions leading to the risk of fire.

122)Halogen bulbs contain pressurised

gas, in the case of breakage they may

burst causing glass fragments to be

projected outwards.

10208026J0030EM

10308026J0031EM

10408026J0009EM

10508026J0026EM

105

Page 113 of 204

CHANGING A WHEEL

JACK

132)

37)

Please note that:

the jack weight is 2.15 kg;

the jack cannot be repaired and in

the event of a fault it must be replaced

by another genuine one;

No tool other than its cranking device

may be fitted on the jack.

Servicing

Prevent any dirt from depositing on

the "worm screw";

Keep the "worm screw" lubricated;

Never modify the jack.

Conditions for non-use

Temperatures below −40°C;

On sandy or muddy ground;

On uneven ground;

On steep roads;

In extreme weather conditions:

thunderstorms, typhoons, hurricanes,

blizzards, storms, etc.

In direct contact with the engine or

for repairs under the vehicle.

On boats.

CHANGING PROCEDURE

127) 128) 129) 130) 131)

35) 36)

Proceed as follows:

stop the car in a position that is not

dangerous for oncoming traffic where

you can change the wheel safely. The

ground must be flat and sufficiently

compact;

stop the engine, engage the hazard

warning lights and the parking brake;

engage first gear or reverse or, for

versions with automatic transmission (if

present), move the lever to position P

(Park);

wear the reflective safety jacket

before getting out of the car (anyway

comply with the laws in force in the

country you are driving in);

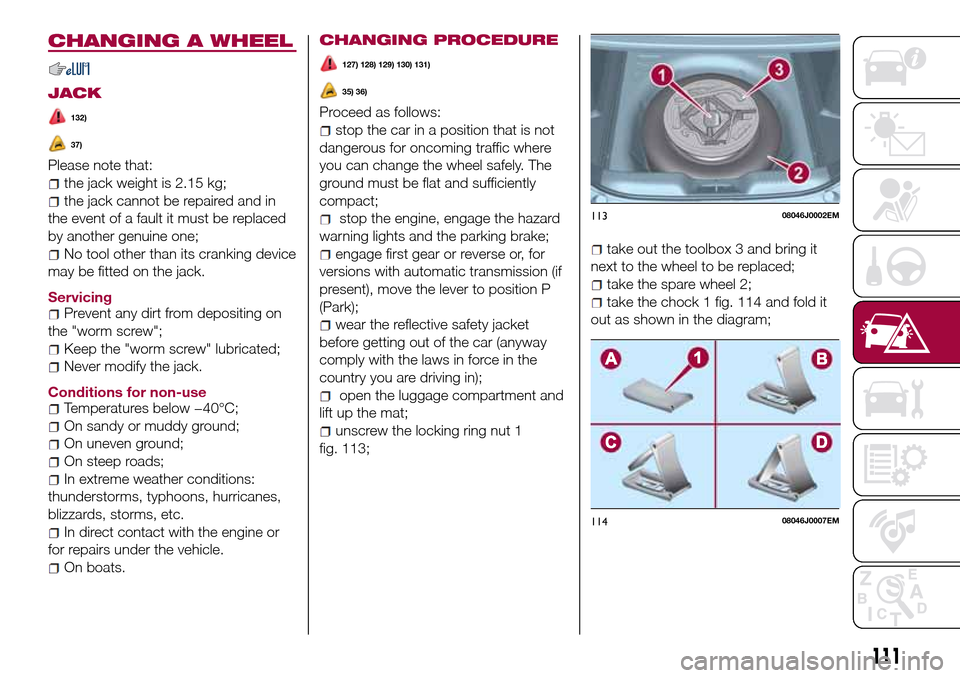

open the luggage compartment and

lift up the mat;

unscrew the locking ring nut 1

fig. 113;

take out the toolbox 3 and bring it

next to the wheel to be replaced;

take the spare wheel 2;

take the chock 1 fig. 114 and fold it

out as shown in the diagram;

11308046J0002EM

11408046J0007EM

111